Method for preparing flour nutrition intensifying Vitamin A microcapsule

A nutritional enhancer and vitamin technology, applied in food preparation, dough processing, active ingredients of hydroxyl compounds, etc., can solve problems such as nutritional deficiencies and nutritional imbalances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

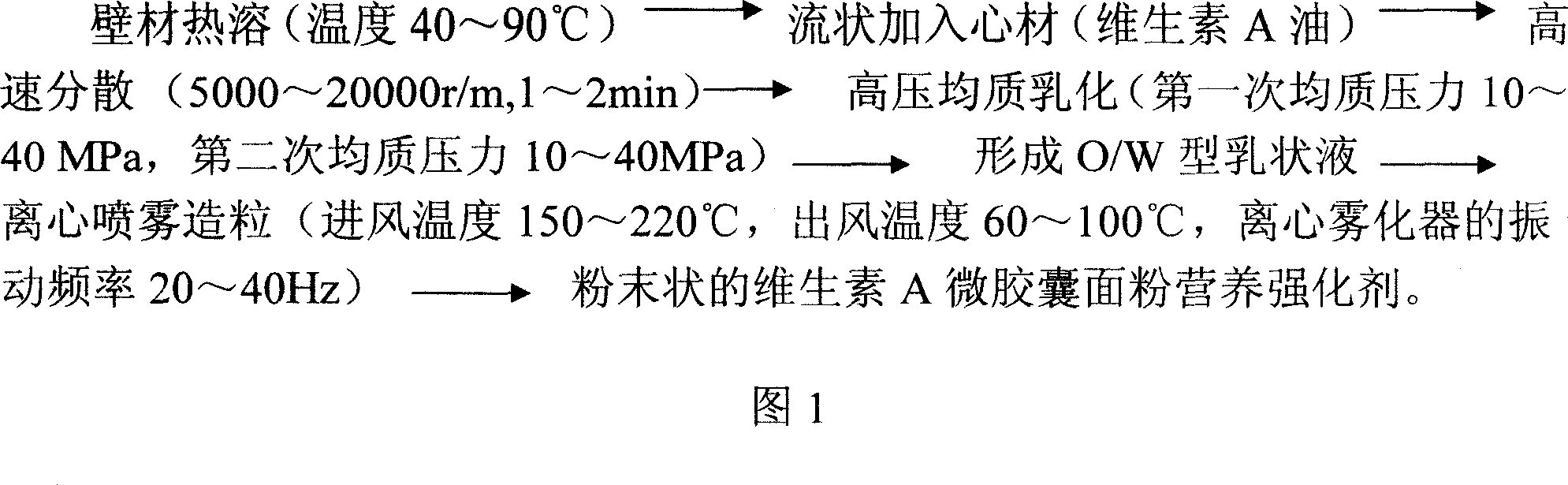

[0028] The amount of octenyl succinic acid starch ester HI-CAP100 is 40-80g, soak in 400ml hot water at 40-50°C for 1-5 hours, stir at 200-400 rpm until completely dissolved, and configure to a concentration of 10% ~20% (W / V) wall material solution. Add 10-35g of vitamin A oil (loading capacity is about 20%-30%) in a fluid form under stirring, disperse at high speed (5000-20000r / m, 1-2min), and homogenize twice under high pressure, the first homogenization pressure is 10-40MPa, the second homogeneous pressure is 10-40MPa, forming O / W emulsion.

[0029] The air inlet temperature is 170-220° C., the air outlet temperature is 70-100° C., and the vibration frequency of the centrifugal atomizer is 20-40 Hz for centrifugal spray granulation to obtain powdered vitamin A microcapsule flour nutrition enhancer.

[0030] The vitamin A microencapsulated flour nutrition fortifier is mixed with the flour at a ratio of 2 mg / kg vitamin A amount to obtain vitamin A nutrition fortified flour. ...

Embodiment 2

[0032] The amount of octenyl succinic acid starch ester HI-CAP100 is 120-160g, soaked in 400ml hot water at 60-70°C for 1-5 hours, stirred at 200-400 rpm until completely dissolved, and configured to a concentration of 30%-40 % (W / V) wall material solution. Then add 50-100g of vitamin A oil (loading capacity is about 30%-40%) in a flowing state under stirring, high-speed dispersion (5000-20000r / m, 1-2min), high-pressure homogenization twice, the first homogenization pressure is 10-40MPa, the second homogeneous pressure is 10-40MPa, forming O / W emulsion.

[0033] The air inlet temperature is 160-210° C., the air outlet temperature is 60-90° C., and the vibration frequency of the centrifugal atomizer is 20-40 Hz for centrifugal spray granulation to obtain powdered vitamin A microcapsule flour nutrition enhancer.

[0034]The vitamin A microcapsule flour nutrition fortifier is mixed with the flour at a ratio of 2 mg / kg vitamin A amount to obtain vitamin A nutrition fortified flou...

Embodiment 3

[0036] The amount of octenyl succinic acid starch ester HI-CAP100 is 160-200g, soaked in 400ml of 70-90°C for 1-5 hours, stirred at 200-400 rpm until completely dissolved and configured to a concentration of 40%-50% ( W / V) wall material solution. Then add 100-200g of vitamin A oil (loading capacity is about 40%-50%) in a flowing state under stirring, high-speed dispersion (5000-20000r / m, 1-2min), high-pressure homogenization twice, the first homogenization pressure is 10-40MPa, the second homogeneous pressure is 10-40MPa, forming O / W emulsion.

[0037] The air inlet temperature is 150-200° C., the air outlet temperature is 60-80° C., and the vibration frequency of the centrifugal atomizer is 20-40 Hz for centrifugal spray granulation to obtain powdered vitamin A microcapsule flour nutrition enhancer.

[0038] The vitamin A microcapsule flour nutrition fortifier is mixed with the flour at a ratio of 2 mg / kg vitamin A amount to obtain vitamin A nutrition fortified flour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com