Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100 results about "Shear speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Speed Shear. the component of wind shear resulting from a change in wind speed with height (e.g., southwesterly winds of 20 mph at 10,000 feet increasing to 50 mph at 20,000 feet). Speed shear is an important factor in severe weather development, especially in the middle and upper levels of the atmosphere.

Cloth rolling device for textile production

The invention relates to a cloth rolling device, in particular to a cloth rolling device for textile production. The cloth rolling device for textile production aims to achieve the technical effects of being convenient to use, easy to operate, capable of achieving flat rolling and flat shearing and high in shearing speed and improves the work speed. The cloth rolling device for textile production comprises a base, a first sliding block, a threaded rod, a first air cylinder, a right side plate, a holding frame, a left side plate, a fixed plate, a first bearing seat, a first bearing, a thumb cylinder and the like. The right side of the base is provided with a sliding groove. The first sliding block is arranged inside the sliding groove in a sliding manner. The middle portion of the first sliding block and the front side of the portion, located in front of the sliding groove, of the base are provided with threaded holes at equal intervals. The threaded rod is connected into the corresponding threaded hole in a threaded manner. According to the cloth rolling device for textile production, through rotation of a first roller, cloth is rolled, and the cloth is cut through a cutter.

Owner:浙江云中马股份有限公司

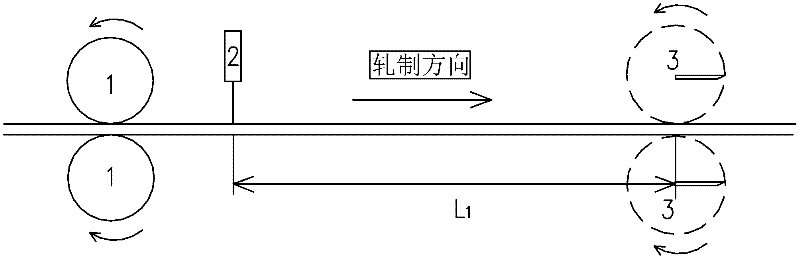

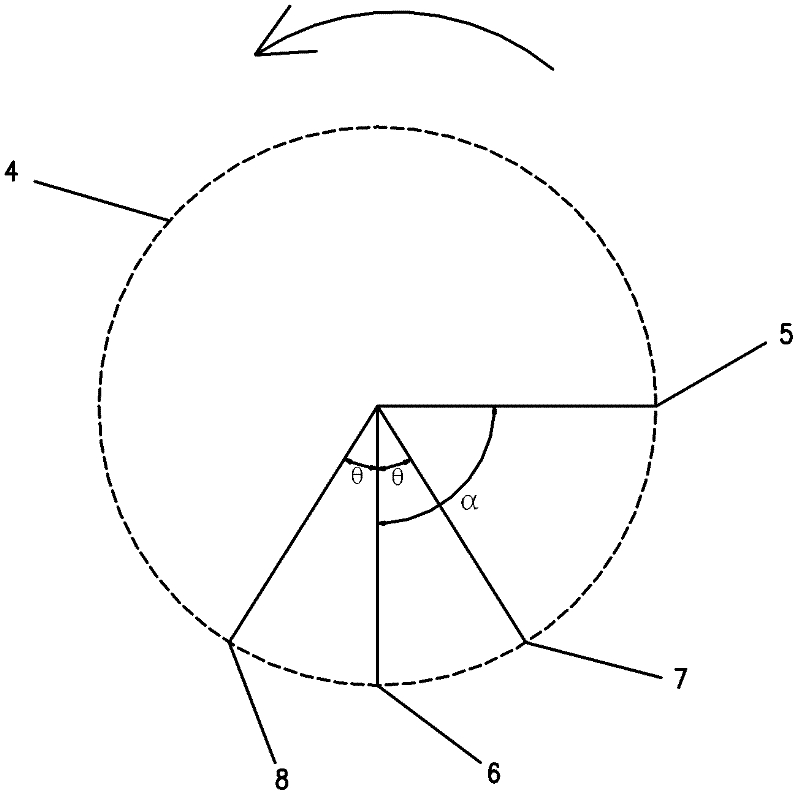

New method for controlling flying shears for bars and wires based on T400

InactiveCN102441569ASimple control structureImprove cut qualityRoll mill control devicesMetal rolling arrangementsWire rodStart stop

The invention provides a new method for controlling flying shears for bars and wires based on T400, which is an advanced electrical control method for start-stop type flying shears for bars and wires. The method comprises the steps of accurate shearing-blade position control, shearing length control and automatic shearing optimization, and the like; in the process of production, when an upstream rolling mill has an accident, or the quality of a section of a rolled piece is poor, a fragmentation function can be started on line so as to carry out partial fragmentation or complete fragmentation on the rolled piece, and the fragmentation and shearing speed is in step with the running speed of the rolled piece automatically; and when the fragmentation operation is stopped, a flying shear is automatically positioned to a start position and enters into a standby state of the normal shear mode. In the invention, the powerful computation function of the T400 is fully used, core control parts of the flying shear are completely integrated into the T400, and high-speed counters, shaft positioning modules and touch screens are not required, therefore, the cost is reduced, and high accuracy is obtained; and when the flying shear carries out double-length shearing at a speed of 21 m / s, the double-length error is basically within 75 mm, and partial double-length error can be within 30 mm.

Owner:WISDRI WUHAN AUTOMATION

Instant powdery grease treating starch sodium octenylsuccinate as wall material, and its preparation method

The invention relates to an instant powdery grease treating starch sodium octenylsuccinate as a wall material. The instant powdery grease comprises 30-70% by mass of the wall material, 5-60% by mass of grease, 5-60% by mass of an auxiliary wall material, 0.5-3% by mass of an emulsifier, 0.1-2% by mass of an antioxidant and 0.1-0.5% by mass of a cosolvent. The invention also relates to a preparation method of the powdery grease. The preparation method is characterized in that a microencapsulation technology is adopted to embed fat-soluble grease in order to prepare a microcapsule, the wall material used for embedding is starch sodium octenylsuccinate, the addition of the emulsifier and the addition of the auxiliary wall material improve the emulsification shear speed, improve the homogenization pressure and increase the homogenization frequency, grease is embedded in the wall material and undergoes spray drying, and the addition of the cosolvent forms the instant powdery grease. The preparation method has the advantages of simplicity and low cost, and the prepared powdery grease has the advantages of good water solubility, fast dissolving, high oil carrying amount, and good fluidity and can be applied to the food field, the daily-use chemical engineering field, the medicine field and the like.

Owner:ZHEJIANG ZHONGTONG TECH

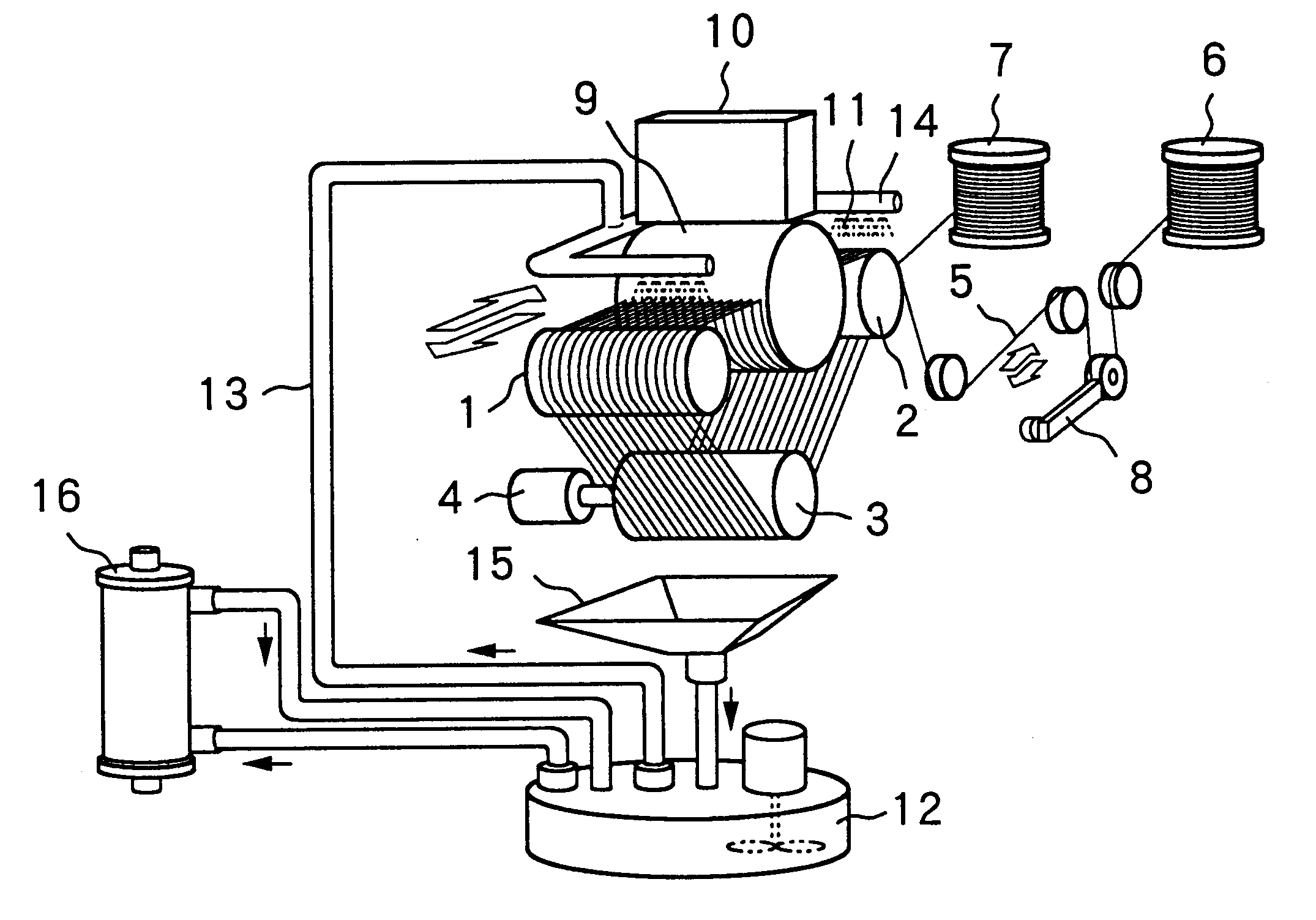

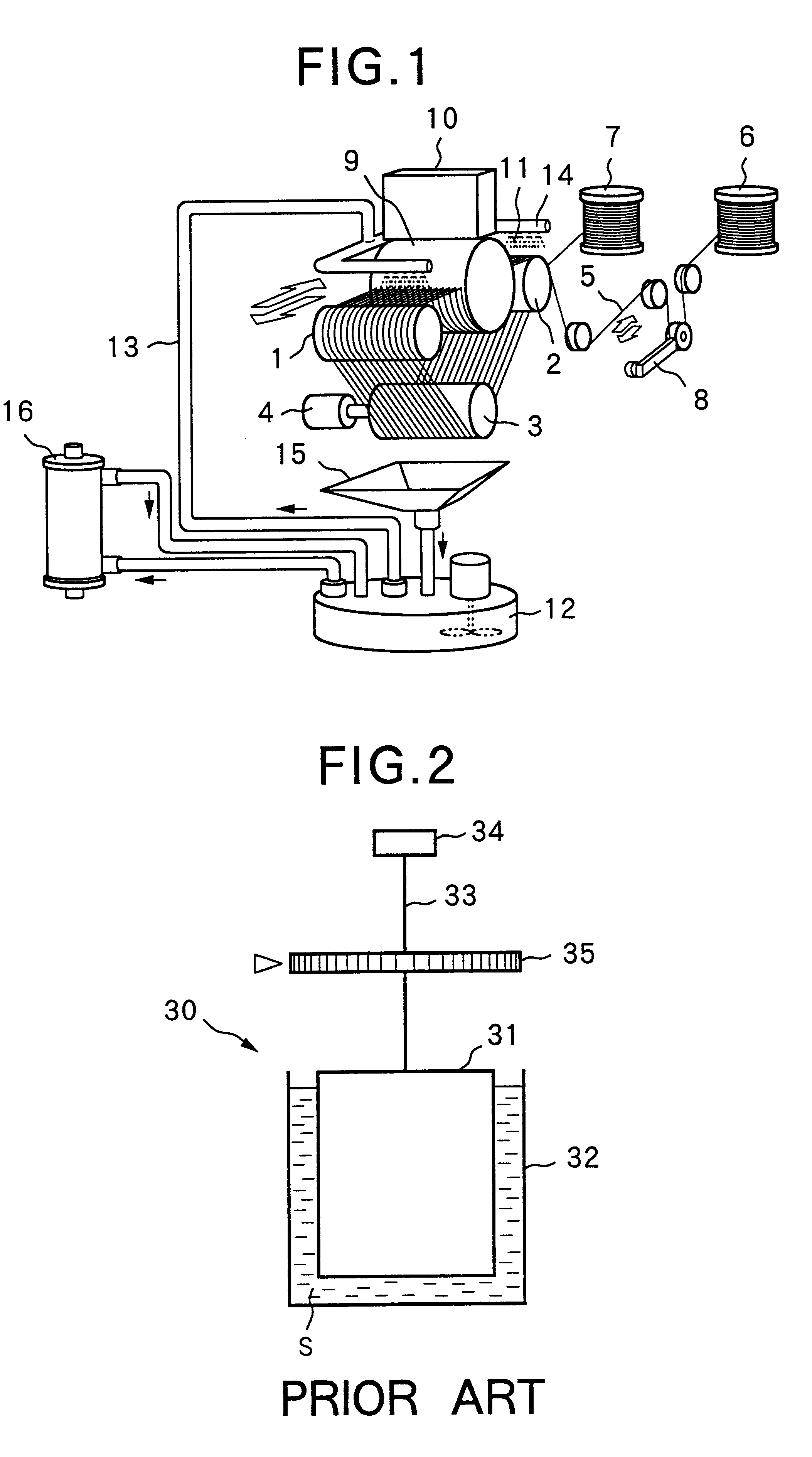

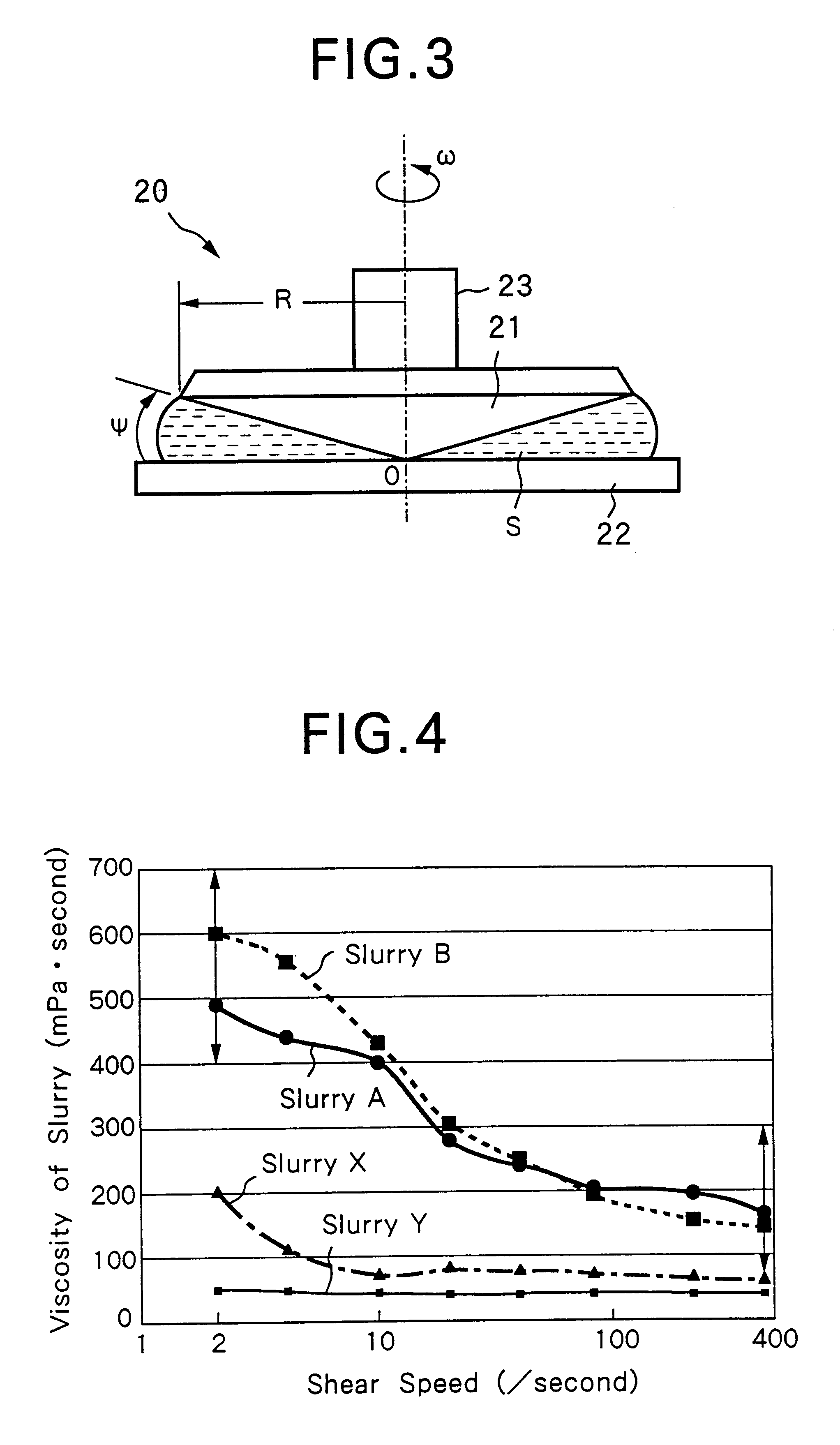

Slurry useful for wire-saw slicing and evaluation of slurry

Slurry useful for wire-saw slicing has viscosity adjusted to 400-700 mPa.second at a shear speed of 2 / second and of 50-300 mPa.second at a shear speed of 380 / second. The viscosity of slurry is measured using a cone and plate type viscometer which can measure viscosity at different shear speeds. Since the slurry sufficiently flows into inner parts of grooves formed in an ingot and consumed for wire-saw slicing due to the viscosity controlled in response to the shear speed, the ingot can be efficiently sliced to wafers or discs.

Owner:SUPER SILICON KENKYUSHOKK +1

Melt-kneaded products, molded resin products, and production method thereof

InactiveUS20090123731A1Evenly dispersedMaintain good propertiesNanotechRotary stirring mixersCyclic processElastomer

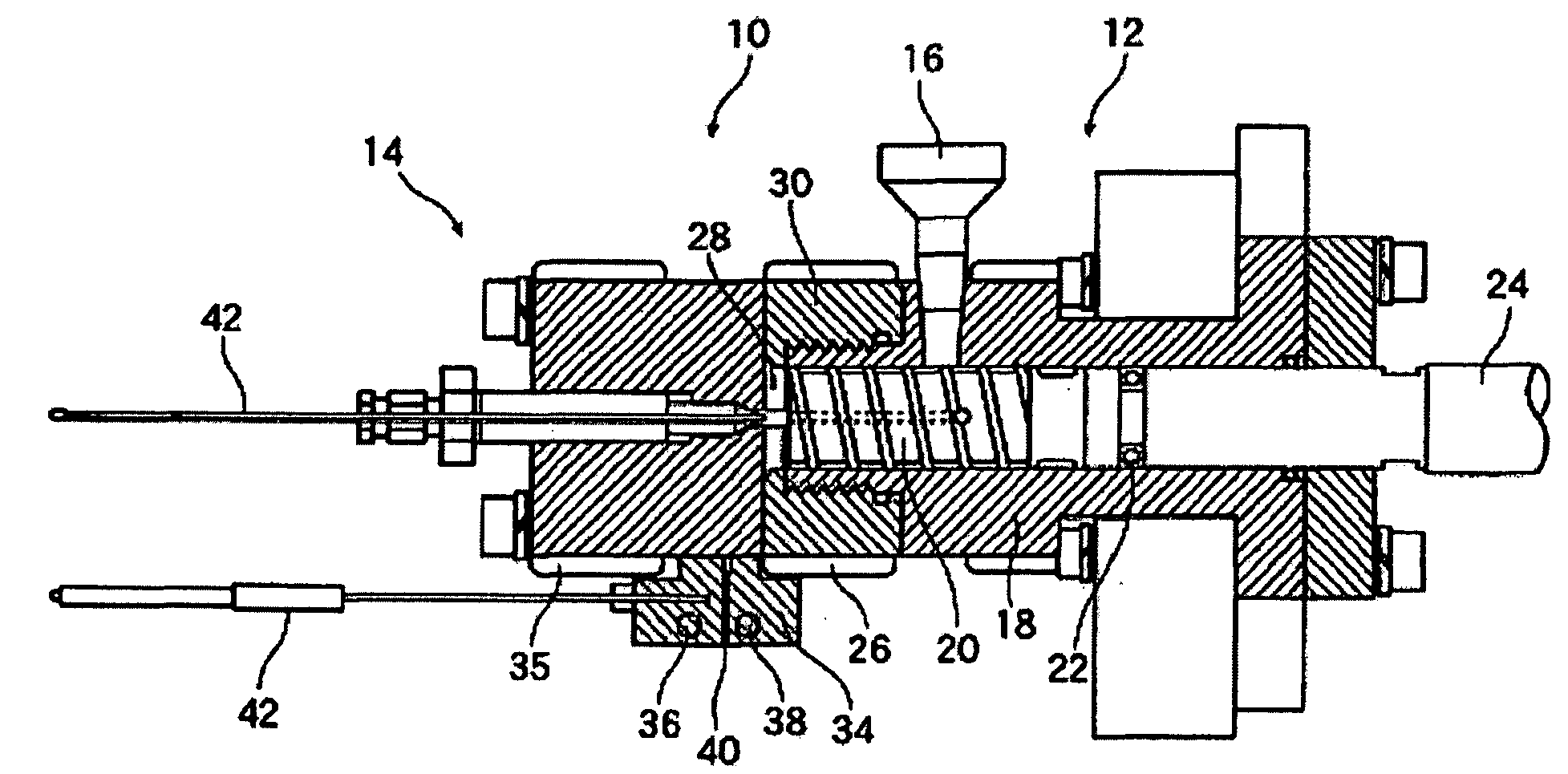

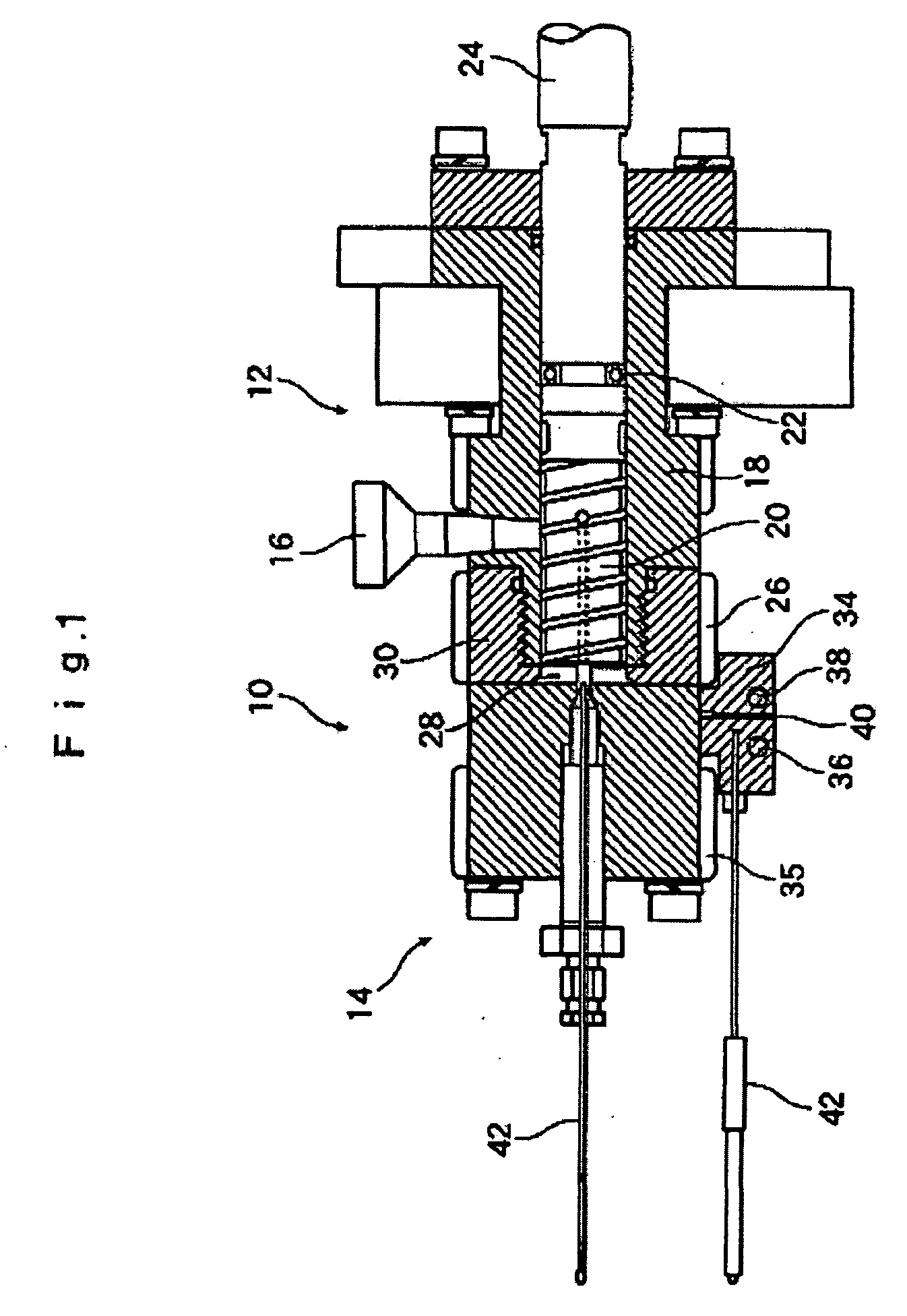

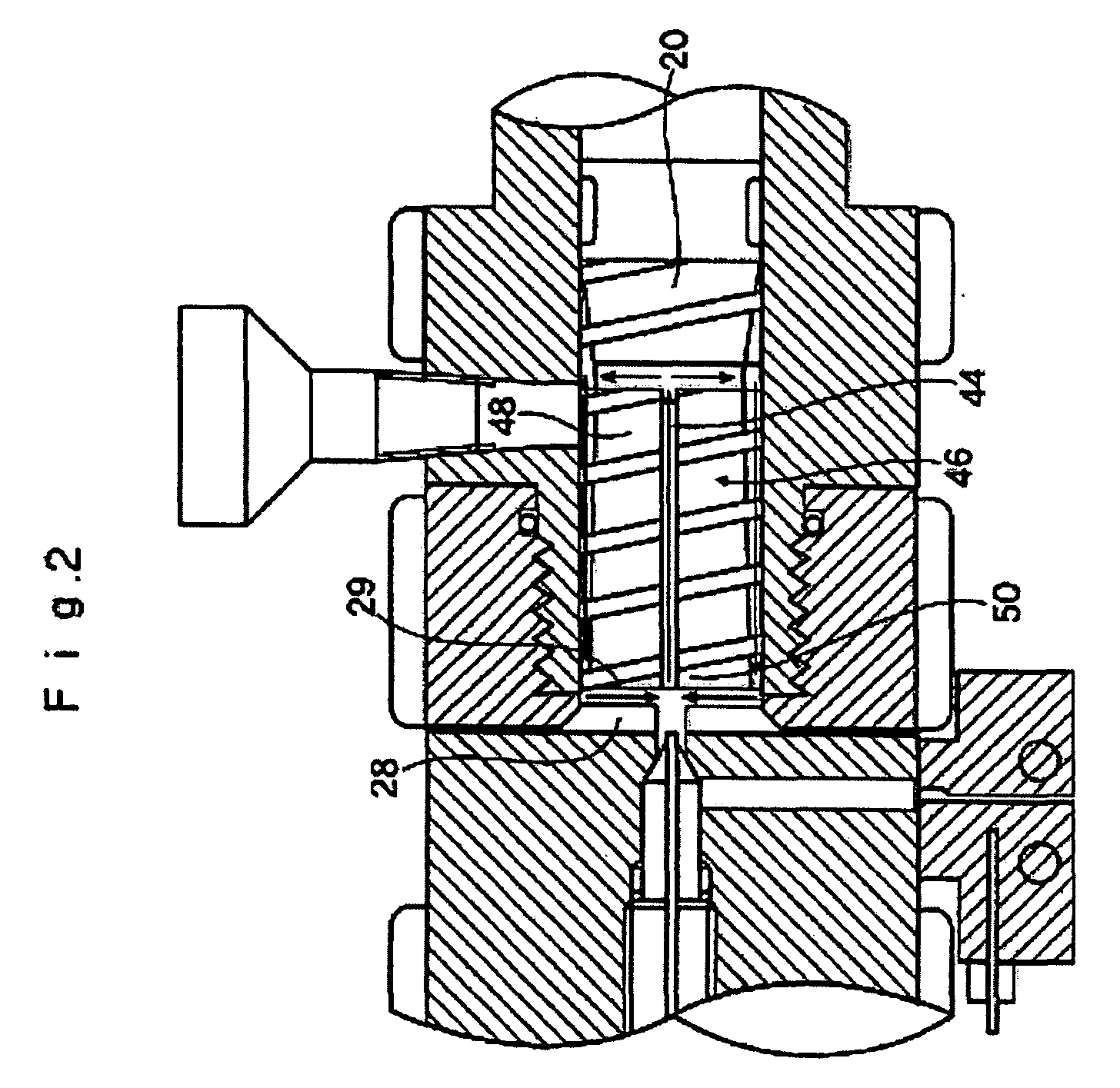

A melt-kneading method for filling material and elastomer or resin, characterized in that a filling material constituted by a filler, and an elastomer or resin (thermoplastic resin or thermosetting resin), are introduced from a material introduction part at the end of a melt-kneading part having a cylinder with a screw and a heater, and the molten elastomer or resin and filling material constituted by a filler are kneaded under the conditions of 1000 to 3000 rpm in the rotation speed of the screw and 1500 to 4500 sec−1 in shear speed to feed the mixture from the rear edge to tip of the screw to be trapped in a space provided at the tip of the screw, after which the mixture is moved from the space to the rear edge of the screw through a hole provided at the center of the screw, with the cycle process performed for a specified period based on recirculation using the screw.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Multilayer sheet made of polyglycolic acid resin

InactiveUS7785682B2Improve barrier propertiesImprove biodegradabilityWrappersBio-packagingMoisture resistanceOxygen barrier

A polyglycolic acid resin-based multilayer sheet, comprising: a plant substrate sheet and a biodegradable resin layer laminated by melt-adhesion onto the plant substrate sheet, wherein said biodegradable resin layer comprises one or plural layer including at least a polyglycolic acid resin layer, and the multilayer sheet includes on the substrate sheet a melt-adhesion layer comprising a biodegradable resin exhibiting a melt viscosity of 10-5.0×103 Pa·sec as measured at a temperature of 240° C. and a shear speed of 122 sec−1 and having a melting point of at most 235° C. The multilayer sheet has a laminate structure composed of biodegradable materials exerting little load to the environment at the time of disposable thereof and yet is excellent in oxygen-barrier property and moisture resistance, thus being suitable as a food container-forming material.

Owner:KUREHA KAGAKU KOGYO KK

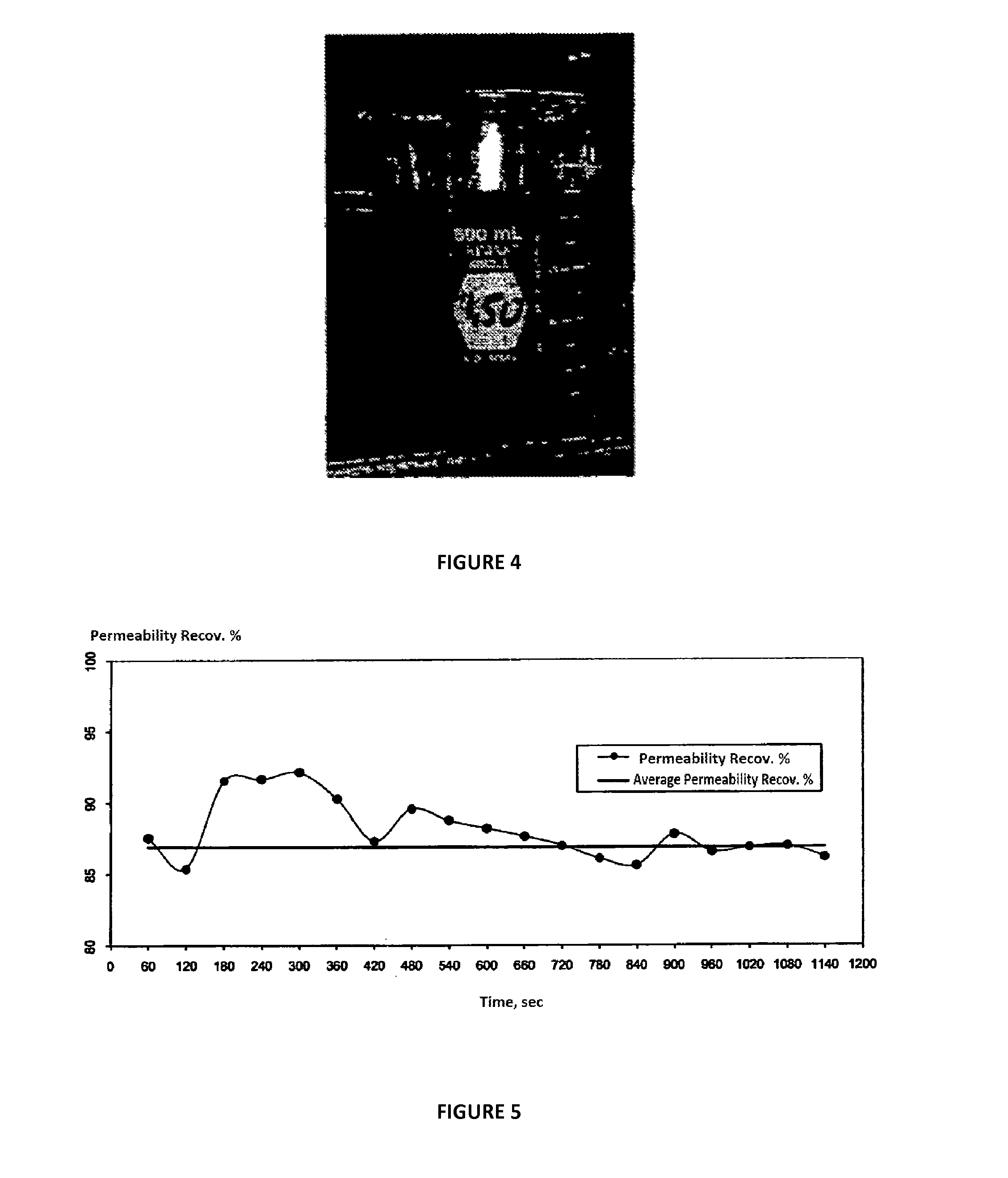

High-pressure/high-temperature solids-free fluid system for drilling, completing and repairing petroleum and gas wells

The present invention relates to the composition, preparation method and use of a solids-free drilling fluid system formulated with a mixture of divalent heavy brines, which is resistant to high pressures and high temperatures. The system has the special feature that it significantly reduces productive-formation permeability damage as it uses mixtures of different salts of water-soluble divalent metals to provide the features of density, polymers and special additives to provide the system with the physicochemical properties that any fluid for drilling, completing and repairing wells requires in order to fulfill the functions thereof and to provide heat resistance up to 200° C. A main feature of the present invention is that the composition that embeds the drilling / completing / repairing of oil wells fluid contains synthetic polymers and biopolymers that do not require large amounts of time, high shear speeds or heating for hydration thereof in divalent metal salt derived simple or binary brines.

Owner:PROTEXA S A DE

Multilayer Sheet Made of Polyglycolic Acid Resin

InactiveUS20080069988A1Improve barrier propertiesImprove biodegradabilityWrappersBio-packagingPolymer scienceOxygen barrier

A multilayer sheet made of a polyglycolic acid resin which is constructed by the fusion / lamination of a biodegradable resin layer on a base sheet of vegetable origin, characterized in that the biodegradable resin layer comprises one or more layers involving at least one polyglycolic acid resin layer and the layer fused with the base sheet is made of a biodegradable resin having a melt viscosity of 10 to 5.0×103 Pa·sec at a temperature of 240° C. and a shear speed of 122 sec−1 and a melting point of 235° C. or lower. Although the multilayer sheet has a lamination structure made of biodegradable materials with light environmental burden at disposal, it is excellent in oxygen-barrier properties and resistance to moisture transmission. Thus, it is appropriately usable as a food container material.

Owner:KUREHA KAGAKU KOGYO KK

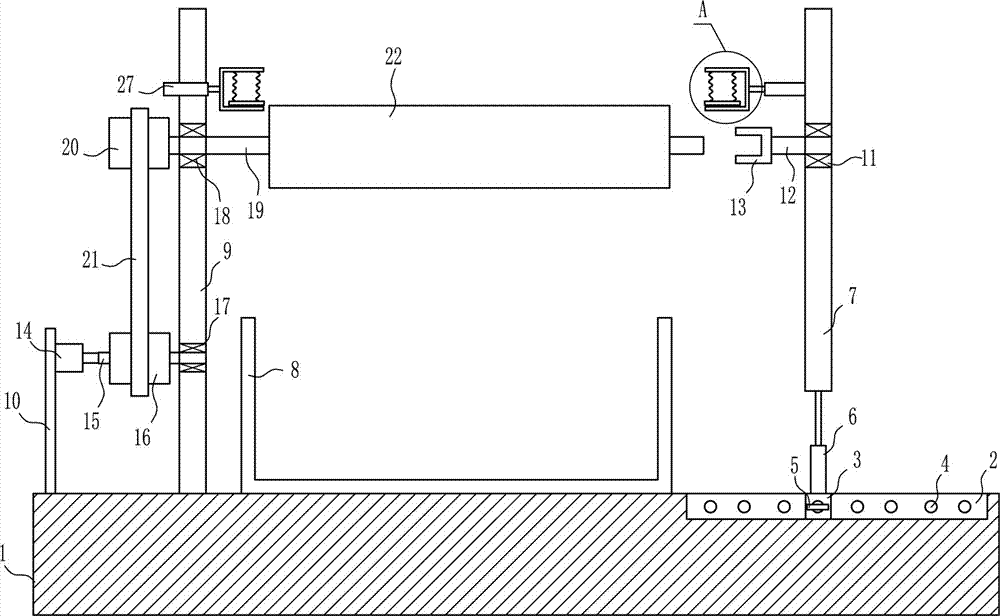

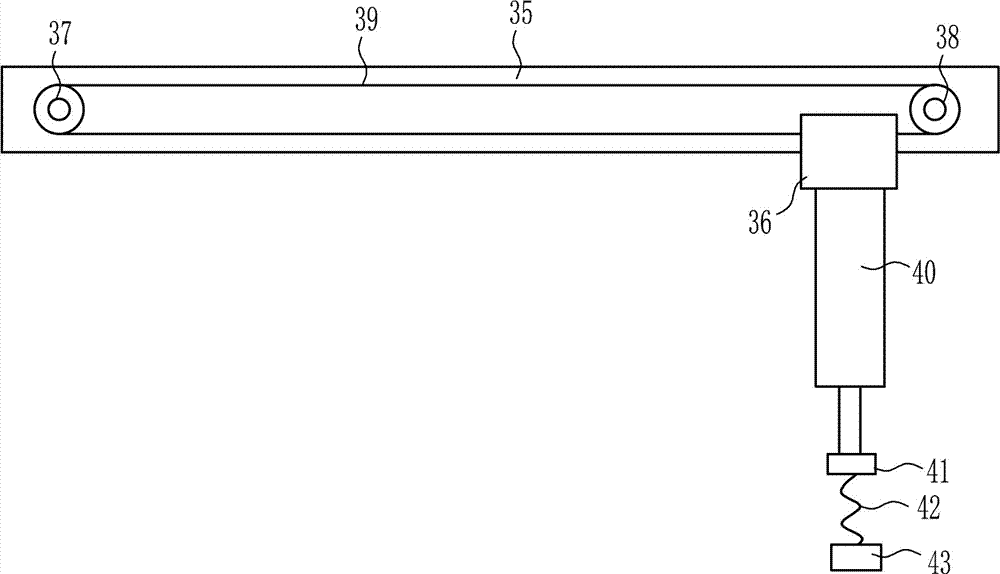

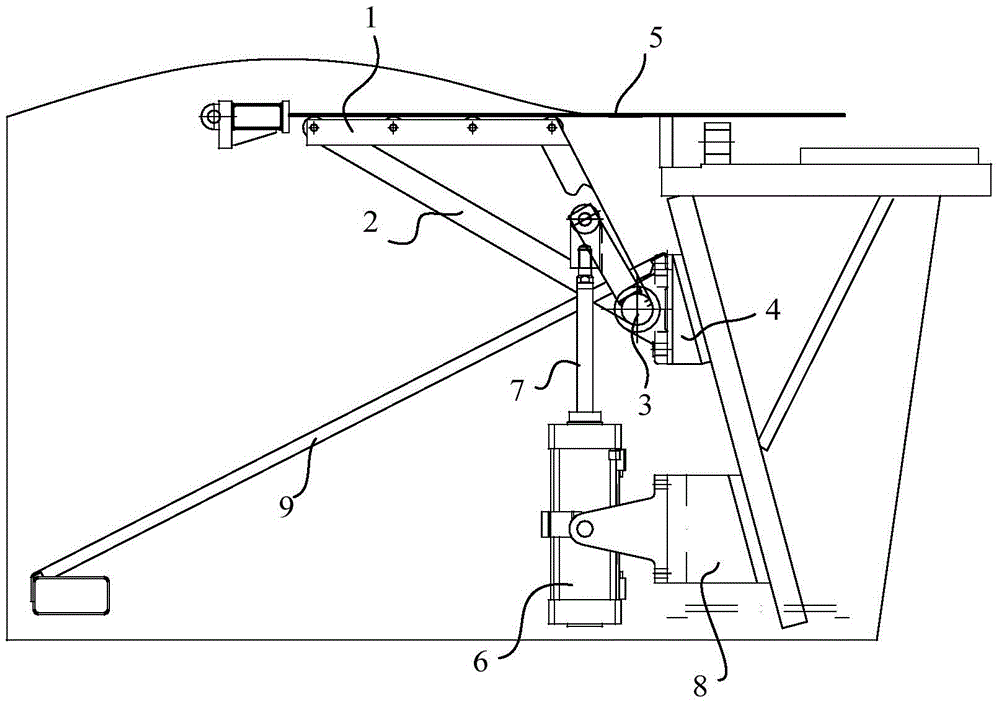

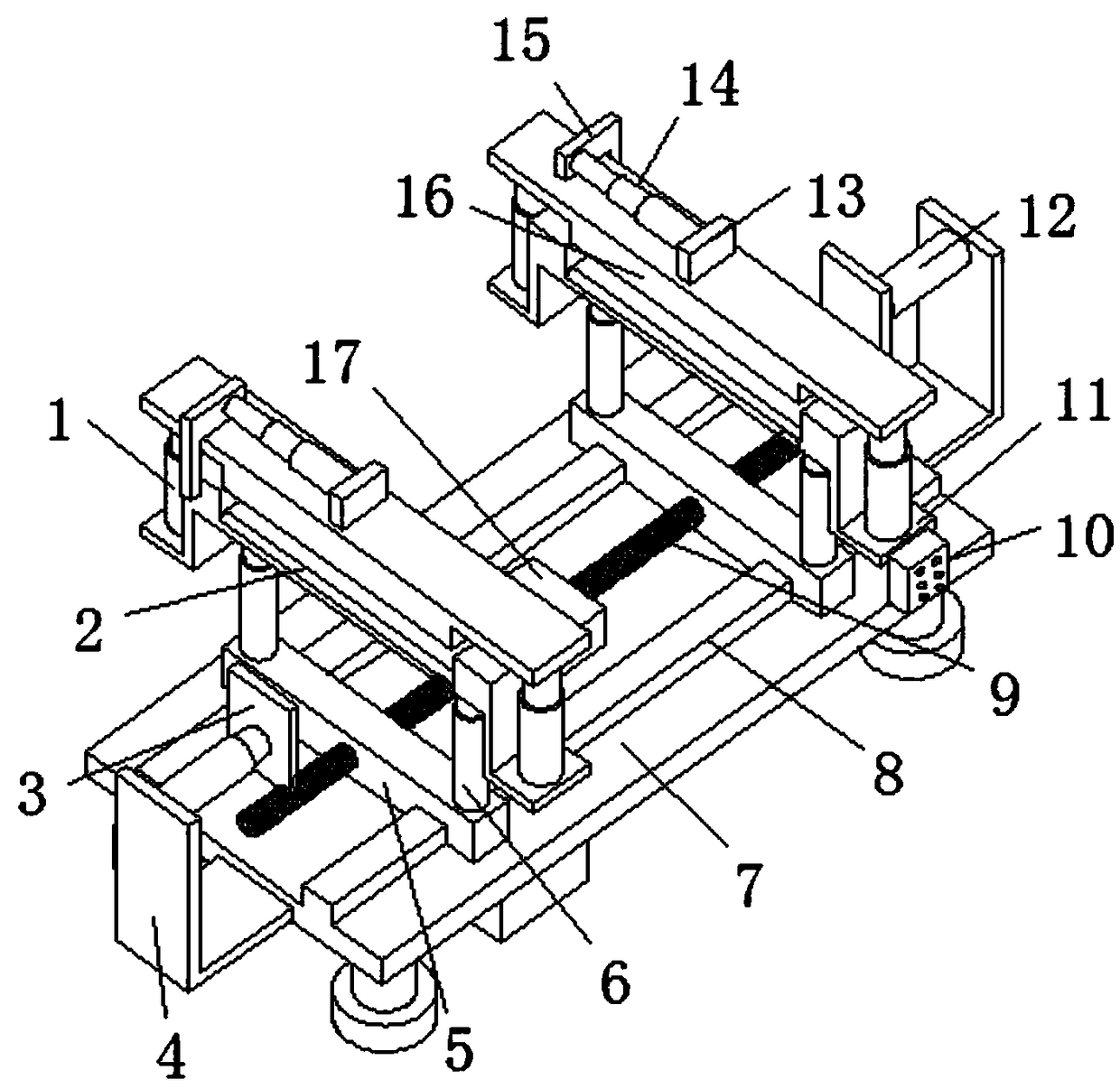

Back support device of plate shearing machine

ActiveCN105478886AEasy to manufactureAvoid collisionShearing machinesShearing machine accessoriesModular designEngineering

The invention discloses a back support device of a plate shearing machine, and relates to the technical field of plate shearing machines. The back support device of the plate shearing machine comprises a synchronous lifting mechanism, and a support frame capable of lifting along with the synchronous lifting mechanism; the synchronous lifting mechanism includes two lifting base assemblies; and the two lifting base assemblies can enable the support frame to ascend and swing to a horizontal state in the support process under the effect of the synchronous lifting mechanism, can enable the horizontal descending speed of the support frame to be the same with the plate shearing speed in the shearing process, and can realize swing unloading of the support frame in the unloading process. The back support device of the plate shearing machine, proposed by the invention, can enable the ascending speed of the support frame to be the same with the plate shearing speed, can prevent the support frame from being collided with an upper scissor, can support a plate, can reduce the distortion of the plate, improves the plate shearing quality, adopts a modular design, can be wholly manufactured, can be mounted on different plate shearing machines, is convenient for installation, and is stronger in practicability.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Easy-processing and halogen-free flame retardant thermoplastic polyurethane elastomer and preparation method thereof

Owner:SUZHOU HENGLI COMM MATERIAL

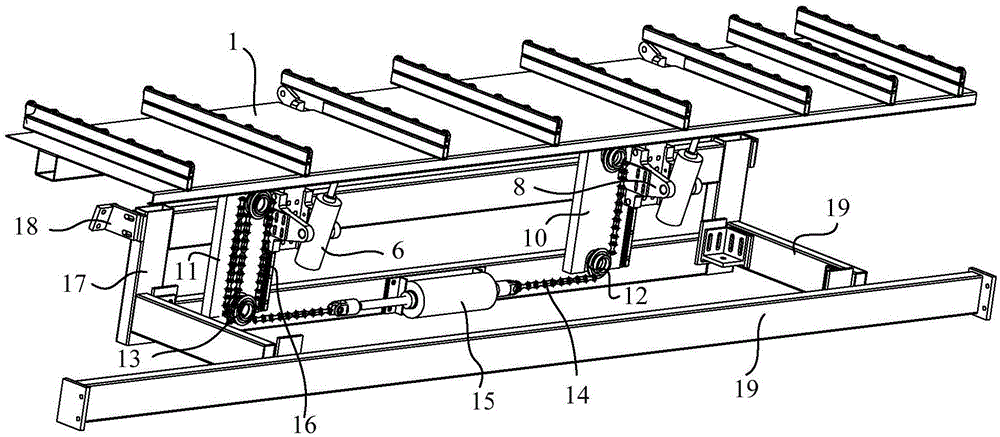

Special hydraulic insulated shearing tool for relay protection small bus

InactiveCN102198478AAvoid short circuitElectric shock preventionSwitchgearHydraulic cylinderMechanical engineering

The invention belongs to the technical field of shearing of relay protection small buses, and discloses a special hydraulic insulated shearing tool for a relay protection small bus. The shearing tool comprises a groove-shaped bottom plate provided with a lateral hole, the groove-shaped bottom plate is fastened and connected with a unidirectional acting spring reset hydraulic cylinder, the end of a piston rod of the unidirectional acting spring reset hydraulic cylinder passes through the lateral hole, the end of the piston rod is fastened and connected with a cutter head, the end of the unidirectional acting spring reset hydraulic cylinder is fastened and connected with a fixed handle and movably connected with a hydraulic handle through at least two pivots, wherein one pivot is movably connected with a plunger piston, and the plunger piston is positioned in the unidirectional acting spring reset hydraulic cylinder; and except the cutter head, the whole exterior of the shearing tool is provided with an insulated layer. The shearing tool is simple in principle, convenient to manufacture, small in volume, light in weight, safe and convenient to carry and use, high in shearing speed and efficient, saves the time, has low cost, and is convenient to popularize and use.

Owner:XUCHANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Fluid boundary control-based quantitative measurement method for fluid slippage on super-hydrophobic surface

InactiveCN101776561AImprove test accuracyGuaranteed measurement accuracySurface/boundary effectTest platformShear speed

The invention discloses a fluid boundary control-based quantitative measurement method for fluid slippage on a super-hydrophobic surface, which is characterized by comprising the following steps: preparing the super-hydrophobic surface, treating the prepared super-hydrophobic surface, clamping the treated super-hydrophobic surface on a rheological test platform, and calibrating the position of a clamp and mapping the clamp; and performing rheological test operation on the super-hydrophobic surface and performing rheological test operation on the fluid on a smooth hydrophobic surface under the same test condition to acquire torques applied to the clamp when the fluids are at the same shear speed under the two conditions, and calculating the slippage length according to the measured torques. The method has a wider test range, and not only can measure the length of the fluid slippage on the super-hydrophobic surface on which the super-hydrophobic area is circular and the outside of the super-hydrophobic area is the smooth hydrophobic surface, but also can measure the length of the fluid slippage on the prepared common super-hydrophobic surface.

Owner:JIANGSU UNIV

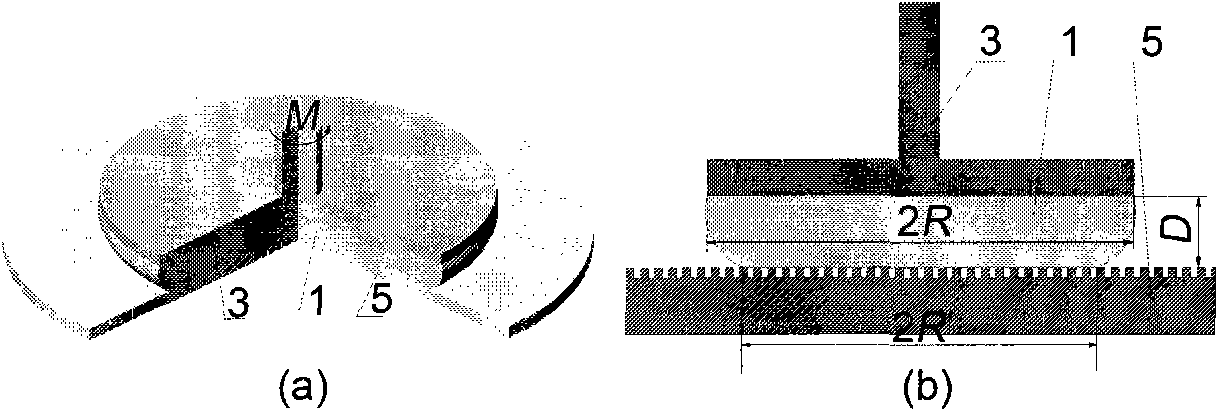

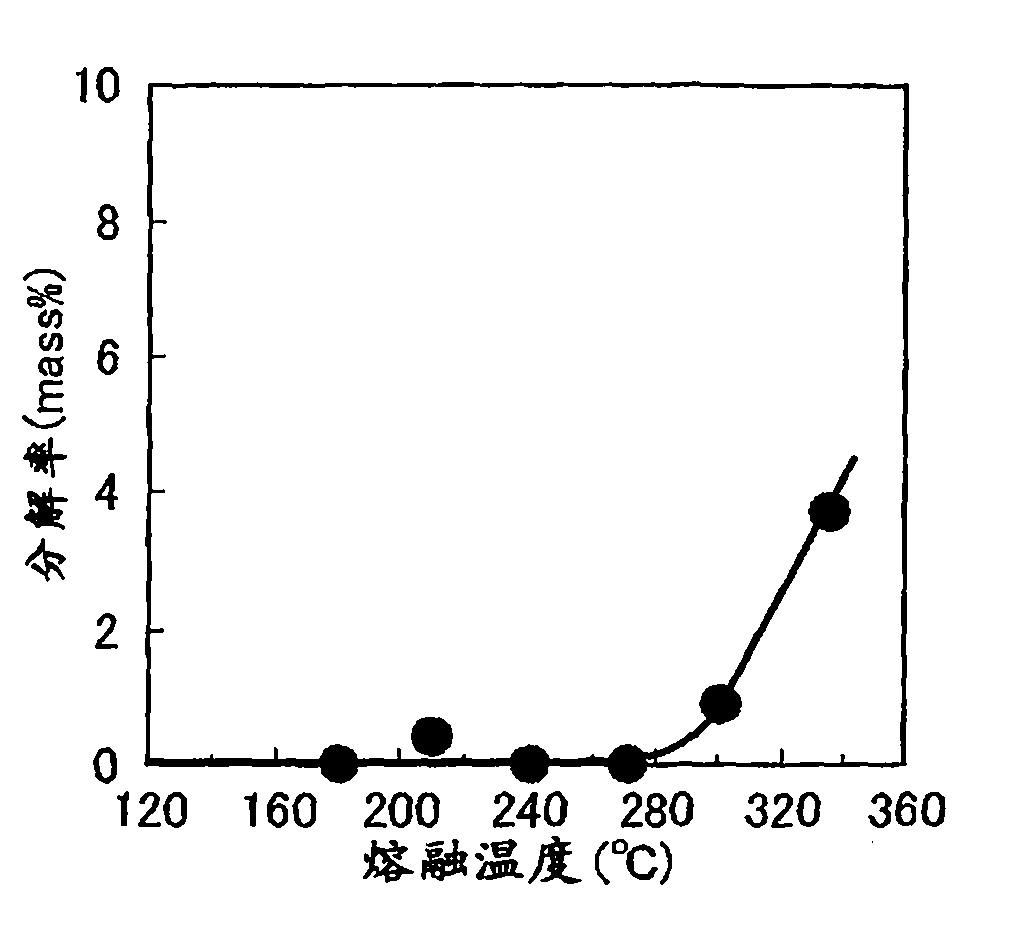

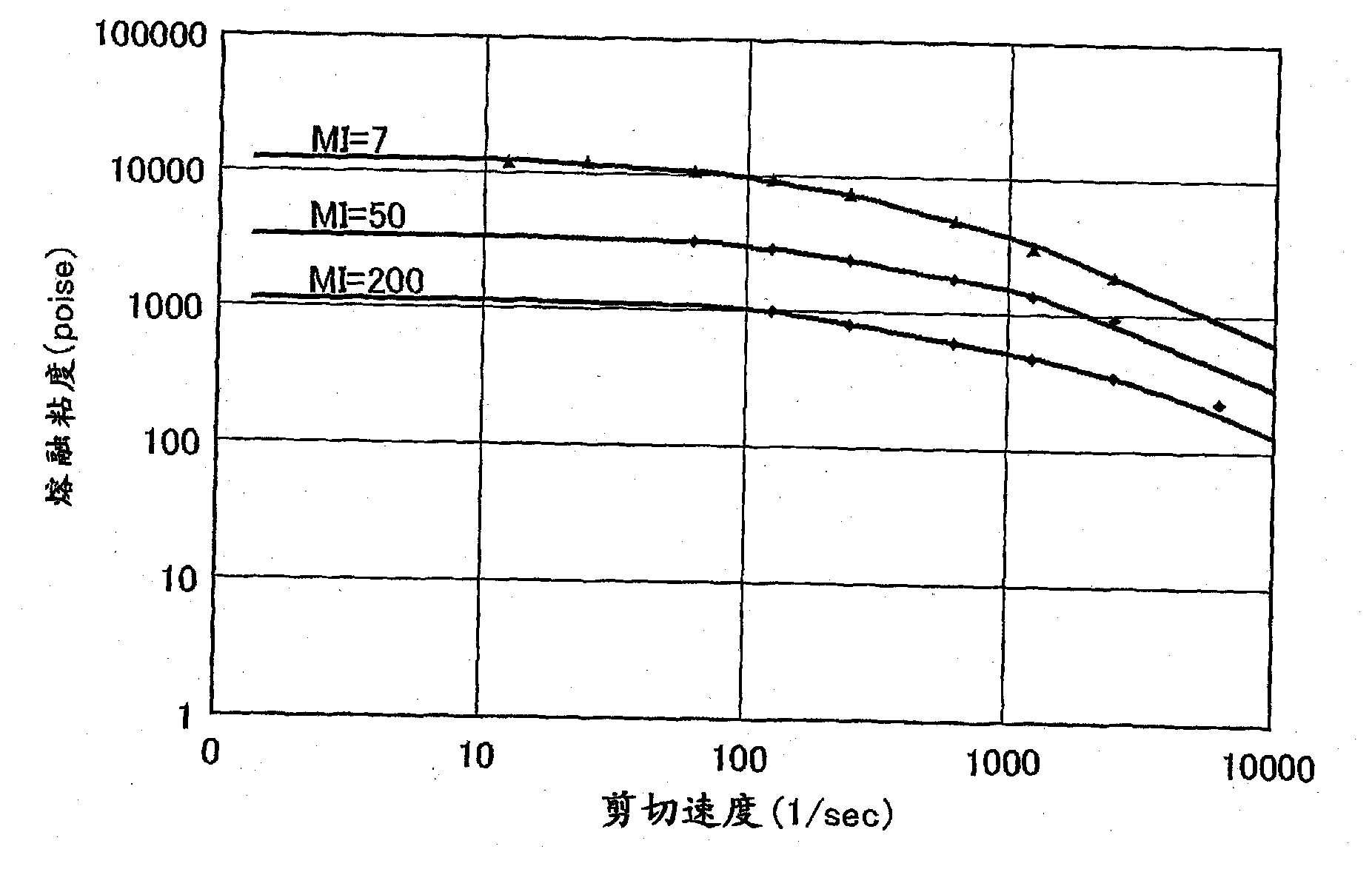

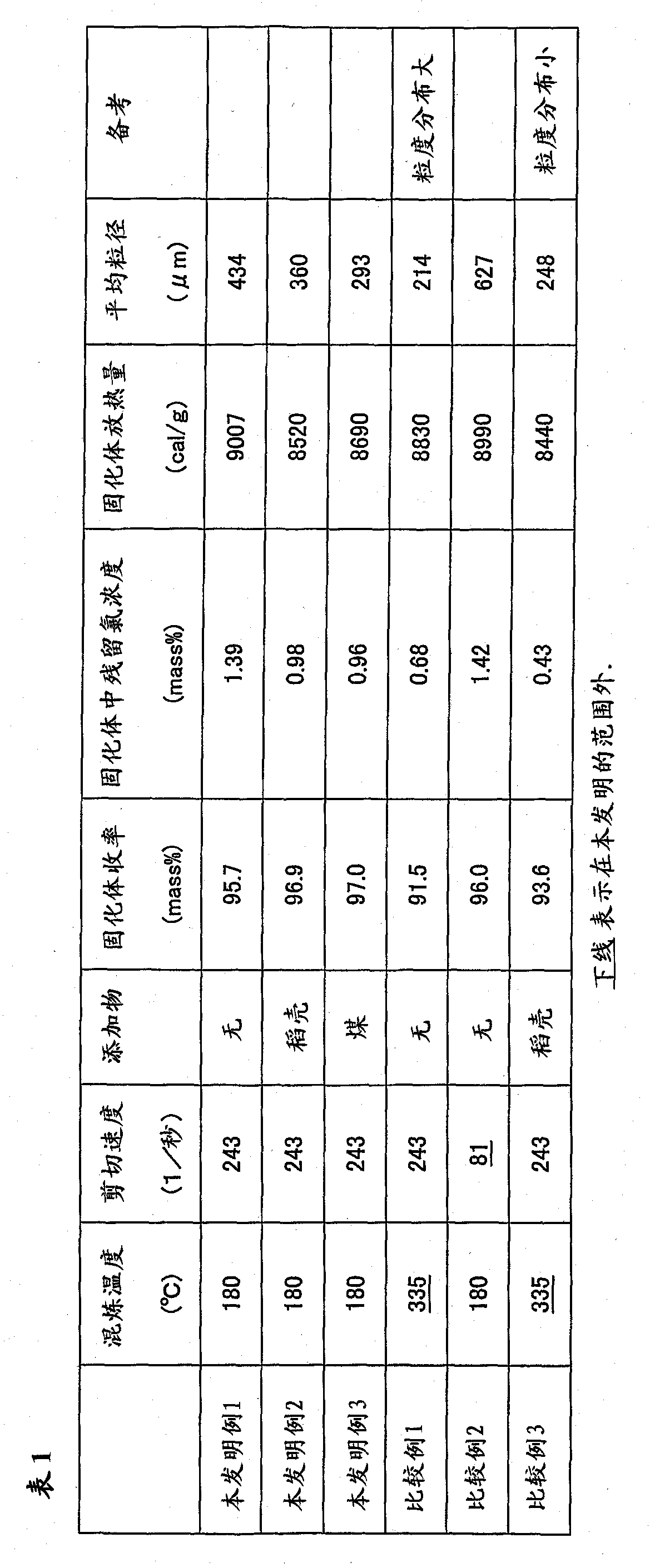

Method for producing pulverized waste plastic and solid fuel or mineral reduction material

ActiveCN102149526ALow costReduce flammabilitySolid waste disposalBiofuelsProduction rateDecomposition

Provided is a method for producing a pulverized waste plastic wherein it is possible to produce at a low cost and with improved productivity a pulverized product by micropulverization of waste plastic. The method for producing a pulverized waste plastic is characterized in that waste plastic is kneaded at a shear speed of 100 (1 / second) or greater as it is being melted at a temperature that is the softening and melting temperature or greater, preferably 160 DEG C, but is a temperature at which flammable decomposition gases are not generated, preferably 270 DEG C or lower, and then is cooled and solidified and the solid product is pulverized. Melting and kneading are preferably performed using an extruder, particularly a biaxial extruder.

Owner:JFE STEEL CORP

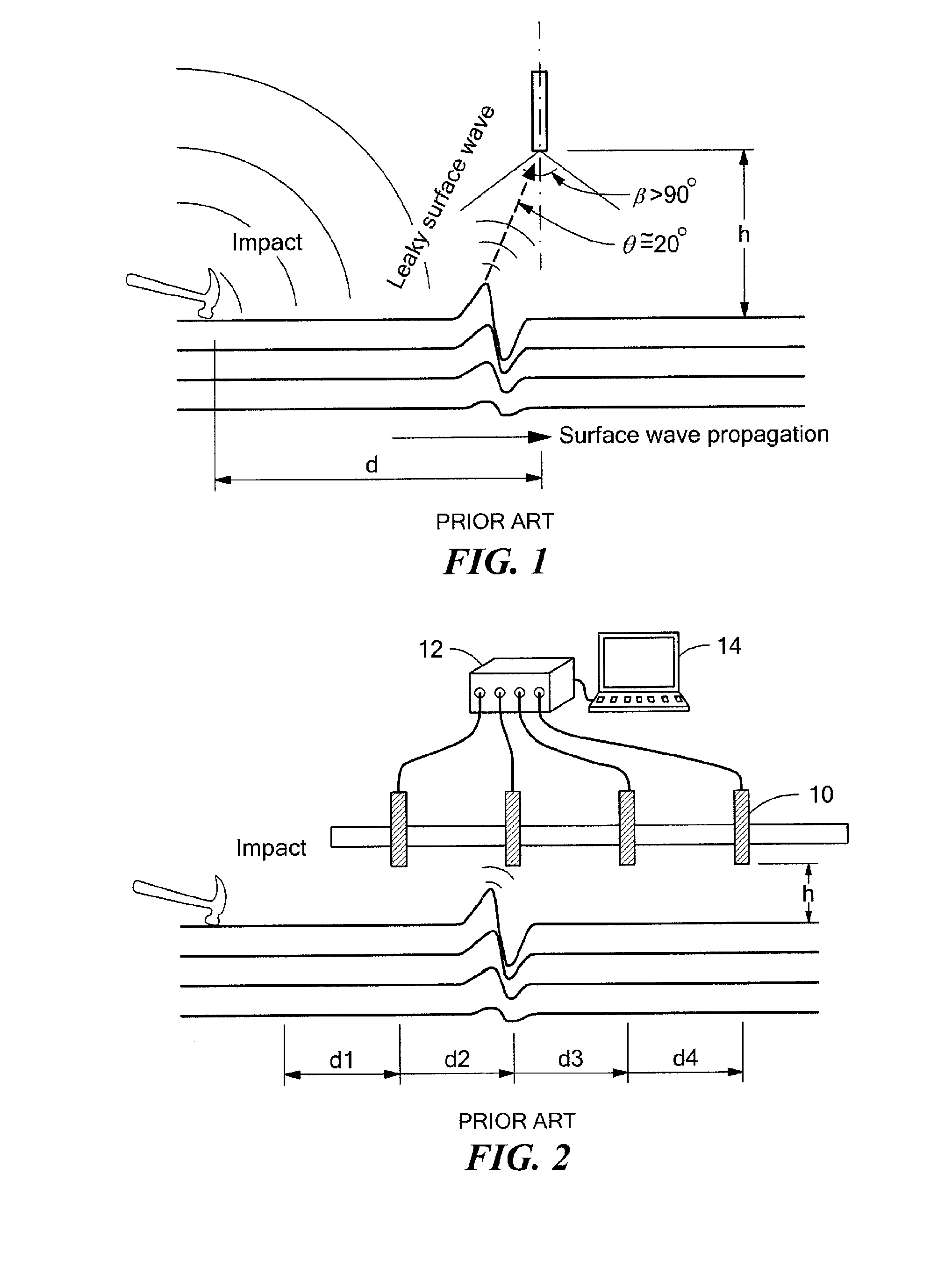

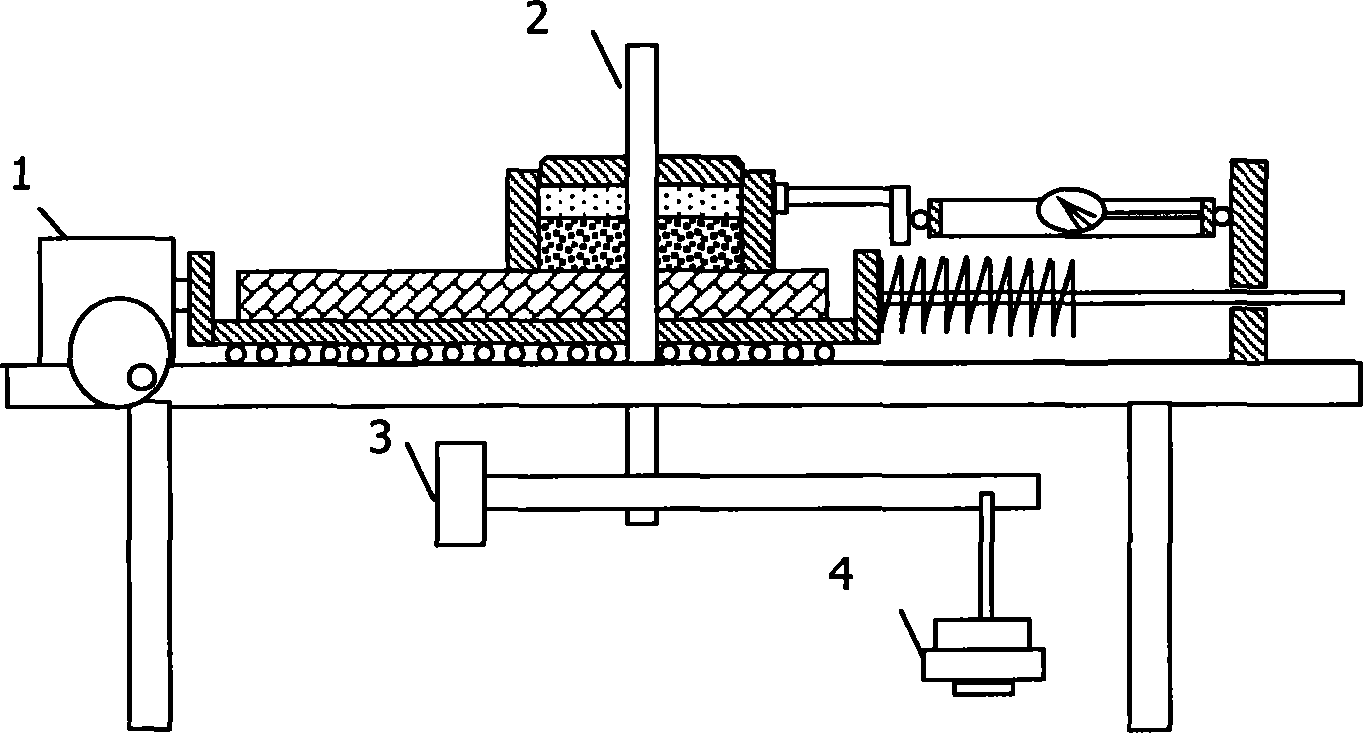

Real-time pavement profile sensing system using air-coupled surface wave

InactiveUS20130289896A1Method is fastAnalysing solids using sonic/ultrasonic/infrasonic wavesSeismologyDispersion curveAir coupled

A non-contact testing system and method using acoustic sensors and a mobile sensing system using this system and method is disclosed. The leaky surface wave is recorded with directional microphones. A fast inversion analysis algorithm is introduced to estimate the shear velocity profile and elastic modulus for the subsurface layers of pavement structures, using the dispersion curves obtained from the acoustic signals. An electrical hammer is used to produce impact impulses automatically. A mobile sensing system is integrated on a mobile cart to perform the mobile subsurface sensing for pavement structures.

Owner:NORTHEASTERN UNIV

Anti-stab fabric with shear thickening fluid and rheid

ActiveCN109944074AComfortable to wearImprove wearing comfortFibre treatmentFluid viscosityHigh intensity

The invention provides an anti-stab fabric with shear thickening fluid and rheid. The fabric is characterized by comprising a three-dimensional-structure fabric as a framework structure, the three-dimensional-structure fabric is provided with a cavity, and the cavity of the three-dimensional-structure fabric is filled with the shear thickening fluid. According to the anti-stab fabric, since the viscosity of the shear thickening fluid is rapidly increased at high shear speed, and the shear thickening fluid has an energy consumption characteristic of liquid and high strength performance of a solid, the novel anti-stab fabric for the rheid, particularly the anti-stab fabric for the shear thickening fluid and rheid is provided. The shear thickening fluid is injected into the three-dimensional-structure fabric, if the fabric is subjected to any impact or shearing force, the viscosity of the shear thickening fluid is quickly increased, the shear thickening fluid is in a solid state, and accordingly the anti-stab function is achieved.

Owner:DONGHUA UNIV

Method of denaturing whey protein

Owner:MORINAGA MILK IND CO LTD

Calculating method of plastic injection moulding technological window

The invention provides a calculating method of a plastic injection moulding technological window. The method comprises the following steps: selecting types of technological parameters, determining factors of an orthogonal test, determining the level of each factor according to the value range of the technological parameters, and selecting an orthogonal table according to the numbers of factors and levels; calculating pressure distribution, melt temperature distribution and shearing speed distribution of a product in a moulding process, and calculating the inlet maximum pressure, the melt maximum temperature difference and the maximum shearing speed; evaluating each technological parameter combination in the orthogonal table in the second step according to the calculating result to establish quality evaluation of the product; training a training sample by a support vector sorting machine according to the quality evaluation of the product to calculate an optimal solution and a threshold value; and constructing a discriminant according to the training sample, the optimal solution and the threshold value to describe the technological window of selected parameters. The method provided by the invention is free from comprehensive tests, the calculated amount of numerical simulation is less, and the high-dimensional non-linear technological window can be directly described through a discrimination function.

Owner:HUAZHONG UNIV OF SCI & TECH

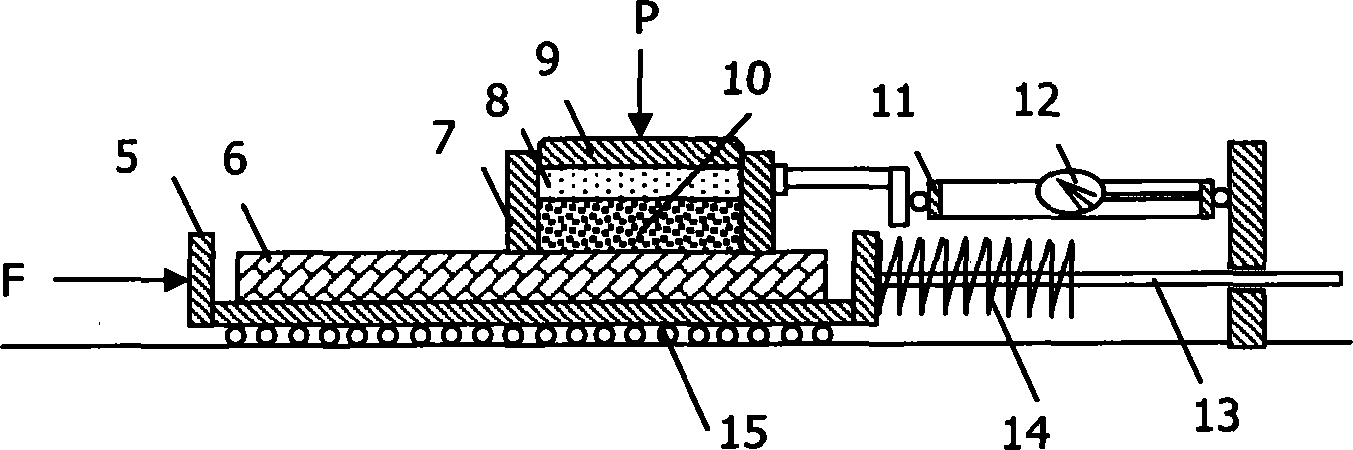

Pile soil sliding friction testing method

InactiveCN104345028AReduce shear rateThe contact area does not changeUsing mechanical meansMaterial analysisStatic frictionEngineering

The invention relates to a testing method for simulating the static friction and the sliding friction of pile soil. On the basis of a direct shearing instrument of soil, necessary improvement is made for simulating the sliding friction of pile soil, and a special pile soil sliding friction testing instrument is designed, so that the static friction and the sliding friction of pile soil can be tested under different bearing stratum conditions, and the static friction and the sliding friction of pile soil can be relatively well measured under different testing conditions. By using a special shearing box, the situation that the contact area is changed in an ordinary shearing process is effectively avoided; as springs for simulating a soil body are additionally arranged, the shearing speed is increased, and the measurement on the friction of pile soil with a bearing stratum and without a bearing stratum can be relatively well completed.

Owner:SUN YAT SEN UNIV

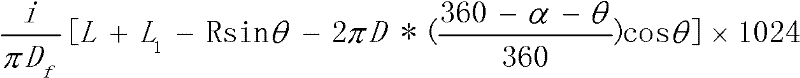

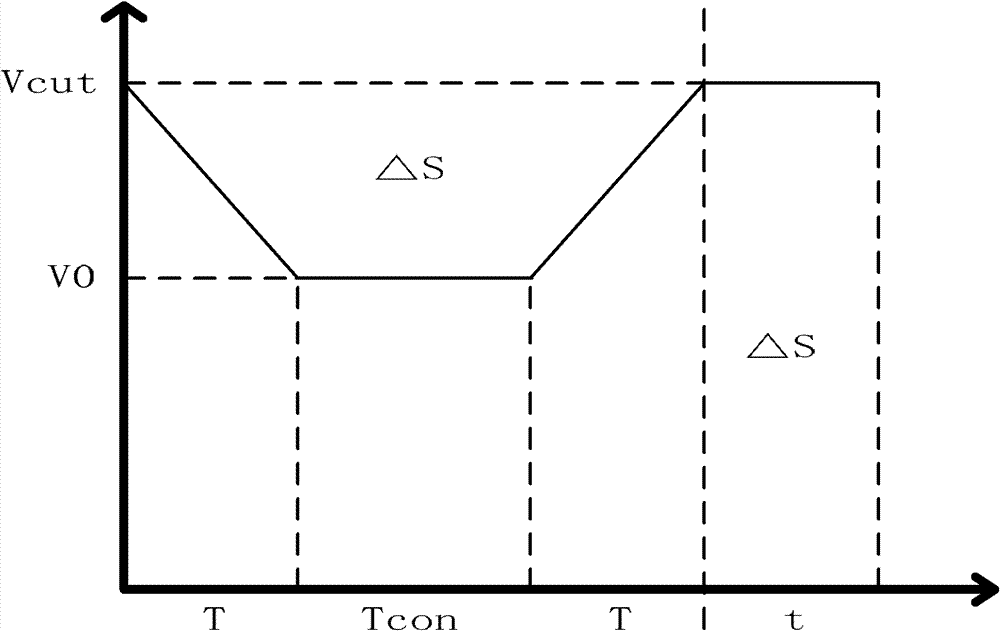

Optimal control method for strip tail shear by flying shear at continuous annealing unit inlet

The invention discloses an optimal control method for strip tail shear by flying shear at a continuous annealing unit inlet. The method includes keeping a unit delivering strip steel at a constant speed VL; during strip tail shear, controlling the flying shear to evenly decelerate from a shearing speed Vcut at an acceleration A for T, operating at a low constant speed after the deceleration for Tcon, constantly accelerating from the low speed at the acceleration A for T to Vcut, so that the strip shearing amount is increased by delta L and the last waste strip steel of the strip tail falls into a waste transmitting system through the flying shear, wherein the Tcon is determined according to the delta L, and the calculation of the T is as follows. According to the method, variable speed control on the flying shear is performed through optimal calculation of the waste length, the last waste can fall into the waste transmitting system through the flying shear, and breakdown time of the unit can be effectively reduced.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD +1

Thixotropy high-strength gel diverting agent

The invention relates to a thixotropy high-intensity gel diverting agent which is used for high water-cut oil field cracks and the plugging of extra-high permeable zone channeling path. The process for preparation comprise the following steps: adding xanthan gum (XC) 0.1%-1%, chromic acetate 0.001-0.1%, 0.025-0.5% thixotropic control system of mixed solution of ammonium phosphate and monoammonium phosphate in a nomer solution system which is formed by conventional acrylamide monomer, wherein the viscosity is 12.6-32.0MPa.S under the temperature scope which is 30-80 DEG C, and shearing speed which is 100s-1, wherein viscosity can rapidly backs up to 50-100 times in 30 min under low-shearing state in carks and big pore path, the intensity G' is 0.5-1Pa, effectively protecting plugging agent solution system from being diluted by water, guaranteeing the stability of each water soluble component ratio of the plugging agent system, and the final gelling time is 2-10 hours, which can be controlled, and the final intensity G' is 200-500 Pa.

Owner:PETROCHINA CO LTD

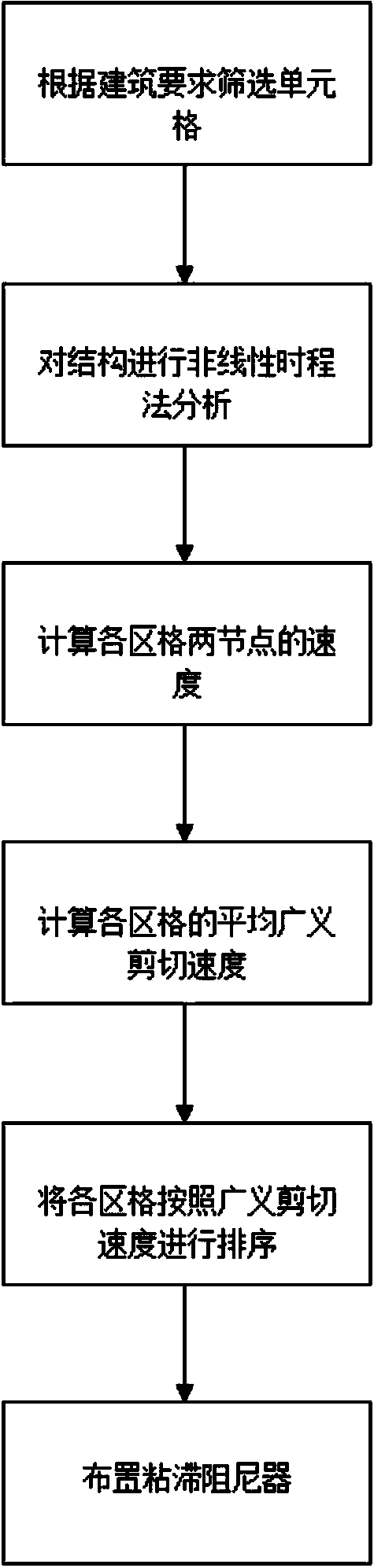

Viscous damper arranging method based on generalized shear speed

ActiveCN103899000AOperableMeet the development needs of engineering and constructionSpecial data processing applicationsShock proofingElastic plasticEngineering

The invention relates to a viscous damper arranging method based on generalized shear speed. The method includes the steps of firstly, screening cells appropriate for arranging viscous dampers in a structure; secondly, using a nonlinear time-history method or a power elastic-plastic time-history method to analyze the structure, calculating the speed of optional two nodes in each cell screened in the first step, wherein the speed includes the horizontal speed and vertical speed under each step length; thirdly, calculating the generalized shear speed of each cell under each step length; obtaining the absolute average value of the generalized shear speed of all points in each cell so as to obtain the average generalized shear speed of each cell; fourthly, sorting the cells according to the average generalized shear speed; fifthly, sequentially arranging the viscous dampers according to expected damper arranging effect and the generalized shear speed. Compared with the prior art, the method is high in calculation efficiency, good in optimization effect, simple to operate, and the like.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

Solidification- and extrusion-molded article of polyglycolic acid and method for manufacturing same

InactiveUS20150290858A1High strengthReduce residual stressLayered productsMetal rolling stand detailsShell moldingUltimate tensile strength

Provided are: a polyglycolic acid (PGA) solidification- and extrusion-molded article that is formed from a resin material containing PGA, the PGA having a weight average molecular weight of 100,000 to 300,000 and a melt viscosity (temperature: 270° C.; shearing speed: 120 sec−1) of 100 to 2,000 Pa·s, and that has a tensile strength at a temperature of 150° C. of 20 to 200 MPa; a downhole tool or component thereof for drilling and completion of petroleum recovery formed by machining the solidification- and extrusion-molded article; an isolation plug provided with the component; an isolation plug mandrel; and a method for manufacturing the PGA solidification- and extrusion-molded article and a method for manufacturing the downhole tool or component thereof that comprise the steps of: supplying the resin material to an extruder (preferably from a fixed-quantity feeder); and after solidification- and extrusion-molding, pressurizing the solidification- and extrusion-molded article, and drawing the same while applying back pressure thereto in a direction of a forming die to suppress the expansion of the solidified and extruded matter.

Owner:KUREHA KAGAKU KOGYO KK

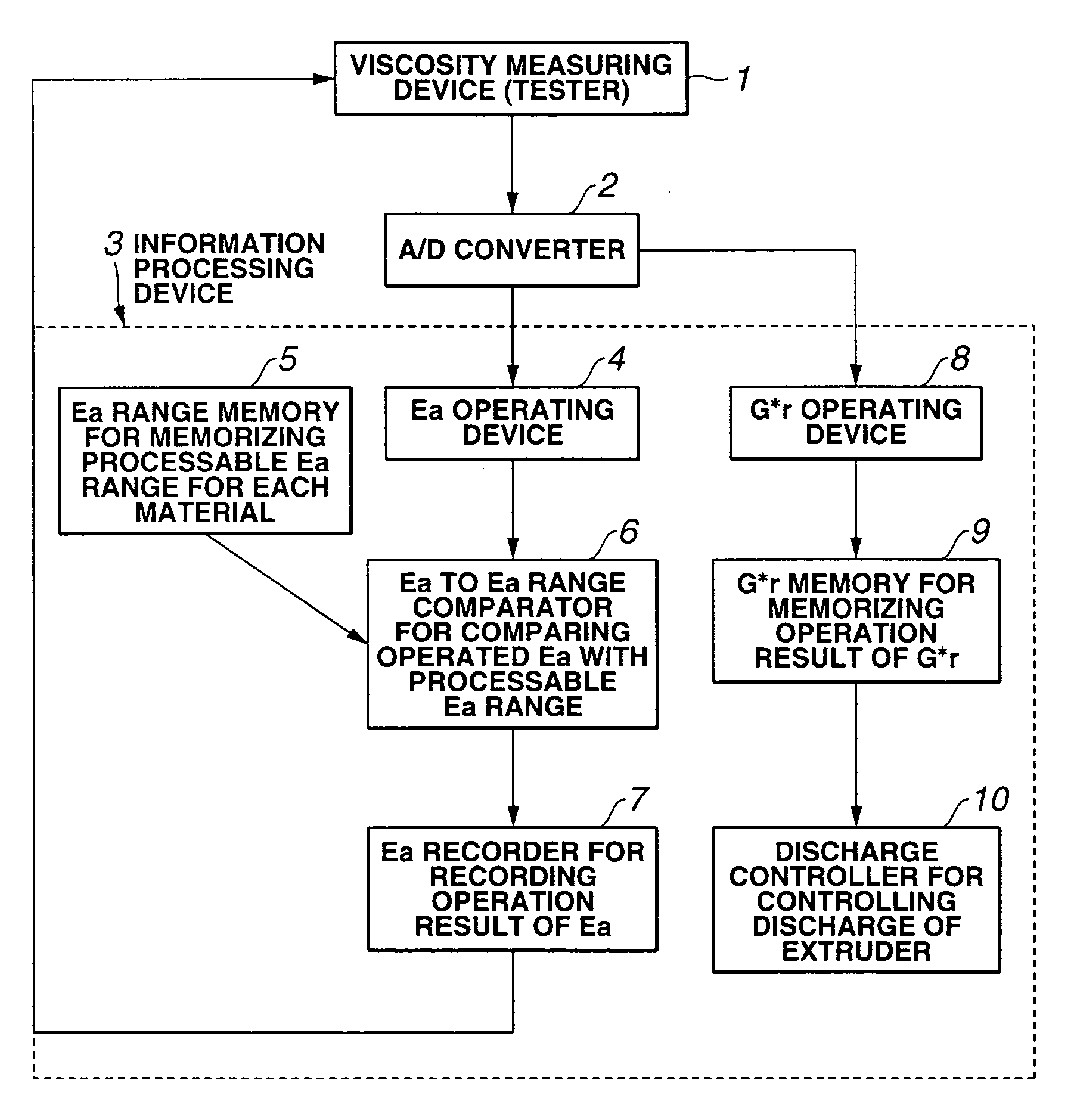

Method and device for evaluating processability of viscoelastic material, method for setting condition for processing viscoelastic material, and device for processing viscoelastic material; and method for controlling processing operation of viscoelastic material

InactiveUS20040148112A1Improve reliabilityQuality improvementFlow propertiesForce measurementVibration amplitudeShear stress

A method and a device evaluate a processability of a viscoelastic material. A measuring step and means measure a complex viscosity modulus .eta.* and two complex elasticity moduli G*1, G*2 in respective two shear ranges with different shear speeds, by the following: varying a vibration frequency and a vibration amplitude at a given temperature range, and controlling a shear stress applied to the viscoelastic material which is mixed under a given mixing condition. The shear stress causes a reactive stress. The complex viscosity modulus .eta.* and the two complex elasticity moduli G*1, G*2 are measured based on the reactive stress. A first operation operates an apparent activation energy Ea by the following: .eta.*=A.multidot.exp(Ea / RT) where T is temperature, R is gas constant, .eta.* is complex viscosity modulus. A second operation operates a complex elasticity modulus change ratio G*r, a ratio between the two complex elasticity moduli G*1, G*2.

Owner:KINUGAWA RUBBER IND CO LTD

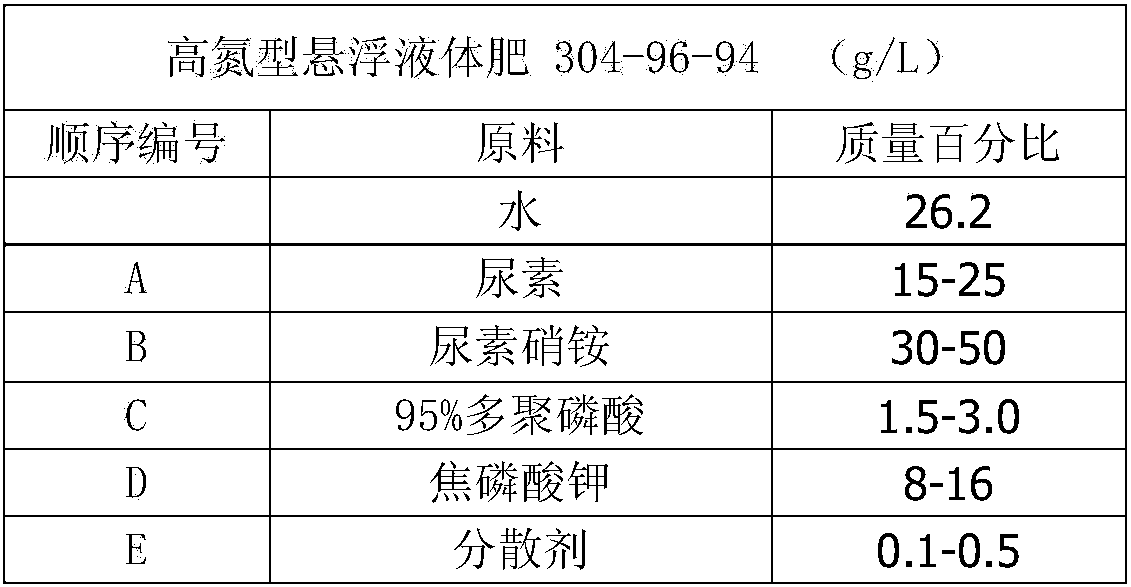

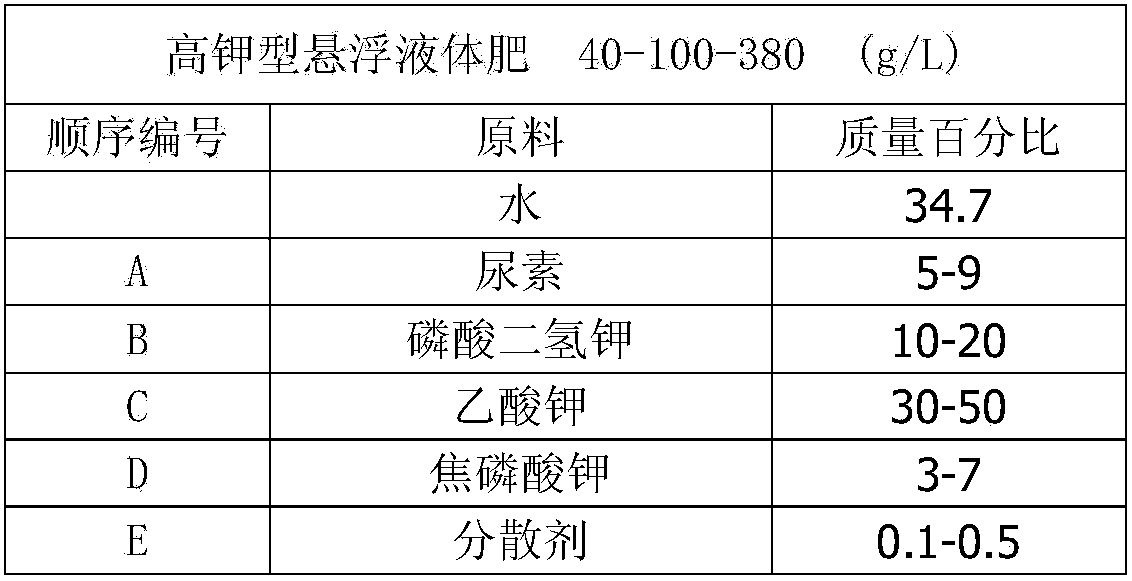

Suspension type liquid fertilizer and preparation method thereof

InactiveCN108059518AImprove stabilityHydrogen bond richAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersStable stateRoom temperature

The invention discloses a suspension type liquid fertilizer and a preparation method thereof. The suspension type liquid fertilizer comprises a dispersing agent, wherein the dispersing agent comprisesthe following components in percentage by mass: 80% of guar gum, 15% of xanthan gum and 5% of glucose, and the mass percentage content of the dispersing agent in the suspension type liquid fertilizeris 0.1-0.5%. The preparation method of the suspension type liquid fertilizer provided by the invention comprises the following steps: S1, according to the proportion of each component, adding a corresponding amount of water into a combined stirrer reaction kettle, and controlling the temperature to be 30-60 DEG C, the stirring speed to be 15-90 revolutions per minute, and the shear speed to be 1500-4500 revolutions per minute; S2, according to the proportion of each component, sequentially adding other raw materials into the combined stirrer reaction kettle spoon by spoon uniformly and dispersedly; and S3, after the feeding is finished, carrying out stirring for shearing for 25-35 minutes while carrying out cooling. According to the suspension type liquid fertilizer provided by the invention, 80% of guar gum, 15% of xanthan gum and 5% of glucose are used as the dispersing agent, strong emulsification stability and high suspension capability are achieved, and when the suspension type liquid fertilizer is placed at room temperature for 18 months, no solid sinking or caking occurs in the dispersion system, and the dispersion system is still in a stable state.

Owner:上海永通生态工程股份有限公司

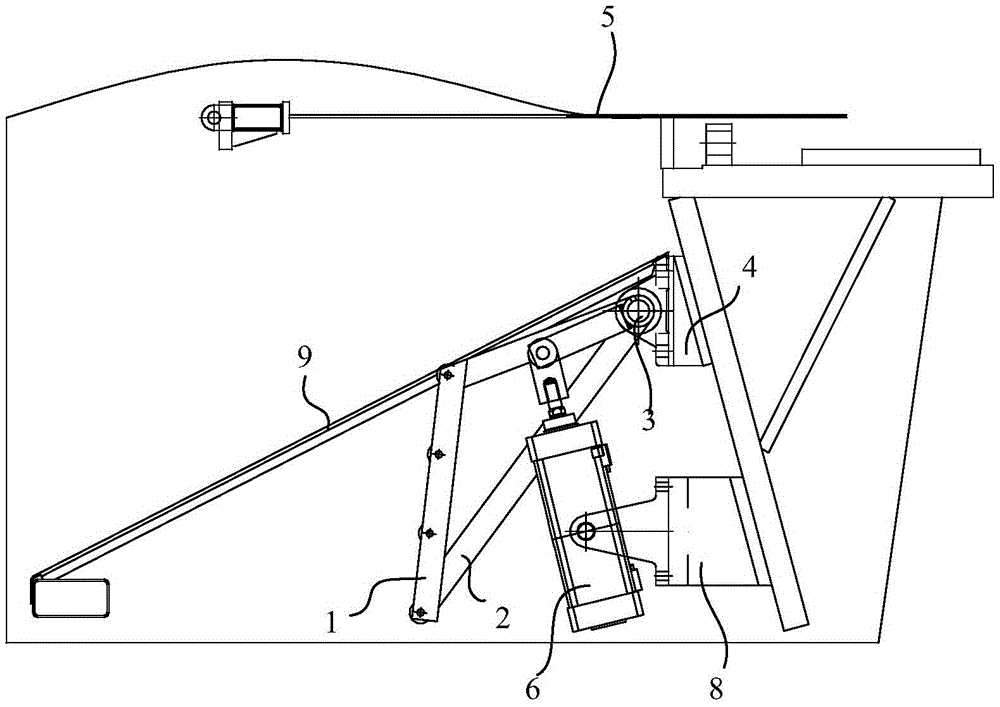

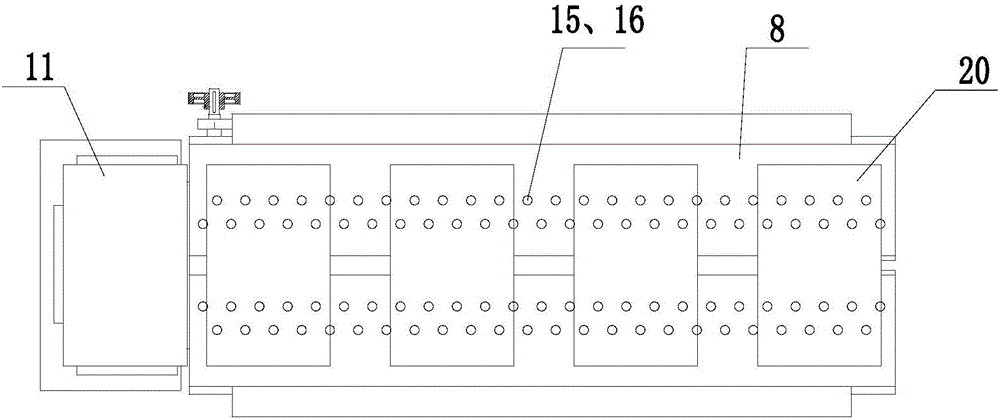

Metal sheet conveying device

The invention relates to a metal sheet conveying device, in particular to tinplate (aluminum sheet) coil stock high-speed uncoiling, flattening and sheared sheet conveying used in the metal printing tinmaking industry. The metal sheet conveying device comprises a motor, a synchronous belt, a synchronous pulley, a driving roller, a tensioning roller, a conveyor frame, a belt base plate and a conveying flat belt. The conveyor frame is arranged in a closed space, and the closed space is connected with an air draft device. The belt base plate covers the upper side of the closed space. The belt base plate is provided with a plurality of first small hole belts. The first small hole belts are composed of a plurality of first small holes which are longitudinally arranged and connected with the closed space. The conveying flat belt is arranged above the belt base plate. Second small hole belts are arranged on the conveying flat belt and correspond to the first small hole belts. The second small hole belts are composed of a plurality of second small holes which are longitudinally arranged and connected with first small holes. By means of the metal sheet conveying device, the problems caused in the tinplate high-speed conveying process are solved, the tinplate shearing speed is greatly increased, and thus high-speed shearing is made possible.

Owner:HANGZHOU HENGLI CUTTING EQUIP

Method for reducing viscosity of polystyrene melt

The invention discloses a method for reducing the viscosity of polystyrene resin and relates to the technical field of chemical engineering and materials. The method comprises the following steps: firstly, modifying a cationic chain transfer agent containing a trithiocarbonate group on the surface of polyoxometalate through electrostatic interaction, thus obtaining a polyoxometalate compound; then, grafting polystyrene to the periphery of the polyoxometalate compound through an RAFT (Reversible Addition-Fragmentation Chain Transfer) polymerization reaction, thus obtaining a star polymer which takes the polyoxometalate as a core and a polymer as an arm; finally, taking the star polymer as nano filler, and compounding the star polymer to a polystyrene matrix through a solution blending method, thus realizing reduction of the viscosity of a melt. The principle of the method is that through compatibility of a polymer chain on the surface of the polyoxometalate and the polystyrene matrix, the star polymer is introduced into a polystyrene entanglement network, and disentanglement of a polystyrene chain is promoted under a shear condition, so that the viscosity of the polystyrene melt is reduced. The method disclosed by the invention is capable of effectively reducing the viscosity of the polystyrene melt under the condition that the shear speed is switched from 0 to 10<5> rad.S<-1>.

Owner:长春艾德斯新材料有限公司

Method for preparing snowman-like organic/inorganic hybrid particles by adopting one-step miniemulsion polymerization method

The invention relates to a method for preparing snowman-like organic / inorganic hybrid particles by adopting one-step miniemulsion polymerization method. The method comprises the following steps: coupling agent modified inorganic particles are dispersed in emulsifier-containing deionized water for ultrasonic processing, and a solution I is obtained; deionized water containing a monomer, a co-emulsifier and an emulsifier is subjected to ultrasonic processing, and a solution II is obtained; the solution I and the solution II are mixed, stirred at a low speed and sheared at a high speed, an initiator is added to initiate polymerization, and the snowman-like organic / inorganic hybrid particles are obtained. Monomer droplets are dispersed into stable microspheres under an ultrasonic effect by means of the emulsifier and the co-emulsifier, the monomer microspheres collide with the inorganic particles under the action of high-speed shearing, and the size and number of the monomer microspheres and the collision and binding degrees of the monomer microspheres with the inorganic particles can be controlled through proper matching of the emulsifier and the co-emulsifier, proper ultrasonic power and ultrasonic time as well as proper high-speed shearing speed and time. The method has the advantages of simple technological process, high yield of snowman-like particles and easiness in scale production.

Owner:SHANGHAI JIAO TONG UNIV

Control method of head shearing speed of flying shears for hot continuously rolled band steel

InactiveCN106077805AEnsure consistencySolve the effect of actual speedShearing control devicesSlip coefficientEngineering

The invention provides a control method of the head shearing speed of a pair of flying shears for hot continuously rolled band steel and belongs to the technical field of metallurgy. The control method comprises the steps that firstly, an HMD60 hot metal detector is installed at the position 3 meters away from the flaying shears; secondly, the head shearing speed of the flying shears is set to be 0.8 m / s- 1.5 m / s; thirdly, no band steel exists in the area of the flying shears, the speed of a roller way in the area of the flying shears is 0.8 m / s- 1.5 m / s; and fourthly, when the band steel passes through the area of the flying shear, the speed of the roller way in the area of the flying shear is the product of the F0 machine frame speed actual value and the F0 machine frame backward slip coefficient. By the adoption of the control method of the head shearing speed of the pair of flying shears for the hot continuously rolled band steel, the influence of frequent change of the speed of the roller way on the actual band steel speed is eliminated, and the problem of the influence of faults of a laser velocimeter on production operation is also solved; and the stability of band steel head shearing control is achieved, and fault time is shortened.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Steel plate shear positioning system and utilization method thereof

ActiveCN108856873APrecise positioningSimple stepsShearing machinesShearing machine accessoriesMotor driveArchitectural engineering

The invention discloses a steel plate shear positioning system and a utilization method thereof. The system comprises a supporting bottom plate, front and rear sides of the upper surface of the supporting bottom plate are provided with two slide rails, two slide connection seats in slide connection are arranged on the slide rails, and second hydraulic telescopic rods are connected to two ends of the upper surface of each slide connection seat through bolts. A double-shaft motor drives a threaded rod to rotate, the two slide connection seats are driven to move through the threaded rod to further adjust a distance between two lower end fixing plates, upper end fixing plates are driven to move downwards through first hydraulic telescopic rods, and a steel plate is fixed to positioning groovesof the lower end fixing plates through the upper end fixing plates. The steel plate shear positioning system and the utilization method thereof have advantages that simple steps and simplicity and convenience in operation are realized, convenience in steel plate positioning is achieved while manpower is greatly saved, convenience is provided for people, high positioning speed is realized, and theplate shear speed is increased.

Owner:马鞍山市中亚机床制造有限公司

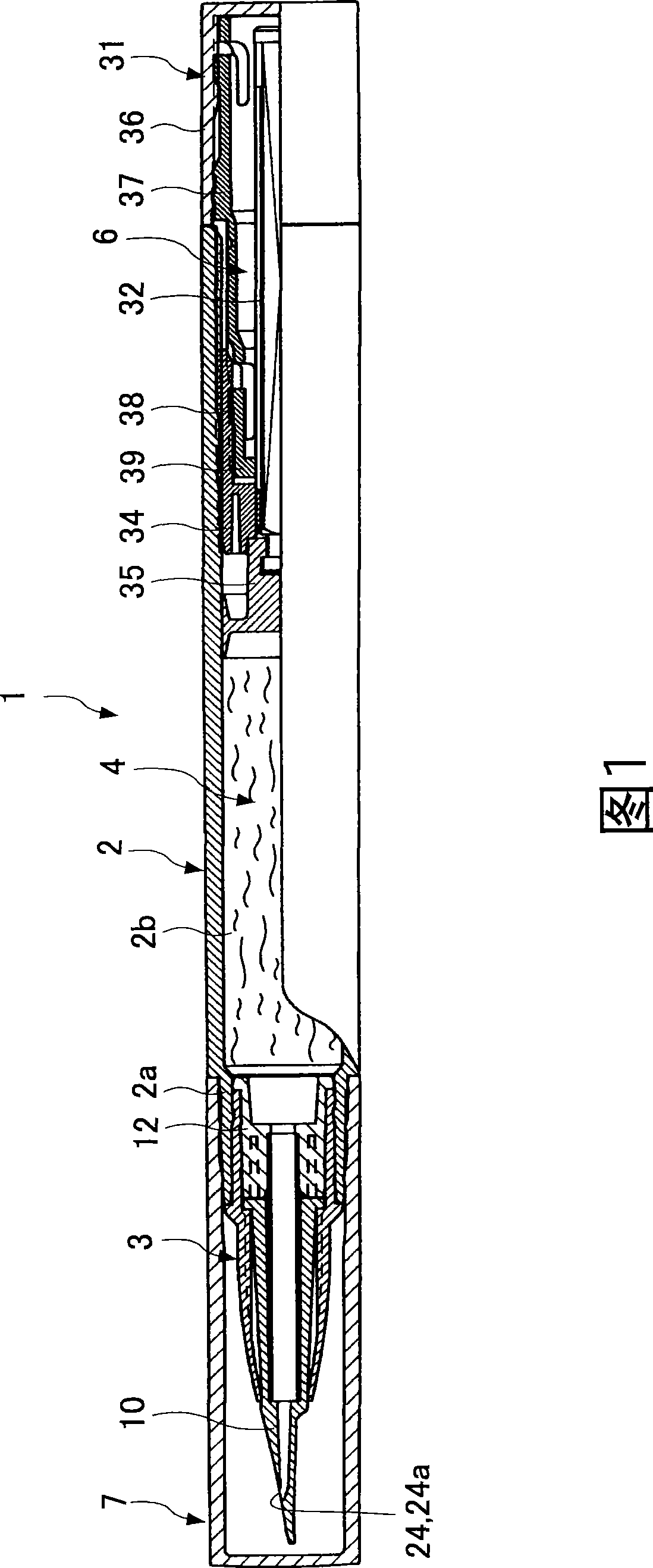

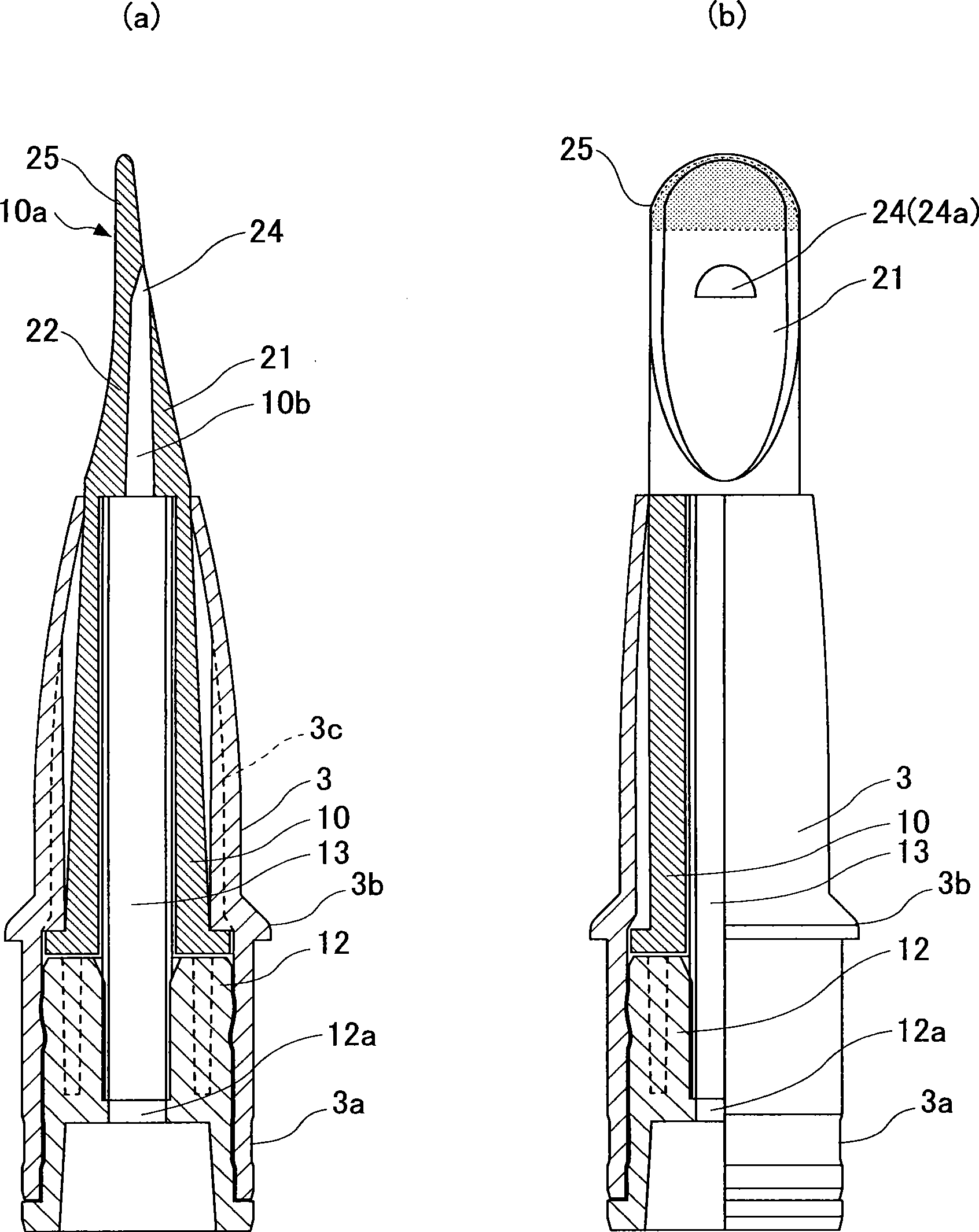

Viscous cosmetic

ActiveCN101453922AGood coating effectEffective movementCosmetic preparationsMake-upDipropylene glycolViscosity

It is intended to provide a viscous cosmetic packed in an extrusion container, into which the contents (i.e., the viscous cosmetic) once taken out therefrom can be put back, wherein the container has a shape ensuring the effective application of the viscous cosmetic while the viscous cosmetic has a viscosity appropriate for the shape. In a viscous cosmetic packed in an extrusion container, into which the contents (i.e., the viscous cosmetic) once taken out therefrom can be put back, the applicator of the container is made of an elastic material; the application face is a smooth face inclining to the longitudinal axis of the container body; the diameter of a tubular viscous cosmetic-supplying pipe of the container is from 1.7 to 2.2 mm; a discharge port (an opening) for discharging the viscous cosmetic outward is located in the application face in connection to the pipe; and the viscous cosmetic has a viscosity of 19000 mPa s or above at a shear speed of from 0 to 5 sec<-1> and a viscosity of 11000 mPa s or below at a shear speed of 40 sec<-1>, and further contains 0.2 wt% or more of dipropylene glycol.

Owner:SHISEIDO CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com