Back support device of plate shearing machine

A shearing machine and material support technology, which is applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problems of positioning accuracy, impact on shearing rhythm, loss, etc., and achieve geometric accuracy and improve The effect of shearing quality and less distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

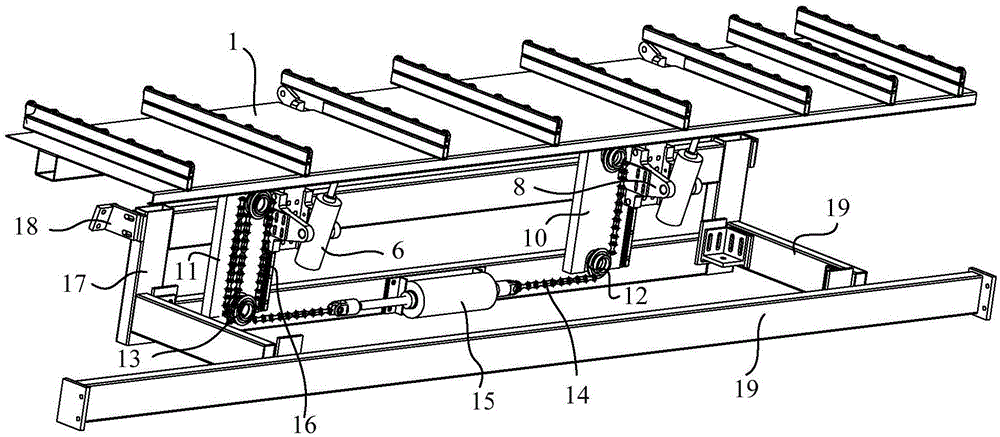

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

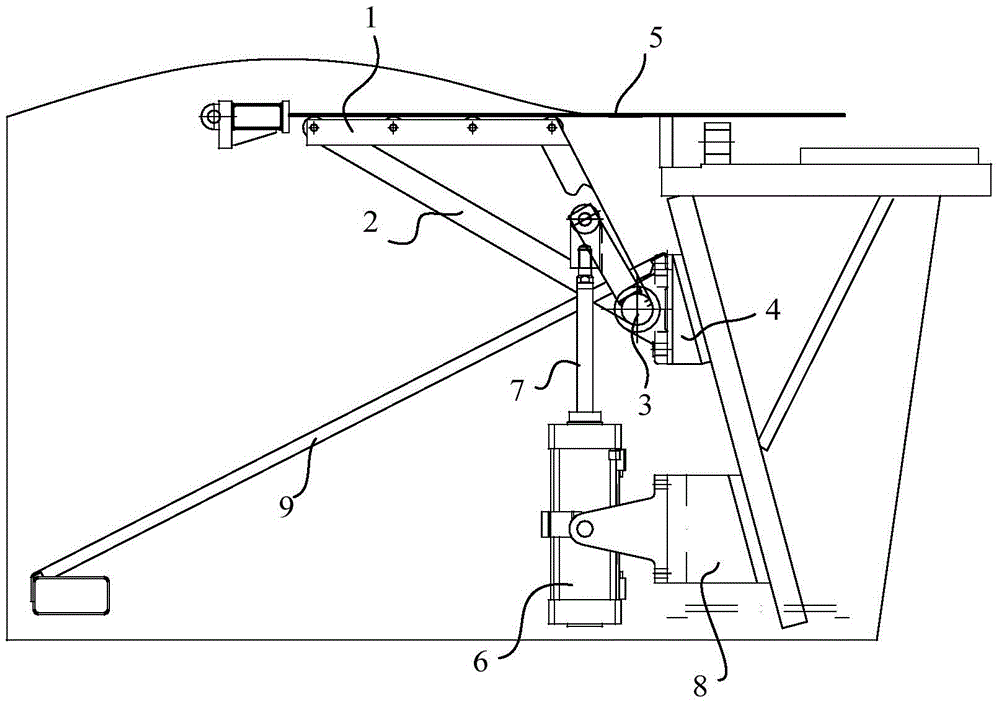

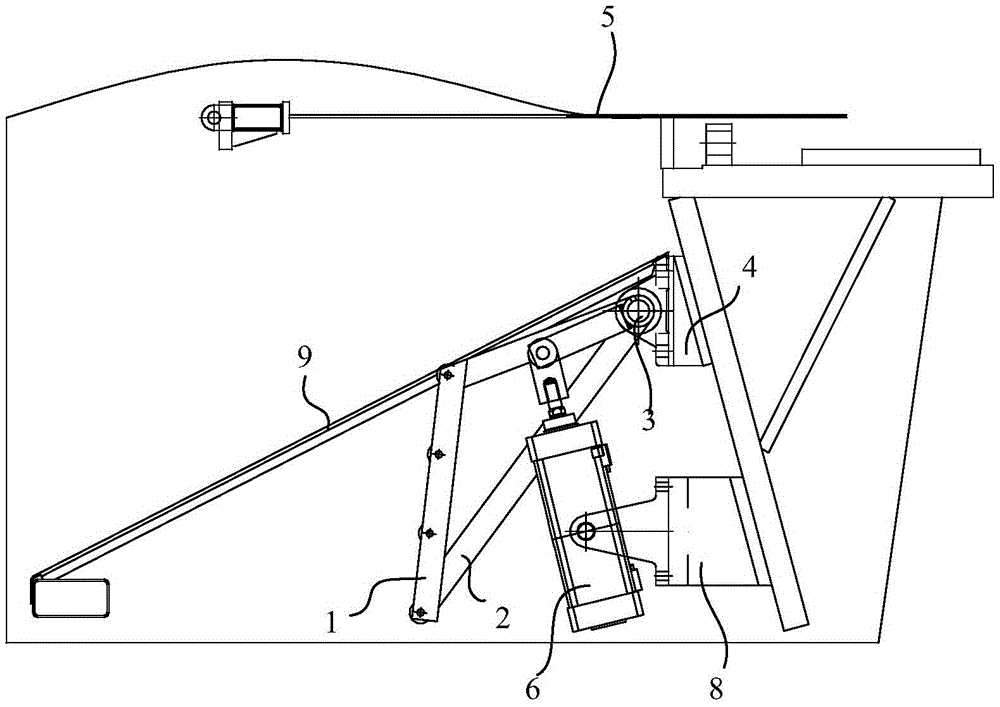

[0027] Such as image 3 As shown, a material supporting device for a shearing machine includes a synchronous lifting mechanism and a material support frame 1 that can be lifted and lowered with the synchronous lifting mechanism. The synchronous lifting mechanism includes two lifting seat assemblies, and two lifting seat assemblies Under the action of the synchronous lifting mechanism, the support frame 1 can be raised and swung to a horizontal state during the material support process, and the support frame 1 can be horizontally lowered at the same speed as the shearing plate during the shearing process Avoid the collision between the support frame 1 and the upper scissors, and can support the sheet material, so that the geometric accuracy of the sheared workpiece is greatly improved, the sheet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com