Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

881 results about "Viscometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A viscometer (also called viscosimeter) is an instrument used to measure the viscosity of a fluid. For liquids with viscosities which vary with flow conditions, an instrument called a rheometer is used. Thus, a rheometer can be considered as a special type of viscometer. Viscometers only measure under one flow condition.

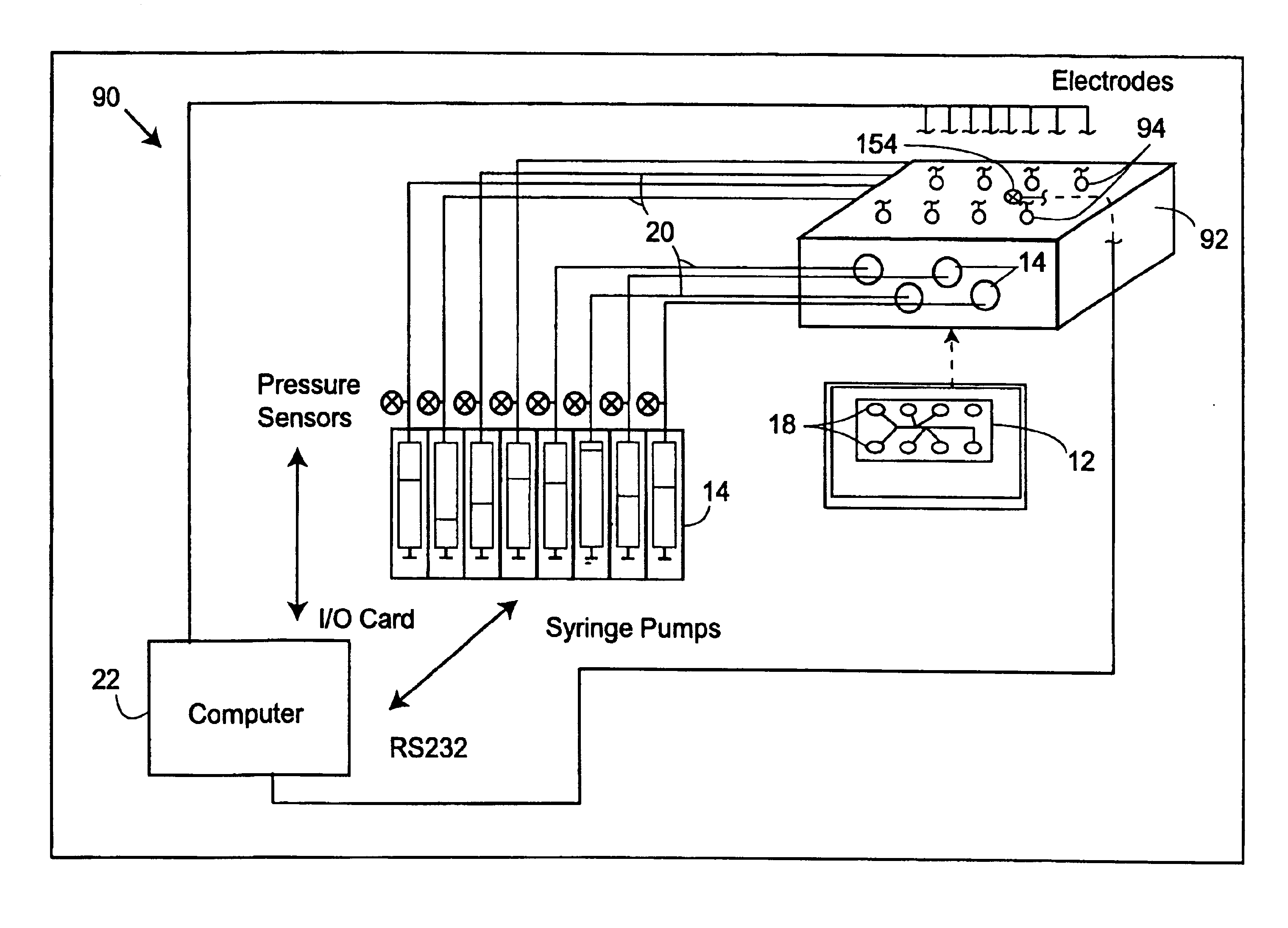

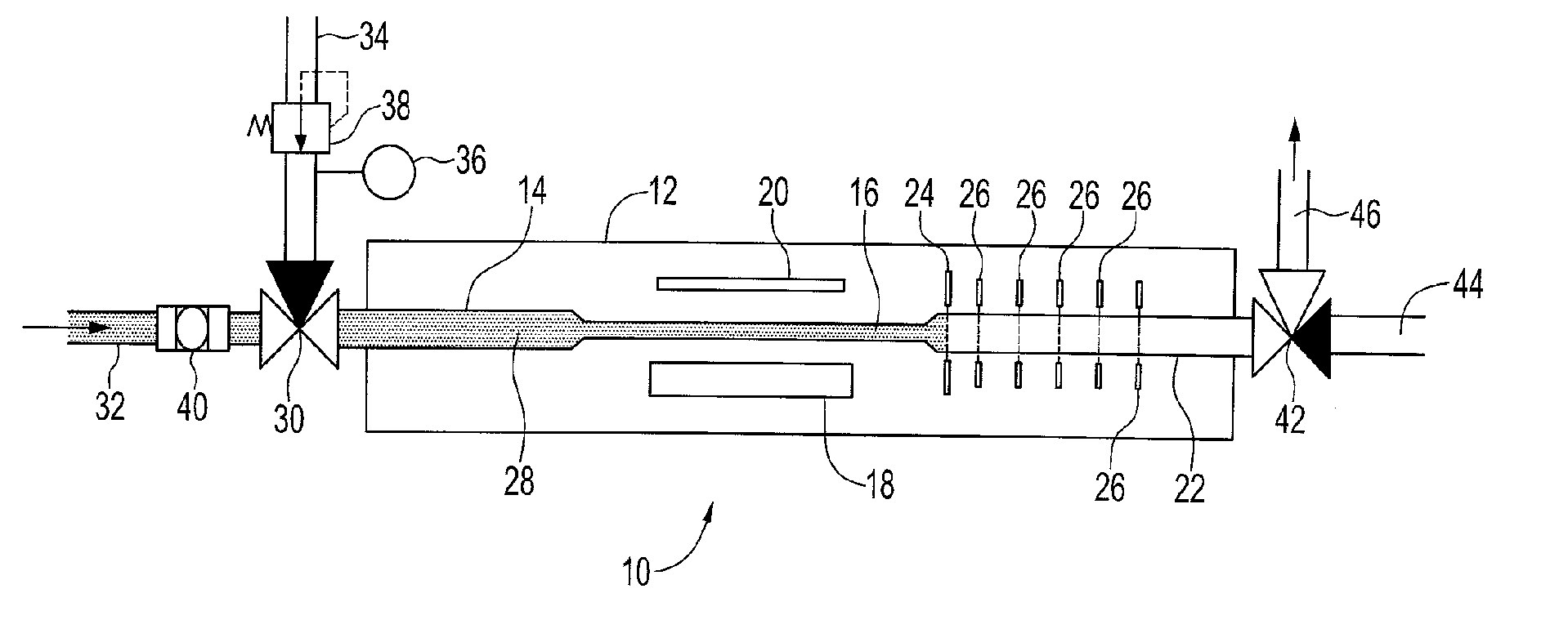

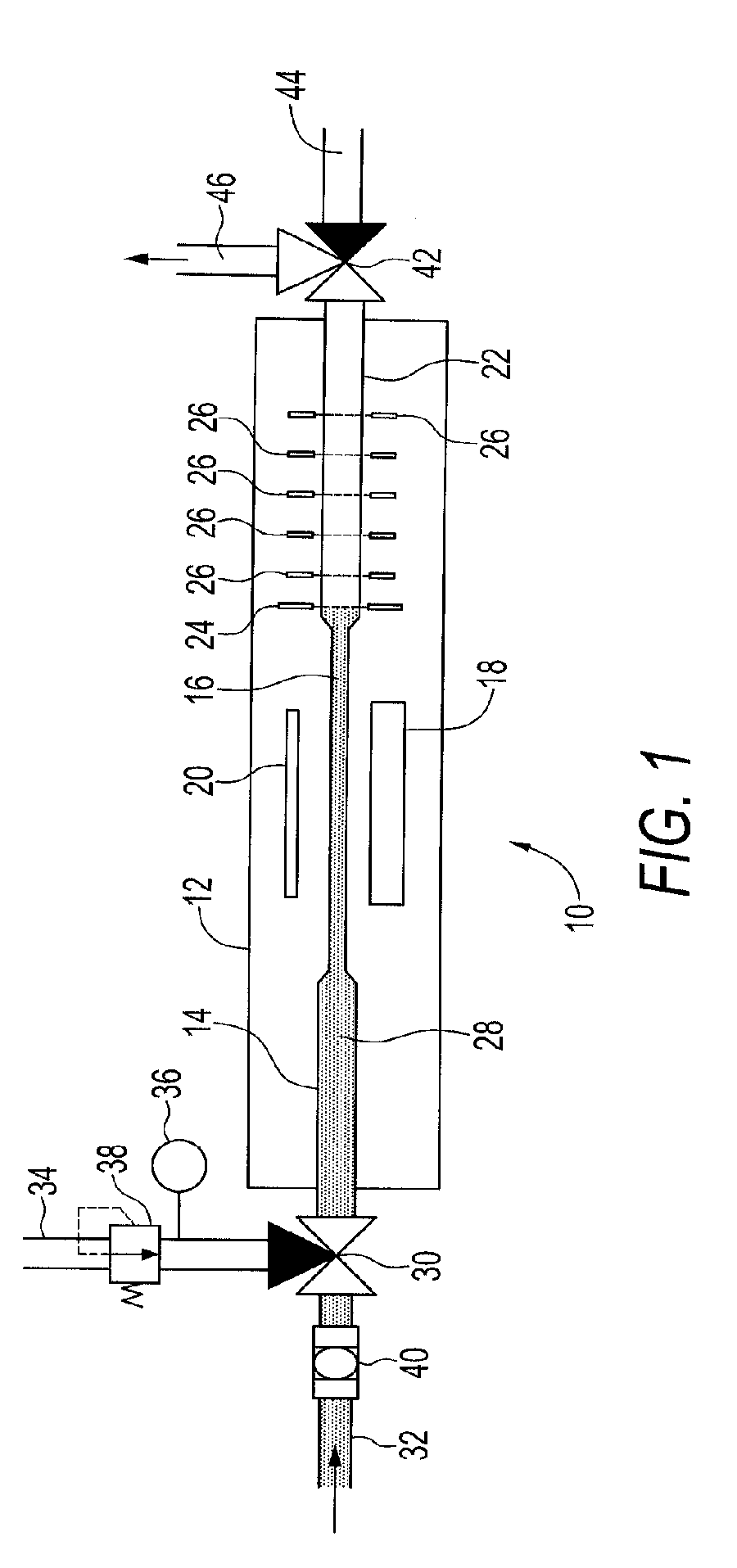

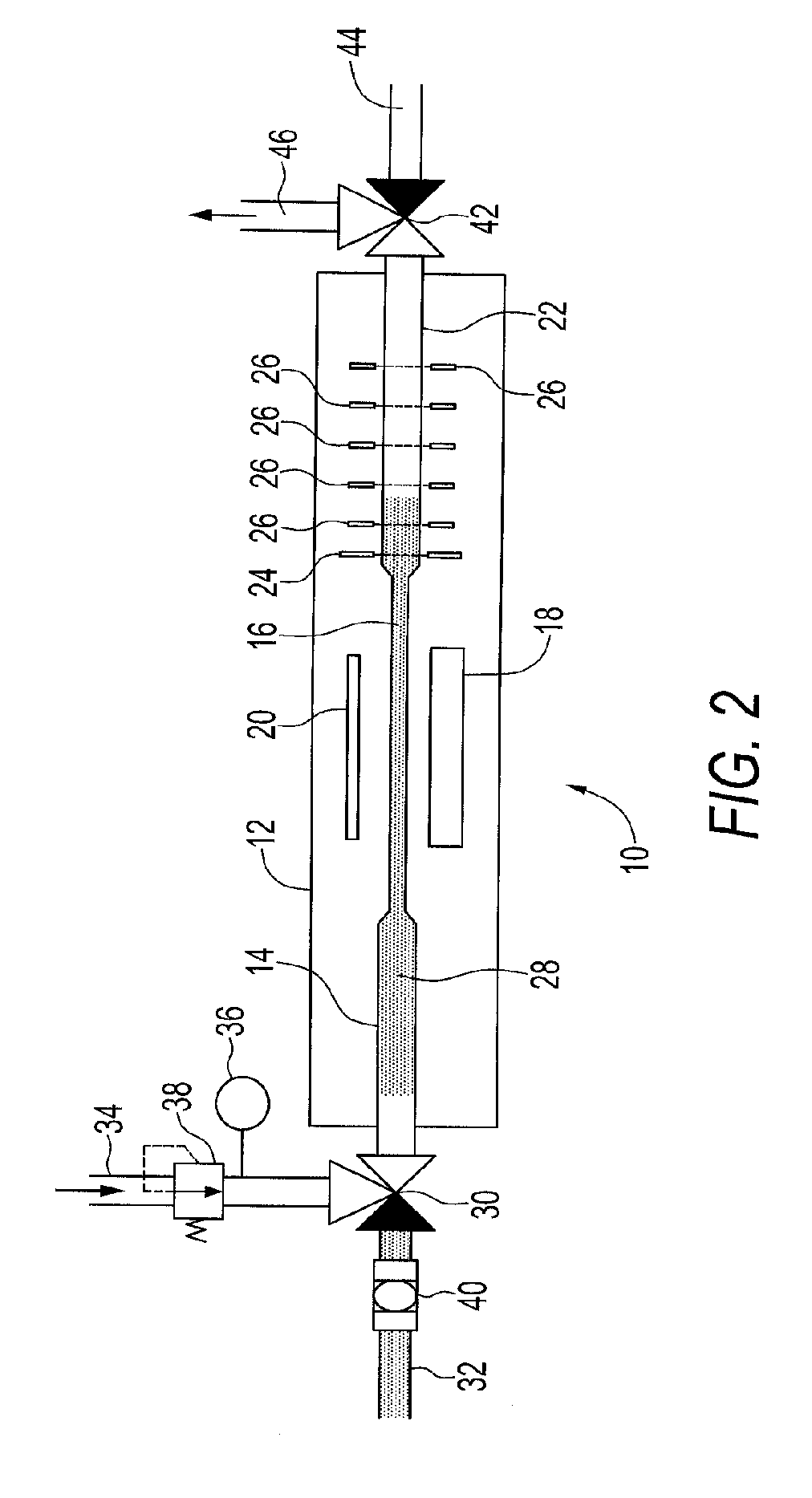

Multi-reservoir pressure control system

InactiveUS6915679B2Sufficient oscillationAccurate and stable and reliable assayAnalysis by electrical excitationLaboratory glasswaresFluid transportFlow resistivity

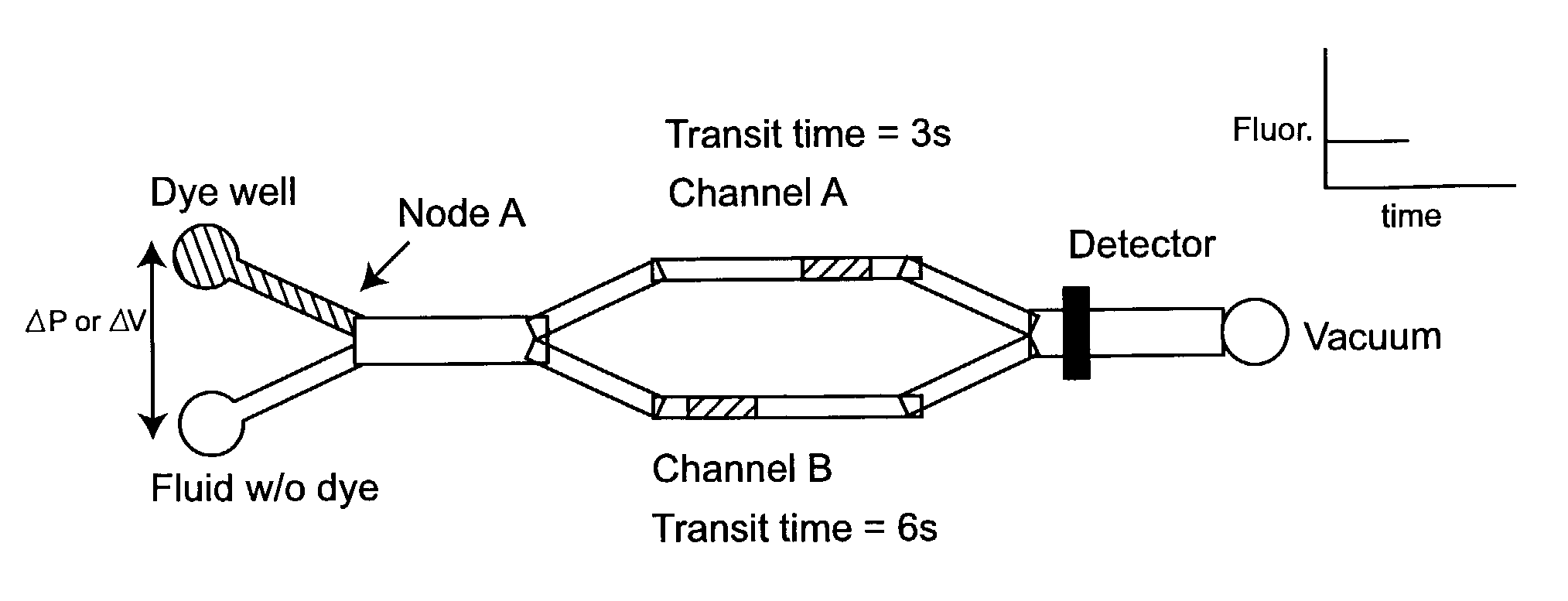

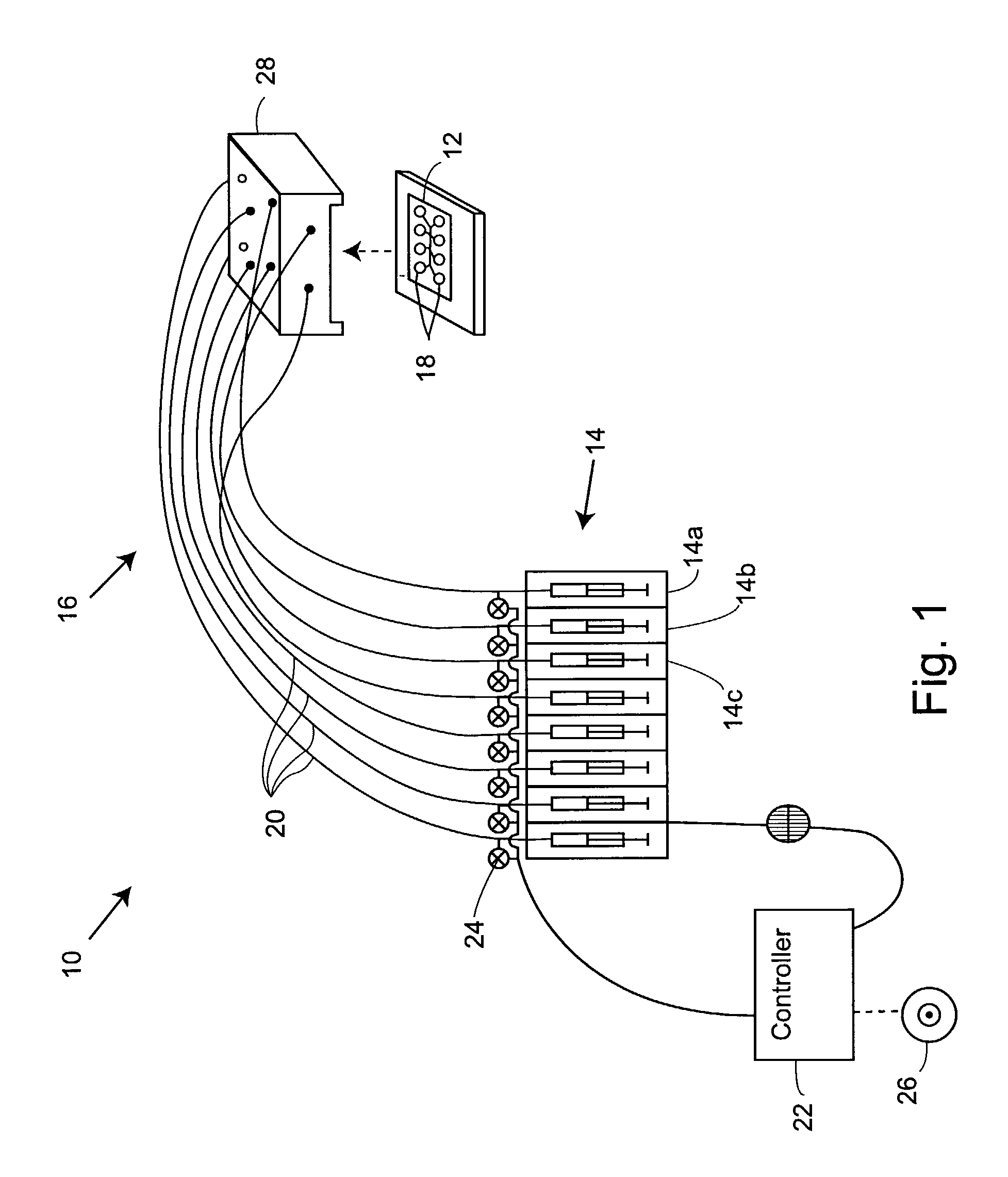

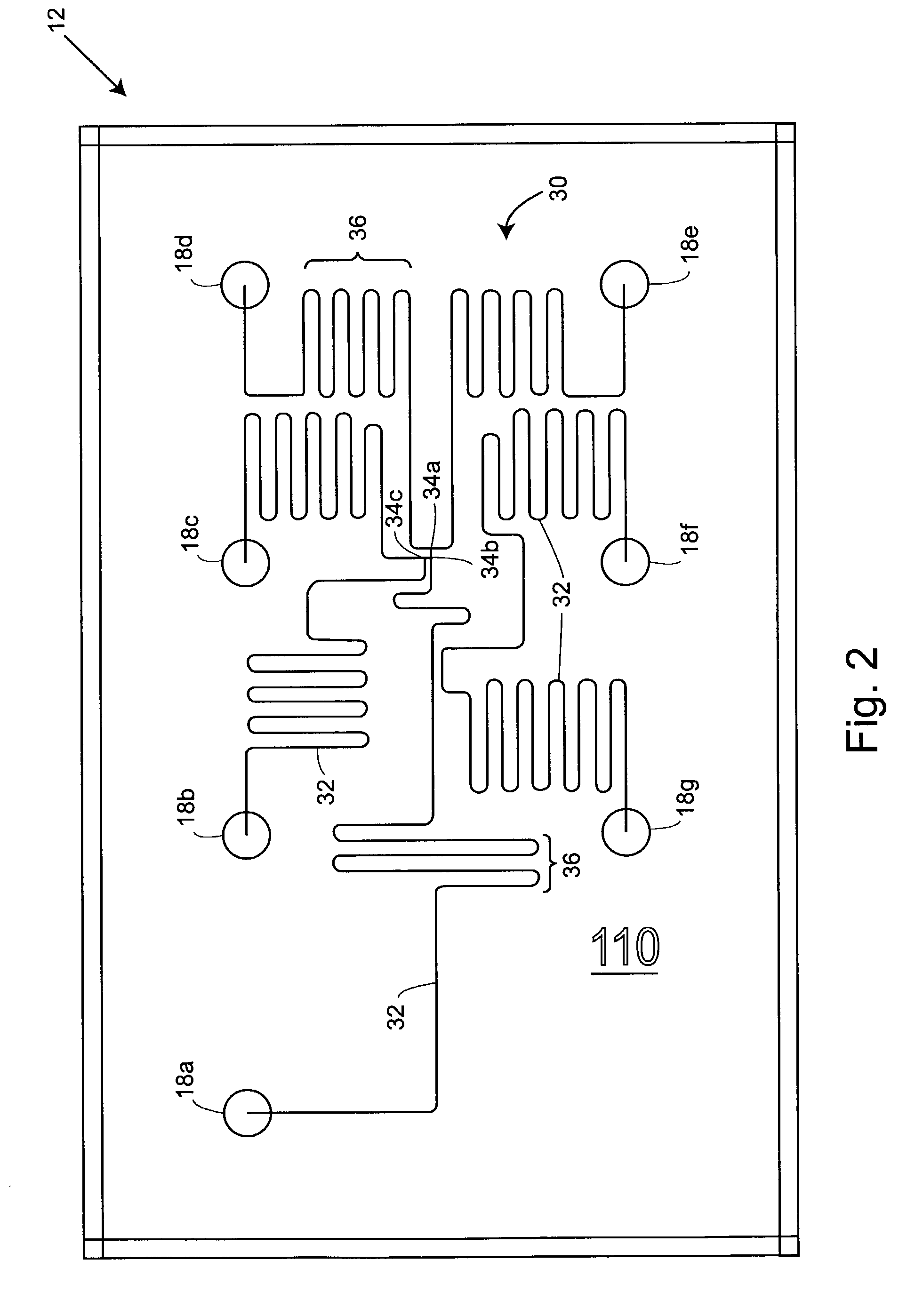

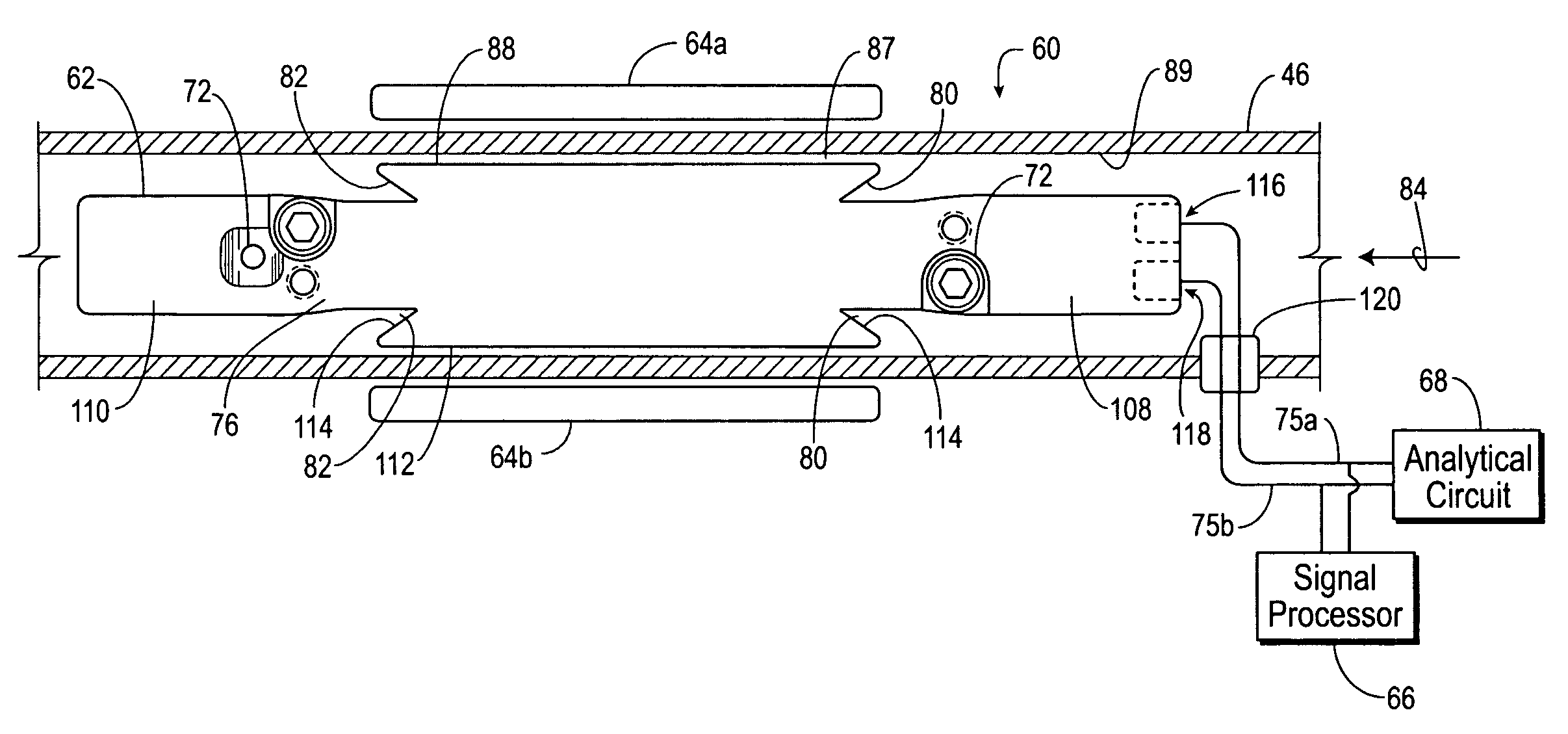

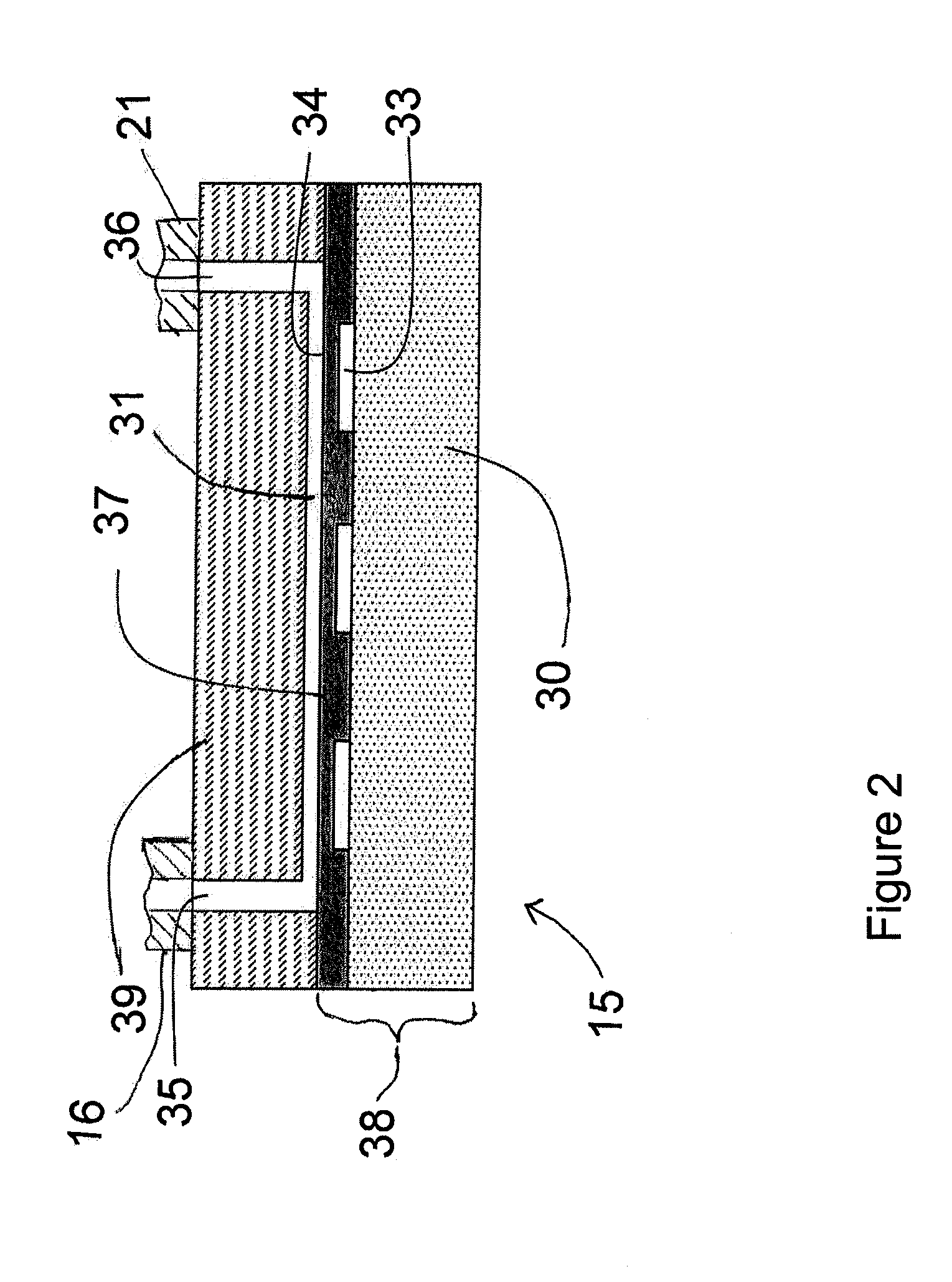

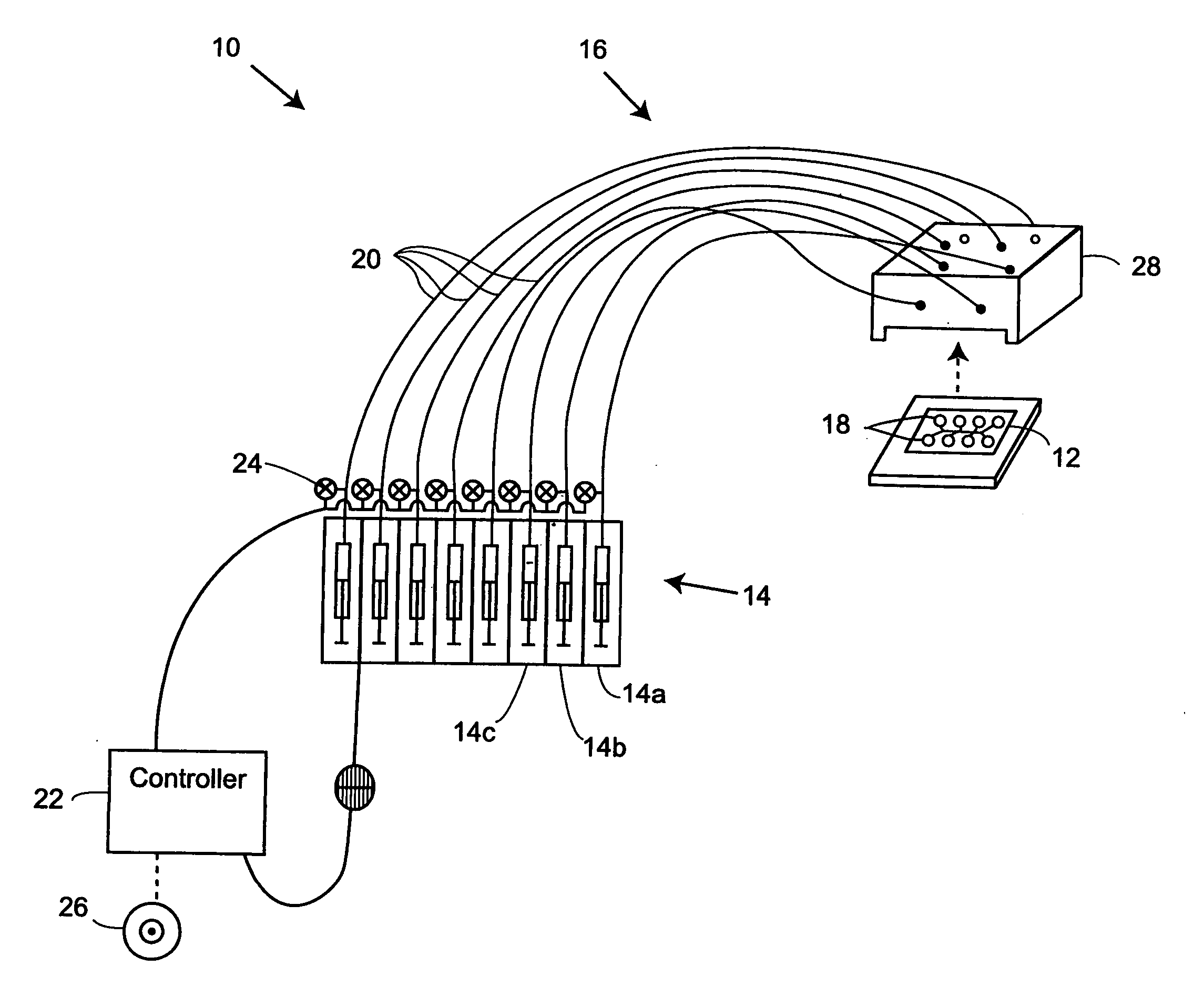

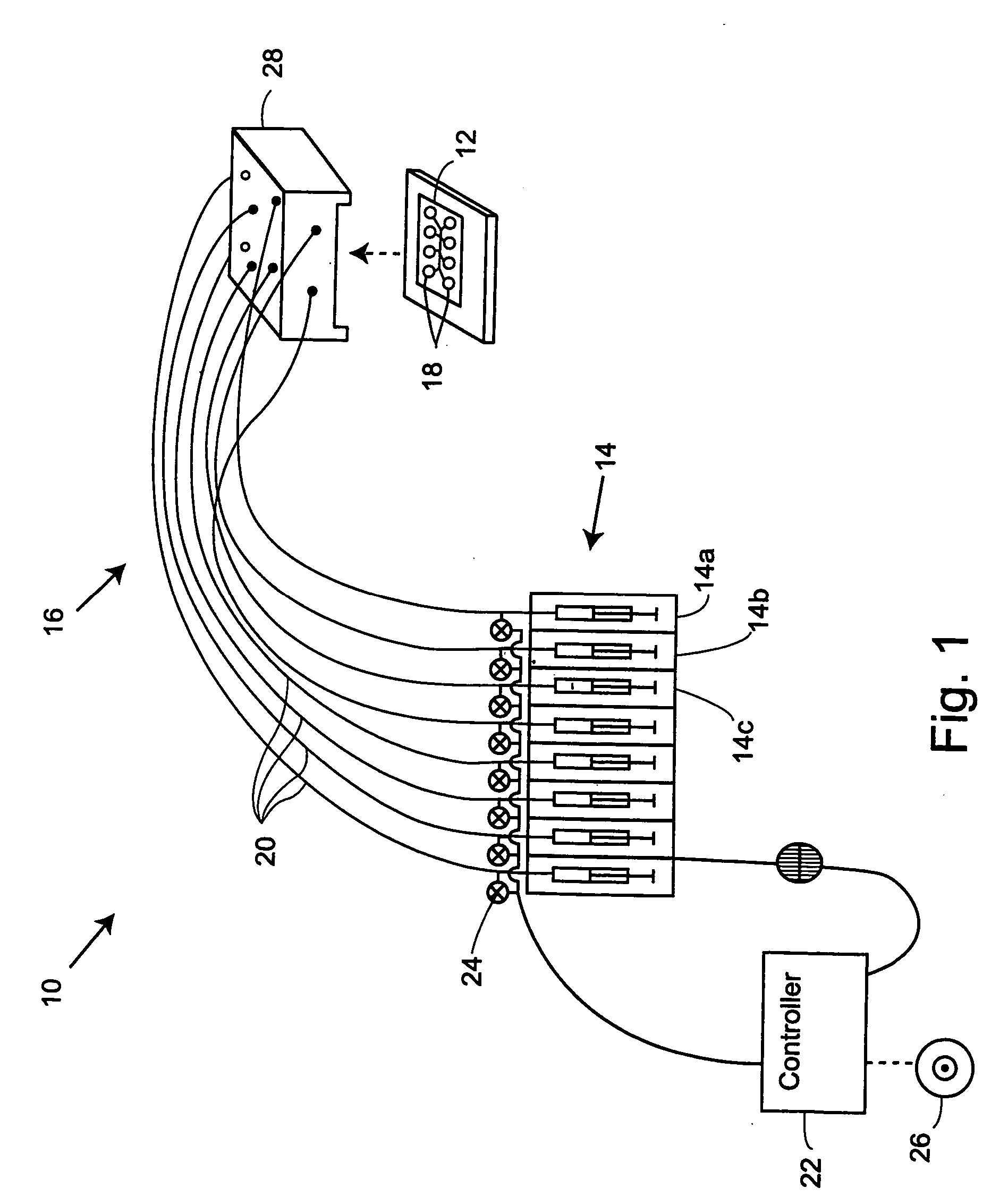

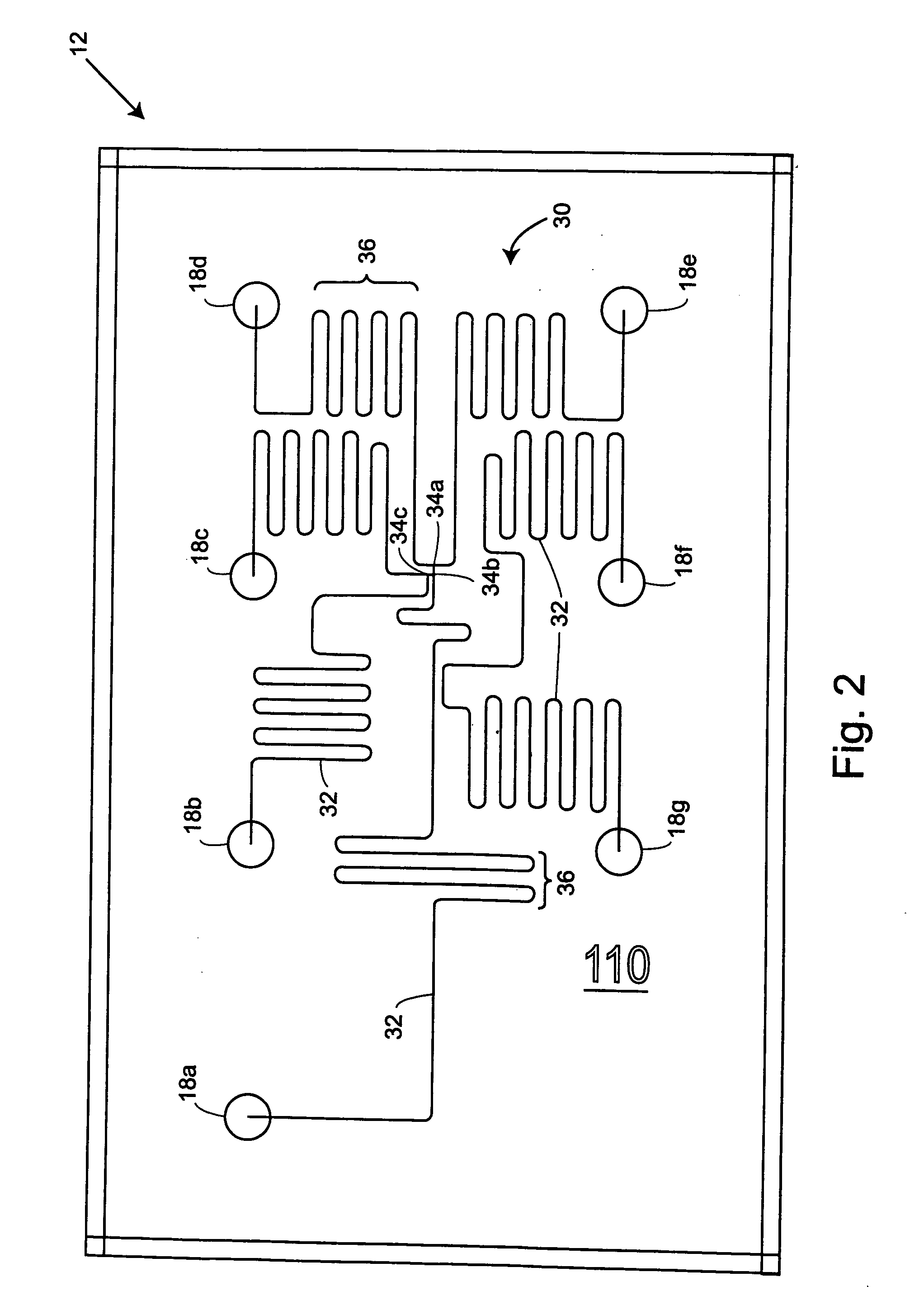

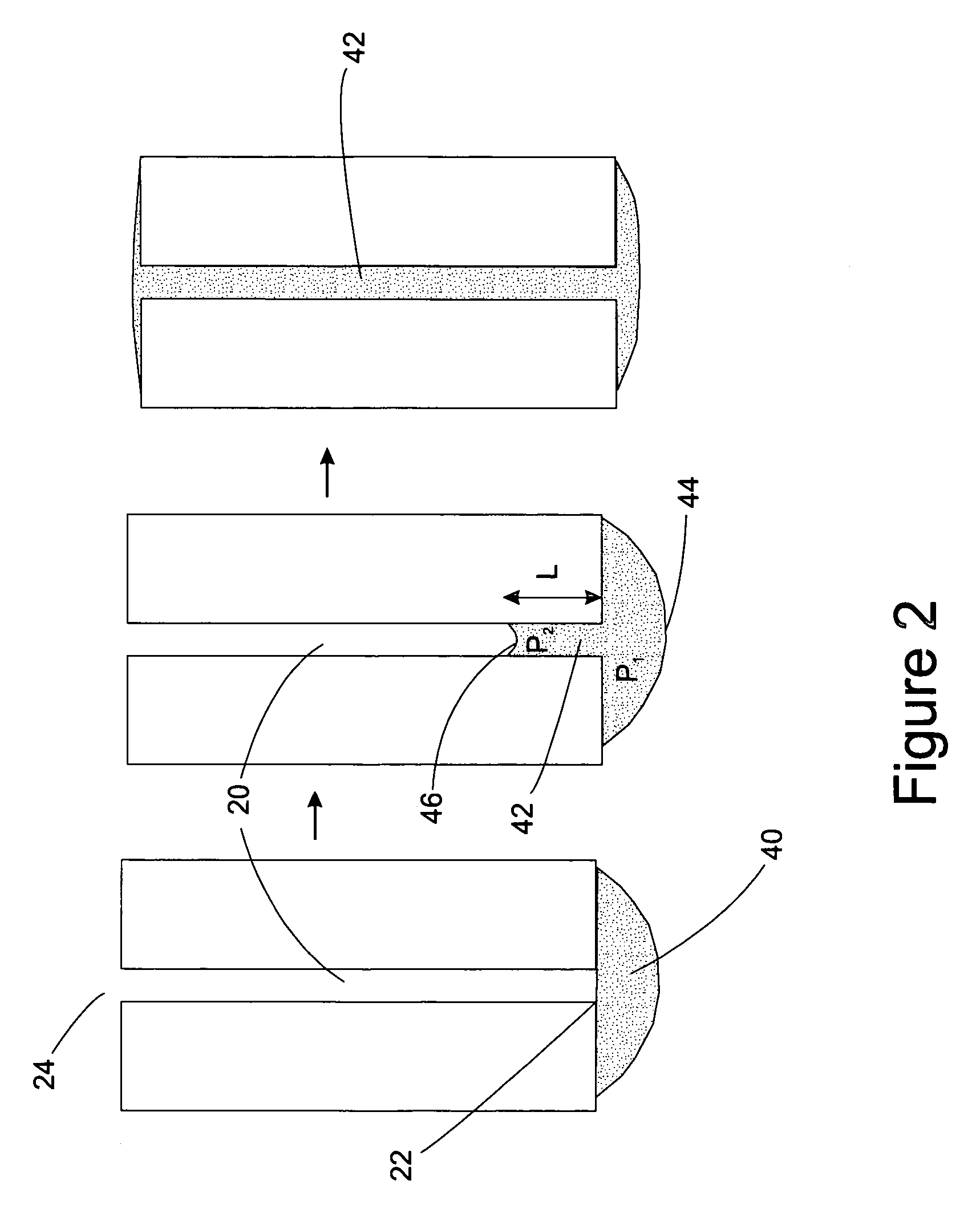

Improved microfluidic devices, systems, and methods allow selective transportation of fluids within microfluidic channels of a microfluidic network by applying, controlling, and varying pressures at a plurality of reservoirs. Modeling the microfluidic network as a series of nodes connected together by channel segments and determining the flow resistance characteristics of the channel segments may allow calculation of fluid flows through the channel segments resulting from a given pressure configuration at the reservoirs. To effect a desired flow within a particular channel or series of channels, reservoir pressures may be identified using the network model. Viscometers or other flow sensors may measure flow characteristics within the channels, and the measured flow characteristics can be used to calculate pressures to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems can optionally be used in conjunction with electrokinetic or other fluid transport mechanisms.

Owner:CAPLIPER LIFE SCI INC

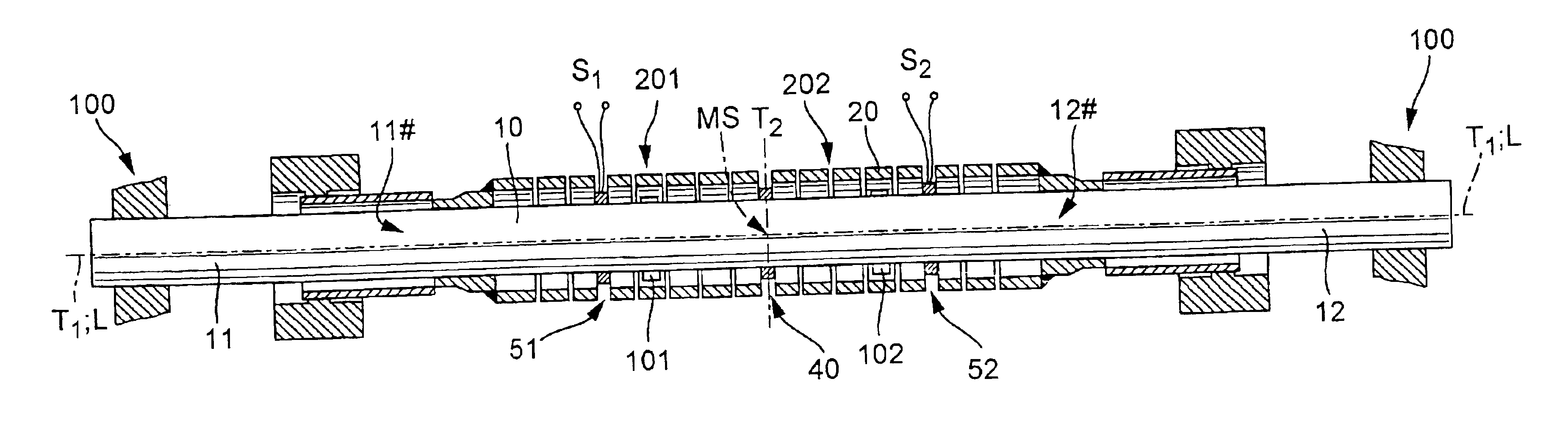

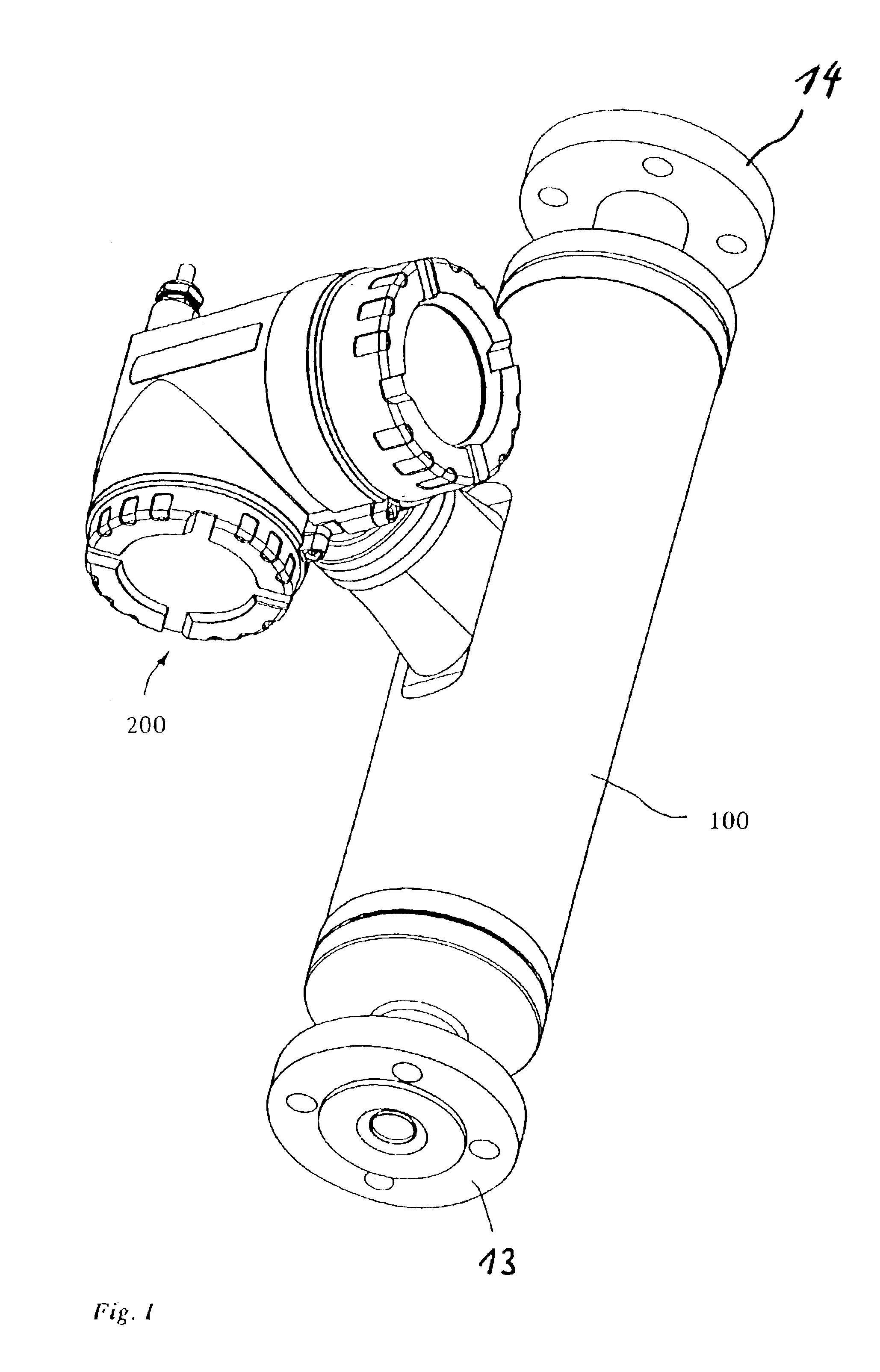

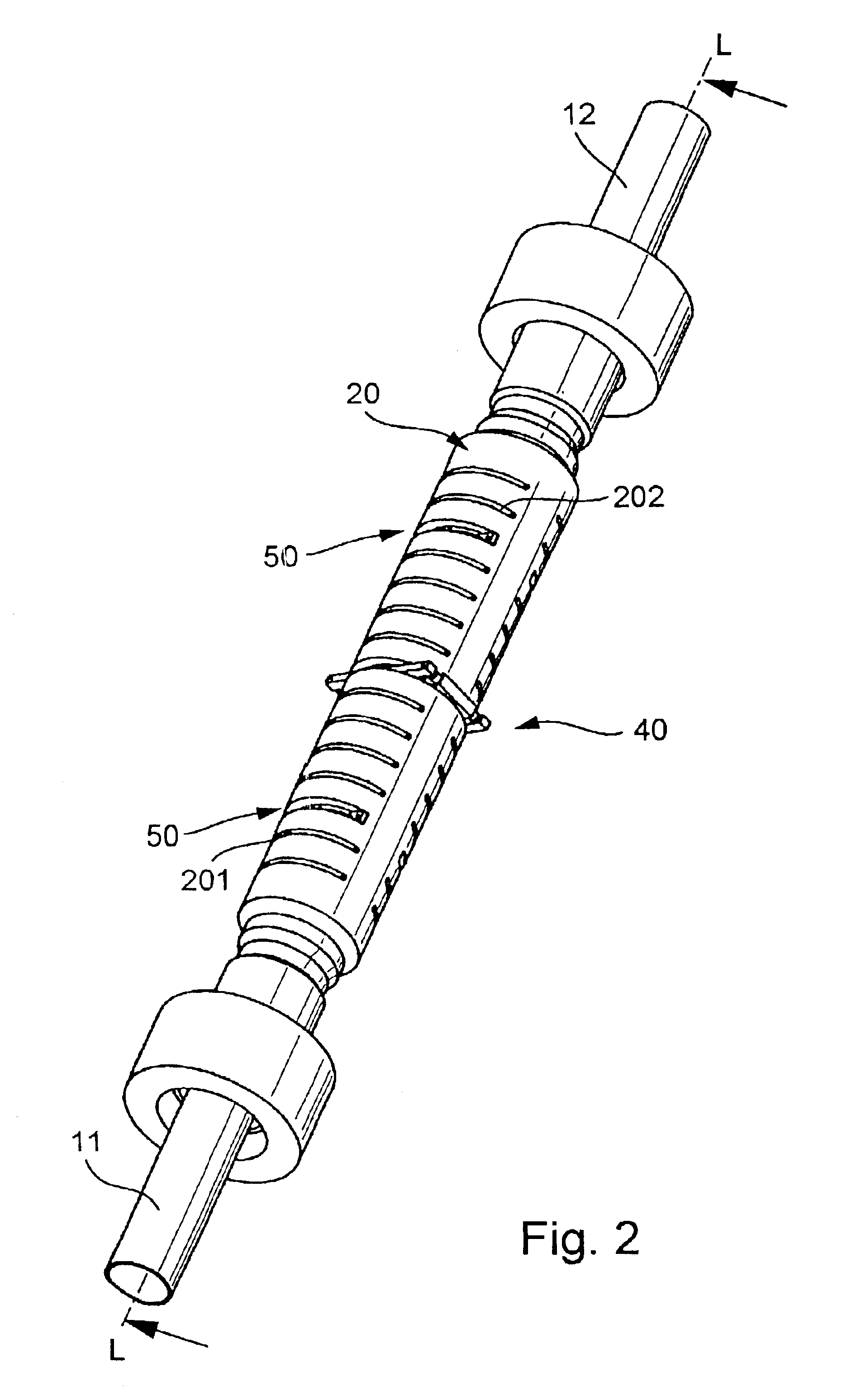

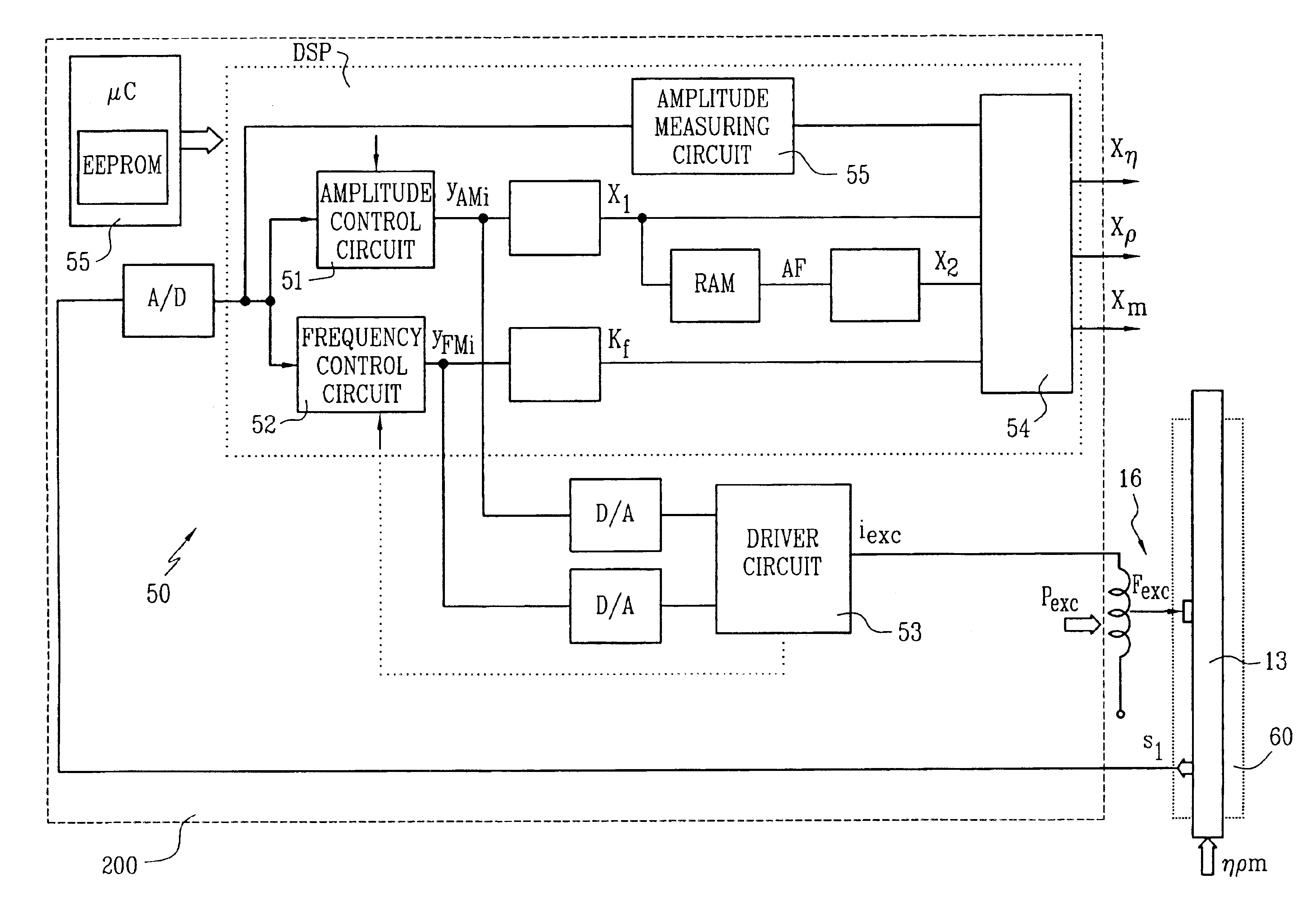

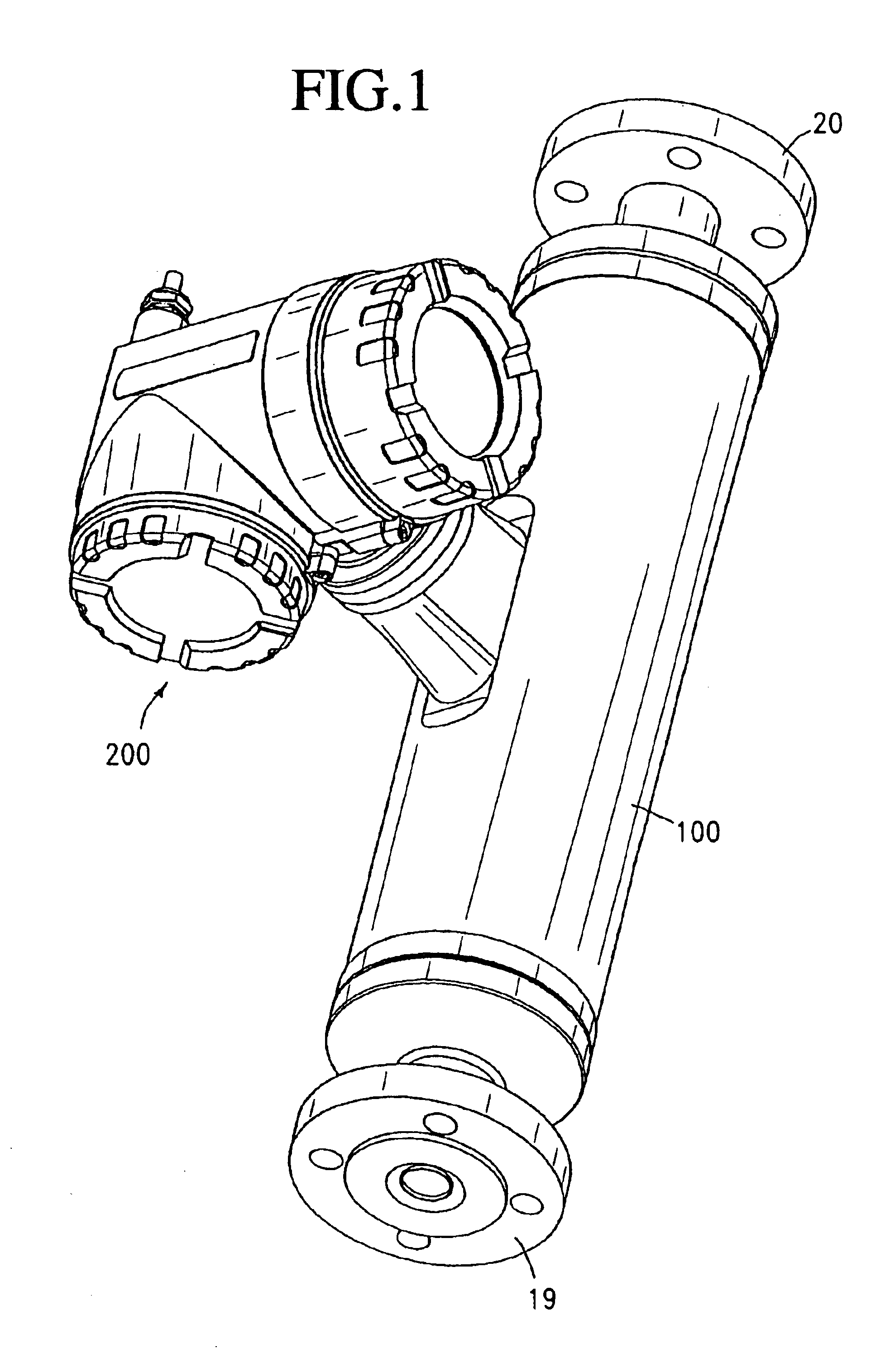

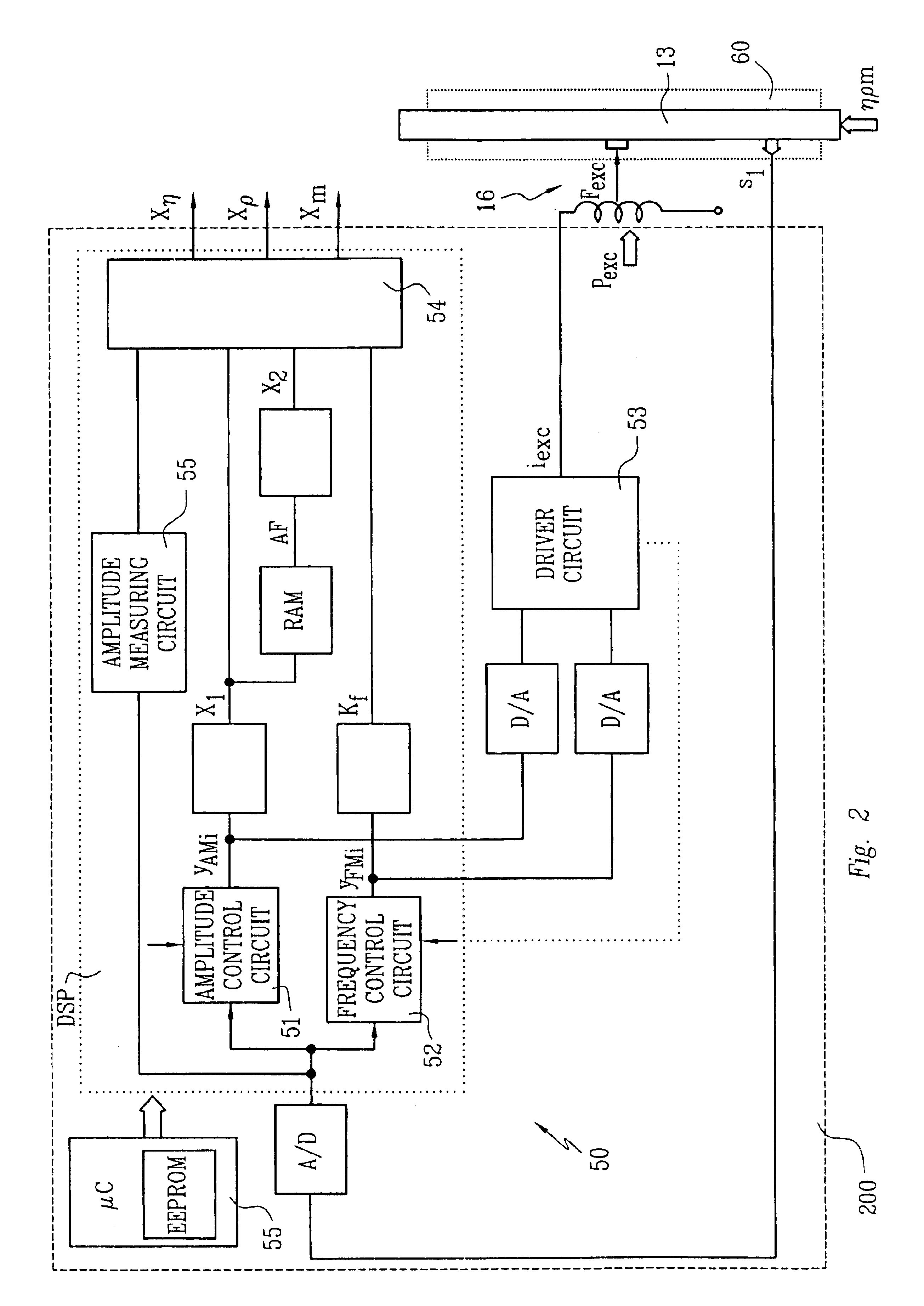

Vibratory transducer

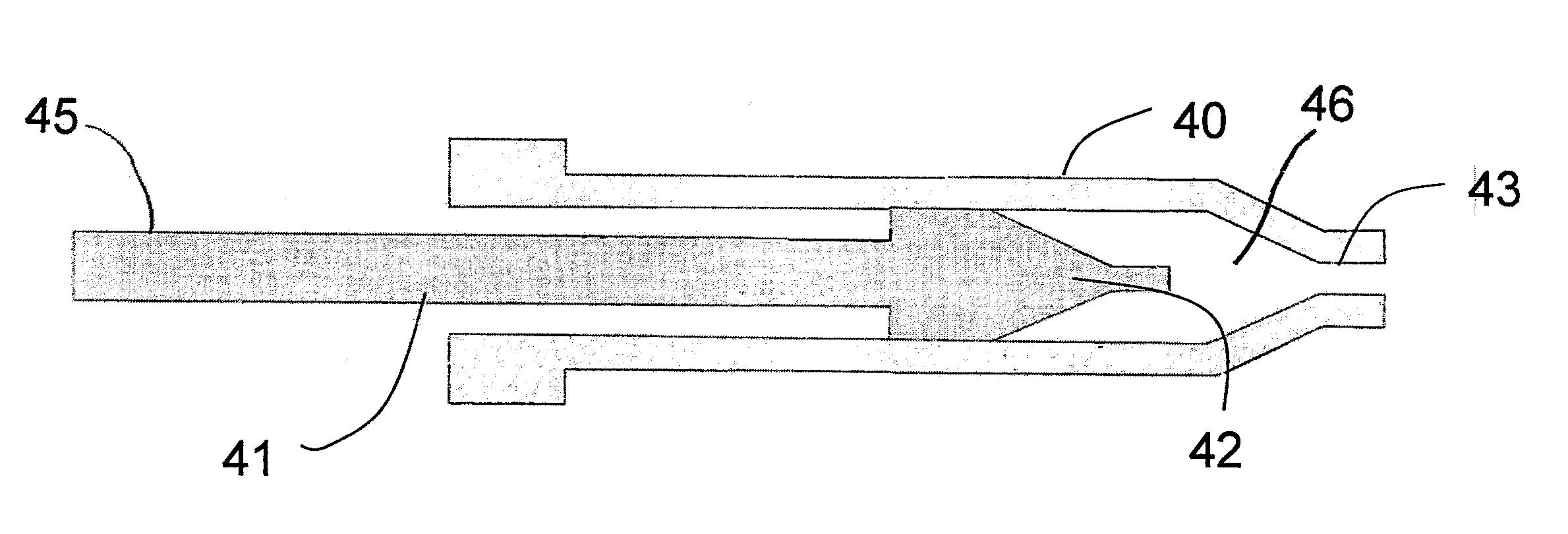

InactiveUS6840109B2Simple and robust mannerSimplifies isolationVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesTransducerEngineering

To conduct a fluid, the transducer has a flow tube which in operation vibrated by an excitation assembly. Inlet-side and outlet-side vibrations of the flow tube are sensed by means of a sensor arrangement. To produce shear forces in the fluid, the flow tube is at least intermittently excited into torsional vibrations about a longitudinal flow-tube axis. An internal portion of the transducer, formed at least by the flow tube, an antivibrator, the sensor arrangement, and the excitation assembly and mounted at least on the inlet and outlet tube sections, has a centroid which is located inside the flow tube. The transducer is suitable for use in viscometers or Coriolis mass flowmeter-viscometers. In spite of using only a single straight flow tube, it is dynamically well balanced in operation, and the development of bending moments by the torsionally vibrating flow tube is largely prevented. This also effectively prevents the transducer case or the connected pipe from being excited into sympathetic vibration. Measurement signals representative of mass flow rate are readily distinguishable from measurement signals representative of viscosity, particularly if the sensors used for the viscosity measurement are also used for the mass flow measurement.

Owner:ENDRESS HAUSER FLOWTEC AG

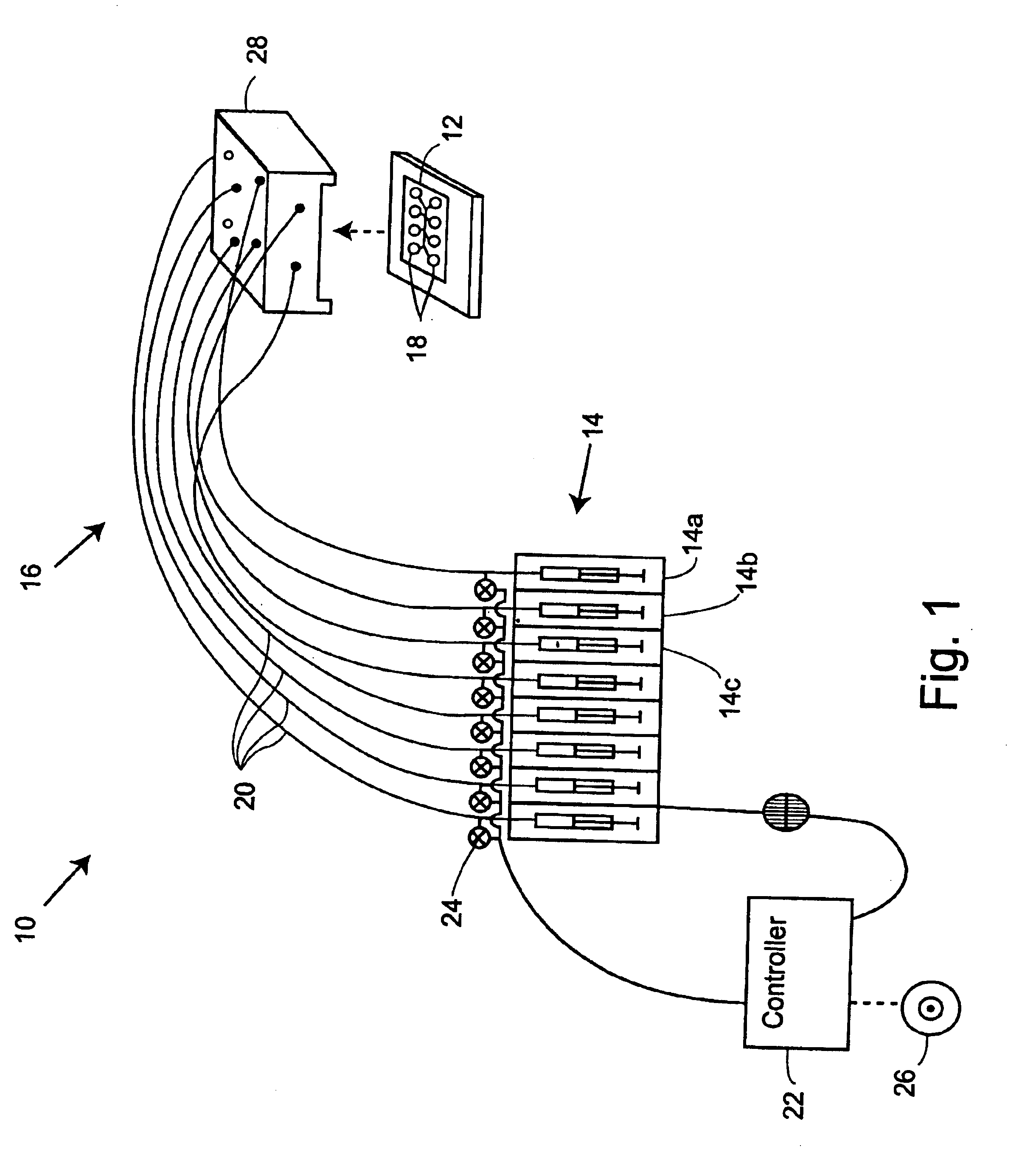

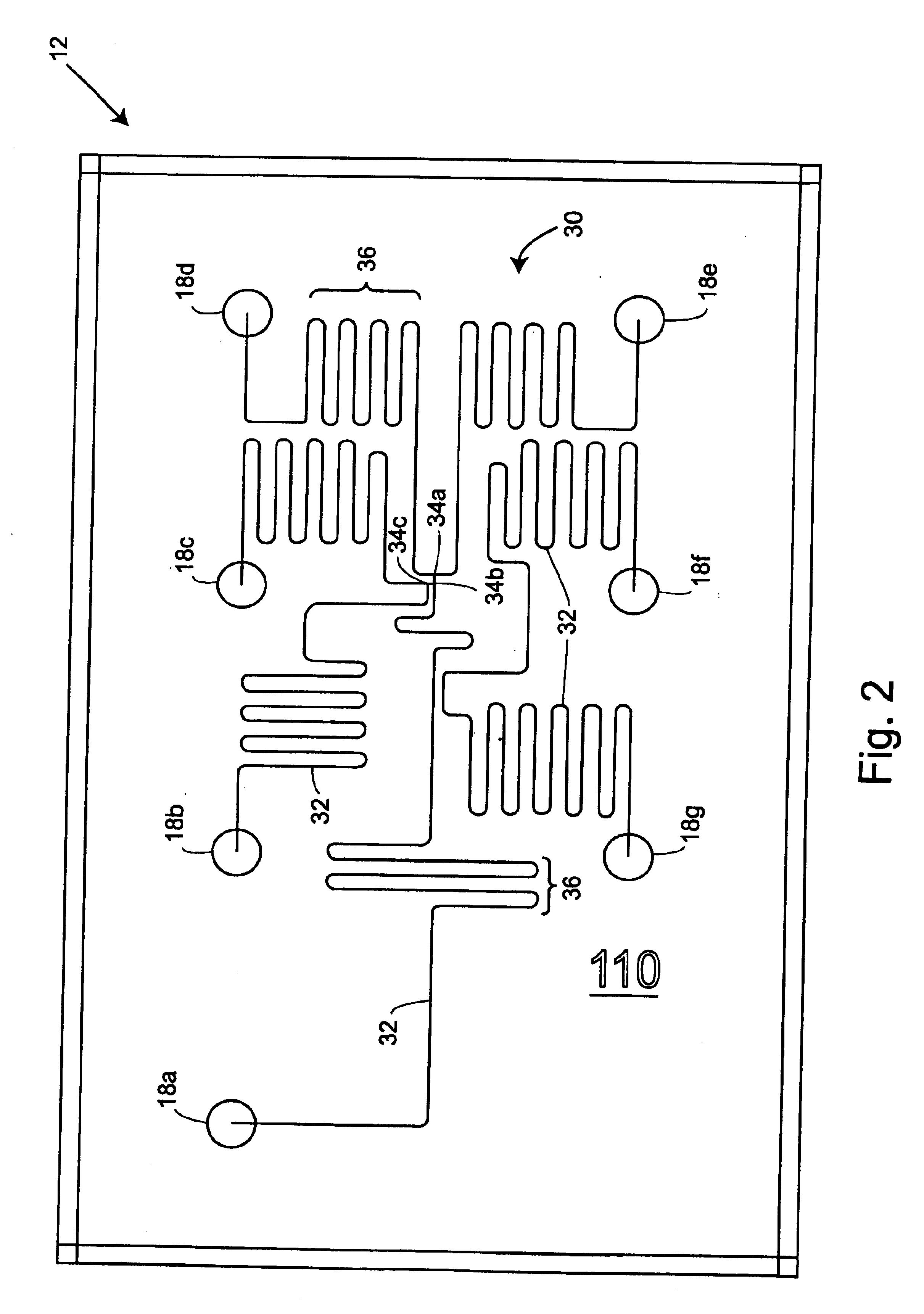

Microfluidic viscometer

InactiveUS7040144B2Determine viscosityVolume/mass flow measurementFlow control using electric meansFluid transportEngineering

Microfluidic devices, systems, and methods measure viscosity, flow times, and / or pressures, other flow characteristics within the channels, and the measured flow characteristics can be used to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems, electrokinetic systems and / or other fluid transport mechanisms can generate the flow, controllably mix fluids, and the like.

Owner:CAPLIPER LIFE SCI INC

Viscometer

The viscometer provides a viscosity value (Xη) which represents the viscosity of a fluid flowing in a pipe connected thereto. It comprises a vibratory transducer with at least one flow tube for conducting the fluid, which communicates with the pipe. Driven by an excitation assembly, the flow tube is vibrated so that friction forces are produced in the fluid. The viscometer further includes meter electronics which feed an excitation current (iexc) into the excitation assembly. By means of the meter electronics, a first internal intermediate value (X1) is formed, which corresponds with the excitation current (iexc) and thus represents the friction forces acting in the fluid. According to the invention, a second internal intermediate value (X2), representing inhomogeneities in the fluid, is generated in the meter electronics, which then determine the viscosity value (Xη) using the two intermediate values (X1, X2). The first internal intermediate value (X1) is preferably normalized by means of an amplitude control signal (yAM) for the excitation current (iexc), the amplitude control signal corresponding with the vibrations of the flow tube. As a result, the viscosity value (Xη) provided by the viscometer is highly accurate and robust, particularly independently of the position of installation of the flow tube.

Owner:ENDRESS HAUSER FLOWTEC AG

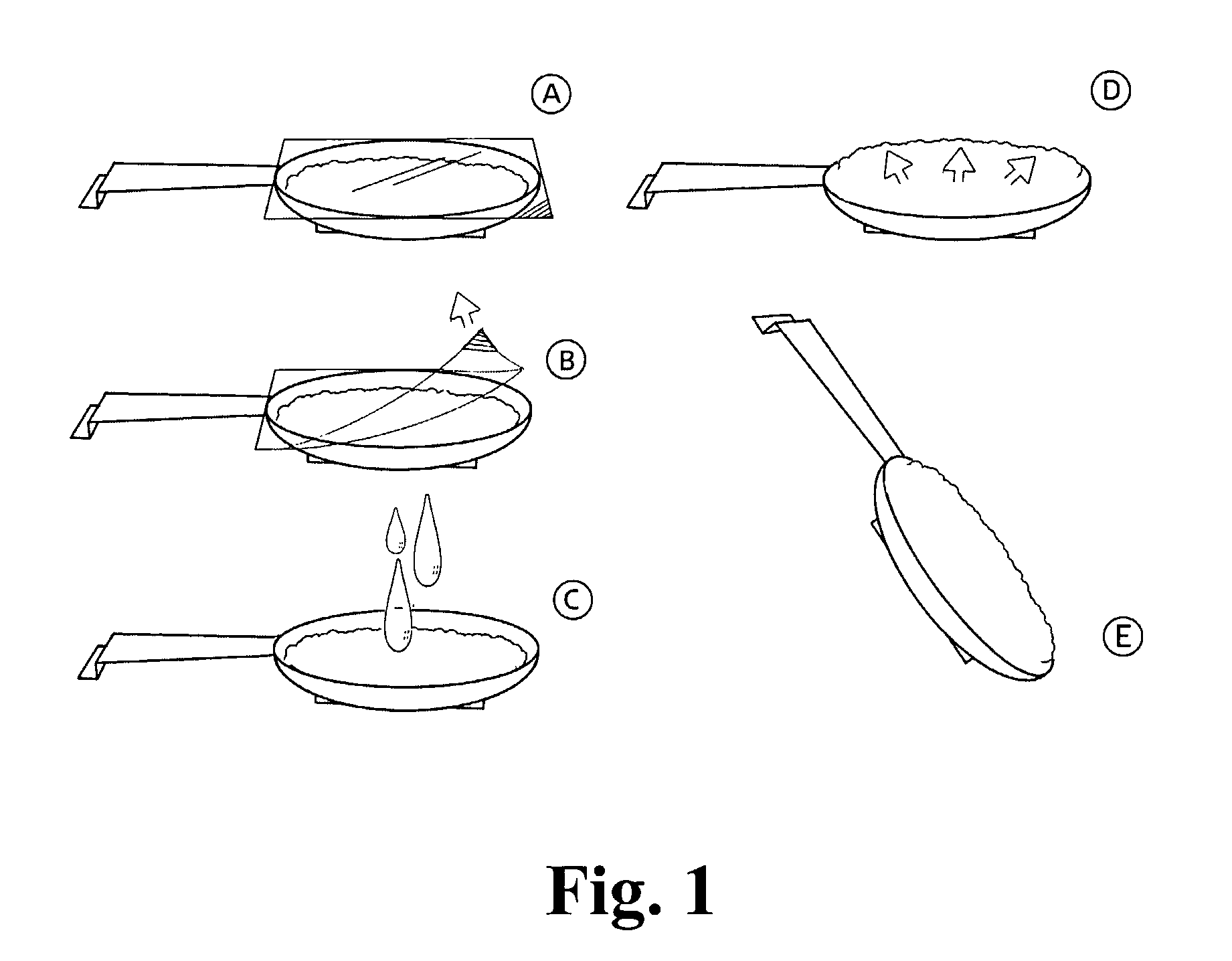

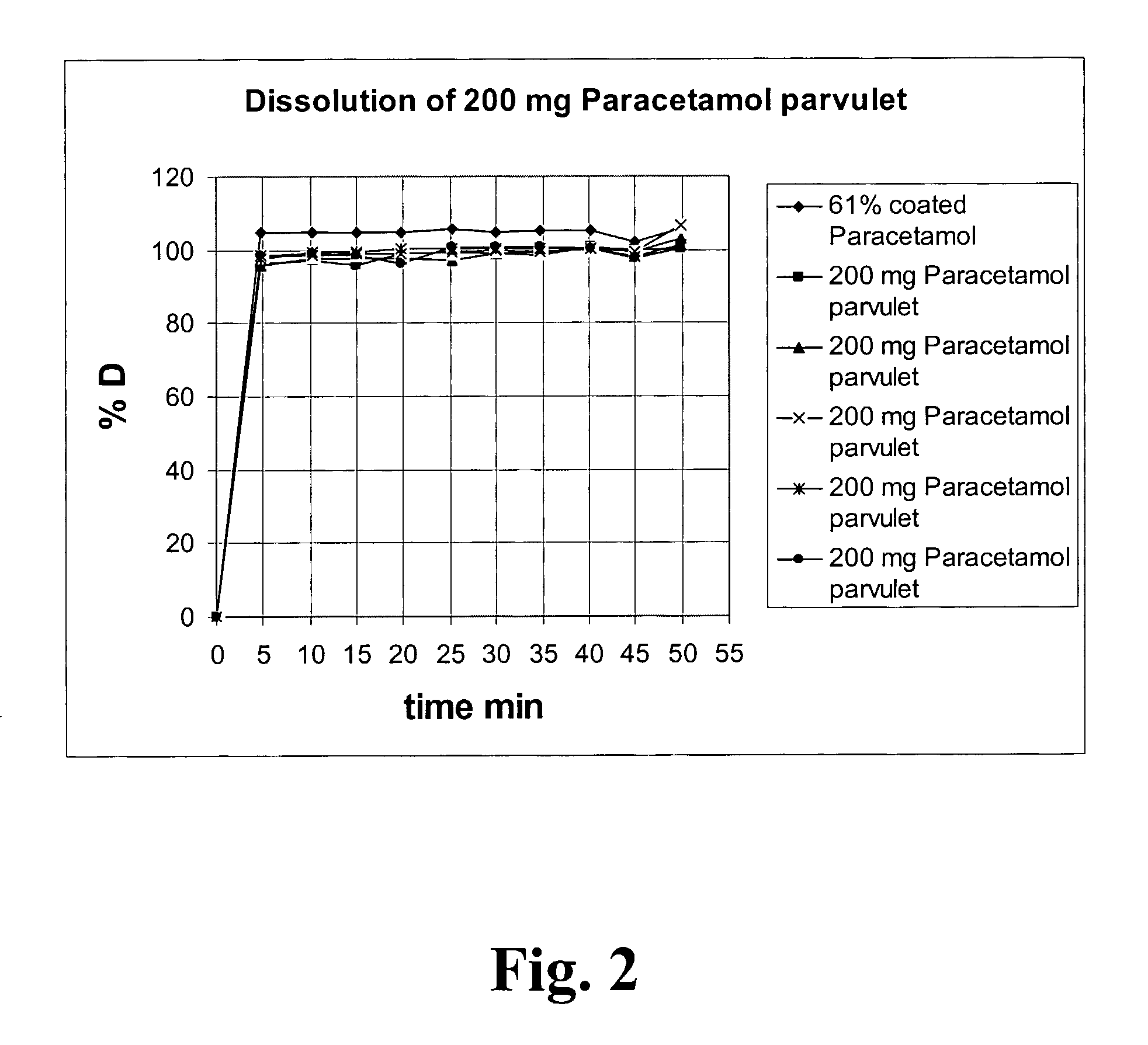

Swellable Dosage Form Comprising Gellan Gum

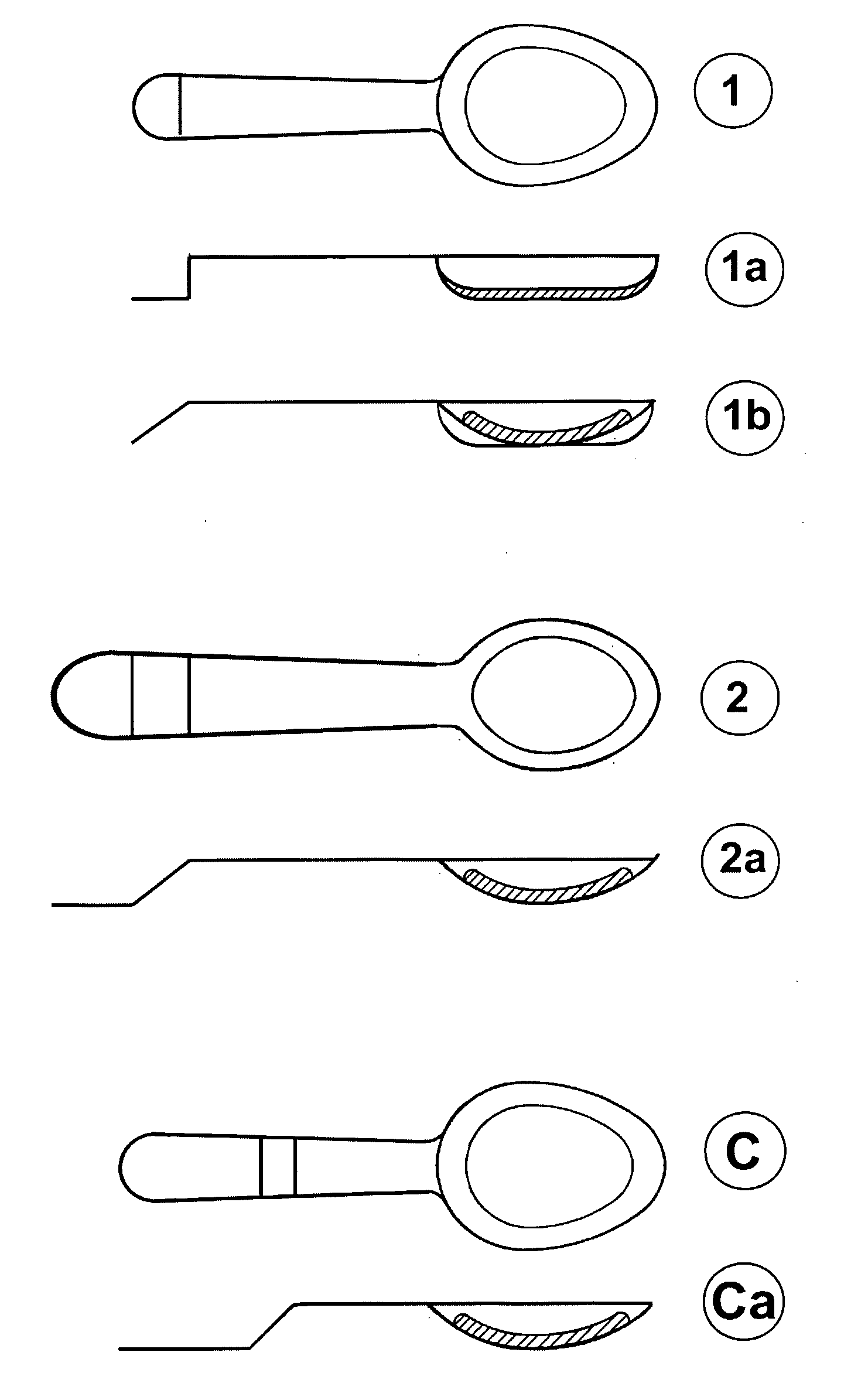

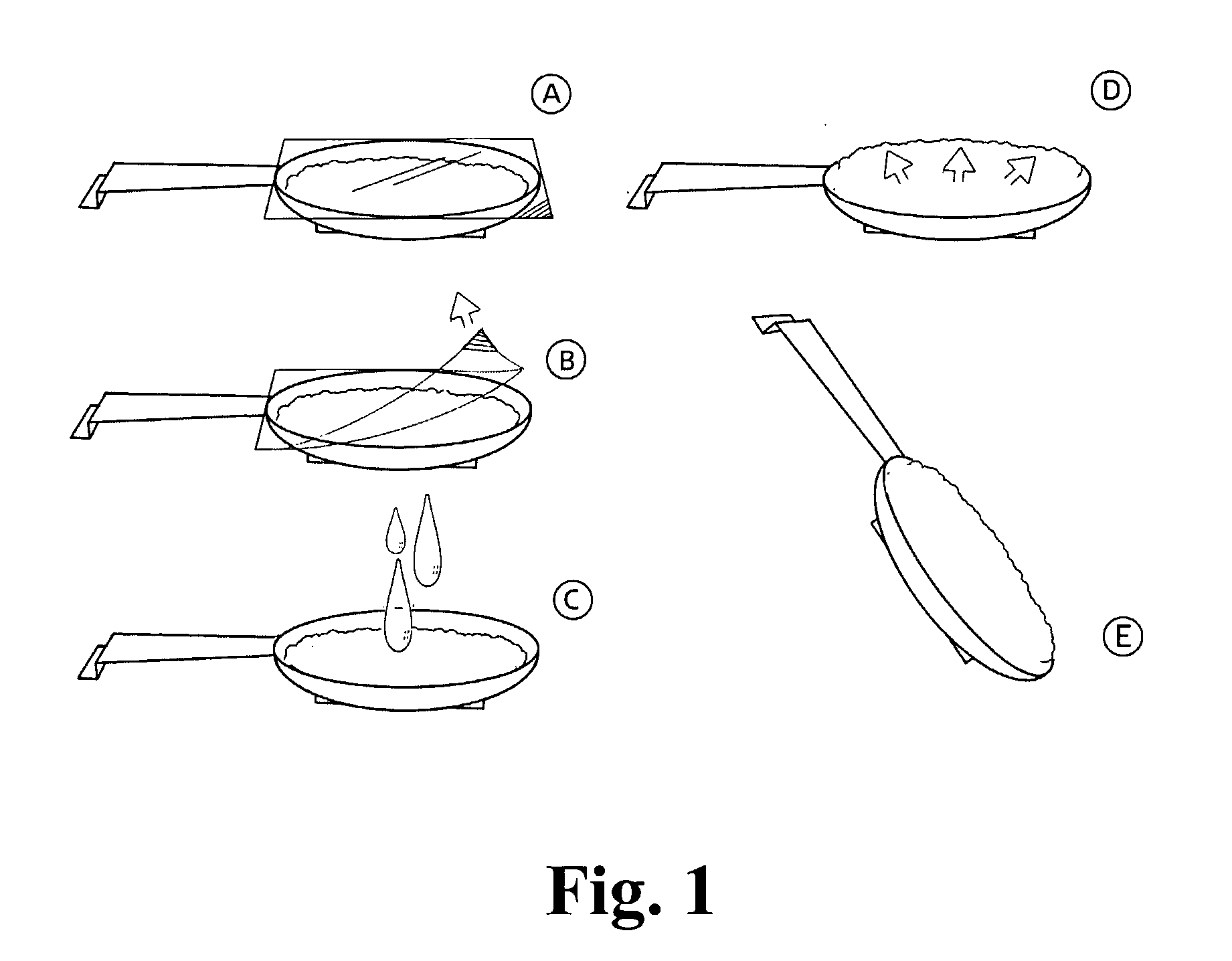

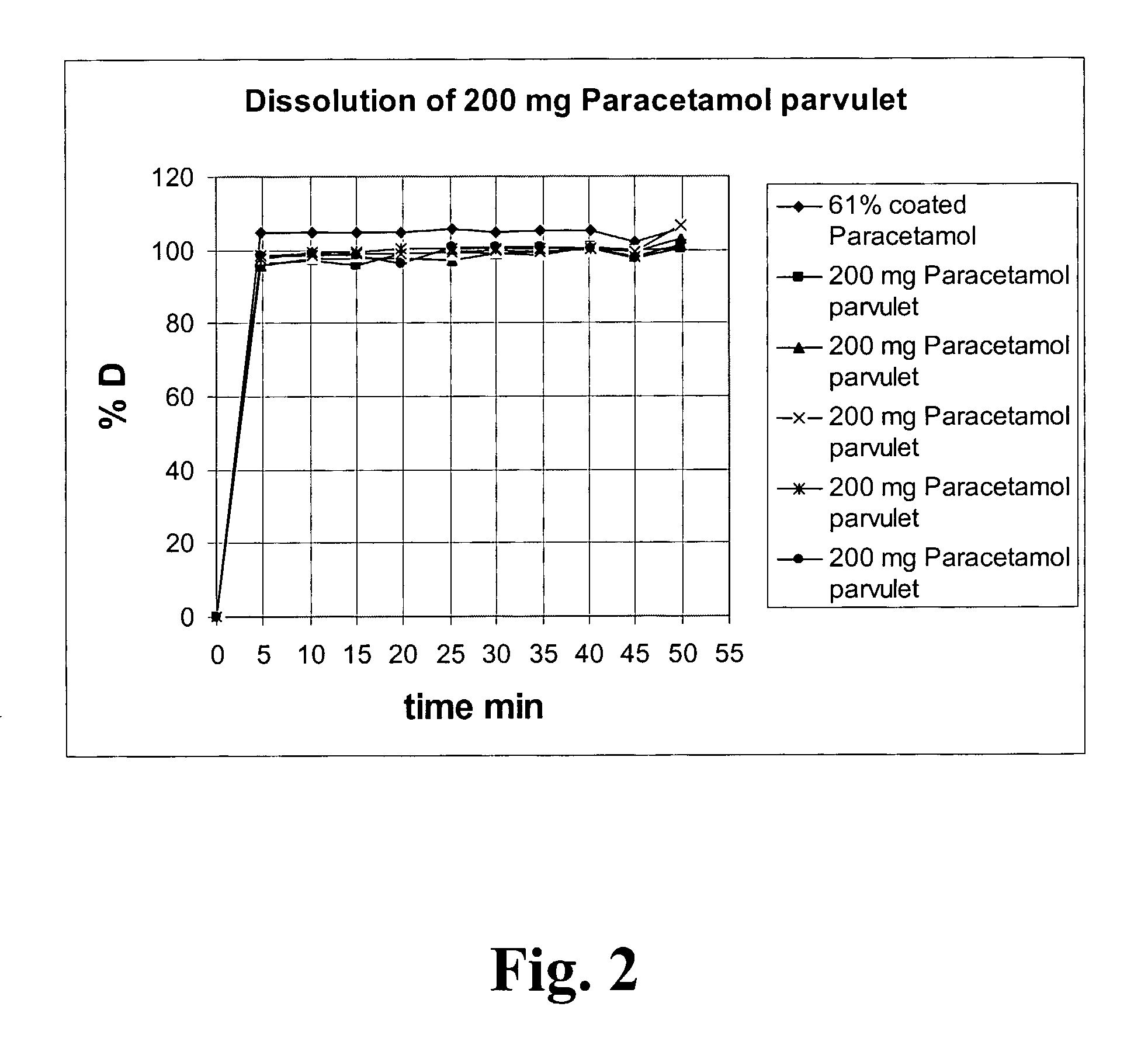

ActiveUS20080299199A1Easily can be orally ingestedIncrease intakeHeavy metal active ingredientsOrganic active ingredientsParticulatesGellan gum

A novel dosage form. The dosage form is presented in particulate form and before oral ingestion the particulate material is subjected to an aqueous medium, whereby it is converted to a semi-solid form by swelling or gelling of one or more of the components, especially of a gellan gum, of the particulate matter. The invention also relates to a vehicle for oral administration of one or more active substances, the vehicle comprising a gellan gum arranged in a configuration allowing optimal water diffusion so that upon addition of a predetermined amount of an aqueous medium, without the necessity of applying shear forces or other mixing forces, within a time period of 5 minutes or less swells and / or gels and the texture of the swelled vehicle being similar to that of a soft pudding and having a viscosity of at least about 10,000 cps as measured by a Brookfield Viscometer with a #4 LV spindle at 6 rpm and at 20-25° C. In one embodiment of the invention, the particulate matter can be moulded into a desired shape or pressed onto a dispensing unit such as a spoon.

Owner:ADARE PHARM INC

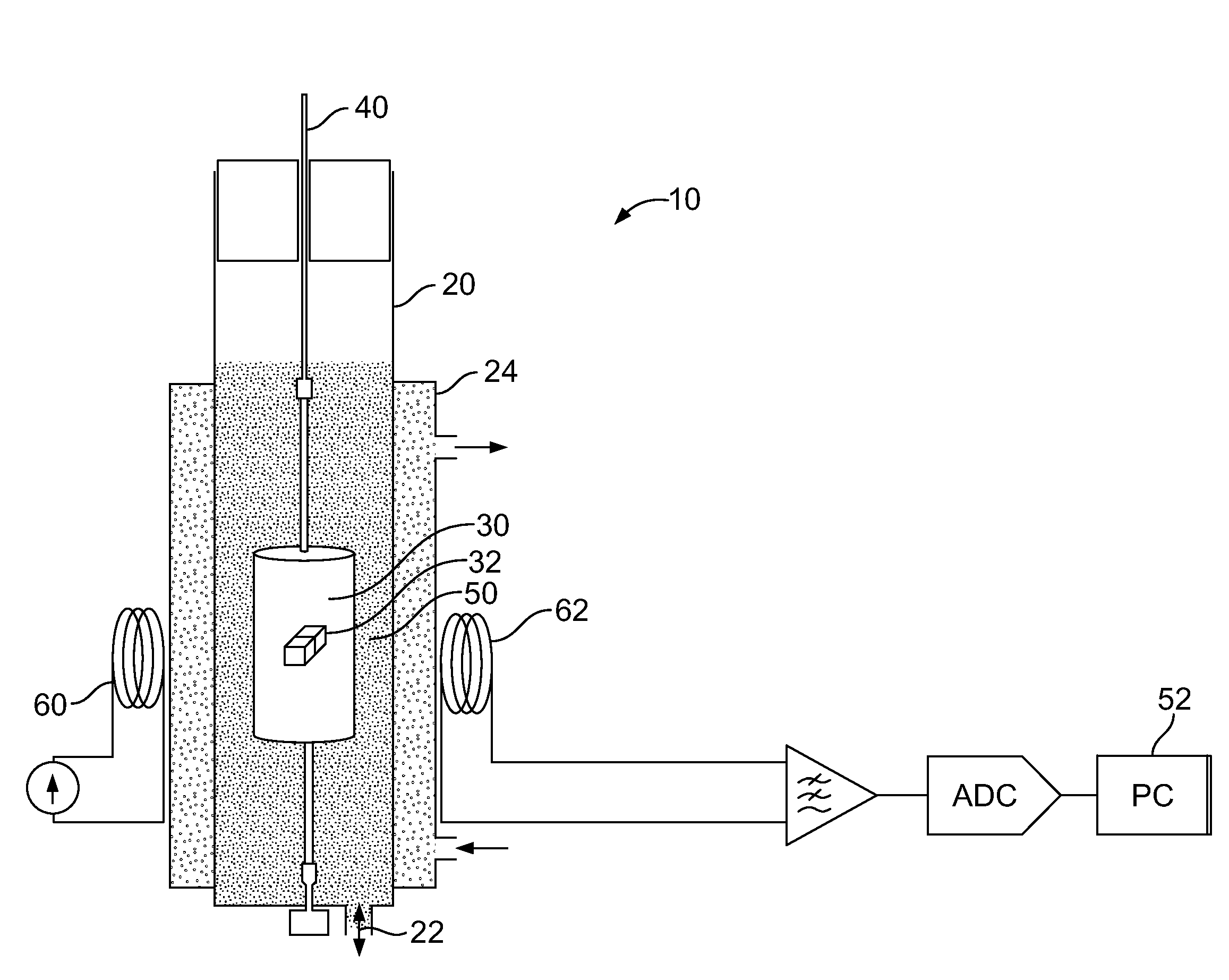

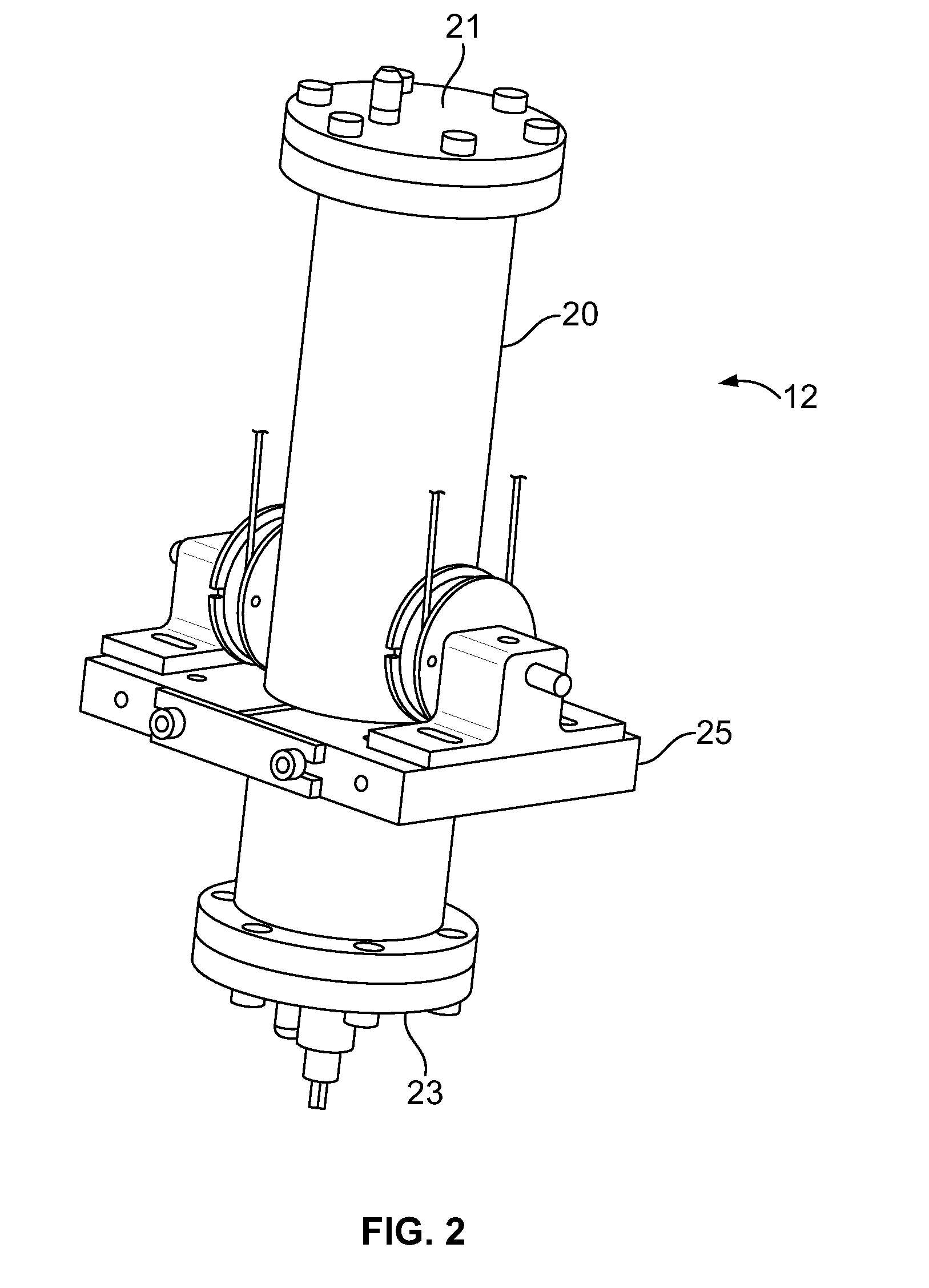

Apparatus and method for formation evaluation

ActiveUS7194902B1Eliminate variationFlow propertiesWithdrawing sample devicesFormation evaluationWellbore

A viscometer-densimeter for a down hole tool positionable in a well bore penetrating a subterranean formation is described. The formation contains at least one fluid therein. The down hole tool is adapted to convey at least a portion of the fluid to the viscometer-densimeter. The viscometer-densimeter comprises a sensor unit, and at least one magnet. The sensor unit is positionable within the down hole tool and comprises at least two spatially disposed connectors and a wire suspended in tension between the at least two connectors such that the wire is available for interaction with the fluid when the viscometer-densimeter is positioned within the down hole tool and the down hole tool is positioned within the subterranean formation and receives the fluid from the subterranean formation. The connectors and the wire are constructed so as to provide a frequency oscillator.

Owner:SCHLUMBERGER TECH CORP

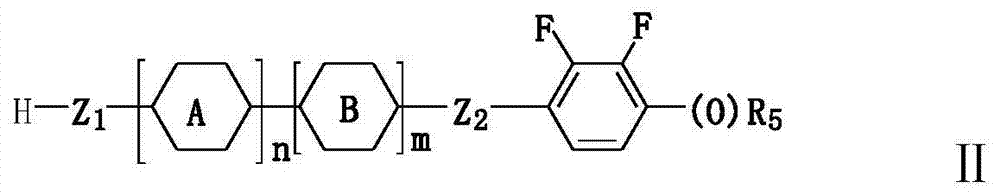

Liquid crystal medium and application

ActiveCN104513666AEasy to combineThe absolute value of the negative dielectric anisotropy is largeLiquid crystal compositionsNon-linear opticsDielectric anisotropyActive matrix

The invention discloses a negative dielectric anisotropic liquid crystal medium which comprises 15 to 55 weight percent of one or more dielectric neutral compounds shown in general formulae I1 and I2, 1 to 60 weight percent of one or more negative dielectric compounds shown in general formula II and 1 to 80 weight percent of one or more negative dielectric compounds shown in general formula III. The optical anisotropy of the liquid crystal medium ranges from 0.080 to 0.150, and the liquid crystal medium has lower rotary viscometer, proper negative dielectric anisotropy and higher K value, and can be used for an active matrix display element with the liquid crystal medium, such as an active matrix display with ECB, FFS or IPS, MVA, PVA or HVA effects (referring to the Specification for the general formulae I1 and I2 as well as the general formula II).

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

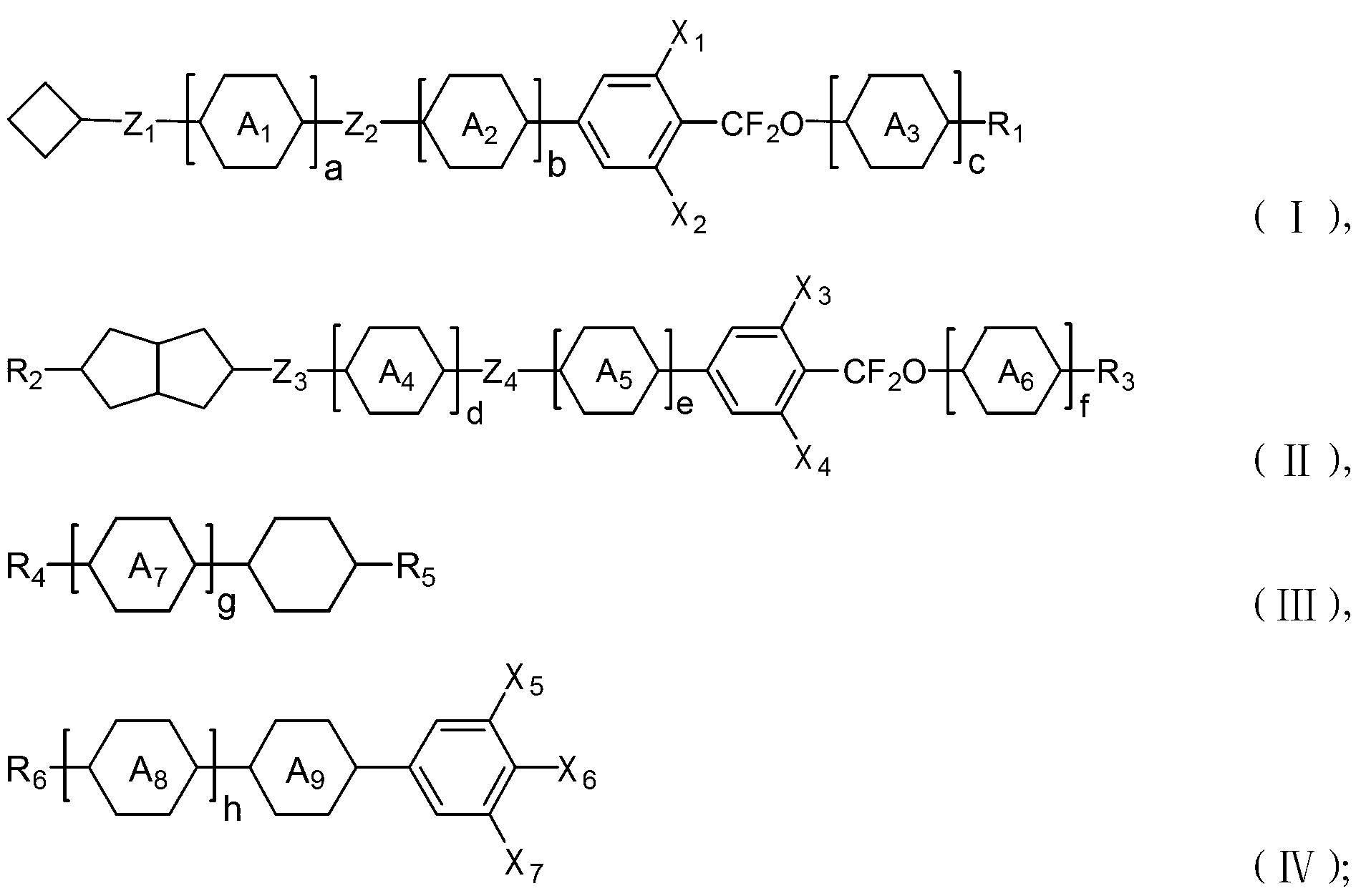

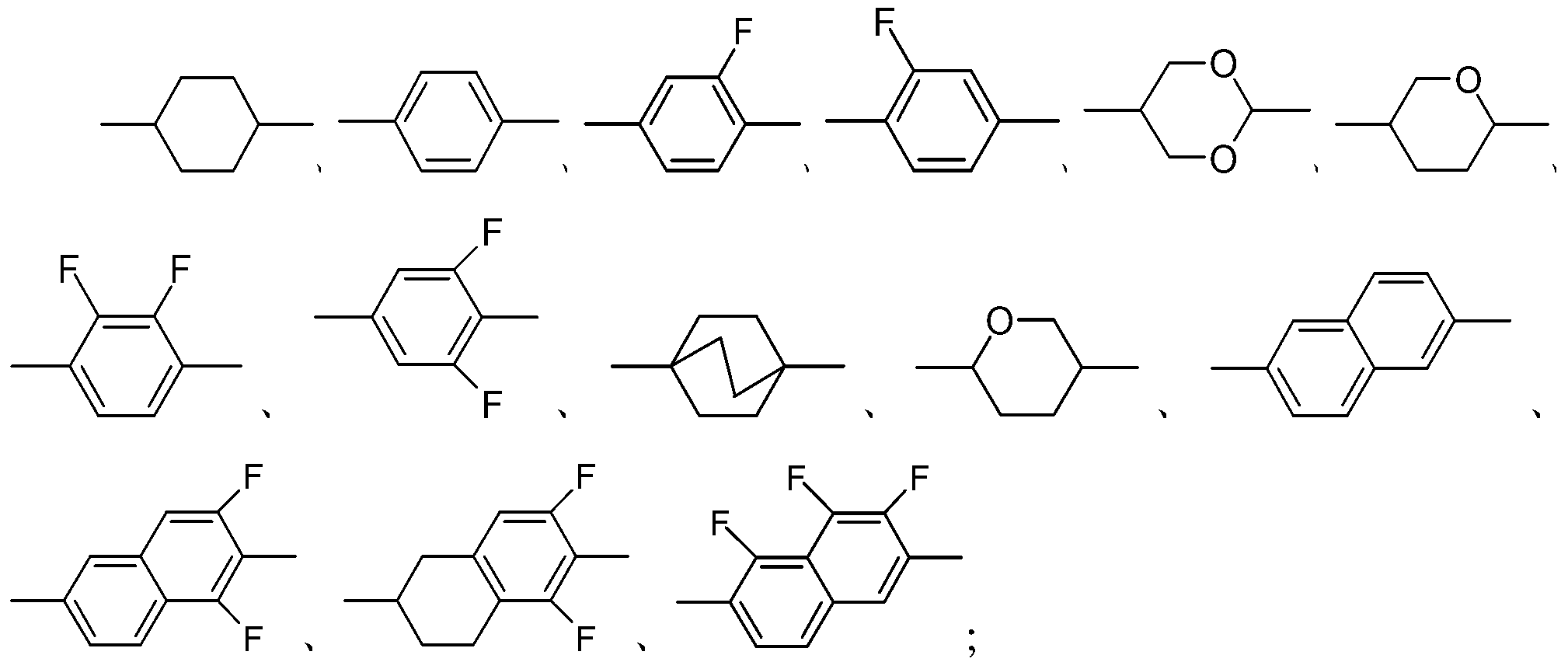

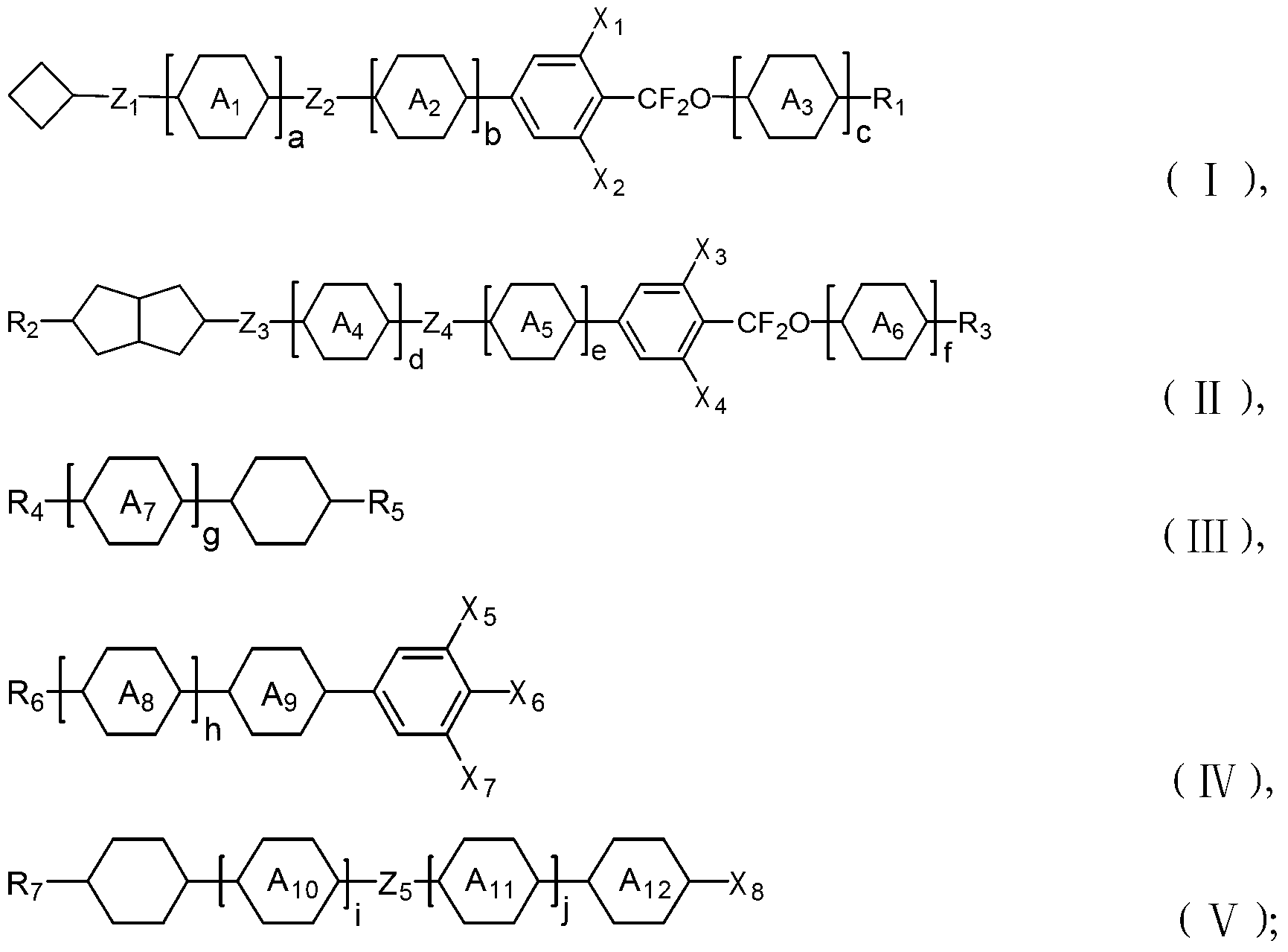

Positive dielectric anisotropy liquid crystal combination with rapid response

ActiveCN103254911AImprove high temperature stabilityLow viscosityLiquid crystal compositionsNon-linear opticsIn planeCharge retention

The invention discloses a positive dielectric anisotropy liquid crystal combination with rapid response. The positive dielectric anisotropy liquid crystal combination comprises 5-60 percent of first component, 1-50 percent of second component, 1-40 percent of third component, 0-40 percent of fourth component and an optically active compound, wherein the first component is formed from compounds with a structural formula I and a structural formula II, a compound with a structural formula III is used as the second component, a compound with a structural formula VI is used as the third component, a compound with a structural formula V is used as the fourth component, and the mass of the optically active compound is 0-0.2 percent of the mass sum of the liquid crystal combination. The liquid crystal combination has high charge retention, larger positive dielectric anisotropy, higher clearing point, good low-temperature stability, lower rotary viscometer and higher response speed and is particularly suitable for manufacturing active matrixes TN-TFT(Twisted Nematic-Thin Film Transistor), IPS (In-Plane Switching)-TFT liquid crystal display elements and liquid crystal displays.

Owner:BEIJING CHENGZHI YONGHUA DISPLAY TECHNOLOGY CO LTD

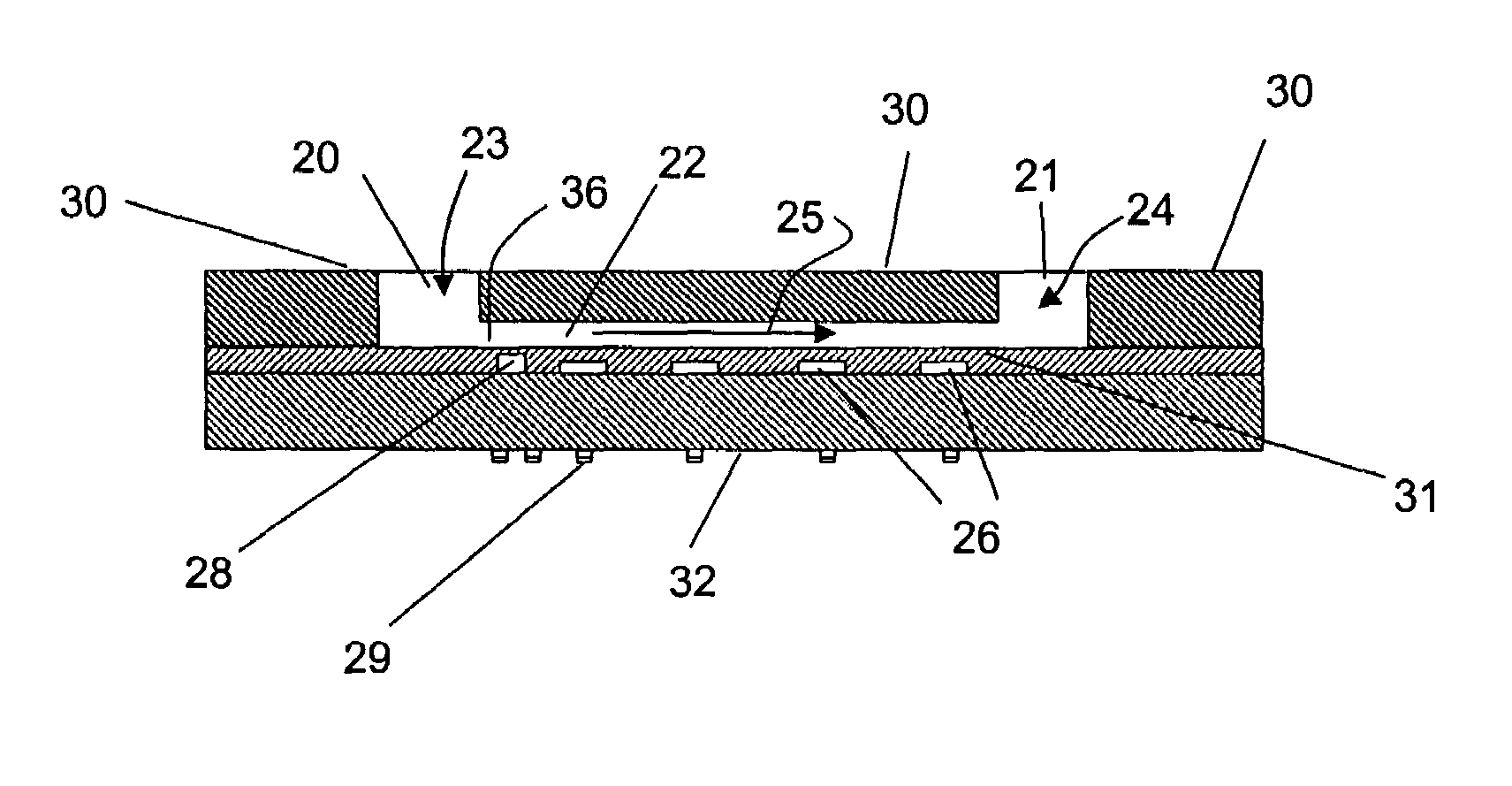

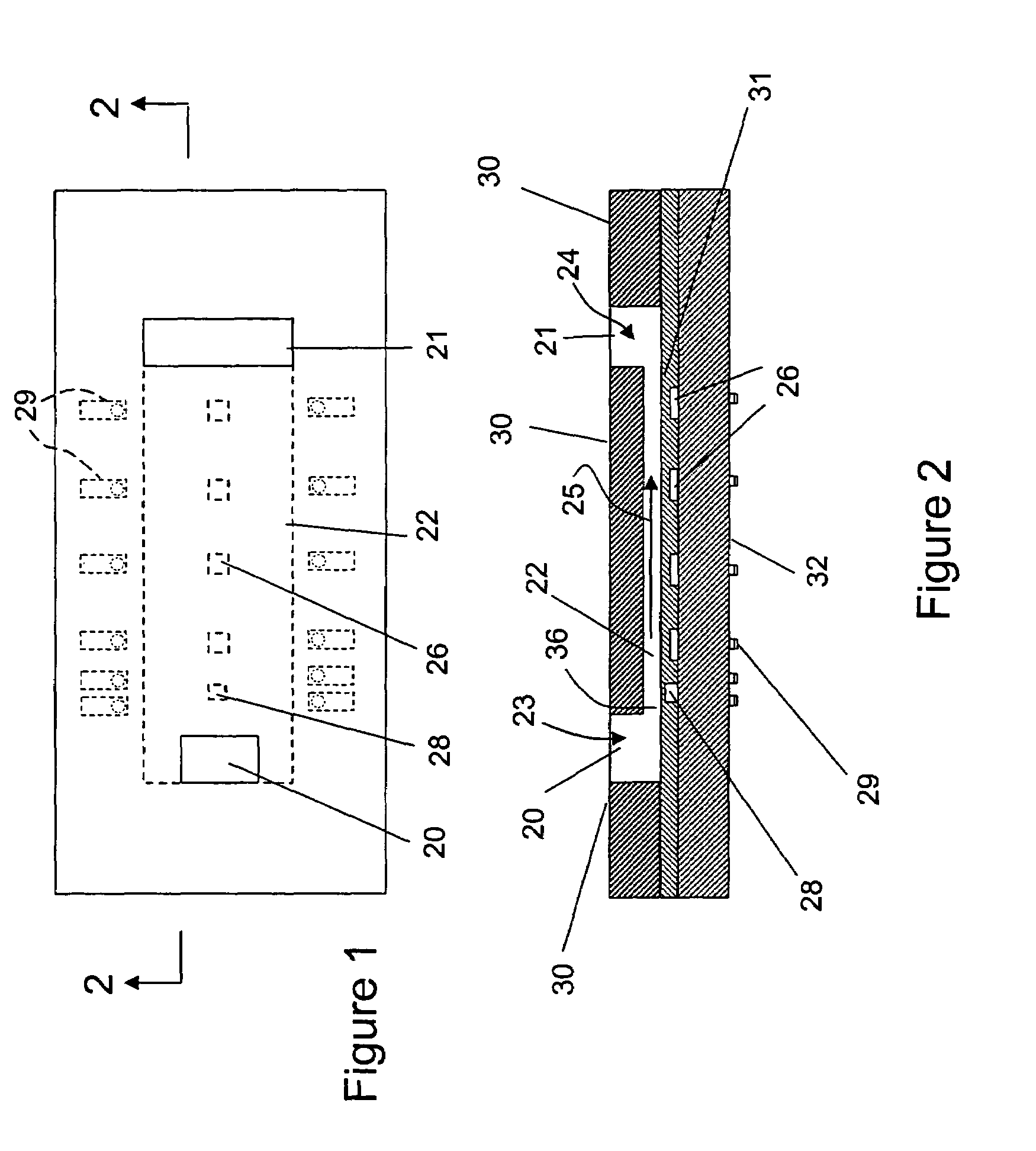

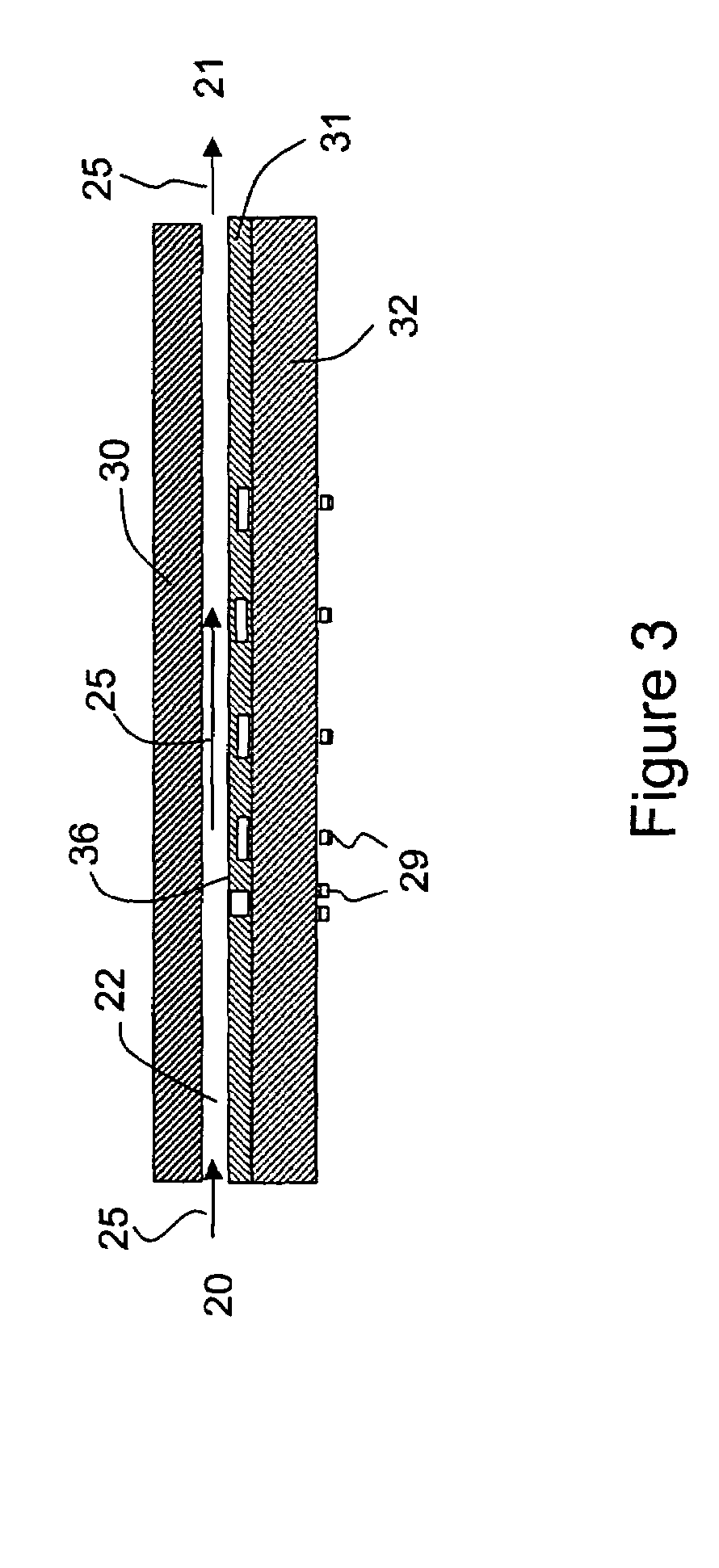

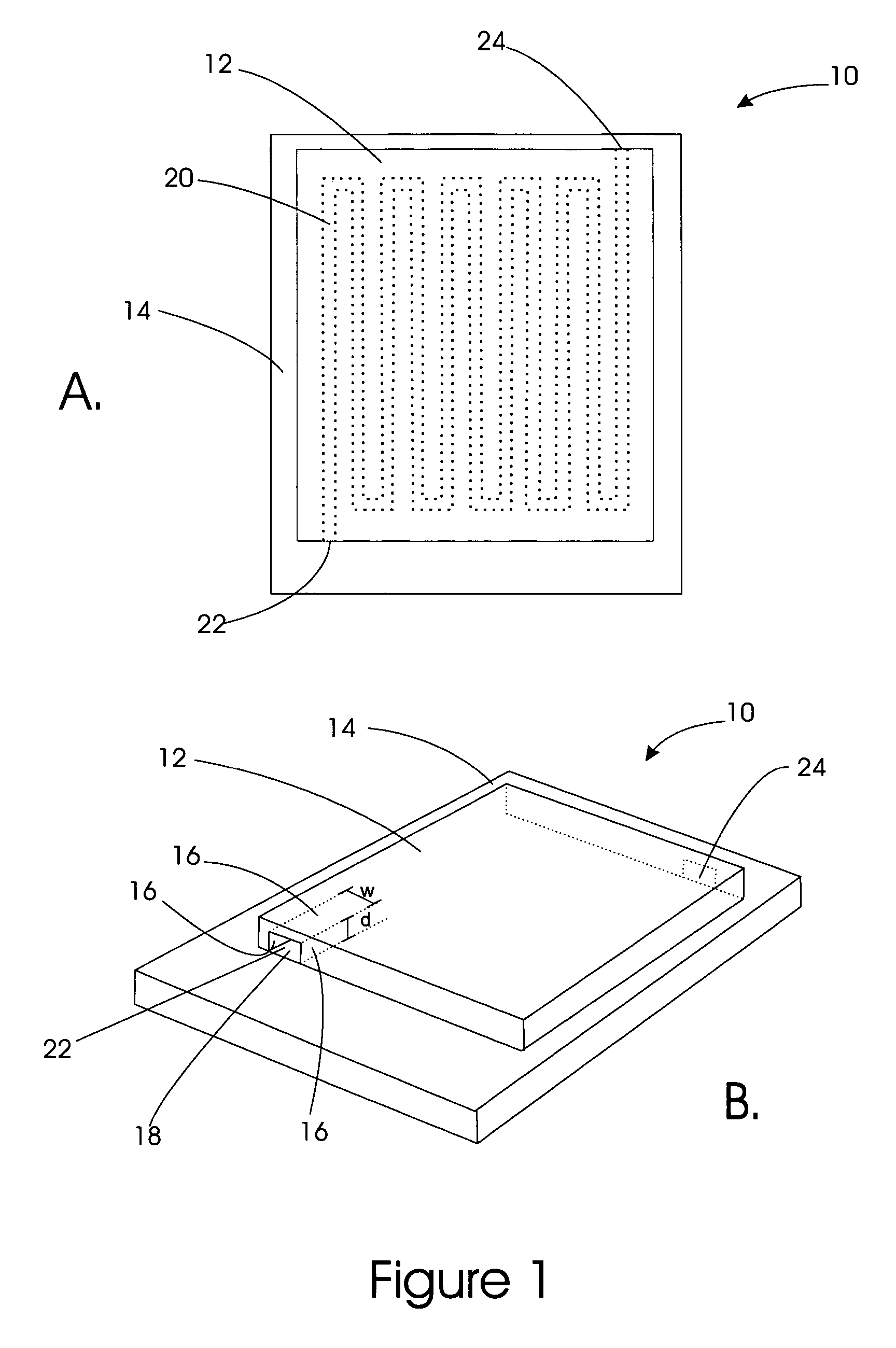

Micro slit viscometer with monolithically integrated pressure sensors

InactiveUS7290441B2Smooth inner surfaceReduce manufacturing costMaterial analysis by optical meansDirect flow property measurementTest sampleMicrometer

An improved micro slit viscometer includes a combined micrometer depth rectangular slit flow channel with monolithically integrated multiple pressure sensors in the flow channels and a pumping system that injects a test sample to the channel at a desired flow rate. Pressure sensing diaphragm of the monolithically integrated pressure sensors is smooth to minimize the flow disturbance thereby measuring accurate local pressures. With the measurement of the pressures at various locations of the channel the true viscosity of test sample can be calculated. The viscometer may consist of multiple flow channels and thus the true viscosity at multiple shear rates can be measured simultaneously for a given flow rate thereby obtaining a full viscosity curve as a function of shear rate of non-Newtonian liquids in a much faster manner. The viscometer needs only a miniscule amount of sample, which minimizes a waste of test material. The flow channels and the monolithically integrated pressure sensors are fabricated using microfabriaction processes on wafers and combined, which greatly reduce the production costs.

Owner:RHEOSENSE

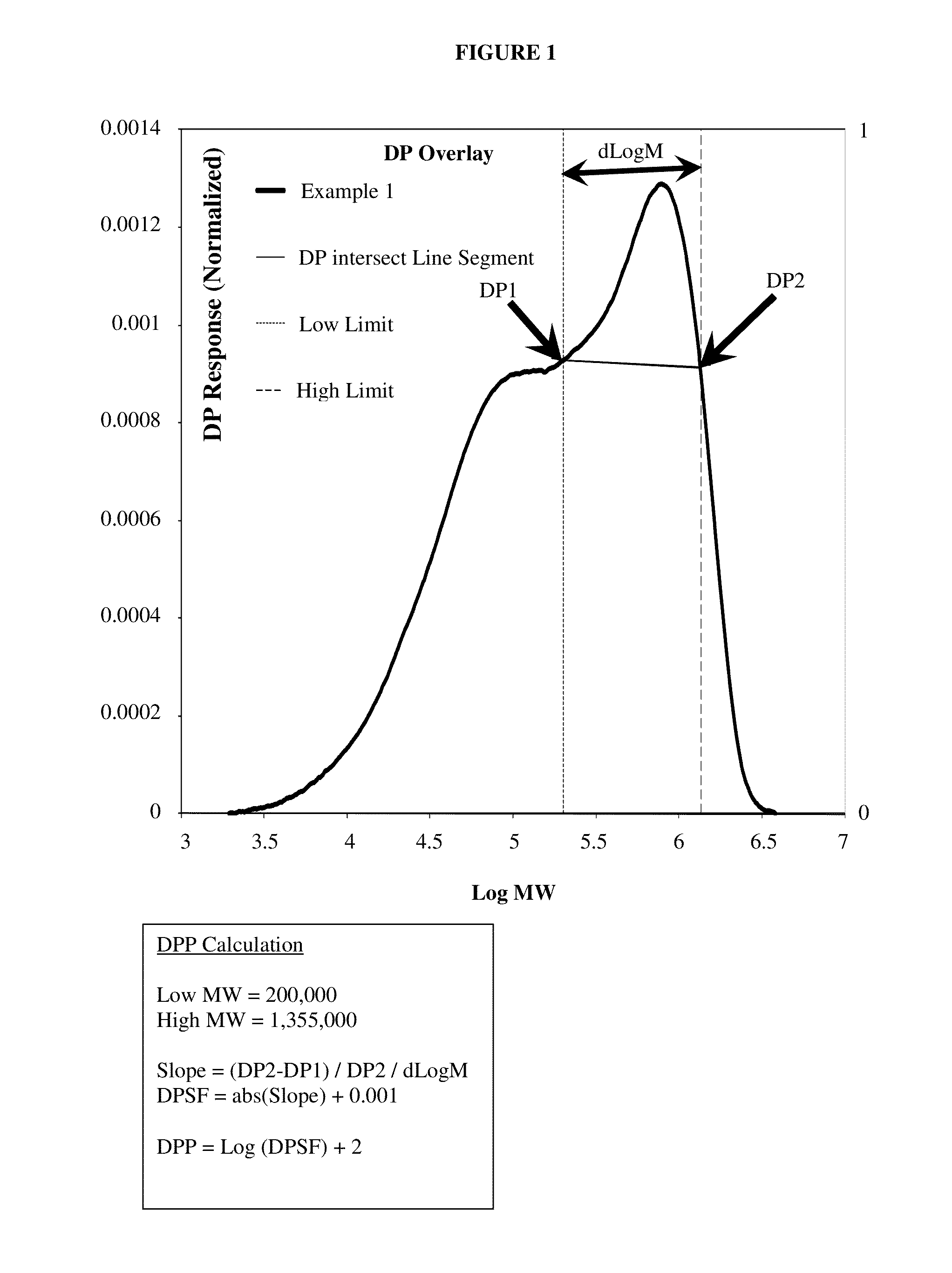

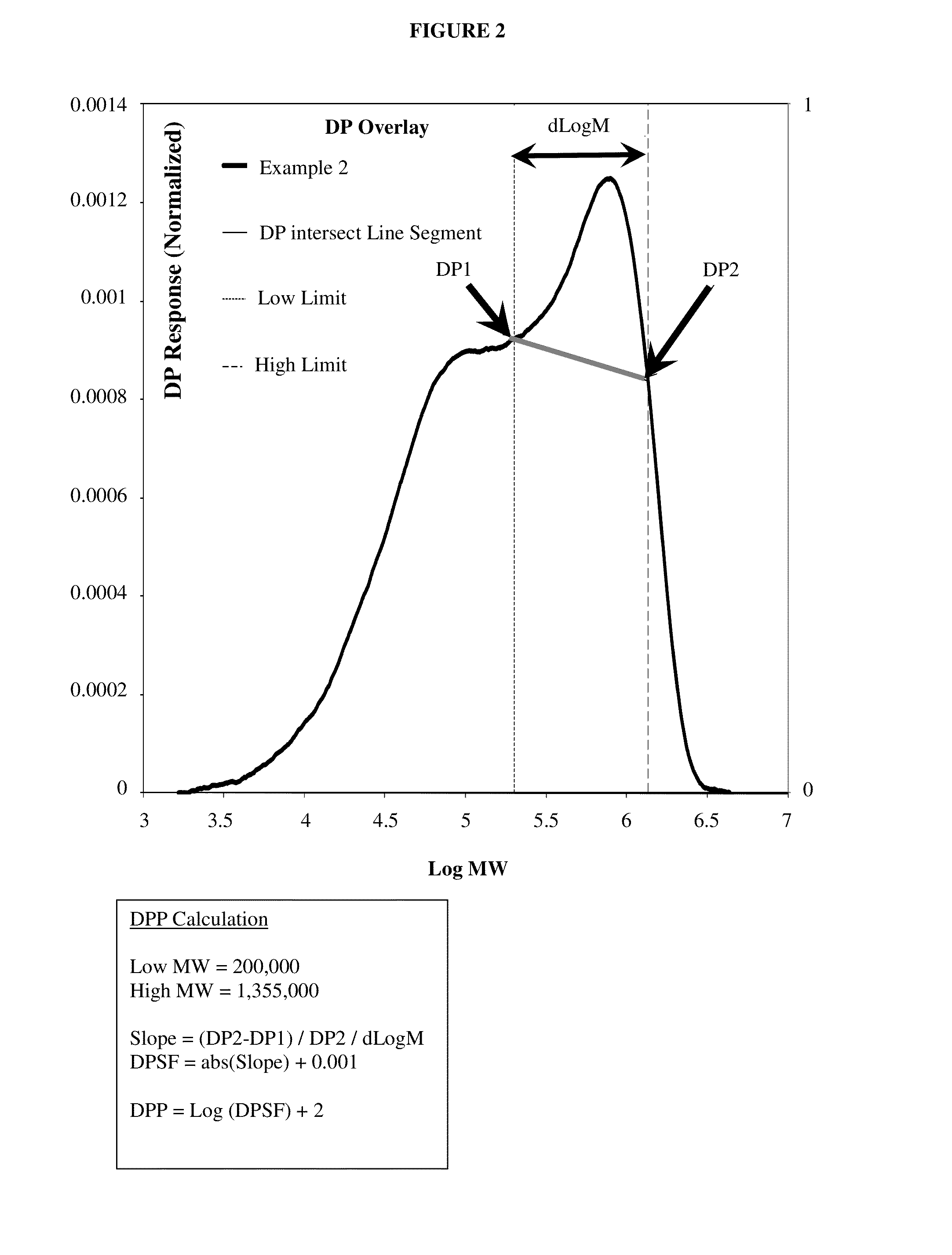

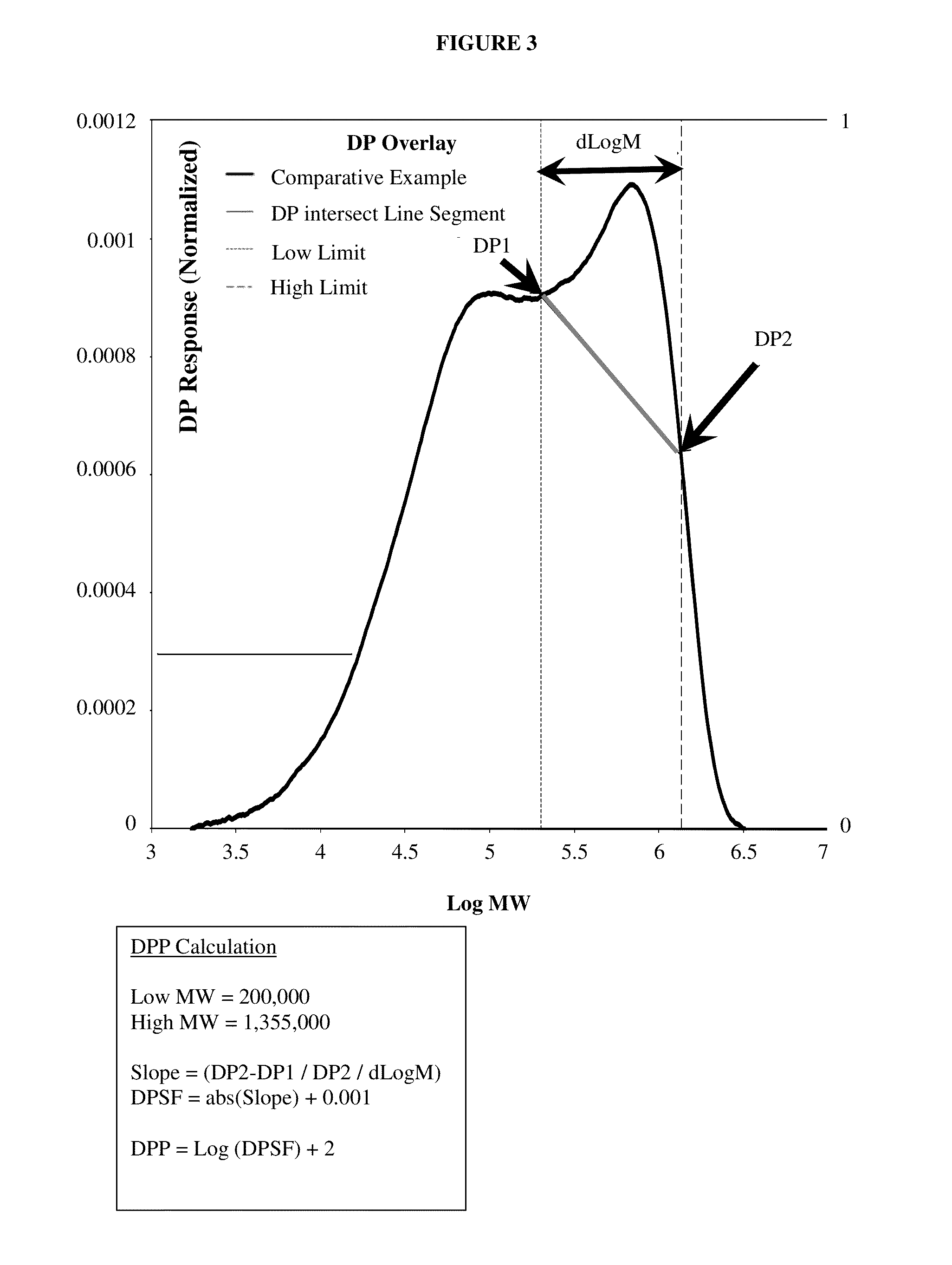

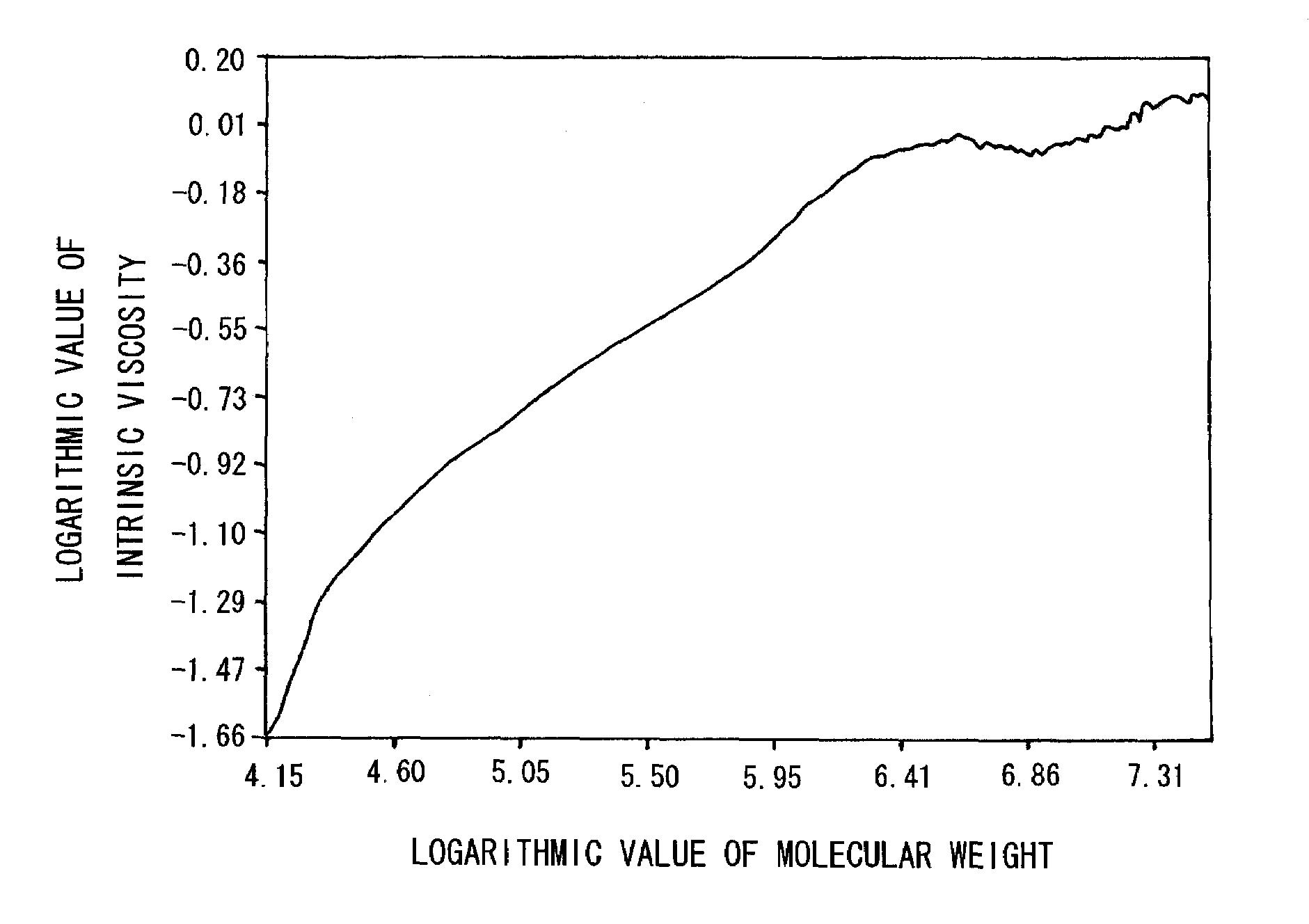

Ethylene-based polymers and processes to make the same

The invention provides a composition comprising a low density polyethylene (LDPE) obtained by free radical polymerization of ethylene, and wherein the LDPE has a GPC-Viscometer parameter “DPP” less than 1.3. The invention also provides a composition comprising an ethylene-based polymer that comprises the following features: a) at least 0.1 amyl groups per 1000 total carbon atoms; b) a melt index from 0.5 to 0.9 c) a MWD(conv) [(Mw(conv) / Mn(conv))] from 9 to 13. The invention also provides a composition comprising an ethylene-based polymer that comprises the following features: a) at least 0.1 amyl groups per 1000 total carbon atoms; b) a MWD(conv) from 9 to 13; c) a gpcBR value from 2.0 to 5.0; and d) a melt strength (MS) greater than 20 cN.

Owner:DOW GLOBAL TECH LLC

Stable sunscreen compositions containing zinc oxide

A stable, oil-in-water (O-W) emulsion-based sunscreen composition having at least one water-insoluble, organic UV-absorber having a water-solubility of much less than 0.1% by weight, contained in the oil phase of the sunscreen emulsion, comprising i) zinc oxide (ZnO) particles having a surface free of any prior coating of any inorganic oxide and hydrophobic material, remaining dispersed in the water phase of the sunscreen emulsion; ii) at least one non- or low-foaming, non-cationic, hydrophilic polymer, capable of dispersing or deflocculating the ZnO particles but incapable of thickening an aqueous composition to a viscosity of greater than 100 cps at 25° C., wherein the viscosity is measured using a Brookfield viscometer operated at 10 rpm for 15 seconds, when the polymer is added at an amount of 1%, based on the total weight of the polymer and water in the aqueous composition; iii) at least one phenolic polymer, capable of functioning as a dispersing or deflocculating agent for particulate material(s), and adsorbing at an oil-water interface; and v) a buffering agent for the water phase of the sunscreen emulsion.

Owner:AMCOL INTERNATIONAL CORPORATION

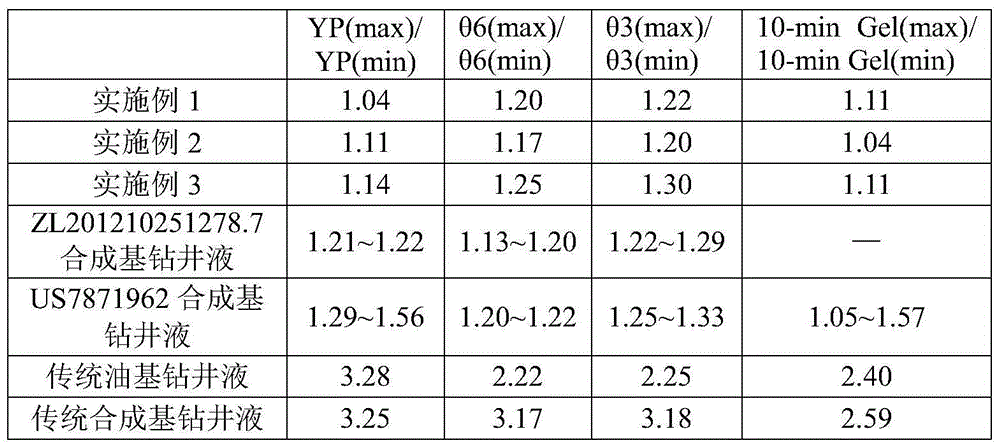

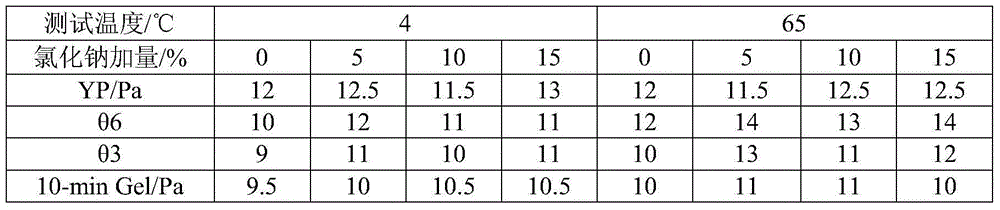

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

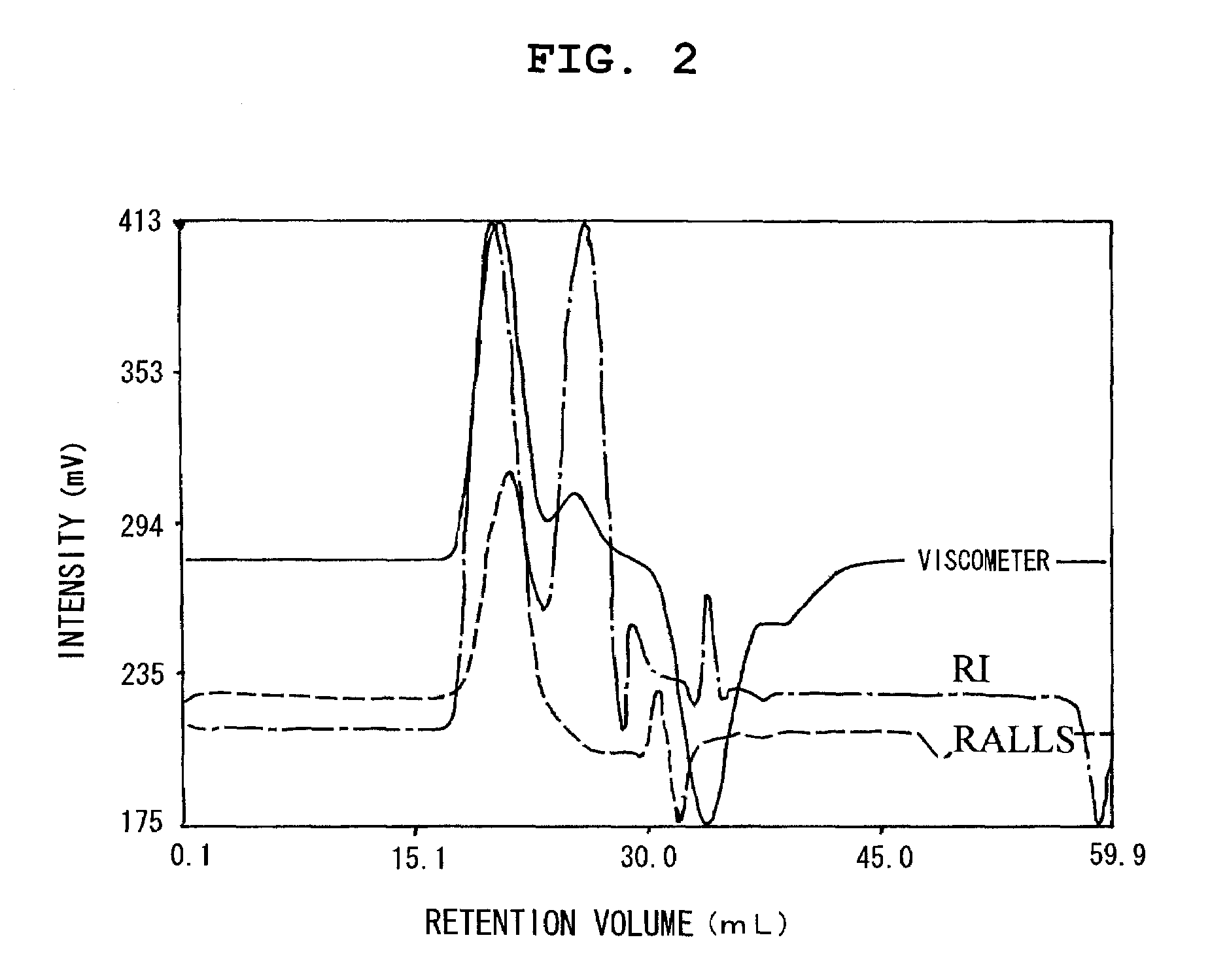

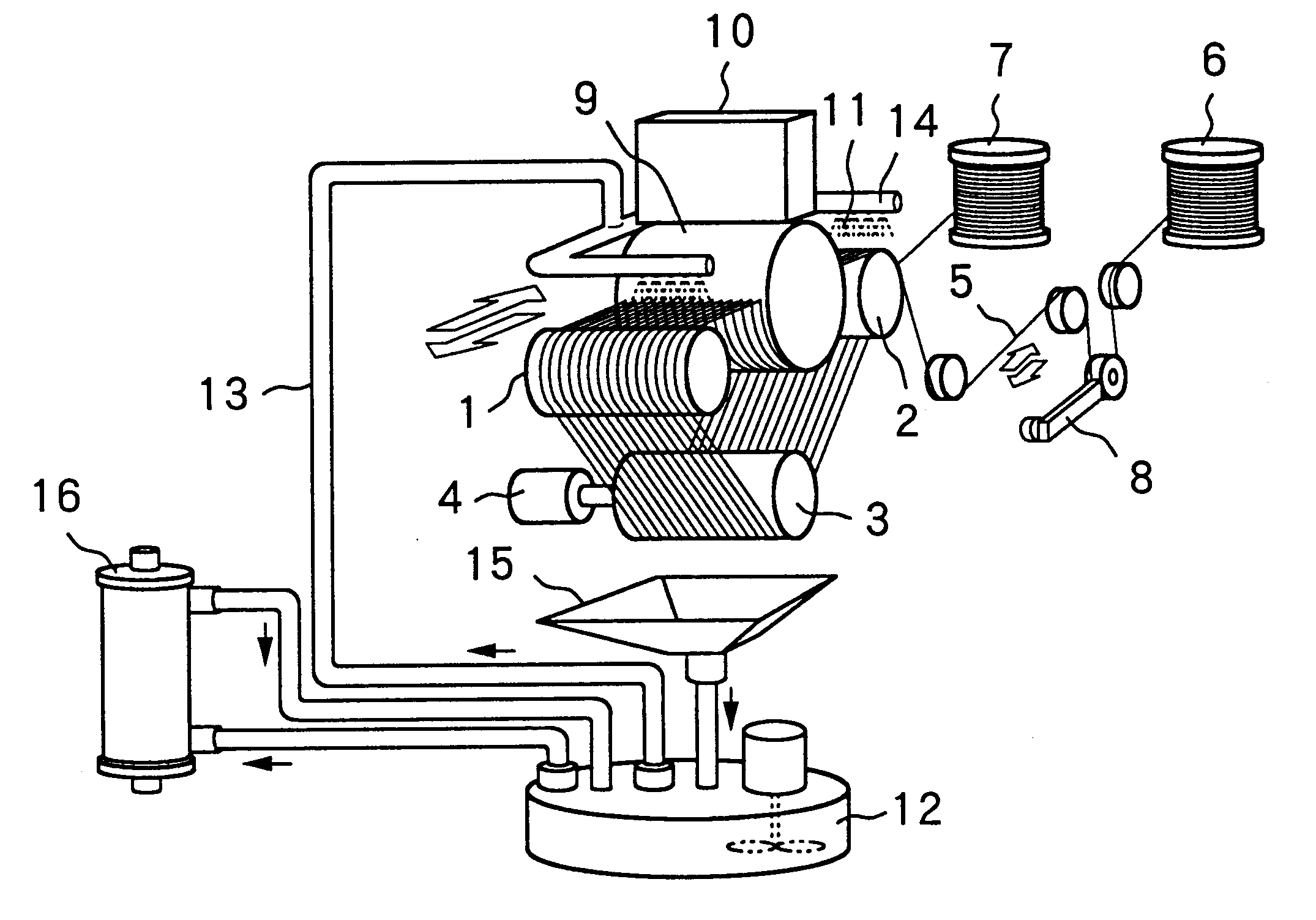

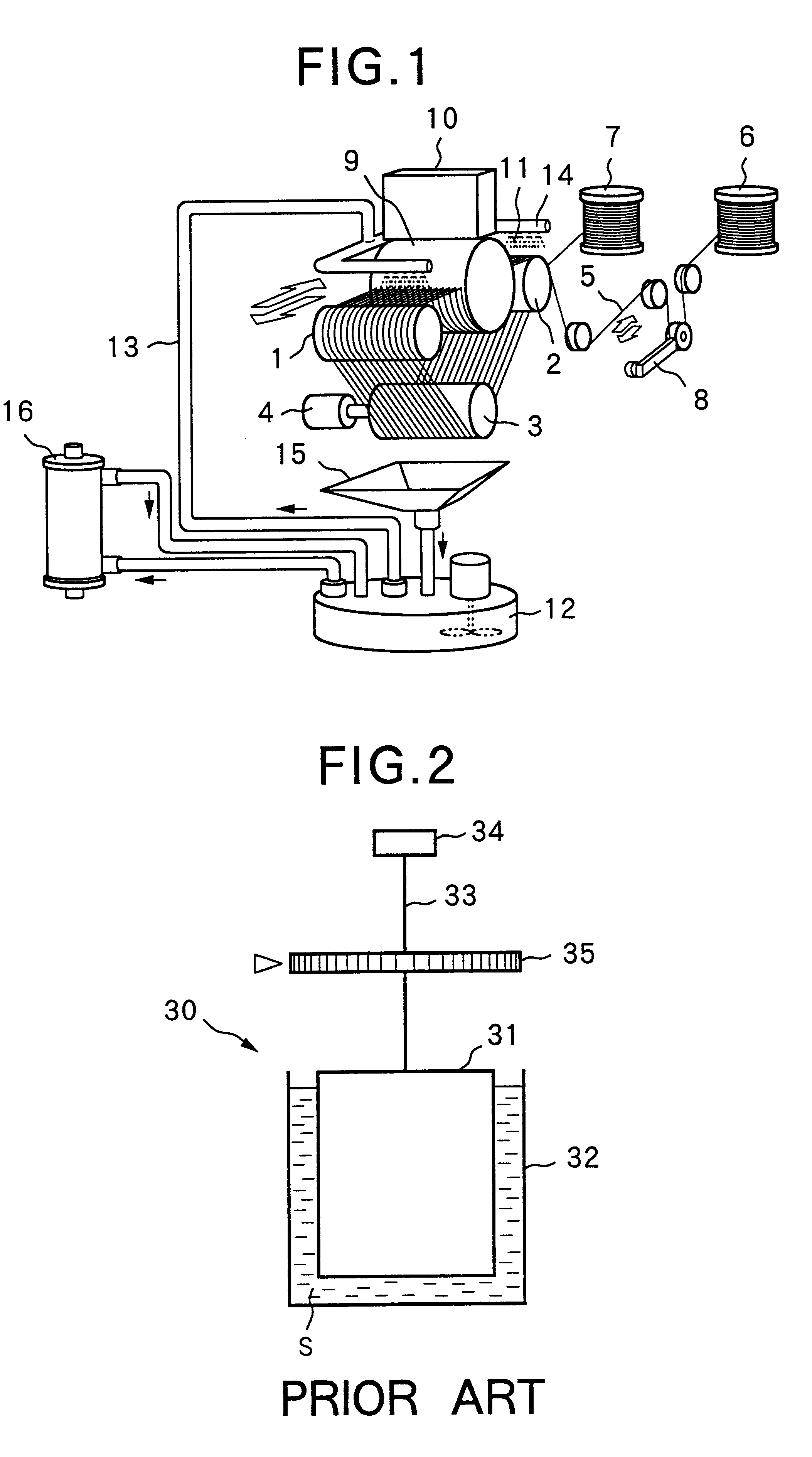

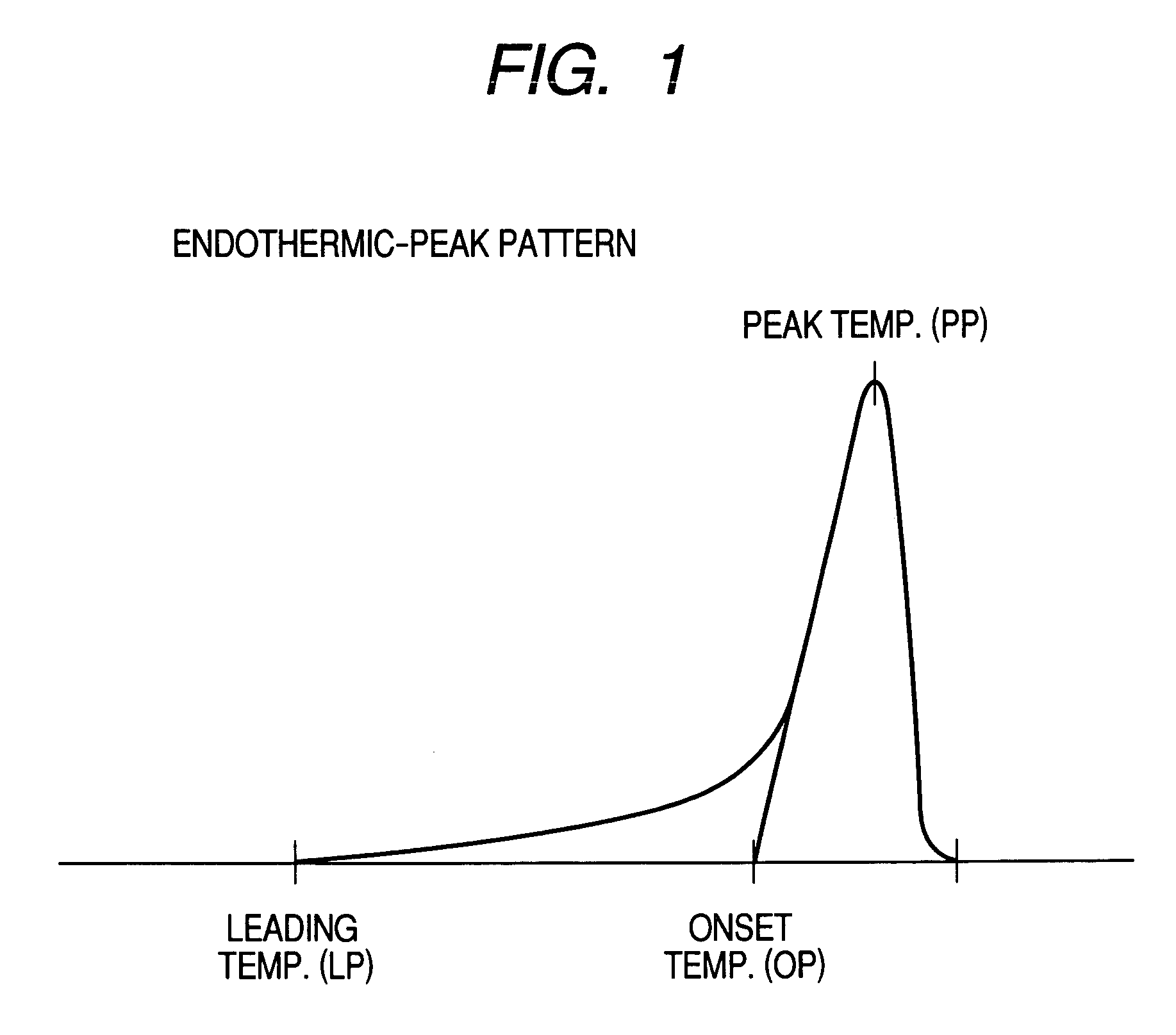

Toner with specified amounts of the THF-soluble matter having certain intrinsic viscosity

ActiveUS7700254B2Excellent developabilityExcellent low temperature fixabilityDevelopersEngineeringIntrinsic viscosity

The present invention aims to provide a toner having excellent developability and excellent low-temperature fixability without causing adhesion of ejected sheets even in a high-speed oilless fixing system and capable of preventing a frameless printing from causing a twisted offseting phenomenon. Specifically, provided is a toner having toner particles including at least a binder resin and a colorant, in which, when the toner is dissolved in a tetrahydrofuran (THF) solvent at 25° C. for 24 hours, the ratio of a THF-soluble matter having an intrinsic viscosity of 5.0×10−2 dl / g or less with respect to the total amount of the THF-soluble matter in a GPC-RALLS-viscometer analysis is 15.0 mass % to 60.0 mass %, and the ratio of a THF-soluble matter having an intrinsic viscosity of 1.5×10−1 dl / g or more with respect to the total amount of the THF-soluble matter in a GPC-RALLS-viscometer analysis is 20.0 mass % to 40.0 mass %.

Owner:CANON KK

Slurry useful for wire-saw slicing and evaluation of slurry

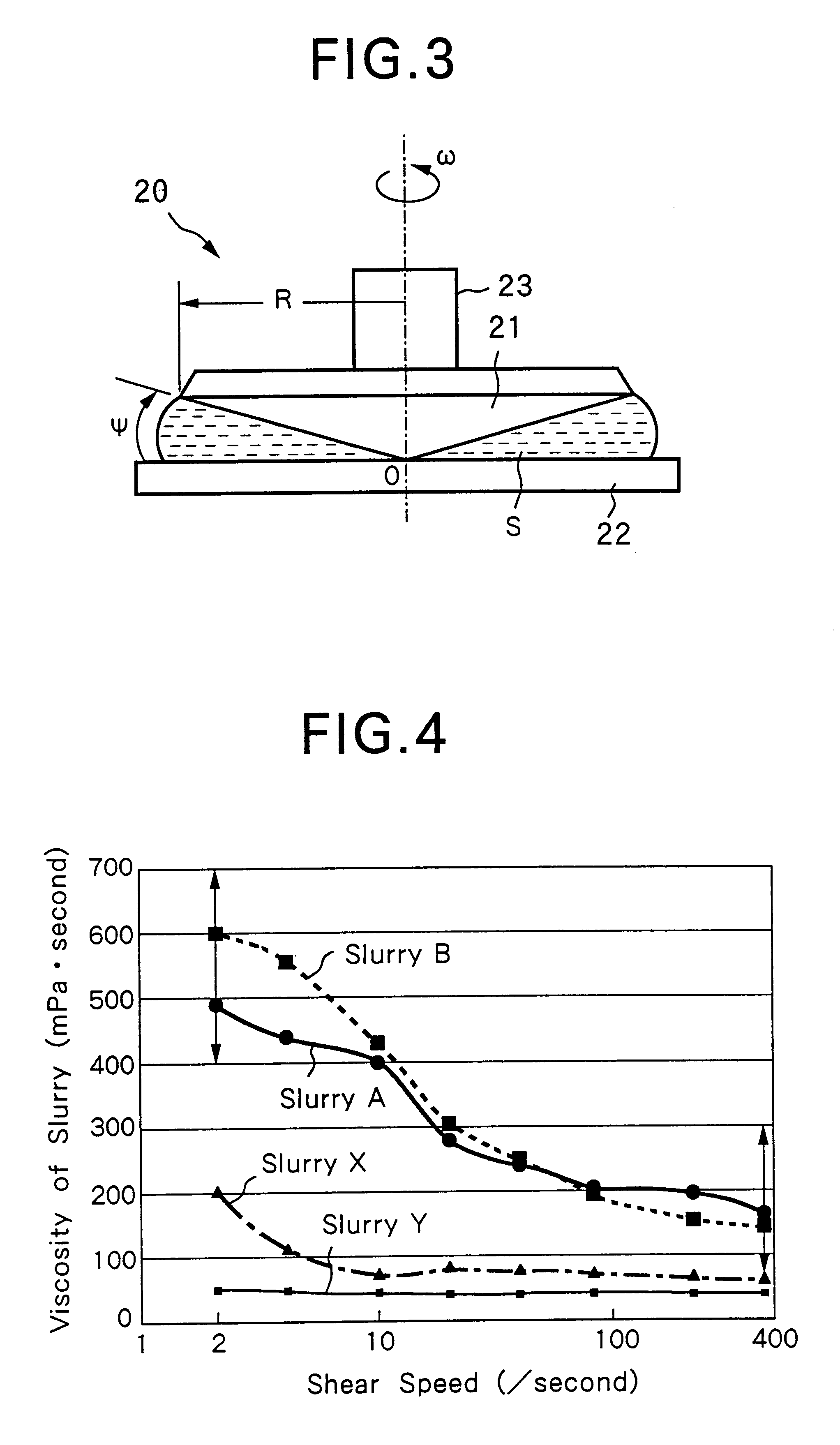

Slurry useful for wire-saw slicing has viscosity adjusted to 400-700 mPa.second at a shear speed of 2 / second and of 50-300 mPa.second at a shear speed of 380 / second. The viscosity of slurry is measured using a cone and plate type viscometer which can measure viscosity at different shear speeds. Since the slurry sufficiently flows into inner parts of grooves formed in an ingot and consumed for wire-saw slicing due to the viscosity controlled in response to the shear speed, the ingot can be efficiently sliced to wafers or discs.

Owner:SUPER SILICON KENKYUSHOKK +1

High efficiency master gels for thickening oil based compositions

InactiveUS20070071703A1Pronounced effect rheological propertyIncrease loadCosmetic preparationsHair removalOrganoclaySilicone fluid

The composition, preparation and use of a thickening system or master gel for oil based compositions, especially cosmetic compositions is described. These highly efficient master gels include: i) greater than about 10% to about 40% of an organoclay, ii) from about 70% to less than about 90% of a carrier oil comprising a substantially dissolved mixture of at least one silicone fluid and at least one organic oil wherein the total silicone fluids comprise from about 10% to about 90% of the carrier based on the total weight of the carrier, and ii) from 0.5% to about 6% of a polar activator. In a preferred embodiment the master gel contains from about 15% to about 30% of an organoclay and is chosen so that the viscosity of the master gel composition is at least 2.5 million cP as measured with a Brookfield viscometer at 1 rpm.

Owner:LIN SAMUEL QCHENG SUN

Slurry for lithium ion secondary battery positive electrodes

ActiveUS20150357648A1High target accuracyHigh positive electrode active material densityNon-metal conductorsConductive materialLithiumOrganic solvent

To provide a slurry for positive electrodes having excellent weight accuracy at the time of application, which enables the production of a lithium ion secondary battery that has high capacity and excellent cycle characteristics at high potentials, said lithium ion secondary battery being flexible and free from the occurrence of cracks in an active material layer when bent.[Solution] A slurry for lithium ion secondary battery positive electrodes according to the present invention contains a positive electrode active material, a binder, a conductive material and an organic solvent. The binder contains a nitrile group-containing acrylic polymer and a fluorine-containing polymer; and the viscosity ratio ((viscosity at a shear rate of 2 sec−1) / (viscosity at a shear rate of 20 sec−1)) of this slurry as measured by a coaxial double cylinder viscometer is 1.0-2.5.

Owner:ZEON CORP

Toner

ActiveUS7351509B2Increased durabilityImprove performanceDevelopersIntrinsic viscosityPolymer chemistry

Owner:CANON KK

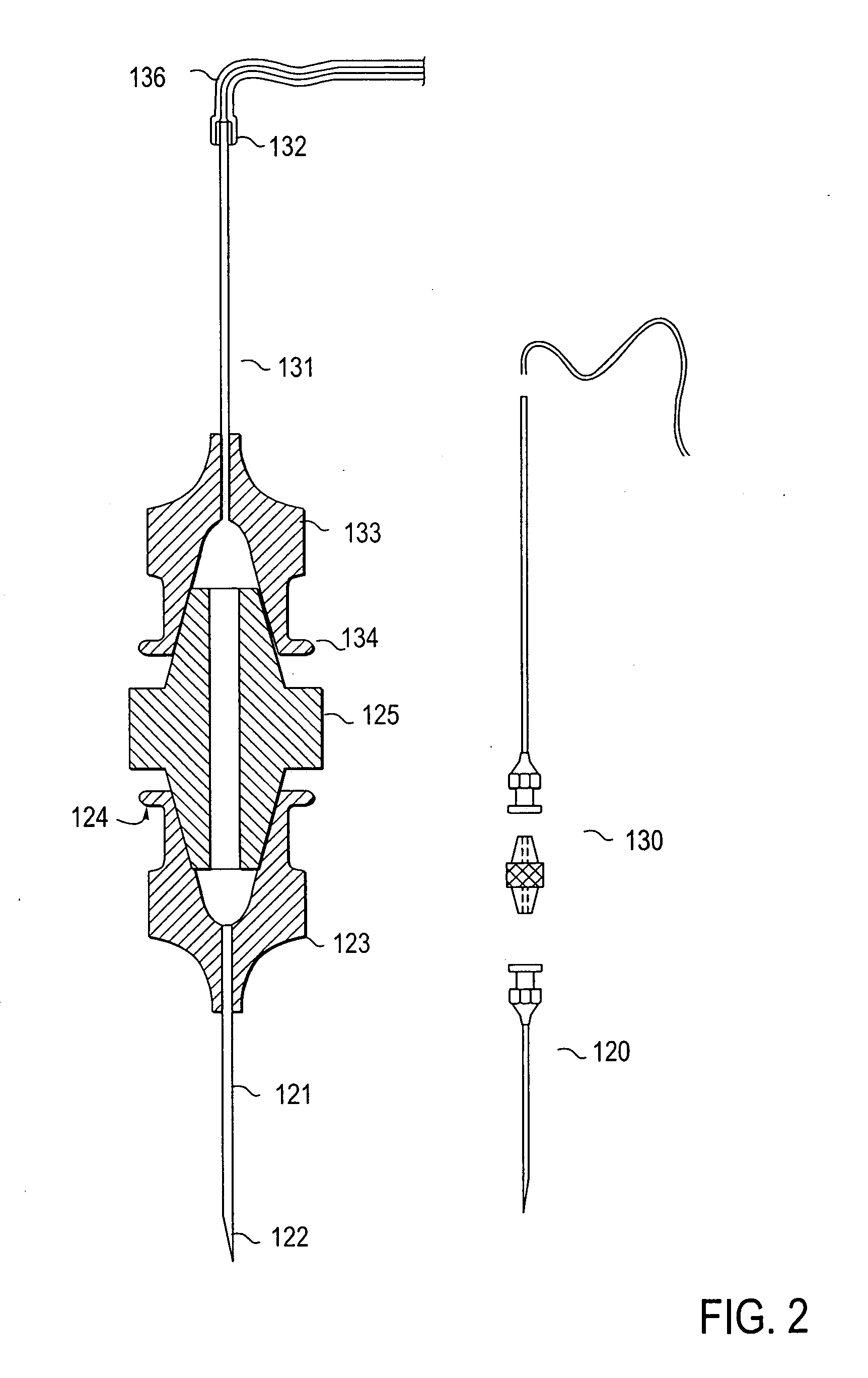

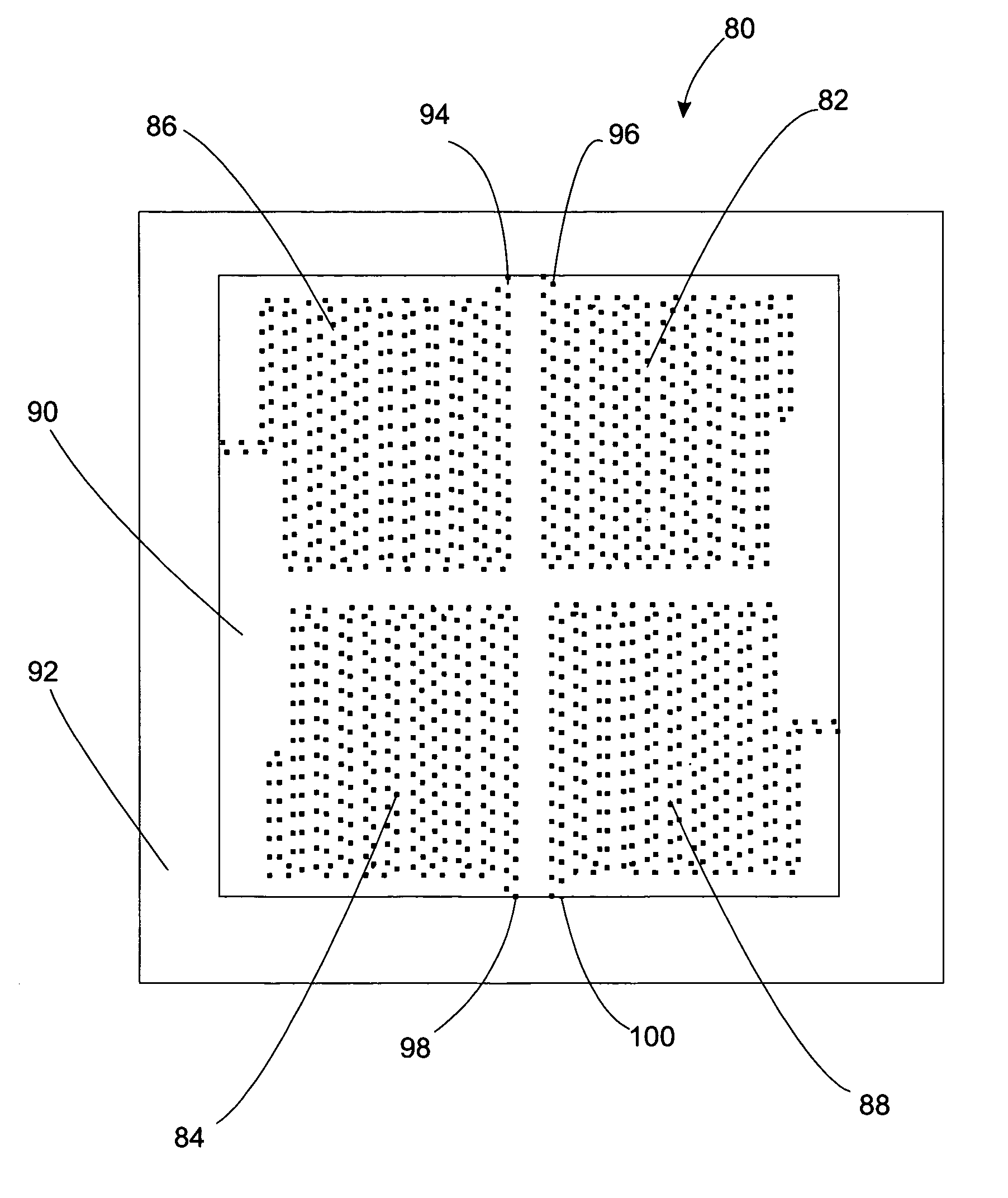

Nanoliter viscometer for analyzing blood plasma and other liquid samples

ActiveUS20060179923A1Easy to measureDetermine viscosityLaboratory glasswaresNanosensorsBlood plasmaPhysics

A microfabricated, a nanoliter capillary viscometer includes a first channel that is defined by a first channel-defining surface in a first substrate and a second channel defining surface in a second substrate. The progress of liquid through this first channel is monitored and used to determine viscosity. Viscosities in the range of 1 cP to 1000 cP are easily measured. Self-calibrating versions of the viscometer are also disclosed.

Owner:RGT UNIV OF MICHIGAN

Viscometer

A viscometer including a thermal block, a thermo device to control temperature of the thermal block, a temperature sensor to sense temperature of the thermal block, a capillary tube embedded in the thermal block such that the capillary tube is in thermal contact with the thermal block, an entrance tube connected to the capillary tube and embedded in the thermal block, a velocity tube connected to the capillary tube and embedded in the thermal block and at least two flow sensors aligned along the velocity tube adapted to measure velocity of the test specimen in the velocity tube.

Owner:POULTEN SELFE & LEE +1

Swellable dosage form comprising gellan gum

ActiveUS8383154B2Increase intakeEasy to doPowder deliveryHeavy metal active ingredientsParticulatesGellan gum

A novel dosage form. The dosage form is presented in particulate form and before oral ingestion the particulate material is subjected to an aqueous medium, whereby it is converted to a semi-solid form by swelling or gelling of one or more of the components, especially of a gellan gum, of the particulate matter. The invention also relates to a vehicle for oral administration of one or more active substances, the vehicle comprising a gellan gum arranged in a configuration allowing optimal water diffusion so that upon addition of a predetermined amount of an aqueous medium, without the necessity of applying shear forces or other mixing forces, within a time period of 5 minutes or less swells and / or gels and the texture of the swelled vehicle being similar to that of a soft pudding and having a viscosity of at least about 10,000 cps as measured by a Brookfield Viscometer with a #4 LV spindle at 6 rpm and at 20-25° C. In one embodiment of the invention, the particulate matter can be molded into a desired shape or pressed onto a dispensing unit such as a spoon.

Owner:ADARE PHARM INC

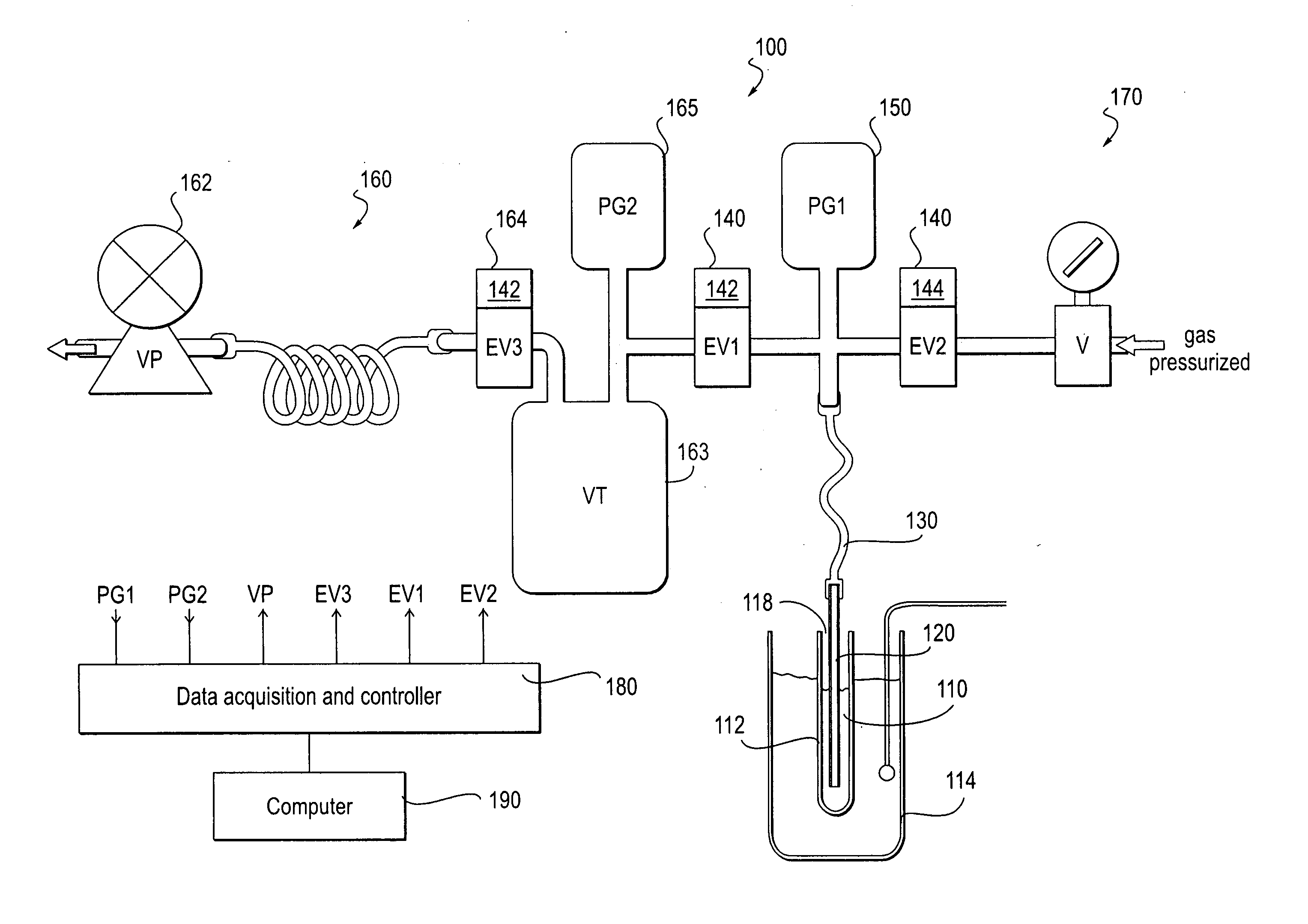

Method for using an alternate pressure viscometer

InactiveUS20080127718A1Variation of viscosity can be affectedMaterial analysis by electric/magnetic meansMaterial analysis by optical meansShear ratePressure difference

A method for determining the viscosity and relative change of viscosity of a fluid over plural shear rates caused by a decreasing or increasing pressure differential resulting from fluid flow to a defined chamber in a capillary system. The flow of liquid through the capillary restriction, the pressure variation rate and known dimensions of the system can be used typically by a processor to determine a rheological property of a fluid.

Owner:CHEVRON ORONITE SA

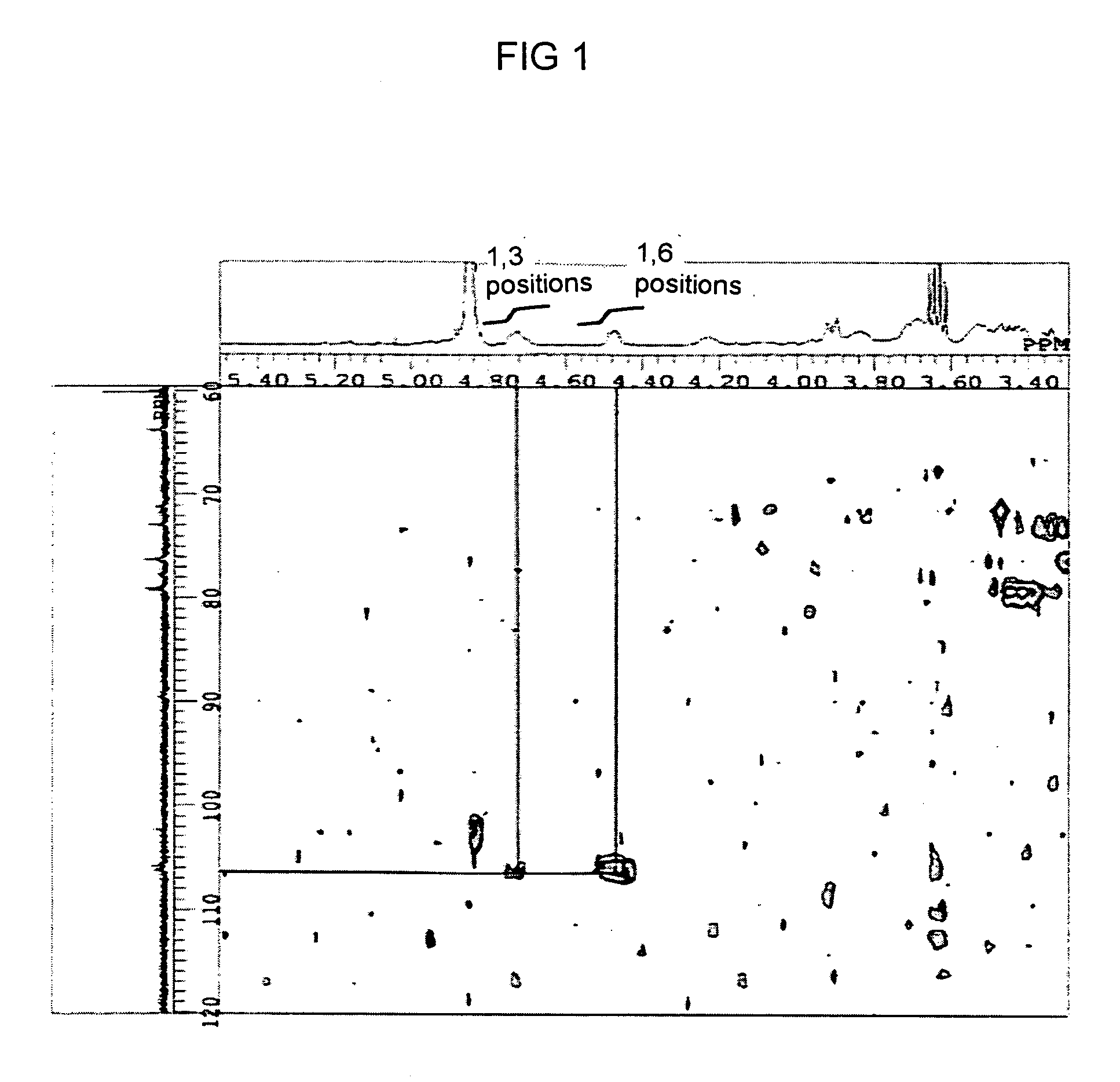

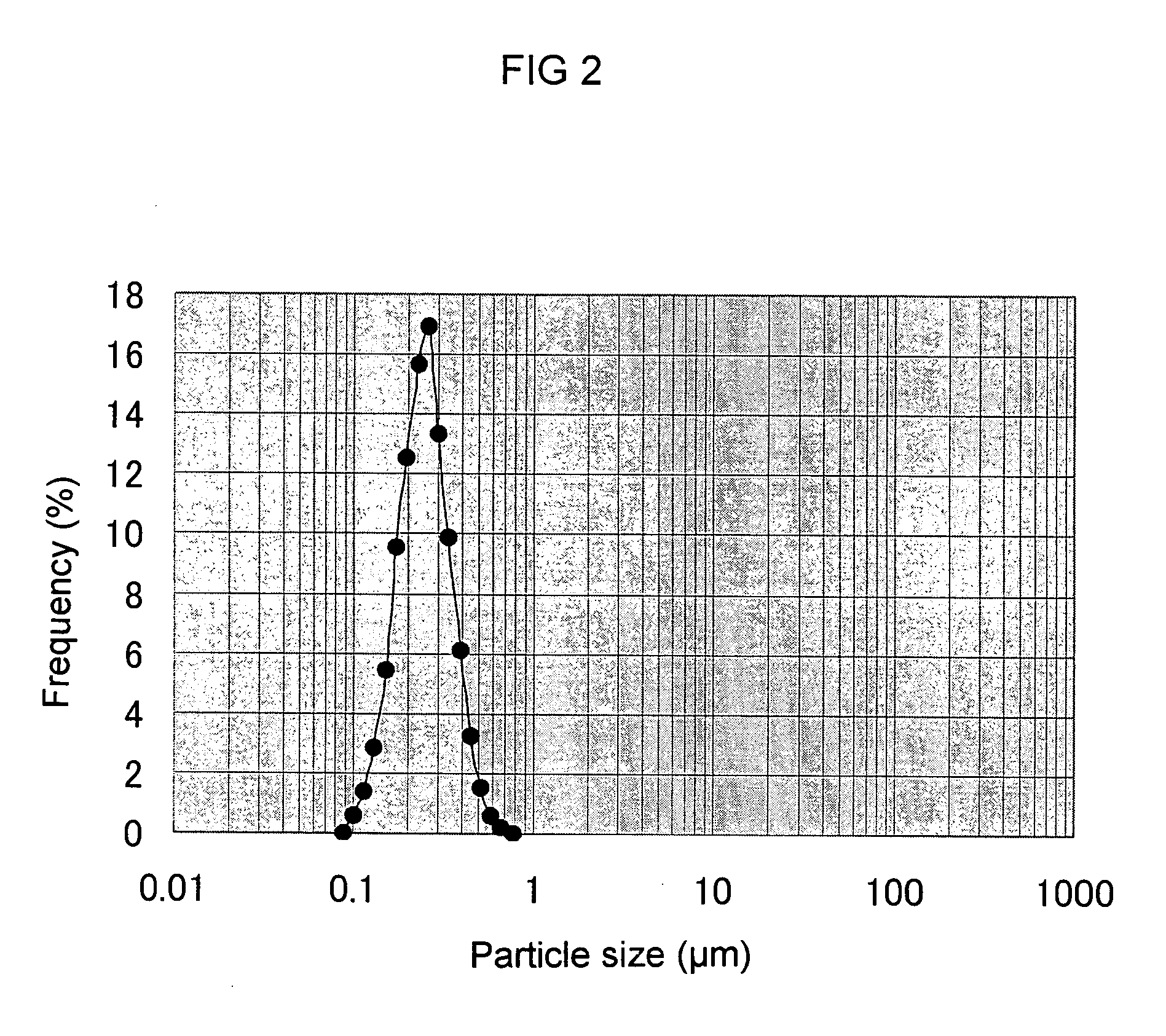

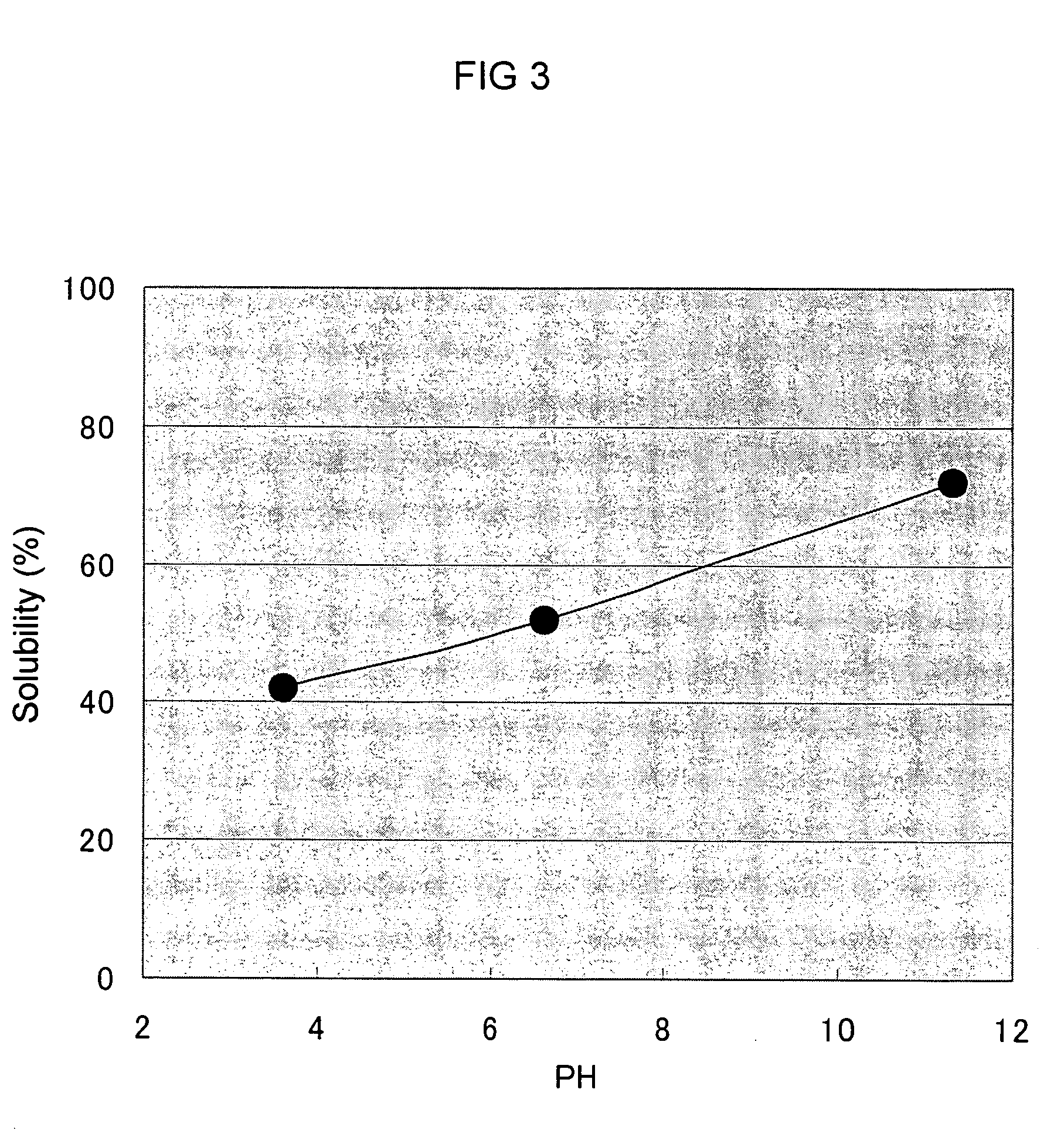

Beta-1, 3-1, 6-D-glucan and its use

An aqueous β-1,3-1,6-D-glucan solution, wherein 1HNMR spectra on its solution containing in 1N aqueous sodium hydroxide heavy solution have two signals of 4.7 ppm and 4.5 ppm and the viscosity (BM type rotary-viscometer, 12 rpm) of its solution at 30° C., pH5.0, and its concentration 0.5% (w / v) is 50 cP ([mPa.s]) or less.

Owner:DAISO CO LTD

Portable viscometer

A portable viscometer includes a pump mechanism which cooperates with a positive displacement sample container referred to as a positive displacement pipette, for dispensing, at a known flow rate, a sample of liquid for which viscosity is desired to be determined. The dispensed liquid flows through a flow through miniature viscosity sensor having at least two pressure sensors which measure the pressure drop of the liquid as it flows through a rectangular flow channel, the pressure drop at the known flow rate being proportional to the viscosity. A controller controls operation of the viscometer and processes sensor data, and the resulting measurements of viscosity can be displayed on a display. The positive displacement pipette is removably positioned in the viscometer so that it can be removed from the viscometer when a viscosity test is completed and replaced with another positive displacement pipette containing another liquid to be tested.

Owner:RHEOSENSE

Multi-reservoir pressure control system

InactiveUS20050005684A1Sufficient oscillationAccurate and stable and reliable assayFlow control using electric meansLaboratory glasswaresFluid transportFlow resistivity

Improved microfluidic devices, systems, and methods allow selective transportation of fluids within microfluidic channels of a microfluidic network by applying, controlling, and varying pressures at a plurality of reservoirs. Modeling the microfluidic network as a series of nodes connected together by channel segments and determining the flow resistance characteristics of the channel segments may allow calculation of fluid flows through the channel segments resulting from a given pressure configuration at the reservoirs. To effect a desired flow within a particular channel or series of channels, reservoir pressures may be identified using the network model. Viscometers or other flow sensors may measure flow characteristics within the channels, and the measured flow characteristics can be used to calculate pressures to generate a desired flow. Multi-reservoir pressure modulator and pressure controller systems can optionally be used in conjunction with electrokinetic or other fluid transport mechanisms.

Owner:CAPLIPER LIFE SCI INC

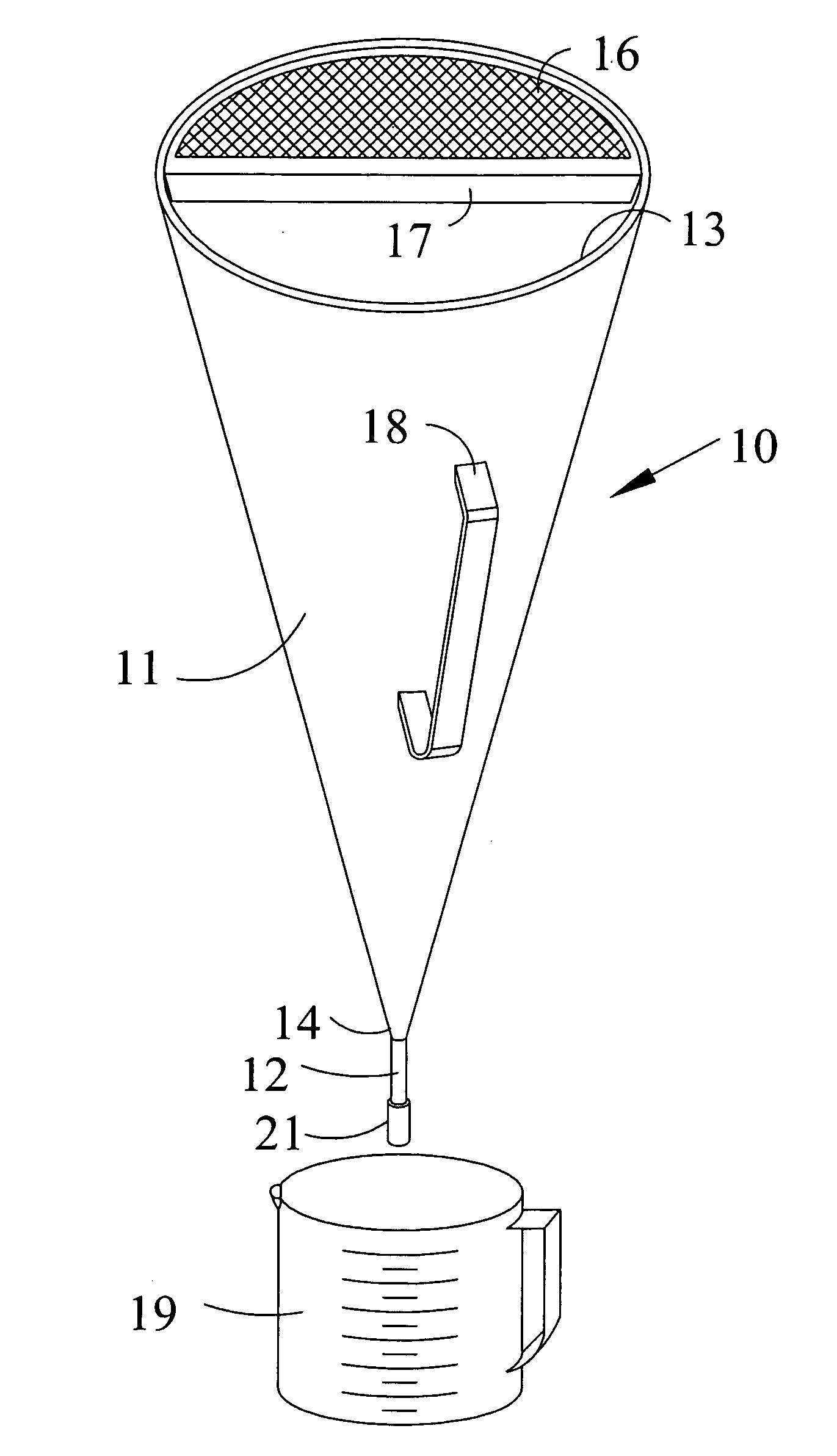

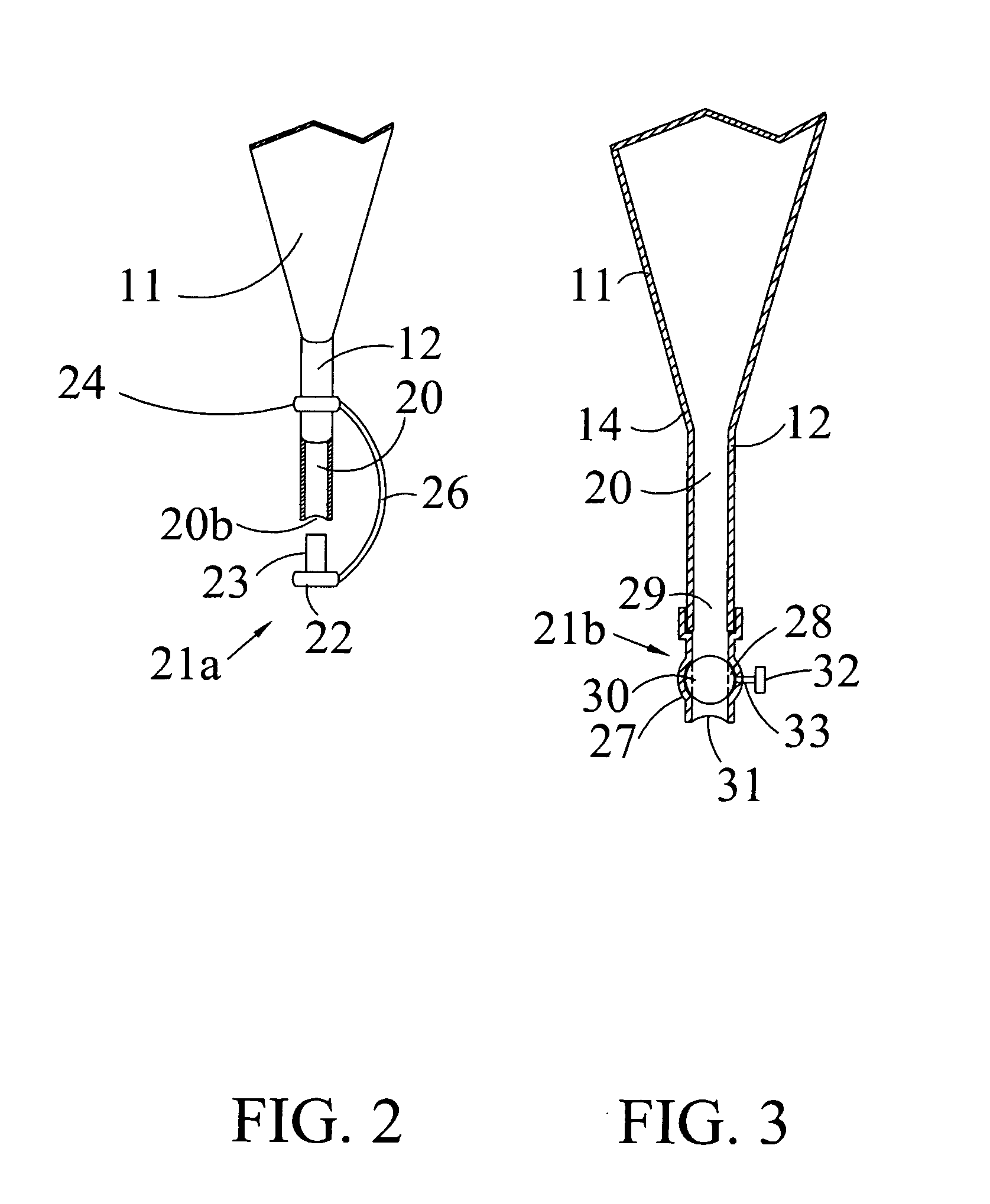

Funnel viscosimeter

InactiveUS20070227234A1Easy to collectImprove testLarge containersMaterial testing goodsSpool valveButterfly valve

Owner:PICHOTTA LARRY G

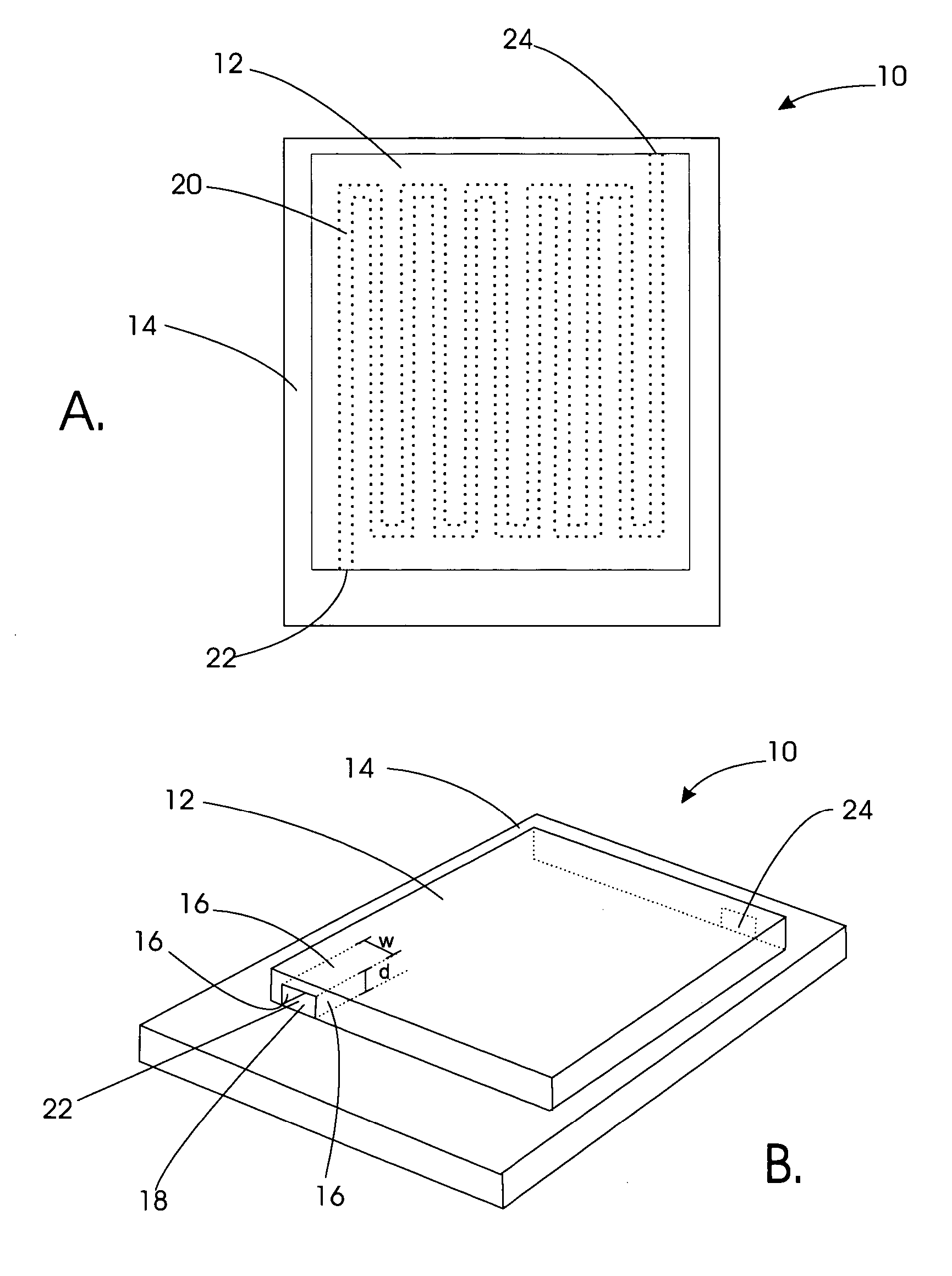

Nanoliter viscometer for analyzing blood plasma and other liquid samples

ActiveUS7188515B2Easy to measureDetermine viscosityMaterial analysis by optical meansLaboratory glasswaresBlood plasmaPhysics

A microfabricated, a nanoliter capillary viscometer includes a first channel that is defined by a first channel-defining surface in a first substrate and a second channel defining surface in a second substrate. The progress of liquid through this first channel is monitored and used to determine viscosity. Viscosities in the range of 1 cP to 1000 cP are easily measured. Self-calibrating versions of the viscometer are also disclosed.

Owner:RGT UNIV OF MICHIGAN

Engine oil compositions and preparation thereof

A multi-grade engine oil composition meeting required specifications of manufacturers is provided. In one embodiment, the engine oil composition contains a sufficient amount of a Pour Point Reducing Blend Component for the engine oil to have cold crank simulator viscosity at −20° C. of less than have a cold crank simulator viscosity at −20° C. of less than 9000 cP and a mini rotary viscometer (MRV) viscosity at −20° C. of less than 60,000 cP. The Pour Point Reducing Blend Component is selected from 1) an isomerized Fischer-Tropsch derived bottoms product; 2) a bottoms product prepared from an isomerized highly waxy mineral oil, or 3) an isomerized oil having a kinematic viscosity at 100° C. of at least about 8 mm2 / s made from polyethylene plastic.

Owner:CHEVROU USA INC

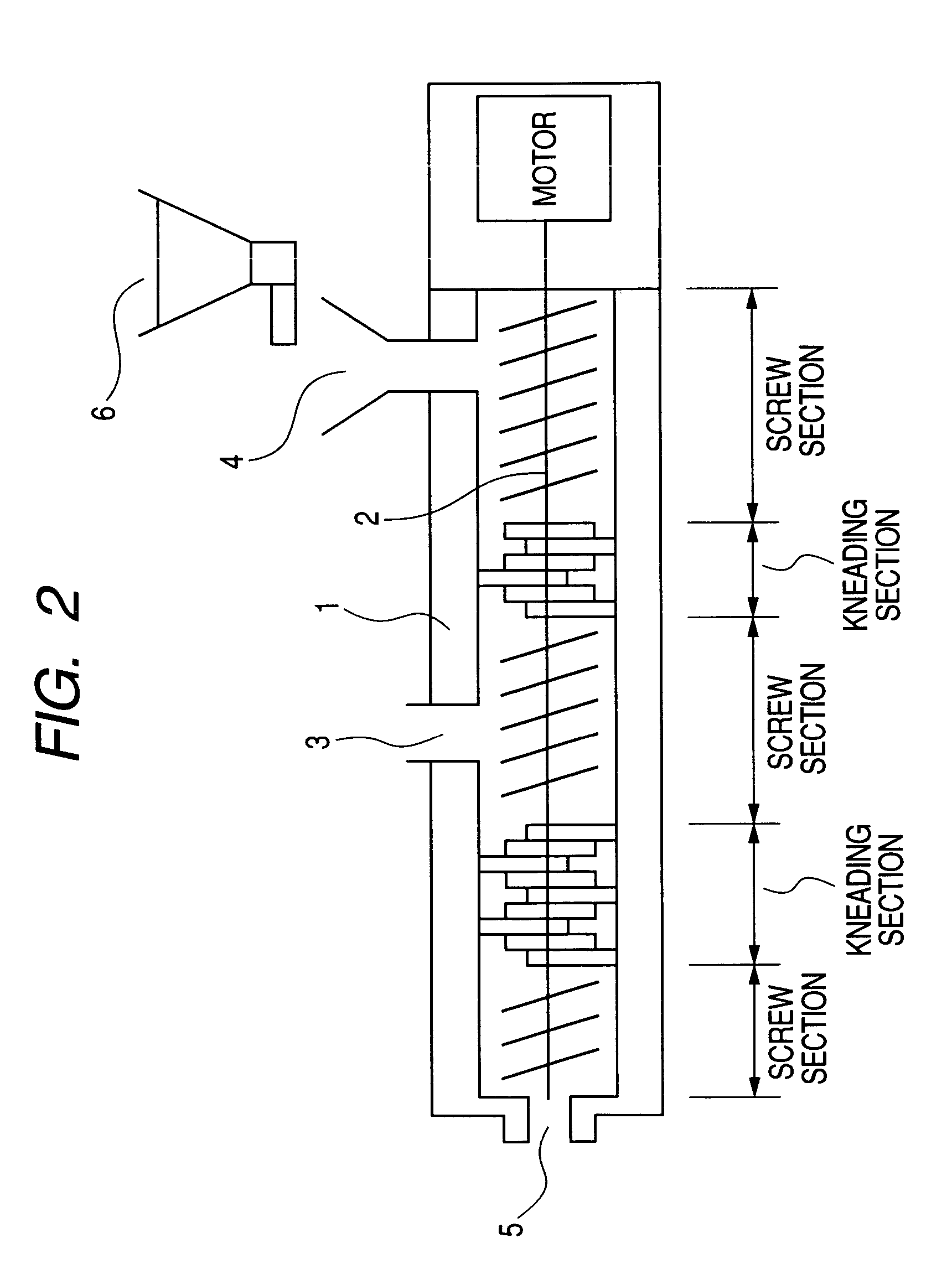

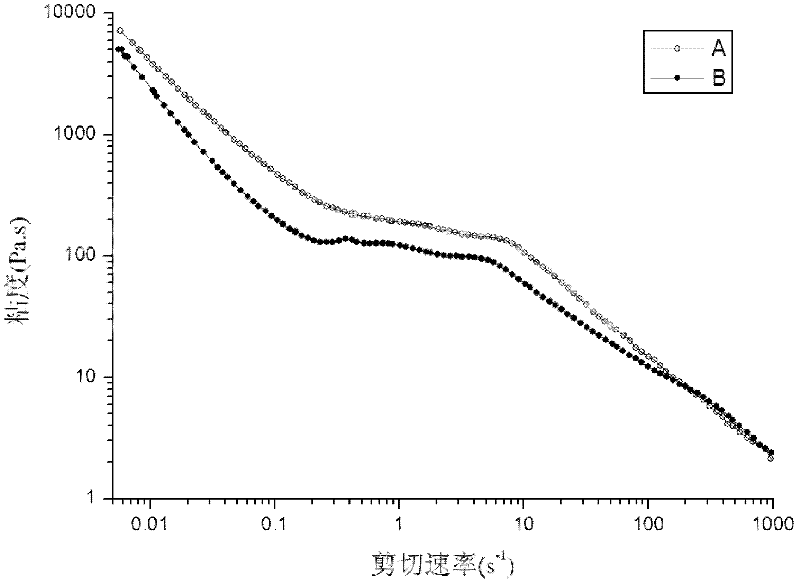

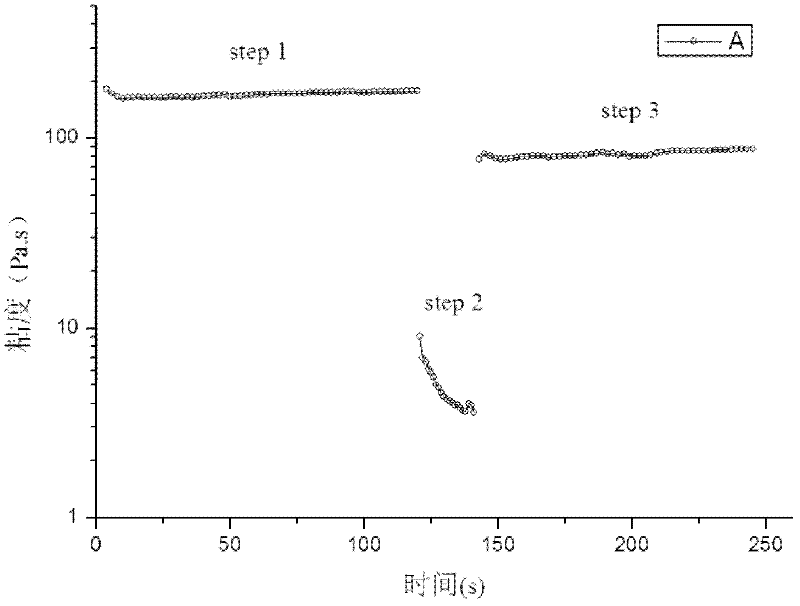

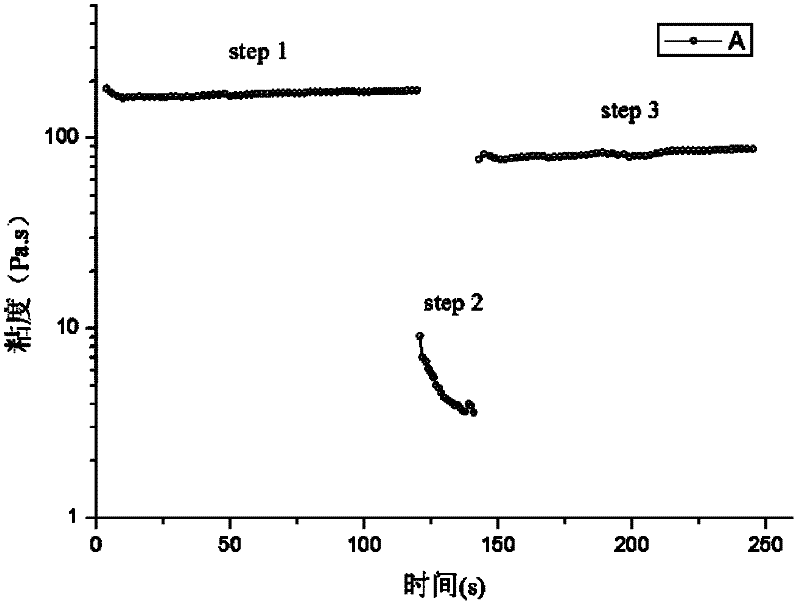

Method for testing rheological property of conductive slurry

InactiveCN102393348AComprehensive Rheological CharacterizationRheological CharacterizationFlow propertiesTemperature controlPhotovoltaic industry

The invention relates to the photovoltaic industry and in particular relates to a method for testing the rheological property of a conductive slurry. The method comprises the following steps: calibrating the instrument accuracy; setting a temperature; selecting and calibrating a clamp; loading and testing a sample; and determining the rheological property. Compared with a viscometer, the test method provided by the invention has a measurement accuracy which is one order of magnitude higher than that of the viscometer, needs a few samples, can be used for realizing accurate temperature control and quick experiment operations, and can represent the rheological property of the conductive slurry more comprehensively.

Owner:TRINA SOLAR CO LTD

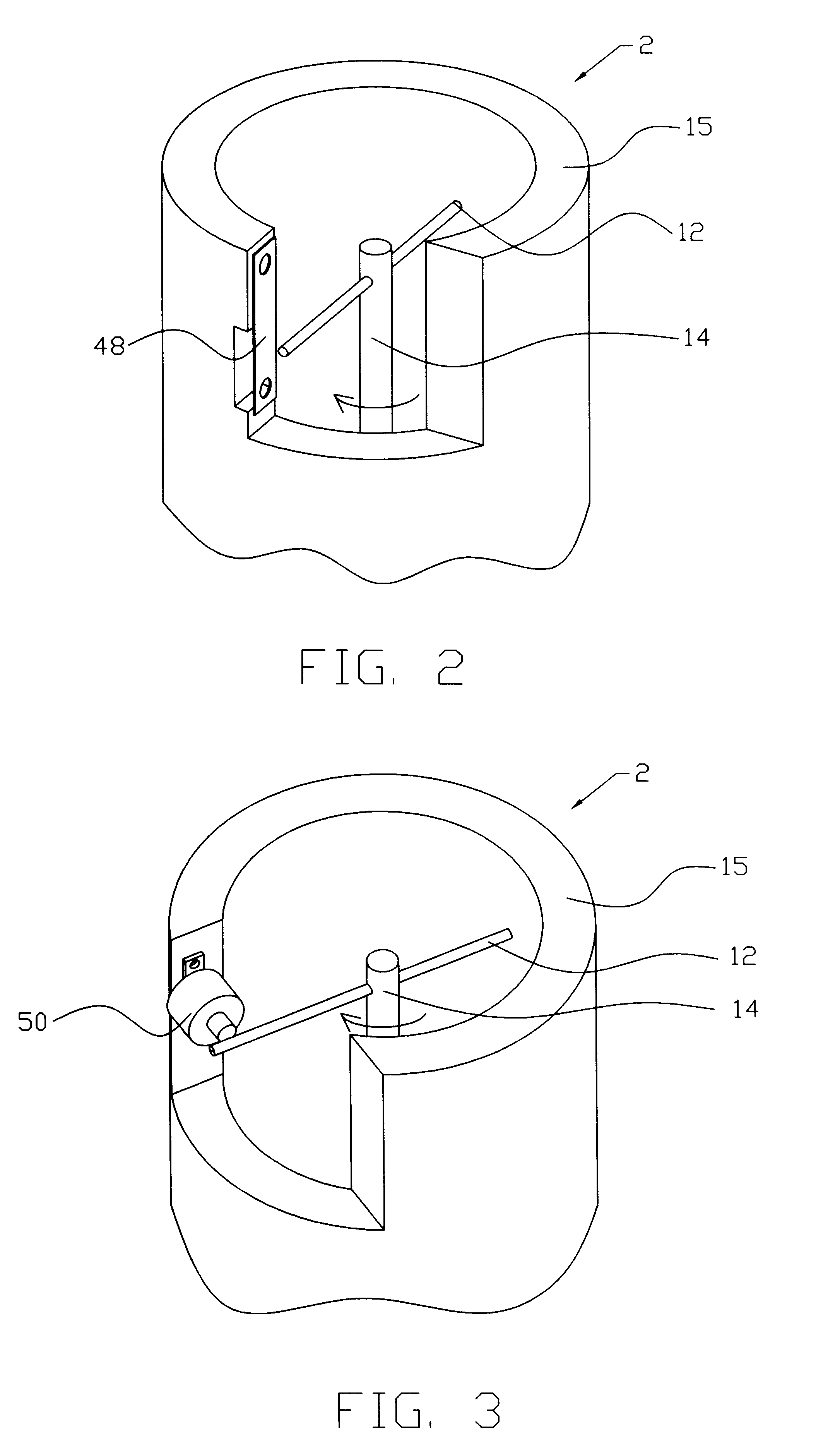

Viscometer

A viscometer includes a housing and a bob disposed in the housing such that a gap is provided between the bob and the housing. The bob includes a magnet. A linear support supports the bob such that the bob is free to rotate with respect the housing. A flow inlet in the housing provides fluid flow into the housing. A flow outlet provides fluid flow out of the housing. At least one coil is disposed adjacent the housing for providing a magnetic field to induce oscillating rotational movement in the bob and to measure the movement of the bob. The viscometer is configured to measure a viscosity of a fluid by inducing movement in the bob and measuring a dampening effect of the fluid.

Owner:VIDEOJET TECH INC

Digital viscometer with arm and force sensor to measure torque

Viscometer (2) with a sleeve (30) rotatable by a sprocket (20) and a timing belt (44) to shear a tested fluid thus imparting torque to a bob (28) mounted on a shaft (14) supported via axially spaced bearings (16, 22), an arm (12) connecting to the top of the shaft (14) applies force to a force sensor (10) which is proportional to the torque applied to the bob.

Owner:BI HONGFENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com