Method for testing rheological property of conductive slurry

A technology of rheological properties and testing methods, applied in the directions of flow properties, measuring devices, analytical materials, etc., can solve the problems of different, no testing fluid viscosity, inability to fluid thixotropic properties, etc. , the effect of comprehensive characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

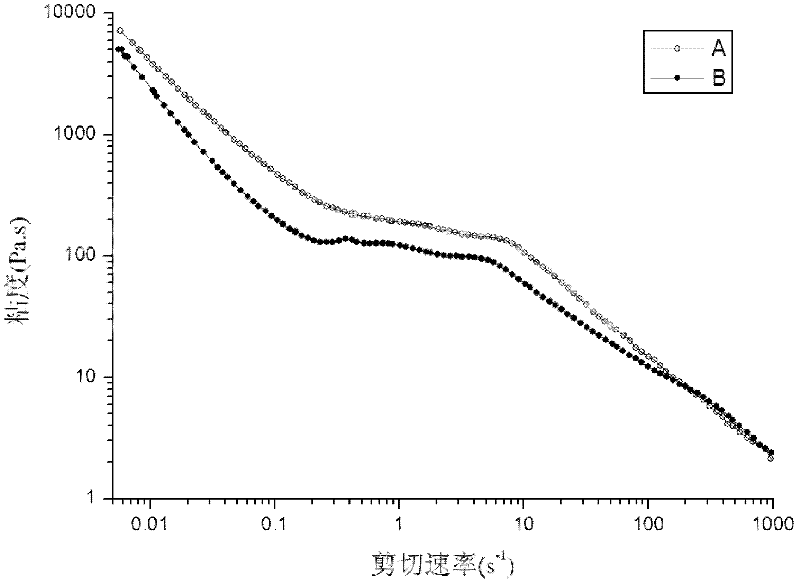

[0048] Embodiment 1 - the test of apparent viscosity

[0049] 1. Calibrate the rheometer and set the test temperature to 25°C;

[0050] 2. According to the composition and initial viscosity of the conductive silver paste, select a cone-plate fixture with a diameter of 40mm, a cone angle of 1°, and a gap of 29um;

[0051] 3. For the cone-plate fixture, verify the system calibration factors on the air bearing friction coefficient, air bearing inertia, measurement system inertia, torque mapping and the zero point of the gap value Gap between the fixture and the bottom plate;

[0052] 4. Use a sample spoon to take the conductive silver paste and place it in the center of the base plate, lower the fixture by 30um, and set the descending speed when the fixture is 1cm away from the base to 100um·s -1 , Scrape the extruded sample with a rectangular wooden strip along the periphery of the fixture, and then lower the fixture to the inherent Gap 29um.

[0053] 5. After the sample is lo...

Embodiment 2

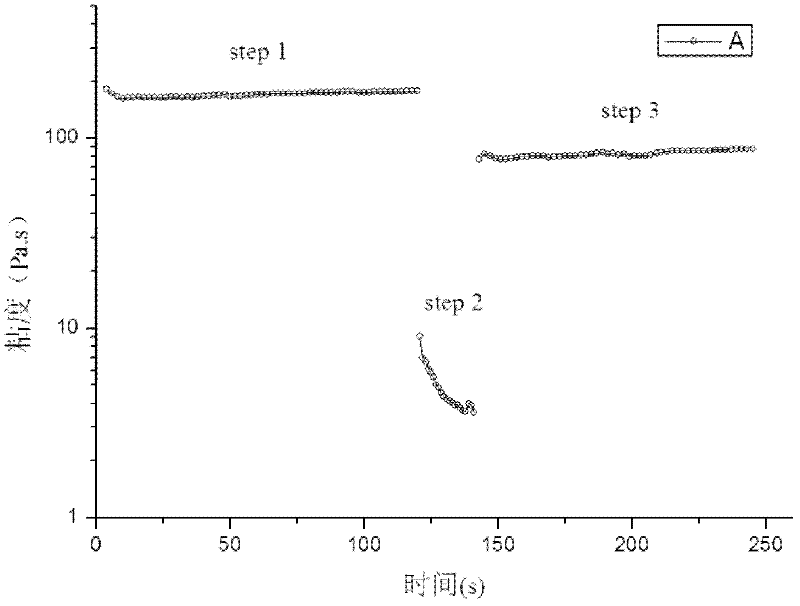

[0055] Embodiment 2—Thixotropic properties of shear-thinning fluid

[0056] 1. Calibrate the rheometer and set the test temperature to 25°C;

[0057] 2. According to the composition and initial viscosity of the conductive silver paste, select a cone-plate fixture with a diameter of 40mm, a cone angle of 1°, and a gap of 29um;

[0058] 3. For the cone-plate fixture, verify the system calibration factors on the air bearing friction coefficient, air bearing inertia, measurement system inertia, torque mapping and the zero point of the gap value Gap between the fixture and the bottom plate;

[0059] 4. Use a sample spoon to take the conductive silver paste and place it in the center of the base plate, lower the fixture by 30um, and set the descending speed when the fixture is 1cm away from the base to 100um·s -1 , Scrape the extruded sample with a rectangular wooden strip along the periphery of the fixture, and then lower the fixture to the inherent Gap 29um.

[0060] 5. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com