Deepwater constant-rheology oil base drilling fluid

An oil-based drilling fluid and deep-water technology, which is applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of reducing the equivalent circulating density of drilling fluid and increasing viscosity at low temperature, so as to avoid excessively high equivalent circulating density and cost Low, the effect of meeting the technical requirements of marine deepwater drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

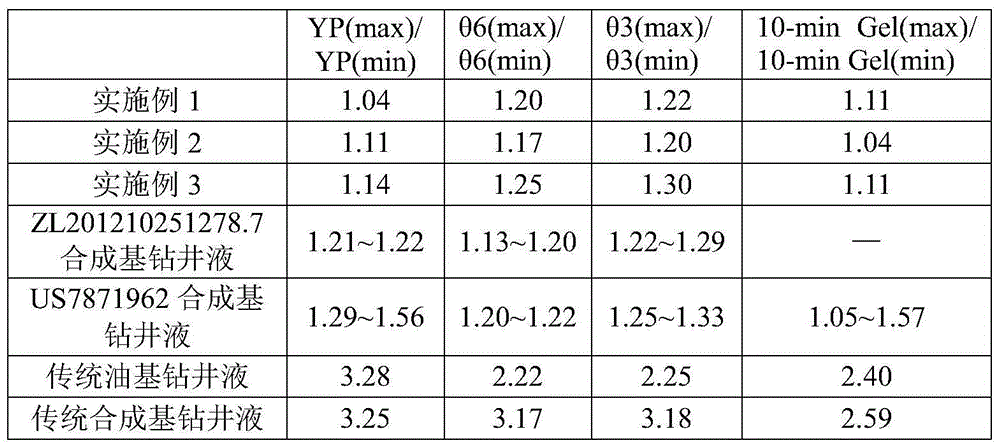

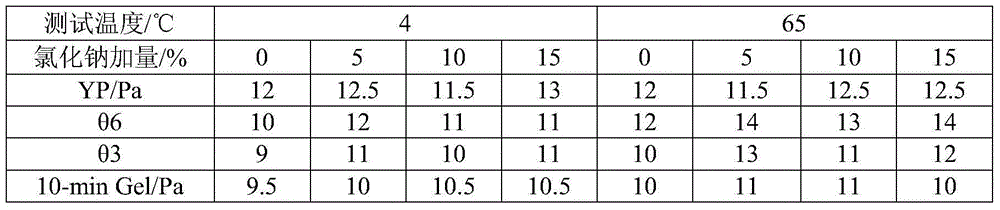

Examples

Embodiment 1

[0029] Deepwater constant rheology oil-based drilling fluid includes the following components in parts by mass:

[0030] 80 parts of 5# white oil, 20 parts of calcium chloride aqueous solution, 3.5 parts of flow regulator, 3 parts of emulsifier, 2 parts of wetting agent, 1 part of organic soil for drilling fluid, 2 parts of fluid loss reducer, 0.4 parts of calcium oxide Parts, 50 parts of weighting agent.

[0031] The mass fraction of the calcium chloride aqueous solution used in the present embodiment is 25%.

[0032] The flow regulator used in this example is made by mixing trimer acid and diethylene propylene rubber in a mass ratio of 1:1.

[0033] The emulsifier used in this example is formed by mixing oxyethyl alkylphenol ether and a copolymer formed by the reaction of oleic acid and ethanolamine in a mass ratio of 2:1.

[0034] The wetting agent used in this example is prepared by mixing naphthenic acid amide and polyoxyethylene alkylphenol ether in a mass ratio of 1:1...

Embodiment 2

[0039] Deepwater constant rheology oil-based drilling fluid includes the following components in parts by mass:

[0040] 75 parts of 0# white oil, 25 parts of calcium chloride aqueous solution, 3.5 parts of flow regulator, 3 parts of emulsifier, 2 parts of wetting agent, 1 part of organic soil for drilling fluid, 3 parts of fluid loss reducer, 0.5 parts of calcium oxide Parts, weighting agent 100 parts.

[0041] The mass fraction of the calcium chloride aqueous solution used in the present embodiment is 20%.

[0042] The flow regulator used in this example is formed by mixing dimer acid, a copolymer formed by the reaction of ethanolamine and triethylenetetramine, and ethylene-propylene-diene rubber in a mass ratio of 2:1.

[0043] The emulsifier used in this example is formed by mixing oleic acid amide and sodium alkylbenzene sulfonate in a mass ratio of 1.5:1.

[0044] The wetting agent used in this example is prepared by mixing naphthenic acid amide and octylphenol ethoxyl...

Embodiment 3

[0049] Deepwater constant rheology oil-based drilling fluid includes the following components in parts by mass:

[0050]80 parts of 3# white oil, 20 parts of calcium chloride aqueous solution, 4 parts of flow regulator, 3.5 parts of emulsifier, 2.5 parts of wetting agent, 1 part of organic soil for drilling fluid, 3 parts of fluid loss reducer, 0.6 parts of calcium oxide Parts, 260 parts of weighting agent.

[0051] The mass fraction of the calcium chloride aqueous solution used in the present embodiment is 20%.

[0052] The flow regulator used in this example is a copolymer produced by the reaction of dimer acid, ethanolamine and diethylenetriamine and a copolymer produced by the reaction of N-hexadecyl acrylamide, styrene and methacrylic acid according to 2:1 mass ratio mixed.

[0053] The emulsifier used in this example is formed by mixing oleic acid amide and oxyethyl alkylphenol ether in a mass ratio of 1.5:1.

[0054] The wetting agent used in this example is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com