A deep-water constant-rheology oil-based drilling fluid

An oil-based drilling fluid and deep water technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as low-temperature viscosity increase and lower equivalent circulation density of drilling fluid, so as to achieve low cost and avoid excessive equivalent circulation density. High, reduce workload and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

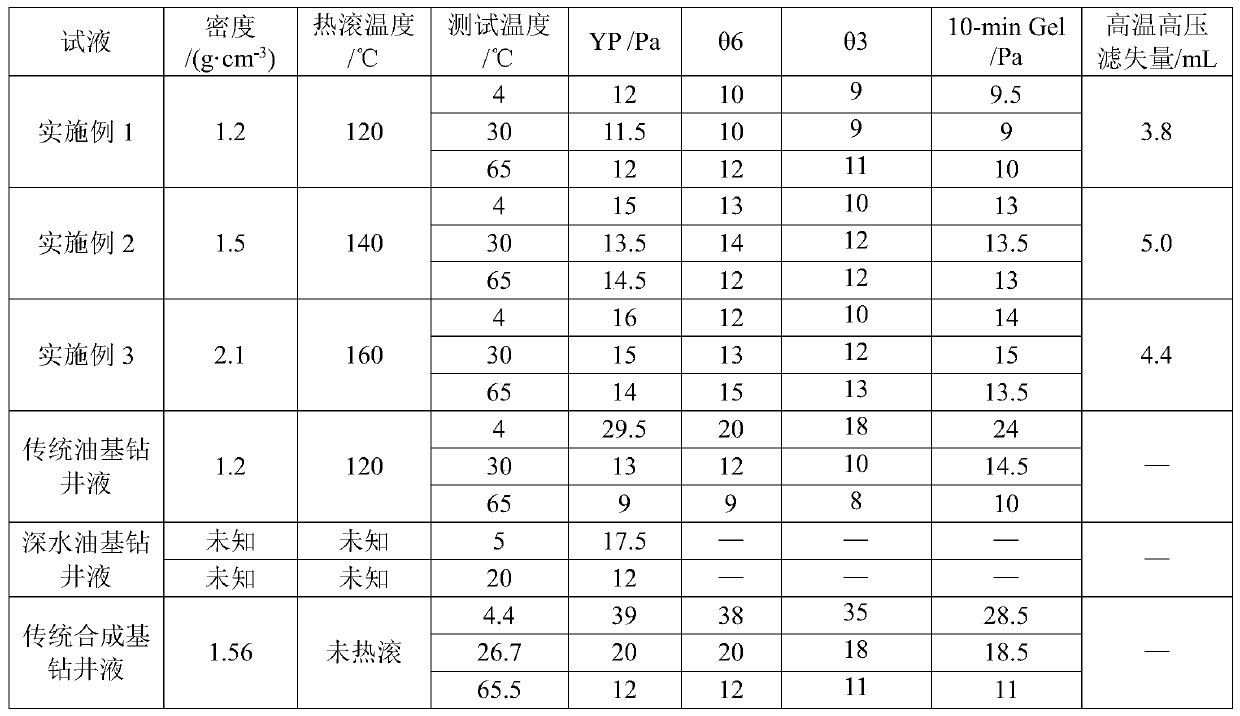

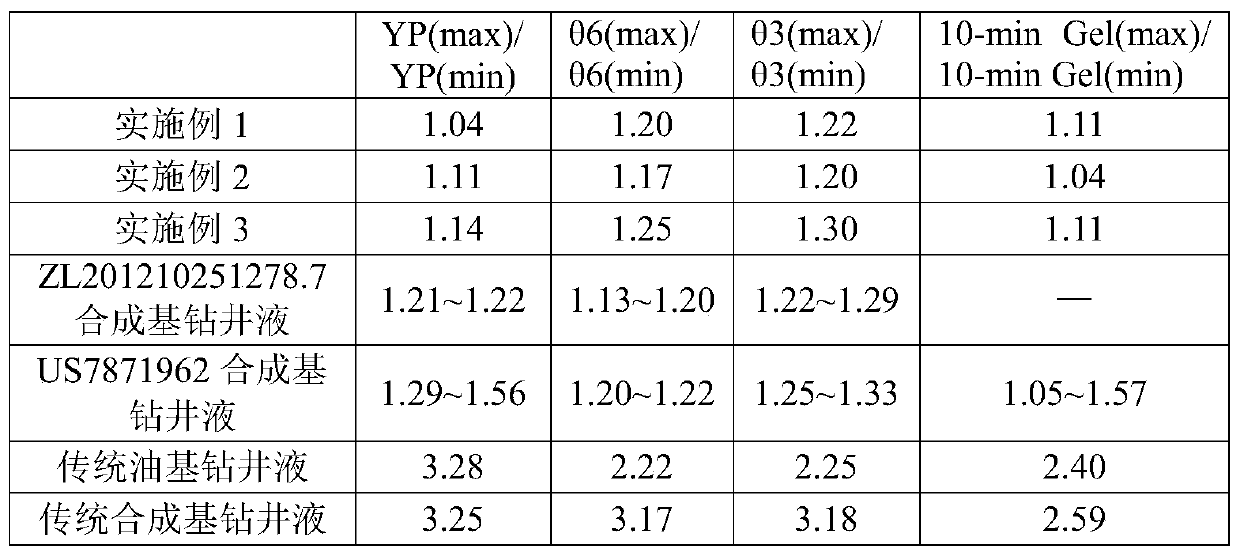

Examples

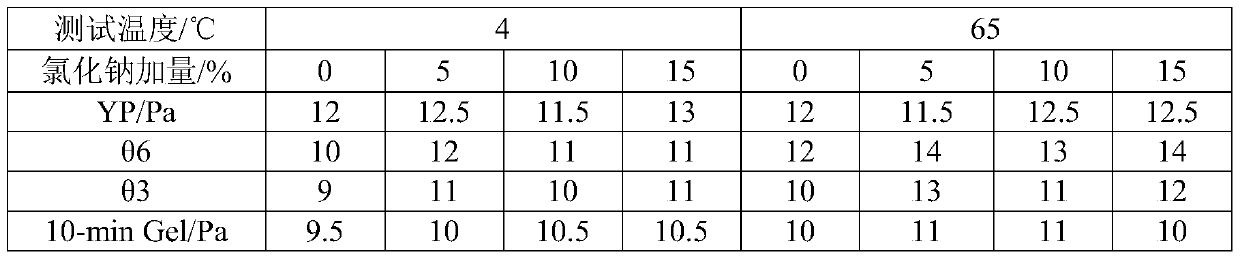

Embodiment 1

[0029] Deepwater constant rheology oil-based drilling fluid includes the following components in parts by mass:

[0030] 80 parts of 5# white oil, 20 parts of calcium chloride aqueous solution, 3.5 parts of flow regulator, 3 parts of emulsifier, 2 parts of wetting agent, 1 part of organic soil for drilling fluid, 2 parts of fluid loss reducer, 0.4 parts of calcium oxide Parts, 50 parts of weighting agent.

[0031] The mass fraction of the calcium chloride aqueous solution used in the present embodiment is 25%.

[0032] The flow regulator used in this example is made by mixing trimer acid and diethylene propylene rubber in a mass ratio of 1:1.

[0033] The emulsifier used in this example is formed by mixing oxyethyl alkylphenol ether and a copolymer formed by the reaction of oleic acid and ethanolamine in a mass ratio of 2:1.

[0034] The wetting agent used in this example is prepared by mixing naphthenic acid amide and polyoxyethylene alkylphenol ether in a mass ratio of 1:1...

Embodiment 2

[0039] Deepwater constant rheology oil-based drilling fluid includes the following components in parts by mass:

[0040] 75 parts of 0# white oil, 25 parts of calcium chloride aqueous solution, 3.5 parts of flow regulator, 3 parts of emulsifier, 2 parts of wetting agent, 1 part of organic soil for drilling fluid, 3 parts of fluid loss reducer, 0.5 parts of calcium oxide Parts, weighting agent 100 parts.

[0041] The mass fraction of the calcium chloride aqueous solution used in the present embodiment is 20%.

[0042] The flow regulator used in this example is formed by mixing dimer acid, a copolymer formed by the reaction of ethanolamine and triethylenetetramine, and ethylene-propylene-diene rubber in a mass ratio of 2:1.

[0043] The emulsifier used in this example is formed by mixing oleic acid amide and sodium alkylbenzene sulfonate in a mass ratio of 1.5:1.

[0044] The wetting agent used in this example is prepared by mixing naphthenic acid amide and octylphenol ethoxyl...

Embodiment 3

[0049] Deepwater constant rheology oil-based drilling fluid includes the following components in parts by mass:

[0050]80 parts of 3# white oil, 20 parts of calcium chloride aqueous solution, 4 parts of flow regulator, 3.5 parts of emulsifier, 2.5 parts of wetting agent, 1 part of organic soil for drilling fluid, 3 parts of fluid loss reducer, 0.6 parts of calcium oxide Parts, 260 parts of weighting agent.

[0051] The mass fraction of the calcium chloride aqueous solution used in the present embodiment is 20%.

[0052] The flow regulator used in this example is a copolymer produced by the reaction of dimer acid, ethanolamine and diethylenetriamine and a copolymer produced by the reaction of N-hexadecyl acrylamide, styrene and methacrylic acid according to 2:1 mass ratio mixed.

[0053] The emulsifier used in this example is formed by mixing oleic acid amide and oxyethyl alkylphenol ether in a mass ratio of 1.5:1.

[0054] The wetting agent used in this example is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com