Method for preparing perilla oil powder through microencapsulation

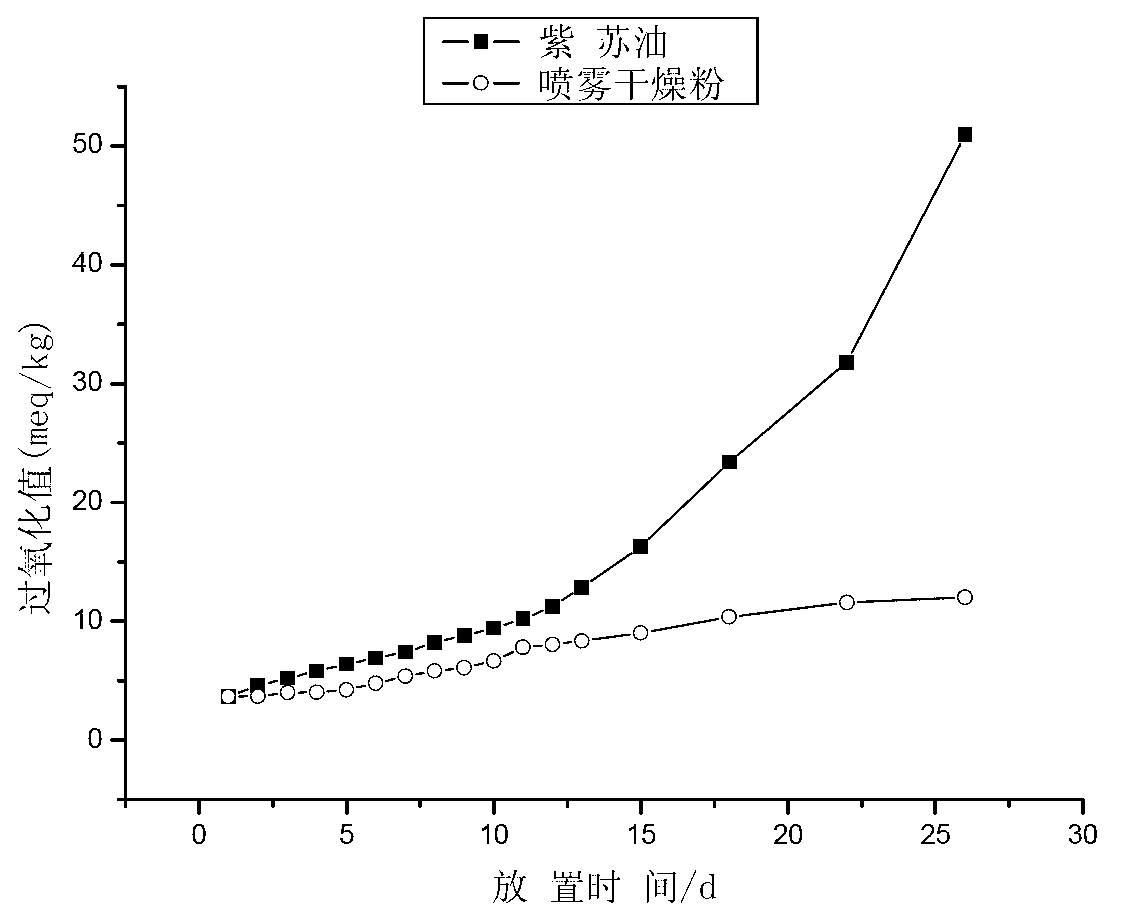

A technology of microencapsulation and perilla oil, applied in the field of food processing, can solve the problems of inconvenient carrying of perilla oil, poor protein water solubility, short product shelf life, etc., and achieves good water solubility and stability, and fast film forming speed. , the effect of increasing the density of the capsule wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Gelatinize starch octenyl succinate in a near-boiling water (90-100°C) water bath for 10 minutes, and cool naturally to room temperature.

[0031] (2) The gelatinized starch octenyl succinate is made into an aqueous solution of starch octenyl succinate with a mass concentration of 30%.

[0032] (3) Add perilla oil to the aqueous solution of starch octenyl succinate at a core-to-wall ratio of 1:5, and then magnetically stir at 60°C to obtain an emulsion.

[0033] (4) Homogenize the emulsion obtained in step (3) at a speed of 13000r / min for 2 minutes to obtain a uniform and stable emulsion.

[0034] (5) Rapidly spray-dry the above-mentioned homogenized emulsion to obtain perilla oil powder. During spray drying, the inlet air temperature is 190°C, the outlet air temperature is 100°C, and the feed flow rate is 55mL / min.

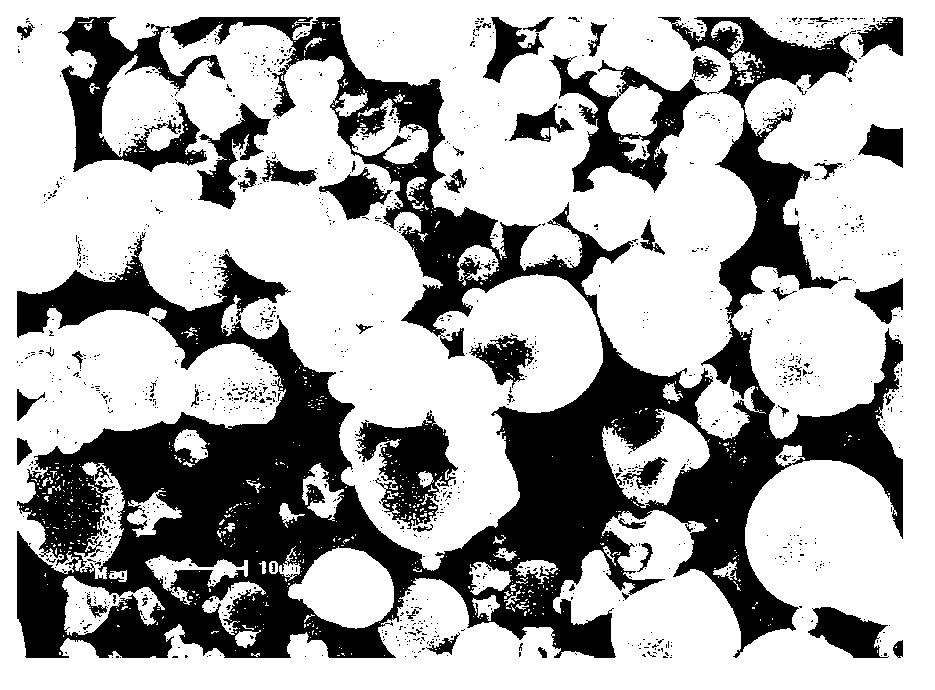

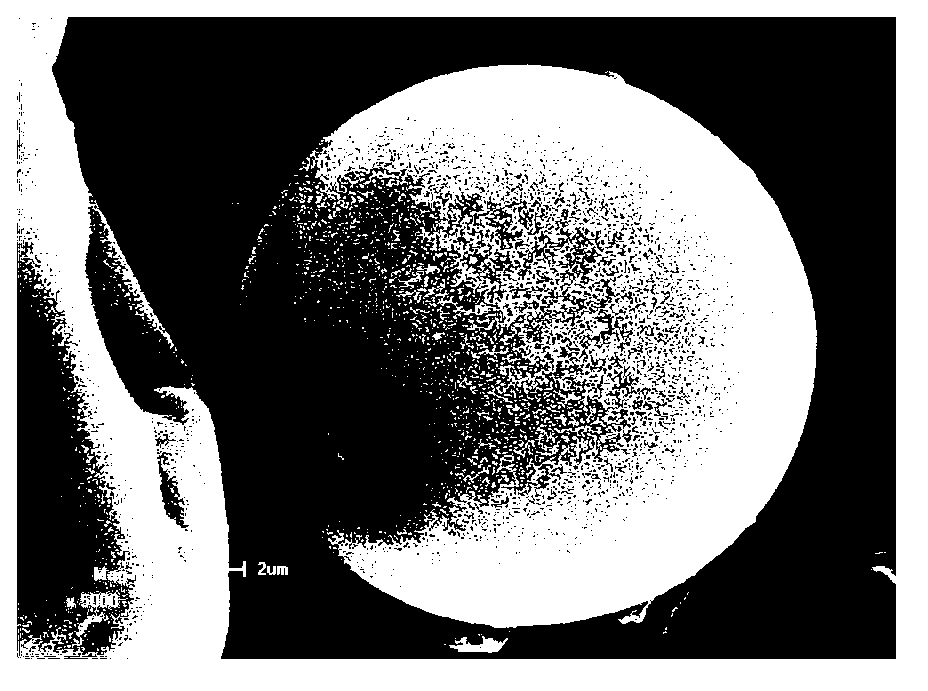

[0035] The scanning electron micrograph of the product obtained in the present embodiment is as follows: figure 1 , 2 shown, from figure 1 , 2 It...

Embodiment 2

[0048] (1) Gelatinize starch octenyl succinate in a near-boiling water (90-100°C) water bath for 10 minutes, and cool naturally to room temperature.

[0049] (2) The gelatinized starch octenyl succinate is made into an aqueous solution of starch octenyl succinate with a mass concentration of 40%.

[0050] (3) Add perilla oil to the aqueous solution of starch octenyl succinate at a core-to-wall ratio of 1:5, and then magnetically stir at 60°C to obtain an emulsion.

[0051] (4) Homogenize the emulsion obtained in step (3) at a speed of 13000r / min for 2 minutes to obtain a uniform and stable emulsion.

[0052] (5) Spray-dry the above-mentioned homogenized emulsion to obtain perilla oil powder. During spray drying, the inlet air temperature is 190°C, the outlet air temperature is 100°C, and the feed flow rate is 55mL / min.

[0053] The perilla oil microcapsule product obtained in Example 2 was observed under a scanning electron microscope and showed rounded particles, smooth surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com