Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1932results about How to "Soft taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-fat surface mould mature soft cheese and preparation method thereof

The invention relates to the field of dairy processing, in particular to low-fat surface mould mature soft cheese and a preparation method thereof. According to the low-fat surface mould mature soft cheese, the raw materials based on 100 parts by weight comprise skimmed milk and 5 to 15 parts of inulin, wherein the fat content in the skimmed milk ranges from 0 to 0.5 percent. The fat in the milk is separated to obtain the skimmed milk of which the fat content is not more than 0.5 percent. The skimmed milk serving as a raw material is added with 5 to 15 parts of fat to replace the inulin. The low-fat surface mould mature soft cheese prepared by the method is the original cheese, has low fat content, fine texture, soft mouthfeel and good taste, is compared favorably with natural cheese, and meets the requirement of consumers on health food, and the type of the cheese is enriched.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method of tea liquor

The invention relates to a preparation method of tea liquor, which comprises the following steps of: 1) preparation of tea leaf liquid; 2) preparation of sticky rice mash; 3) preparation of distiller's yeast; 4) mixed fermentation of the tea leaf liquid and the sticky rice mash; 5) distillation, aging, filtration and filling to obtain finished products. The preparation method of the tea liquor has the advantages of simplicity in preparation and easiness in realization of industrialization. The prepared tea liquor not only has the fragrances of fermented liquor and tea leaves, but also reserves the nutritive values of the tea leaves and sticky rice, tastes soft, full-bodied, mellow and fine, can take the effects of preventing diseases and building bodies when the tea liquor is drunk frequently, and is nutritive healthcare liquor.

Owner:QINGDAO LANGYATAI GRP

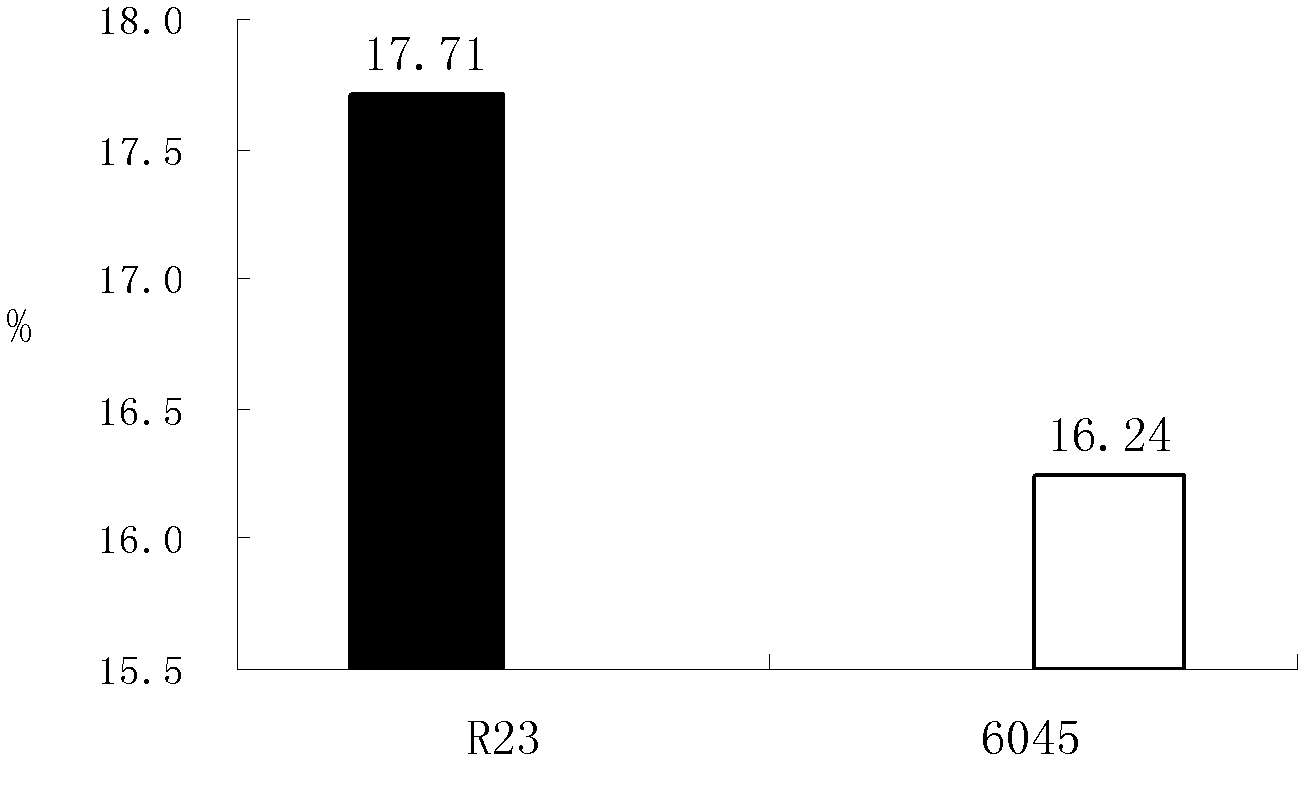

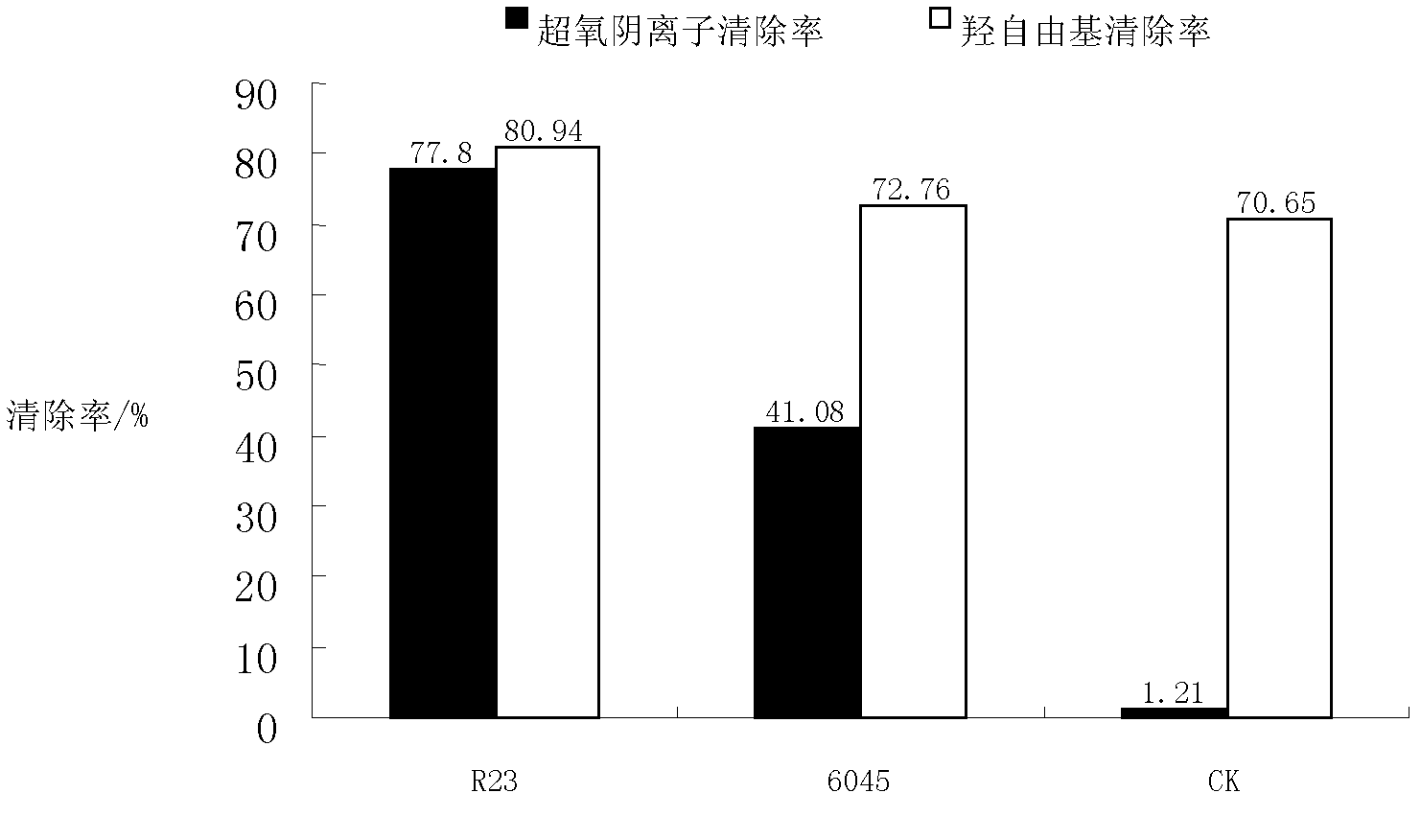

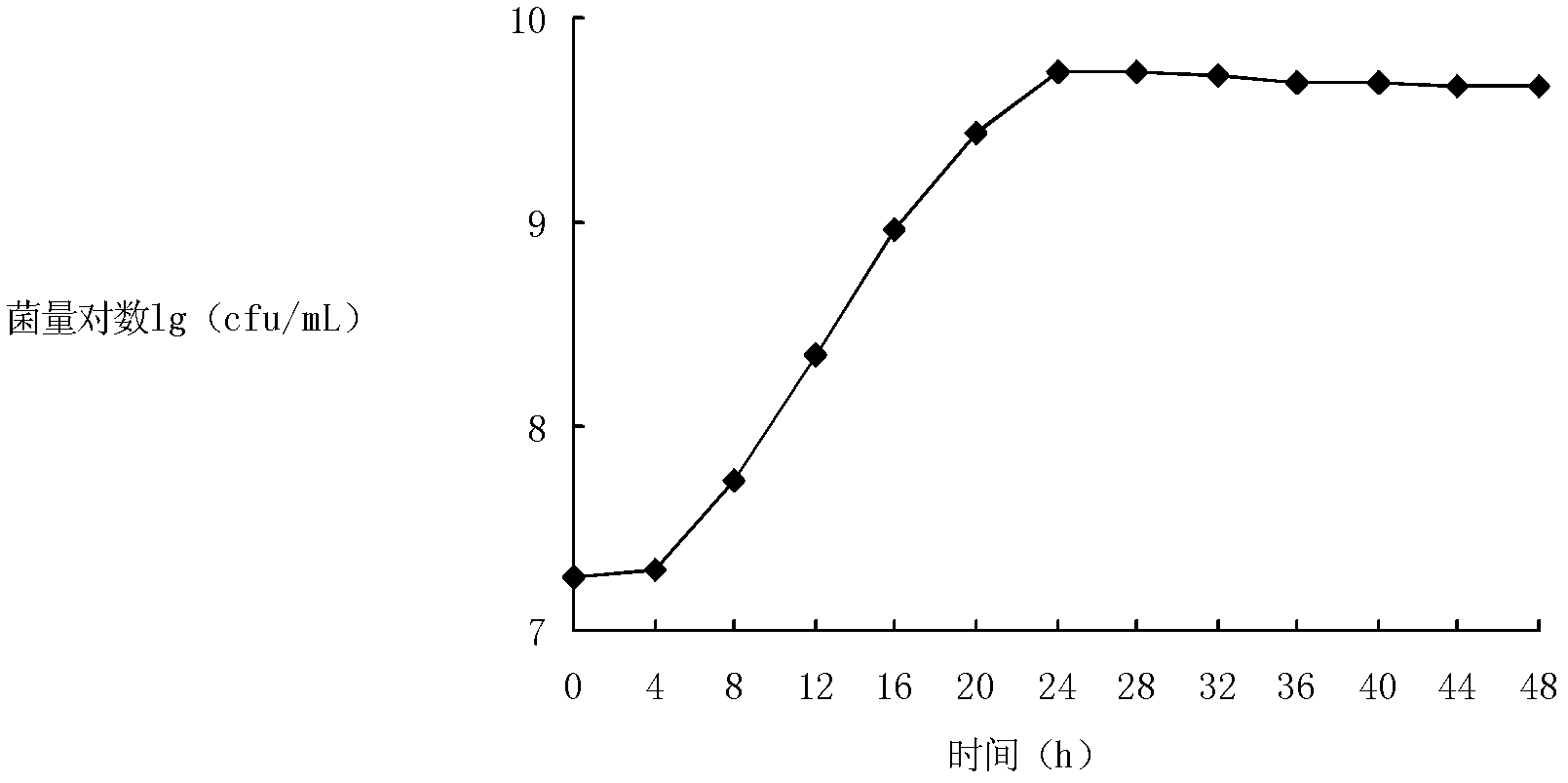

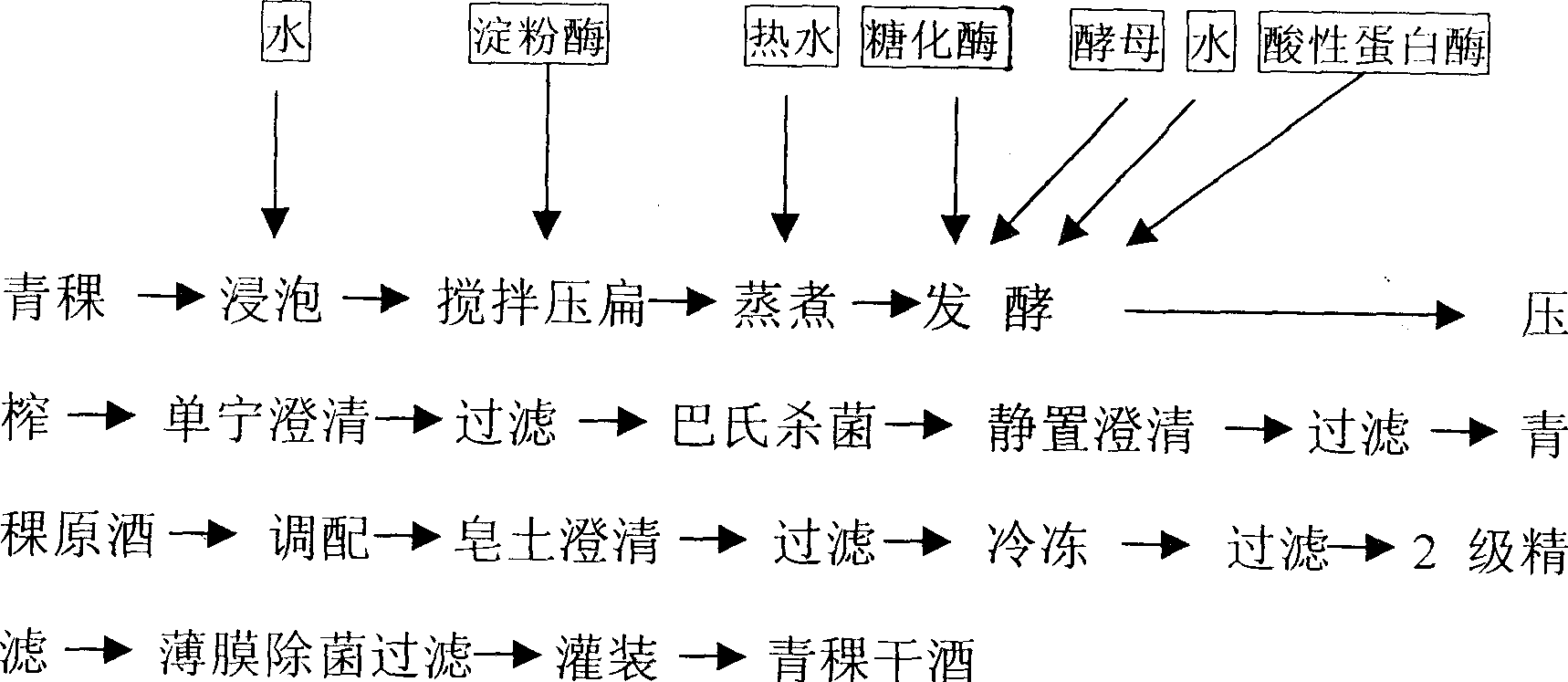

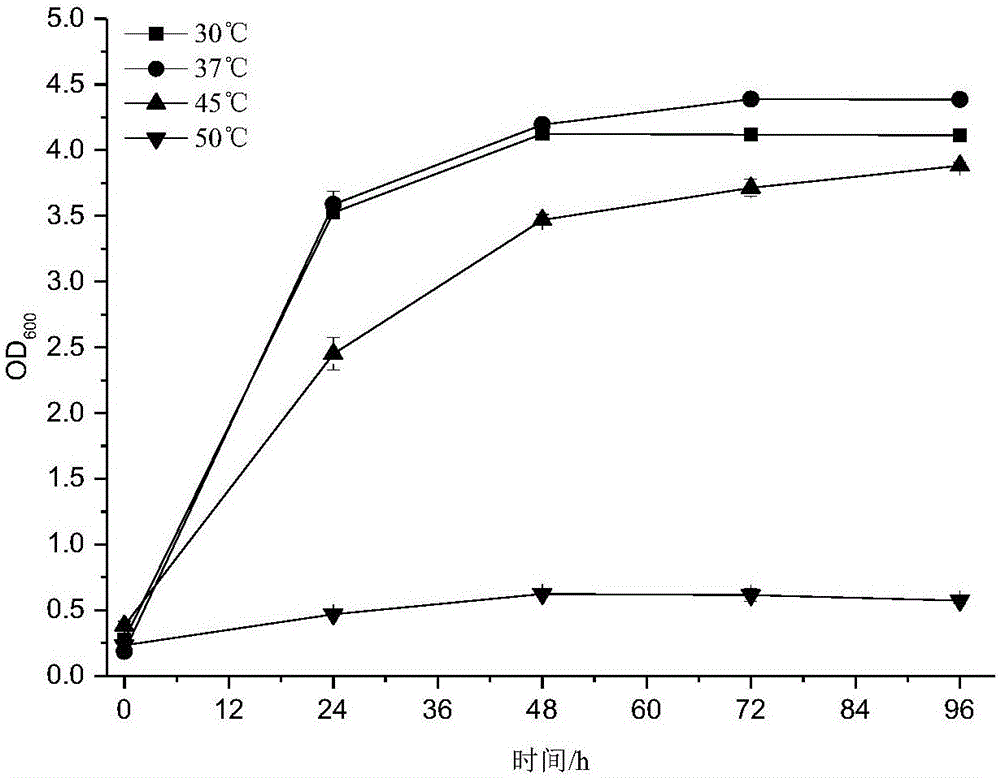

Lactobacillus plantarum R23

InactiveCN102358888AStrong Prebiotic PropertiesSoft tasteBacteriaAlcoholic beverage preparationFruit juiceMalolactic enzyme

The invention relates to Lactobacillus plantarum R23 which is characterized in that: the Lactobacillus plantarum is conserved in China General Microbiological Culture Collection (CGMCC) on August 1, 2011 with the conservation number of CGMCC No.5105. The Lactobacillus plantarum R23 not only can produce malolactic enzyme at high yield and has good biological deacidification capability, but also has the following stronger beneficial characteristics of (1) stronger resistance, (2) stronger oxidation resistance and (3) stronger adhesion capability. The Lactobacillus plantarum can utilize malic acid in priority in the fruit wine containing malic acid, and then carries out lactic acid fermentation of the malic acid to achieve biological deacidification. The Lactobacillus plantarum can be used in fruit juice beverage processing to produce fermented sterile fruit juice beverages, and can also be used in fruit juice beverage processing to produce fermented lactobacillus live bacterial beverages.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Preserved passion fruits and processing method thereof

The invention discloses preserved passion fruits and a processing method thereof. The method comprises the concrete steps of firstly, cleaning and cutting fresh passion fruits as raw materials, and separating peels from pulp by removing the pulp; secondly, boiling the peels, removing cuticula, enzymatically hydrolyzing, protecting the color and sugaring; thirdly, mixing the pulp with white granulated sugar and citric acid or citric acid to prepare mixed pulp, and burying the mixed pulp into the peels; finally performing processes of drying, cooling and the like to prepare finished products of preserved passion fruits. According to the method, the selectivity on fruit raw materials is good; the processed preserved passion fruits keep the original aroma and taste of passion fruits, are bright as ever and soft in mouth feel, and have remarkable market competition advantages; a new way is opened up for deep processing of the passion fruits, a very good method is provided for improving the value of the passion fruits, and relatively large profit space is created for enterprises.

Owner:广西田阳嘉佳食品有限公司

Brewing process of soybean paste

ActiveCN102715500AShorten the formation timeEasy to shapeFood preparationBiotechnologyFermentation broth

The invention discloses a brewing process of a soybean paste, belonging to the field of brewing of fermented products. The process comprises the following steps of: raw material preparation; material steaming and yeast preparation; fermentation; and cooking. Through adding saline fermentation broth at the earlier stage of fermentation of the soybean paste and improving other processes for brewing the soybean paste, the fermentation period is shortened, a bean are kept in an intact shape, and the soybean paste is better in color and flavor. The invention also discloses a making process of the saline fermentation broth.

Owner:山东玉兔食品股份有限公司

Method for making passion fruit vinegar

The invention relates to the technical field of food brewing, in particular to a method for making passion fruit vinegar by using passion fruit as a main raw material. The method specifically comprises following three steps: (1) the passion fruit is juiced to obtain passion fruit juice, then pectinase is added to the passion fruit juice, the sugar degree of the passion fruit juice is regulated, and the passion fruit juice is sterilized; (2) the passion fruit juice is subject to alcohol fermentation and acetic acid fermentation to obtain an initial product of the passion fruit vinegar; (3) the initial product of the passion fruit vinegar is aged, and then a finished product of the passion fruit vinegar can be obtained. The finished product of the passion fruit vinegar, which is made through adopting the method, has the advantages of well retention of nutritional components, greasing and natural taste, no bitter taste, steady quality and bright color; and meanwhile, as no artificial preparation is added to the passion fruit vinegar, the natural flavor of the passion fruit can be better retained.

Owner:CHONGQING UNIV

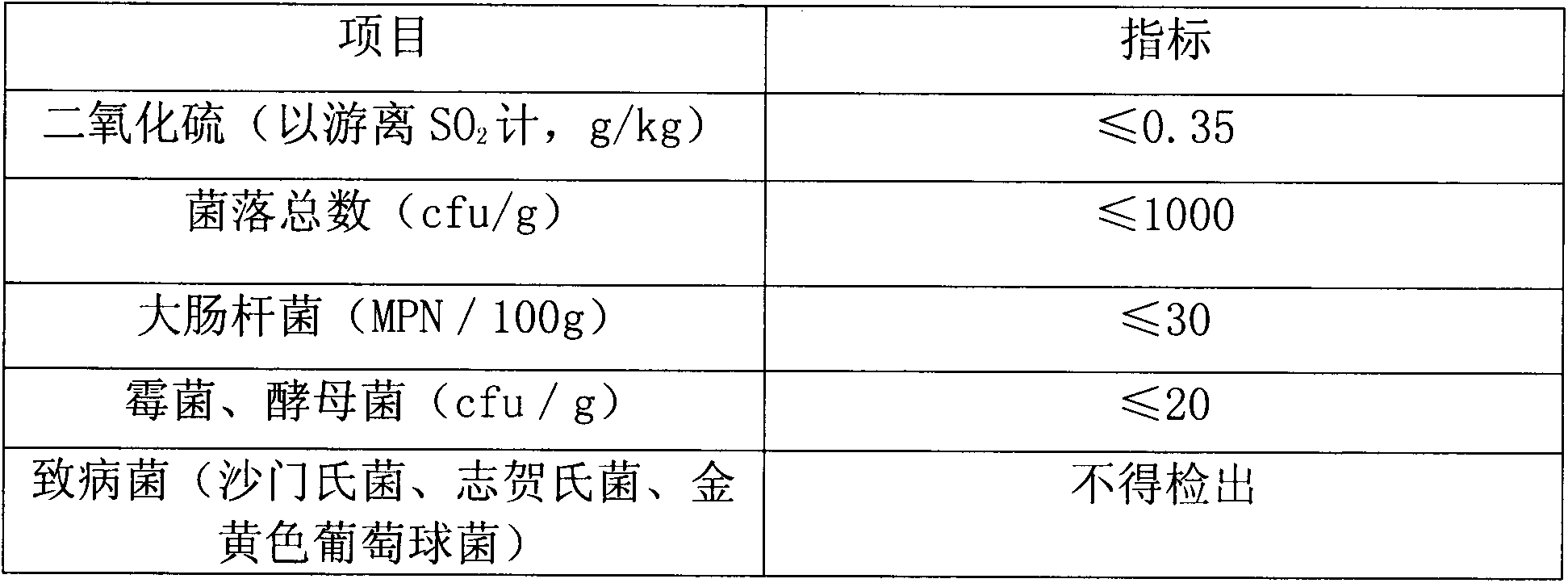

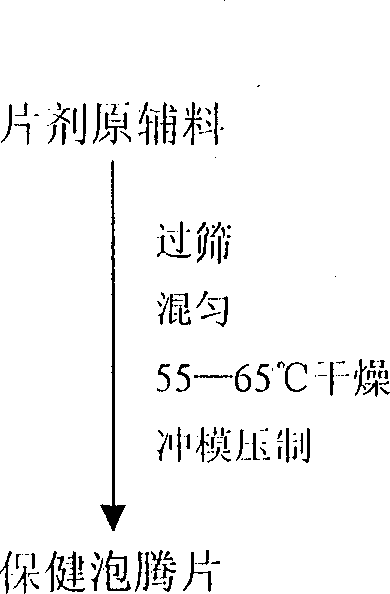

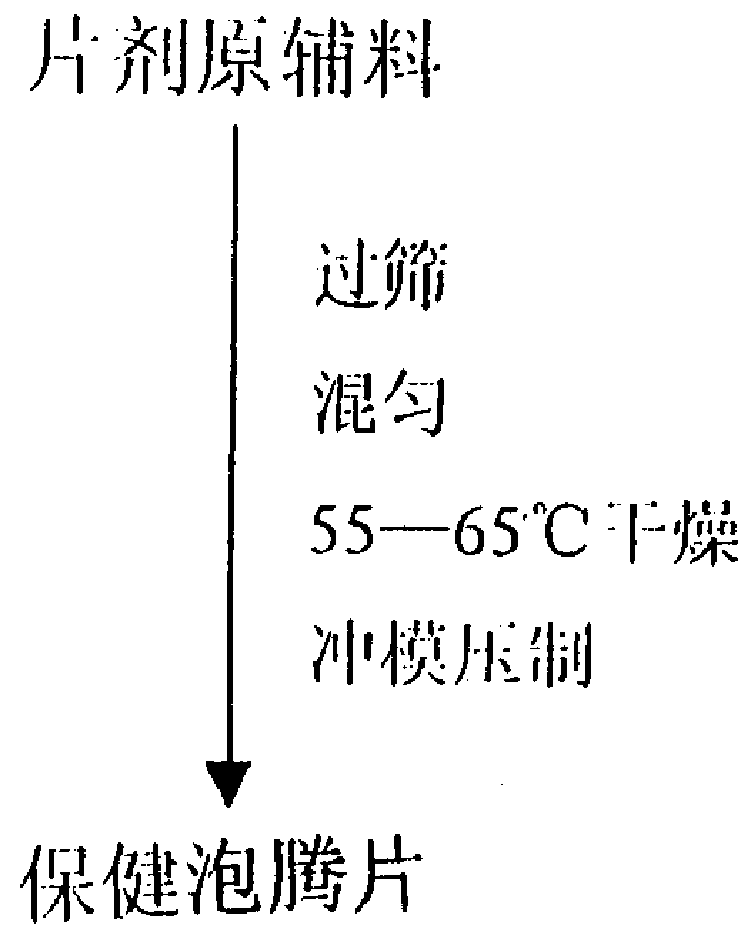

Healthy effervescent tablet and its prepn

InactiveCN1344516AImprove liquidityGood compressibilityFood scienceBifidobacteriumEffervescent tablet

The effervescent health beverage table is featured by that it contains functional oligosaccharide, such as oligo-xylose, oligo-fructose, oligo-galactose, oligo-isomaltose, etc., with bifidobacterium proleferating function and may contain medicine, vitamins, minerals, soluble chitin and other functional factors. The tablet is produced through sieving, mixing, drying at 55-65 deg.c and tableting. The effervescent health beverage tablet, when being thrown into water, will be dissolved instantly into homogeneous beverage, health liquid, medicated tea, etc. while producing bubbles and turning up and down.

Owner:卢济台

Method for manufacturing Chinese yam noodles

ActiveCN103141762AImprove intelligenceImprove nurturingFood preparationProcess engineeringDioscorea polystachya

The invention belongs to the technical field of food machining, and in particular relates to a method for manufacturing Chinese yam noodles. The method comprises the following steps of: a. selecting raw materials, namely, finely selecting Chinese yam which is free of mildew or scar, washing and slicing; b. pulping, namely, taking the sliced Chinese yam, adding water according to the ratio, of the Chinese yam to water, of (12-8):1, pulping in a pulping machine, and adding salt; c. mixing the materials, namely, adding eggs according to a weight ratio, of the eggs to the Chinese yam pulp, of 1:(90-120), into the Chinese yam pulp obtained in the step b, so as to obtain egg Chinese yam pulp, and further mixing the egg Chinese yam pulp with flour according to the weight ratio of (1-3):6, and kneading into dough; and d. aging, rolling, cutting into bars, drying, cutting off, measuring and packaging the kneaded dough in the step c so as to obtain a finished product. The noodle prepared by using the method is soft and pure in taste, tough and chewy, smooth, free of breakage, safe, healthy and green, is fragrant and thick in noodle soup, and has the functions of protecting human intestines and stomachs and improving the immunity.

Owner:山东志同农业科技有限公司

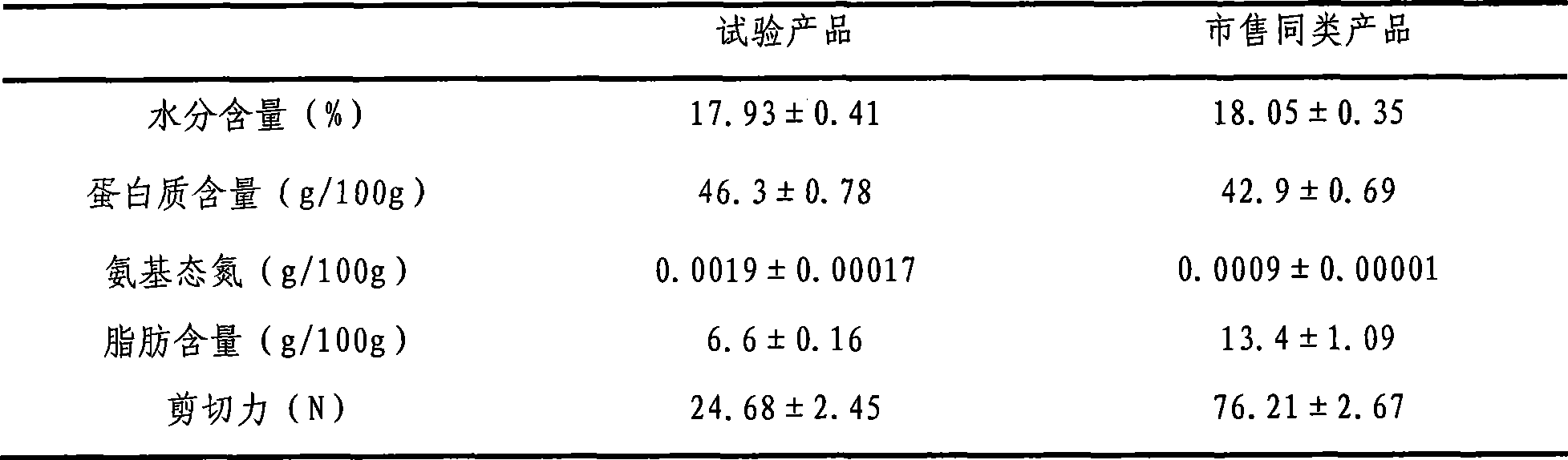

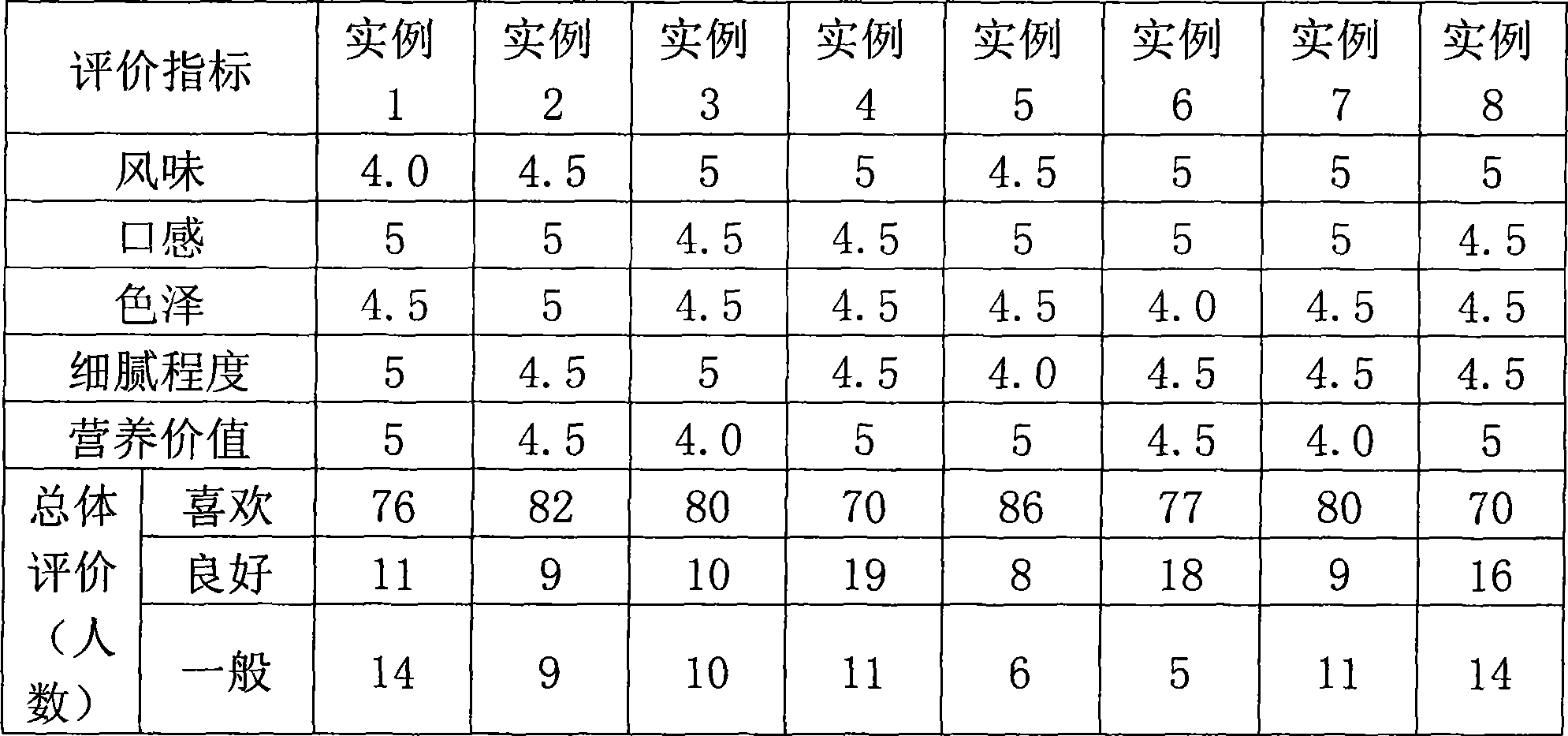

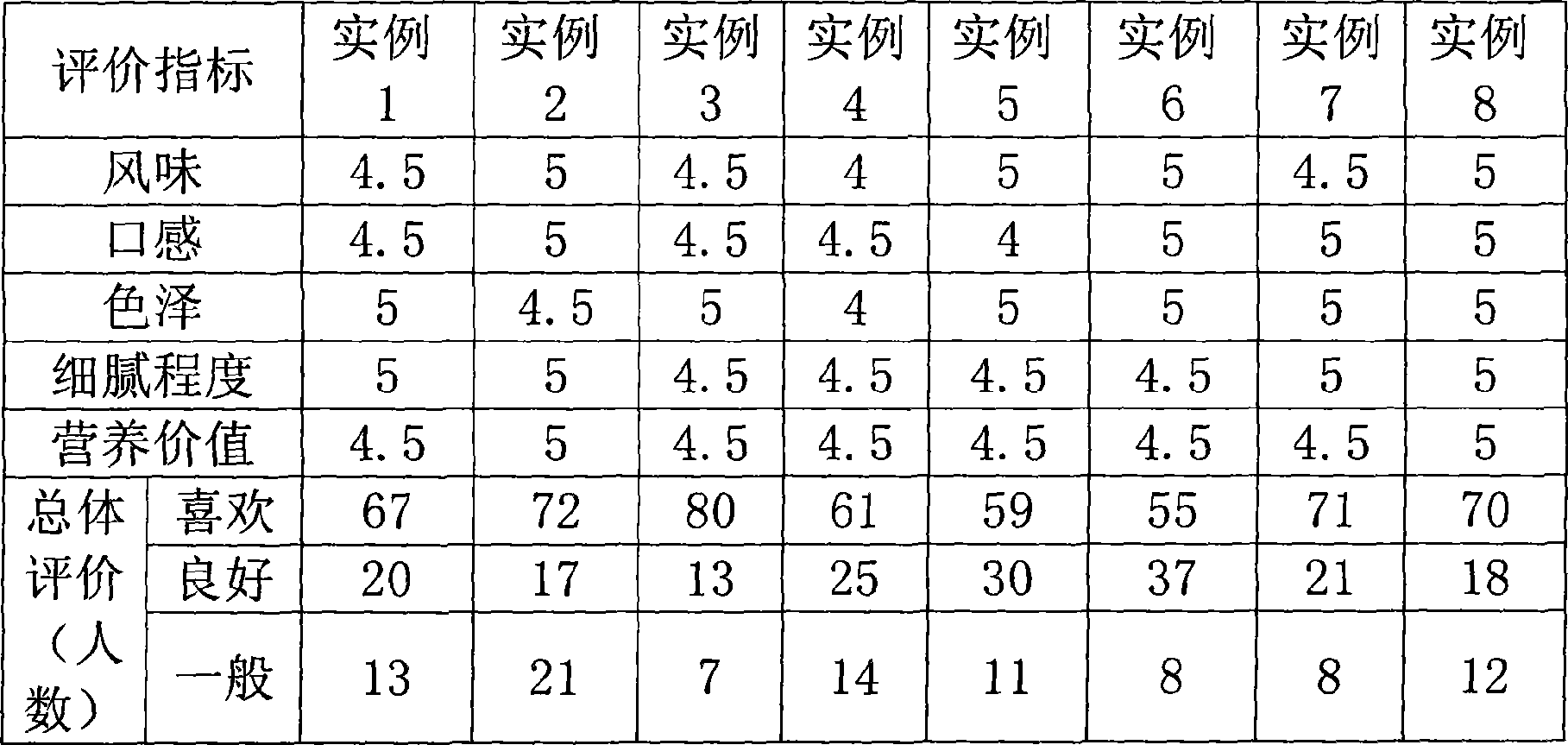

Method for processing recombined dried meat

The invention discloses a manufacture method of recombinant dried beef. The method comprises the following steps: green beef or thawed beef is selected; regarding the beef sample quantity of 0.46mg / g as a reference, bromelain is weighed (specific activity unit: 1200Mu / g ) and diluted into bromelain solution, and then is injected into different parts of the beef; after being rolled and rubbed for 10 to 20 minutes, the beef reacts at the temperature of 40 DEG C for 1.5 hours; the beef is prickled; the prickled beef is dewatered and divided into two parts; one part is steamed and boiled until maturity, and cut and blended as beef grains; the other part of the green beef is dewatered and cut and blended as beef emulsion; the boiled and cut and blended beef grains and the green beef emulsion are evenly mixed; the proportion of the beef grains and the beef emulsion is 0.5-2: 1; TG enzyme is added to the beef by 2-10mg / g; the cooked and the fresh beef are jointed and shaped under the condition that the TG enzyme and the pressure are 1.5-3 N / cm<2>; and then the beef is steamed and boiled, roasted and packaged. The dried beef has the advantages of soft mouth feel, low hardness and bright color and luster.

Owner:GUIZHOU UNIV

Moxa leaf rice paste and its making method

The name of the invention is an artemisia leaf glutinous rice cake and aprepration method, belonging to the glutinous rice cake food technical field. The invention mainly solves the problem that artemisia leaf is not capable of being added directly to glutinous rice cake to be eaten. The invention has the main characteristics that: the manufacturing materials contain sticky rice and artemisia leaf; the sticky rice is 56 to 66 and the artemisia leaf is 37 to 41. the preparation method for artemisia leaf glutinous rice cake is that: {1}the clean-washed tender green artemisia leaf is put into boiling water containing dietary alkali, with a viscosity of 4 percent to 6 percent, and is stewed for five to eight minutes and then the leaf base is removed after being cooled to 40 DEG C to 48 DEG C; {2}the sticky rice is grinded into powder after being soaked in the water for five to eight hours;{3}the dietary alkali water, with a viscosity of 2 percent, is added into the sticky water and the artemisia leaf and is mixed evenly, cut into pieces and grained completely, and then becomes a paste;{4}the paste is changed into an oblate shape or stuffings are wrapped into the paste in an oblate shape;{5}the oblate-shaped paste is covered with big bamboo leaves and tender tug oil tree leaves and is steamed in a steam box. The invention mainly provides the artemisia leaf glutinous rice cake and the preparation method. The taste of the artemisia leaf glutinous rice cake is soft and smooth. Besides, the artemisia leaf glutinous rice cake has the health care function.

Owner:XIANGYANG JINHENG ELECTRIC CO LTD

Preparation method of spiced beef with good mouthfeel

InactiveCN105918886AReduce heat and drynessReduce greasy feelingFood ingredient functionsIce waterSoya sauce

The invention discloses a preparation method of spiced beef with good mouthfeel, which comprises the following steps: putting beef in flowing clear water for soaking until no watery blood separates out, and then draining the beef to obtain preprocessed beef; putting the preprocessed beef in an oven for drying, taking the beef out of the drying oven, jetting an injection into the beef, putting the beef in a rolling and rubbing machine for carrying out primary rolling and rubbing, then adding curing seasonings into the rolling and rubbing machine for carrying out secondary rolling and rubbing, taking the beef out of the rolling and rubbing machine, and carrying out low temperature standing to obtain the cured beef; putting blanched cow leg bones, fresh ginger, garlic cloves, fistular onion stalk and water in a boiling container for decocting, and carrying out filtering to obtain soup stock; adding cloves, tea leaves and the like into the soup stock, performing boiling, carrying out filtering, and then adding dark soy sauce, yeast extracts and the like, performing continuous boiling to obtain boiling liquid; and cutting the cured beef into cubes, blanching the beef cubes, then adding the blanched beef cubes into the boiling liquid for boiling to obtain spiced beef cubes, taking the spiced beef cubes out of the boiling liquid, putting the spiced beef cubes in ice water, after the boiling liquid is cooled to room temperature, putting the spiced beef cubes in the boiling liquid again, carrying out low temperature standing, and then putting the spiced beef cubes in the oven for baking to obtain the spiced beef with good mouthfeel.

Owner:FENGYANG COUNTY ZHONGDU FOOD CO LTD

Non-fermentation type sour milk and preparation method thereof

The invention relates to non-fermentation type sour milk and a preparation method thereof. The non-fermentation type sour milk uses fresh cow milk as principal raw material. After being hydrolyzed by milk sugar, the cow milk is pasteurized and concentrated in vacuum to be 40 percent of the original volume. After the cow milk is cooled, probiotic powder is added. The invention has the core that transglutaminase is added at an optimal temperature; under the action of the transglutaminase, milk protein is connected together to form a protein network, thereby a uniform stable gelatin system is easily formed; delta-gluconolactone is then added, and the gelatin system and the delta-gluconolactone are heated at 35-40 DEG C in a water bath way for 2 to 3 hours so that the uniform, stable and exquisite non-fermentation type sour milk like a quark can be obtained. The invention has simple preparing process, no requirement for fermentation, and full utilization of resources. The non-fermentation type sour milk can be used as a base to develop various products, such as corn non-fermentation type sour milk for breakfast, jelly non-fermentation type sour milk, and the like, and can satisfy the requirements of consumers in nutrition, mouthfeel, texture, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Processing method for stabilized recombined quick-cooking brown rice

InactiveCN102067968ASmooth and beautiful appearanceYellowish colorFood preparationAgricultural engineeringRice grain

The invention discloses a processing method for stabilized recombined quick-cooking brown rice, comprising the following steps: (1) taking paddy as a raw material, drying, cleaning, grading, removing stones, ridging paddy, and separating paddy from brown rice to obtain the brown rice; (2) smashing the brown rice, and regulating the moisture of the material to 15-30%; (3) adding or adding no food ingredients; (4) feeding the material obtained from the above step into an extruder for extruding, restructuring and prilling; and (5) drying, packaging and the like. In the processing method, the problems of short shelf life, long cooking time, rough taste, inconvenient eating and the like of the brown rice are solved. The brown rice processed with the method has the grain shape similar to natural brown rice, keeps the nutrient components of the natural brown rice, improves storage stability, improves processing and eating quality of the brown rice and improves the utilization and the added value benefit of the paddy.

Owner:ACAD OF STATE GRAIN ADMINISTRATION

Instant cheese and preparation method thereof

The invention relates to an instant cheese and a preparation method thereof. The preparation method comprises the steps: using full-cream fresh milk as main material, pasteurizing the milk after being hydrolyzed through lactase, and concentrating the full-cream fresh milk to 35-40 percent of the original volume in vacuum. The preparation method of the instant cheese has the core points that transglutaminase is added at 35 DEG C, and milk proteins are linked to form a protein network under the action of the transglutaminase, thereby forming a uniform and stable gel system easily. Then, chymosin is added for promoting gel to form , and uniform, stable and delicate instant cheese can be obtained in a water bath for half hour at about 30 DEG C. The invention is simple and easy for operation, and can be used for development of various application products on the theoretical basis, including breakfast cereal cheese, jelly cheese and the like. Moreover, the instant cheese can meet the requirements of consumers for taste, texture, nutrition, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

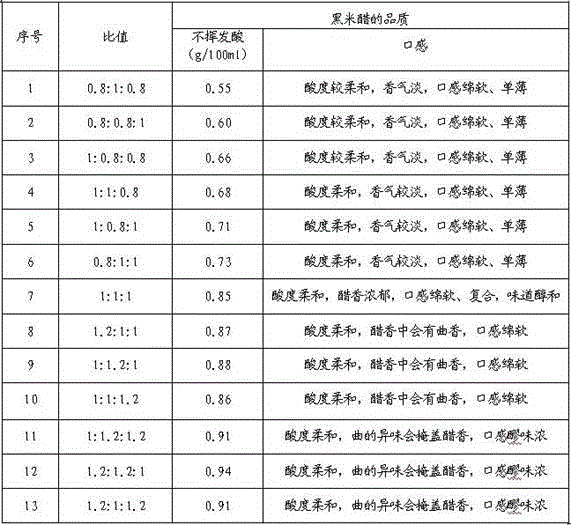

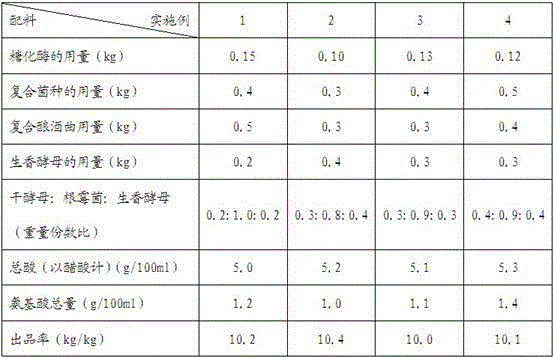

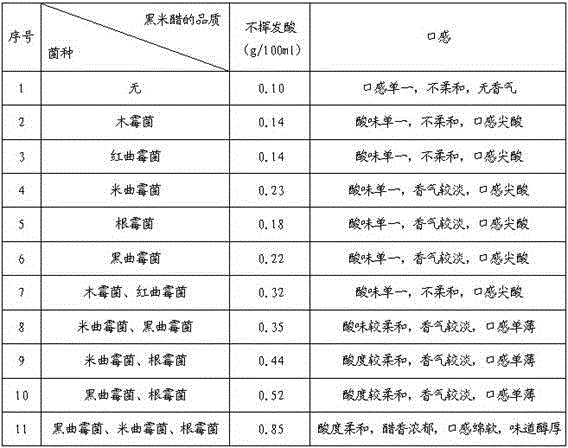

Black rice vinegar and preparation method thereof

ActiveCN103555554ARich vinegarSoft tasteMicroorganism based processesVinegar preparationPickled vegetablesMouthfeel

The invention discloses a black rice vinegar and a preparation method thereof. The black rice vinegar is prepared from black rice as the main material and by adding a starter obtained through starter propagation of mixed bacteria for liquid state fermentation in a saccharification process. The black rice vinegar is rich in vinegar aroma, and soft and complex in taste, pure and mild in flavor and good in stability; the yield of the black rice vinegar is greater than or equal to 10.2kg / kg, the total acid (metered by acetic acid) of the black rice vinegar is greater than or equal to 5.2g / 100ml, and the total amount of amido acids of the black rice vinegar is greater than or equal to 1.2g / 100ml. The preparation method of the black rice vinegar is simple and low in cost, and the process of the preparation method is easy to control; the starter obtained through starter propagation of mixed bacteria is added to the saccharification process so that saccharification is more sufficient, the utilization rate of raw materials is high and the clarity is high. The preparation method provided by the invention is applicable to preparing the black rice vinegar; the prepared vinegar product can be used for pickling vegetables and also for cold mixing and hot cooking of dishes.

Owner:HEBEI FINAL BIOTECH DEV

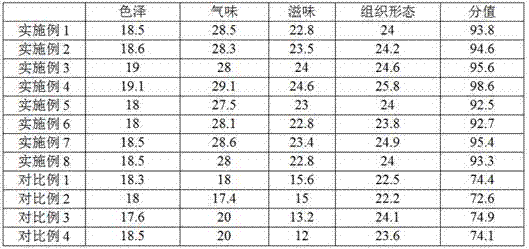

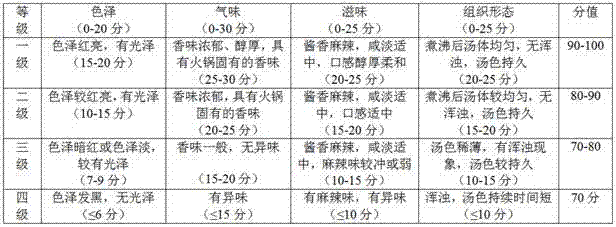

Spicy non-slag hotpot oil with sauce aroma and preparation method thereof

ActiveCN107006828AReduce aroma lossReduce odorLipidic food ingredientsNatural extract food ingredientsAllium fistulosumSOYBEAN SEED OIL

The invention discloses spicy non-slag hotpot oil with sauce aroma and a preparation method thereof and belongs to the field of hotpot condiments. The spicy non-slag hotpot oil with the sauce aroma comprises the following raw materials: soybean oil, palm oil, beef tallow, rapeseed oil, allium fistulosum, ginger, onion, sheep's-parsley, garlic, rock candy, fennel, cinnamon, anise, cumin, clove, black pepper, radix angelicae, Chinese prickly ash, pickled ginger, two-briers pepper, a new generation of pepper, Indian pepper, a broad-bean sauce, fermented soybeans, nutmeg, neolitsea ellipsoides allen, amomum tsao-ko, salt, white granulated sugar, aginomoto, a chicken essence, concentrated pork bone soup and Chinese white spirit. The prepared hotpot oil has a thick fragrance and a sauce aroma, and is spicy, and soft and mellow in taste.

Owner:郑州雪麦龙食品香料有限公司

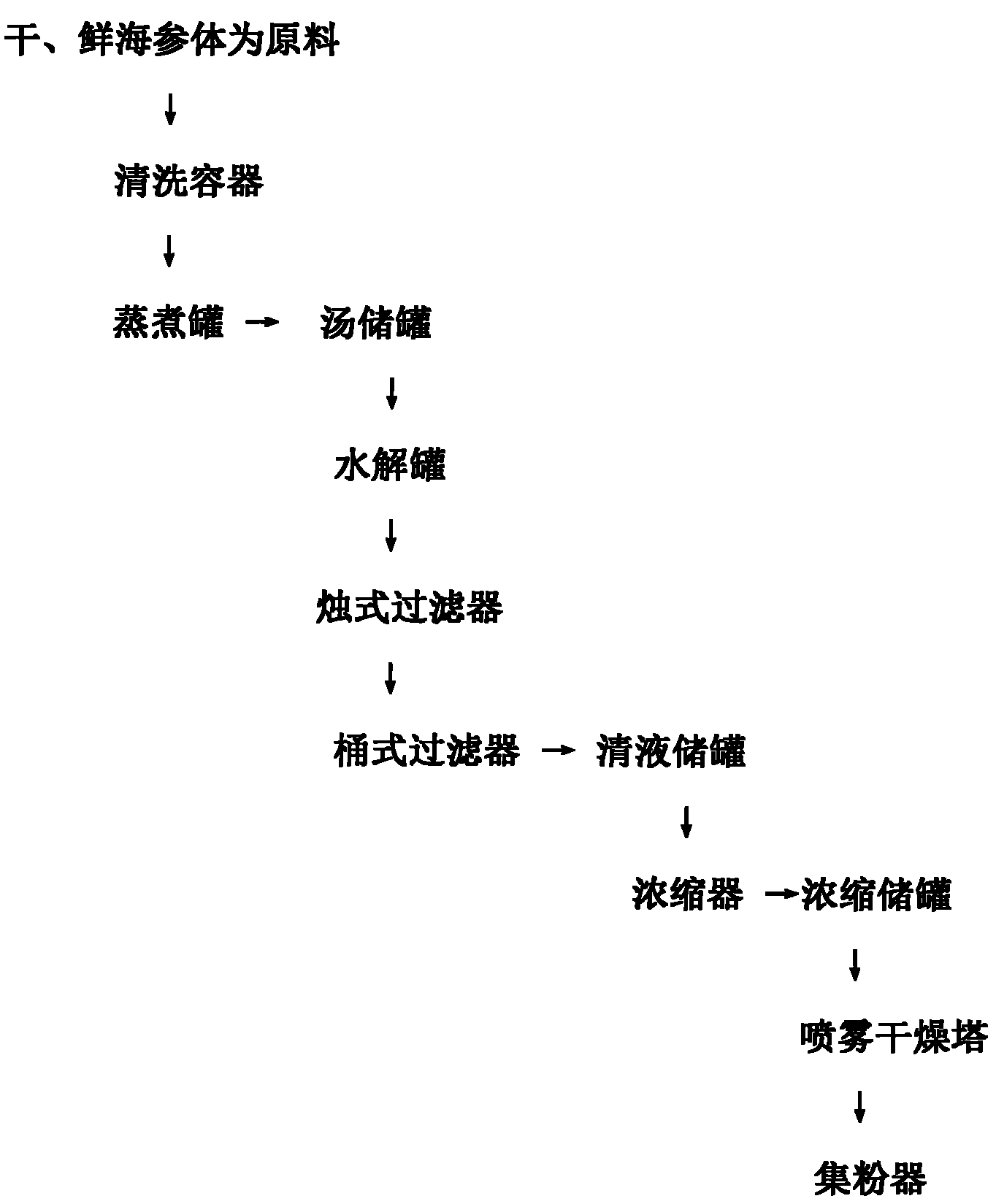

Extraction method of sea cucumber polypeptide

ActiveCN102488073AIndividual smallIncrease elasticityProtein composition from fishHigh pressureStorage tank

An extraction method of sea cucumber polypeptide contains steps of: embathing, high-pressure stewing, enzymatic hydrolysis, deodorizing, filtering, condensation, drying and finished product packaging. The extraction method is characterized in that high-pressure stewing: the temperature is 120-130 DEG C, the pressure is 0.13-0.15 MPa and stewing lasts for 2 hours at constant temperature and constant pressure; enzymatic hydrolysis: the temperature is cooled to 54-56 DEG C after heating and sterilizing, NaOH is added to adjust PH to 7.0 and 0.5% of sea cucumber special-purpose enzyme to perform enzymatic hydrolysis for 6 hours; deodorizing: 17% of active carbon is added for deodorizing; filtering: a standing liquid firstly passes through a candle filter, then passes through a barrel filter and is finally filtered to a clear liquid storage tank; and condensation: condensation pressure is minus 0.04-minus 0.06 MPa, condensation temperature is 75-80 DEG C, and Baume degree determined during the condensation process is controlled at 10. The invention has the following advantages of: sea cucumber is changed into a fully water soluble active component after biological enzyme hydrolysis; the content of small peptides in the product is high, which is more beneficial to the absorption and utilization of the sea cucumber active component; and sea cucumber polypeptide is more acceptable in taste after deodorizing by active carbon. The invention is suitable for the extraction method of sea cucumber polypeptide.

Owner:吴庆林

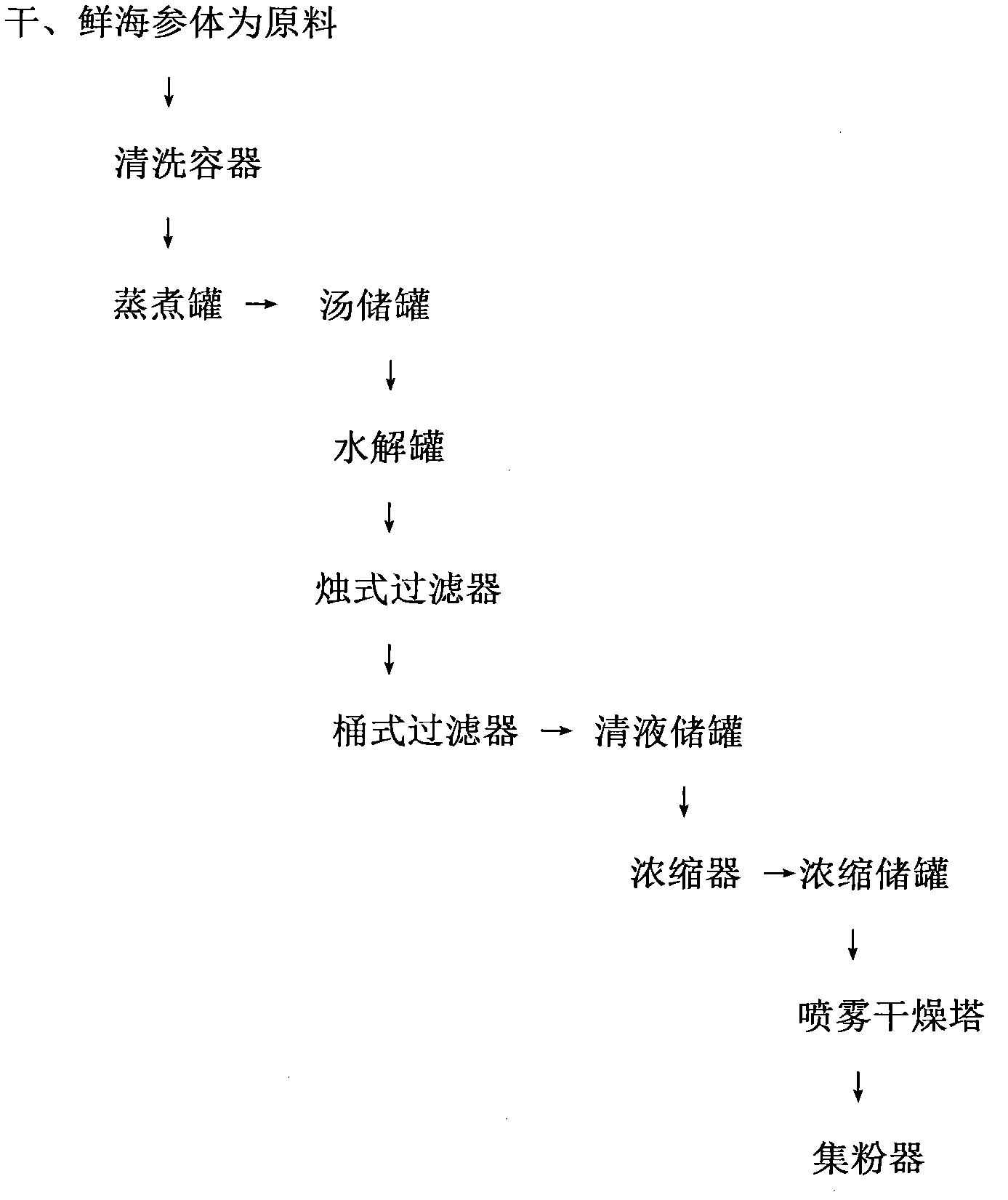

Process for preparing barley dry wine

InactiveCN1435475APaste smoothlyEase of evaluationAlcoholic beverage preparationPolymer scienceAlpha-amylase

A process for preparing dry highland barley wine includes soaking highland barley, steaming, mixing with high-temp.-resistant alpha-amylase, stirring, pressing, saccharifying, fermenting under 30 deg.C, squeezing, clarrifying, mingling and filtering. Its advantages are low content of sugar, and high quality and stability.

Owner:SHANGRI LA WINE CO LTD

Method for strengthening traditional solid fermentation of vinegar by mixed agent and application of mixed agent

ActiveCN106434264AShorten the fermentation cycleImprove fermentation efficiencyBacteriaMicroorganism based processesLaboratory cultureBacillus amyloliquefaciens

The invention discloses a method for strengthening traditional solid fermentation of vinegar by a mixed agent, and belongs to the technical field of food fermentation. The invention further discloses lactobacillus helveticus and application thereof. The lactobacillus helveticus is separated from traditional Chinese vinegar brewing mass and collected with a collection number being CGMCC No. 12062 in China General Microbiological Culture Collection Center, Institute of Microbiology, Chinese Academy of Sciences NO.1, West Beichen Road, Chaoyang District, Beijing, China. The lactobacillus helveticus is resistant to temperatures and acids and capable of highly yielding exopolysaccharides and gamma-aminobutyric acid. The mixed agent prepared from the lactobacillus helveticus, pediococcus acidilactici, hansenula anomala and bacillus amyloliquefaciens is applied to the traditional vinegar fermentation process, so that fermentation period can be remarkably shortened, raw material use ratio is increased, the content of active ingredients such as the exopolysaccharides and the gamma-aminobutyric acid in products is increased, and the antioxidant function of the vinegar products is improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of special flavor pear can

The invention discloses a preparation method of special flavor pear can, comprising the steps of sorting, cleaning, peeling, chopping, removing kernels and trimming, color-protecting, pre-boiling, canning and leaching water, injecting sugar-liquor, alcohol, citric acid, and ascorbic acid, preparing filling liquor with chrysanthemum leach liquor, exhausting gas, sealing, sterilizing and cooling. During storage period for the can products of the invention, alcohol molecules are permeated into fruit chunk tissues after fully associating with water molecules, so that the products have gentle mouth feel when being eaten, special flavors of sweetness, sourness and aroma as well as functions of producing saliva and slaking thirst, and resisting oxidation.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Passion fruit and pear jam and preparation method thereof

The invention discloses passion fruit and pear jam and a preparation method thereof. The passion fruit and pear jam is prepared by the following raw materials in part by weight: 600 to 800 parts of passion fruit, 300 to 400 parts of pears, 400 to 500 parts of water, 40 to 60 parts of lemon juice, 10 to 25 parts of jelly powder and 200 to 280 parts of maltose. The preparation method comprises the following steps that: 1) the passion fruit is washed and sliced to take out passion fruit meat; 2) pears are washed, peeled off, denucleated and sliced into blocks, pear blocks are arranged into a blender to be processed into pear paste; 3) lemons are washed and peeled off, seeds of the lemons are removed, and then the lemons are squeezed to obtain the lemon juice; 4) the passion fruit meat is placed into the water to be boiled, then the jelly powder and the maltose are added into the passion fruit meat to be cooked with slow fire under the stirring state until the jelly powder and the maltose are dissolved, then the pear paste and the lemon juice is added to be cooked with slow fire under the stirring state until the paste is in a thick state, and the paste is bottled and sealed to be stored in a refrigerator after being cooled to obtain the passion fruit and pear jam. The passion fruit and pear jam has strong fruity fragrance, is soft to taste, is appropriately sweet and sour and has functions on producing a refreshing effect to the mind, nourishing the skin, beautifying the feature and helping the digestion.

Owner:刘俊奕

Production process of soya milk film

InactiveCN102687759ASmooth appearanceExtended shelf lifeCheese manufactureFood scienceHigh energySerialization

The invention relates to a production process of soya milk film. The technology comprises the following steps of: 1) grinding pulp: putting carefully chose and immersed soybeans into a pulping machine for grinding; 2) filtering: filtering the ground crude pulp in the step 1) by a slurry-residue separator to form a fine pulp; 3) heating and insulating; 4) crusting: employing a crusting pan to crust by cold air pressurization; 5) peeling: employing conveying belt for automatic continuous peeling until drying; 6) drying: employing a steam heater to carry out continuous drying; and 7) regaining moisture: employing steam sterilization for moisture regain. Compared with handwork process, the process of the invention has advantages of: 1.labor saving; and 2. high degree of automation, high energy saving efficiency, non-intermittent serialization production, unsusceptibility to extraneous climate, soya milk film yield reaching higher than 55% compared with a handwork yield of 50%, and high degree of sanitation.

Owner:温州市华威机械有限公司

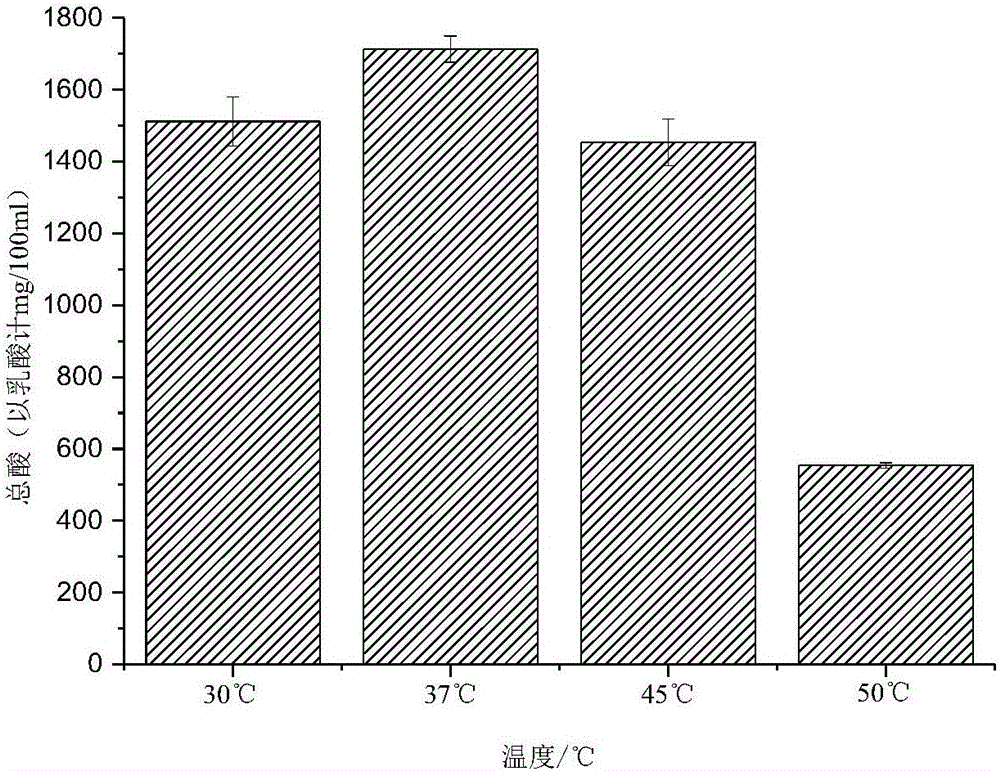

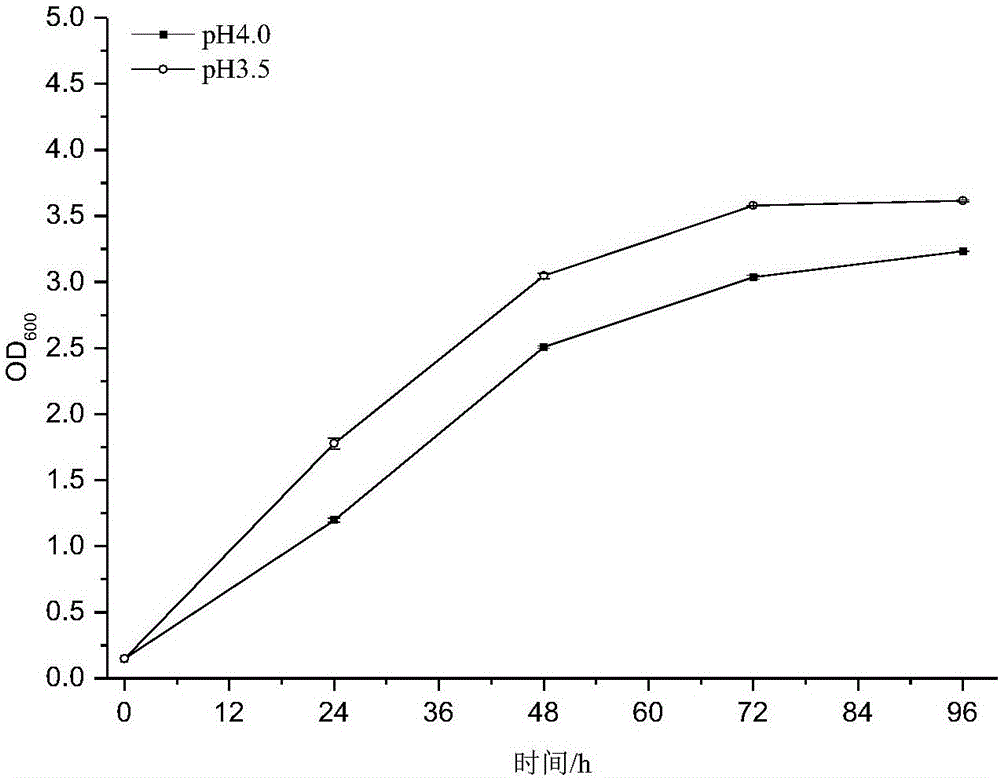

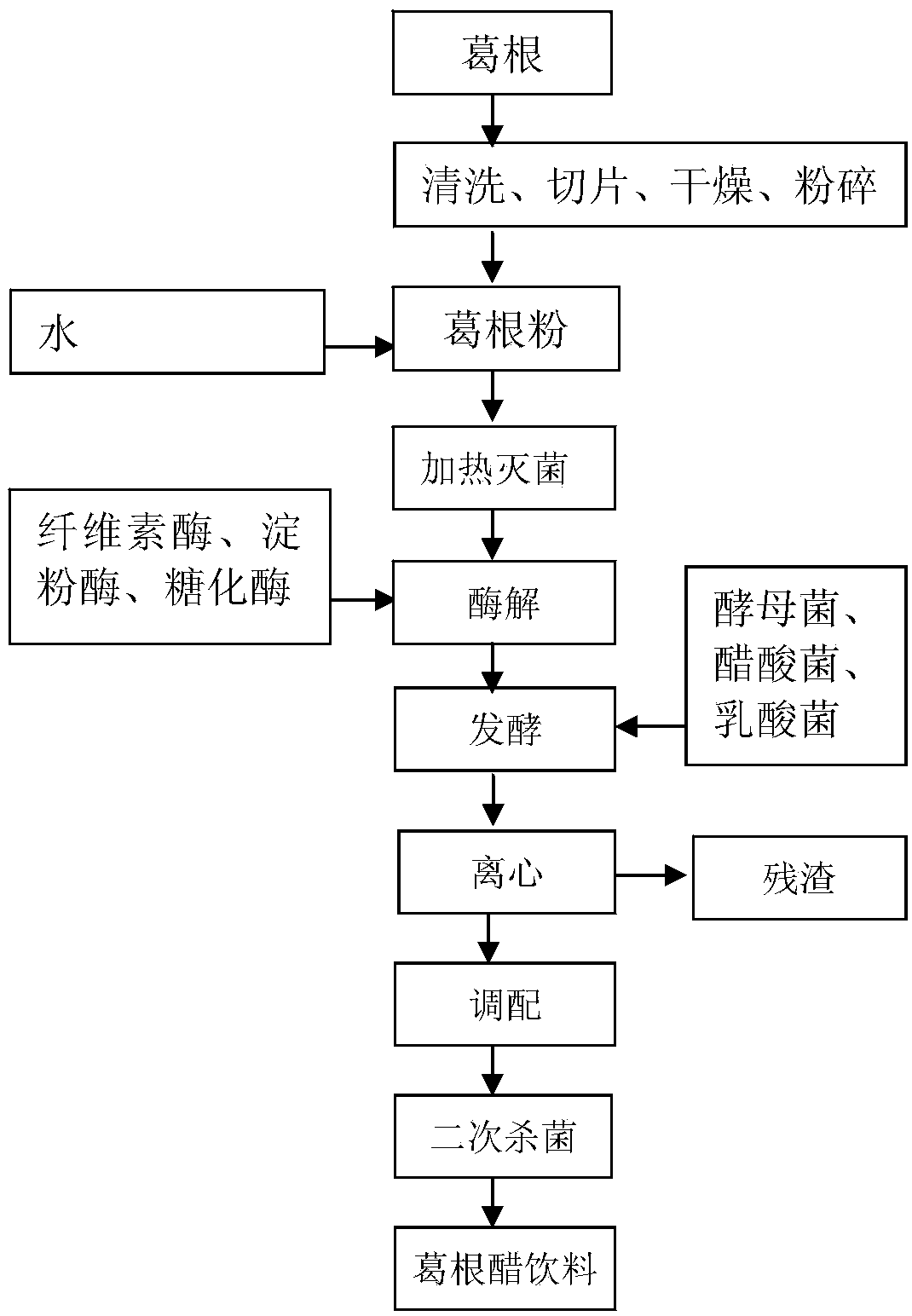

Preparation method of kudzu vine vinegar beverage

ActiveCN103829339AIncrease profitHigh extraction rateFood ingredient as thickening agentBiotechnologyAmylase

The invention discloses a preparation method of a kudzu vine vinegar beverage. The preparation method comprises the following steps of crushing kudzu vines, sterilizing, adding cellulose, amylase and saccharifying enzyme for carrying out synergetic enzymatic hydrolysis; then, adding mixed strains of lactic acid bacteria, saccharomycetes and acetic bacteria for carrying out multi-strain fermentation, filtering and mixing so as to obtain the kudzu vine vinegar beverage finally. According to the invention, the kudzu vine vinegar beverage is high in isoflavone extraction rate, brown orange, clear and transparent, palatable in acidity, soft, mellow and full-bodied in mouthfeel, and has specific flavor of the kudzu vine vinegar beverage.

Owner:JIANGSU UNIV +1

Salad sauce with mustard flavor and preparation method thereof

The invention belongs to the technical field of seasonings, in particular relating to a salad sauce with mustard flavor and a preparation method thereof. The salad sauce with mustard flavor is prepared from the following raw materials in parts by weight: 20-70 parts of salad oil, 35-70 parts of water, 5-20 parts of plain white, 1-8 parts of monosodium glutamate, 1-10 parts of salt, 5-15 parts of sugar, 3-15 parts of powdered milk, 1-10 parts of acetic acid, 0.3-3 parts of xanthan gum, 3-15 parts of mustard powder, 0.5-5 parts of emulsifying agent, and 2-10 parts of modified starch. The salad sauce with mustard flavor is prepared through the following steps: preparing for the raw materials; weighing the raw materials; dissolving the raw materials, and heating up to 90 DEG C-95DEG C; addingthe salad oil and the plain white after cooling to 60-70 DEG C; adding the acetic acid and the water, stirring, homogenizing and emulsifying into the salad sauce; and carrying out quality inspecting,and packaging to obtain the finished product. The salad sauce with mustard flavor has the advantages of low fat, nutrition, healthy, good flavor and wide application range, can be used in the food heating or baking industry, and can endure the high temperature of 180DEG C-200DEG C for more than 10 minutes.

Owner:广东百味佳味业科技股份有限公司

Crispy-skin bread rich in dietary fiber

InactiveCN103798317ACrispy skinSoft tasteDough treatmentPreservation by coatingBiotechnologyFatty acid

The invention discloses crispy-skin bread rich in dietary fiber. The crispy-skin bread is composed of crispy skin and a bread body. The crispy skin is composed of, by weight, 25 parts of white granulated sugar, 3 parts of butter, 1.5 parts of lard oil, 3 parts of eggs, 0.5 part of edible ammonium bicarbonate, 0.5 part of baking powder, 55 parts of flour, 2 parts of flaxseed powder, 1 part of wheat bran, 2 parts of oat bran, 2 parts of rice bran, 2.5 parts of milk powder and two parts of evaporated milk. The bread body is composed of, by weight, 50 parts of strong flour, 7 parts of inulin, 9 parts of white granulated sugar, 0.7 part of yeast, 1 part of table salt, 0.3 part of bread improver, 4 parts of milk powder, 20 parts of water, 4 parts of eggs and 4 parts of cream. The skin of the bread made according to the formula is crispy and tastes soft, and the bread is rich in dietary fiber, Vitamin B and Omega-3 fatty acid, delicious and nutrient.

Owner:BODA NANO SCI TECH DEHUA COUNTY

Method for preparation of white spirit by fermentation of waste distiller's grains

InactiveCN1970718AIncrease enzyme activityConducive to effective degradation and utilizationAlcoholic beverage preparationMicroorganism based processesSlagFermentation

The invention discloses a fermenting method of wine through wine slag, which is characterized by the following: setting the weight rate of allocated culture material, loss slag and tap water at 1:1.8-2.5:0.8-1.2; stirring evenly; sealing through plastic wrap; placing in the insulating culture box at 25-27 deg.c for 10-45d; distilling under normal pressure; obtaining the product with utilizing rate of starch at 46.4-62.4% and alcohl transmitting rate at 46.1-90.1%.

Owner:SICHUAN UNIV

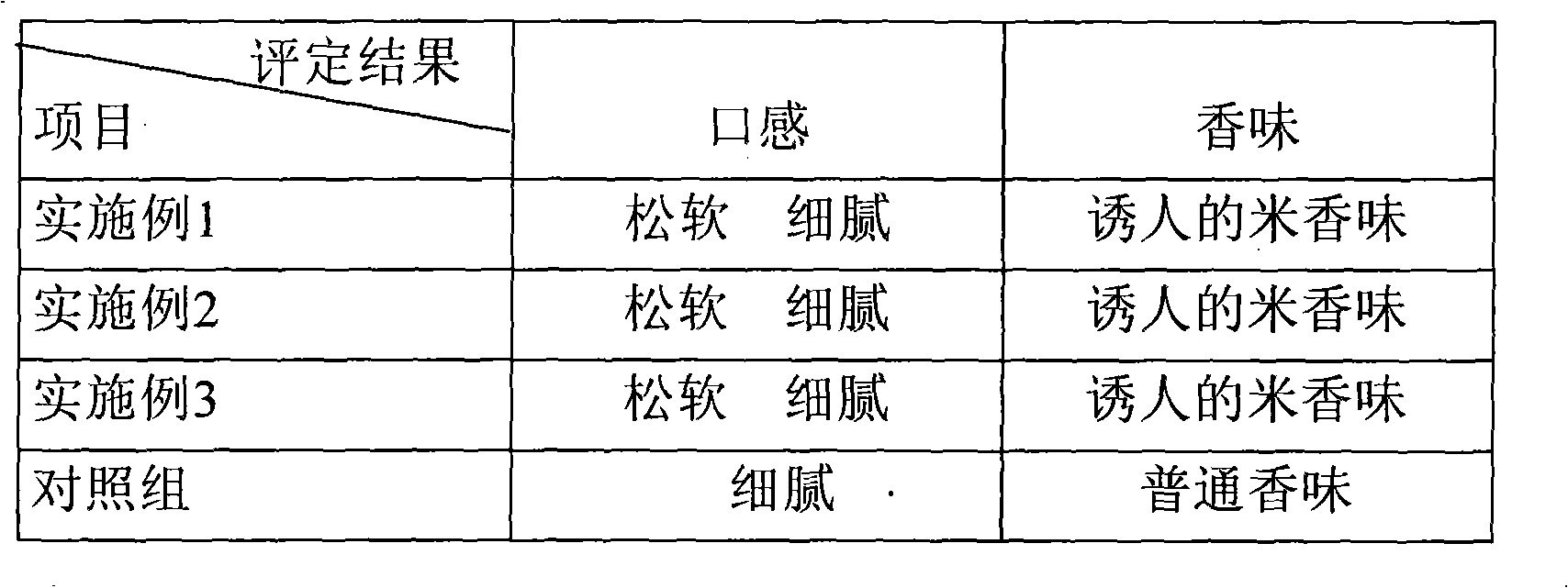

Peart barley cake and preparation method thereof

InactiveCN101292673AGreat tasteDeliciousBakery productsFood preparationToned milkAdditive ingredient

The invention discloses a coix seed cake and a preparation method thereof. The cake is made from the following ingredients by weight proportion: 1500 portions of eggs, 500 portions of white sugar, 280 to 320 portions of unprepared coix seed powder, 180 to 220 portions of baked coix seed powder, 70 to 130 portions of wheat flour, 200 portions of milk powder, 65 portions of creams, 100 portions of salad oil and 70 portions of cake oil; the preparation steps comprises: spreading the coix seed powder evenly in an oven; adjusting the upper heat temperature and the lower heat temperature of the oven to be 160 and 140 DEG C and baking for 15 to 25 minutes to obtain the bake coix seed powder; all the ingredients are weighed; the egg and the white sugar are beaten together into paste; the unprepared coix seed powder, the baked coix seed powder, the wheat flour, the milk powder, the creams, the salad oil and the cake oil are added into the paste and stirred evenly, which are finally put into the oven with the upper heat temperature and the lower heat temperature of 160 and 140 DEG C and baked for 20 to 25 minutes. The prepared cake is soft and has inviting rice scent.

Owner:刘保锐

Preparing method of hand-shredded meat

The invention relates to a preparing method of hand-shredded meat. The preparing method adopts pork, chicken meat, duck meat, goose meat and rabbit meat as raw materials, adds auxiliary materials, spice and seasonings for salination by steps, dries, bakes, boils, cuts the meat into pieces, blocks, dices or silks, packages in vacuum, and produces a finished product after sterilization. The processing technique almost covers all the meat products of the poultry meat, the prepared hand-shredded meat has soft and tender taste, can be prepared into various types of spicy, spiced and cantonese flavor and the like, and provides an instant food with another flavor for people.

Owner:黄海洲

Method of producing mixed grain steamed bread

InactiveCN101223898AIncrease the volume of bunsSoft tasteDough treatmentPre-baking dough treatmentYeastCalcium

The invention discloses a production method of steamed bread made of coarse cereals, which is prepared by the following raw materials by weight proportion: 40-50 portions of medium-strength wheat flour, 40-50 portions of coarse cereals powder, 5-10 portions of soybean flour, 1-5 portions of konjak powder, 0.1-1 portion of the mixture of calcium stearyl lactylate and sodium stearyl lactate and 0.5 portion of yeast. The weight ratio of alcium stearyl lactylate to sodium stearyl lactate is 10:1-1:10.

Owner:河南兴泰科技实业有限公司

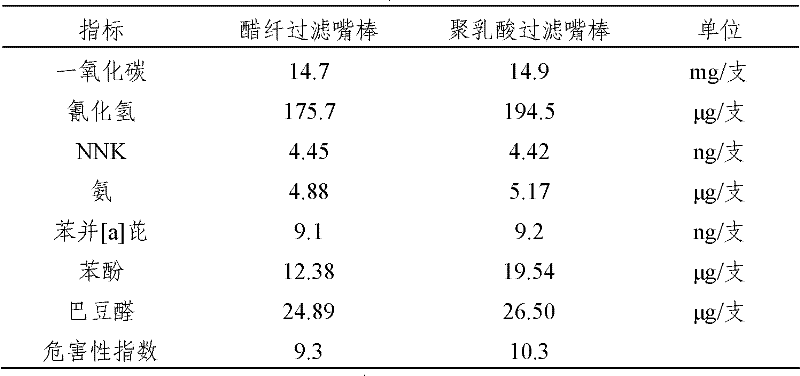

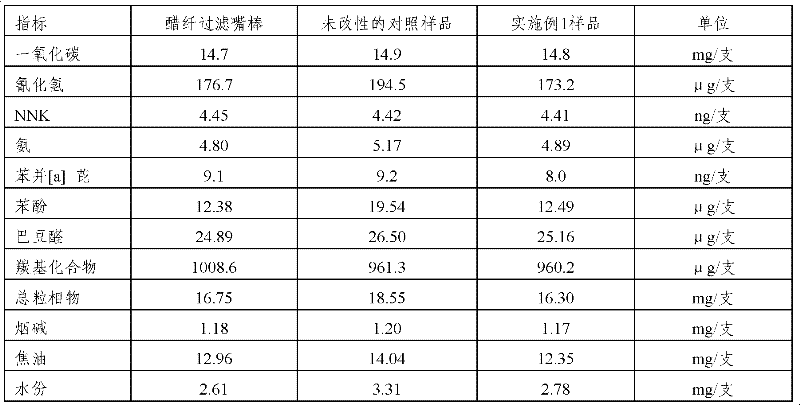

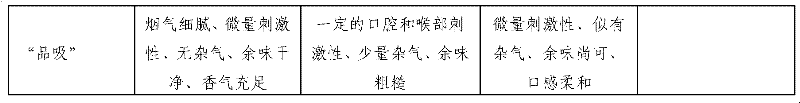

Modified polyactic acid composition for cigarette filter stick and preparation method thereof

ActiveCN102516728ASmall weight contentImprove adsorption capacityTobacco smoke filtersMonocomponent polyesters artificial filamentSODIUM PYRROLIDONE CARBOXYLATECellulose acetate

The invention relates to a modified polyactic acid composition for a cigarette filter stick and a preparation method thereof. The composition comprises following parts of raw materials, by weight, 100 parts of polyactic acid, 0.02-3 parts of polyactic acid-beta-cyclodextrin, 0.08-5 parts of sodium carbonate, 0.05-5 parts of sodium pyrrolidonecarboxylate, 0.01-4 parts of vitamin and 0.01-8 parts of polyacrylamide. The filter stick prepared through the polyactic acid composition is better in absorbing performance on smoke compared with the prior art and good in comprehensive performance, and a part of indexes of the filter stick exceed those of a cellulose acetate filter stick.

Owner:马鞍山同杰良生物材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com