Healthy effervescent tablet and its prepn

A technology of health care bubbles and effervescent tablets, applied in the field of health drinks, can solve the problems of labor, time, equipment, energy consumption, lack of fluidity and compressibility, and low production efficiency, so as to improve fluidity and reliability Compression, soft taste, small footprint of the plant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

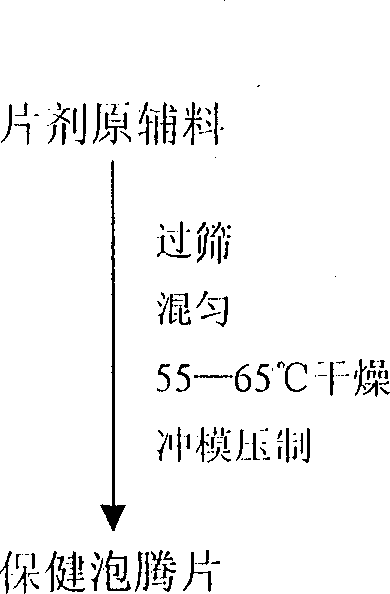

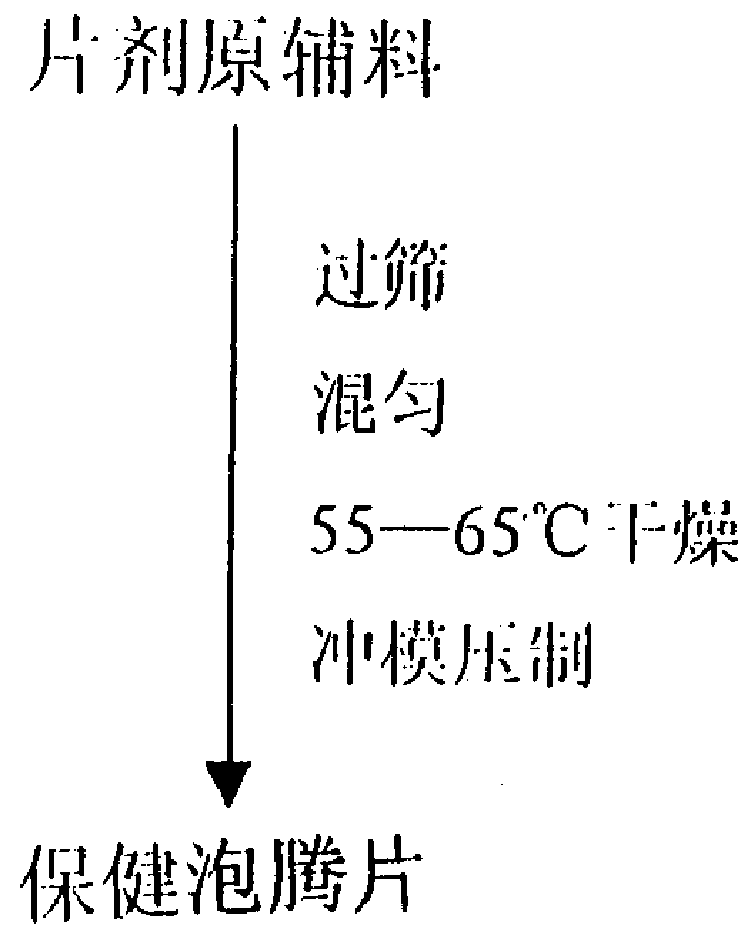

Method used

Image

Examples

Embodiment 1

[0094] Prescription: Xylooligosaccharide 35.0kg Stevia 12.0kg

[0095] Citric Acid 200.0kg Strawberry Flavor 5.0kg

[0096] Sodium bicarbonate 90.0kg Sodium benzoate 3.0kg

[0097] Sodium carbonate 10.0kg

[0098] Process: Take all the raw and auxiliary materials through a sieve with an aperture of 0.5mm and mix them in a conical vertical double-screw mixer, dry them at 55-60°C for 20 minutes, and press them into 3.50±0.10g bubbles with a die with a diameter of 25mm There are about 100,000 Teng tablets, sealed and packaged.

[0099] Others: The xylo-oligosaccharide used in the tablet is a spray-dried powder with a particle size below 0.1mm. The tablet can be completely disintegrated in 250ml of water at 37°C for 60 seconds.

Embodiment 2

[0101] Prescription: Isomaltooligosaccharide 175.0kg Stevia 12.0kg

[0102] Citric acid 106.7kg Sydney essence 5.0kg

[0103] Sodium bicarbonate 48.0kg Sodium benzoate 3.0kg

[0104] Sodium carbonate 5.3kg

[0105]Process: Take all the raw and auxiliary materials through a sieve with a pore size of 1.0mm and mix them in a V-shaped rotary mixer, dry them at 55-60°C for 20 minutes, and press them into 3.50±0.10g effervescent tablets with a diameter of 25mm. 100,000 pieces, sealed package, ready to use.

[0106] Others: The tablet can be completely disintegrated when placed in 250ml water at 37°C for 180 seconds.

Embodiment 3

[0108] Prescription: Isomaltooligosaccharide 65.0kg Stevia 12.0kg

[0109] Shiquan Dabu Fang Extract 70.0kg Traditional Chinese Medicine Essence 5.0kg

[0110] Citric acid 132.7kg Sodium benzoate 4.0kg

[0111] Sodium bicarbonate 59.7kg Sodium carbonate 6.6kg

[0112] Process: Take all the raw and auxiliary materials through a sieve with a pore size of 0.8mm and mix them in a V-shaped rotary mixer, dry them at 55-60°C for 20 minutes, and press them into 3.50±0.10g effervescent tablets with a diameter of 25mm. 100,000 pieces, sealed package, ready to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com