Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

391results about How to "Smooth texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

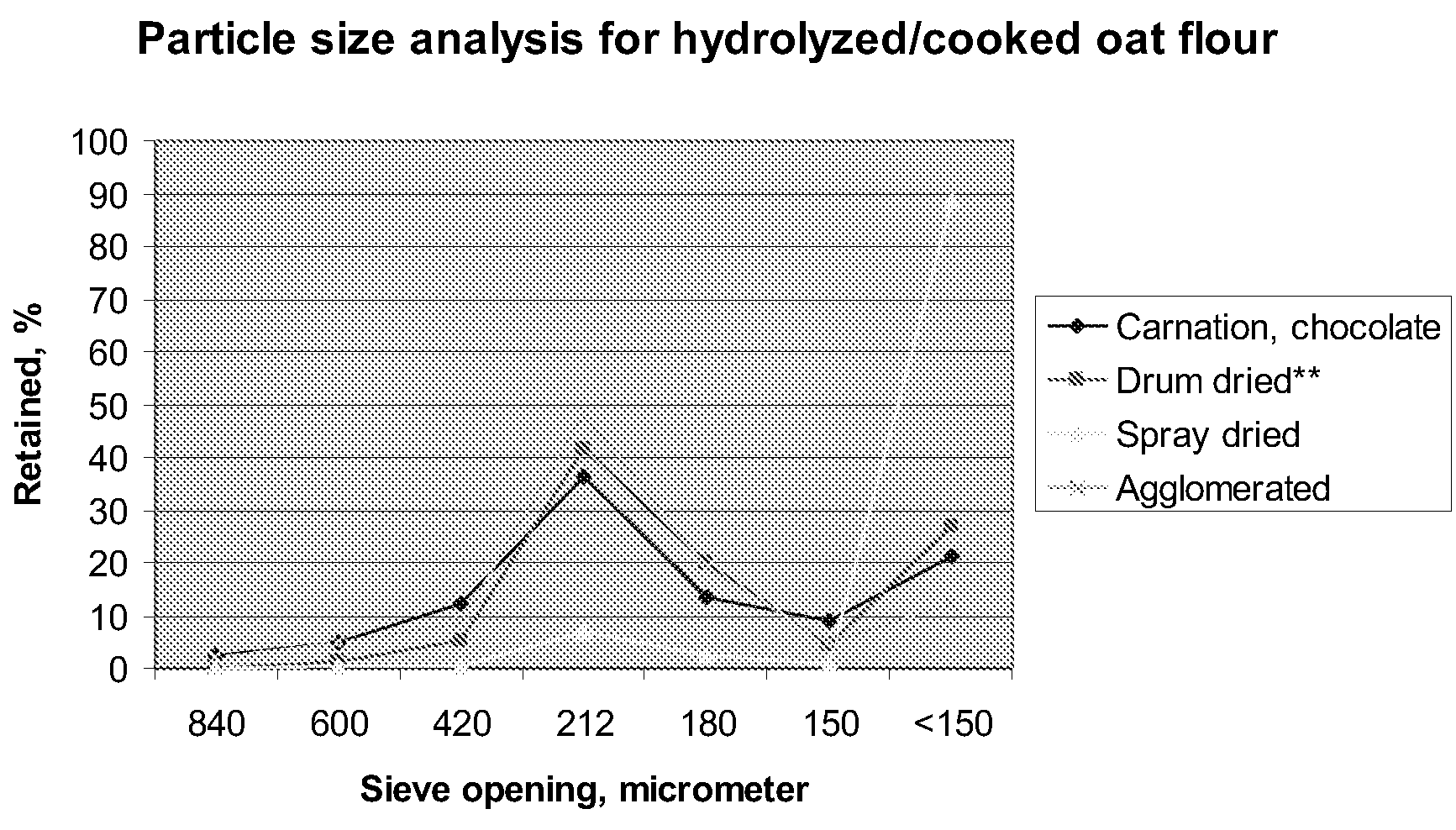

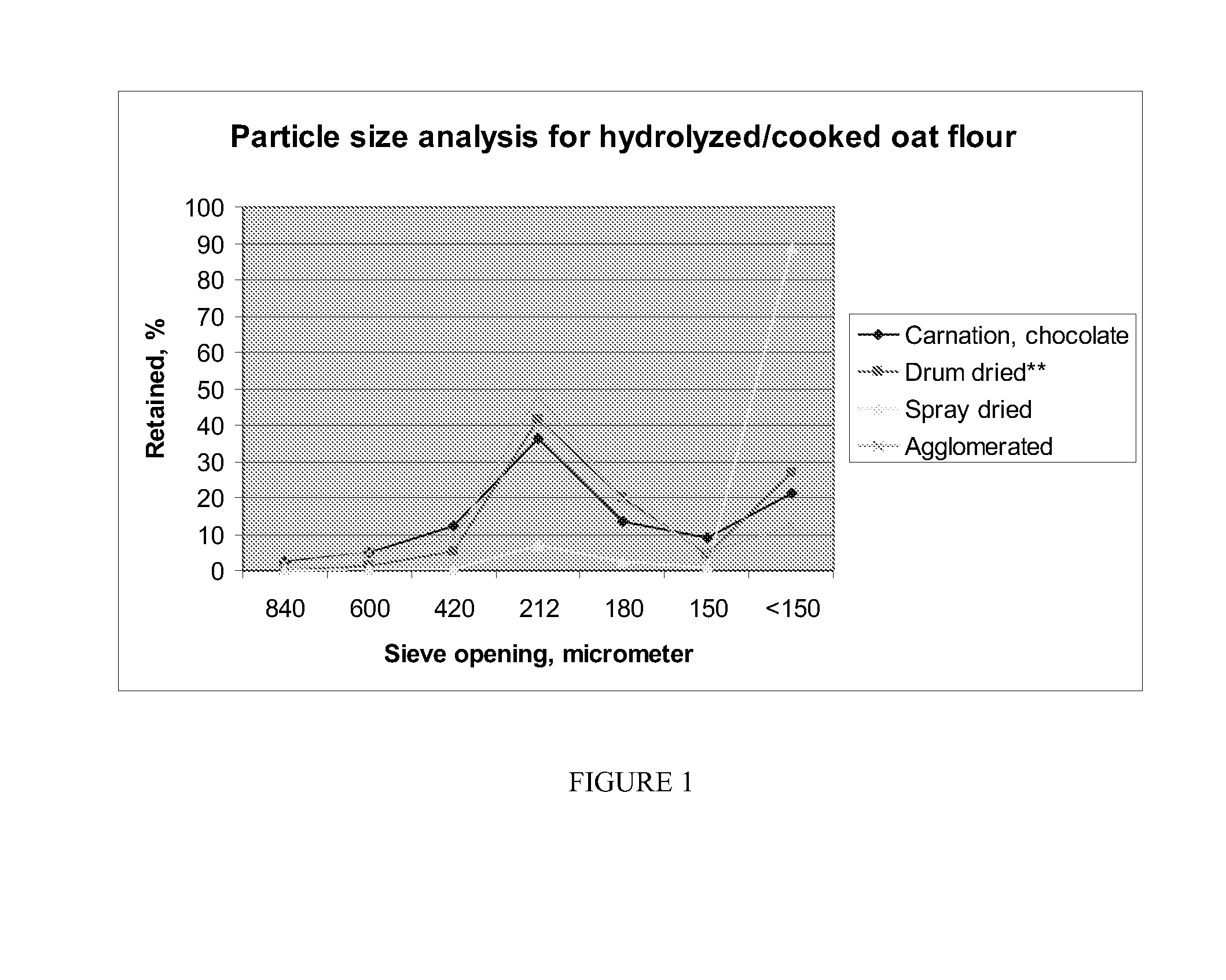

Hydrolyzed, Spray Dried, Agglomerated Grain Powder And Drinkable Food Products

ActiveUS20080260909A1Good dispersionImprove solubilityMilk preparationTea substituesFood productsSpray drying

Owner:THE QUAKER OATS CO

High-fiber dairy product

A process for producing a fermented dairy product supplemented with fiber, especially a purified digestion resistant fiber such as maltodextrin, inulin or oligofructose. This process takes advantage of the naturally acidic nature and enzymatic properties of fermented milk products such as yogurt and specific mixing and blending steps which produce a product having a superior organoleptic and textural properties. A fermented dairy product supplemented with at least 1-5% fiber, especially, a purified digestion-resistant fiber such as maltodextrin, inulin or oligofructose.

Owner:DANNON COMPANY INC THE

Composition for the preparation of homemade frozen confections

InactiveUS20150140193A1Pleasant textureCaloric value easilyMilk preparationFrozen sweetsPolysaccharideChemistry

The present invention relates to a shelf-stable composition for the preparation of a frozen confection comprising: (i) a sweetening agent; (ii) a dairy fat; and (iii) one or more polysaccharide having a Dextrose Equivalent (DE) value of maximum 40; with the proviso that the composition does not comprise added emulsifiers or stabilizers. The present invention also relates to a method of preparing a frozen confection by mixing said composition with ice and an edible liquid and blend the mixture.

Owner:NESTEC SA

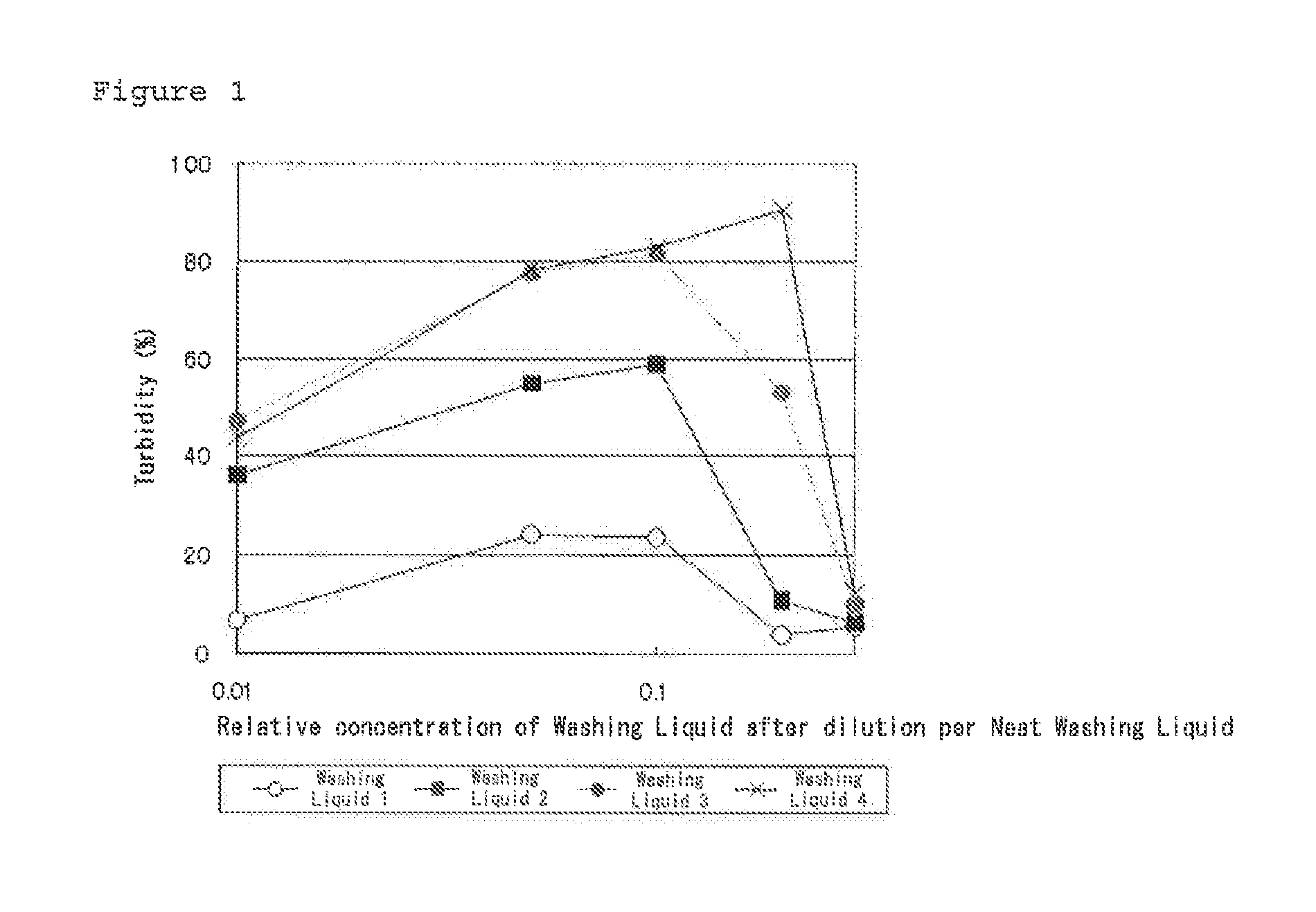

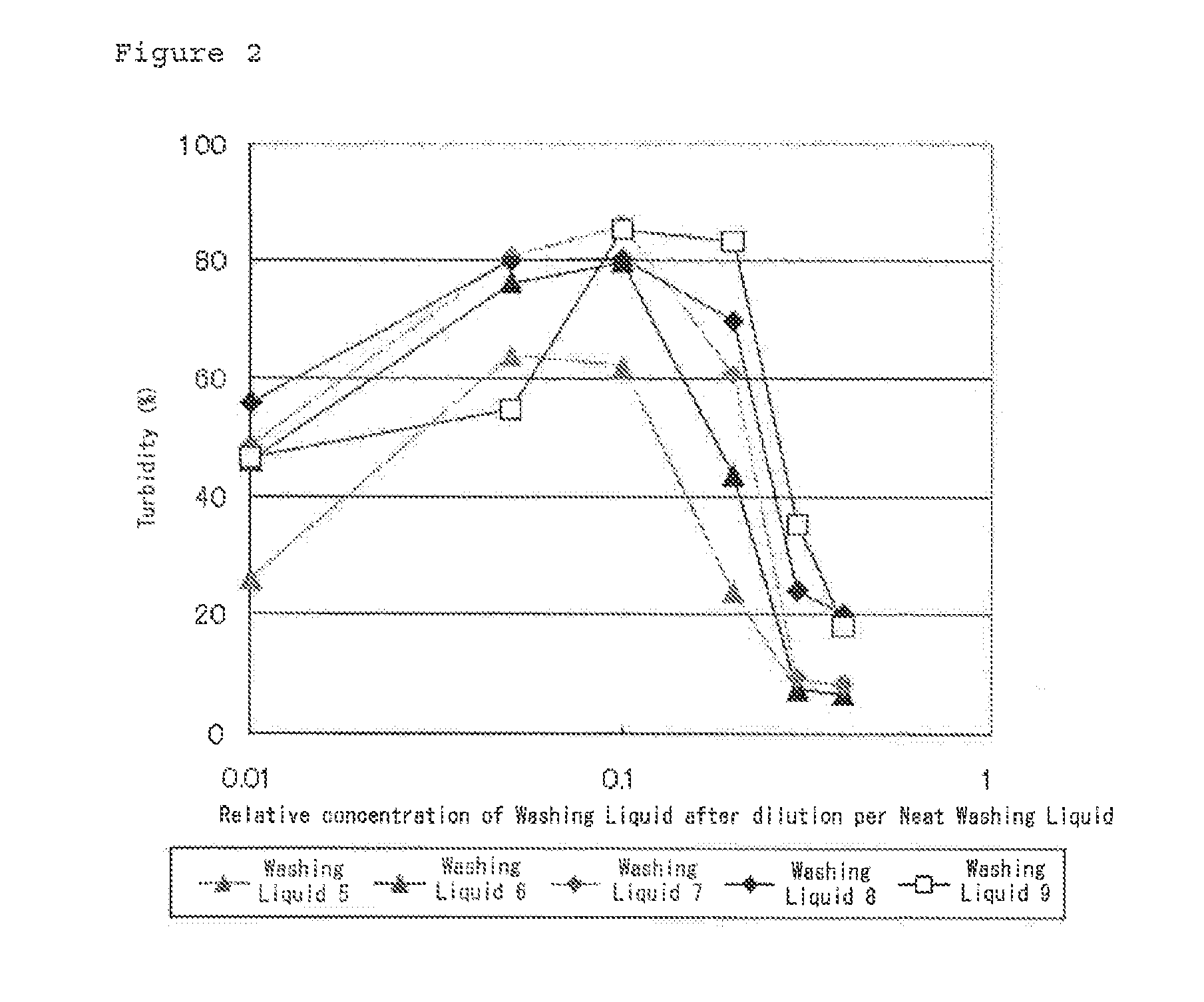

Composition for cleaning scalp and head hair

InactiveUS20130216491A1Excellent conditioning performanceSuitable viscosityCosmetic preparationsHair removalChemistryDandruff

Owner:OTSUKA PHARM CO LTD

Yogurt that is frozen

Owner:SOC DES PROD NESTLE SA

Frozen confection product and a method of preparing such

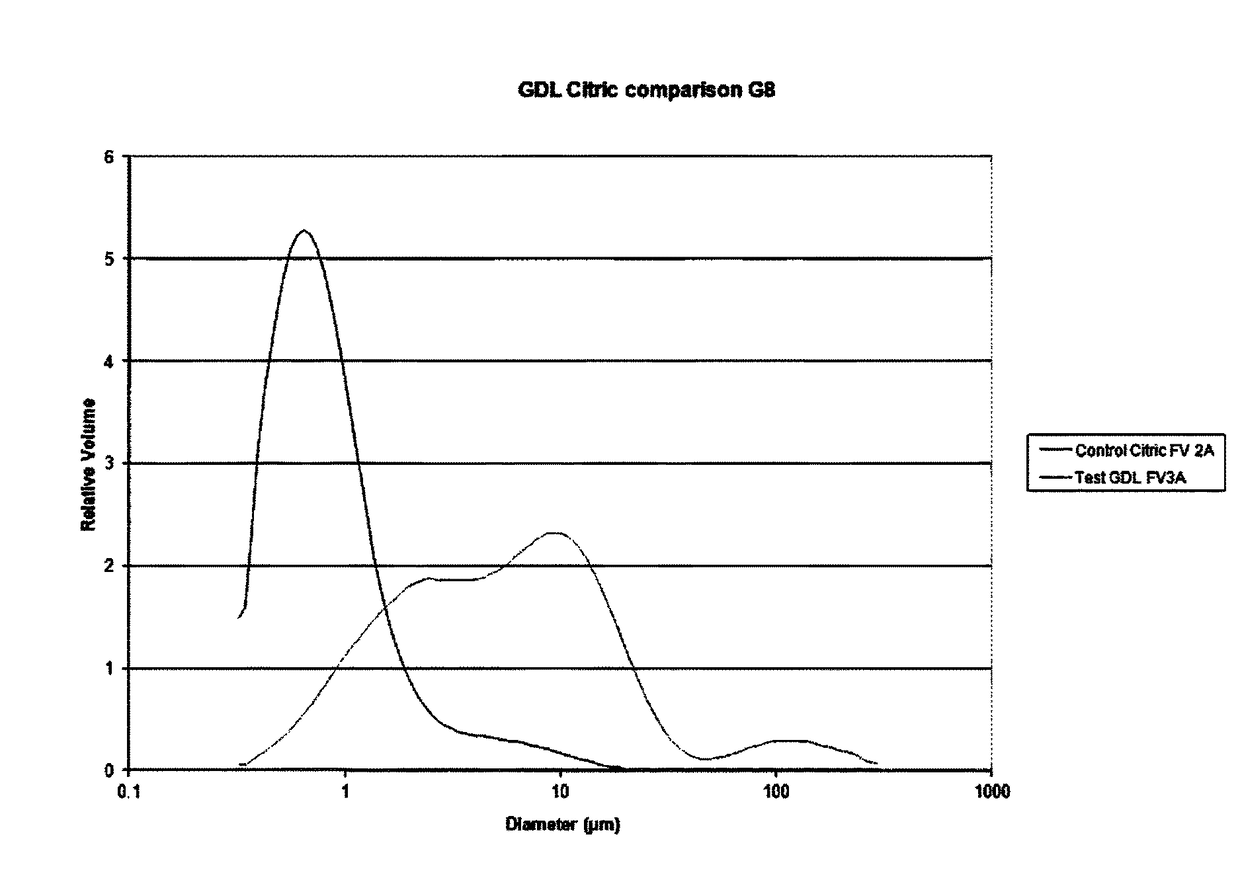

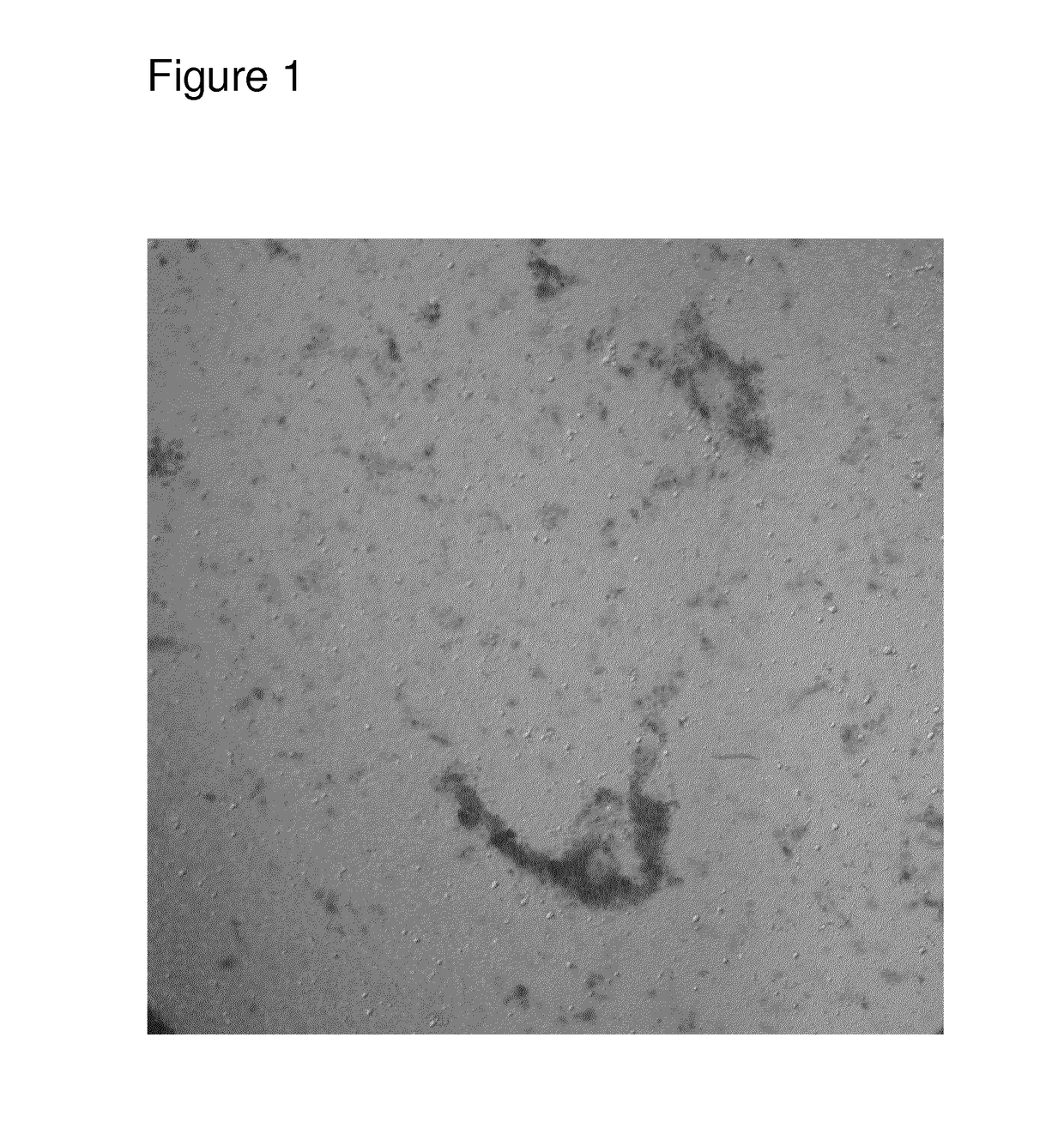

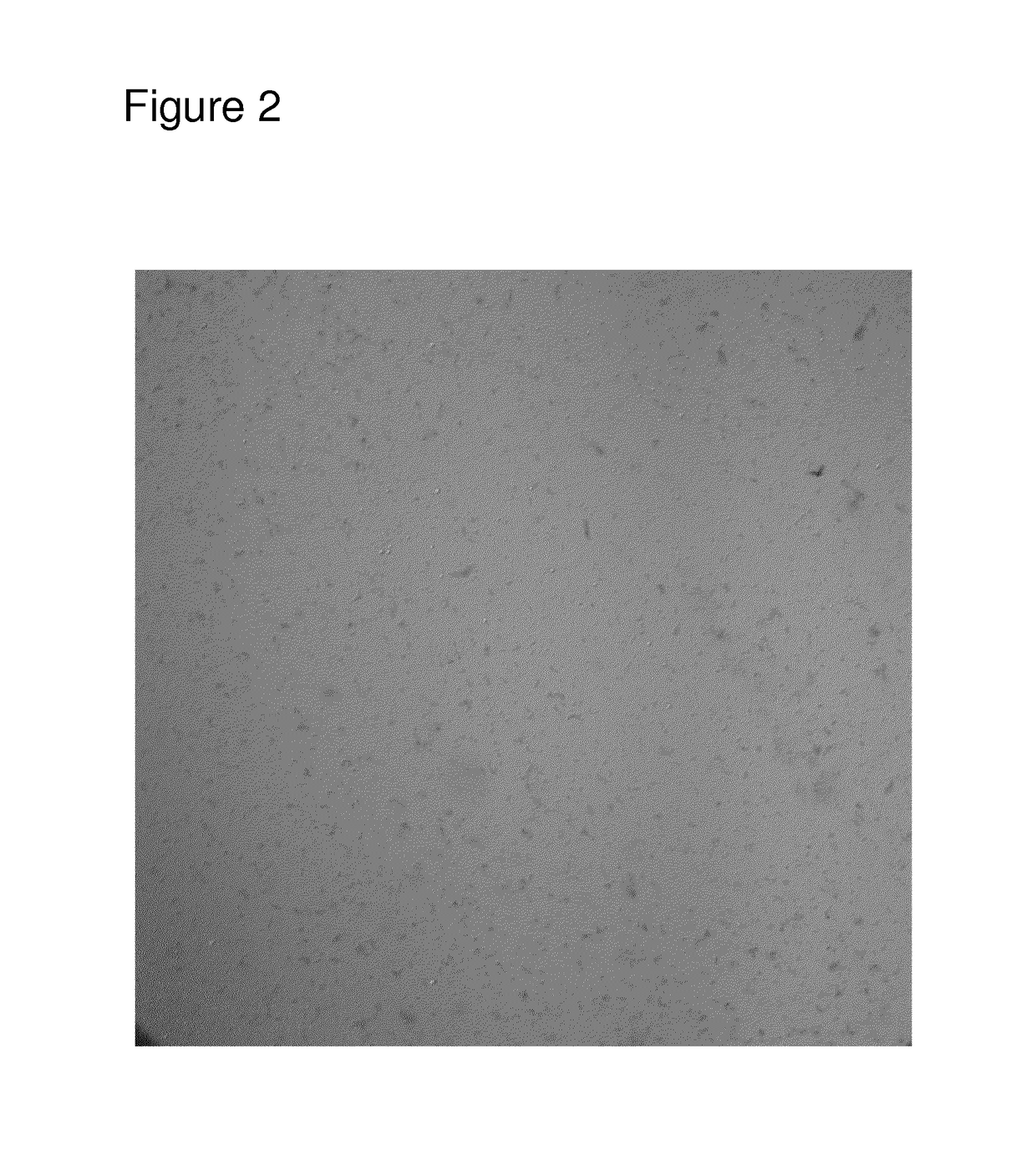

ActiveUS20150245638A1Improved texturalImproved sensorial propertyFrozen sweetsOther dairy technologyGlucono delta-lactoneDelta-gluconolactone

The present invention relates to a frozen confection product comprising glucono-delta-lactone. The present invention also relates to a method of producing a frozen confection product by adding glucono-delta-lactone to an ingredient mix and then homogenize, pasteurize, and freeze the mix. Preferably the method includes a post pasteurization acidification step. Preferably the method uses a standard freezing step followed by low temperature freezing.

Owner:SOC DES PROD NESTLE SA

Frozen confection product and a method of preparing such

ActiveUS9888706B2Improved textural and sensorial propertyGood creamy textureFrozen sweetsOther dairy technologyGlucono delta-lactoneDelta-gluconolactone

The present invention relates to a frozen confection product comprising glucono-delta-lactone. The present invention also relates to a method of producing a frozen confection product by adding glucono-delta-lactone to an ingredient mix and then homogenize, pasteurize, and freeze the mix. Preferably the method includes a post pasteurization acidification step. Preferably the method uses a standard freezing step followed by low temperature freezing.

Owner:SOC DES PROD NESTLE SA

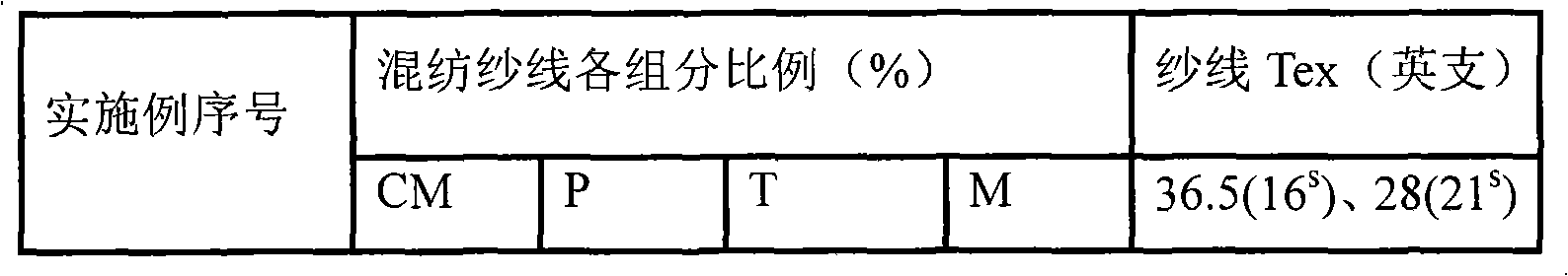

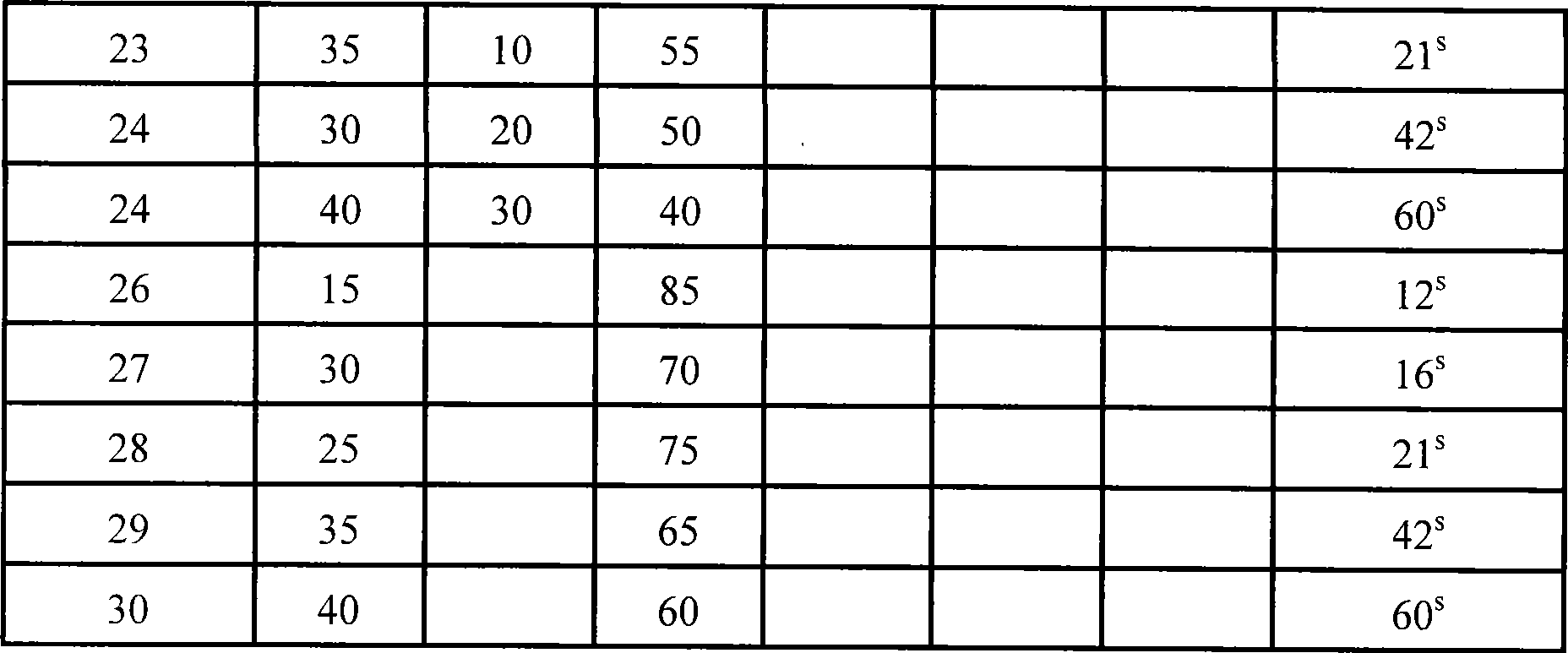

Coolmax fiber/pearl fiber blending knitted fabric with moisture absorption and perspiration health care functions

InactiveCN101608378AMaintain sweat-wicking and quick-drying propertiesSmooth textureWeft knittingWarp knittingYarnPerspiration

The invention relates to a Coolmax fiber / pearl fiber blending knitted fabric with moisture absorption and perspiration health care functions, the fabric is knitted by blending yarns containing pearl fiber, the blending yarns are one or more than one of tencel fiber, modal fiber and viscose, the mass ratio of pearl fiber in the blending yarns is 15-50%, the blending yarns are spun to be 16-60. The fabric of the invention has the health care efficacies of promoting microcirculation of human body blood, preventing ultraviolet rays and protecting skin, keeps the feature of fast perspiration and simultaneously has the advantages of smooth texture, good wearability and comfort wearing.

Owner:DONGHUA UNIV +1

Frozen yogurt process

Owner:SOC DES PROD NESTLE SA

Fiber cotton and its producing method

InactiveCN101050583ASimple production processImprove product qualityNon-woven fabricsAdhesivesFiberMaterials science

The present invention discloses a fiber cotton and its production method. It is made up by using 10%-80% of low melting point fiber and 90%-20% of other fiber as raw material through the processes of opening, carding, forming, baking and bonding, rolling, fast cooling, setting, cutting and packaging.

Owner:黄显飚

Frozen smoothie kit and method

InactiveUS20070042090A1Simple processReduce fluid volumeReady-for-oven doughsFrozen sweetsFruit juiceAdditive ingredient

A frozen pellet for blending with other ingredients to make a smoothie is formed of a sugar sweetened yogurt or yogurt formulation diluted with water and frozen solid at temperatures between 0° F. and 32° F. The frozen-solid yogurt pieces eliminate the need for the use of ice in the smoothie making process. Instead the frozen-solid yogurt pieces simply are blended together with fruits, preferably also frozen, and a liquid such as a juice, soda or milk to make a cold smoothie having a desirable thick consistency.

Owner:BIRDS EYE FOODS

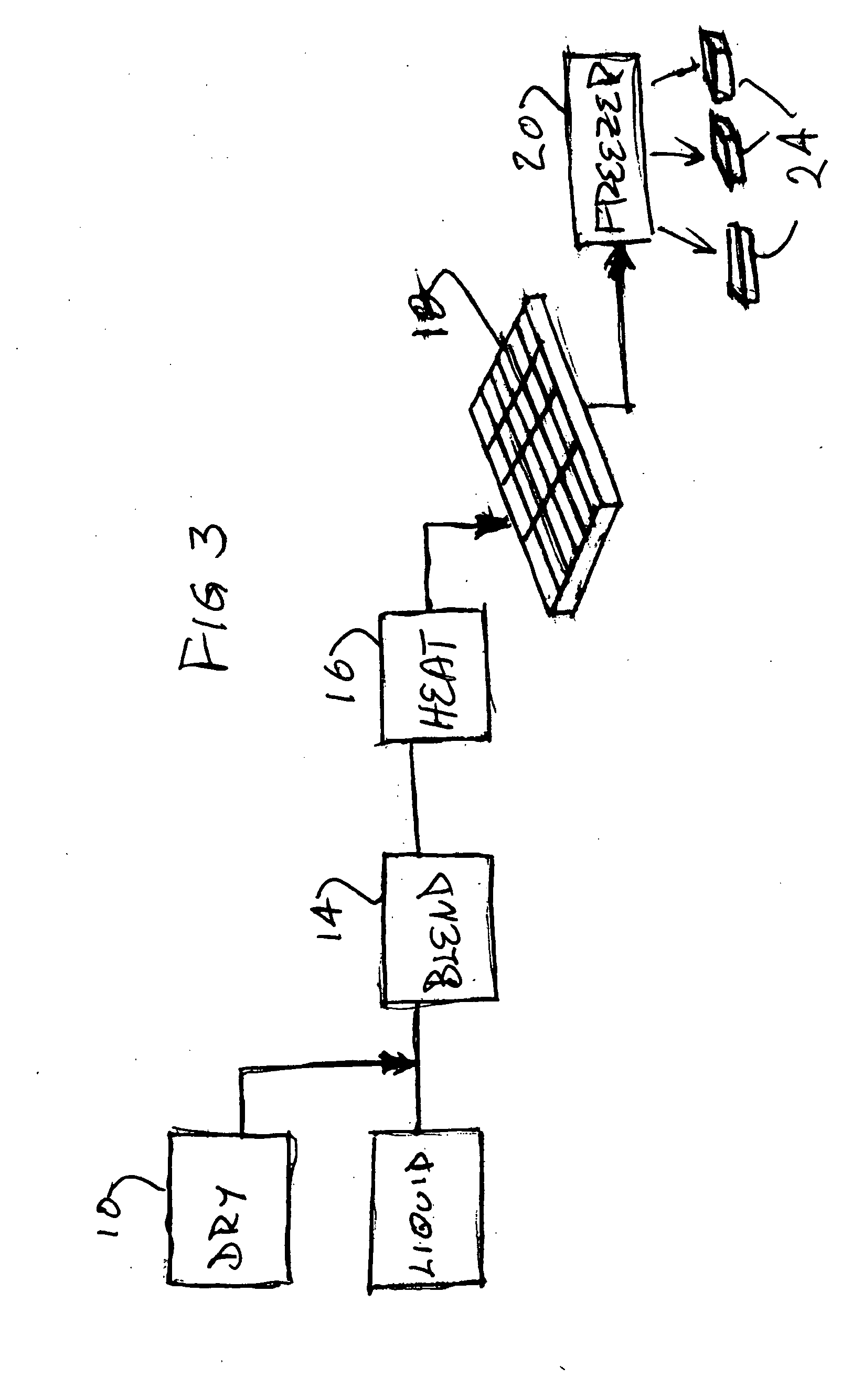

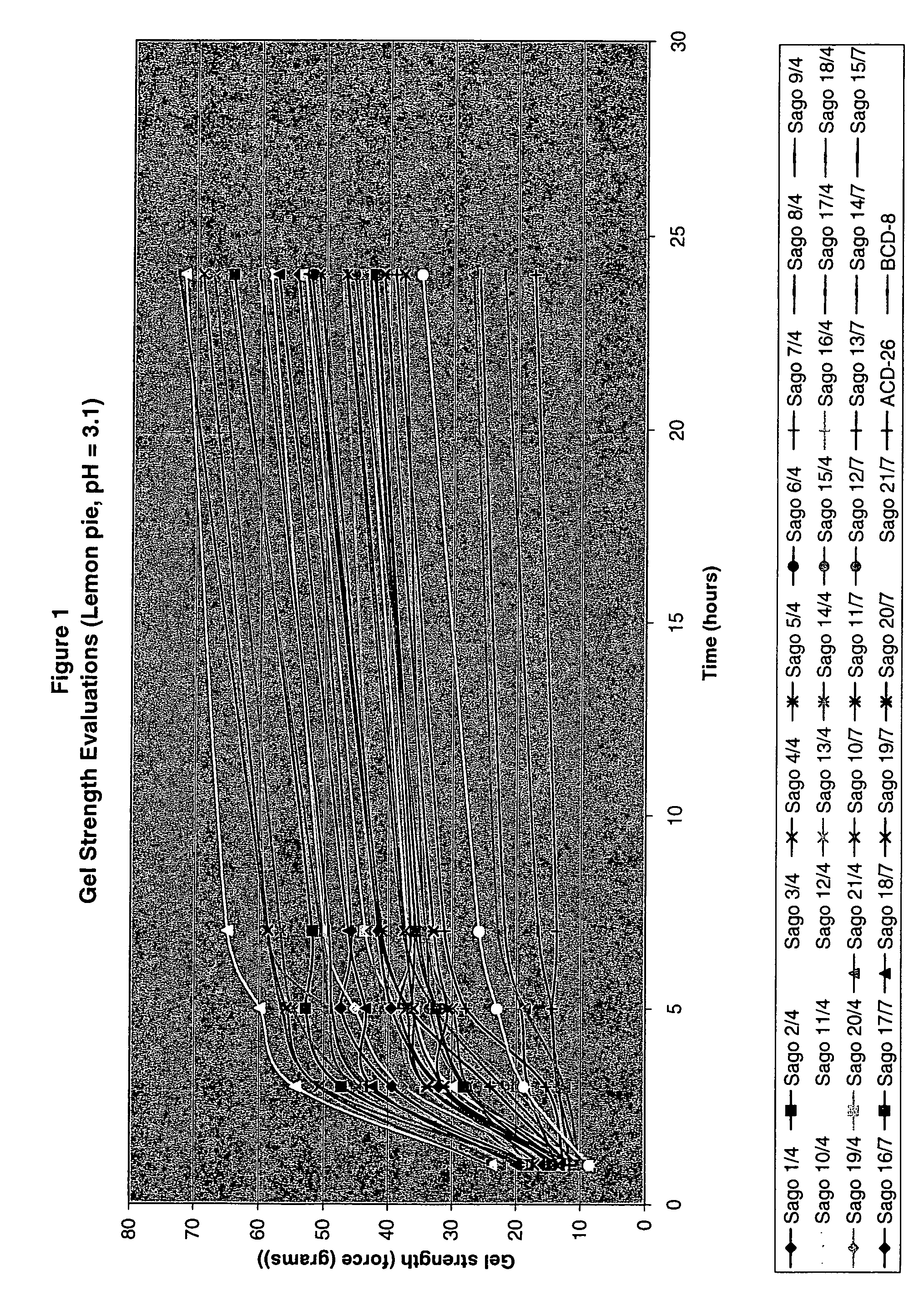

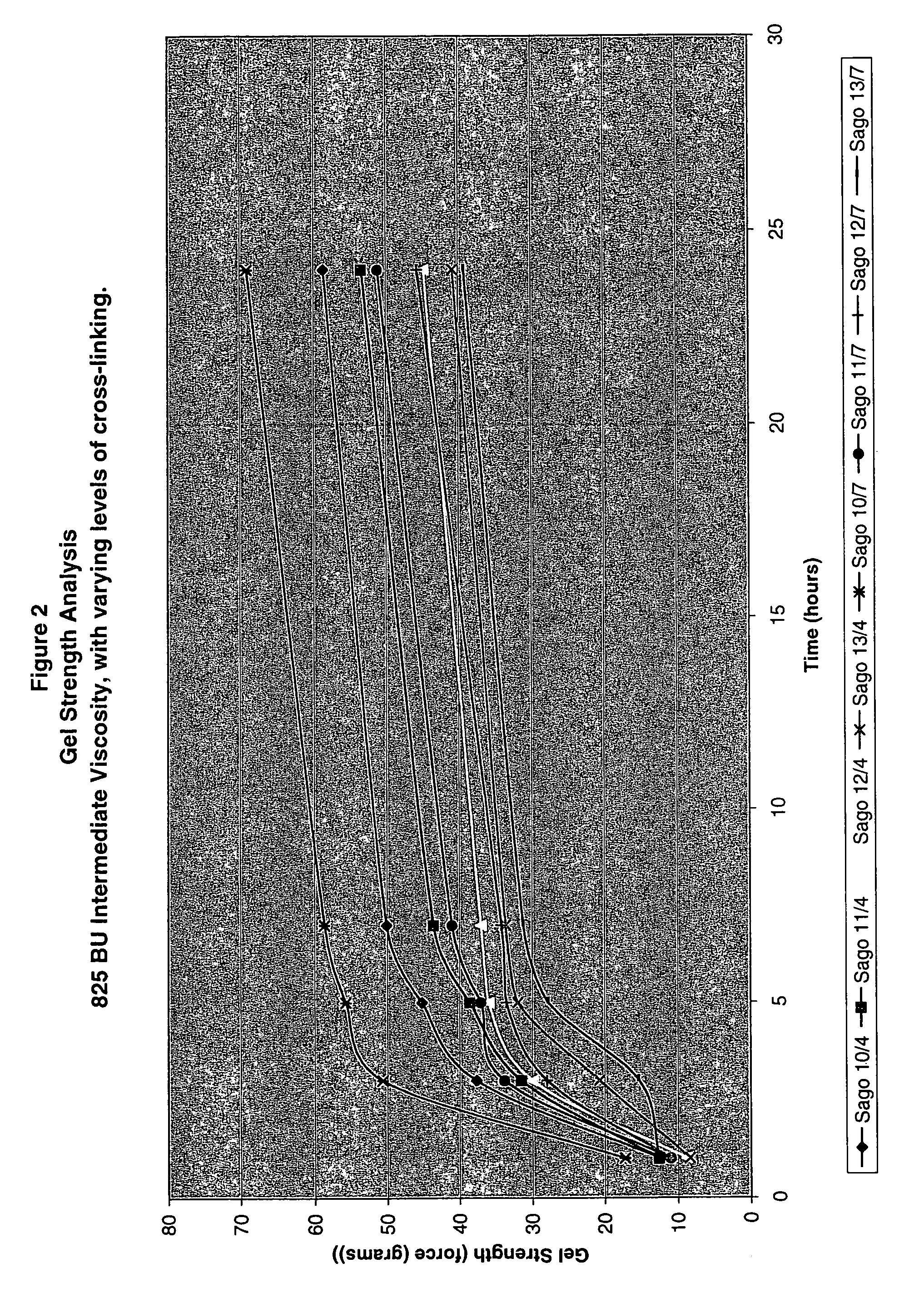

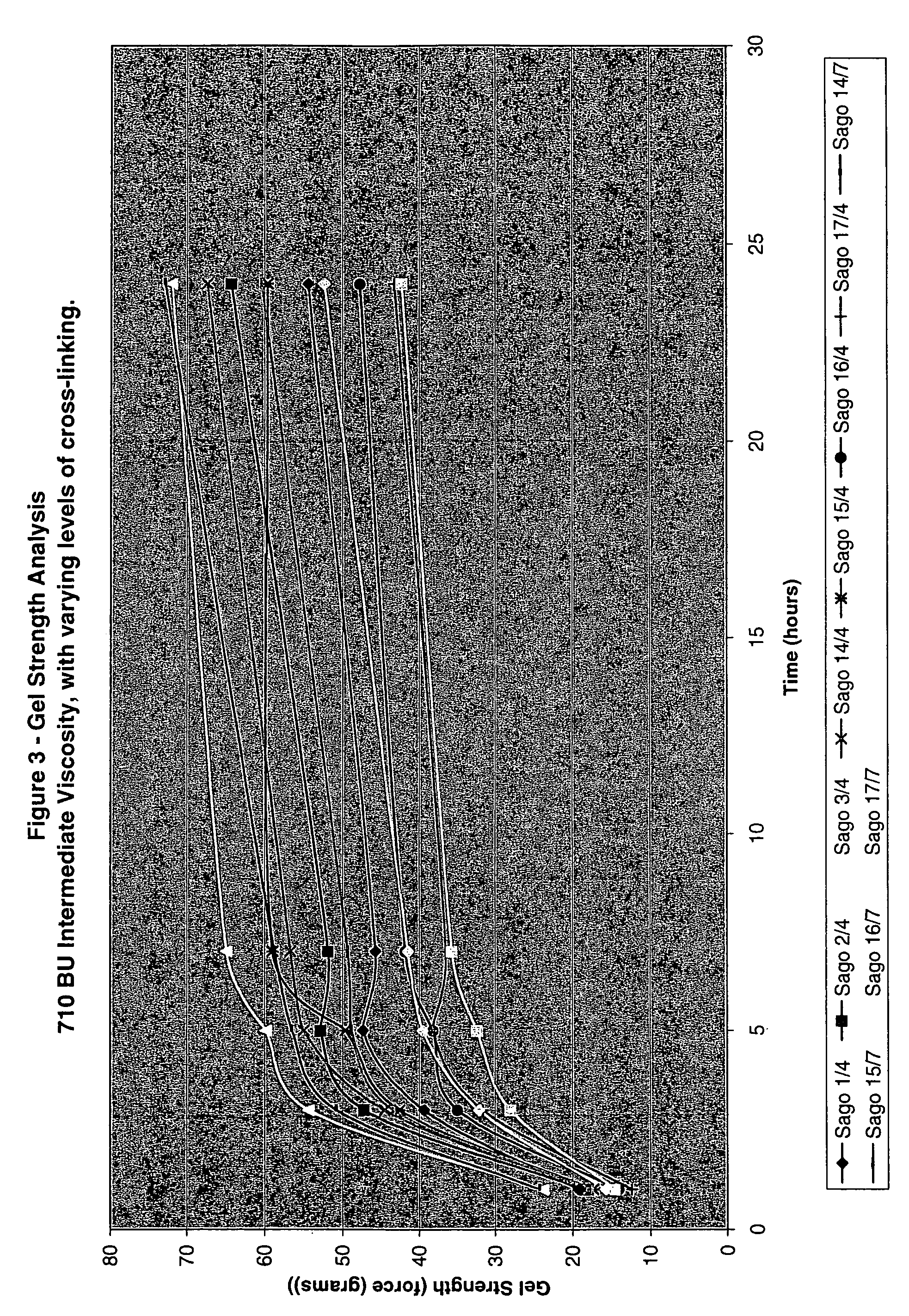

Sago-based gelling starches

InactiveUS7422638B2Fast gelling propertyHigh gel strengthBakery productsFood preparationUltimate tensile strengthFood item

Sago-based gelling starches and the use thereof. Such modified starches exhibit exceptionally fast gelling properties, high gel strengths, and exceptional elasticity. These properties allow for significantly reduced processing times, including reduced hold times. Further, the higher gel strength allows for reduced starch levels without loss of final product gel strength integrity or texture. The instant gelling starches are particularly useful in food systems of the type that gel upon standing, such as pie and cream fillings, puddings, spreads, and jellies.

Owner:CORN PROD DEV INC

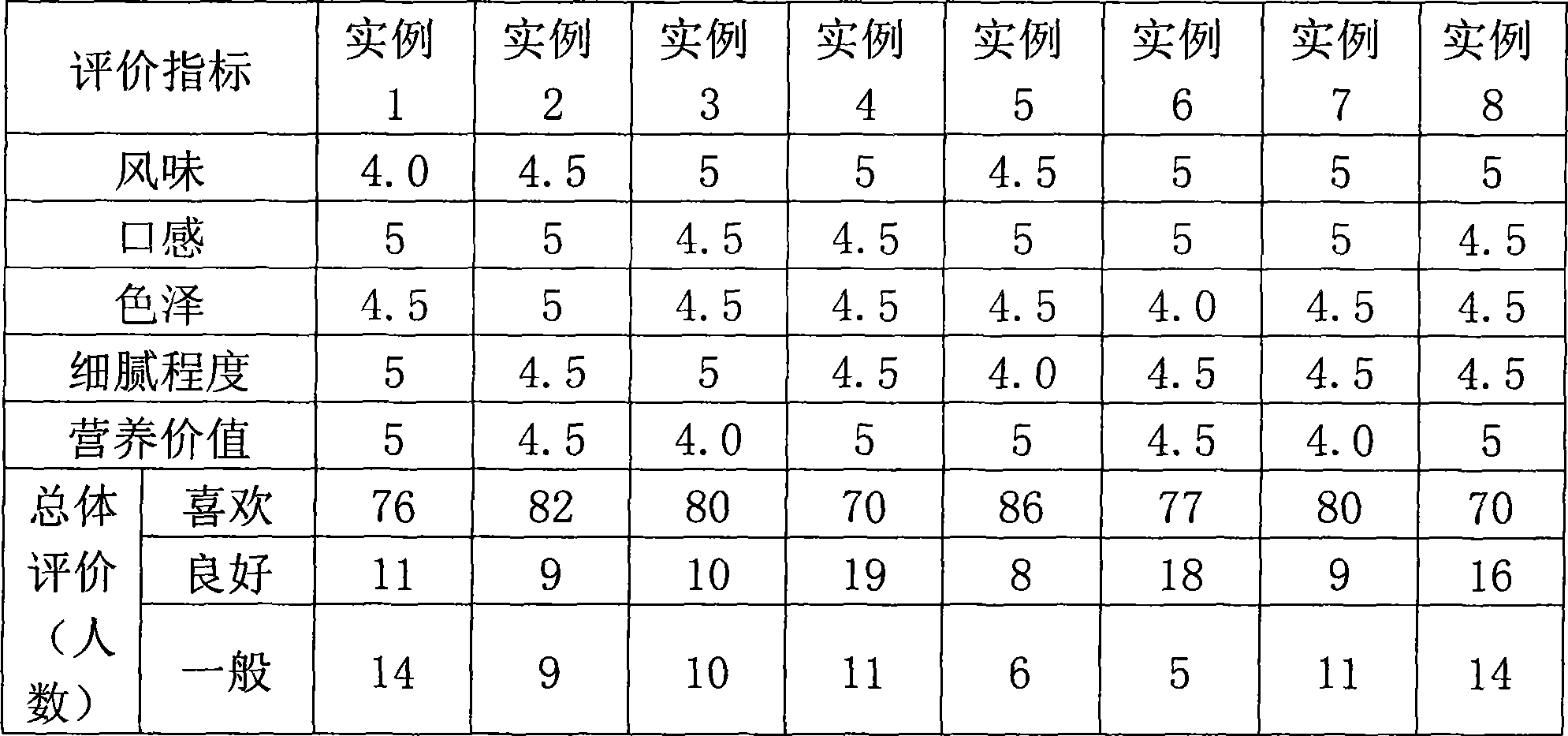

Non-fermentation type sour milk and preparation method thereof

The invention relates to non-fermentation type sour milk and a preparation method thereof. The non-fermentation type sour milk uses fresh cow milk as principal raw material. After being hydrolyzed by milk sugar, the cow milk is pasteurized and concentrated in vacuum to be 40 percent of the original volume. After the cow milk is cooled, probiotic powder is added. The invention has the core that transglutaminase is added at an optimal temperature; under the action of the transglutaminase, milk protein is connected together to form a protein network, thereby a uniform stable gelatin system is easily formed; delta-gluconolactone is then added, and the gelatin system and the delta-gluconolactone are heated at 35-40 DEG C in a water bath way for 2 to 3 hours so that the uniform, stable and exquisite non-fermentation type sour milk like a quark can be obtained. The invention has simple preparing process, no requirement for fermentation, and full utilization of resources. The non-fermentation type sour milk can be used as a base to develop various products, such as corn non-fermentation type sour milk for breakfast, jelly non-fermentation type sour milk, and the like, and can satisfy the requirements of consumers in nutrition, mouthfeel, texture, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Instant cheese and preparation method thereof

The invention relates to an instant cheese and a preparation method thereof. The preparation method comprises the steps: using full-cream fresh milk as main material, pasteurizing the milk after being hydrolyzed through lactase, and concentrating the full-cream fresh milk to 35-40 percent of the original volume in vacuum. The preparation method of the instant cheese has the core points that transglutaminase is added at 35 DEG C, and milk proteins are linked to form a protein network under the action of the transglutaminase, thereby forming a uniform and stable gel system easily. Then, chymosin is added for promoting gel to form , and uniform, stable and delicate instant cheese can be obtained in a water bath for half hour at about 30 DEG C. The invention is simple and easy for operation, and can be used for development of various application products on the theoretical basis, including breakfast cereal cheese, jelly cheese and the like. Moreover, the instant cheese can meet the requirements of consumers for taste, texture, nutrition, and the like.

Owner:TIANJIN UNIV OF SCI & TECH

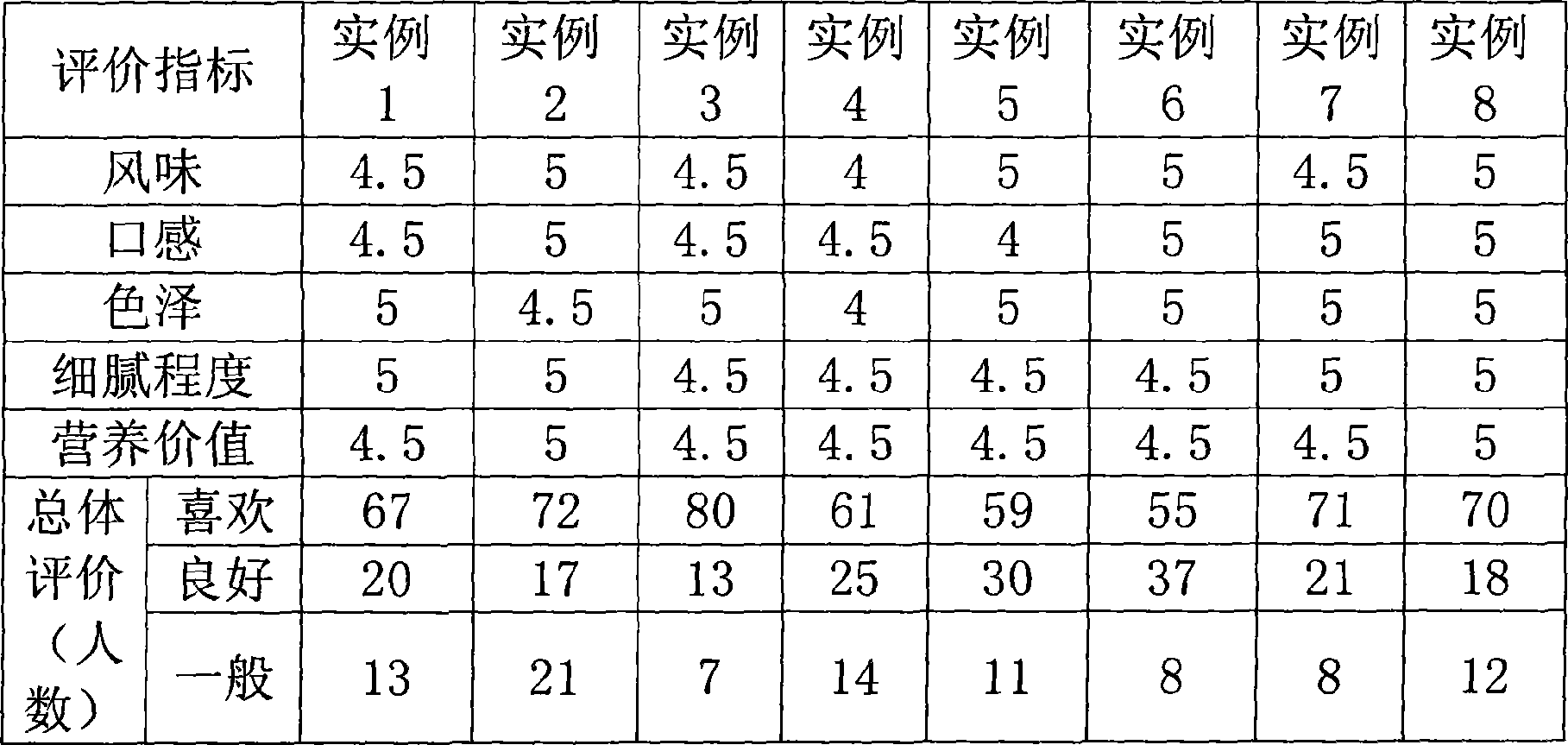

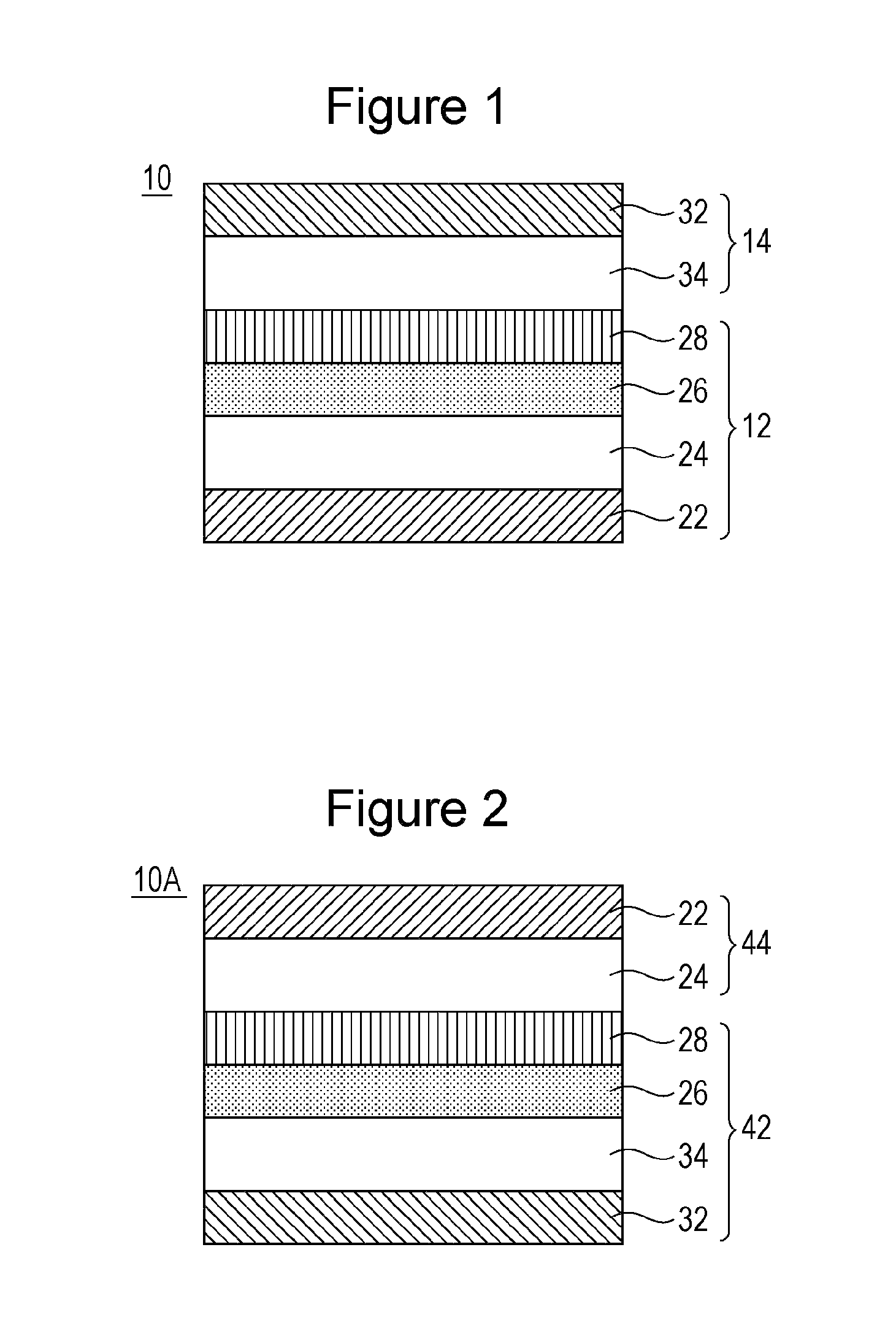

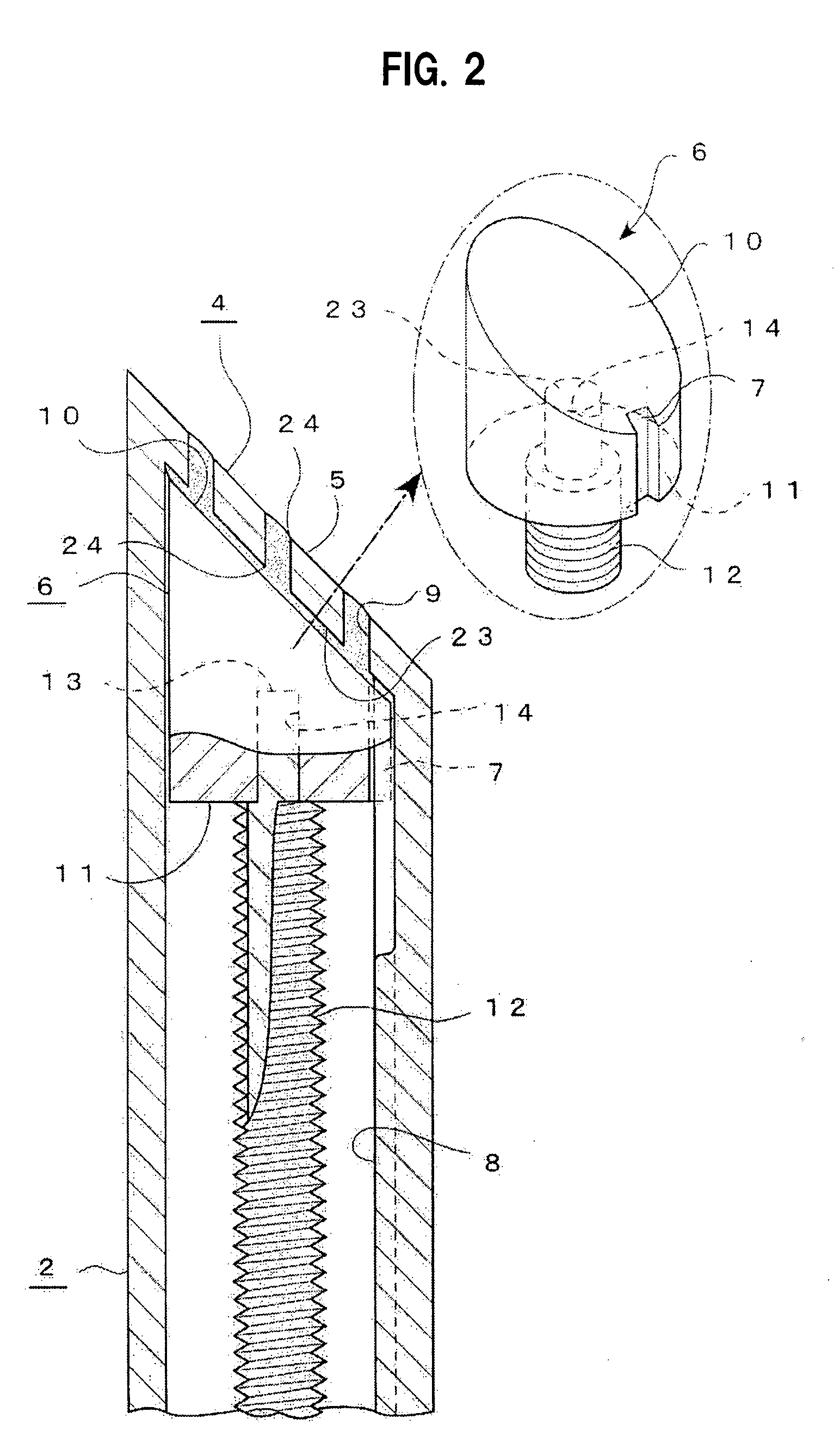

Separator-integrated electrode and nonaqueous electrolyte secondary battery

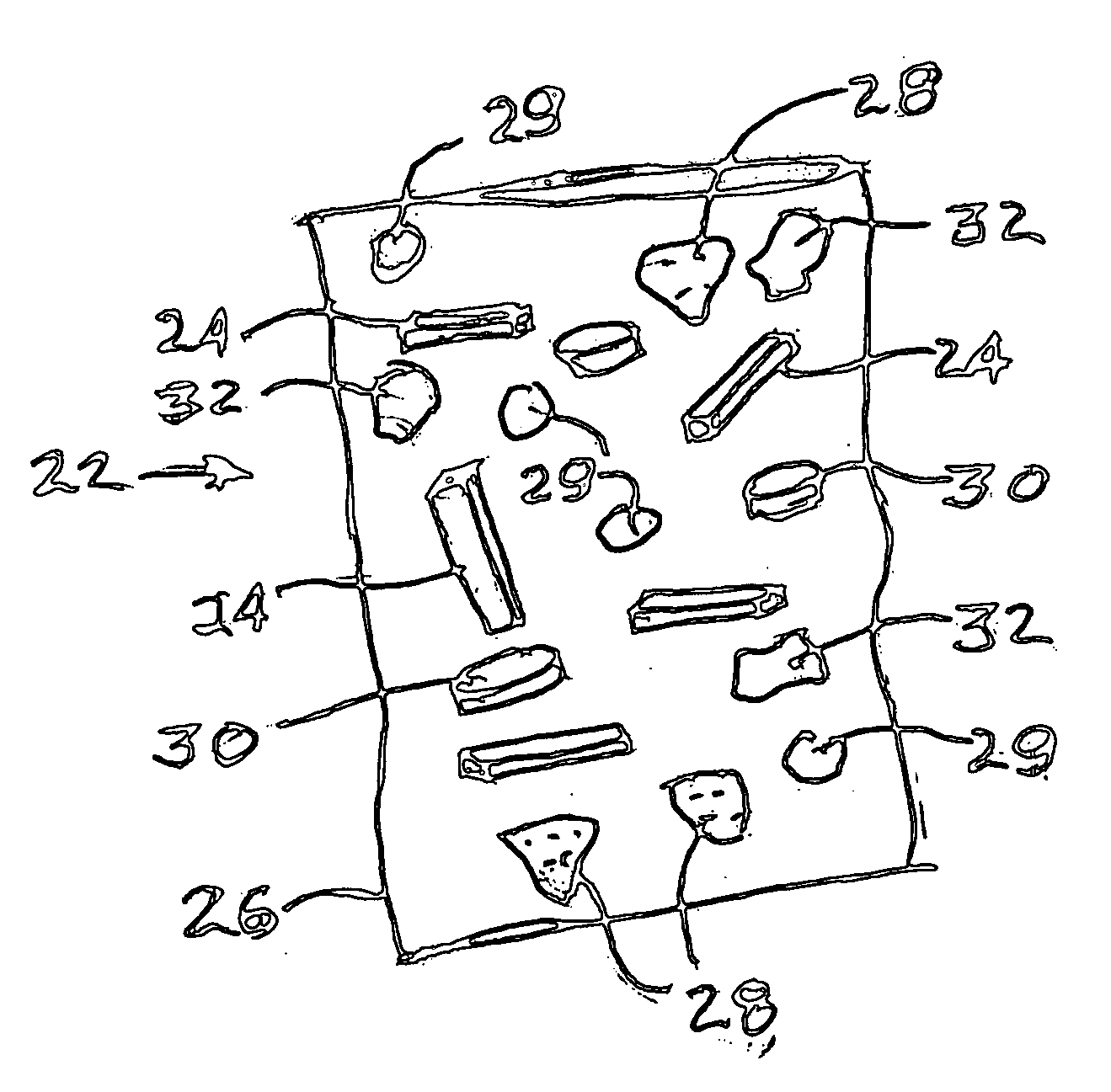

ActiveUS20150249243A1Reduce riskImprove reliabilityFinal product manufactureElectrode carriers/collectorsFiberMetallic lithium

Provided are a separator-integrated electrode and a nonaqueous electrolyte secondary battery with a reduced risk of a short circuit between electrodes due to precipitation of metallic lithium on a surface of an electrode mixture layer. A positive electrode (12) configured as a separator-integrated electrode includes a positive current collector (22), a positive active material layer (24) formed on a surface thereof, a first porous layer (26) formed on a surface of the positive active material layer (24) and containing inorganic particles, and a second porous layer (28) formed on a surface of the first porous layer (26) and made of resin fibers.

Owner:PANASONIC ENERGY CO LTD +1

Pearl fibre socks with skin-protection and health-care functions

The invention discloses a pair of pearl fibre socks with skin care health function, which is weaved by blended yarns. The blended yarns contain pearl fibre, the mass ratio of the content of the peal fibre in the blended yarns is 15-40 percent; and the blended yarns also contain one or the combination of multiple among chitin fibre, tencel fibre, polyamide fibre, modal fibre and cotton fibre. The invention has functions of far infrared ray transmission, ultraviolet ray prevention, skin acid base equilibrium regulation and bacteria inhibition, achieves multiple health effects for accelerating the foot blood circulation, promoting the metabolism of the human body, preventing the ultraviolet ray hurt, beautifying and protecting the skin, and resisting the bacteria and deodorizing, and has the advantages of soft and smooth texture, good durability, and comfortable wearing.

Owner:DONGHUA UNIV +1

Viscous Cosmetic

ActiveUS20070251541A1Improve storage conditionsLight evenlyCarpet cleanersDispensing apparatusFront edgeBiomedical engineering

A viscous cosmetic product that realizes smooth application thereof to application target areas and that prevents liquid dripping thereof onto a surface of a viscous cosmetic substance container and is free from stickiness at use thereof, enabling clean use thereof. A viscous cosmetic substance containing 1.0 to 10.0 wt % of silicic anhydride is accommodated in a tubular accommodation part. A front edge wall of the accommodation part is furnished with one or more distribution ports for the viscous cosmetic substance, and an application face is provided outside the front edge wall. Furthermore, the accommodation part thereinside is fitted with an inner tray that enables pressing the viscous cosmetic substance accommodated in the accommodation part so as to enable the viscous cosmetic substance to be pushed outward through the distribution ports.

Owner:SHISEIDO CO LTD

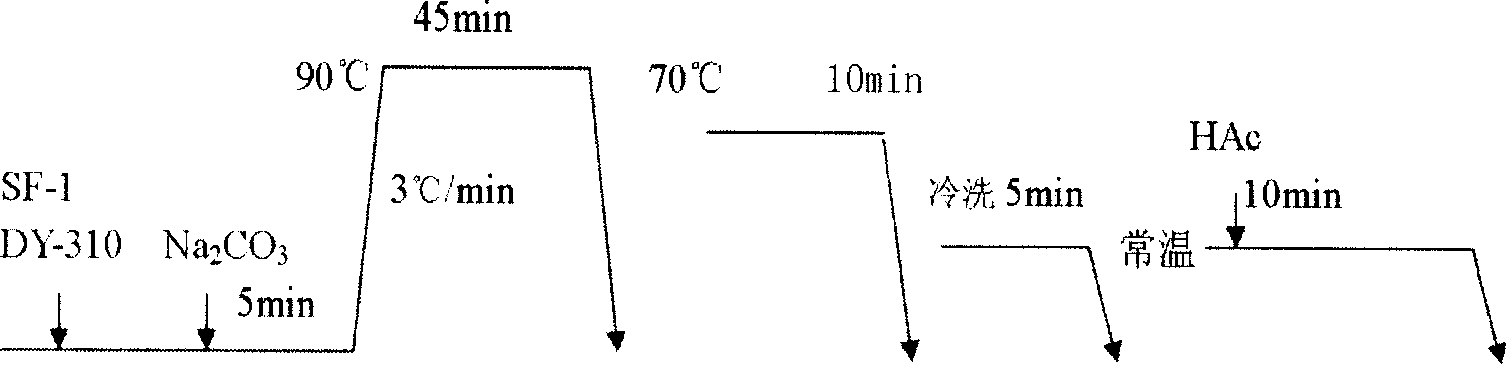

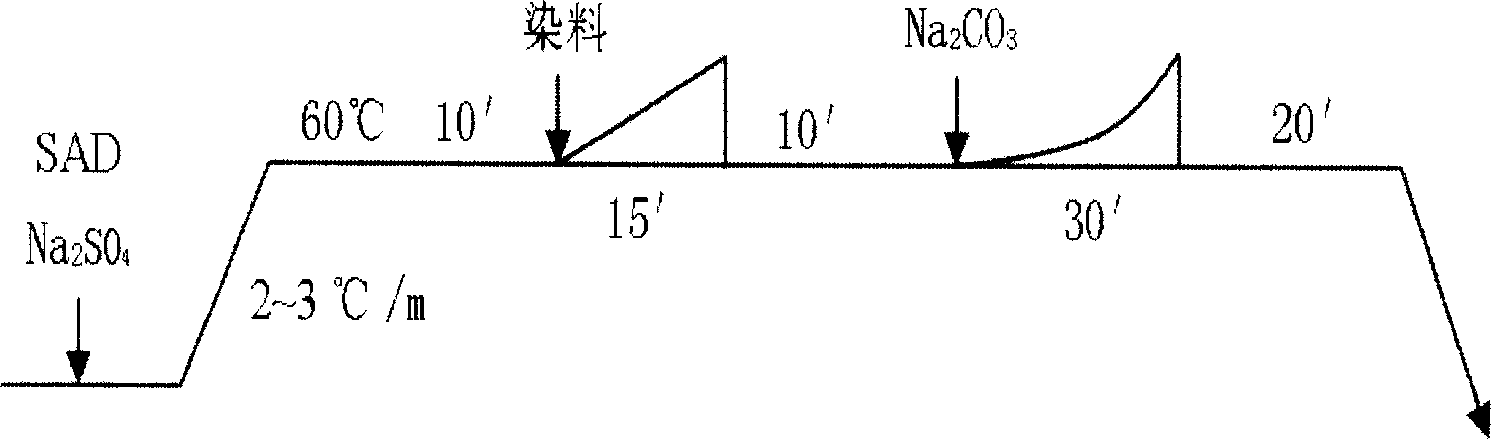

Copper ammonia fiber colored woven fabric and manufacturing process thereof

InactiveCN101173401AGood wear resistanceGood hygroscopicityMercerising of sliversSingeingUptake ratePlain weave

The invention relates to a cuprammonium rayon yarn-dyed fabric and the corresponding manufacturing process. The fabric is woven by interlacing a pure cotton yarn and a cuprammonium rayon yarn; wherein, the warp of the fabric is 32 to 40 pure cotton dyed yarn, and the weft of the fabric is 32 to 40 cuprammonium rayon dyed yarn; the fabric texture is 11 / 13 compound twill or plain weave poplin. The manufacturing process mainly comprises yarn preparation, weaving, finishing and finished product examination, and the key of the process lies in the pre-treatment, dyeing, and post-treatment of the weft and the finishing of the fabric. The invention has the advantages that: for the fabric, the property of strength and good wear resistance of the cuprammonium rayon is rational utilized; the hygroscopicity, the air permeability, the antistatic property, the soft, smooth and qualitative texture, the wearing comport and the excellent wearability of the fabric are ensured; for the manufacturing process, shortcomings such as uneven dyeing, big color difference between inner and outer layers of the package, big color difference between batches and low one time dyeing rate in the package dyeing caused by high dyeing uptake rate, high dyeing uptake amount and high fixation amount of the cuprammonium rayon are overcome.

Owner:天津市荣泽纺织有限公司

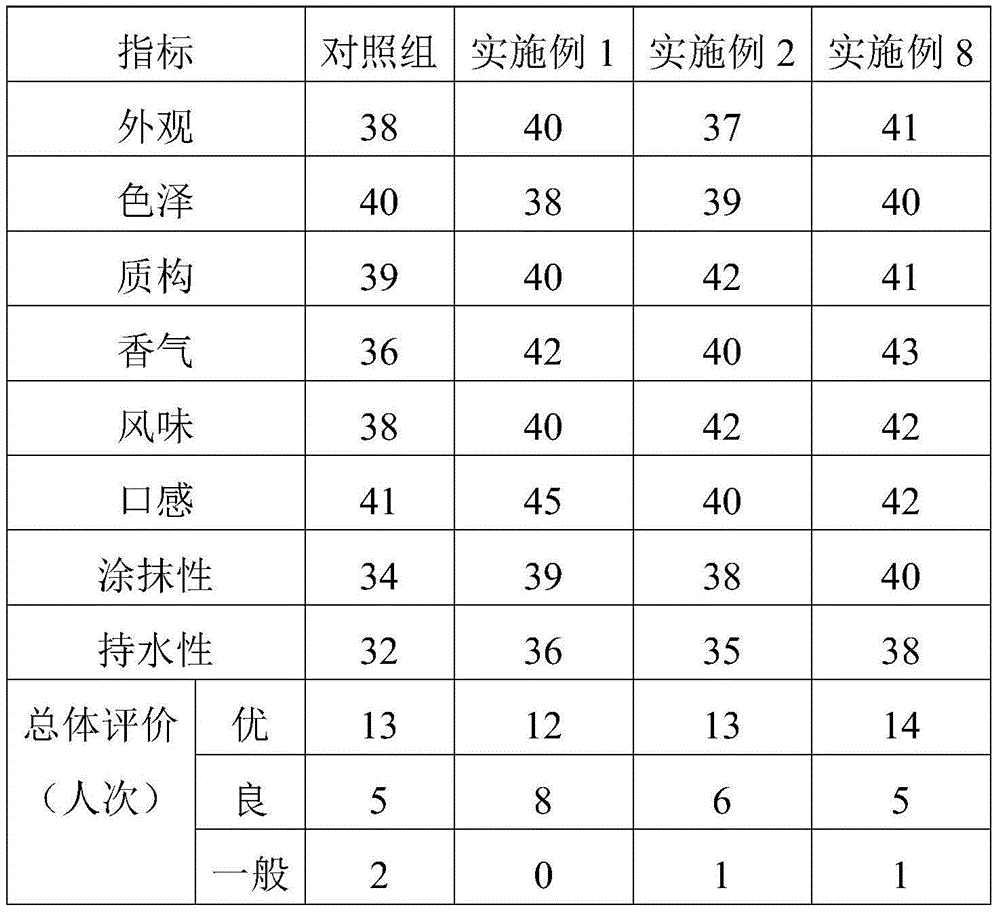

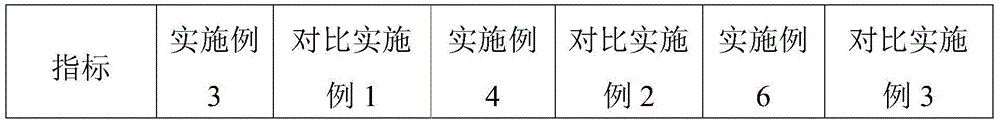

Single cream cheese and preparation method thereof

The invention discloses a single cream cheese and a preparation method thereof. The preparation method of the single cream cheese comprises the following steps: S1: (1) carrying out heat treatment on skimmed milk at 88-95 DEG C for 5-10 minutes and cooling; mixing the skimmed milk with a lactic acid bacteria starter to obtain a mixture; fermenting the mixture at 30-35 DEG C until the pH (Potential of Hydrogen) is 4.5-4.7 to obtain a milk curd; cutting the milk curd and discharging whey to obtain a cheese curd; (2) adjusting the pH value of the whey to 4.5-4.6, agitating and boiling to obtain a whey curd; (3) sterilizing single cream and mixing the single cream with the lactic acid bacteria starter; fermenting at 20-25 DEG C to obtain sour single cream; S2: mixing the following raw materials including the cheese curd, the sour single cream, a milk solid product, a stabilizing agent and table salt; agitating at 80-82 DEG C; homogenizing and filling. The method is rapid in whey discharging and the prepared single cream cheese is relatively good in flavor, texture and coating performance.

Owner:BRIGHT DAIRY & FOOD

Crystal mochi preblended flour, crystal mochi and preparation method thereof

InactiveCN105558755AExcellent acid and high temperature resistanceExcellent mechanical shear resistanceFood scienceSodium dehydroacetateMaltitol

The invention relates to the technical field of food and in particular discloses crystal mochi preblended flour, crystal mochi and a preparation method thereof. The crystal mochi preblended flour is prepared from the following raw materials in parts by weight: 10-15 parts of hydroxypropyl distarch phosphate, 8-13 parts of acetylated distarch phosphate, 0.5-0.7 part of maltitol, 0.2-0.4 part of monoglyceride, 0.04-0.06 part of sodium dehydroacetate and 0.04-0.06 part of citric acid. The crystal mochi is characterized in that a wrapper of the crystal mochi is prepared from raw materials, namely the crystal mochi preblended flour disclosed by the invention, water, emulsified oil and malt syrup. The mochi disclosed by the invention does not harden during storage, has good freeze-thaw stability, does not crack or collapse after being thawed, can maintain the original smooth and glutinous tastes and is long in quality guarantee period; and the prepared mochi is glittering and translucent in appearance and is soft, strong and not sticky and does not stick the mouth when entering the mouth, and the prepared mochi has good elasticity.

Owner:HENAN HENGRUI STARCH TECH CO LTD

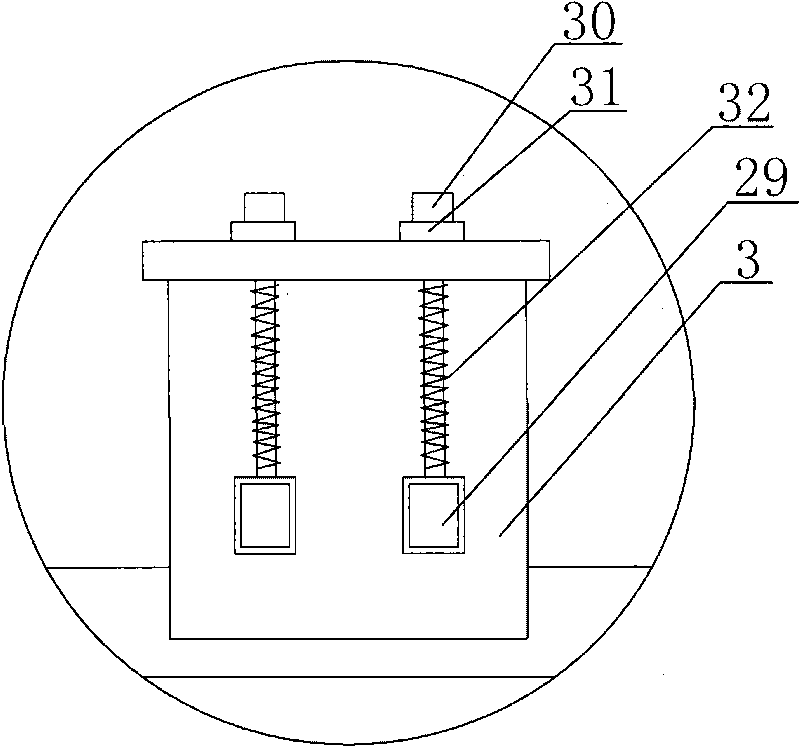

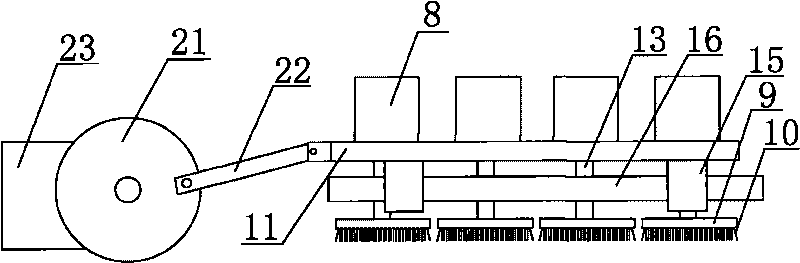

Wire drawing machine

InactiveCN101704206ARealistic three-dimensional effectSmooth texturePlane surface grinding machinesCircular discDrive motor

The invention discloses a wire drawing machine. Along a wood board transmission direction, the upper end face of a frame is orderly provided with a front steel wire roller which performs rough grinding on wood boards, a disk brush group which performs wire drawing on the wood boards and a rear steel wire roller which polishes the wood boards, wherein the disk brush group consists of a plurality of disk brushes which are distributed abreast; each disk brush is driven to rotate by a respective transmission motor of each disk brush and comprises a disk and steel wires densely distributed on the lower end face of the disk; the disks are all parallel to the upper end face of the frame and are all arranged on a disk brush mounting platform; a disk brush driving motor is fixedly arranged on the disk brush mounting platform; an output shaft of the disk brush driving motor runs through the disk brush mounting platform to be fixedly connected with the disks; and the disk brush group drives the steel wires to rotate through the disks. Compared with the conventional wire drawing machine, in the wire drawing machine of the invention, grooves and lines are widened, which not only increases the contact areas of the steel wires and the surfaces of the wood boards, but also increases a drawing force when the steel wires are contacted with the wood boards, thus the widening of the lines is benefited and the aim of achieving optimal wire drawing effect is achieved.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Dry rice noodle and manufacturing method thereof

InactiveCN104187389AWhite and bright appearanceFlexible textureFood shapingFood preparationDying processesEngineering

The invention discloses a manufacturing method of dry rice powder. The method comprises the steps as follows: rice selection, soaking, milk grinding, filter pressing, smashing, accessory adding, rice dough kneading, pressing, threading, aging, loosing and dying processes. Compared with the prior art, the method is characterized by further comprising the milk grinding, stock screening, dewatering, filter pressing and smashing steps. According to the method, after dewatering, an accessory is added, so that compared with conventional dry rice powder, the manufactured dry rice powder is white and bright in surface, flexible in texture, not prone to be burnt by poaching and uneasy to break by dry cooking; and compared with fresh wet rice powder, the dry rice powder is smooth in texture, fragrant, flavorful and good in taste.

Owner:GUILIN QUANZHOU MILANXIANG FOOD

Colorful TPU (thermoplastic polyurethane) foaming material, method for preparing shoe material by colorful TPU foaming material and application

ActiveCN104262940AHigh degree of expansionPrevent interface migrationFootwearThermoplastic polyurethaneHardness

The invention discloses a colorful TPU (thermoplastic polyurethane) foaming material, a preparation method and an application. The colorful TPU foaming material comprises colorful foaming particles or colorful foaming sheets, pigment concentration of the colorful foaming particles or the colorful foaming sheets is 0.01%-5% by weight, pigments inside and outside the colorful TPU foaming material have the same concentration, the hardness of the colorful TPU foaming material is HA 5-65, the density is 0.05-0.5 g / cm<3>, and the average cell size is smaller than 100 mu m. The colorful TPU foaming material has the characteristics of good inside and outside uniformity, absence of wrinkles on the surface and the like.

Owner:JINJIANG GUOSHENG SHOE MATERIAL LTD

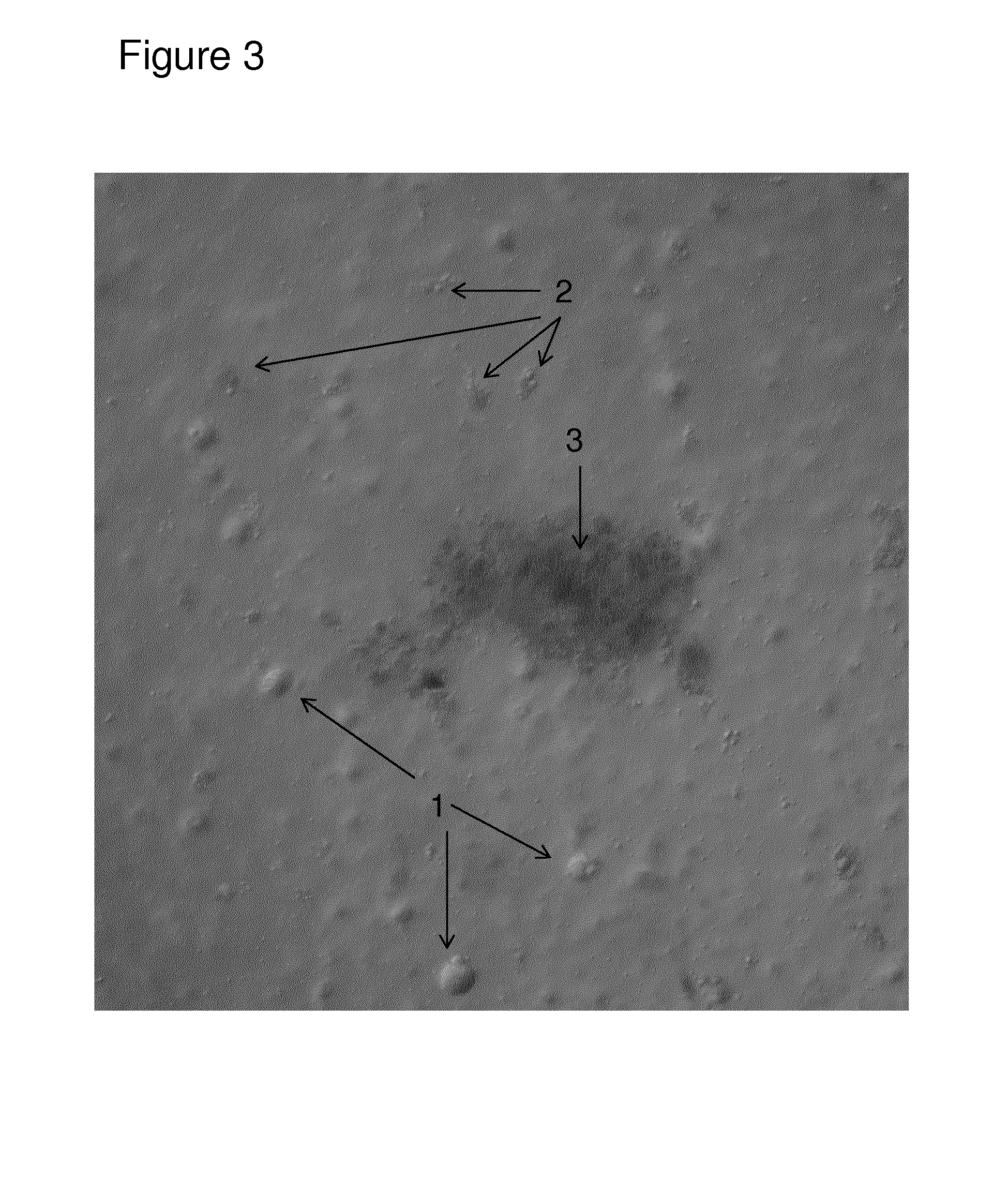

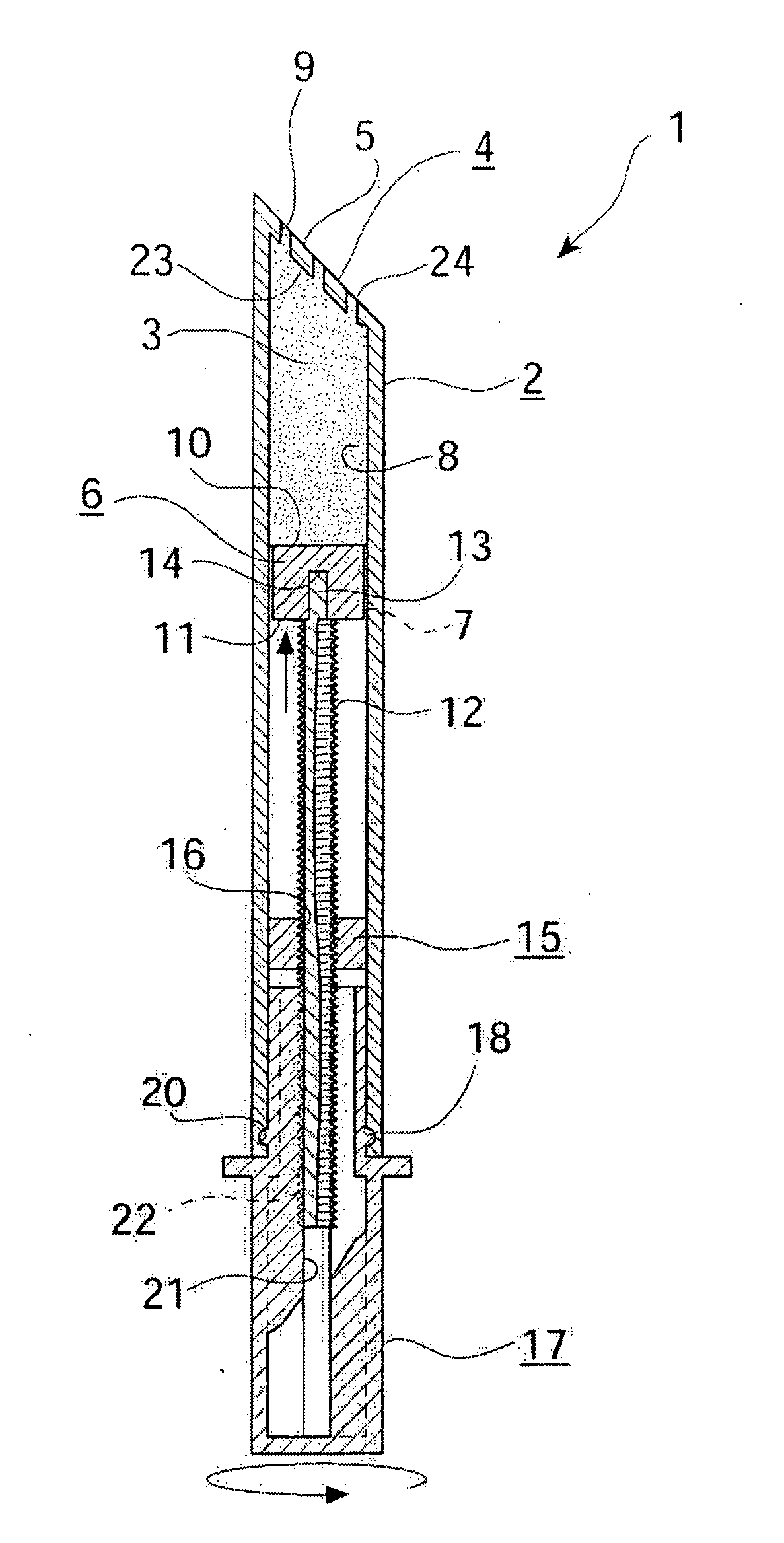

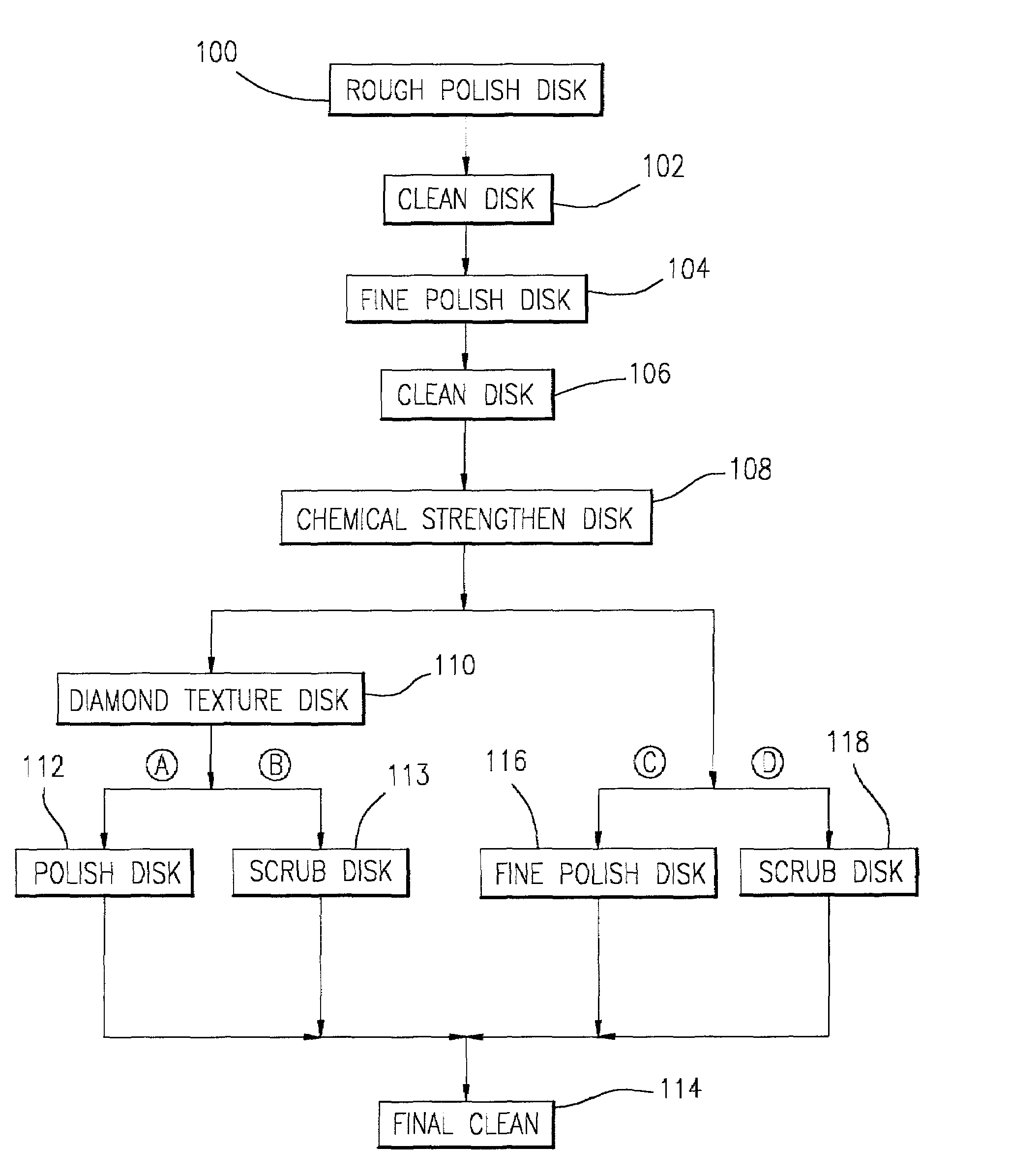

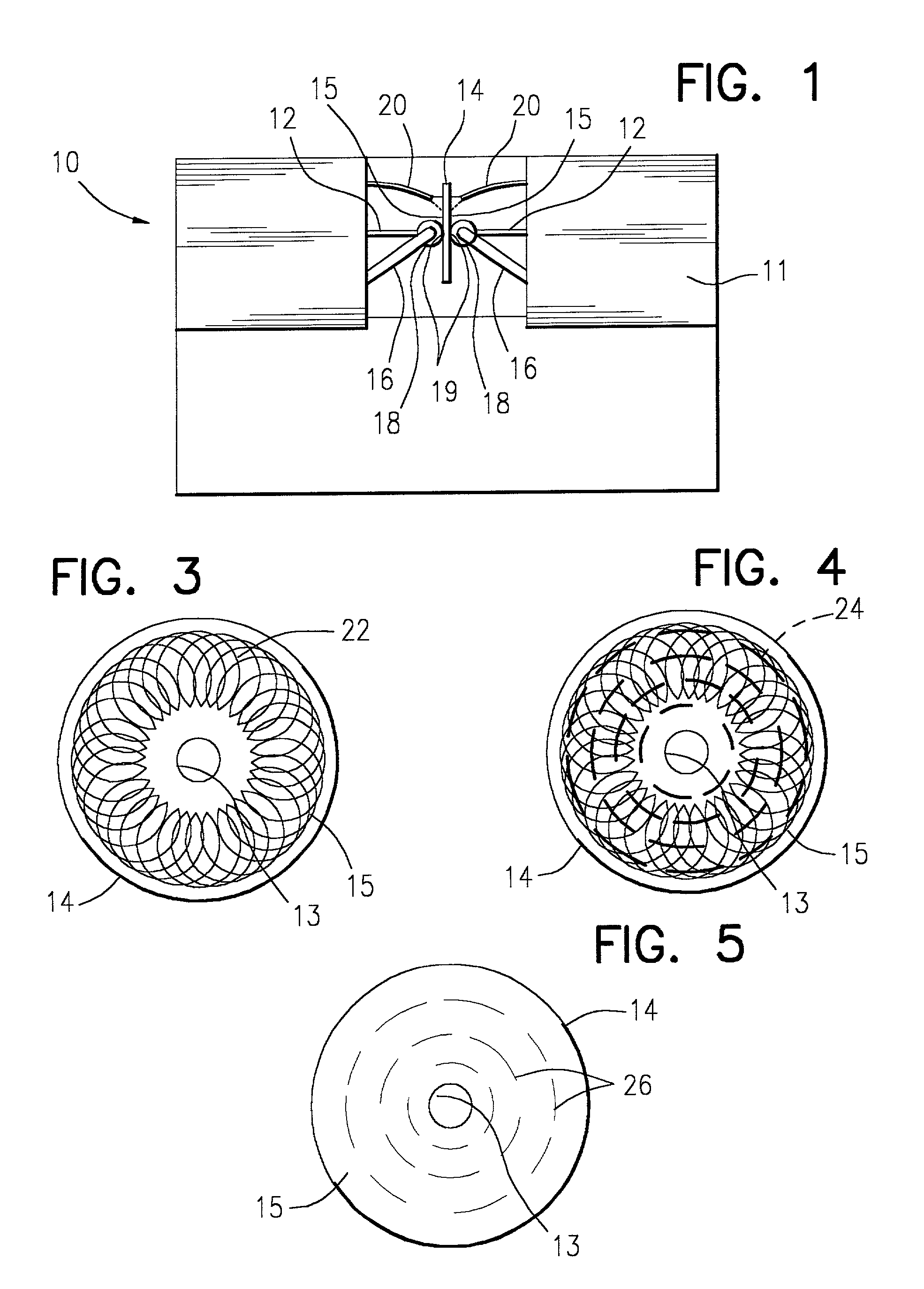

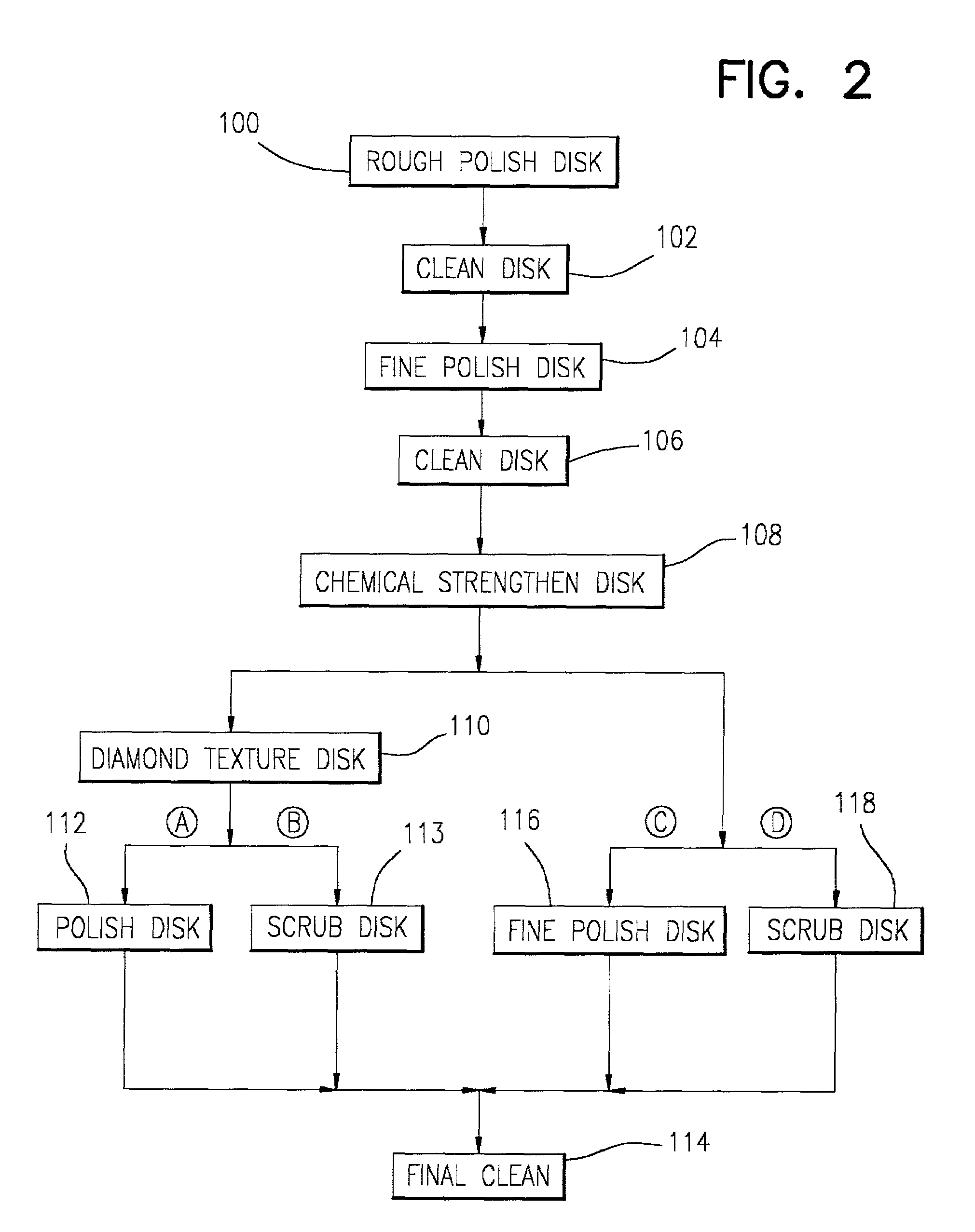

Process for producing glass disk substrates for magnetically recordable data storage disks

InactiveUS7070703B2Reduce failureAvoid layeringPolishing machinesRevolution surface grinding machinesColloidal silicaColloid

A polished glass disk is prepared for a magnetically recordable coating by texturing the surfaces with a highly abrasive material being abrasively engaged with the surfaces as the disk is rotated, thereby creating a relatively coarse texture with the abrasions concentric with the axis of rotation of the disk. Thereafter, the roughness of the texturing is reduced by abrading the surface of the disk with a polishing pad and an etchant slurry of colloidal silica. The etchant component has the property of attacking or softening the glass disk during the fine polishing with the colloidal silica slurry. As both the texturing step and the fine polishing step deposit a plurality of concentric abrasions on a glass disk, these abrasions aid in retaining the magnetically recordable coating deposited thereon to complete a magnetically recordable disk for use as a data storage member.

Owner:WESTERN DIGITAL TECH INC

System and method for food products

InactiveUS20100124592A1Without adversely impacting texture and mouth feel and color and flavorReduce bitter taste and smellFruit and vegetables preservationFood preparationFood formulationAdditive ingredient

A food development method to enrich a target food product recipe by the addition of ingredients made into dehydrated vegetable powders that when incorporated into a target food recipe replicates the taste, color, and texture of the target food product. The dehydrated vegetable powders are designed to minimize impact on color, taste, and texture when added to a target food product recipe.

Owner:FULL TANK FOODS

Health characteristic Caramel Flavored Confection, Chews, Hard Candy, and Caramel Flavored Milk

The present invention provides for caramel flavored confections, chews, hard candies or caramel flavored milk that has an improved, healthier fat structure, unique antioxidant taste profile, fiber component, and a 0% or greater supplement component that can add additional dietary benefits. Cholesterol reduction and cardiovascular health and removal of cholesterol from the bloodstream can be accomplished within certain compositions of this invention. Specific ratios of ingredients create a taste, texture, to mouthfeel, and rich flavor similar to a high milk fat or butter fat based caramel without the negative health ramifications of high milk fat based type caramels. Additionally, the method for preparing a caramel flavored confection, chews, and milk with these improved health characteristics, taste profile, and dietary benefits are covered.

Owner:ERVIN GARY

Topical skin formulation

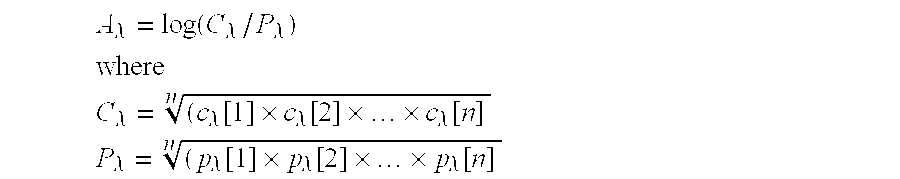

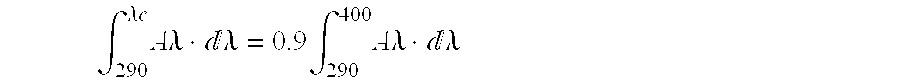

ActiveUS20130118517A1Smooth skinSmooth textureCosmetic preparationsMake-upSunscreen agentsUltraviolet b

Disclosed is a gel, and corresponding methods for its use, having an SPF of at least 15 comprising at least about 50% by weight of a volatile hydrocarbon, a film former, a solvent comprising an ester group, a combination of ultraviolet A (UVA) and ultraviolet B (UVB) sunscreen agents, wherein the UVA sunscreen agent comprises 4-tert-butyl-4′-methoxydibenzoylmethane, wherein the PFA of the gel is at least about 5 or at least about 8, and wherein the gel is capable of drying within two minutes after topical application to skin.

Owner:MARY KAY INC

Use of ace inhibitors and/or angiostensin ii receptor antagonists for the improving and/or maintaining the skin tone and for the treatment of skin ageing

InactiveUS20090143458A1Reduced gene expressionIncrease gene expressionCosmetic preparationsBiocideNK1 receptor antagonistDepressant

The present invention relates to use of an ACE inhibitor and / or angiotensin II receptor antagonist of the preparation of a medicament for the treatment of skin ageing or wrinkling. Furthermore, the present invention relates to use of an ACE inhibitor and / or angiotensin II receptor antagonist for the preparation of a cosmetic composition.

Owner:ACE APS

Essence cream realizing repairing at night

InactiveCN107714562ARepair damageProtection from oxidative damageCosmetic preparationsToilet preparationsSkin colorDimethyl siloxane

The invention provides essence cream realizing repairing at night. The essence cream realizing repairing at night comprises allantoin, EDTA-2NA, acrylic acid (ester) / C10-30 alkanol acrylate cross-linked polymer, hyaluronic acid, hydrogenated polyisobutene, cetyl ethyl hexanoate, glyceryl stearate / PEG-100 stearate, polydimethylsiloxane, C14-22 alcohol / C12-20 alkyl glucoside, shea butter oil, tocopherol acetate, polydimethylsiloxane / dimethiconol, methyl silanol mannuronic acid ester / sodium methyl hydroxybenzoate / sorbic acid / propyl hydroxybenzoate, water / butanediol / 1,2-hexanediol / beta-glucan / phenoxyethanol, water / phenoxyethanol / algae extract, nicotinamide, water / propylene glycol / flos buddlejae extract, and dipotassium glycyrrhizinate. The essence cream belongs to emulsified ointment essencewith the efficacies of repairing skin injuries and realizing the moisturizing effect. The essence cream system realizing repairing at night is stable, realizes permeation and absorption easily, is refreshing but not greasy, can effectively repair injuries caused to the skin by sunlight, can balance the skin color, can resist skin ageing, realizes effective moisturizing, and realizes regenerating and nursing at night.

Owner:NOX BELLCOW COSMETICS CO LTD

Compositions Comprising Soy Products and Dioic Acids

InactiveUS20070041931A1Combating and treating hyperpigmentationImprove skin firmnessBiocideCosmetic preparationsMedicineSoy product

This invention relates to topical compositions comprising soy products and dioic acids and their use in skin lightening, against hyperpigmentation and, in particular, against skin spots.

Owner:JOHNSON & JOHNSON CONSUMER FRANCE SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com