Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

820results about How to "Light evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

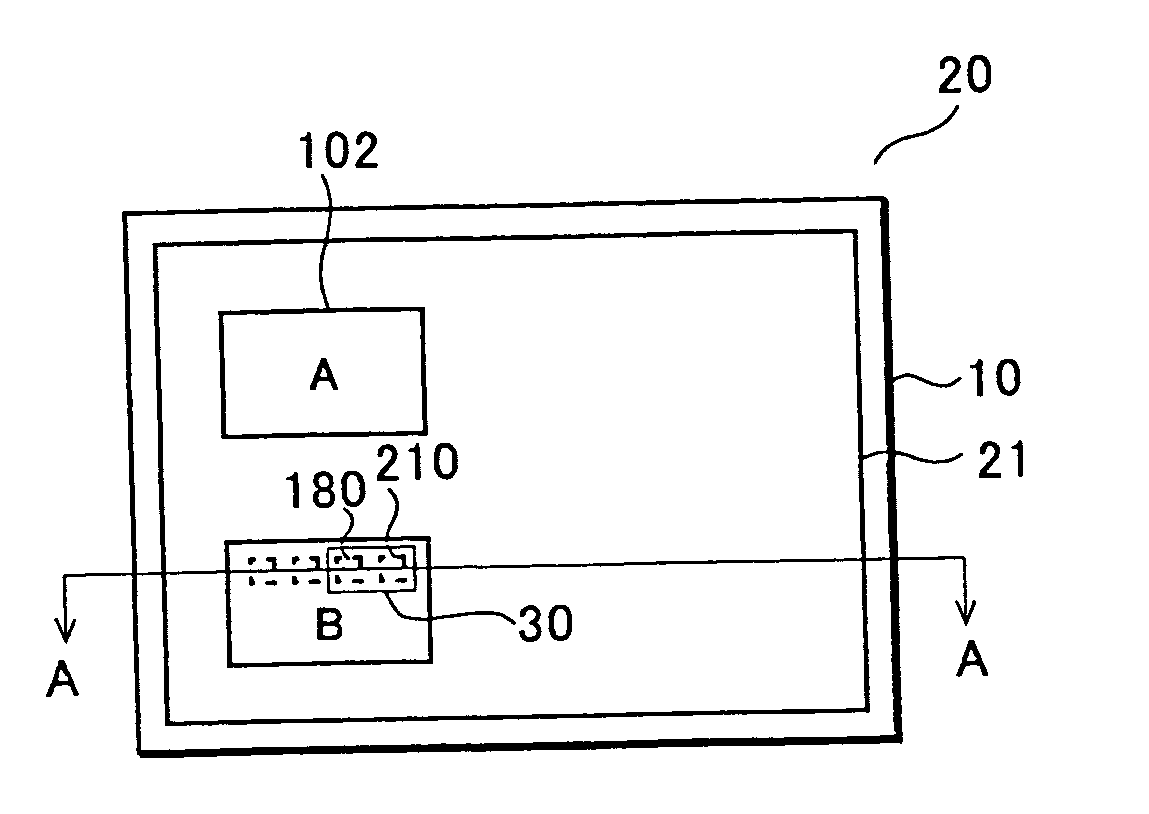

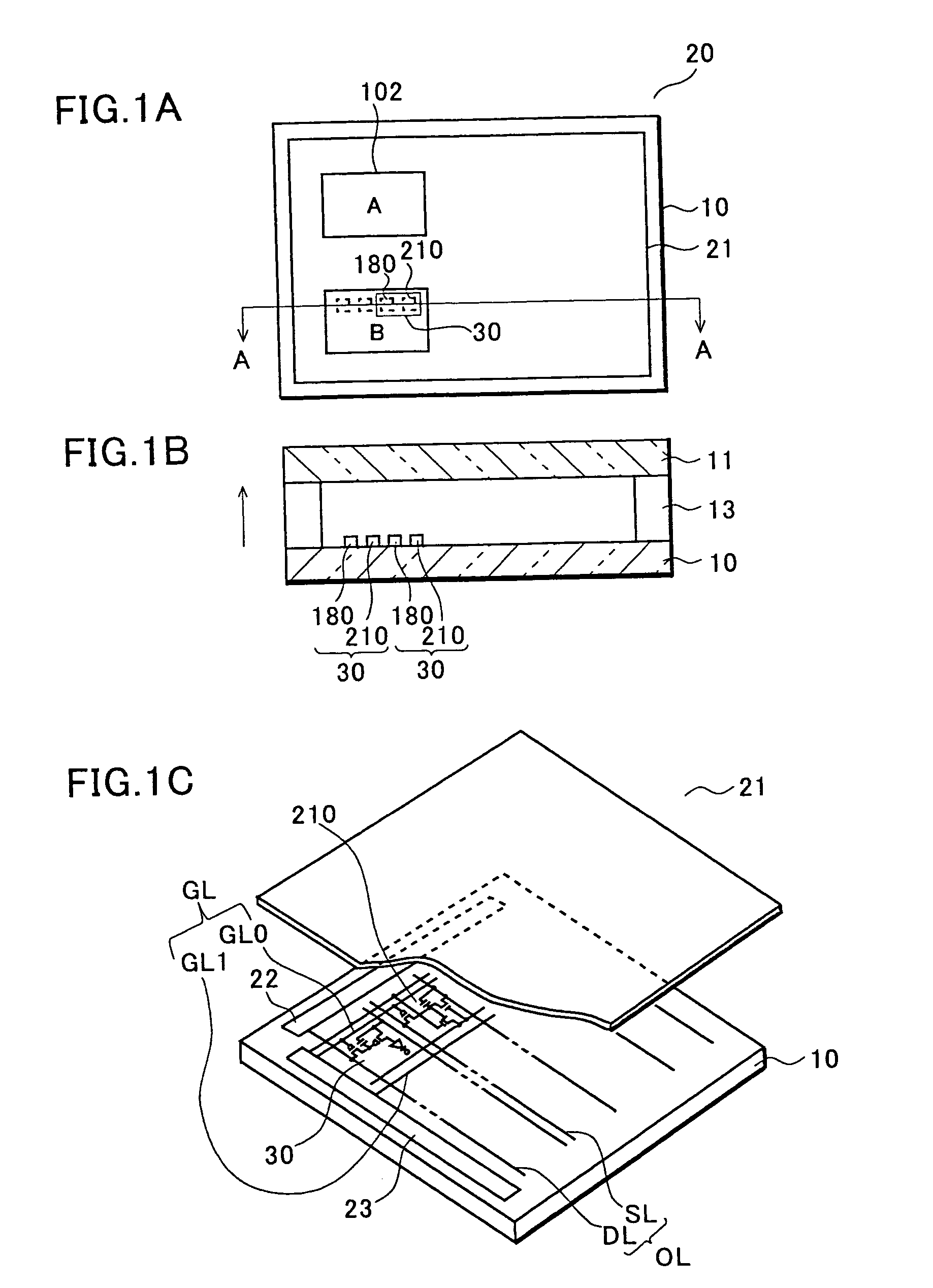

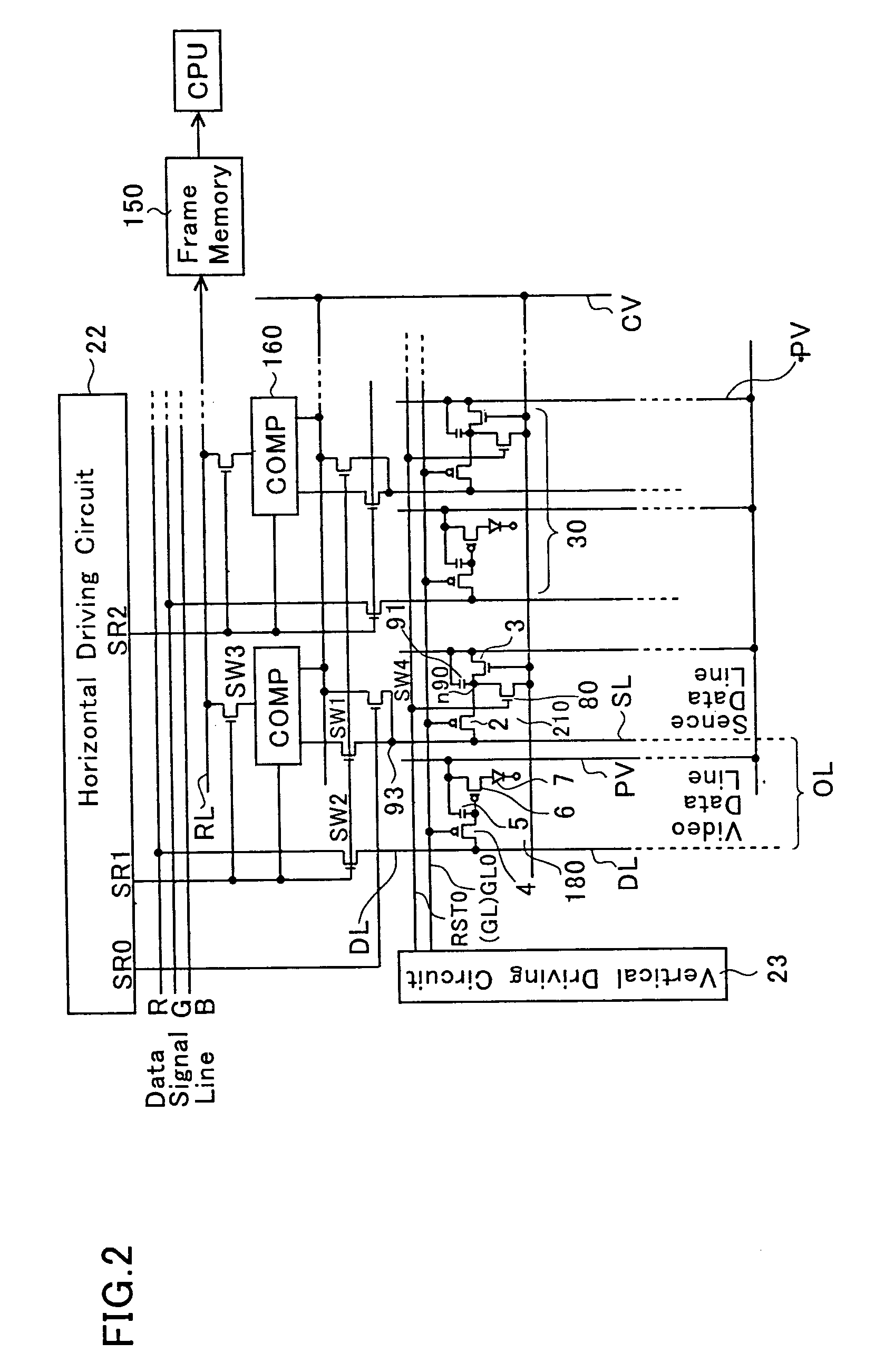

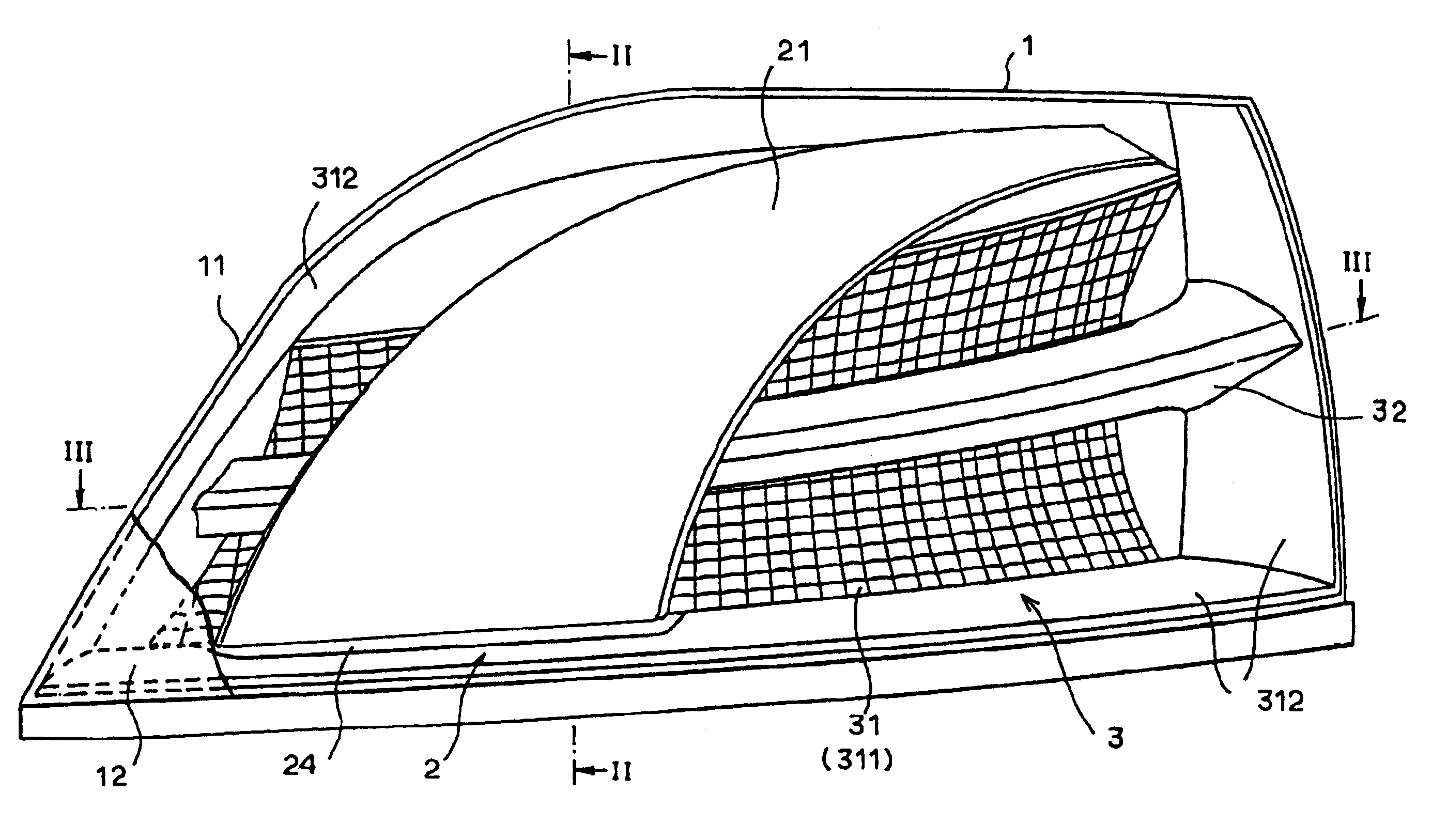

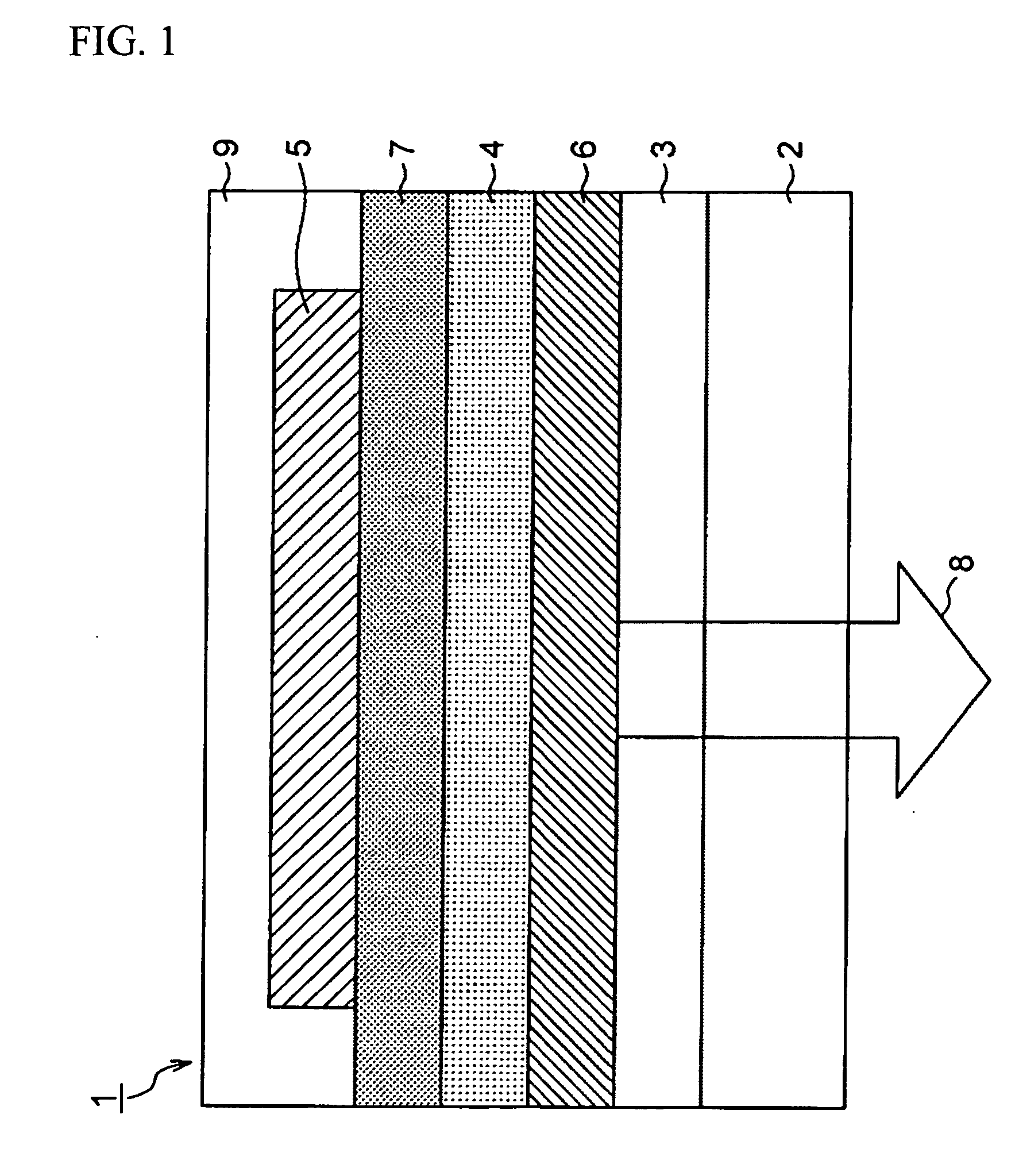

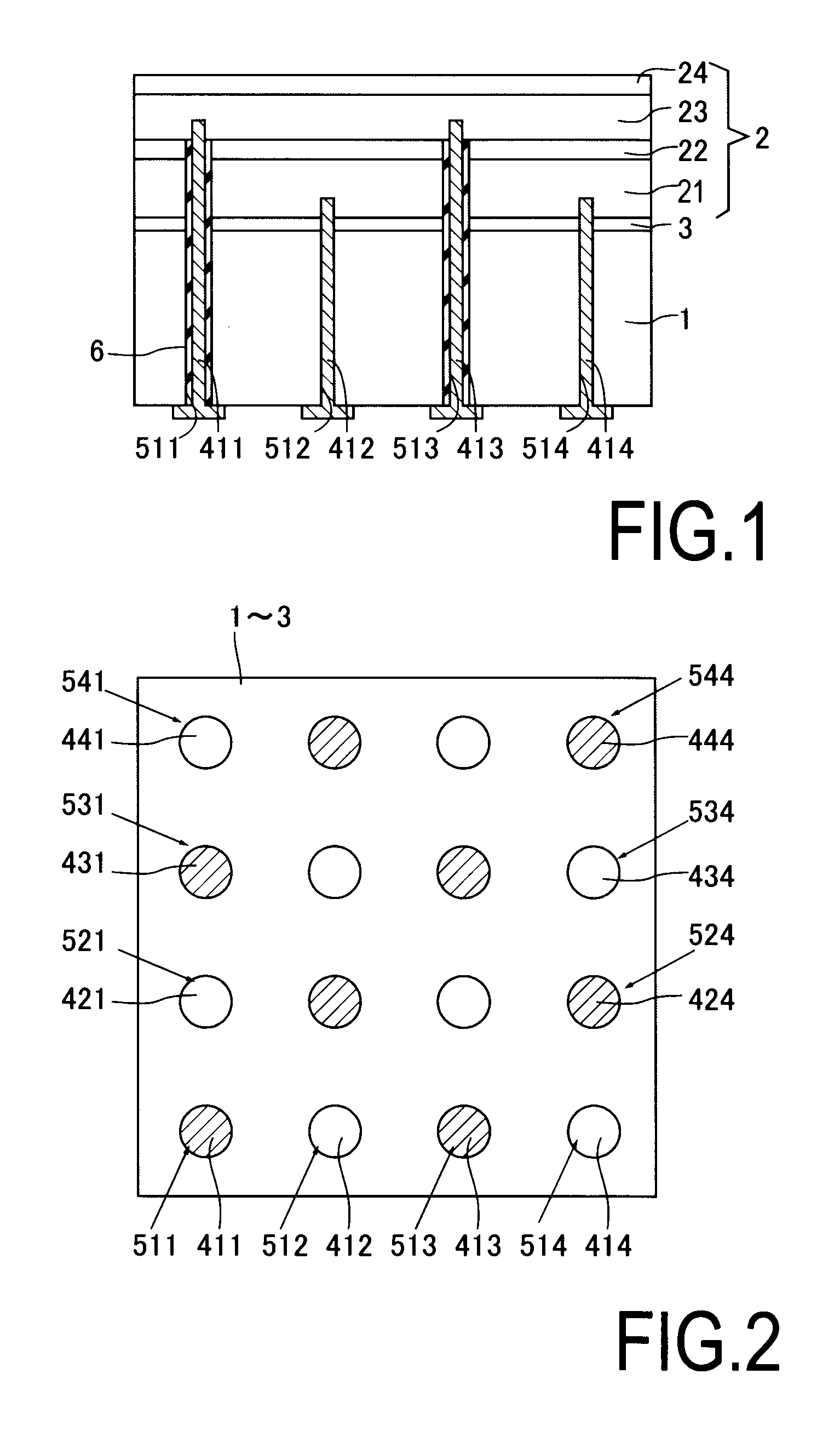

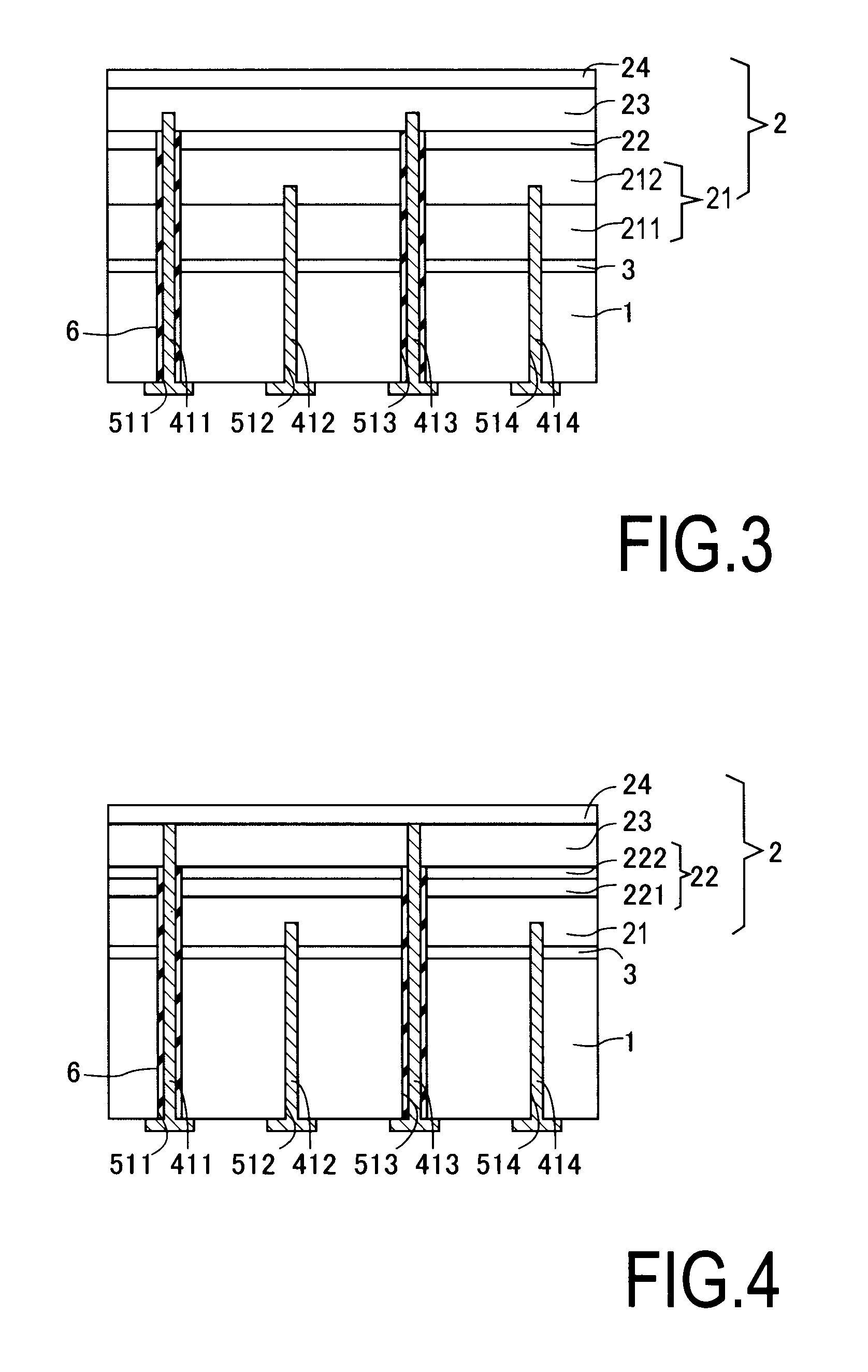

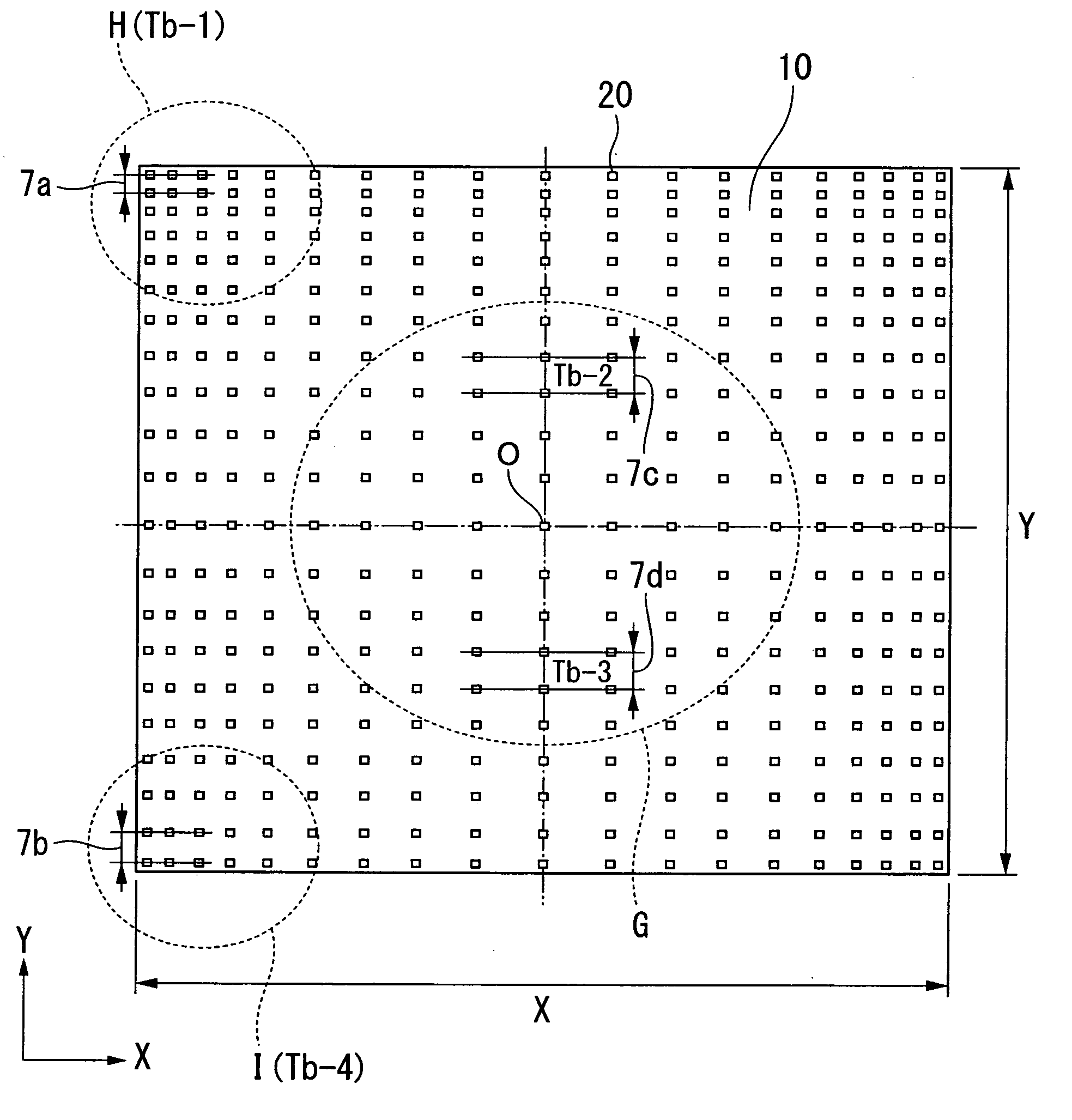

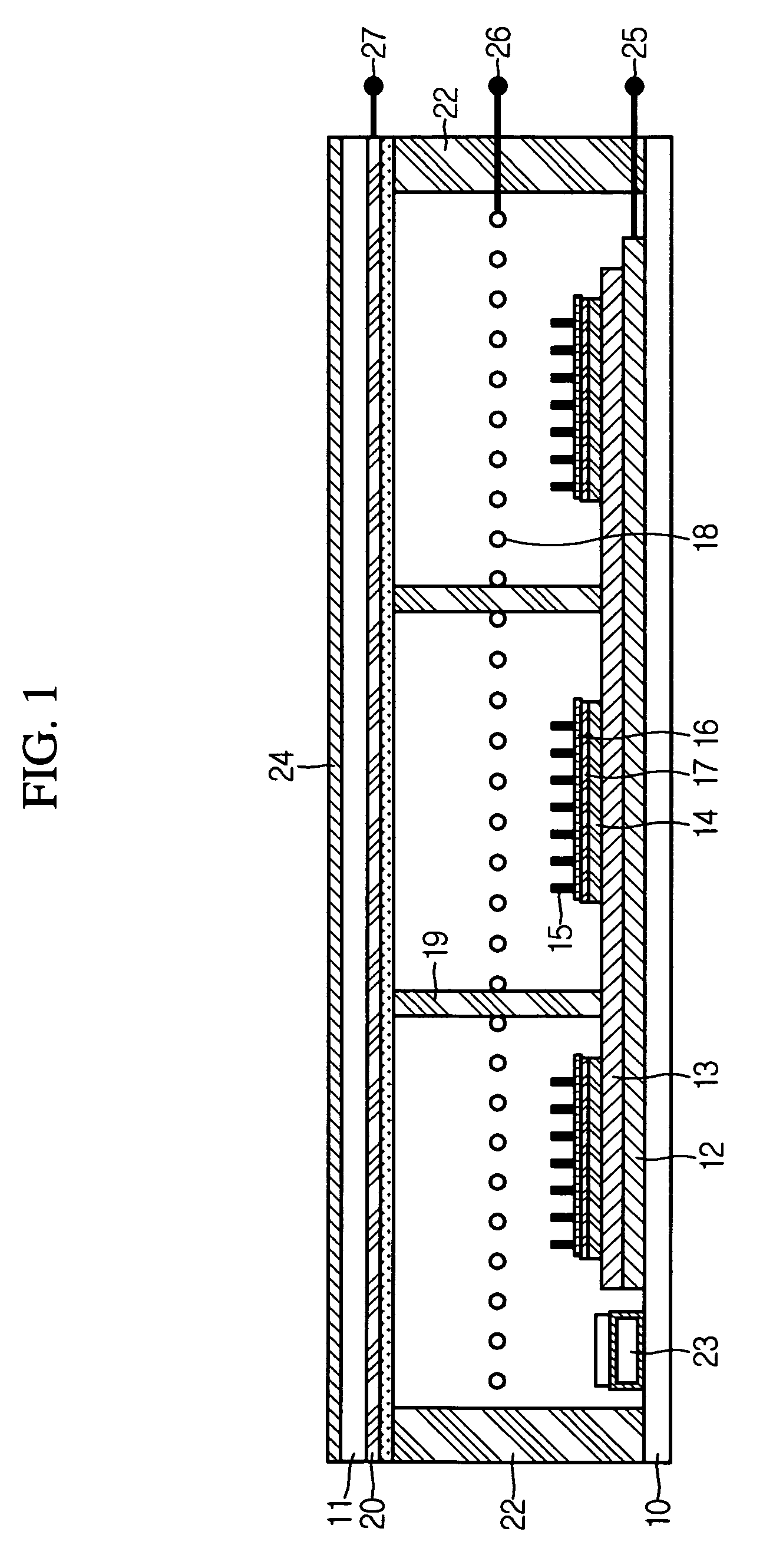

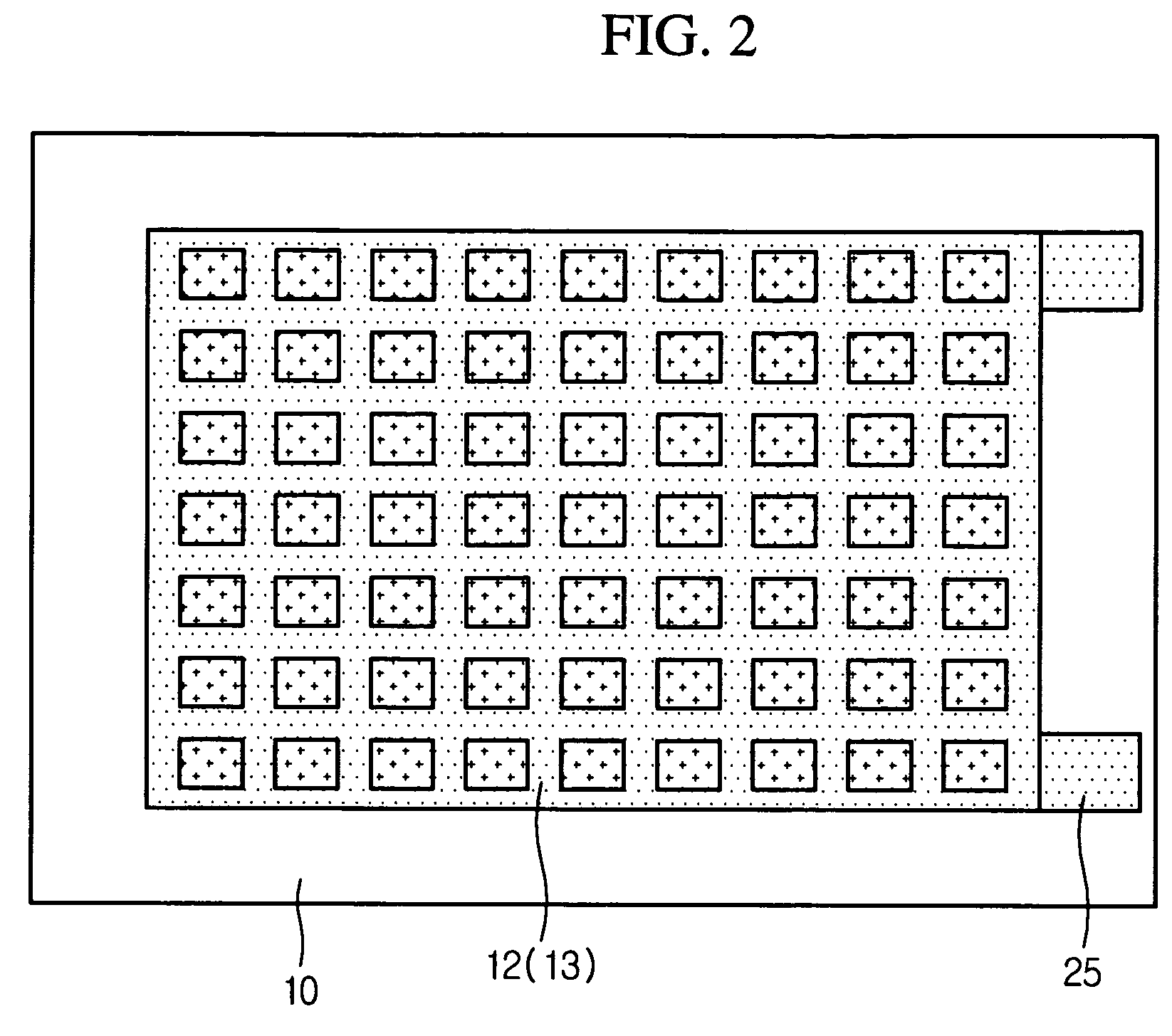

Touch panel

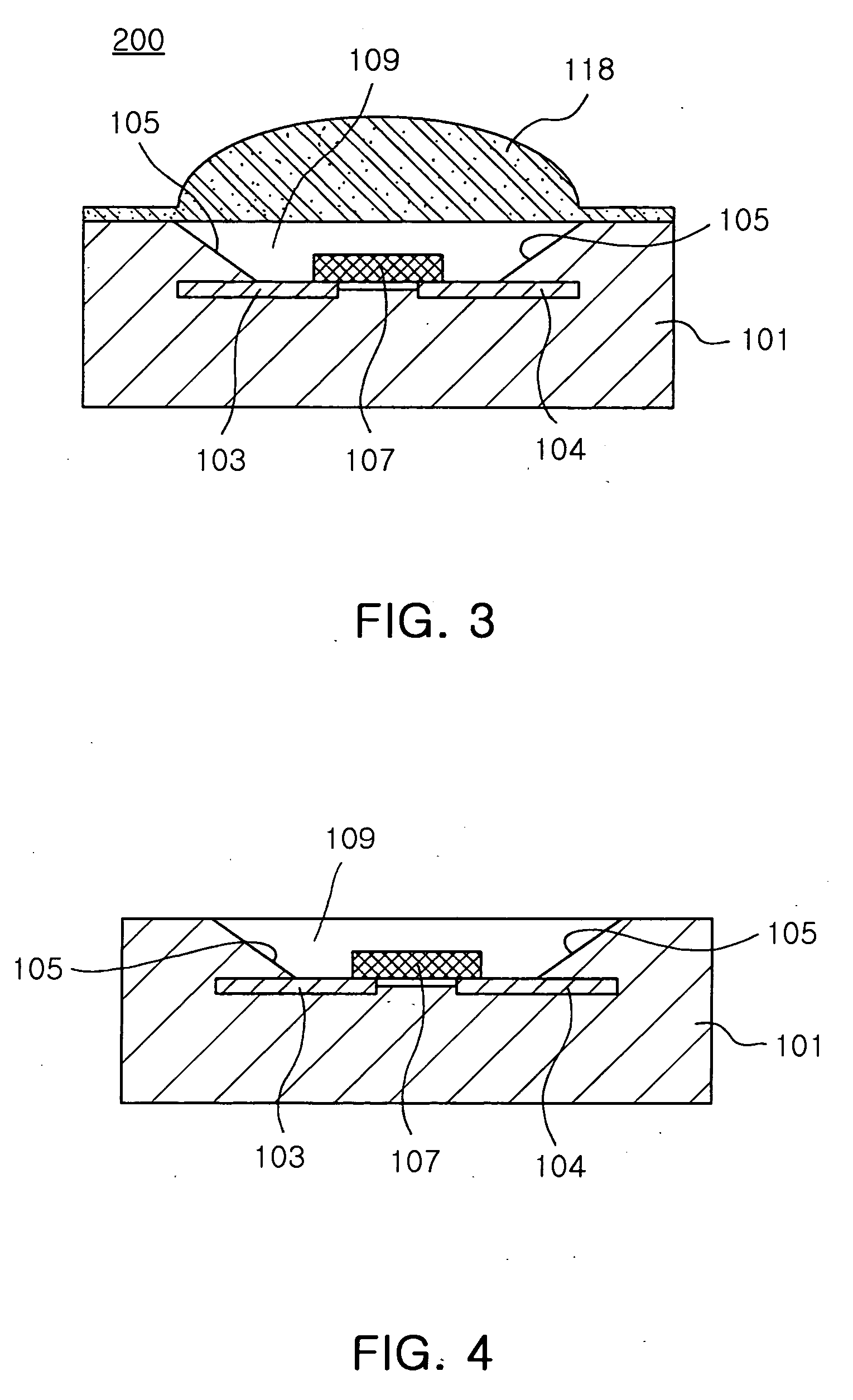

InactiveUS20060033016A1Precise positioningHinders miniaturizationMaterial analysis by optical meansCounting objects on conveyorsTouch panelEngineering

A photosensor and a display unit are fabricated on the same substrate. Input coordinates are identified by comparing the light quantities at positions (pixels) which is and is not touched by a finger or the like by use of a comparison circuit. Thus, TFTs to form the photosensor can be fabricated on the same substrate in the same process, and also reductions in manufacturing cost and the number of parts can be realized. A region required for disposing a sensor in the circumference becomes unnecessary, thus realizing the miniaturization of the device. Moreover, since a region to be a blind spot is eliminated in the display unit, it is possible to utilize the display unit effectively. It is possible to improve the precision of an input recognition and to uniformly perform detection all over the display unit. Furthermore, since the photosensor is constituted of a photoreceptor circuit which is capable of adjusting the sensitivity of receiving light, it is possible to make the sensitivity of receiving light (detection) uniform in the display unit.

Owner:SANYO ELECTRIC CO LTD

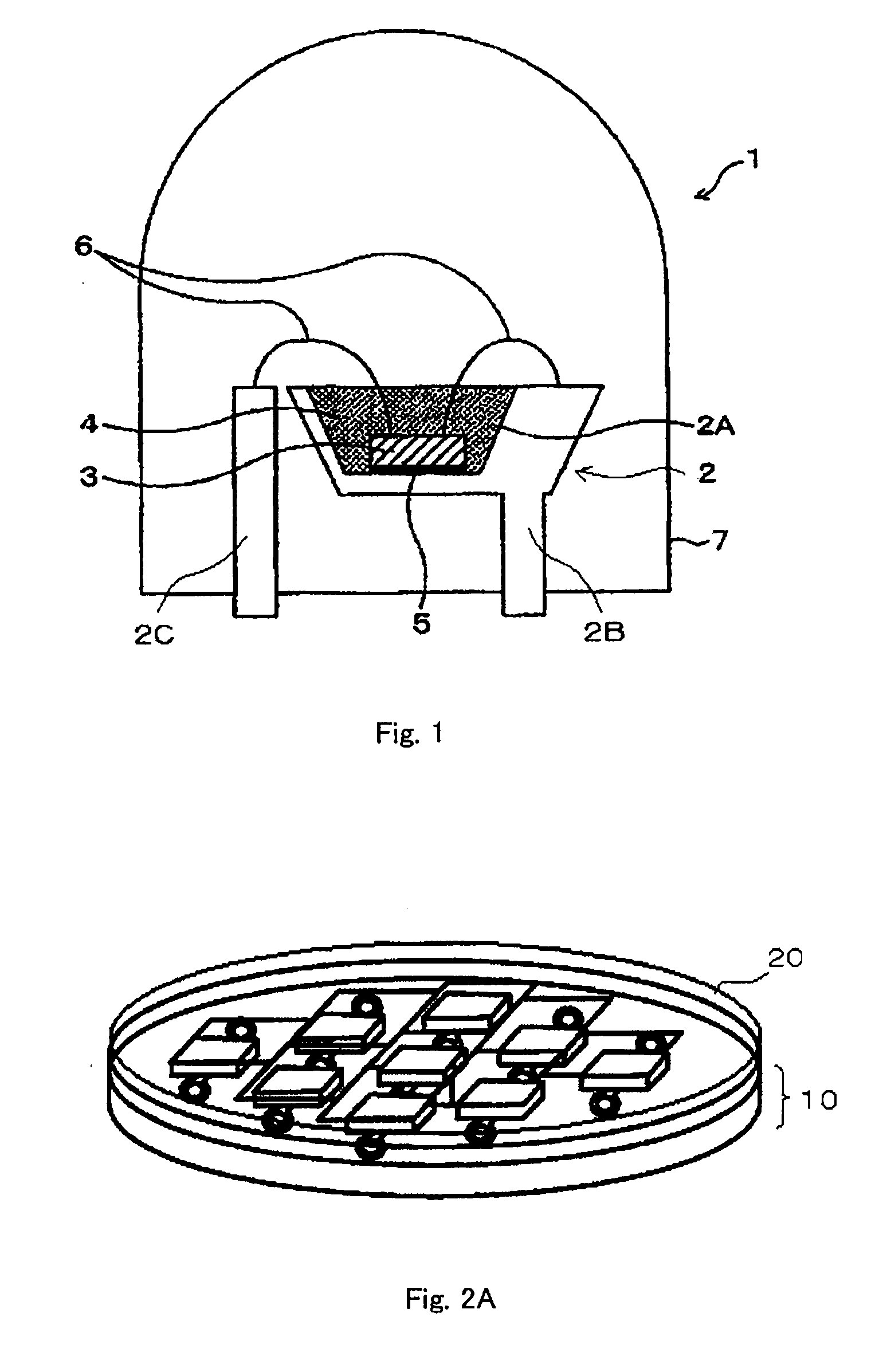

Lamp

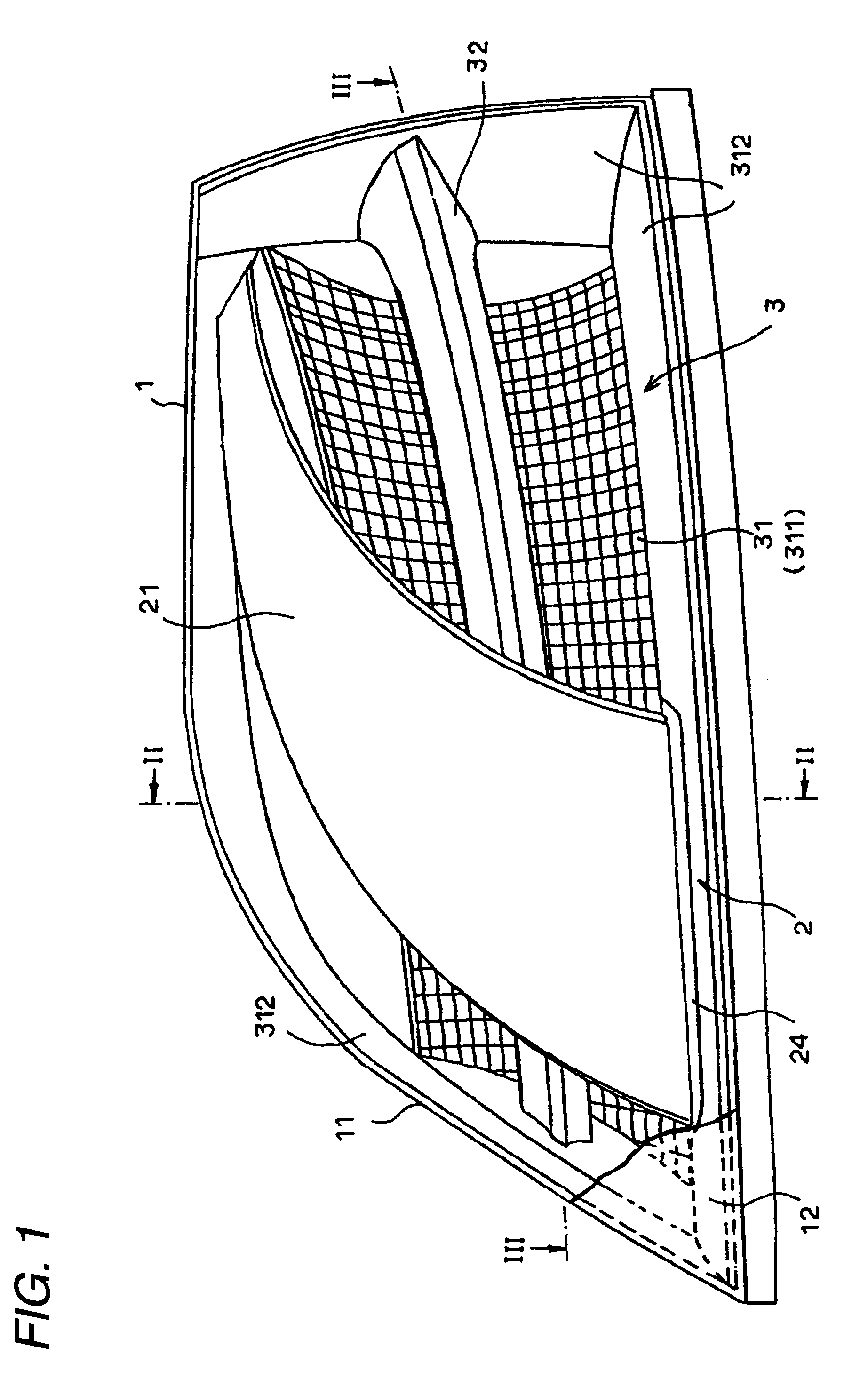

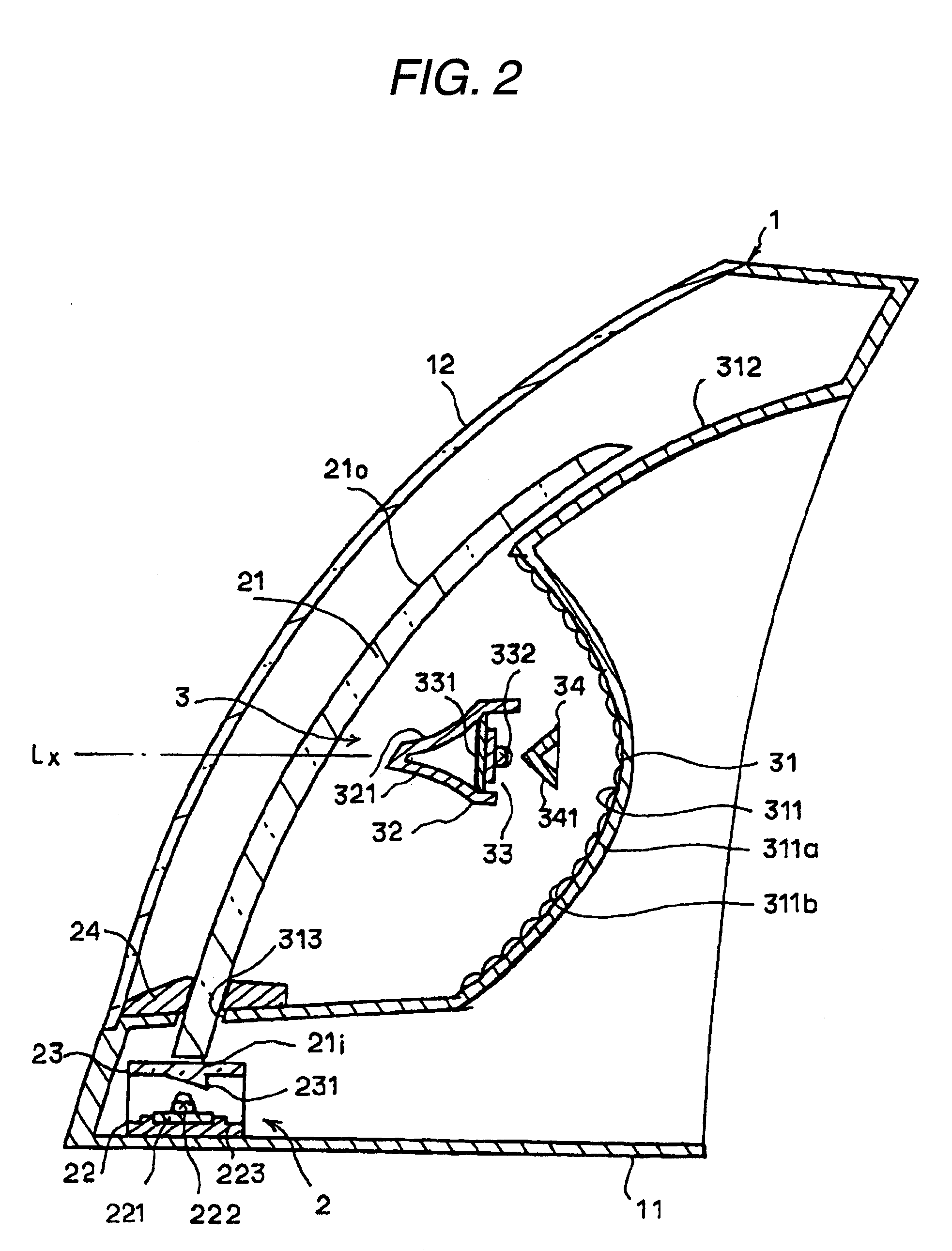

InactiveUS20100008088A1Increase light emitting areaGood lookingLighting support devicesPoint-like light sourceLight-emitting diode

A lamp is provided. The lamp includes a lamp housing; light emitting diodes (LEDs); a main reflector disposed so as to oppose to the LEDs for reflecting light emitted from the LEDs towards a front side of the lamp; a sub-reflector which is interposed between the LEDs and the main reflector, and which reflects and diffuses the light emitted from the LEDs towards the main reflector; an LED element assembly which extends in parallel with the sub-reflector and comprises a plurality of flat portions, each flat portion corresponding to one of the plurality of LEDs and on which the corresponding LED is mounted, adjacent ones of the flat portions being coupled together by at least one step portion; and a center portion which covers the LED element assembly and the LEDs such that the LEDs are not exposed to the front side of the lamp.

Owner:KOITO MFG CO LTD

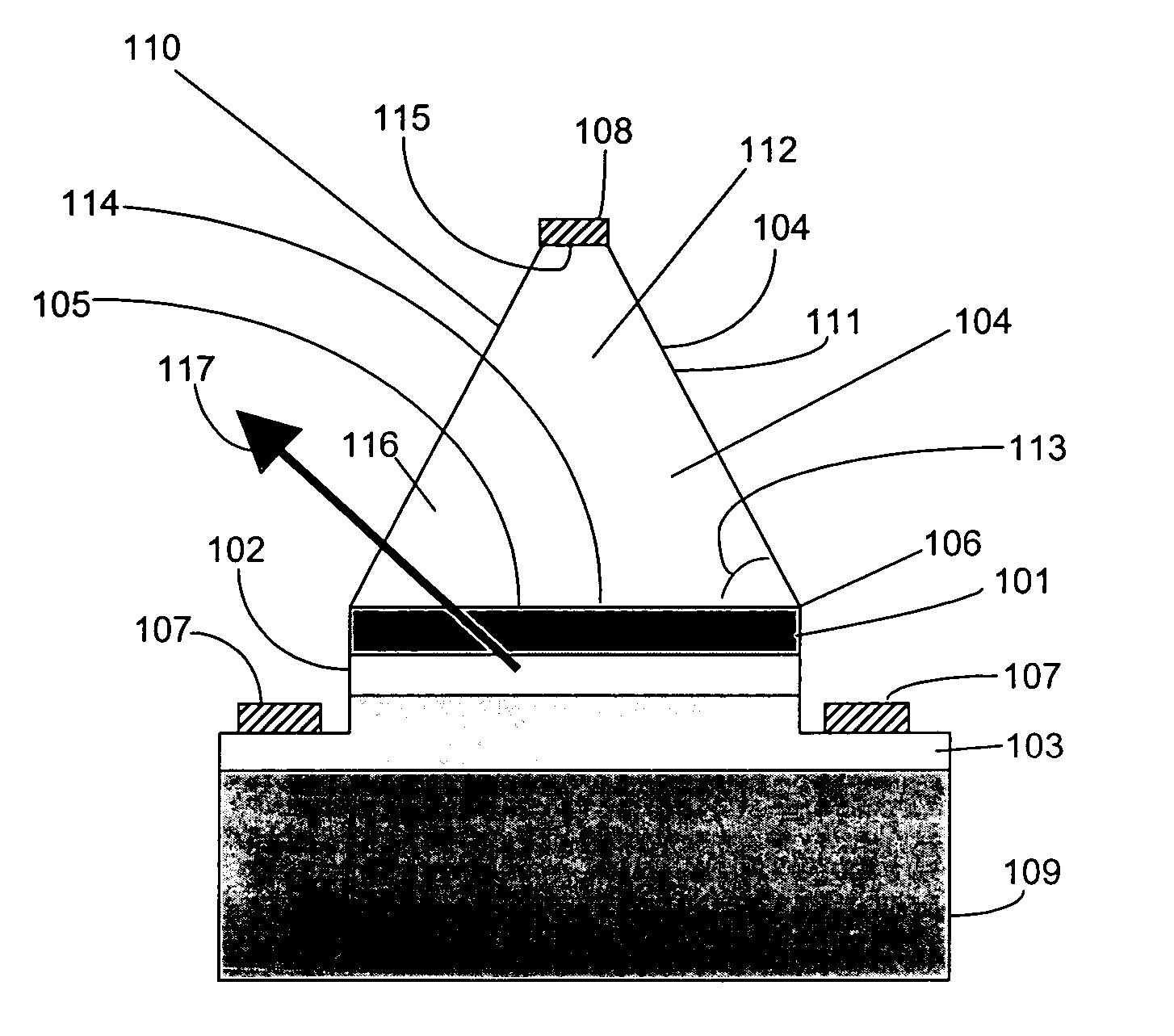

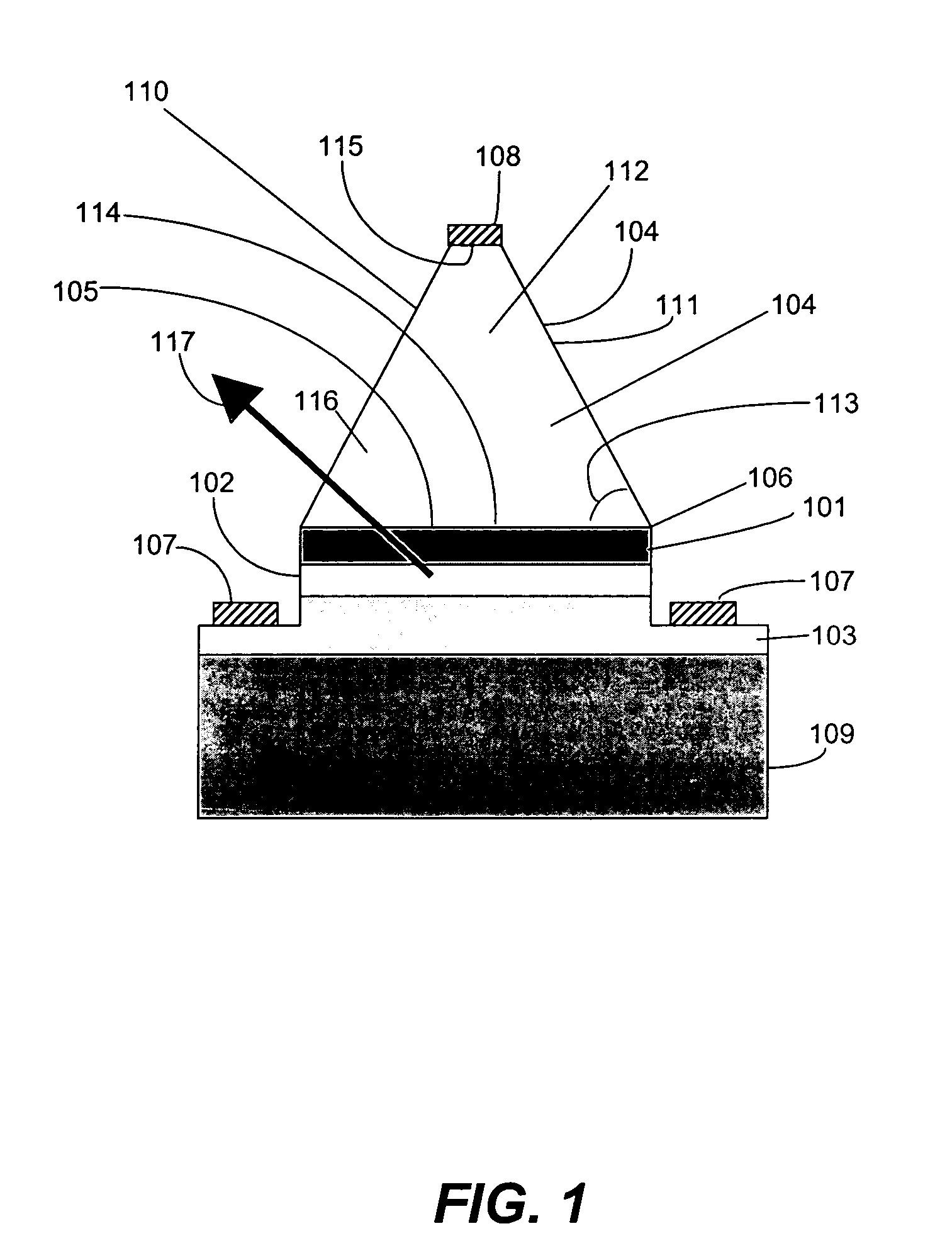

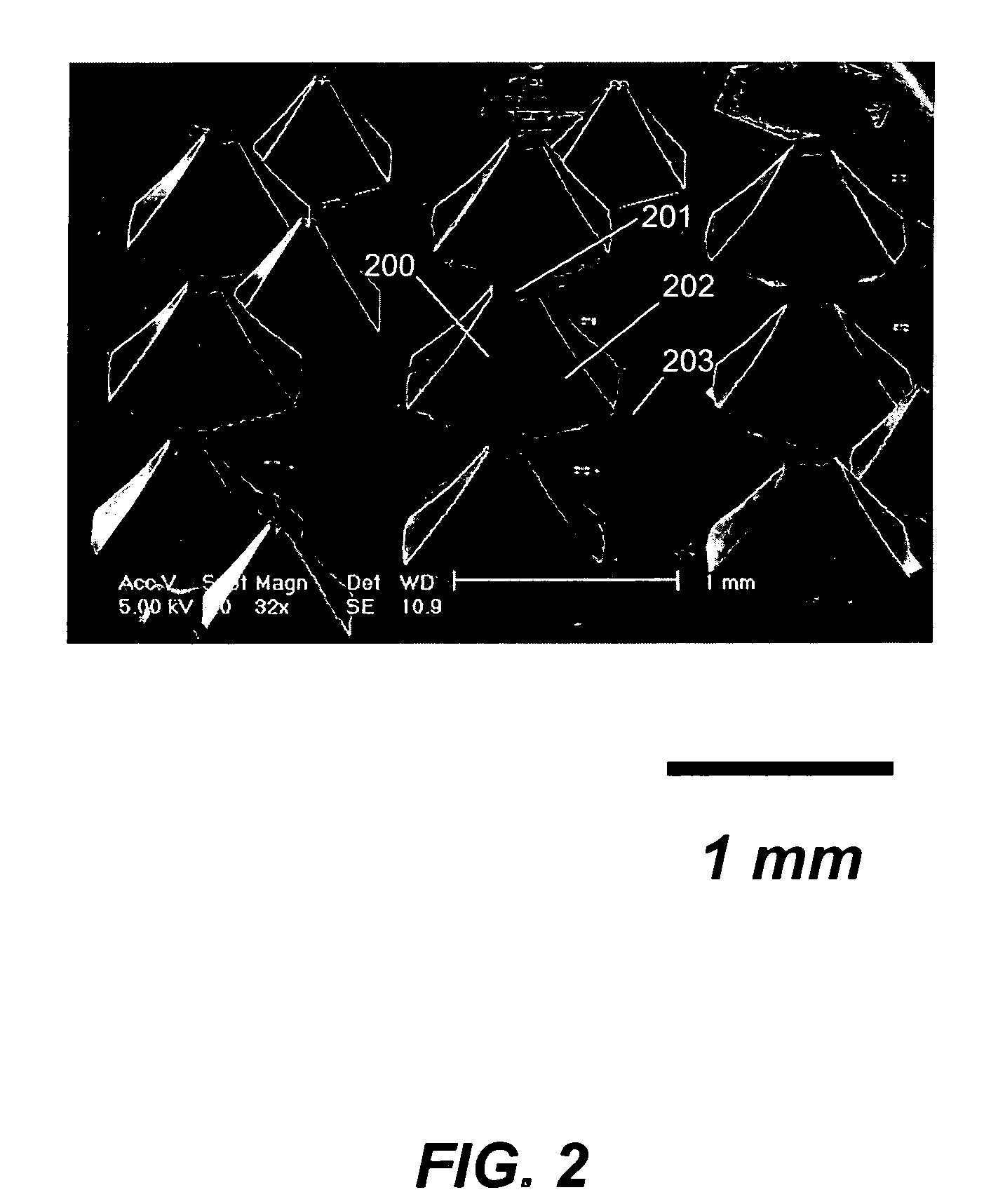

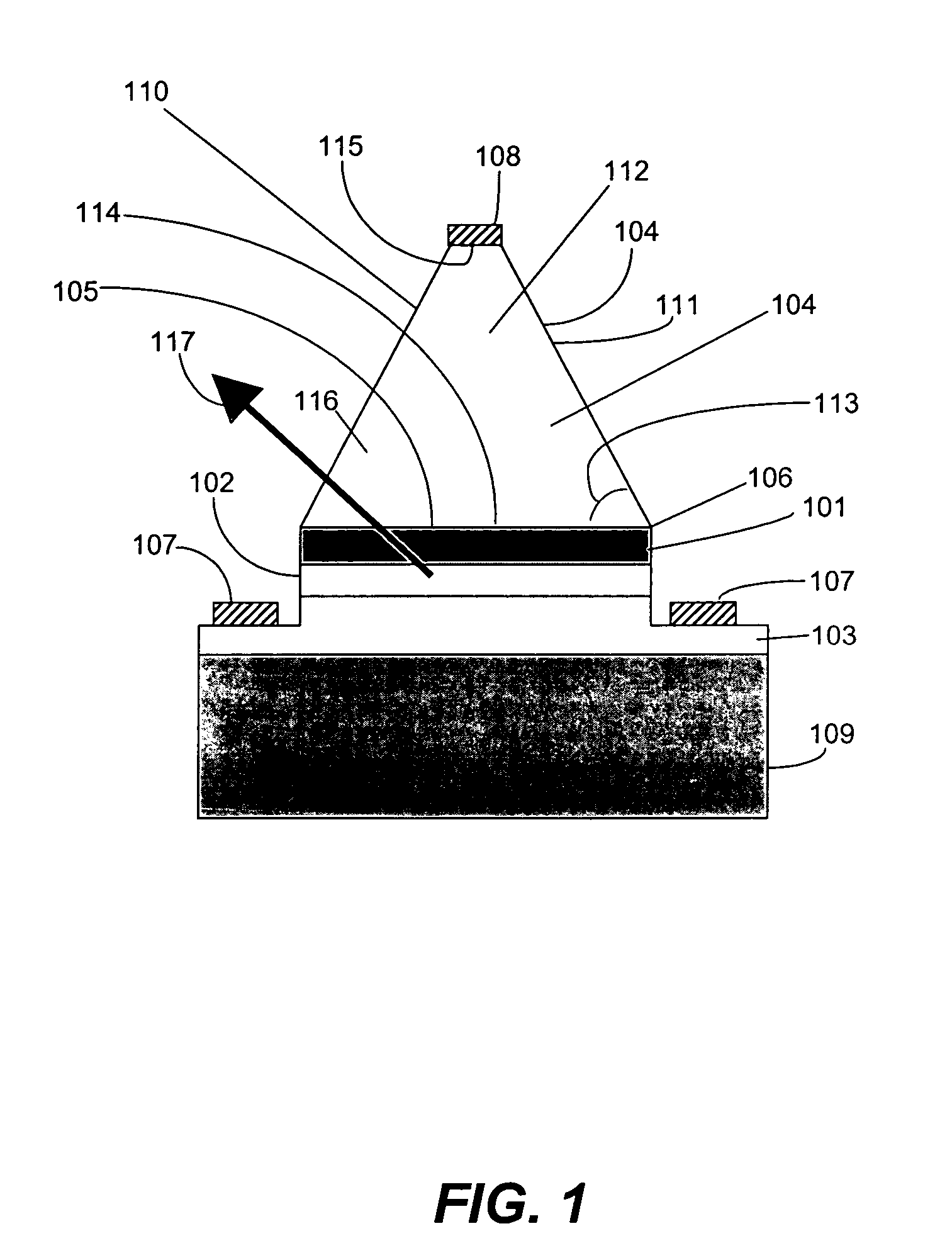

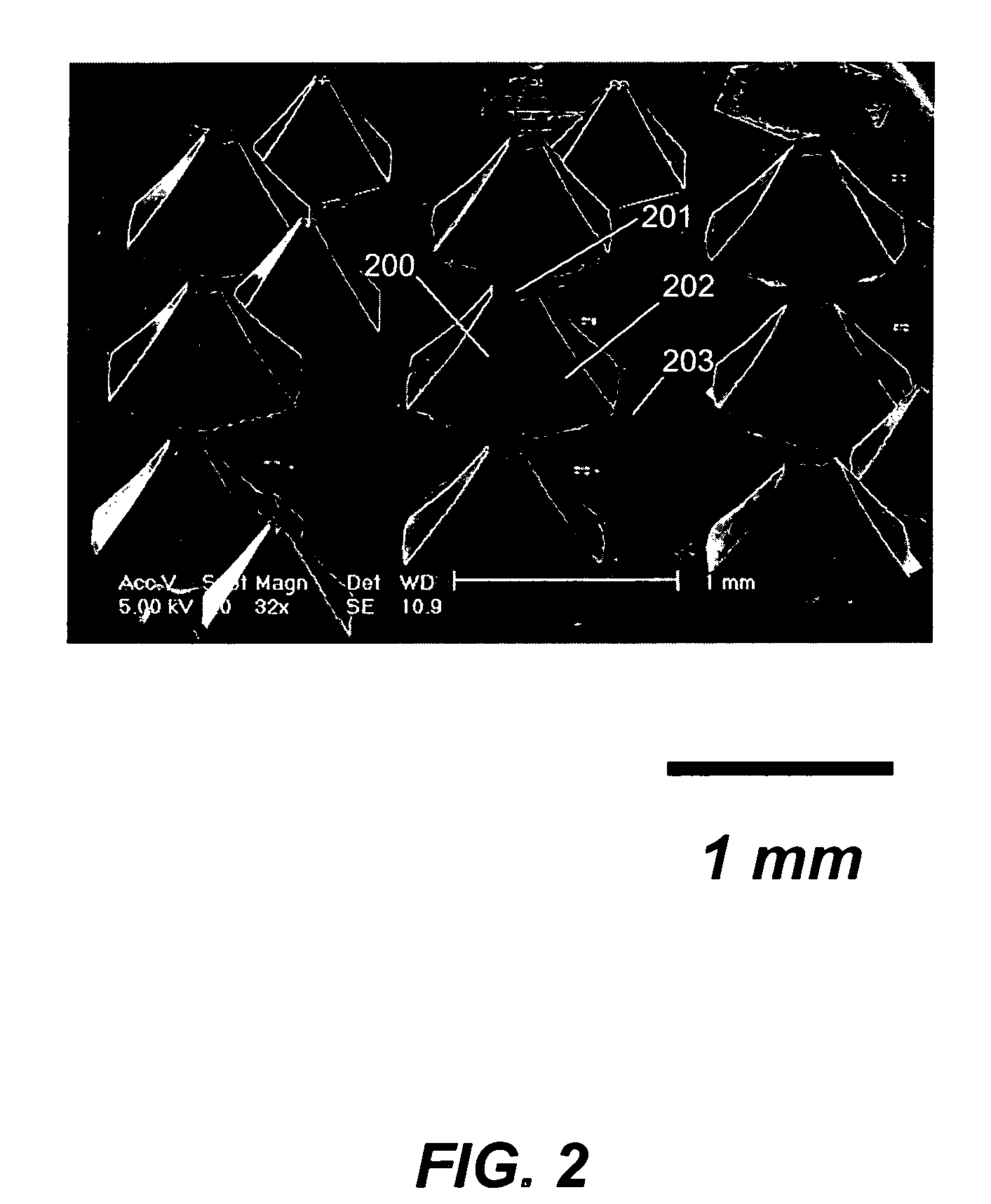

(Al, Ga, In)N and ZnO direct wafer bonded structure for optoelectronic applications, and its fabrication method

InactiveUS20070001186A1Improve conductivityStrong wafer bonded interfaceIncadescent screens/filtersDischarge tube luminescnet screensElectrically conductiveNitrogen gas

An (Al, Ga, In)N and ZnO direct wafer bonded light emitting diode (LED), wherein light passes through electrically conductive ZnO. Flat and clean surfaces are prepared for both the (Al, Ga, In)N and ZnO wafers. A wafer bonding process is then performed between the (Al, Ga, In)N and ZnO wafers, wherein the (Al, Ga, In)N and ZnO wafers are joined together and then wafer bonded in a nitrogen ambient under uniaxial pressure at a set temperature for a set duration. After the wafer bonding process, ZnO is shaped for increasing light extraction from inside of LED.

Owner:JAPAN SCI & TECH CORP

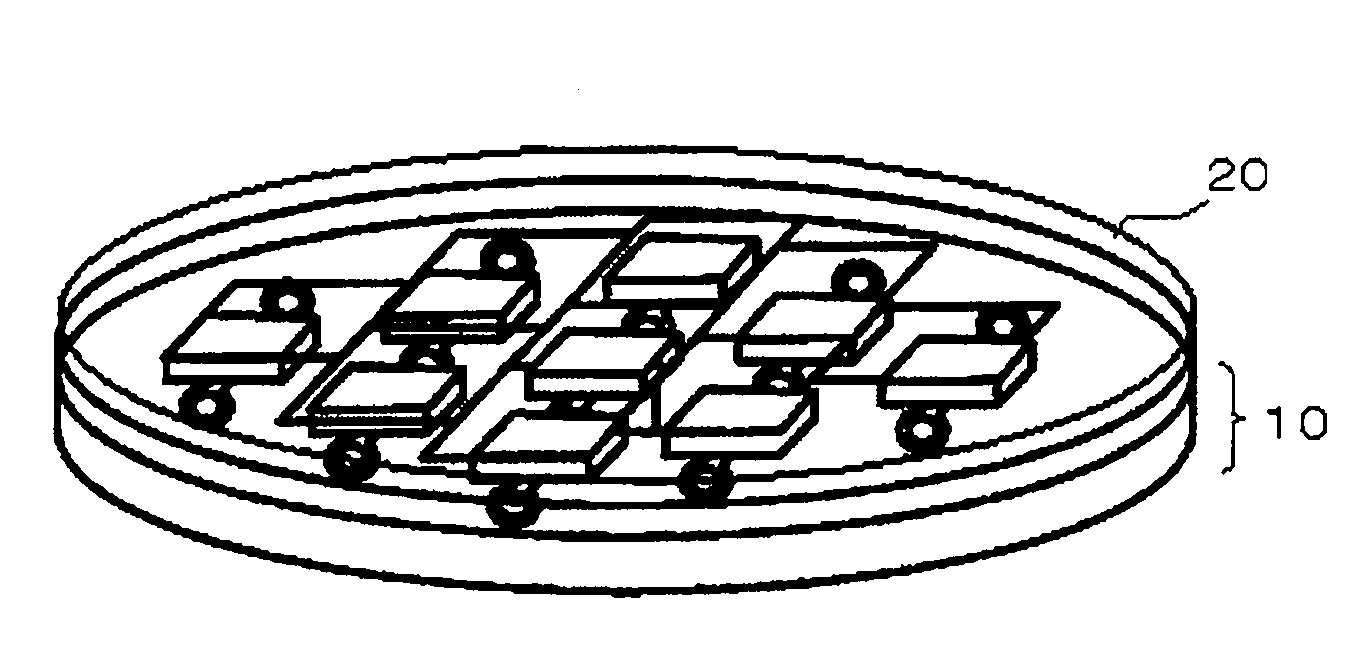

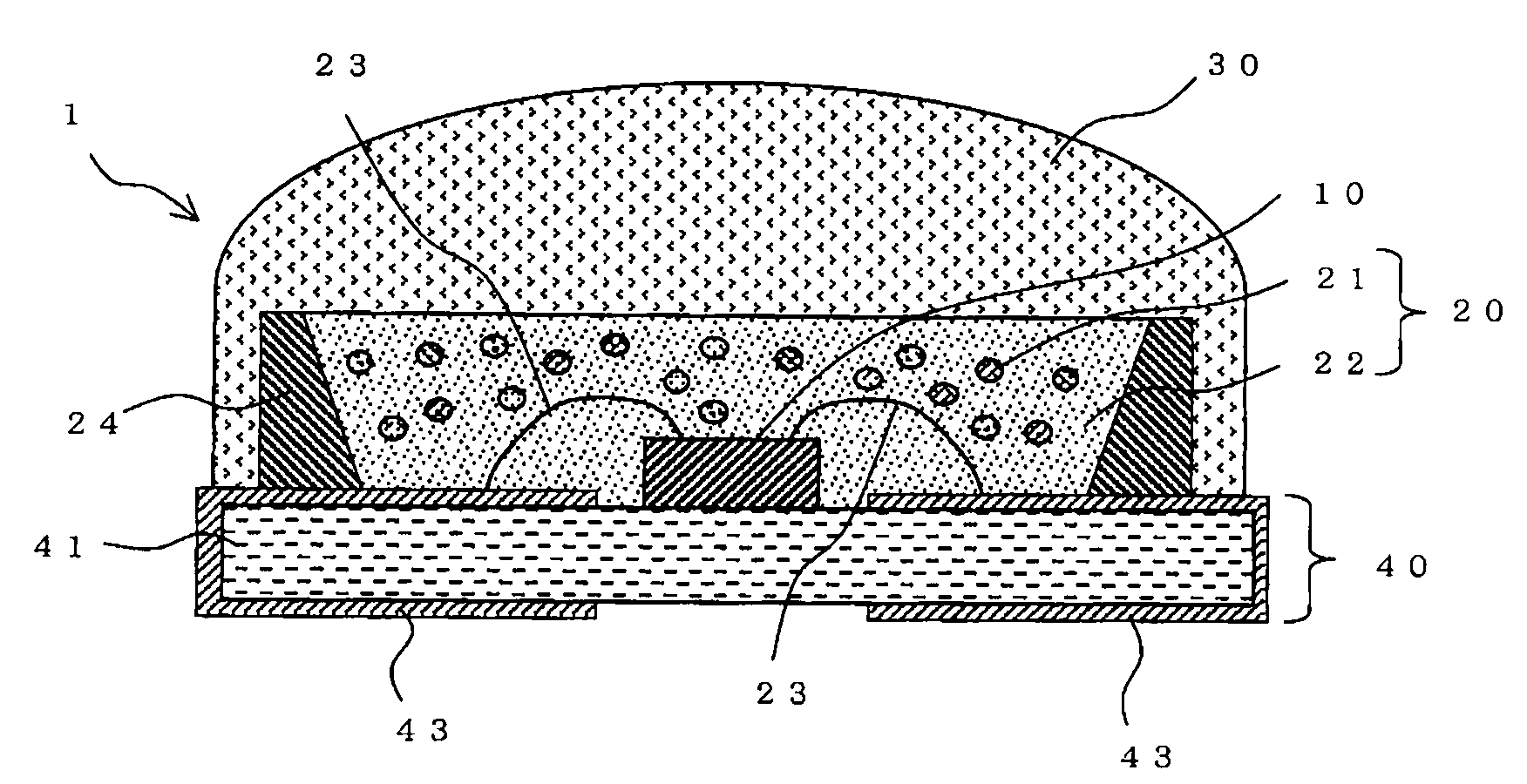

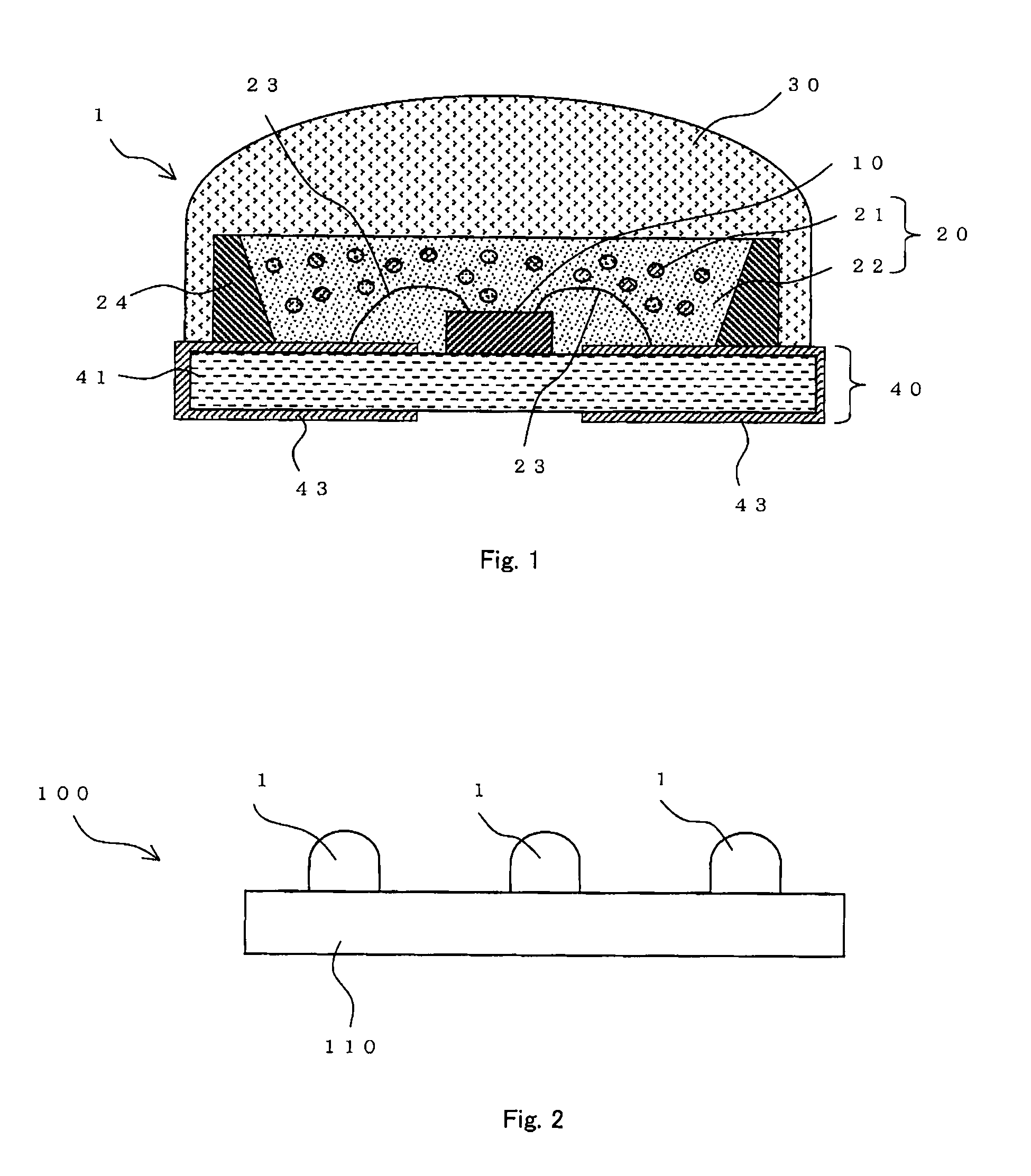

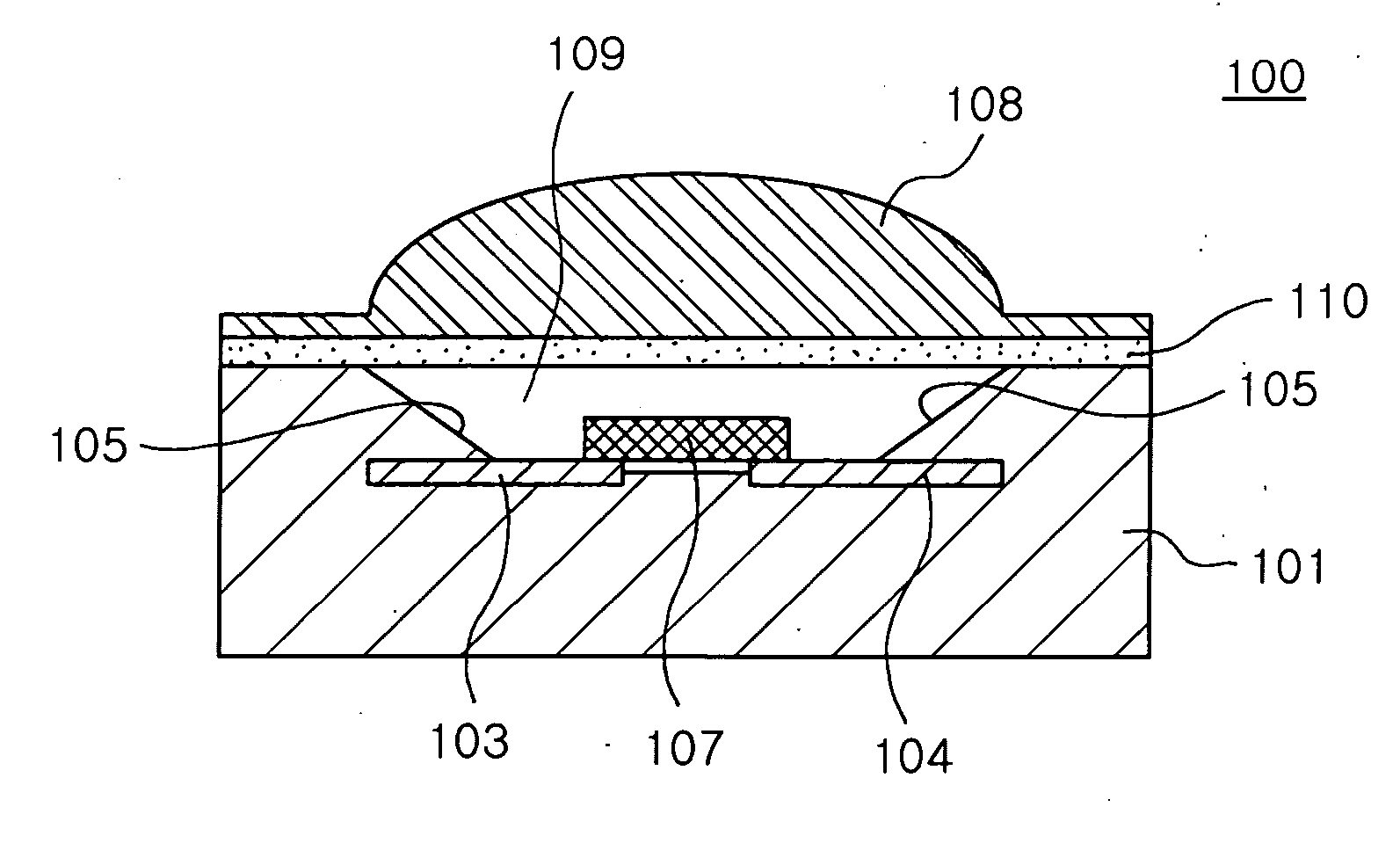

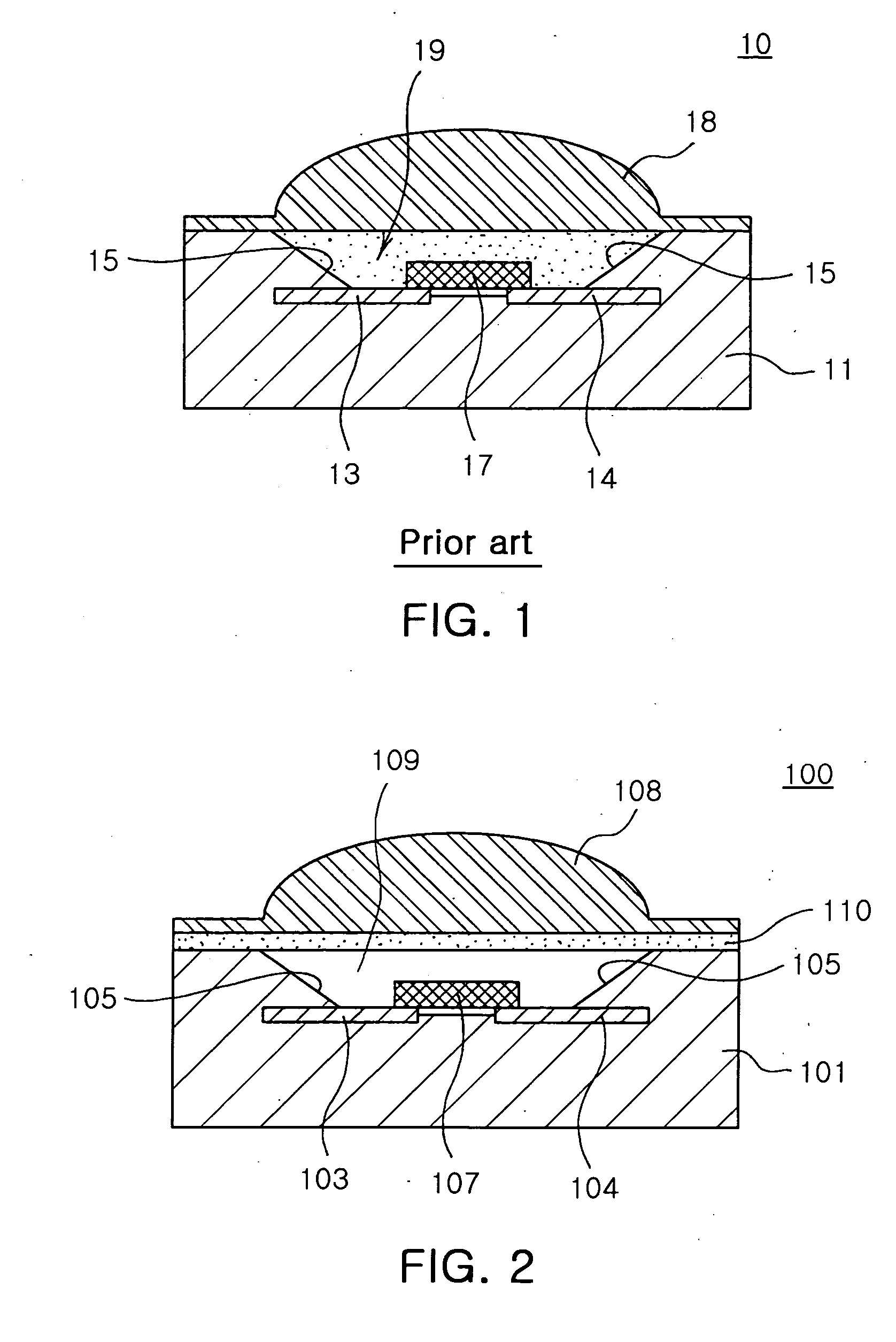

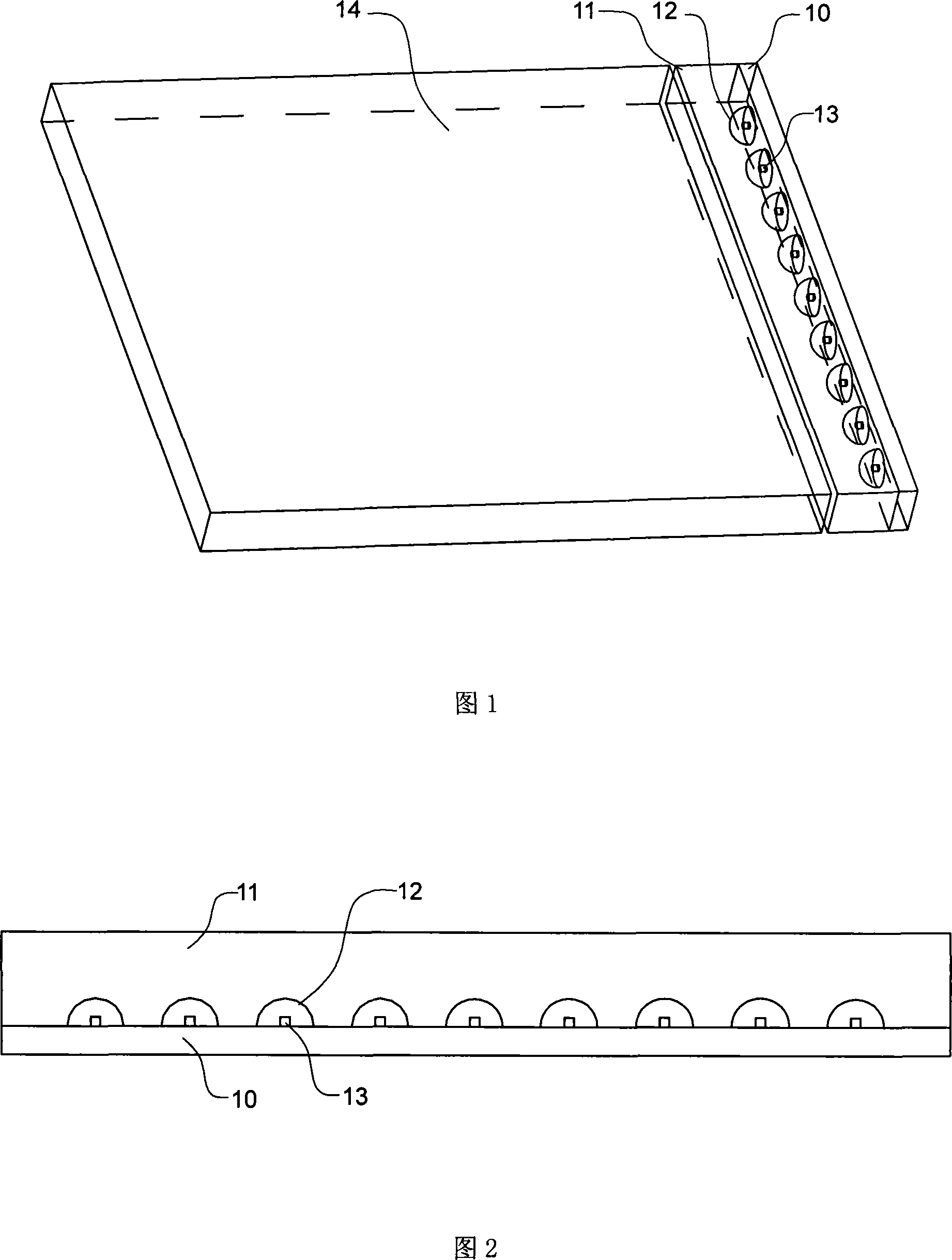

Illuminating device

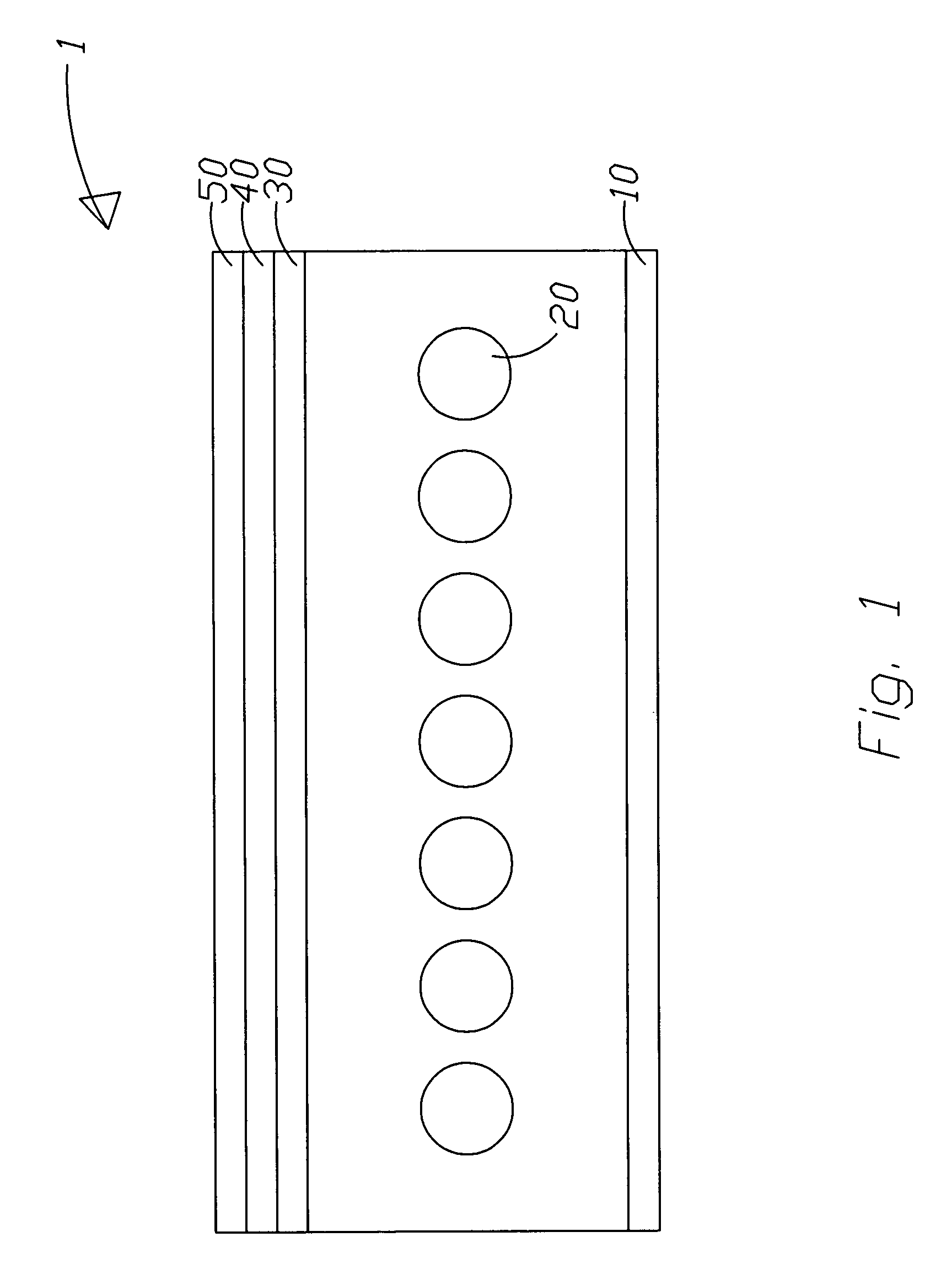

InactiveUS20100171440A1Simple structureLight evenlyLight source combinationsDischarge tube luminescnet screensFluorescenceEngineering

An illuminating device has a solid light-emitting element module (10) and a phosphor module (20) joined to the solid light-emitting element module (10). The solid light-emitting element module (10) has a plurality of the solid light-emitting elements. The phosphor module (20) has a plurality of phosphor-containing parts (22) corresponding to the individual solid light-emitting elements (12). Thus, a light-emitting part is provided, which has more than one kind of luminescence sources having the solid light-emitting element (12) and the phosphor-containing part (22). An illumination intensity of a composite light is 150 lux or more at a distance of 30 cm perpendicularly from the light-emitting surface of the light-emitting part.

Owner:CMC MAGNETICS CORPORATION

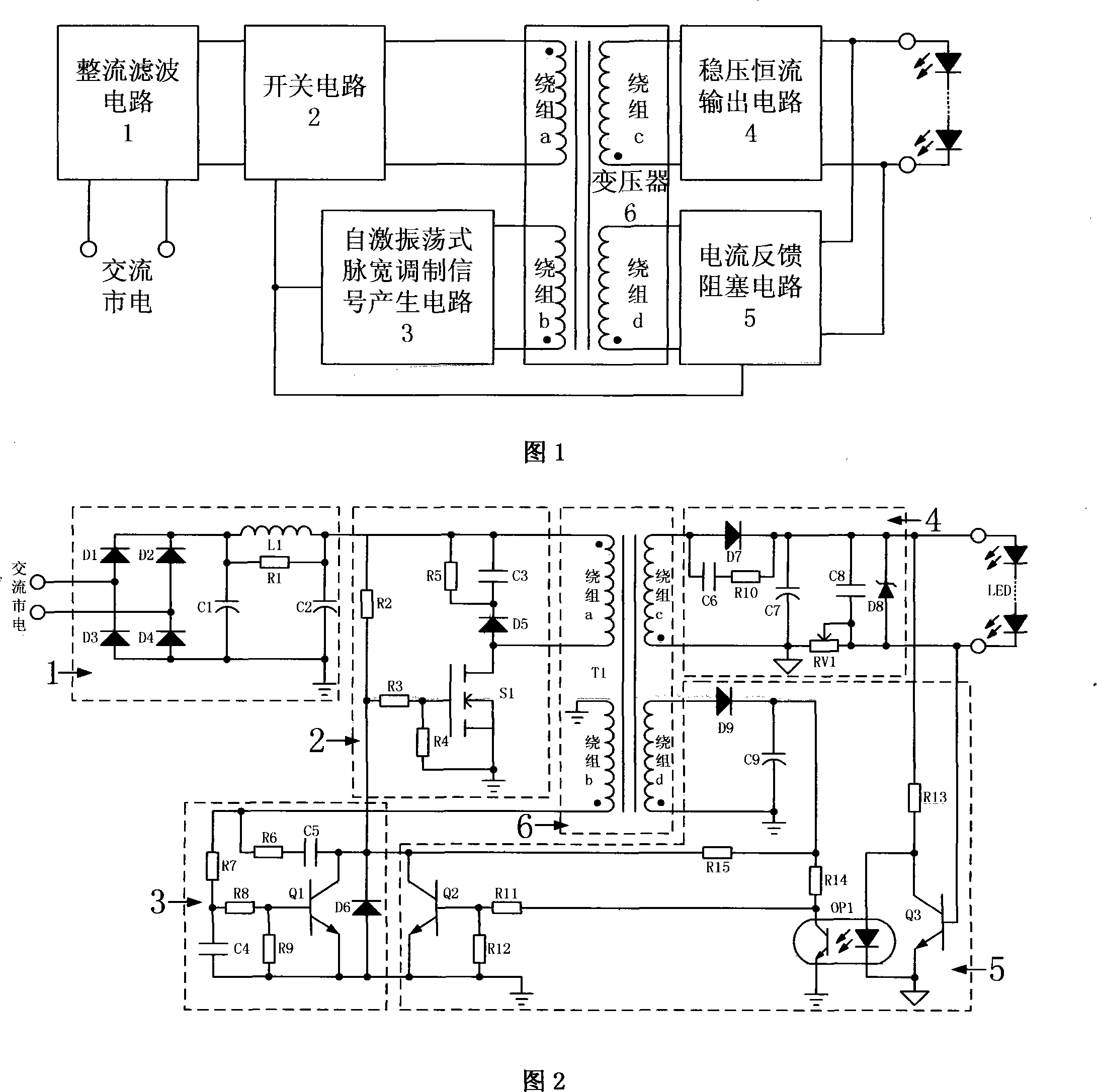

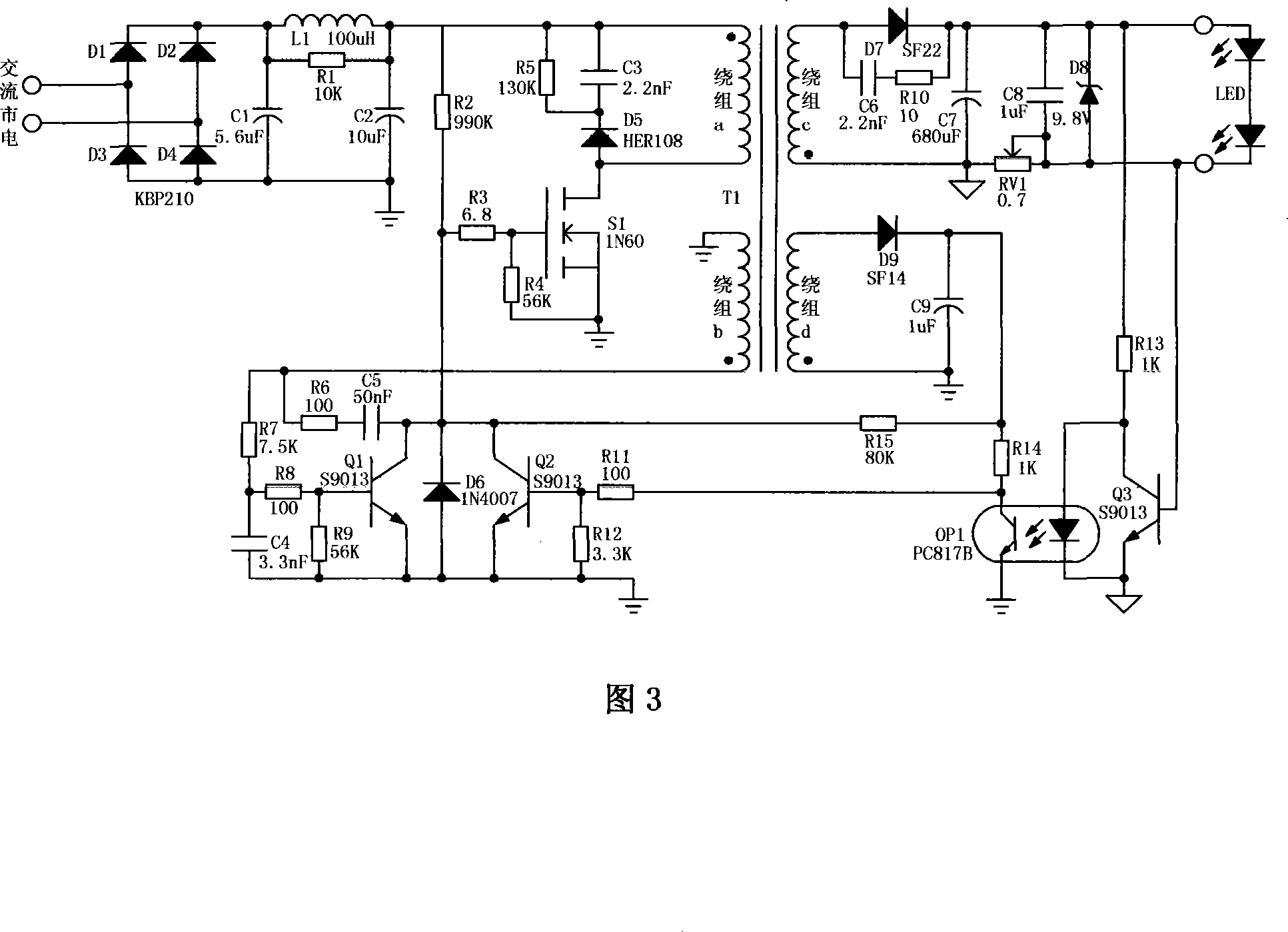

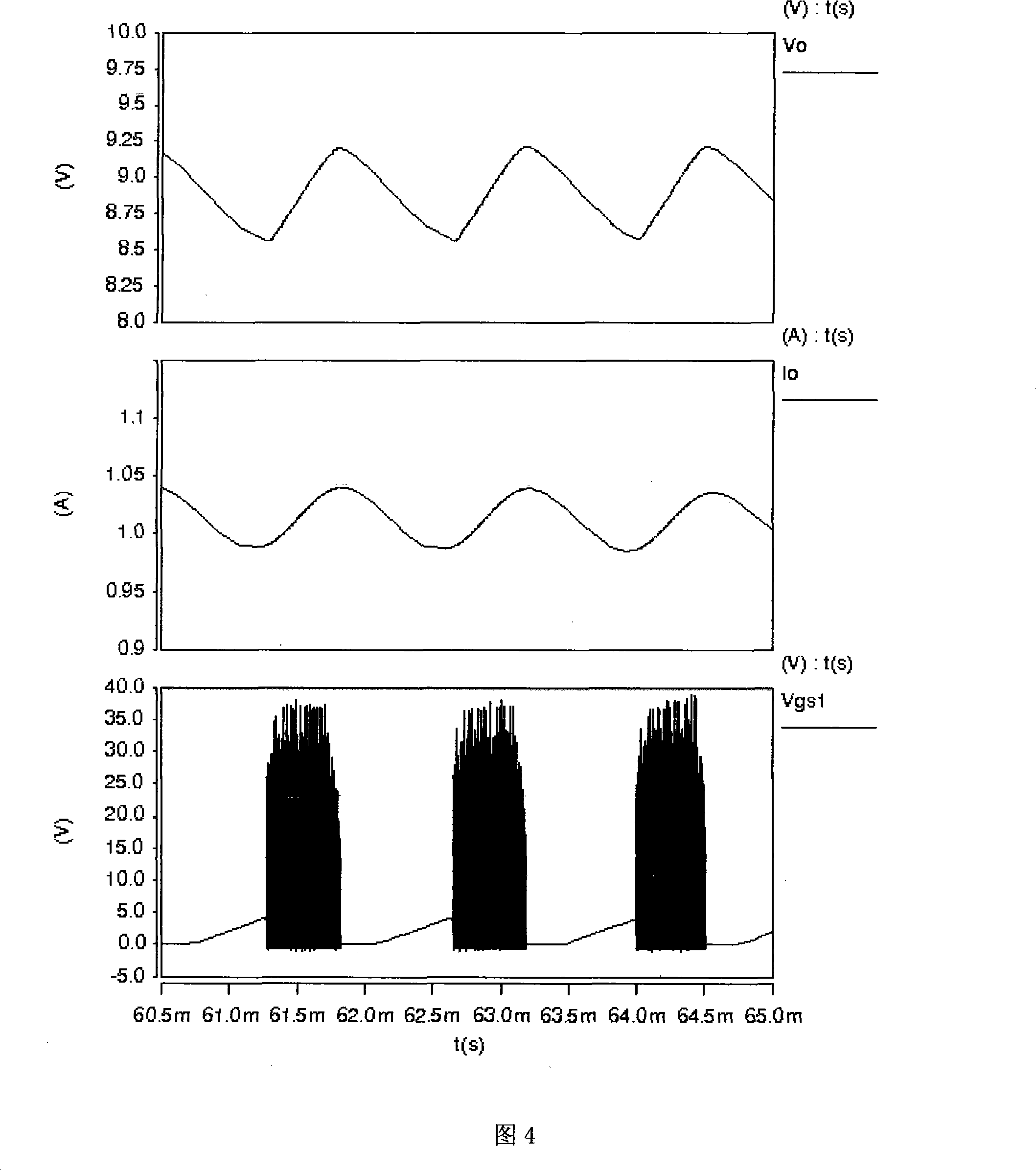

Self-excited oscillation type high power LED constant-current driving circuit

InactiveCN101227778ALow costImprove reliabilityElectric light circuit arrangementElectric variable regulationTransformerSelf-oscillation

The invention provides a self-oscillation type high power LED constant-current drive circuit with low cost, high reliability and stability and high drive efficiency, the circuit comprises a rectifier and filter circuit, a switching circuit, a steady voltage constant current output circuit, a transformer, a self-oscillation type pulse width modulation signals generating circuit and a current feedback obstruction circuit, wherein the rectifier and filter circuit accesses commercial power into rectification, changes the commercial power into direct current, and then outputs commercial power to the switching circuit to switch in a self-oscillation type with high frequency, then high frequency voltage of the steady voltage constant current output circuit is transformed into direct voltage through the transformer to drive the LED, simultaneously sampling current signals produces jam signals through the current feedback obstruction circuit to control the switching circuit to work, the circuit does not adopt any driving chips and only uses fewer common individual devices to form a self-oscillation type structure to drive the switching circuit and to combine current feedbacks, which realizes constant current driving of the high power LED.

Owner:NANTONG LIWANG MACHINE TOOL +1

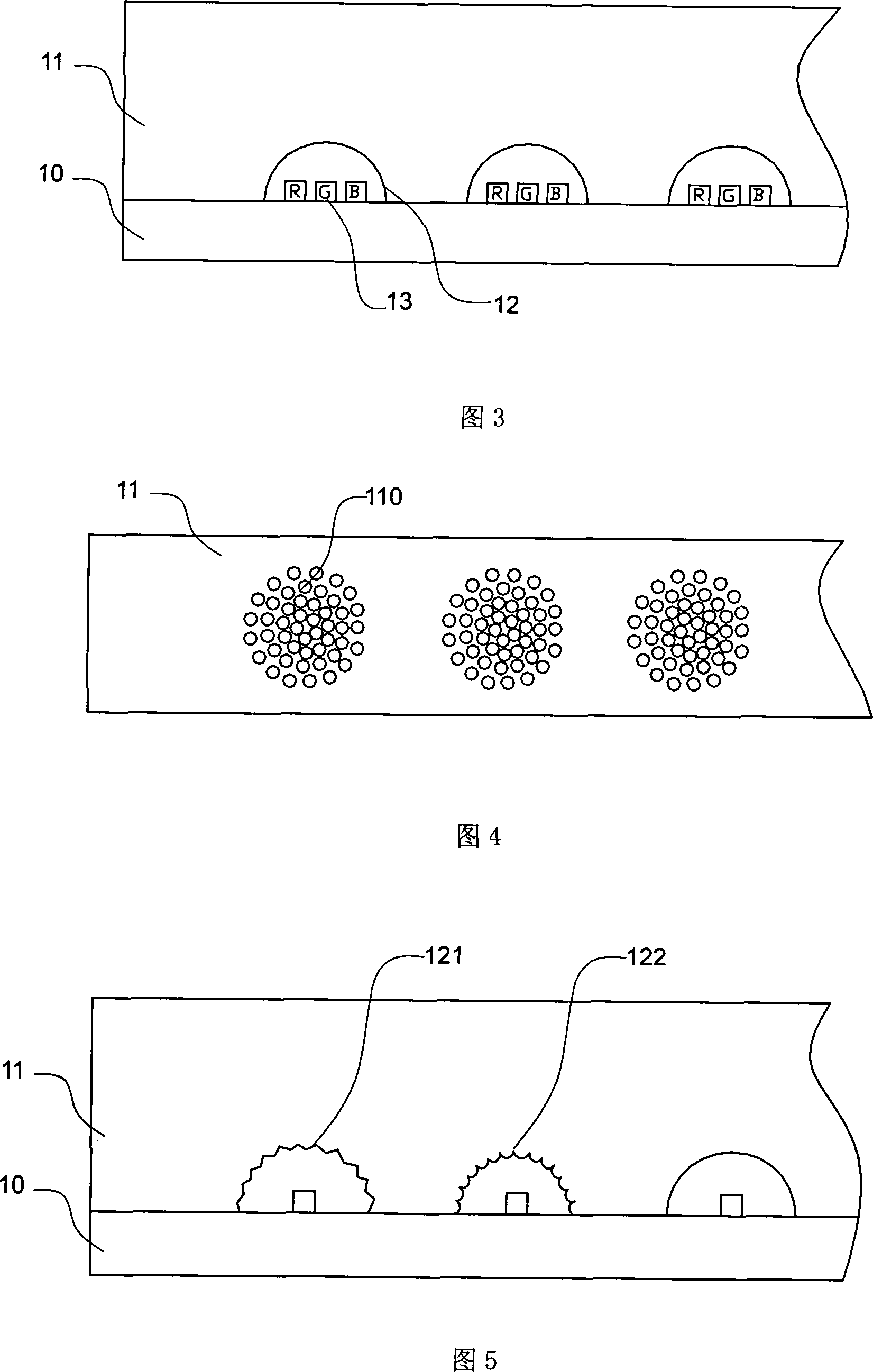

Illuminating device

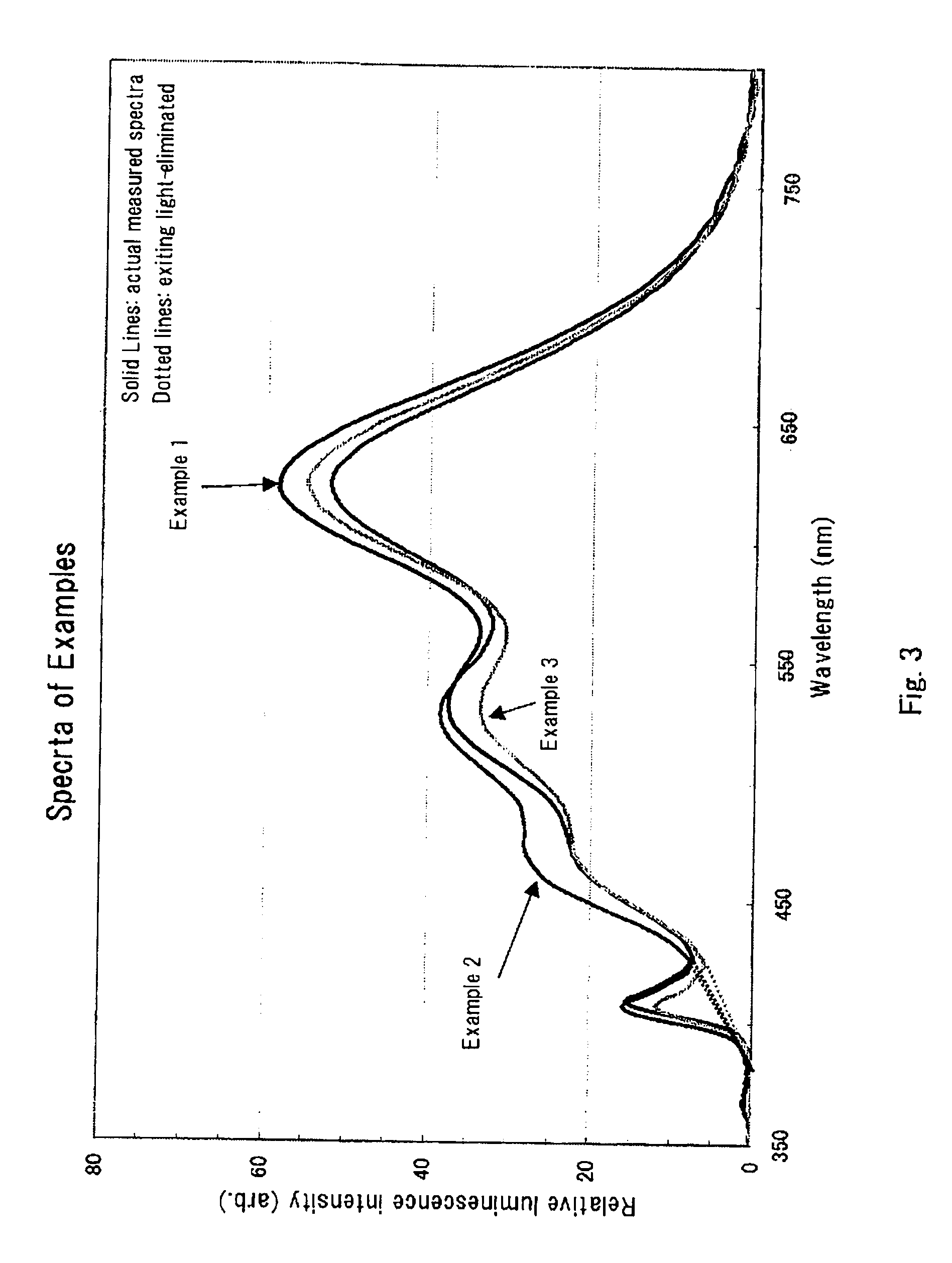

InactiveUS20090267484A1Simple structureLight evenlyDischarge tube luminescnet screensLamp detailsColor rendering indexPeak value

An illuminating device comprises one or more luminescent devices (1). The luminescent device comprises a semiconductor light emitting element (10) emitting a excitation light having an peak within a wavelength range from 350 nm to 430 nm, and a luminescent part (20) comprising a sealing member (22) and a phosphor (21) absorbing the light from the semiconductor light emitting element (10) and emitting a light with different emission spectrum. For the luminescent device (1), an excitation light contribution degree ΔE, an index quantitatively representing what extent of a visible component of the excitation light is involved in color mixing of a combined light of the luminescent device (1), is 0.005 or less, and a mean color rendering index Ra is 70 or more.

Owner:CMC MAGNETICS CORPORATION

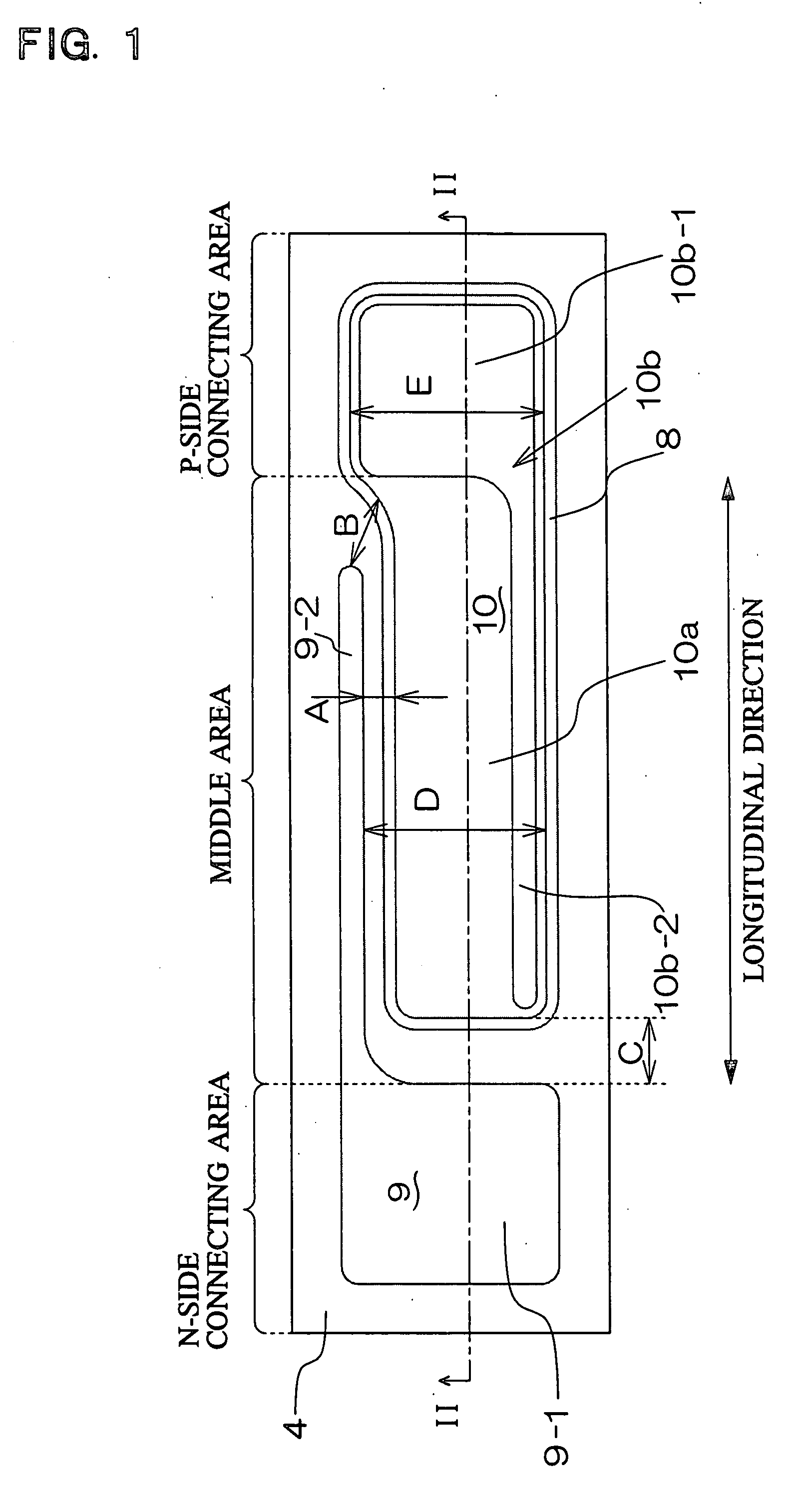

Light-emitting diode

ActiveUS20040124422A1Improve efficiencyProlong lifeSolid-state devicesSemiconductor devicesLight-emitting diodeLight emission

The present invention provide a light-emitting diode capable of making its light emission more uniform without too high a concentration current and of improving efficiency of light outgoing and its life. In the light-emitting diode, the n-side electrode has an n-side connecting portion and an n-side extending portion, which extends in the longitudinal direction from a predetermined part of the n-side connecting portion, and the p-side pad member has at least p-side connecting portion to be connected to a conductive member. The light-emitting diode further comprises an n-side connecting area, in which the n-side connecting portion is provided, provided in proximity to one end in the longitudinal direction, a p-side connecting area, in which the p-side connecting portion is provided, provided in proximity to another end in the longitudinal direction, and a middle area provided between them, and the n-side extending portion is positioned in the middle area, and extends so as to be opposed to the p-side current diffusing member.

Owner:NICHIA CORP

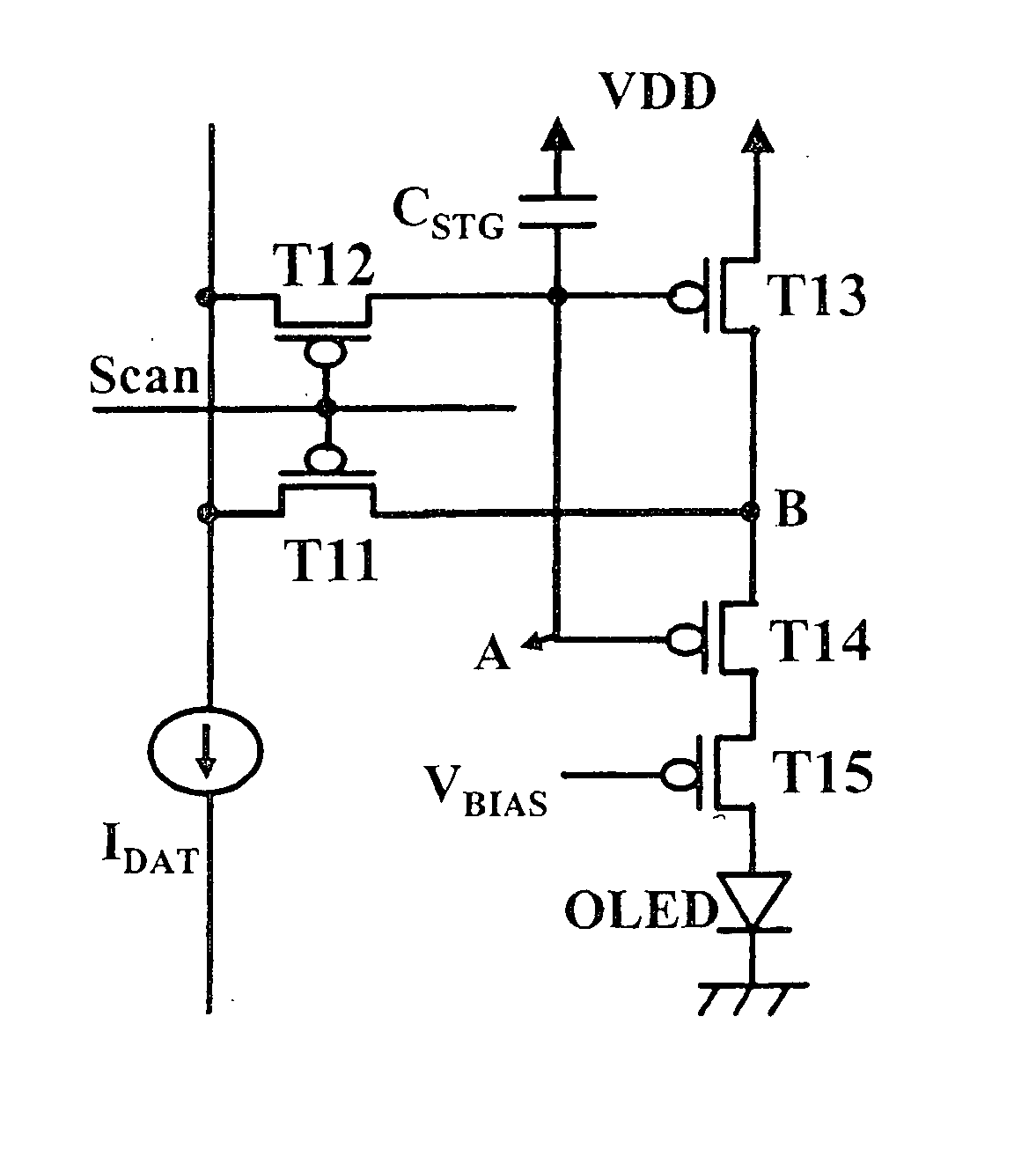

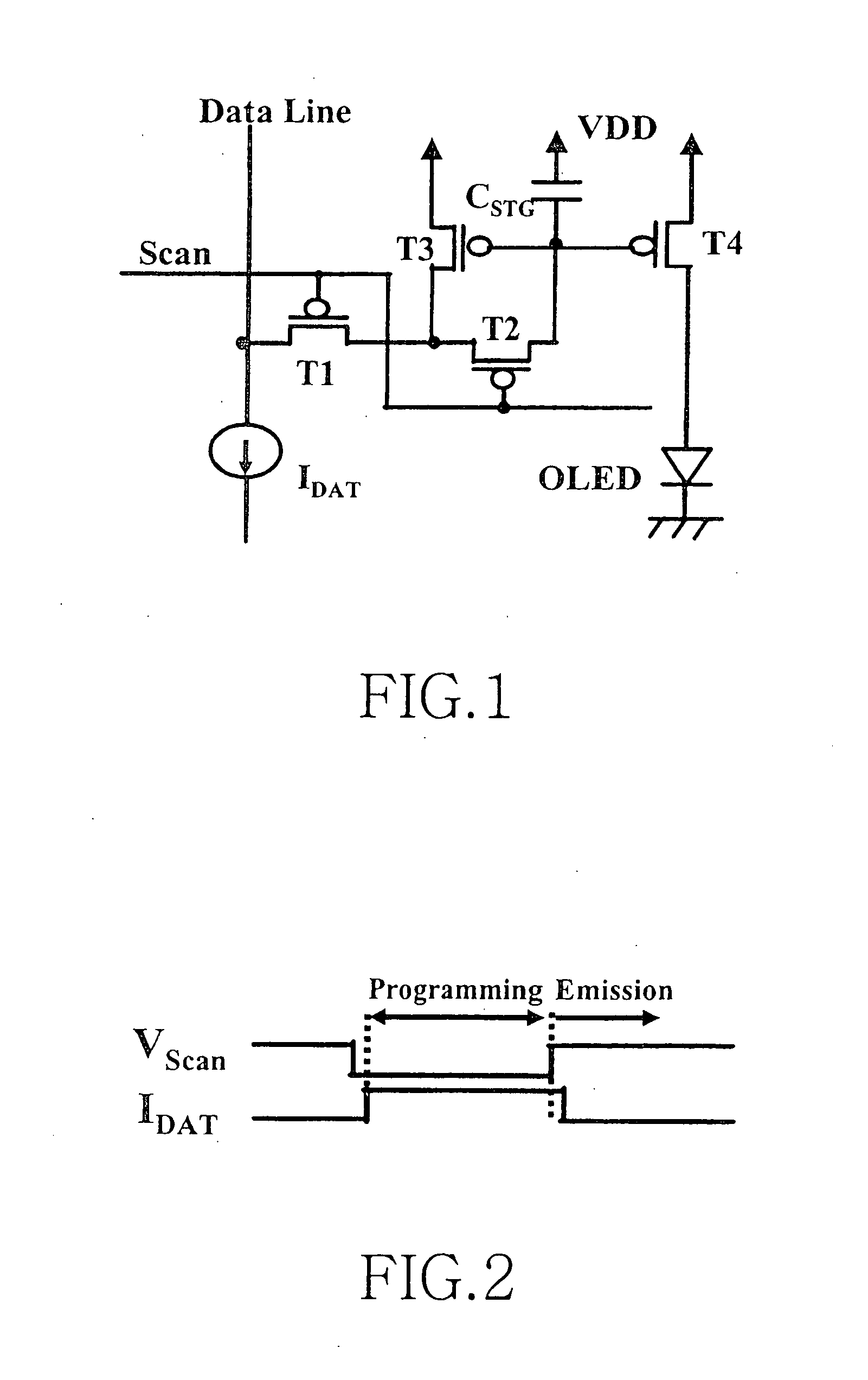

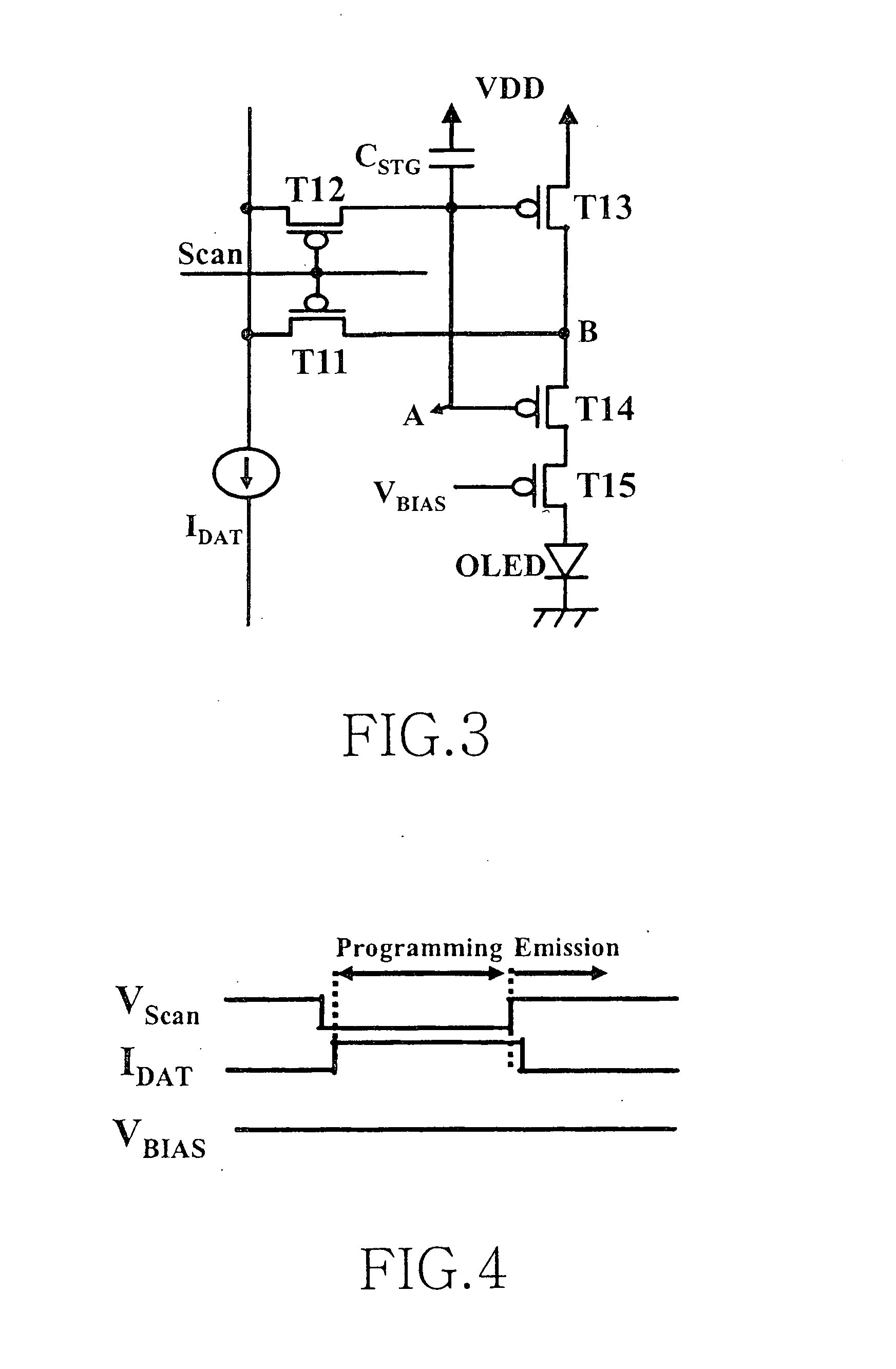

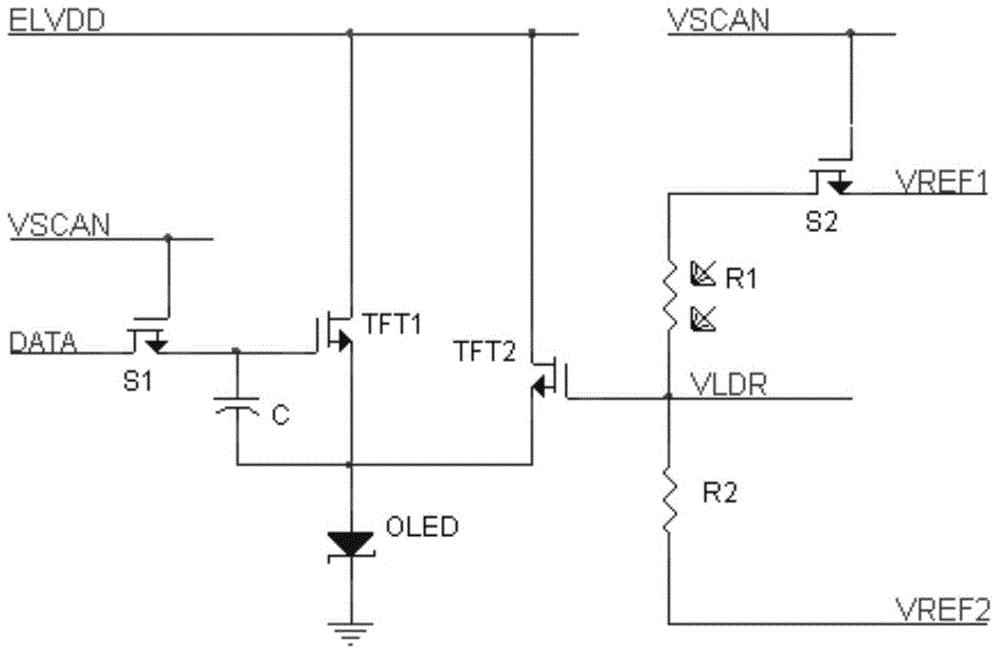

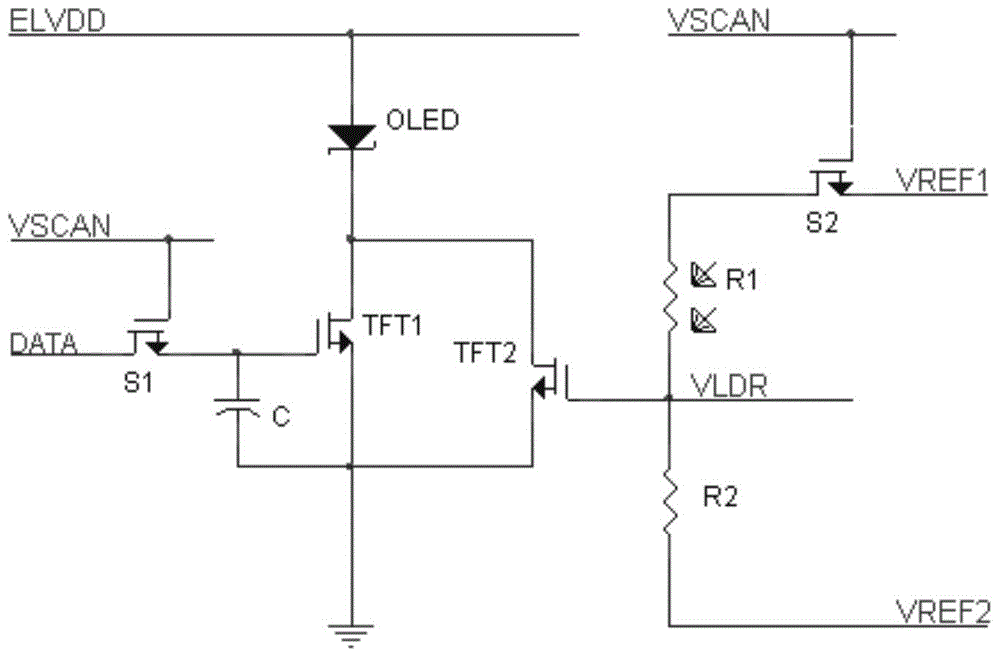

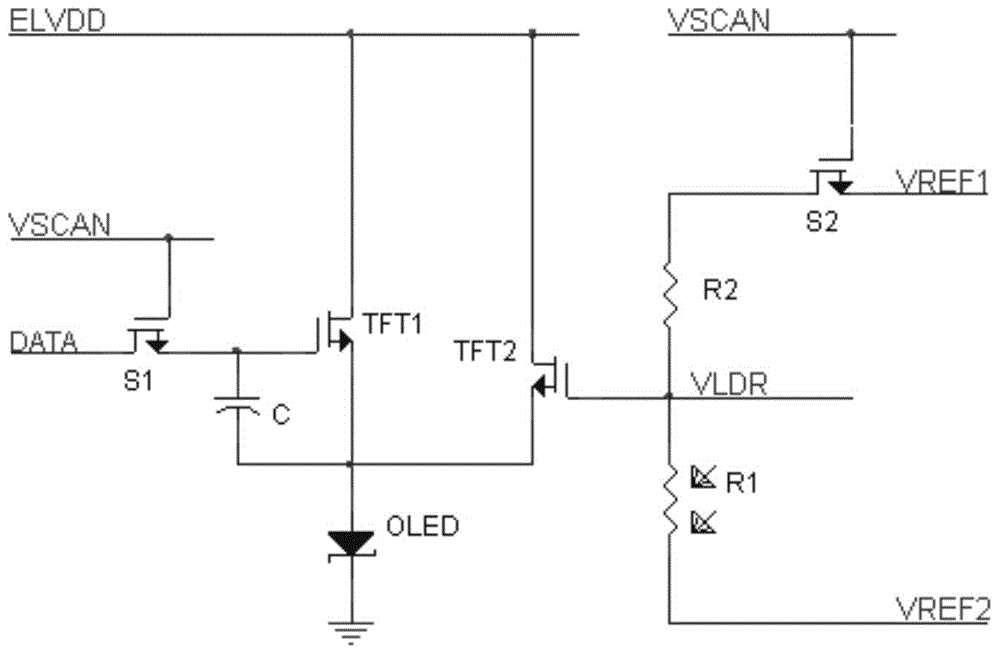

Picture element structure of current programming method type active matrix organic emitting diode display and driving method of data line

ActiveUS20090153459A9Light evenlyIncrease widthStatic indicating devicesActive matrixDevice material

The present invention provides a novel structure of picture elements in current programming-type semiconductor devices, and in particular, the structure of picture elements of an active matrix organic light emitting diode (OLED) display. The device makes a self-compensation for OLED current deviations due to the deterioration in threshold voltage and uneven electric characteristic in thin film transistors. The invention also provides a method for driving a data driver capable of compensating for the uneven electric characteristic of thin film transistors in the driver for driving picture elements in the current programming-type active matrix OLED display device.

Owner:SEOUL NAT UNIV R&DB FOUND

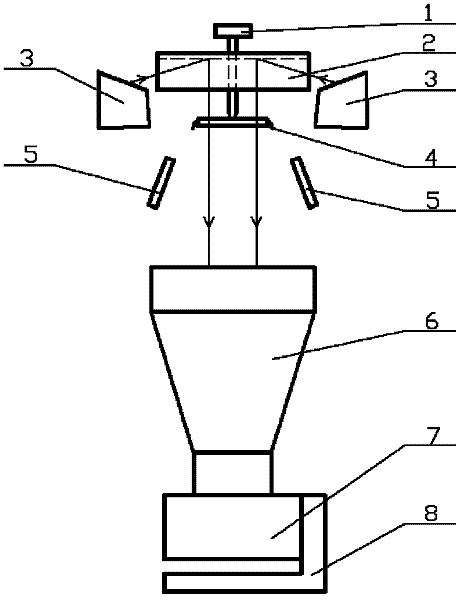

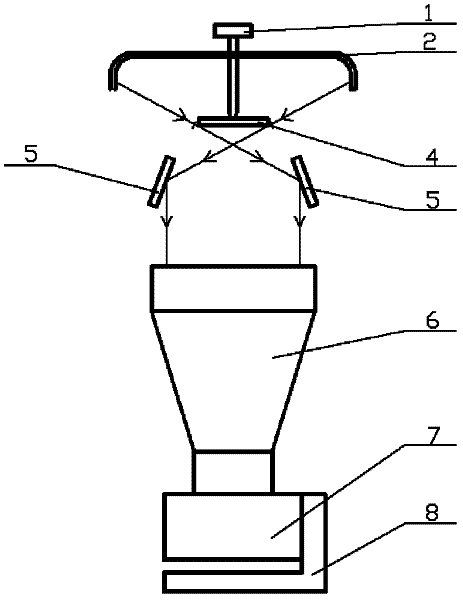

Method for detecting appearance of semiconductor chip

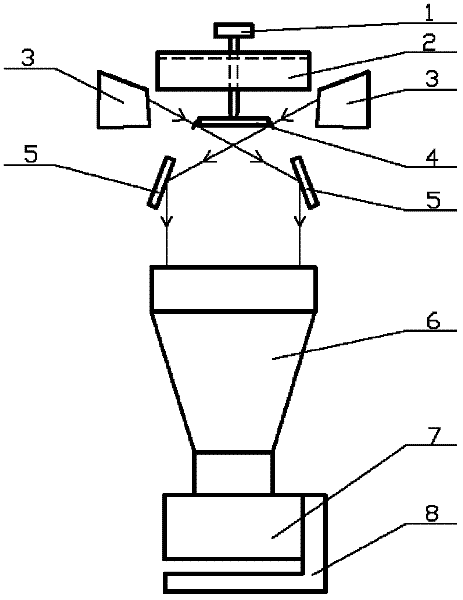

ActiveCN102359758AEasy to handleImprove image contrastOptically investigating flaws/contaminationUsing optical meansCamera lensSemiconductor chip

The invention discloses a method for detecting appearance of a semiconductor chip. The device comprises a sucking mechanism, a U-shaped reflecting plate, two light sources, plane reflecting mirrors, a lens, a camera and an adjusting mechanism, wherein the sucking mechanism is used for sucking a chip to be detected to a position to be detected; the U-shaped reflecting plate is arranged on the sucking mechanism; the two light sources are symmetrically arranged on the side of the chip; one part of light emitted by the two light sources irradiates the U-shaped reflecting plate and performs backlight illumination on the bottom surface and one group of opposite sides of the chip, and the other part of light performs backlight illumination on the other group of opposite sides of the chip; a plurality of plane reflecting mirrors are obliquely and symmetrically arranged at the periphery below the chip, so that light rays reflected by the plane reflecting mirrors are vertically transmitted to the front end face of the lens; the lens is arranged on the camera and positioned below the chip; the camera is arranged on the adjusting mechanism; and the adjusting mechanism is used for adjusting the working distance of the camera. By a backlight illumination technology, a device is clearly imaged, contrast is high, lighting uniformity is achieved, detection time is shortened, and efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

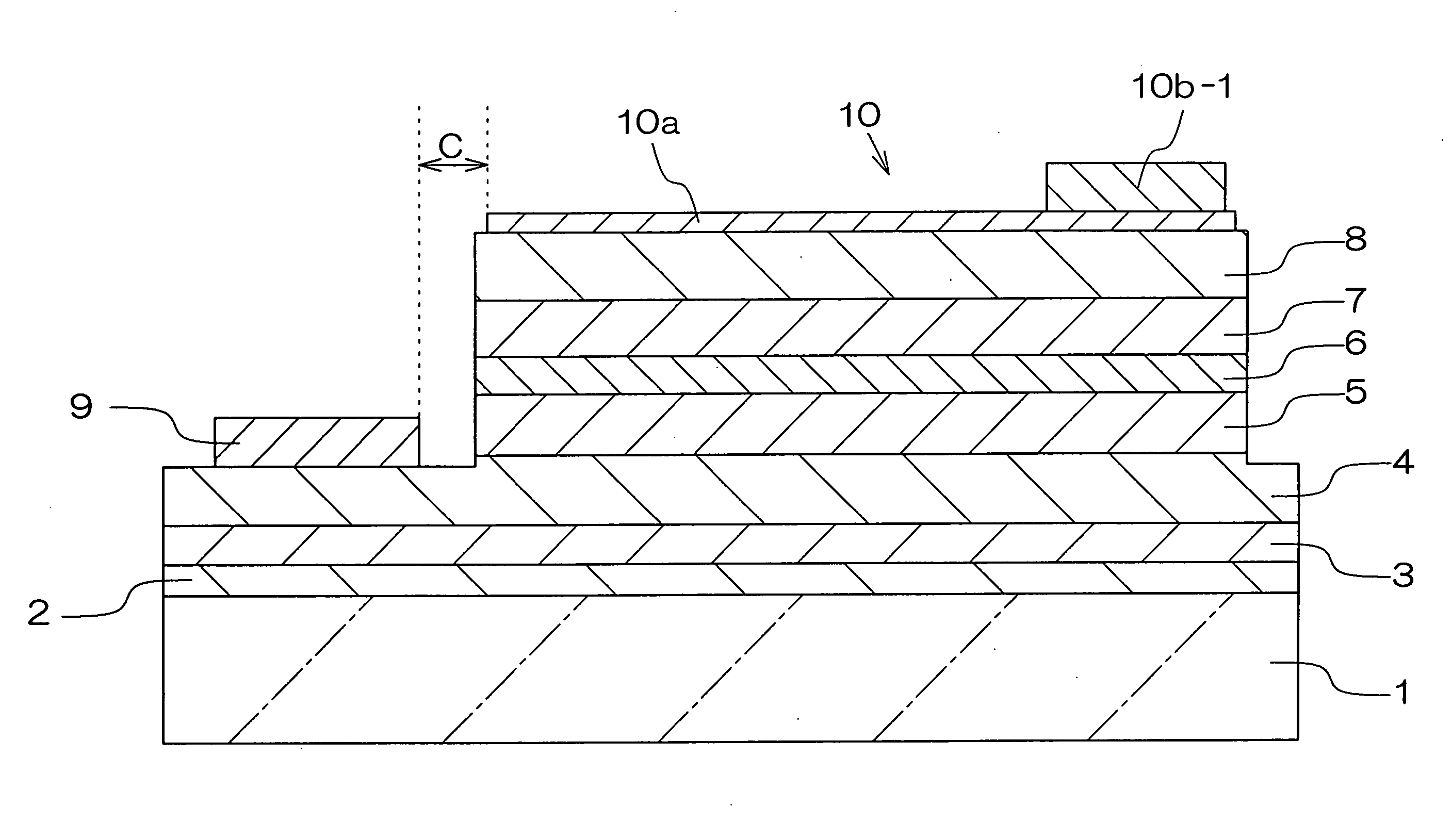

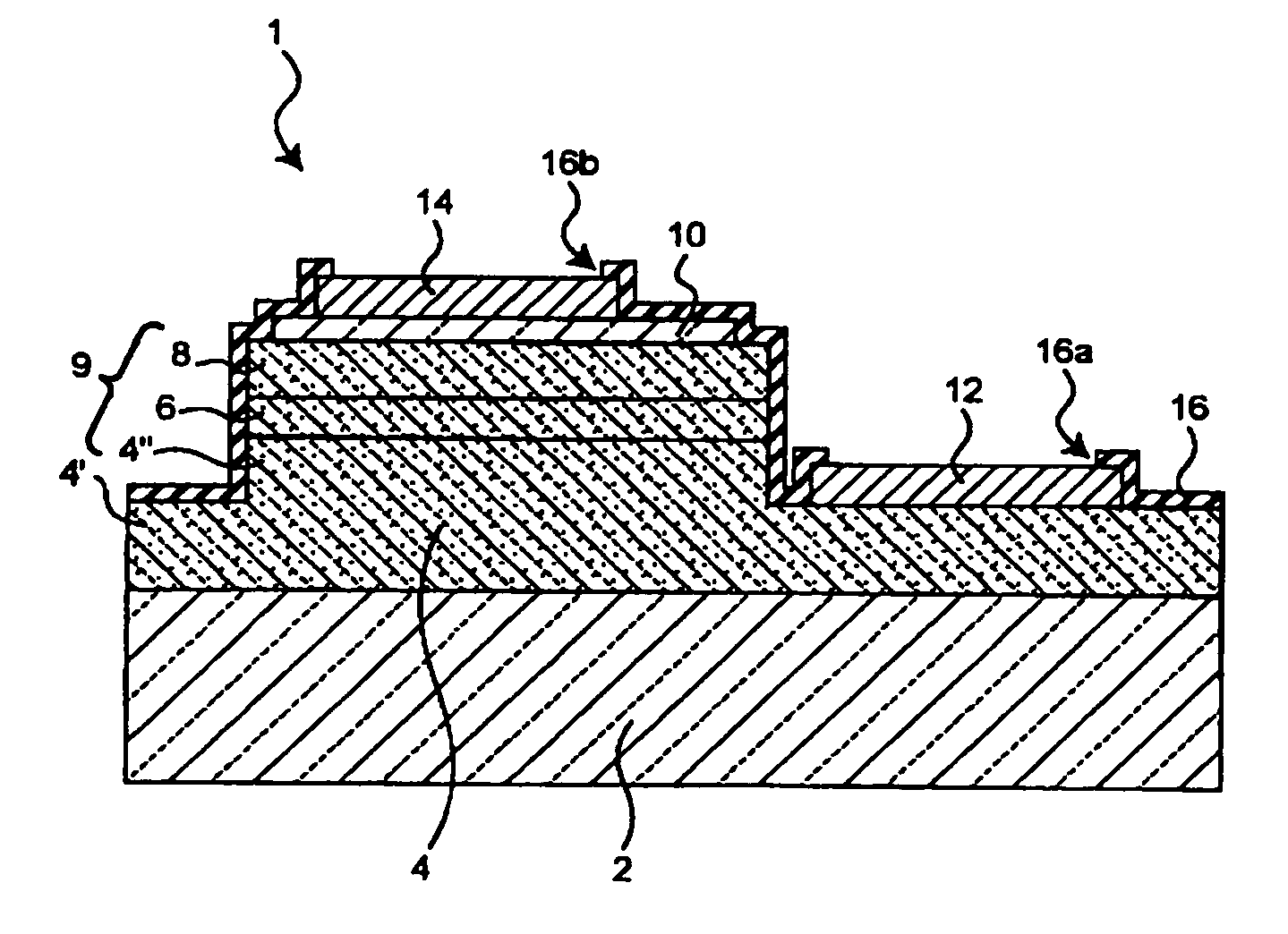

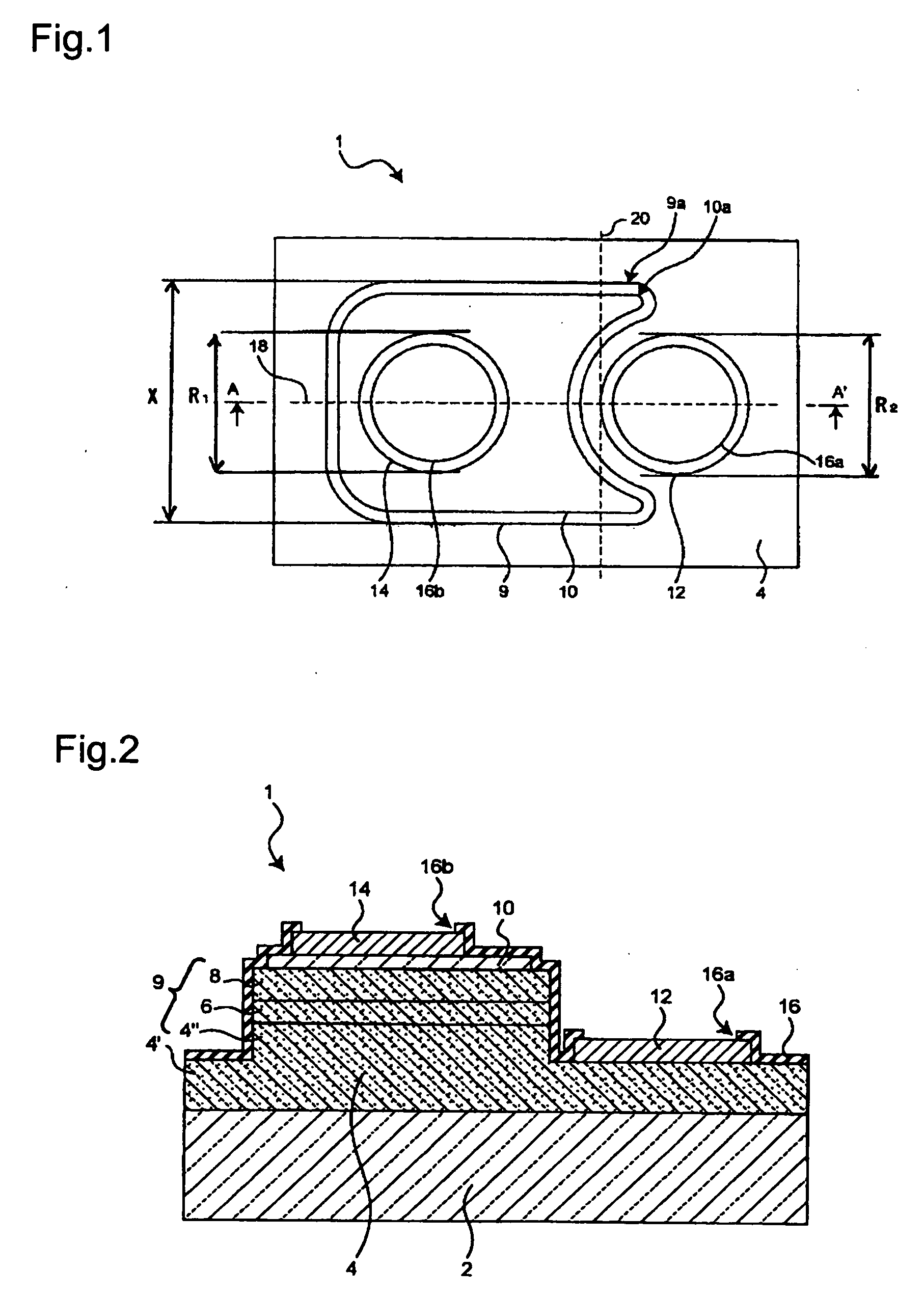

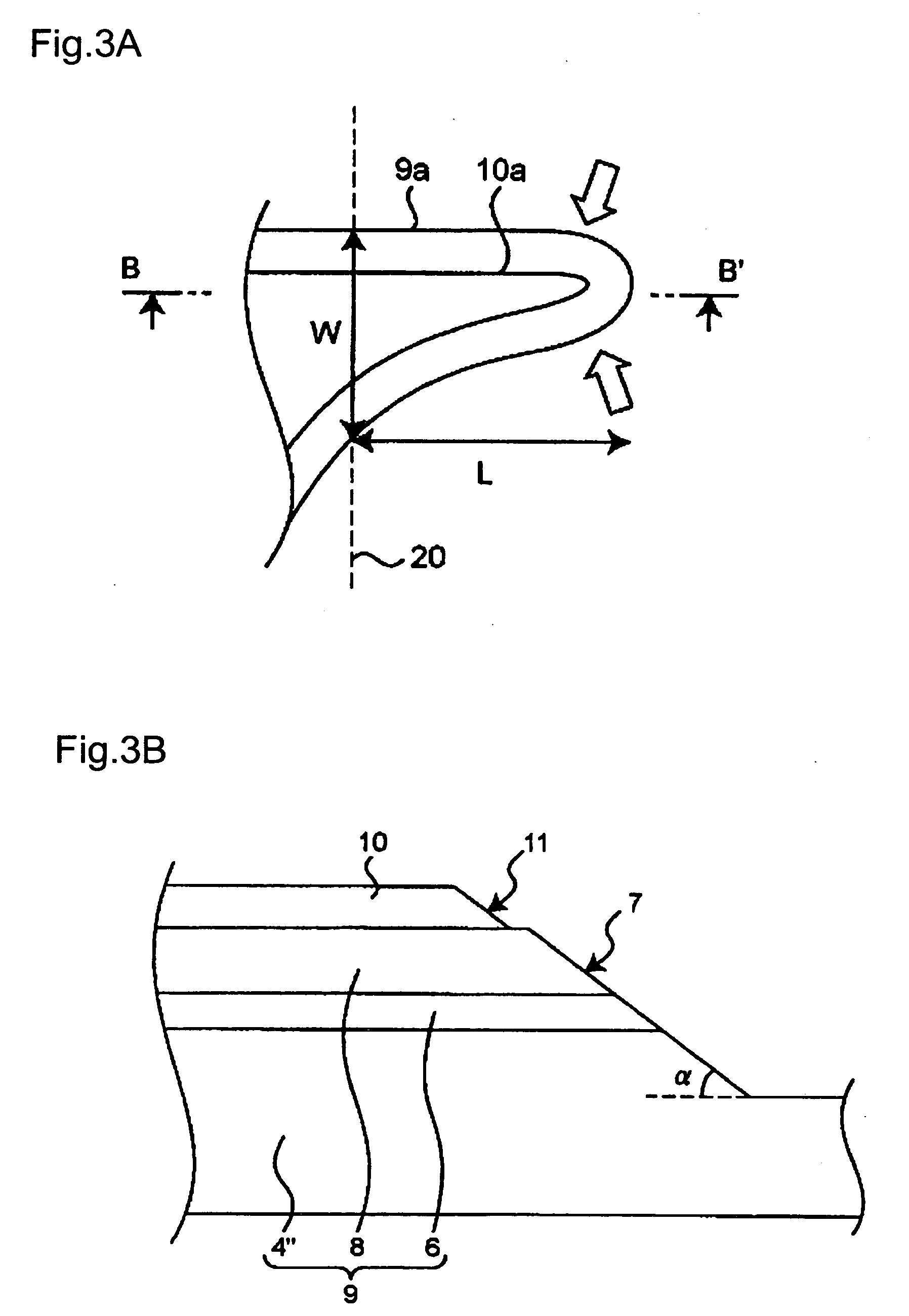

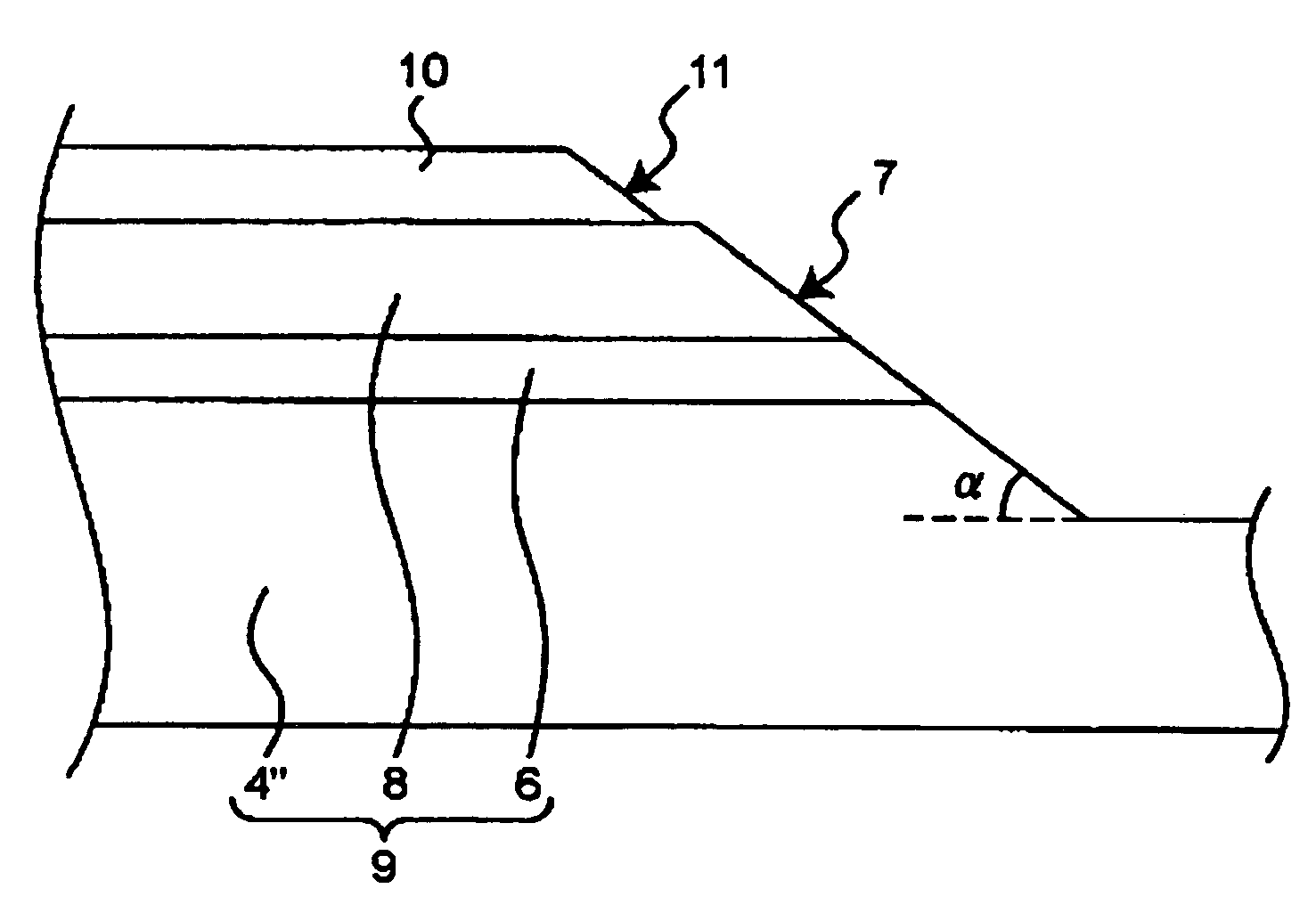

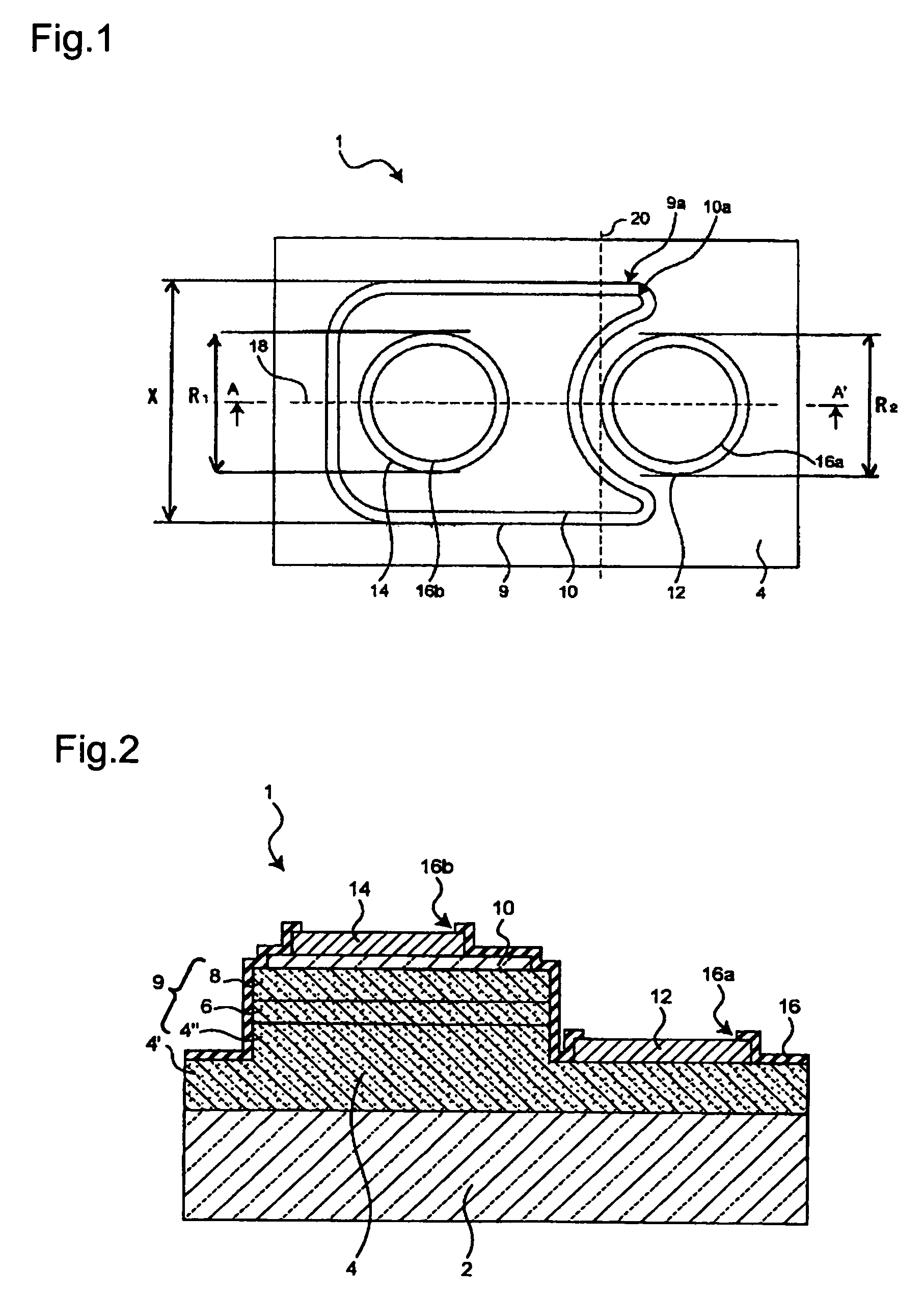

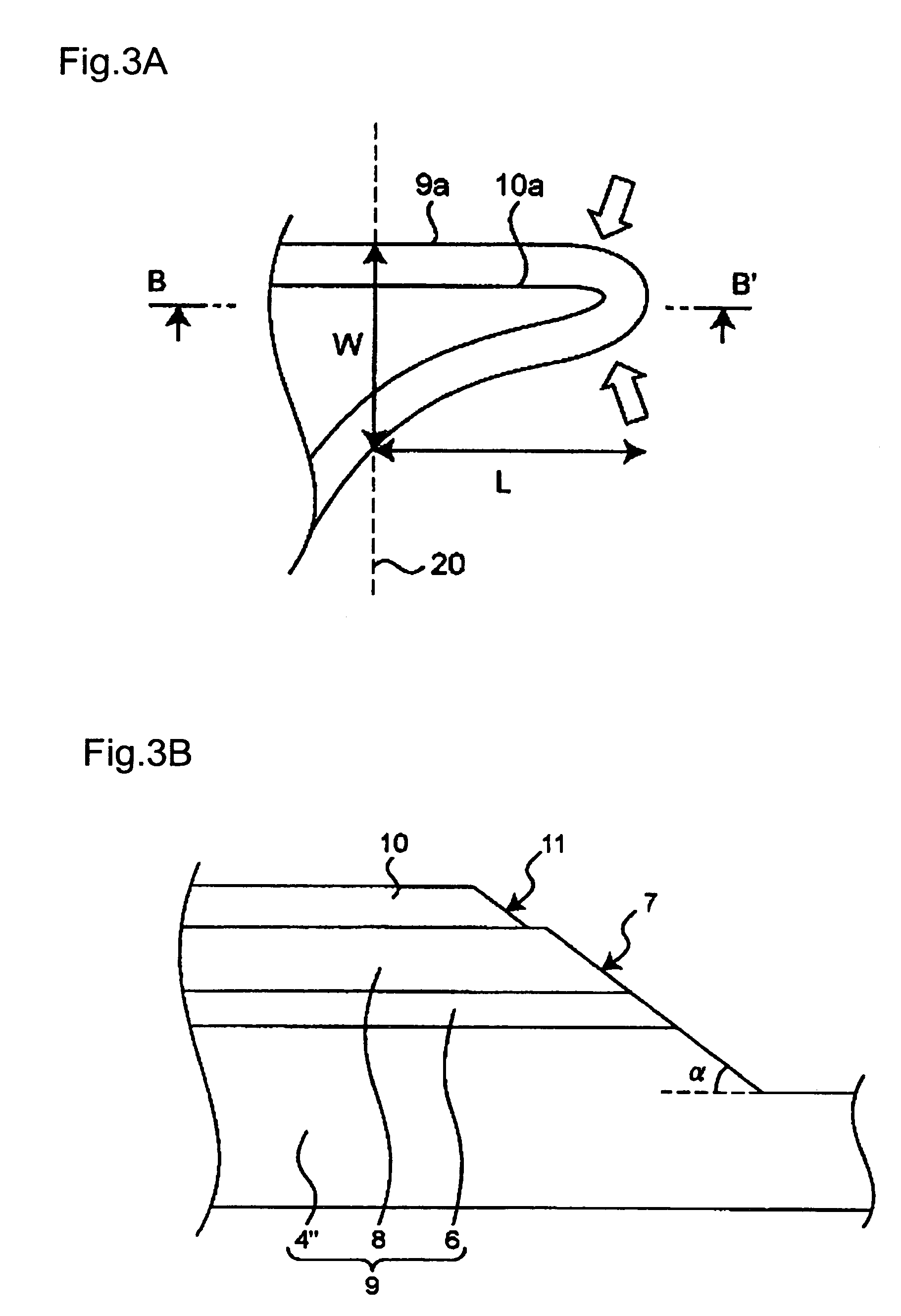

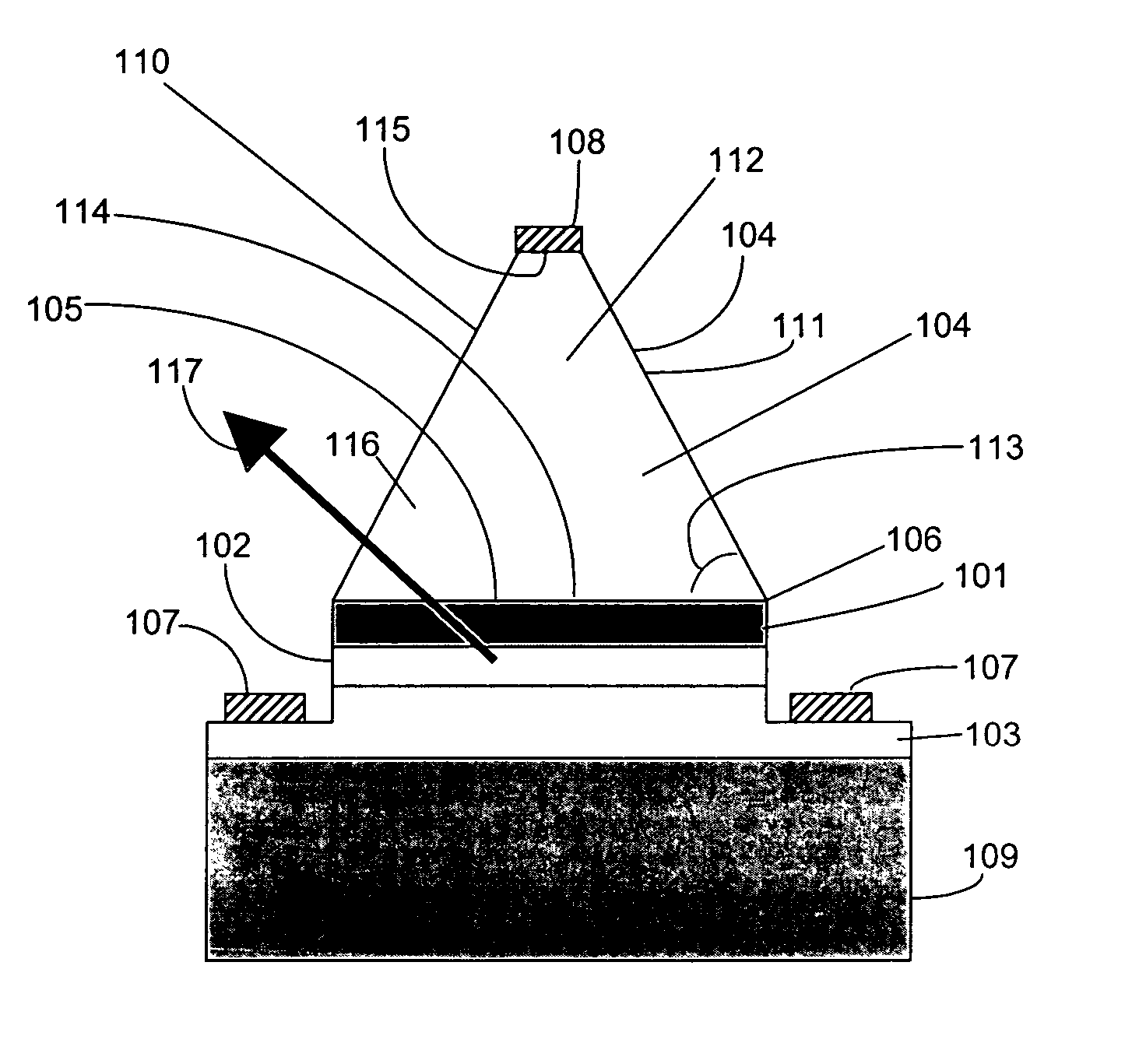

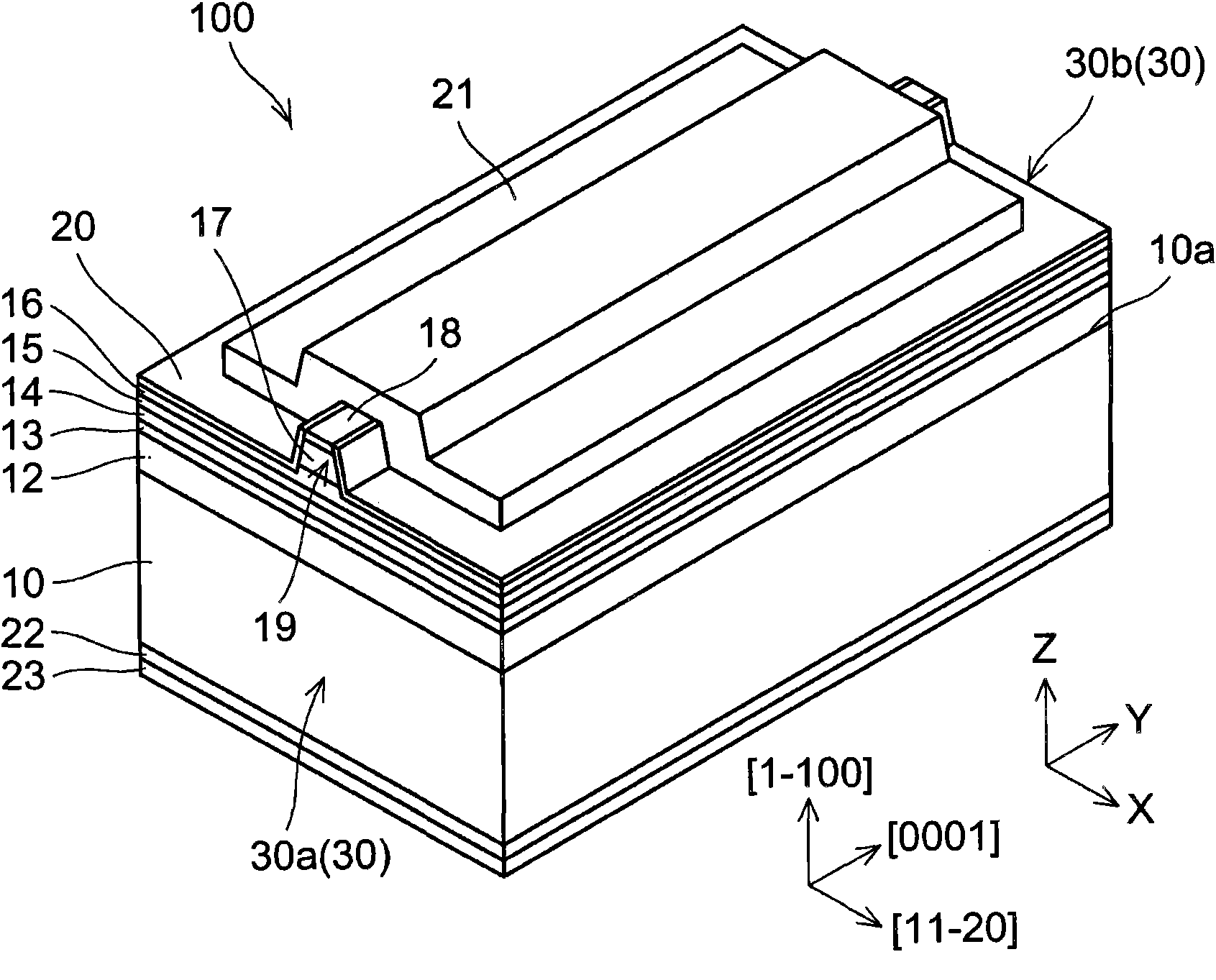

Nitride semiconductor light emitting device

ActiveUS20060017061A1Efficiently extract lightEfficient extractionSolid-state devicesSemiconductor/solid-state device manufacturingExternal circuitElectrode

A nitride semiconductor light emitting device comprising an n-side nitride semiconductor layer and a p-side nitride semiconductor layer formed on a substrate, with a light transmitting electrode 10 formed on the p-side nitride semiconductor layer, and the p-side pad electrode 14 formed for the connection with an outside circuit, and the n-side pad electrode 12 formed on the n-side nitride semiconductor layer for the connection with the outside circuit, so as to extract light on the p-side nitride semiconductor layer side, wherein taper angles of end faces of the light transmitting electrode 10 and / or the p-side nitride semiconductor layer are made different depending on the position.

Owner:NICHIA CORP

OLED pixel circuit and display device thereof

ActiveCN104900186ACompensation for uneven lightingLight evenlyStatic indicating devicesEngineeringPower flow

The invention belongs to the technical field of display and specifically relates to an OLED pixel circuit and a display device thereof. The OLED pixel circuit comprises an OLED, a driving unit for driving the OLED to emit light, and a compensating unit. One electrode of the OLED is connected with the driving unit. The compensating unit comprises a sensing element capable of sensing light and converting an optical signal of the OLED into an electric signal, and reversely compensates the driving current applied by the driving unit to the OLED according to the light-emitting brightness of the OLED. The OLED pixel circuit, by means of the cooperation of a photosensitive resistor and a compensating driving transistor, compensates uneven light emitting of a display panel due to parameter drifting of the driving unit and OLED aging in the TFT-OLED pixel circuit. The display device using the OLED pixel circuit has a better display effect.

Owner:BOE TECH GRP CO LTD

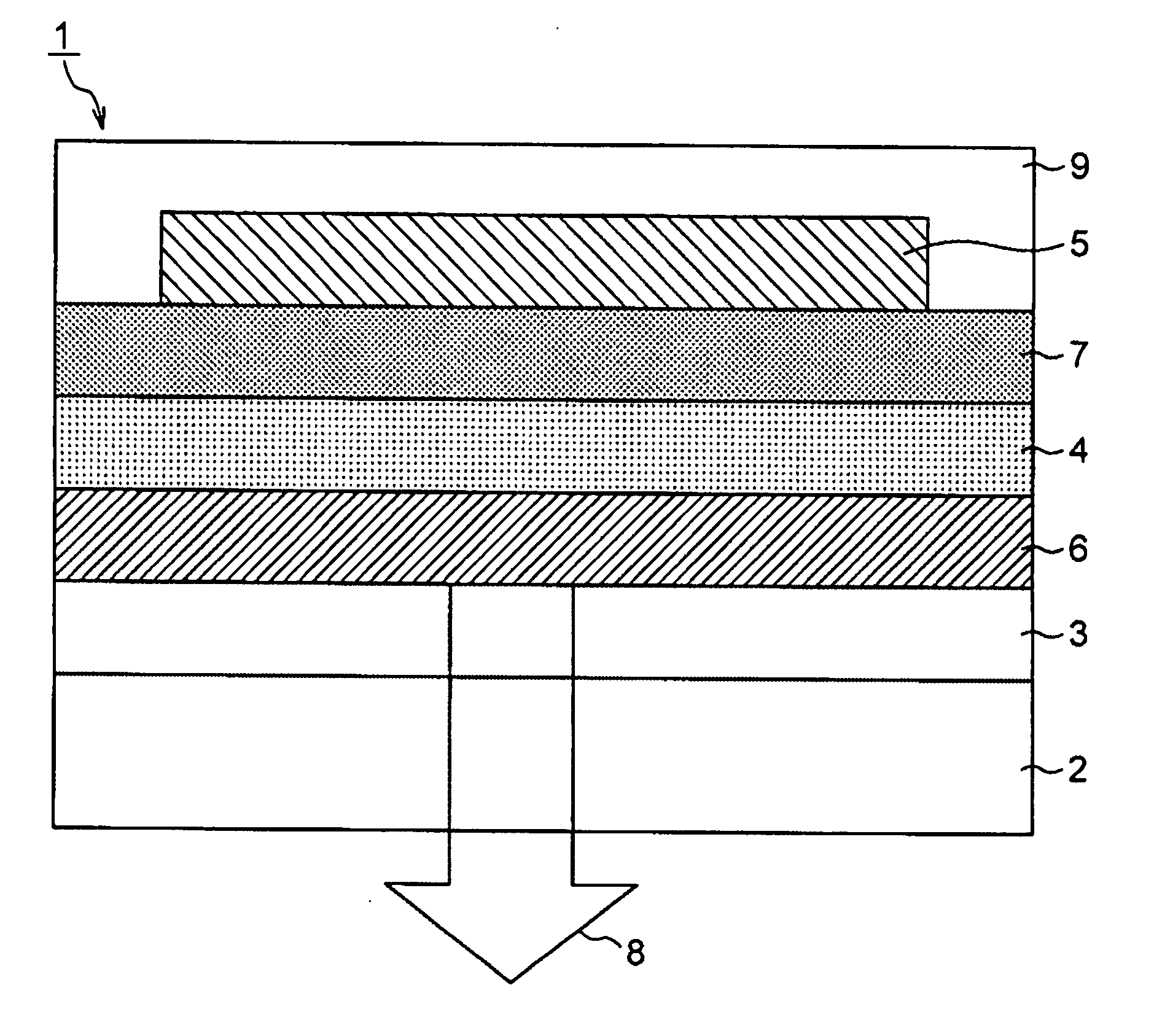

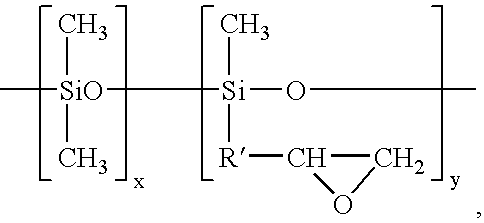

Organic functional element, organic EL element, organic semiconductor element, organic TFT element and method for producing the same

InactiveUS20060066224A1Easy to controlUniform light emitting surfaceDischarge tube luminescnet screensFinal product manufactureLiquid metalOrganic semiconductor

The present invention provides an organic functional element such as an organic EL element, an organic TFT element or the like, wherein the organic functional element does not require vapor deposition in formation of an electrode on an organic material layer, and does not cause an electrode breaking even when bended, and a method for producing the same. An organic functional element of the present invention at least comprises more than one electrode and an organic material layer, wherein at least one electrode is made of a liquid metal.

Owner:DAI NIPPON PRINTING CO LTD

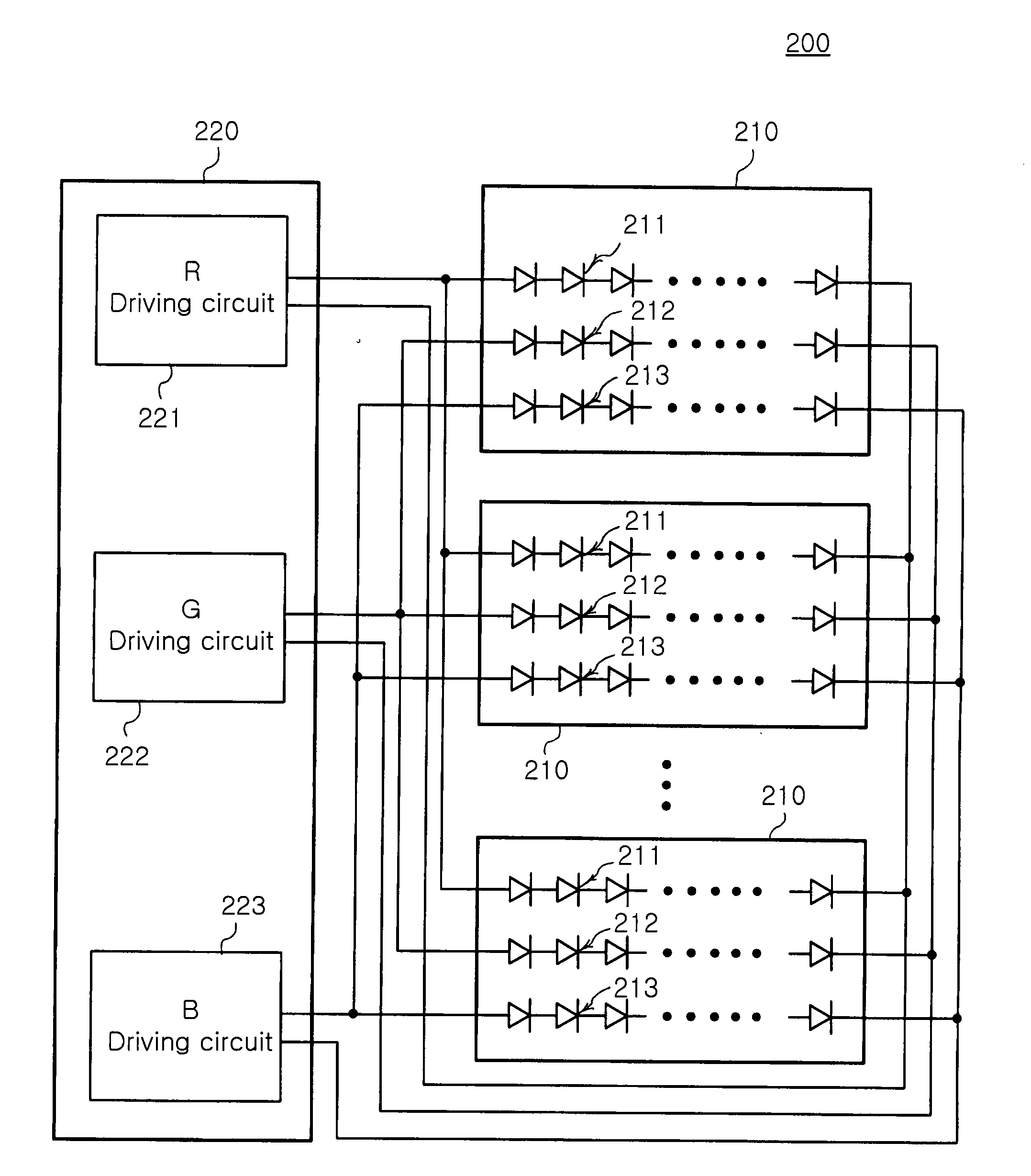

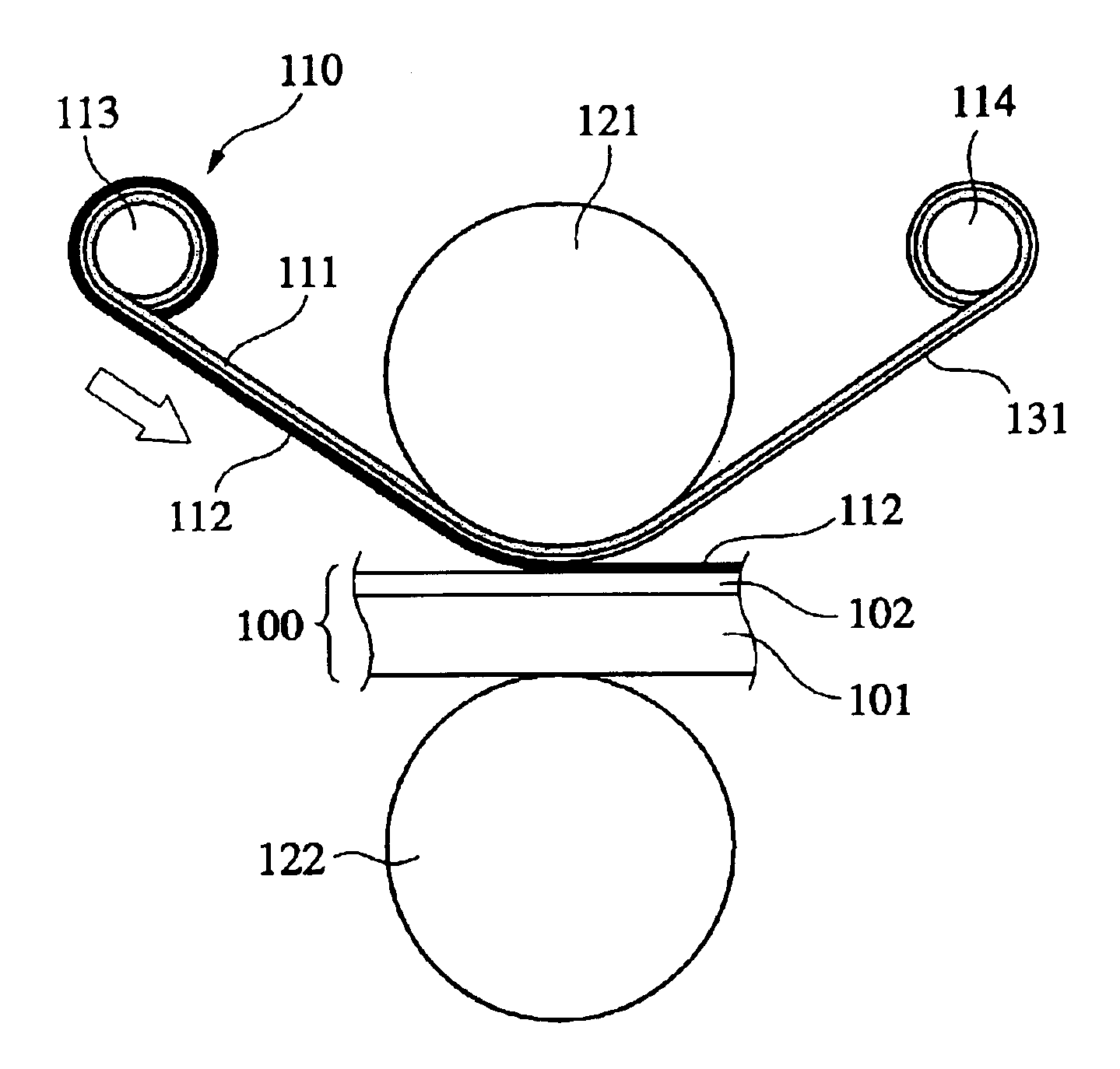

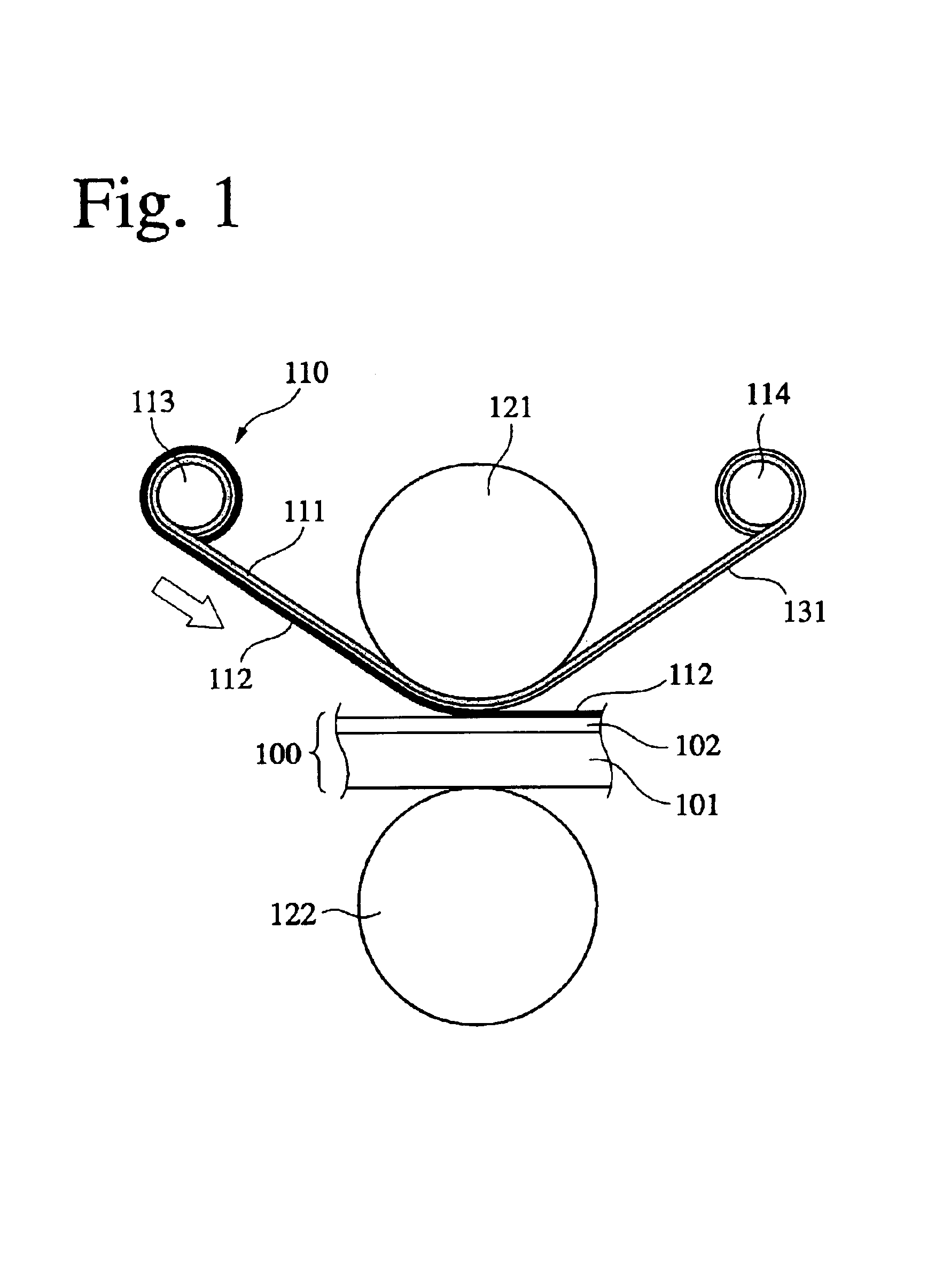

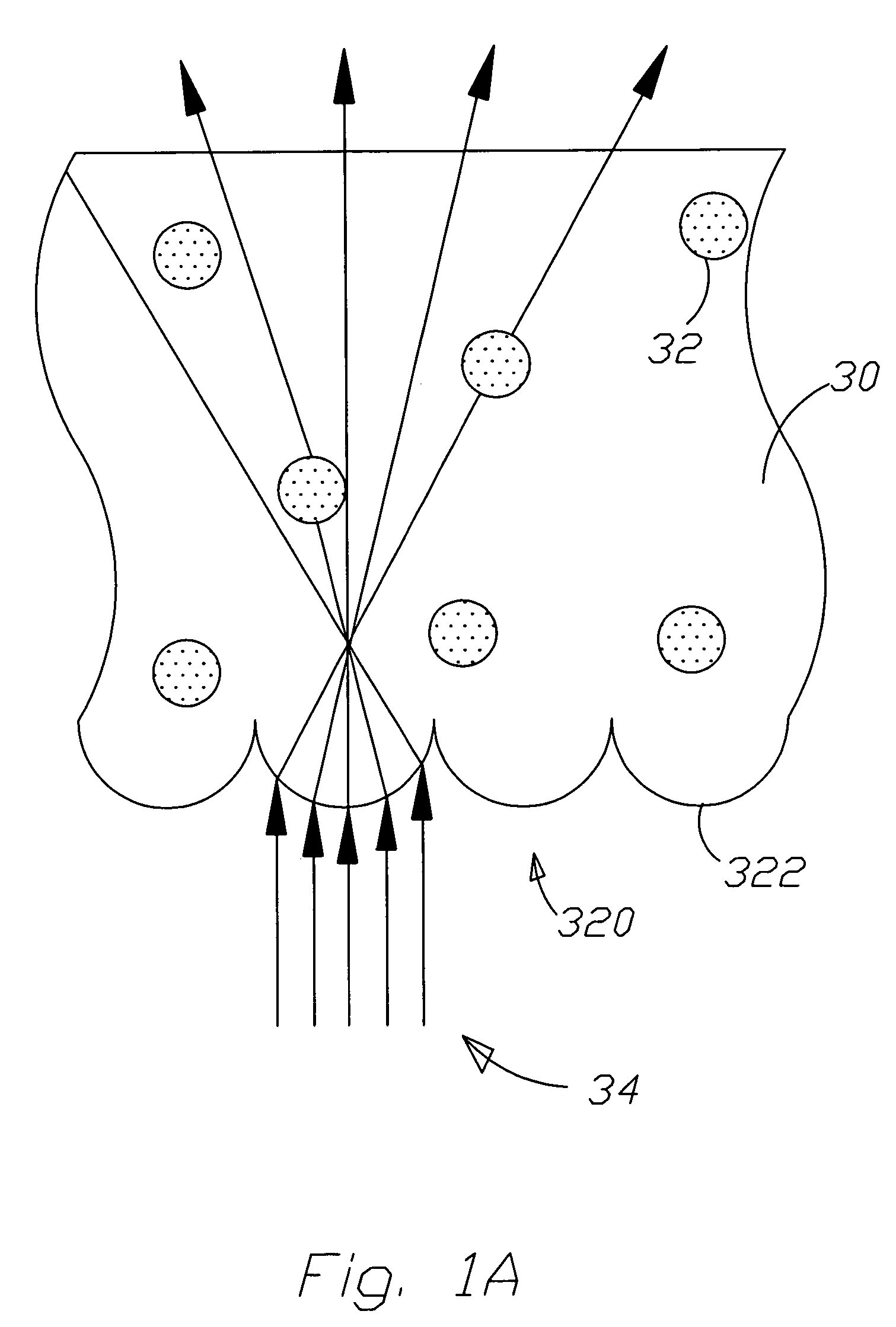

Method of manufacturing light emitting module, and light emitting module

ActiveUS20190294004A1Light evenlyLittle luminance non-uniformitySolid-state devicesOptical light guidesLight guideLight-emitting diode

The method of manufacturing a light emitting module includes: providing a light guiding plate having a first main surface serving as a light emitting surface; and a second main surface positioned opposite to the first main surface and provided with a recess; providing a light adjustment portion containing a fluorescent material; providing a light emitting element unit in which a light emitting element comprising an electrode is integrally bonded to the light adjustment portion; bonding the light adjustment portion of the light emitting element unit to the recess; and forming wiring on the electrode of the light emitting element.

Owner:NICHIA CORP

Light emitting device and method for manufacturing the same

ActiveUS20120248483A1Satisfactory light extraction efficiencyLight evenlySolid-state devicesSemiconductor/solid-state device manufacturingPhosphorReflective layer

A light emitting device includes a substrate having a conductive portion; a light emitting element having one or more electrodes on a lower surface side thereof, the electrodes being positioned on the conductive portion of the substrate; a phosphor layer disposed on a surface of the light emitting element and on a peripheral surface area of the conductive portion next to the light emitting element; and a reflection layer covering a part of the phosphor layer disposed on the peripheral surface area of the conductive portion.

Owner:NICHIA CORP

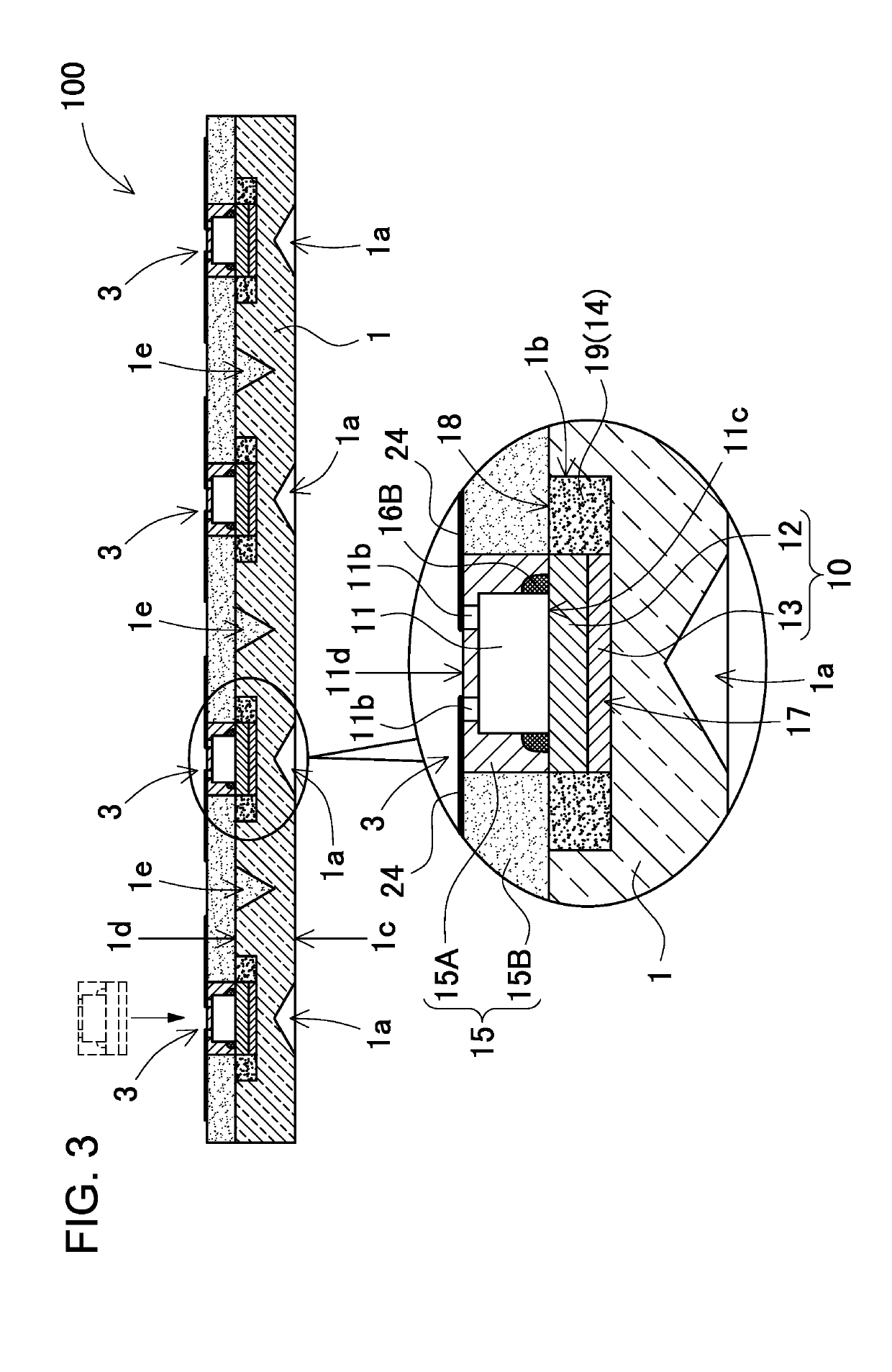

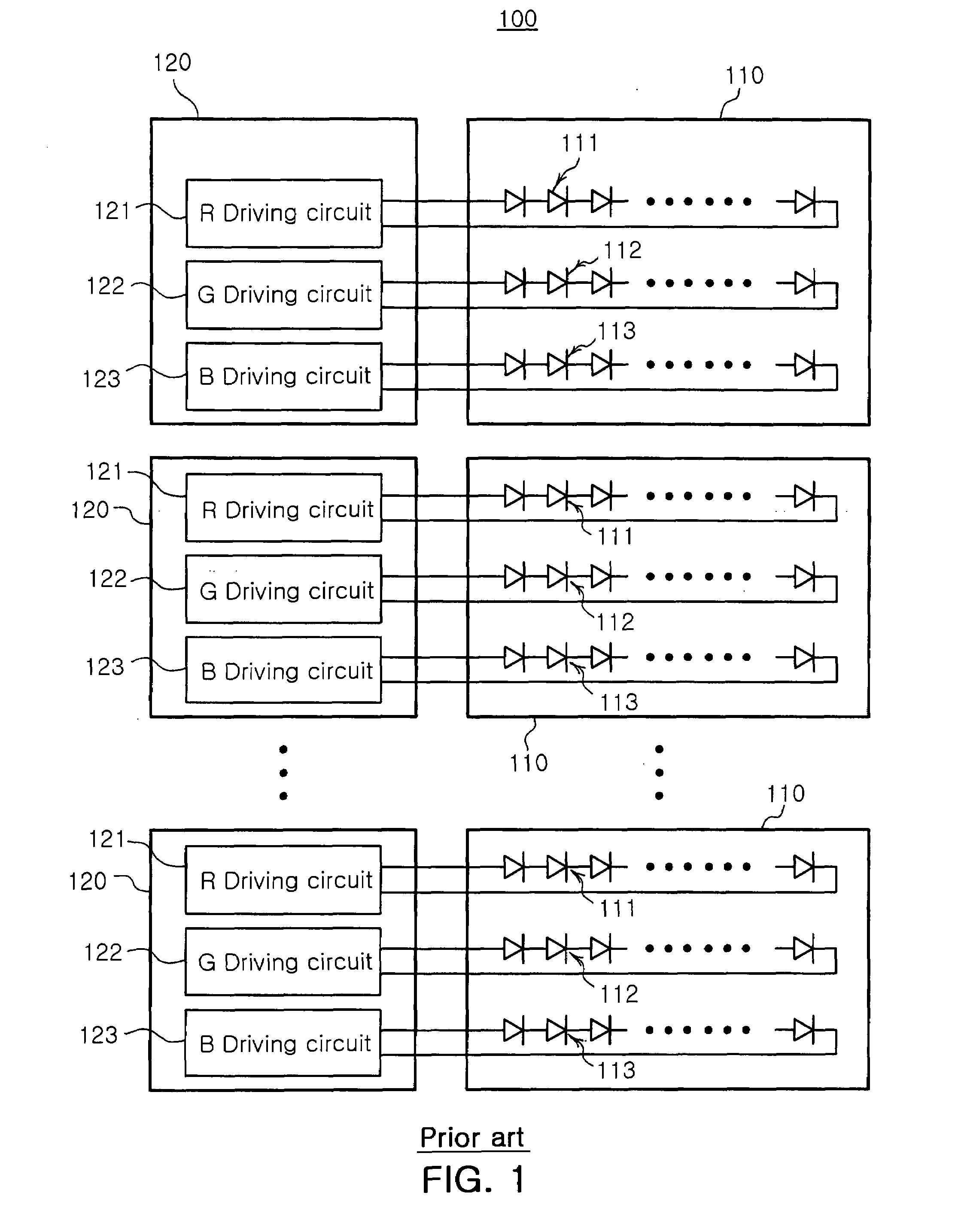

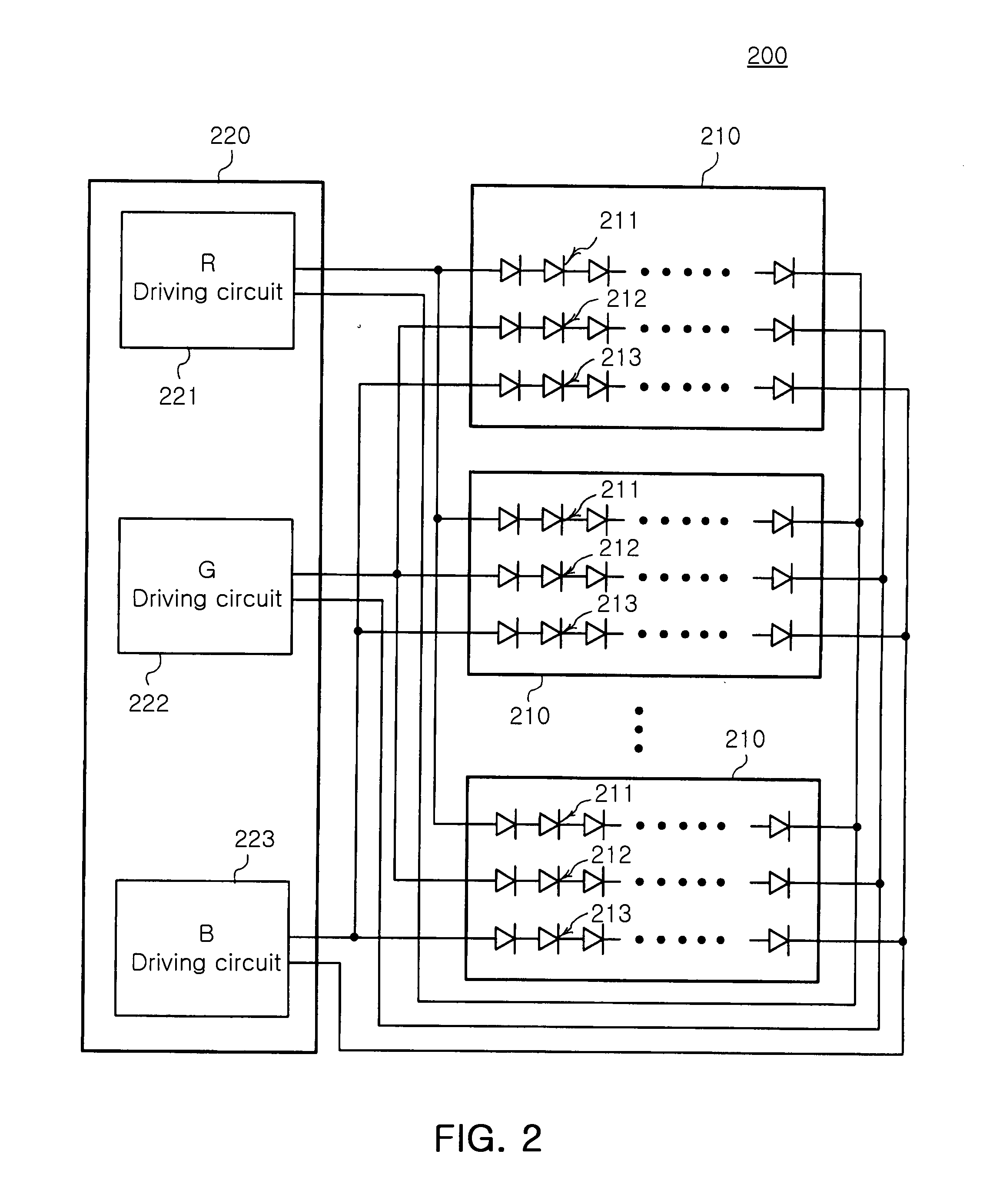

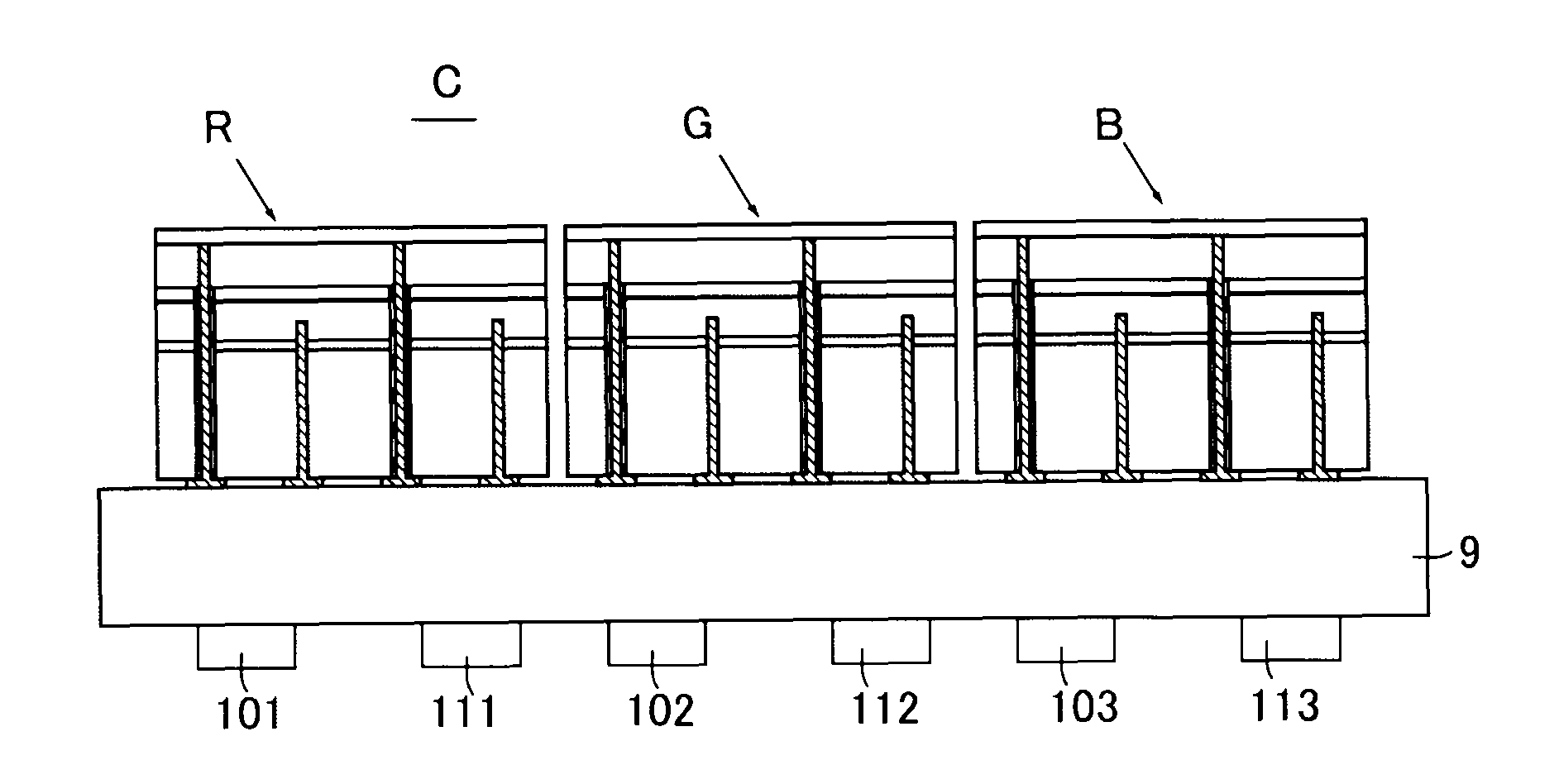

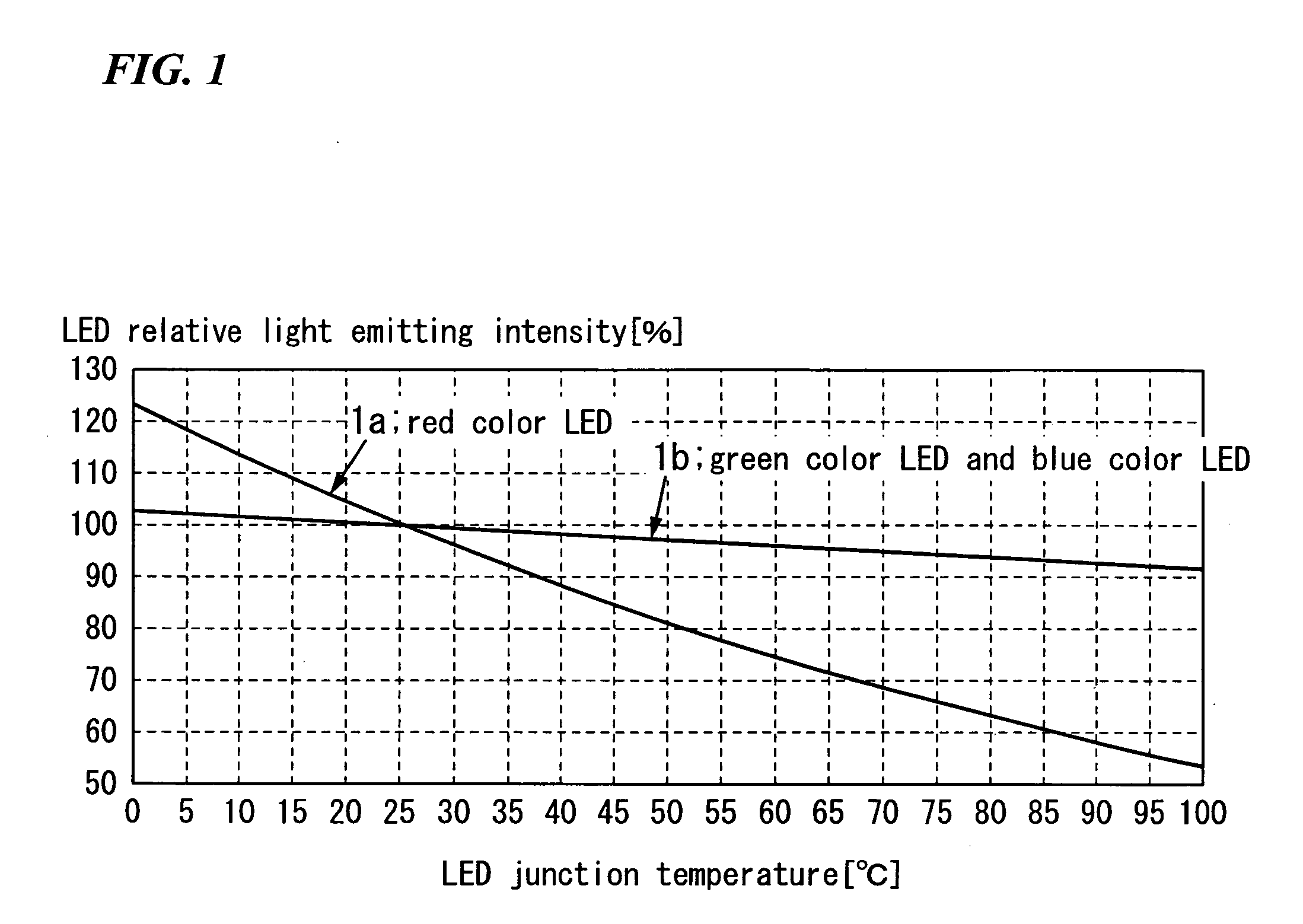

Backlight unit using light emitting diode

InactiveUS20070236447A1Improve image qualityLight evenlyPoint-like light sourceStatic indicating devicesEngineeringGreen led

A backlight unit using LEDs in which a plurality of LEDs of different colors used for a surface light source are connected in an electric connection structure incorporating series and parallel connections so that the LEDs of the same color are driven by a single driving circuit, thereby improving the driving efficiency of LEDs. The backlight unit includes a plurality of LED modules each having a plurality of red LEDs, a plurality of green LEDs, and a plurality of blue LEDs electrically connected, respectively. The backlight unit also includes an LED driver composed of a red LED driving circuit, a green LED driving circuit, and a blue LED driving circuit for driving each color group of the plurality of LEDs provided in the LED modules. The plurality of red LEDs, the plurality of green LEDs, and the plurality of blue LEDs in the respective LED modules are electrically connected, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

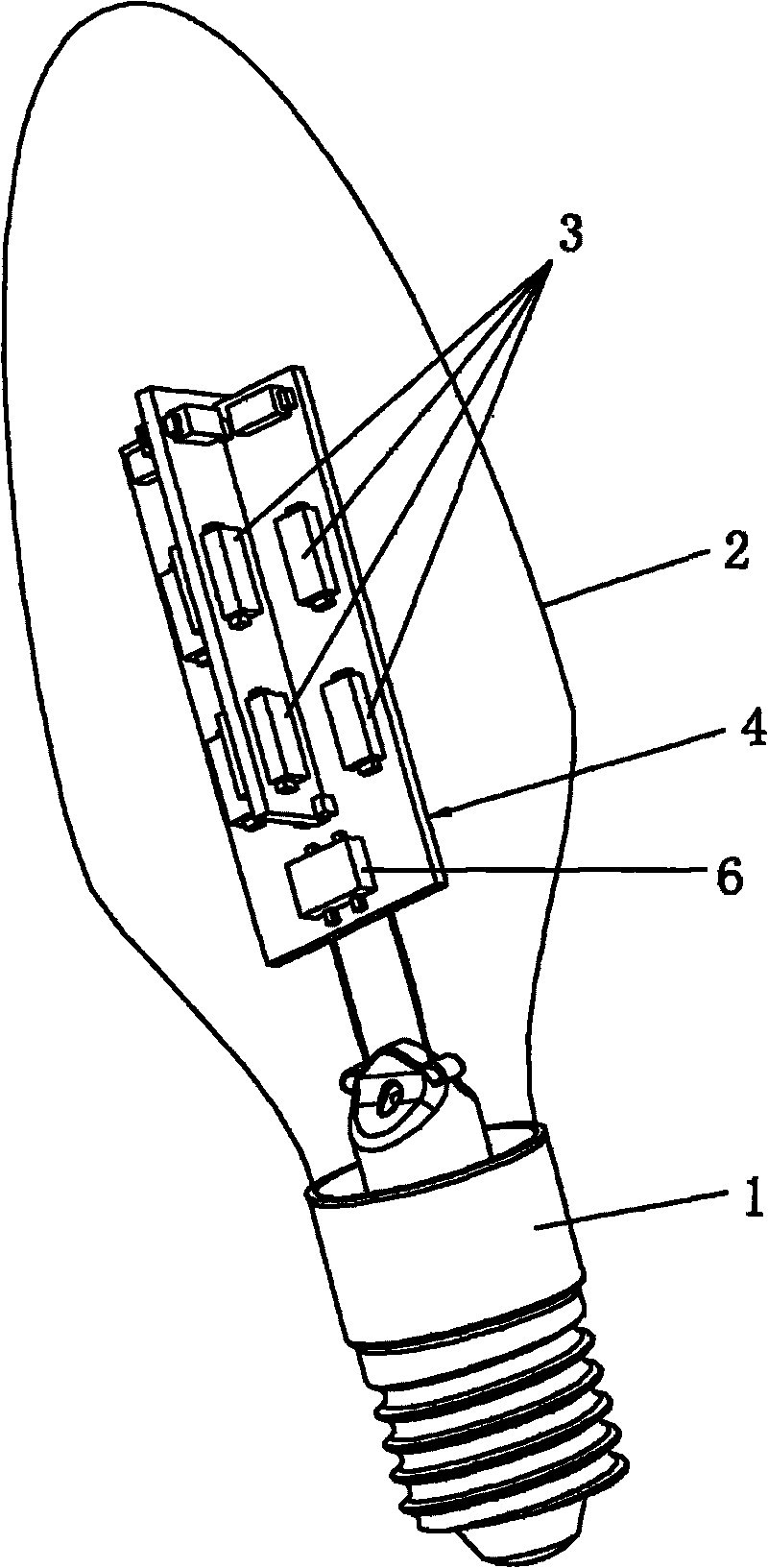

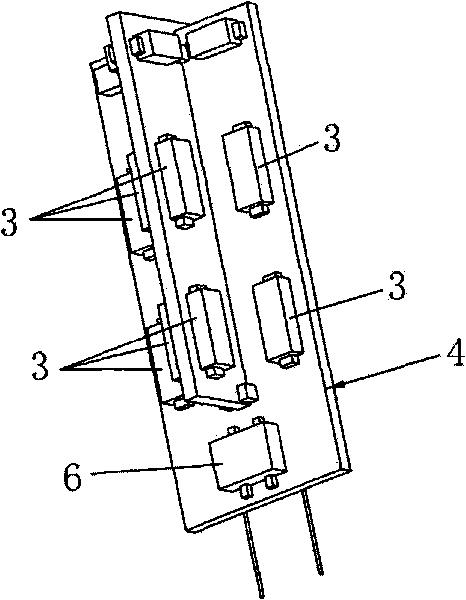

LED lamp bulb

InactiveCN101706058ASolve the cooling problemExtended service lifePoint-like light sourceElectric circuit arrangementsElectricityHeat transmission

The invention relates to the technical field of lighting lamps, in particular to an LED lamp bulb which comprises a lamp holder, a lamp shade, an LED and a circuit board, wherein the bottom end of the lamp shade is installed and fixed at the top end of the lamp holder; the circuit board is installed and fixed inside the lamp shade and electrically connected with the lamp holder; and the interior of the lamp shade is filled with mixed gas used for conducting heat generated by the LED to the exterior of the lamp bulb. As the heat generated by the LED is emitted by the mixed gas, the LED lamp bulb has the characteristics of light weight, small volume and low production cost; in addition, the mixed gas is used as the medium of heat transmission, therefore the LED lamp bulb can quickly emit the heat generated by the LED to the exterior of the lamp bulb, with fast heat dissipation speed, thus effectively resolving the heat dissipation problem of the LED and prolonging the service life of the LED.

Owner:东莞市贺喜光电有限公司

Light-emitting diode, light-emitting device, lighting apparatus, display, and signal light

InactiveUS7842958B1Large light emission amountImprove light emission efficiencyNon-linear opticsSemiconductor devicesDisplay deviceConductive materials

A light-emitting diode includes a substrate, a semiconductive light-emitting layer, and electrodes. The semiconductive light-emitting layer is deposited on one side of the substrate. The electrodes are composed of a conductive material filled in pores leading to the semiconductive light-emitting layer through the substrate. The semiconductive light-emitting layer includes sequentially deposited n-type and p-type semiconductive layers. The electrodes include n-side and p-side electrodes. One of the n-side and p-side electrodes penetrates through one of the n-type and p-type semiconductive layers, which is disposed closer to the substrate but not targeted for connection, and terminates with a tip thereof located within the other semiconductive layer. The other of the n-side and p-side electrodes penetrates through the substrate from the other side opposite to the one side of the substrate and terminates with a tip thereof located within the one semiconductive layer disposed closer to the substrate.

Owner:NAPRA

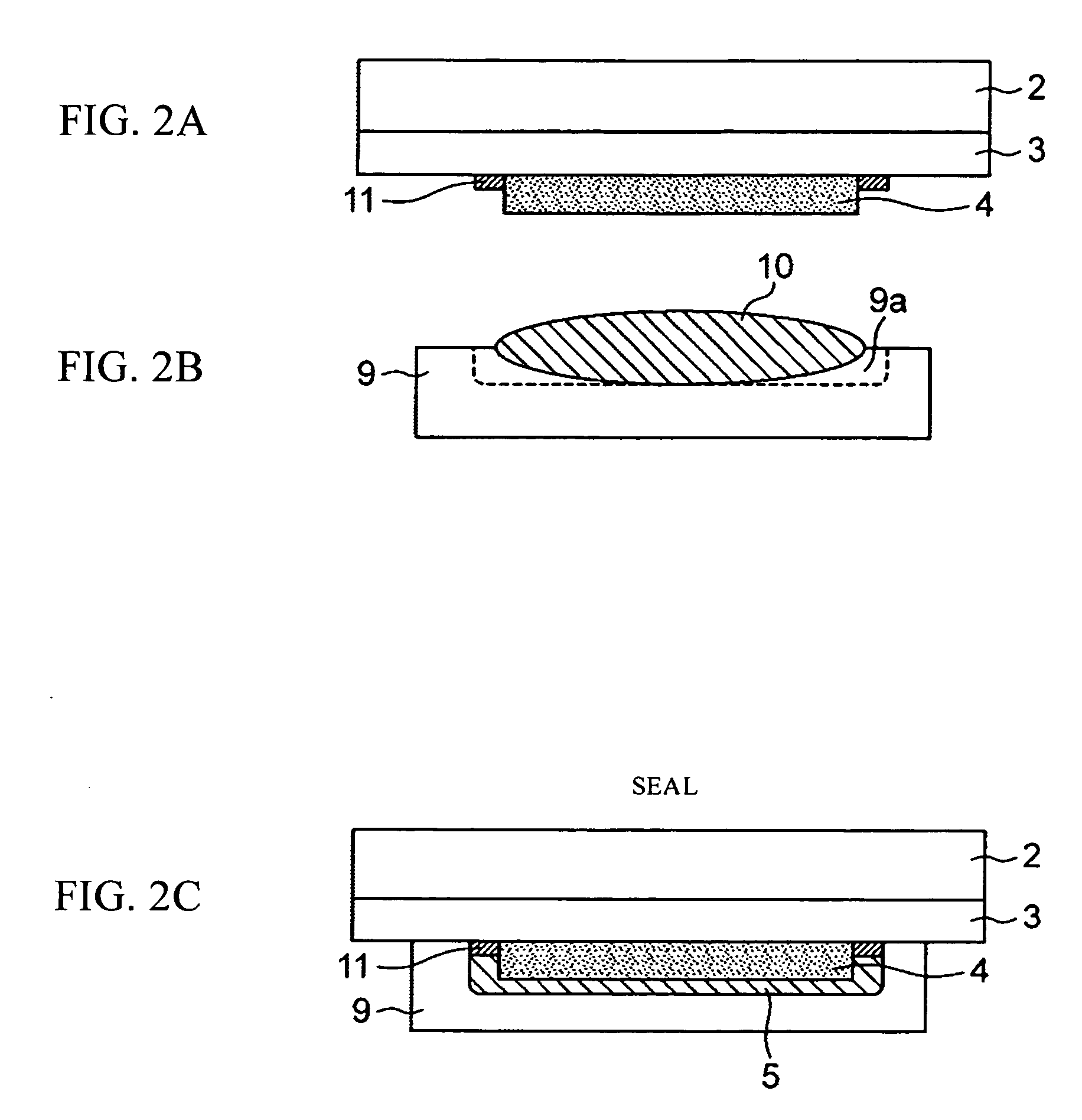

Method for producing organic electroluminescent device and transfer material used therein

InactiveUS6923881B2Good adhesion interfaceLow costDiffusion transfer processesLamination ancillary operationsEngineeringOrganic electroluminescence

Owner:UDC IRELAND

Nitride semiconductor light emitting device

ActiveUS7358544B2Effective lightingEfficient extractionSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceExternal circuit

A nitride semiconductor light emitting device comprising an n-side nitride semiconductor layer and a p-side nitride semiconductor layer formed on a substrate, with a light transmitting electrode 10 formed on the p-side nitride semiconductor layer, and the p-side pad electrode 14 formed for the connection with an outside circuit, and the n-side pad electrode 12 formed on the n-side nitride semiconductor layer for the connection with the outside circuit, so as to extract light on the p-side nitride semiconductor layer side, wherein taper angles of end faces of the light transmitting electrode 10 and / or the p-side nitride semiconductor layer are made different depending on the position.

Owner:NICHIA CORP

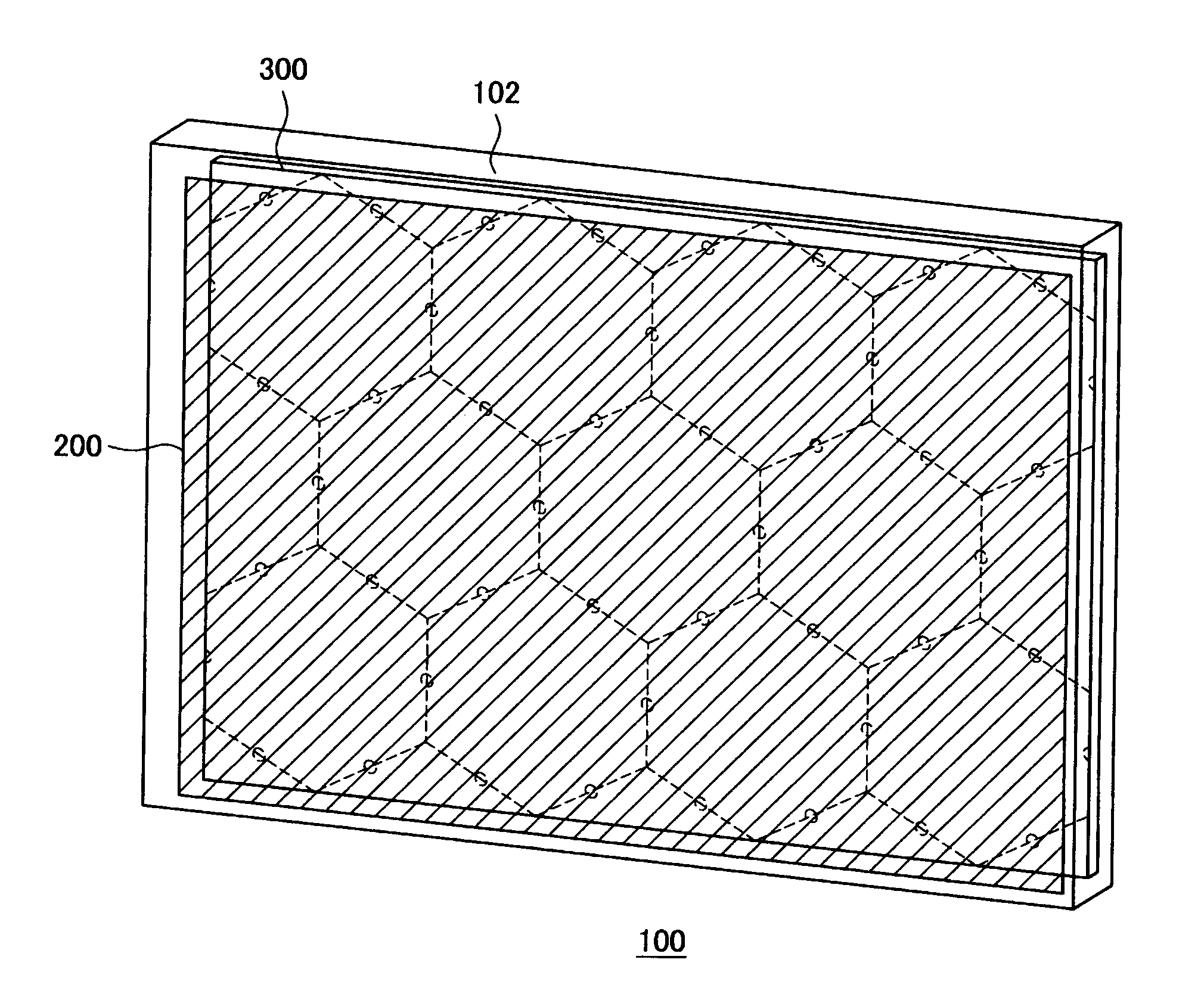

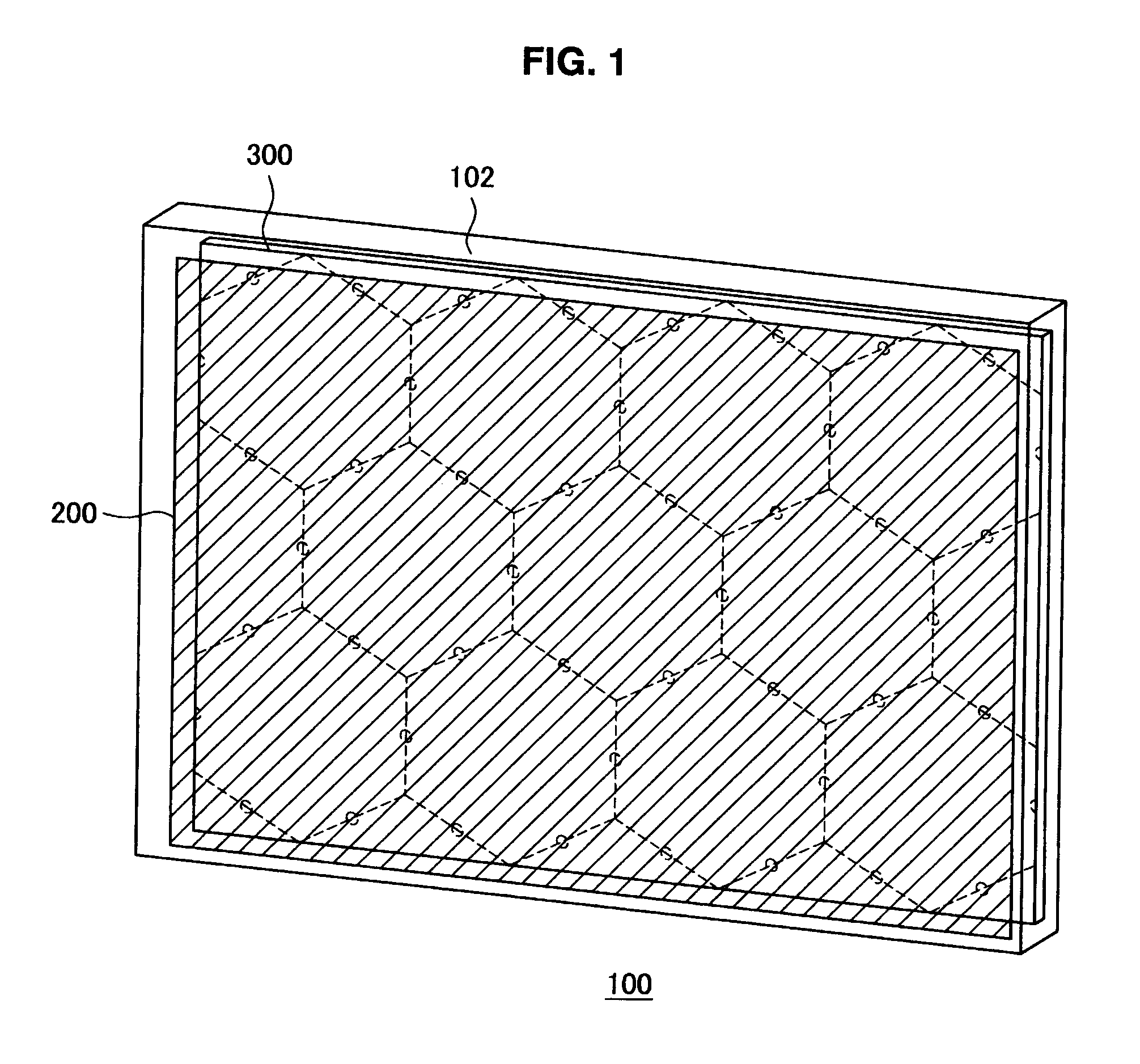

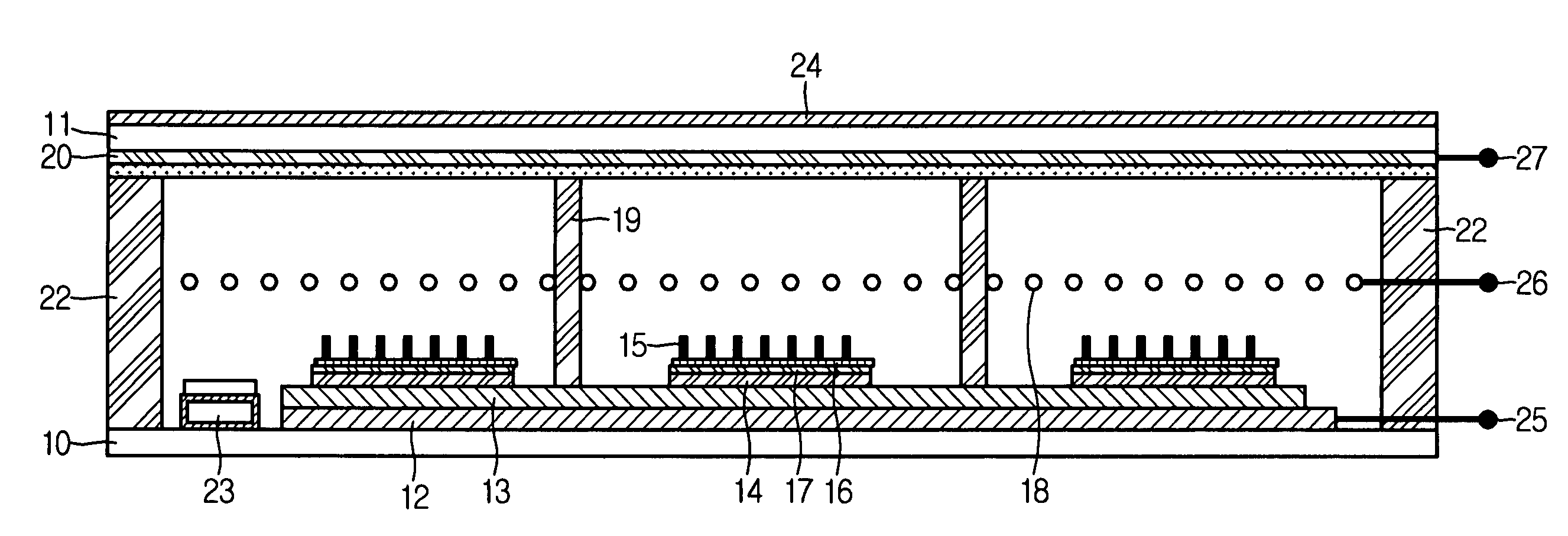

Area light source device and display device

InactiveUS8348446B2Launch evenlyLight evenlyIlluminated signsOptical light guidesLight guideDisplay device

An area light source device according to the present invention includes a plate-shaped light guide plate that has one surface that serves as a transmissive surface and another surface that is on the opposite side from the transmissive surface and in which a plurality of recessed portions are provided. The area light source device also includes at least two light-emitting diodes that are accommodated in each of the recessed portions, that emit light in a direction in which the light guide plate extends, and that are disposed such that they emit light in different directions. In this configuration, directing a light-emitting face of any one of the light-emitting diodes such that it faces a given light-emitting area makes it possible to cause light to be emitted uniformly within the light-emitting area and also makes it possible to cause light to be emitted only within the specific light-emitting area.

Owner:SONY CORP

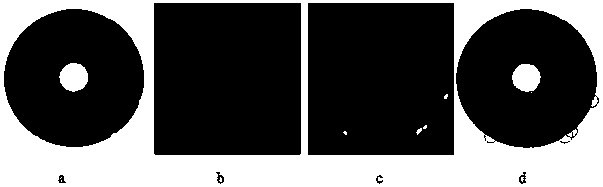

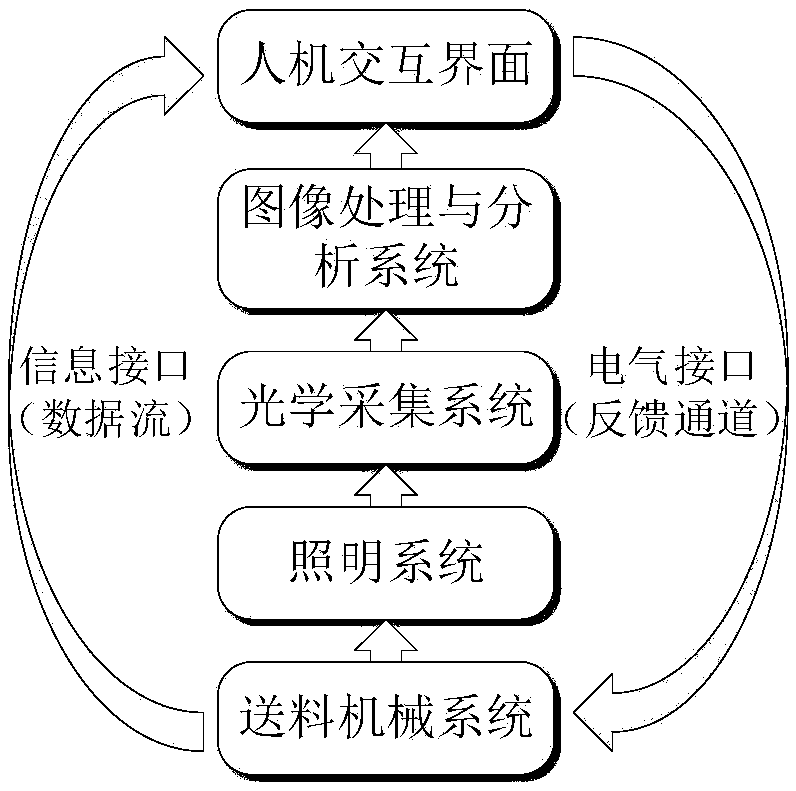

Online detection method for circular plate casting based on machine vision

ActiveCN109141232ALight evenlyImprove signal-to-noise ratioImage enhancementImage analysisSample imageImage pre processing

The invention discloses an online detection method for a circular plate casting based on machine vision, and the method comprises the steps: obtaining the front and back images of a circular plate casting sample through collecting the image of the circular plate casting sample, and performing the preprocessing of the images; detecting the size of the sample according to the collected sample image,performing the preliminary discrimination of defects, and performing the next detection; performing the amplification of a gap through the image processing, extracting the coordinates, and achievingthe detection marking of the sample gap; performing the detection of the rag defects of the sample according to the comparison between the degree of deviation of the edge from the reference and a setthreshold value; and finally completing the discrimination of whether the sample is qualified or not. The method can achieve the real-time quick recognition of the gap and rags of the circular plate casting, and is suitable for a high-speed online detection system.

Owner:CHANGZHOU HIDEA MACHINERY +1

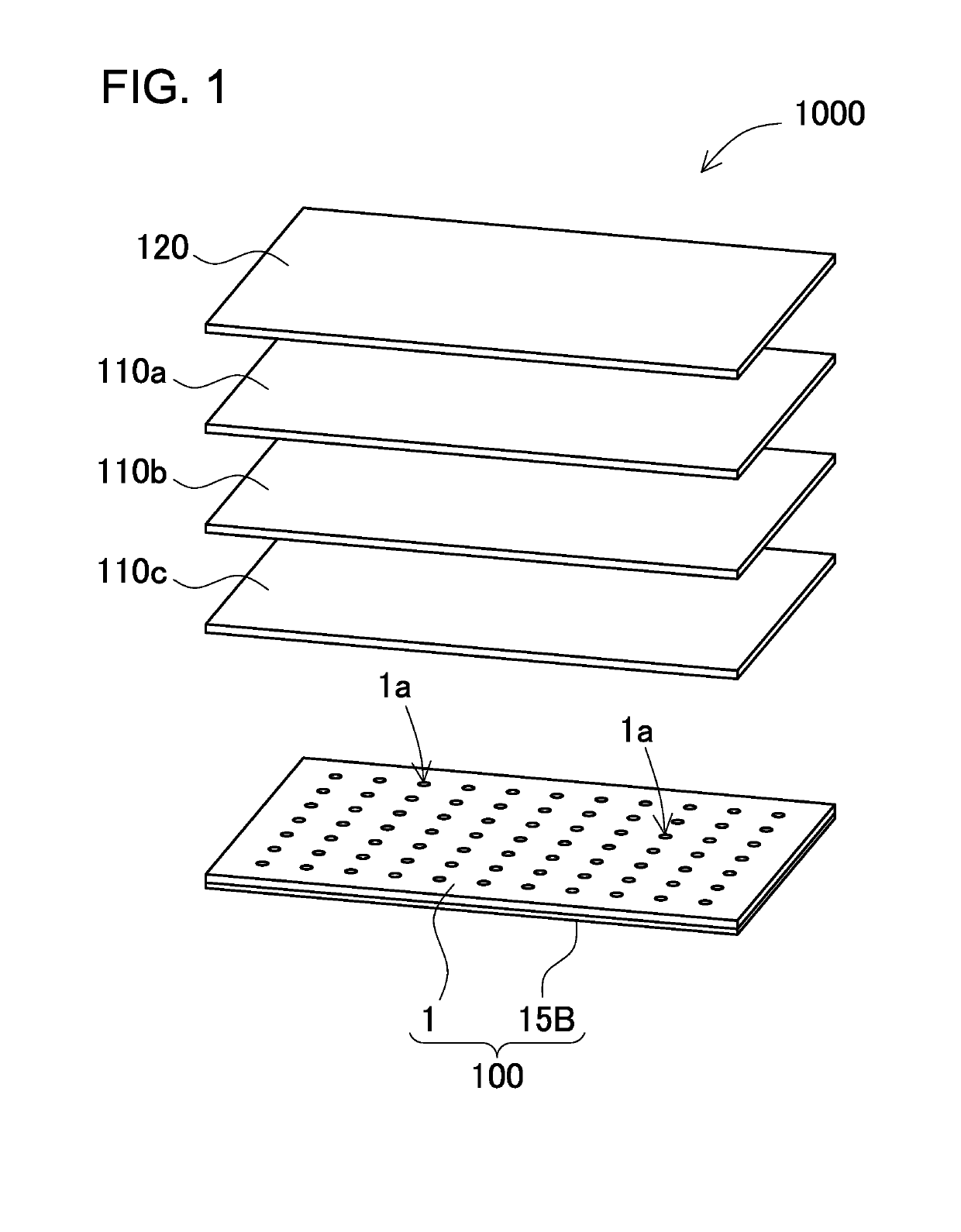

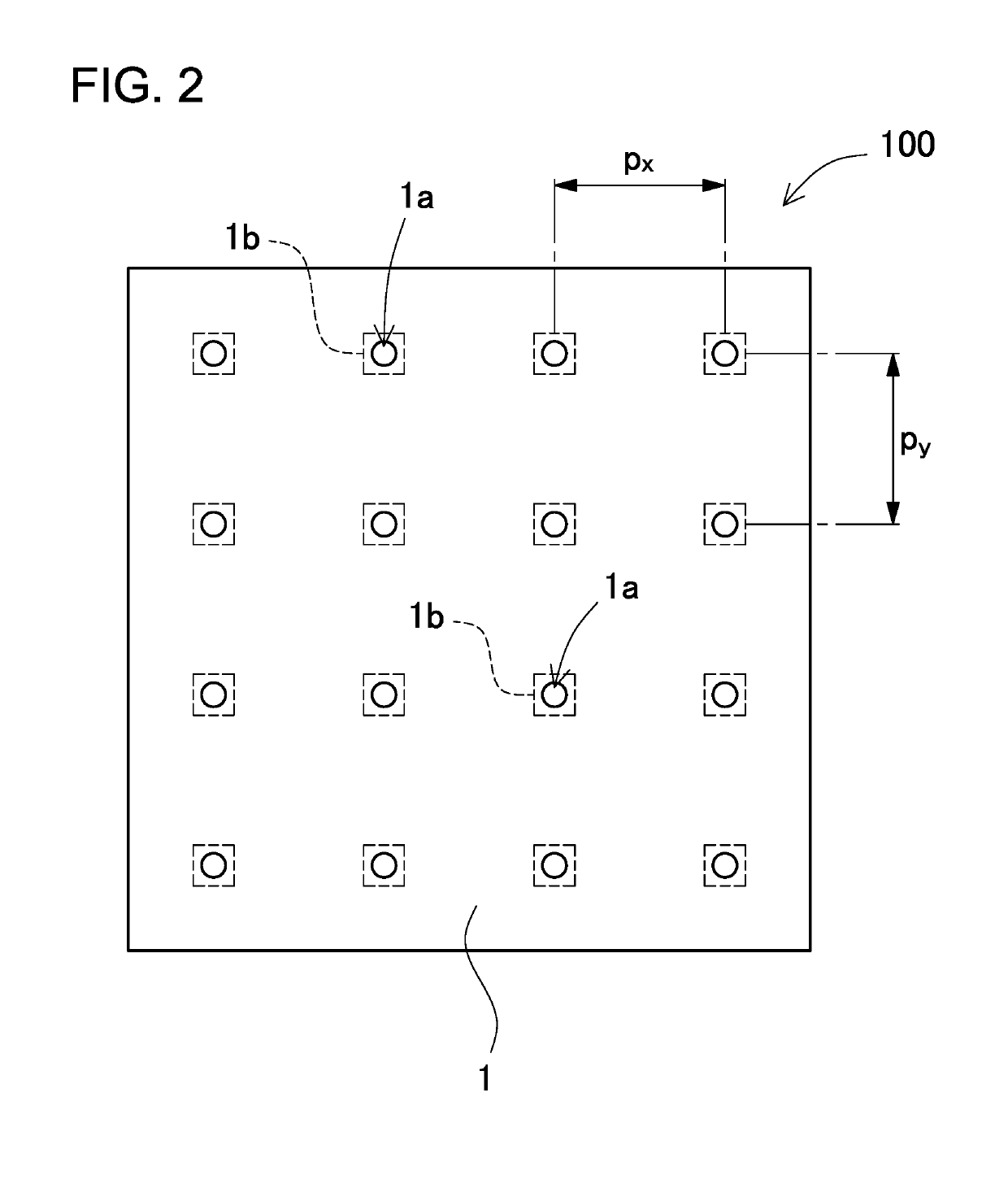

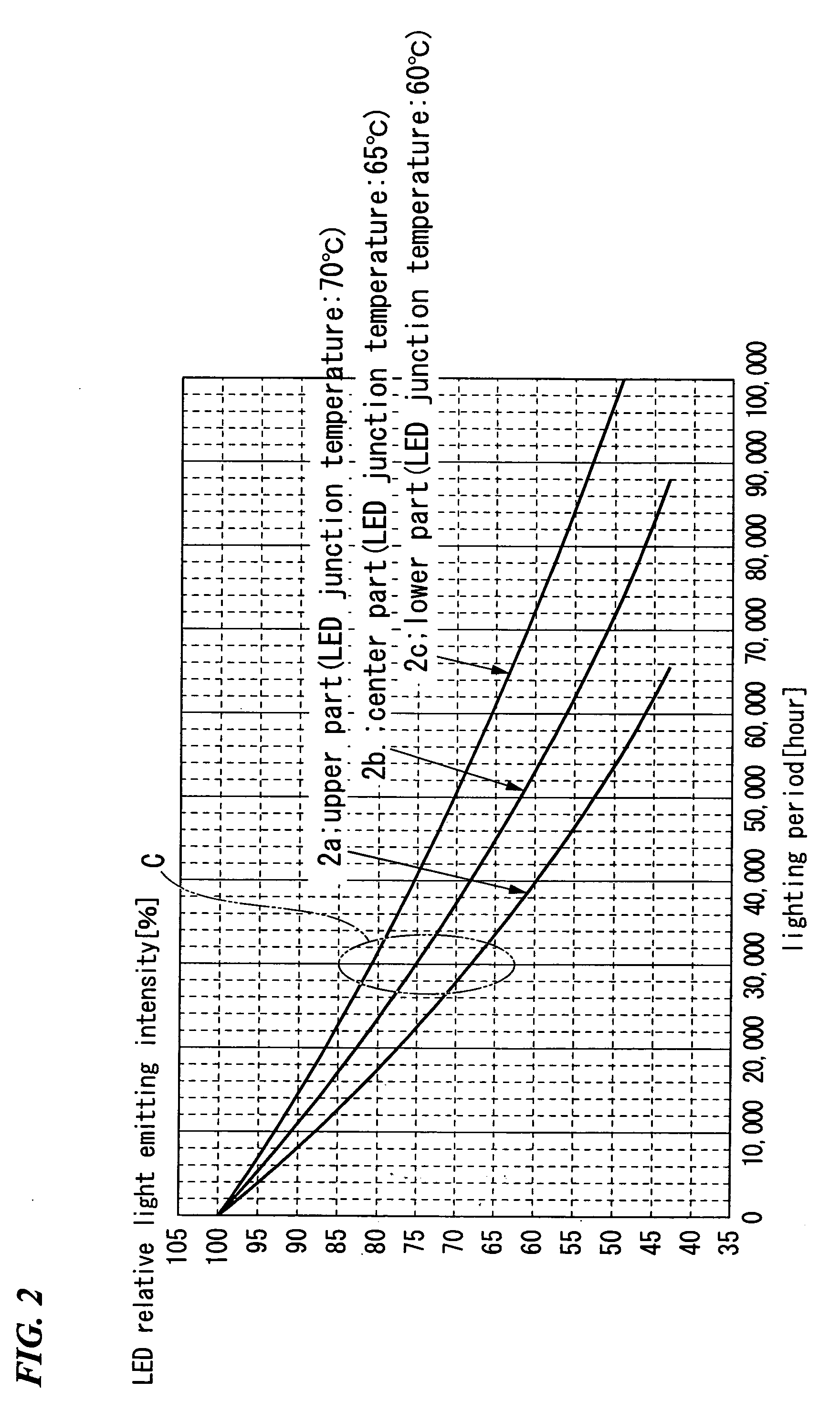

Illumination apparatus

ActiveUS20100141167A1Cost be suppressUniform color and luminancePoint-like light sourceStatic indicating devicesIntensity controlHigh density

An illumination apparatus used in non-light emission transparent display devices includes a base material, light emitting elements arranged two dimensionally on the surface of the base material, a drive section driving the light emitting elements, and a light emitting intensity control section controlling a light emitting intensity of the light emitting elements. An arrangement of the light emitting elements is such that a density at ends of the base material is high compared to that in a center part thereof, and the ends have a high density in regions where the base temperature is high and the center part has a high density in regions where the base material temperature is high.

Owner:SHARP NEC DISPLAY SOLUTIONS LTD

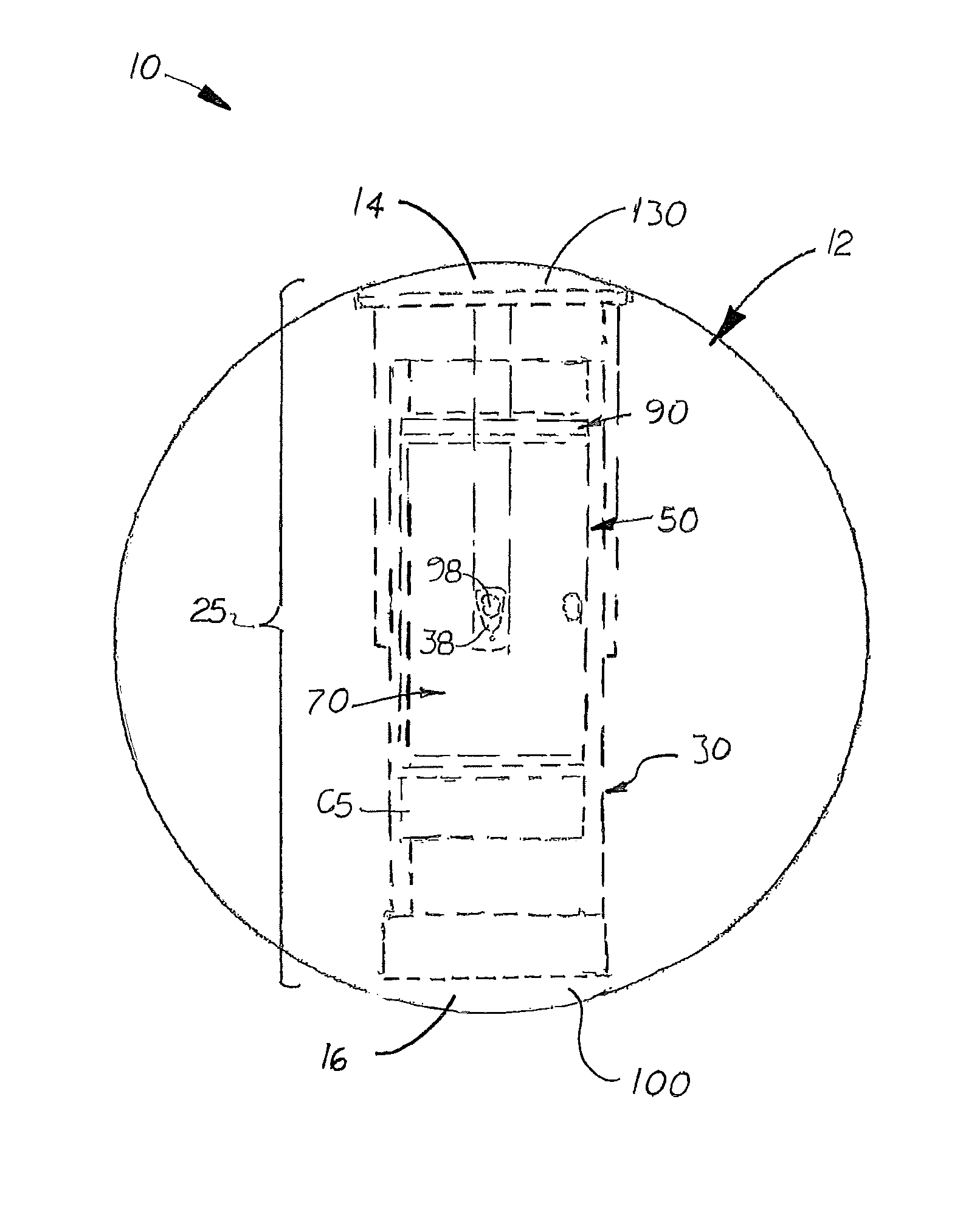

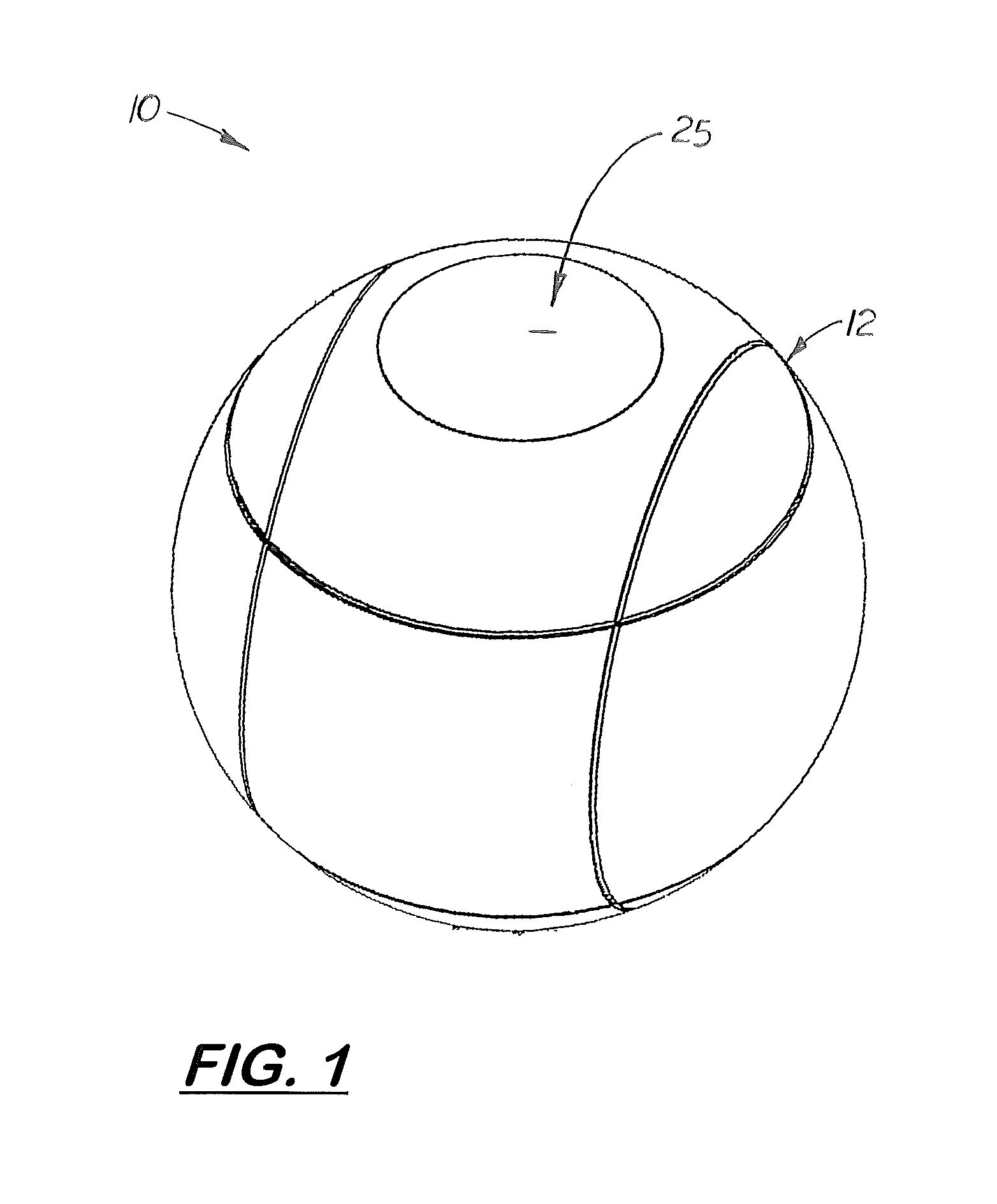

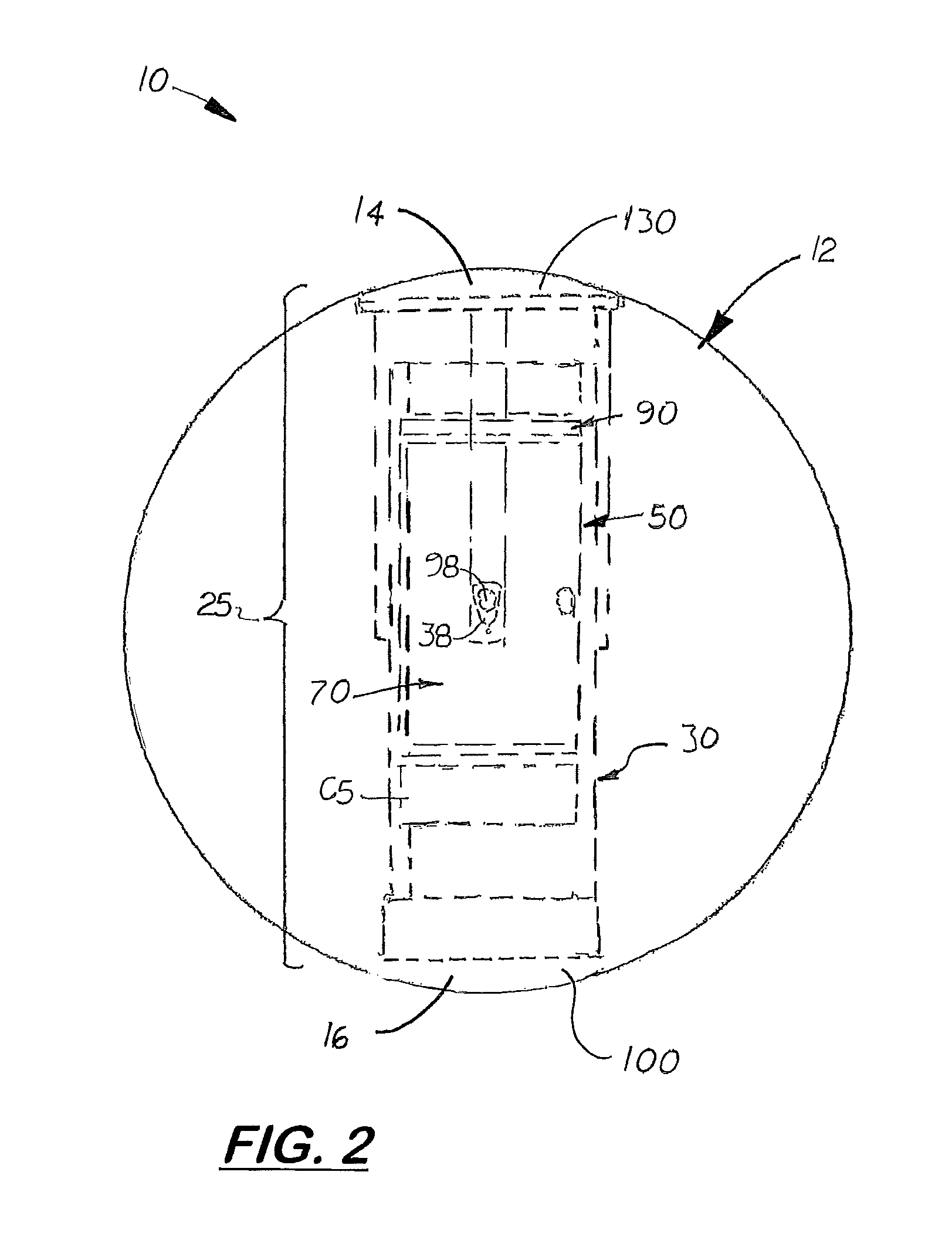

Illuminated rolling game ball

ActiveUS8992353B1Securely holdRoll accuratelyHollow inflatable ballsHollow non-inflatable ballsEngineeringConductive materials

An improved LED illuminated rolling game ball designed to use three AAA batteries. The ball includes a plastic, opaque spherical body with an axially aligned bore in which a multiple LED light assembly extends. The light assembly includes an outer tube, an intermediate sleeve, a multiple AAA battery holder, a multiple LED bulb holder, one switch cap and one end cap. In one embodiment, outer tube is a solid structure made of electrical conductive material includes two opposite end openings that connect to the switch and end caps that hold the outer tube in place in the bore. LED bulb holes are formed on the outer tube. The intermediate sleeve is located inside the outer tube and the battery holder is located inside the intermediate sleeve. The LED bulb holder includes a PCB with two or more LED bulbs arms that hold the LED bulbs outward through the bores formed on the outer tube.

Owner:KORTEGAST BEDE

Light emitting diode lamp

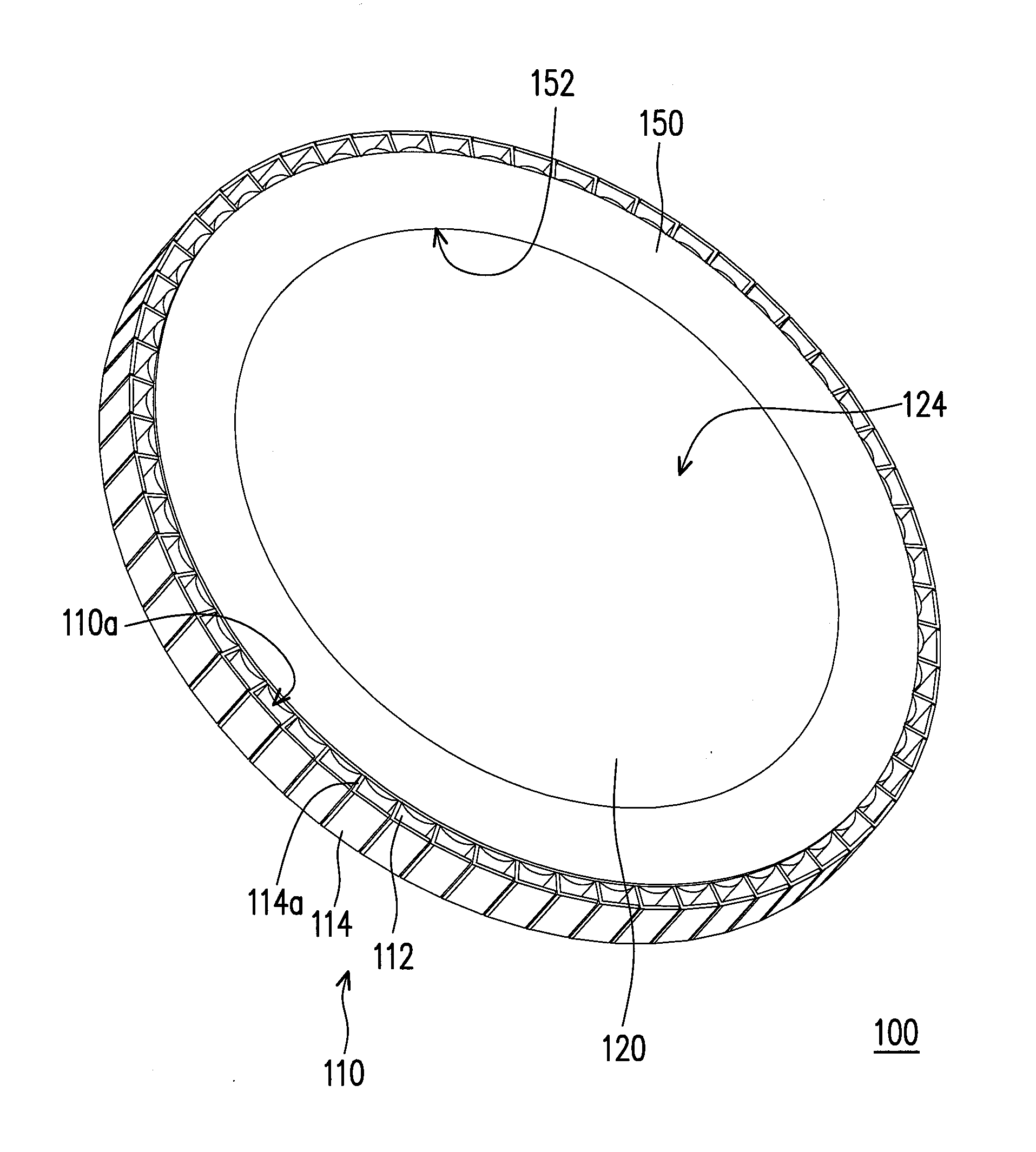

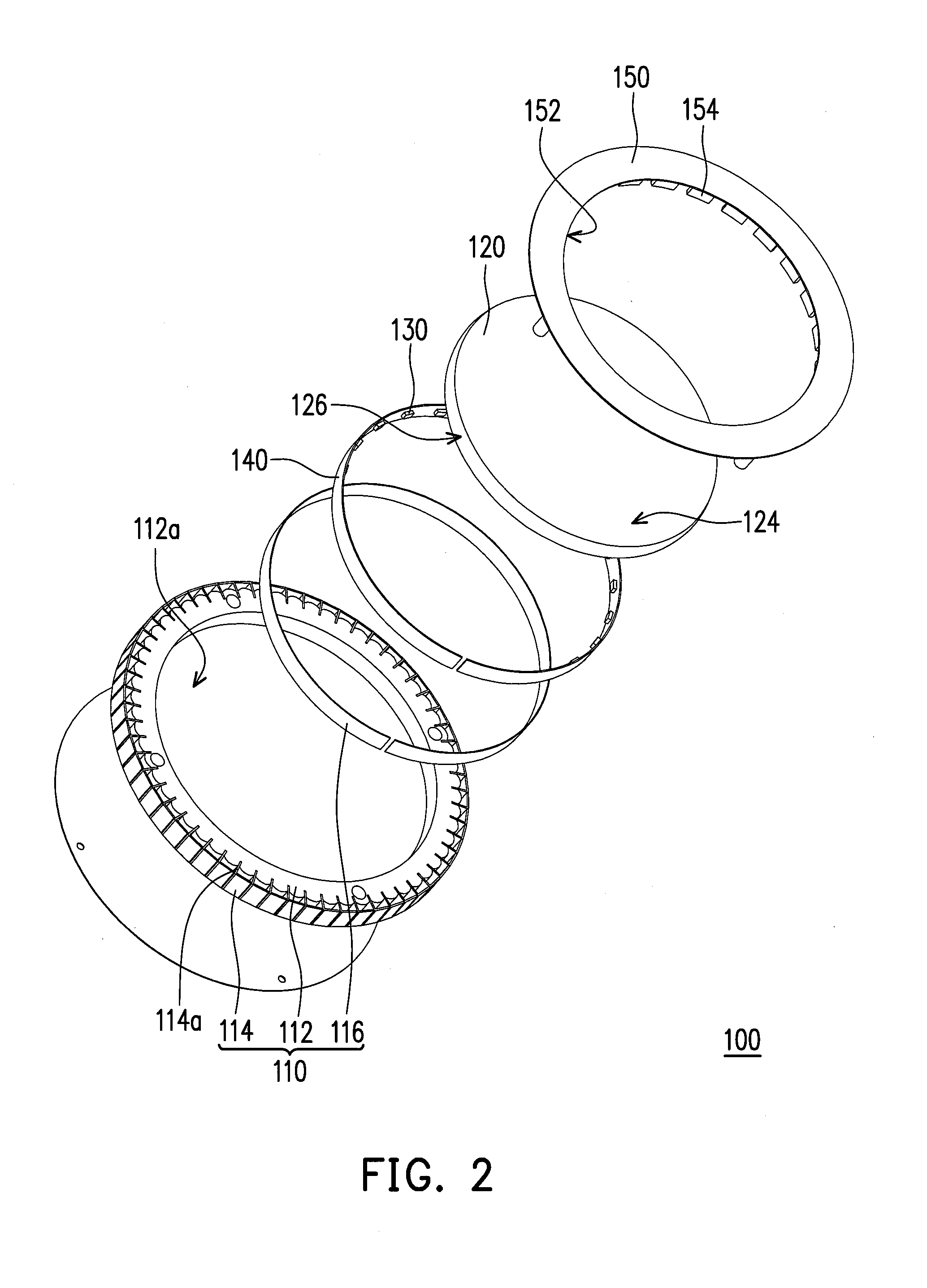

InactiveUS20120236593A1Improve cooling efficiencySimple structureMechanical apparatusPoint-like light sourceHeat conductingLight guide

A light emitting diode (LED) lamp includes a heat dissipation module, a circular light guide plate (LGP), and LED light sources. The heat dissipation module includes a heat dissipation element and a heat-conducting base that has a containing concave. The heat dissipation element connecting and surrounding the heat-conducting base is distant from the circumference of the heat-conducting base. The circular LGP in the containing concave has a top surface, a bottom surface, and an annular side surface. The top surface faces the heat-conducting base and has concentric annular trenches. The LED light sources are configured in the containing concave and face the annular side surface. The LED light sources are suitable for emitting a light beam which is capable of passing through the annular side surface to enter the circular LGP and capable of being reflected by the annular trenches and emitted from the bottom surface.

Owner:CORETRONIC

(Al,Ga,In)N and ZnO direct wafer bonded structure for optoelectronic applications, and its fabrication method

InactiveUS7719020B2Reduce light absorptionLight evenlyIncadescent screens/filtersDischarge tube luminescnet screensWaferingNitrogen

An (Al, Ga, In)N and ZnO direct wafer bonded light emitting diode (LED), wherein light passes through electrically conductive ZnO. Flat and clean surfaces are prepared for both the (Al, Ga, In)N and ZnO wafers. A wafer bonding process is then performed between the (Al, Ga, In)N and ZnO wafers, wherein the (Al, Ga, In)N and ZnO wafers are joined together and then wafer bonded in a nitrogen ambient under uniaxial pressure at a set temperature for a set duration. After the wafer bonding process, ZnO is shaped for increasing light extraction from inside of LED.

Owner:JAPAN SCI & TECH CORP

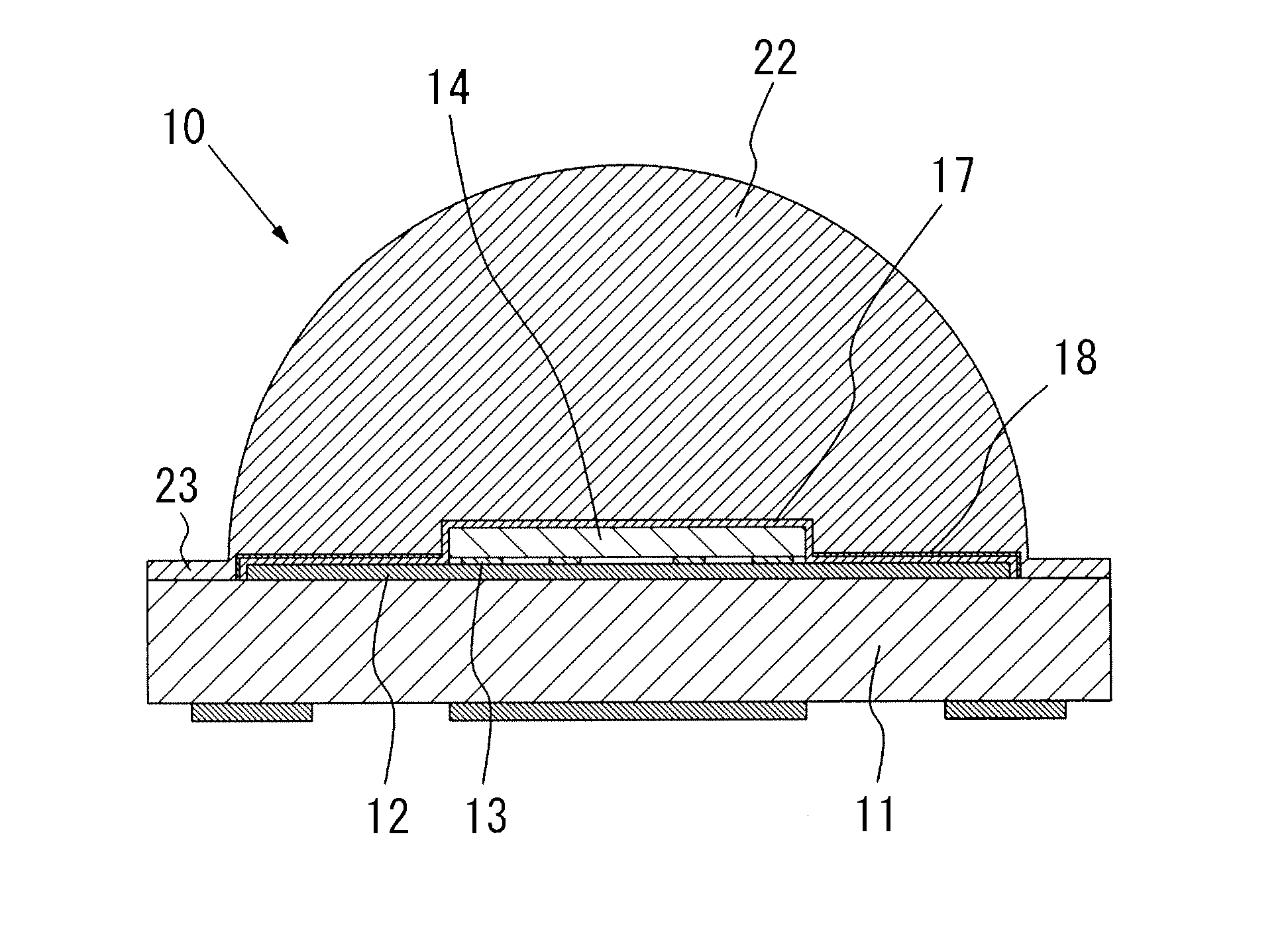

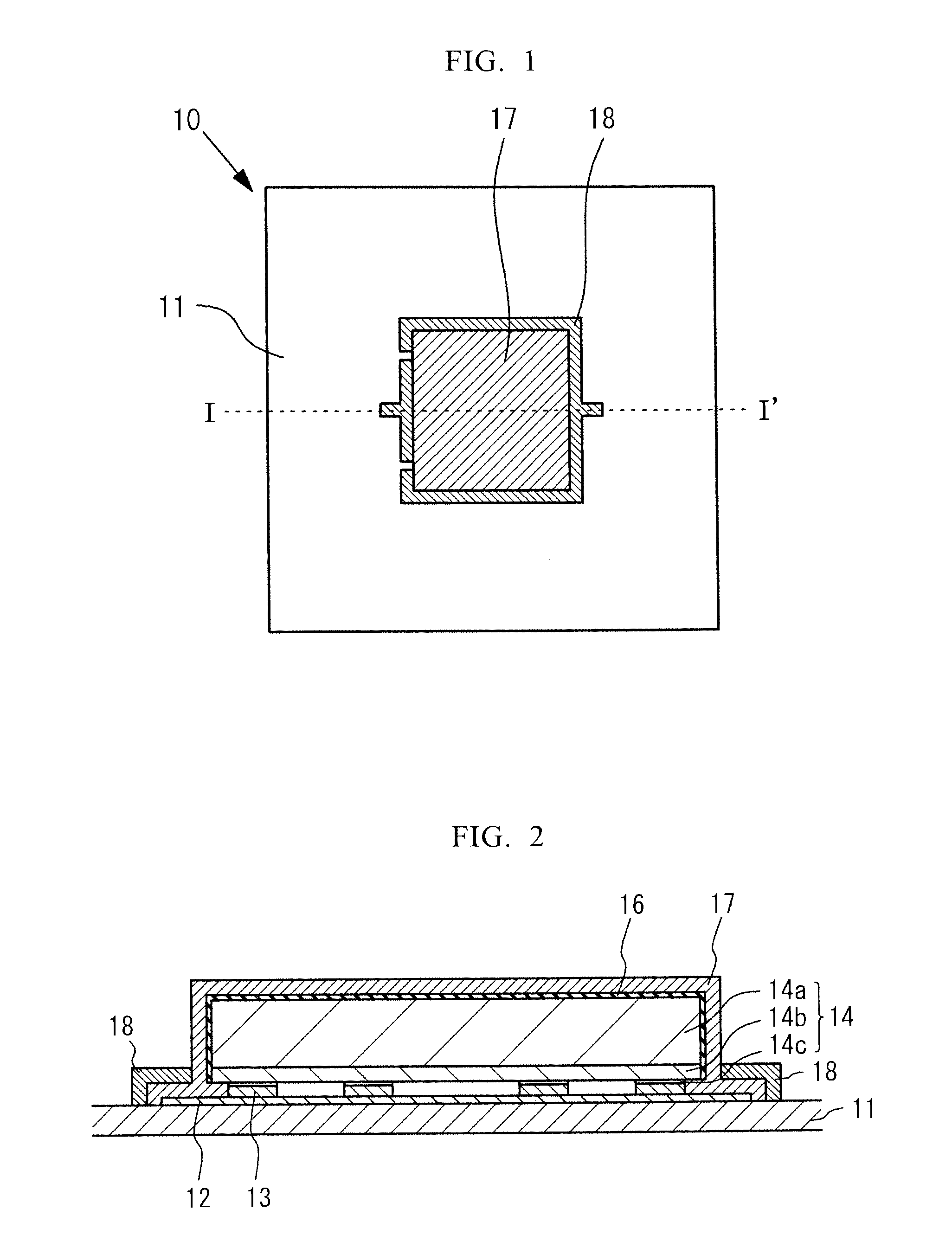

Light emitting diode package and method for manufacturing the same

InactiveUS20070063214A1Inhibit deteriorationImprove extraction efficiencySemiconductor devicesPhosphorLight-emitting diode

The invention relates to a light emitting diode package that can prevent deterioration of phosphor and a method of manufacturing the same. The light emitting diode package includes a package body having a recessed part, a light emitting diode chip mounted on a floor surface of the recessed part and a lens structure disposed on an upper surface of the package body, apart from the light emitting diode chip. Phosphor is dispersed in at least a part of the lens structure.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

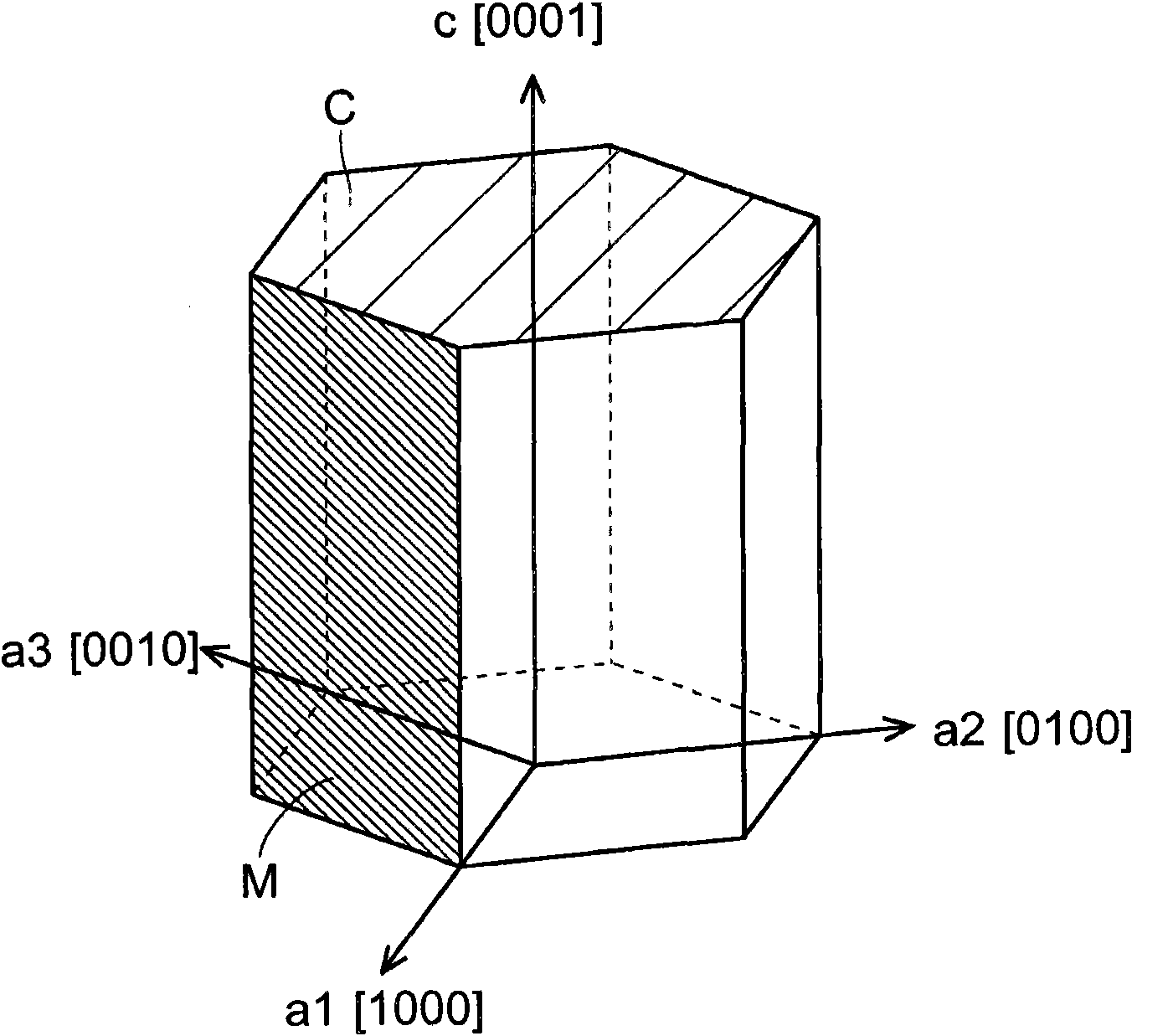

Nitride semiconductor chip, method of fabrication thereof, and semiconductor device

InactiveCN101944480AReduce the driving voltageImprove yieldLaser detailsSemiconductor/solid-state device manufacturingSemiconductor chipNitride semiconductors

A nitride semiconductor chip is provided that offers enhanced luminous efficacy and an increased yield as a result of an improved EL emission pattern and improved surface morphology (flatness). This nitride semiconductor laser chip (nitride semiconductor chip) includes a GaN substrate having a principal growth plane and individual nitride semiconductor layers formed on the principal growth plane of the GaN substrate. The principal growth plane is a plane having an off angle in the a-axis direction relative to the m plane, and the individual nitride semiconductor layers include a lower clad layer of AlGaN. This lower clad layer is formed in contact with the principal growth plane of the GaN substrate.

Owner:SHARP KK

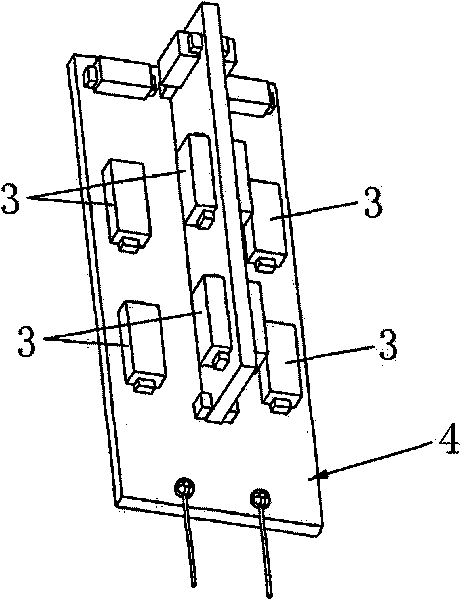

Flat lamp device with multi electron source array

InactiveUS20060244357A1Excellent light emission uniformityImprove uniformity of light emissionDischarge tube luminescnet screensElectroluminescent light sourcesCarbon nanotubeEngineering

Disclosed is a flat lamp device, including lower and upper glass plates facing each other in parallel; spacers interposed between the plates to keep distance therebetween; a cathode electrode singly formed over the entire upper surface of the lower glass plate; an insulation film formed on the cathode electrode; semiconductor films independently patterned on the insulation film at intervals; a catalyst-metal layer laminated on the buffer metal to improve the adhesion of catalyst metal formed on the semiconductor films; carbon nano-tubes formed on the catalyst-metal layer; a grid electrode installed on the carbon nano-tubes between the plates to guide electron emission from the carbon nano-tubes with a mesh shape having an opening for passage of the emitted electrons; an anode electrode formed below the upper glass plate to accelerate the emitted electrons; and a fluorescent layer formed below the anode electrode to emit light by collision with the accelerated electrons.

Owner:LEE SEUNG HO

Side-light type backlight module group using LED light source

InactiveCN101169556ALight evenlyNon-linear opticsPrinted circuit non-printed electric components associationPoint lightEngineering

The invention discloses a sidelight-typed blacklight module which adopts an LED light-source, which comprises a PCB substrate, LED chips, and a light guide plate. A plurality of LED chips are fixed in equal interval at the PBC substrate; a sealing structure can be used for sealing all LED chips arranged on the PBC substrate; the shape of the sealing structure is a rectangular with length and width same to that of the light guide plate. Except the light-outlet surface of the sealing structure, contacting the light guide plate, rest surfaces of the sealing structure are coated or pasted with reflective material. At the position of each LED chip in the sealing structure, a cavity for containing the LED chip is arranged. The sidelight-typed blacklight module of the invention, which adopts the LED light-source, changes the distribution-type point light into the rectangular panel light which matches with the light inlet surface of the light guide plate, so that the invention can lighten like a CCFL light source at the light inlet side of the light guide plate.

Owner:上海广电光电子有限公司

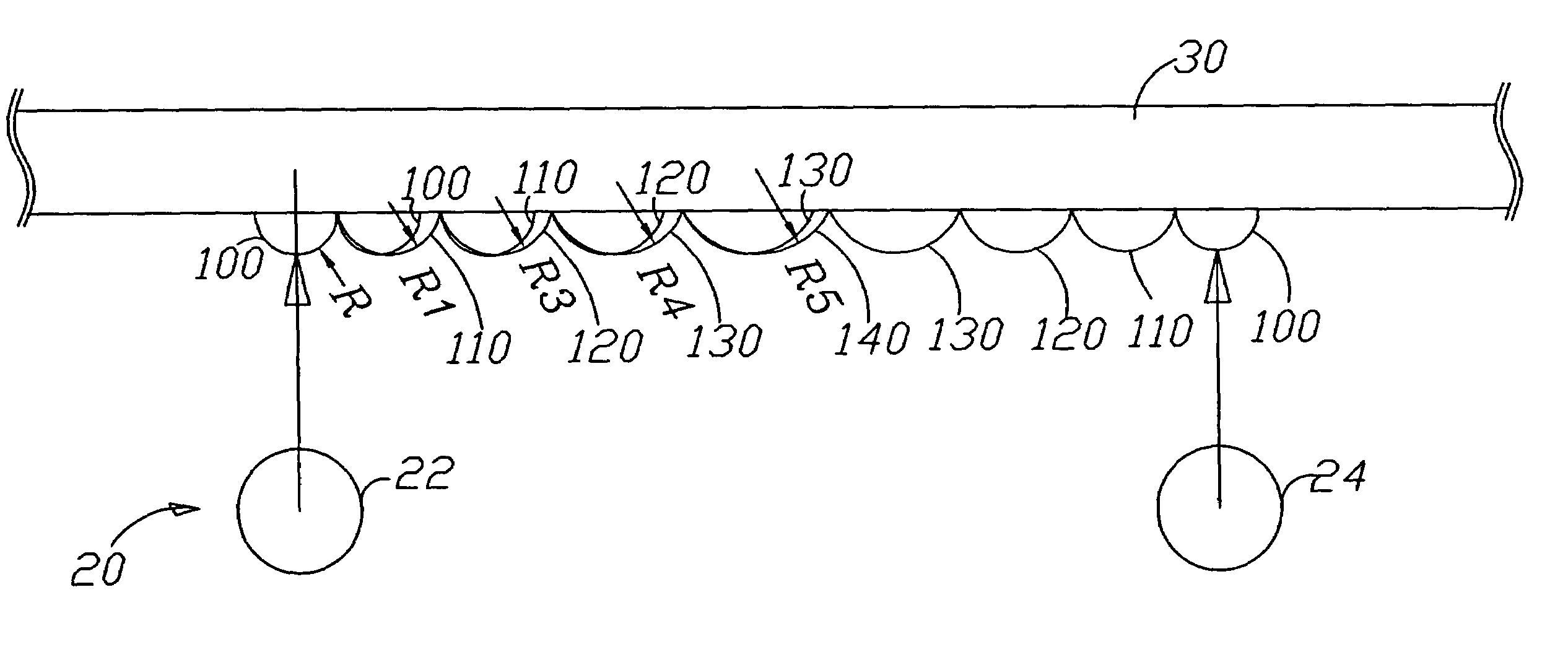

Structure of direct type backlight module with high uniform emitting light

ActiveUS7213936B2High uniform emitting lightFacilitated DiffusionMechanical apparatusElectric lightingLenticular lensOptoelectronics

Owner:ENTIRE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com