Self-excited oscillation type high power LED constant-current driving circuit

A self-excited oscillation, constant current drive technology, applied in the direction of electric lamp circuit layout, electric light source, adjusting electric variables, etc., can solve the problems of low efficiency, uneven quality, large area of linear voltage regulator, etc., to save The effect of circuit cost, life extension, and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

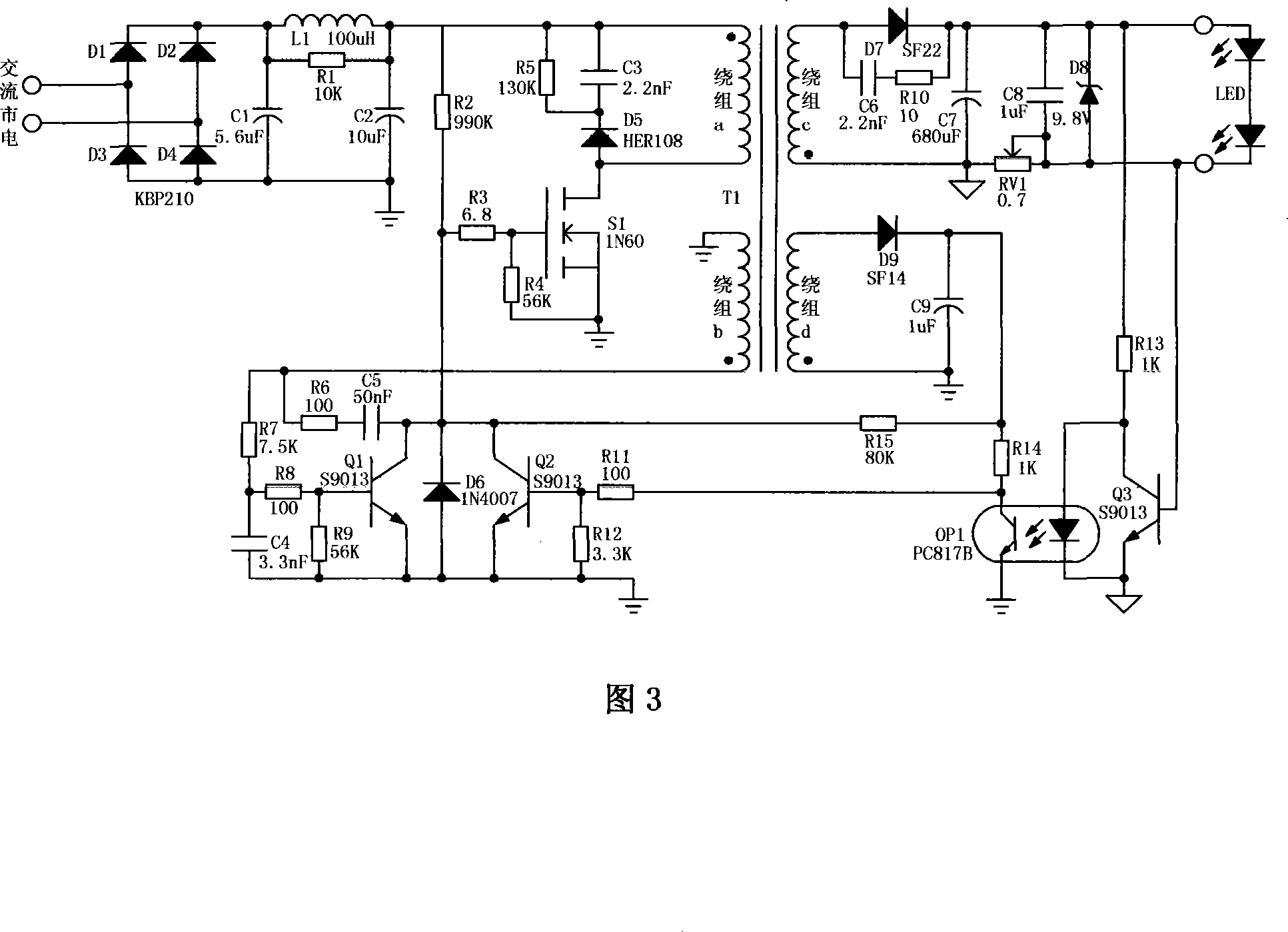

[0023] The purpose, circuit structure and advantages of the present invention will be further described below through specific embodiments of the present invention in conjunction with the accompanying drawings.

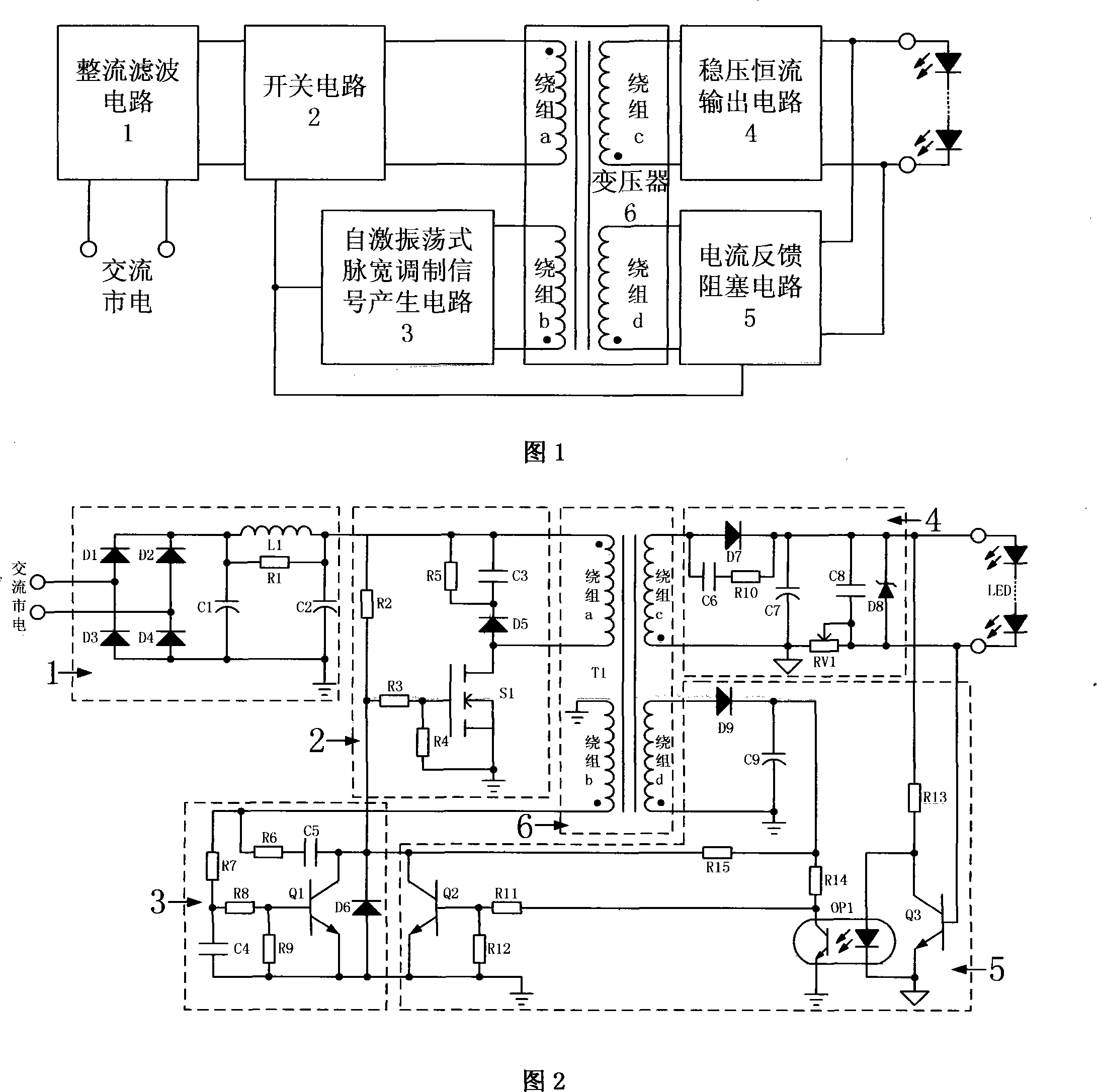

[0024] As shown in FIG. 1 , the present invention includes a rectification filter circuit 1 , a switch circuit 2 , a self-excited oscillation pulse width modulation signal generation circuit 3 , a constant voltage constant current output circuit 4 , a current feedback blocking circuit 5 and a transformer 6 .

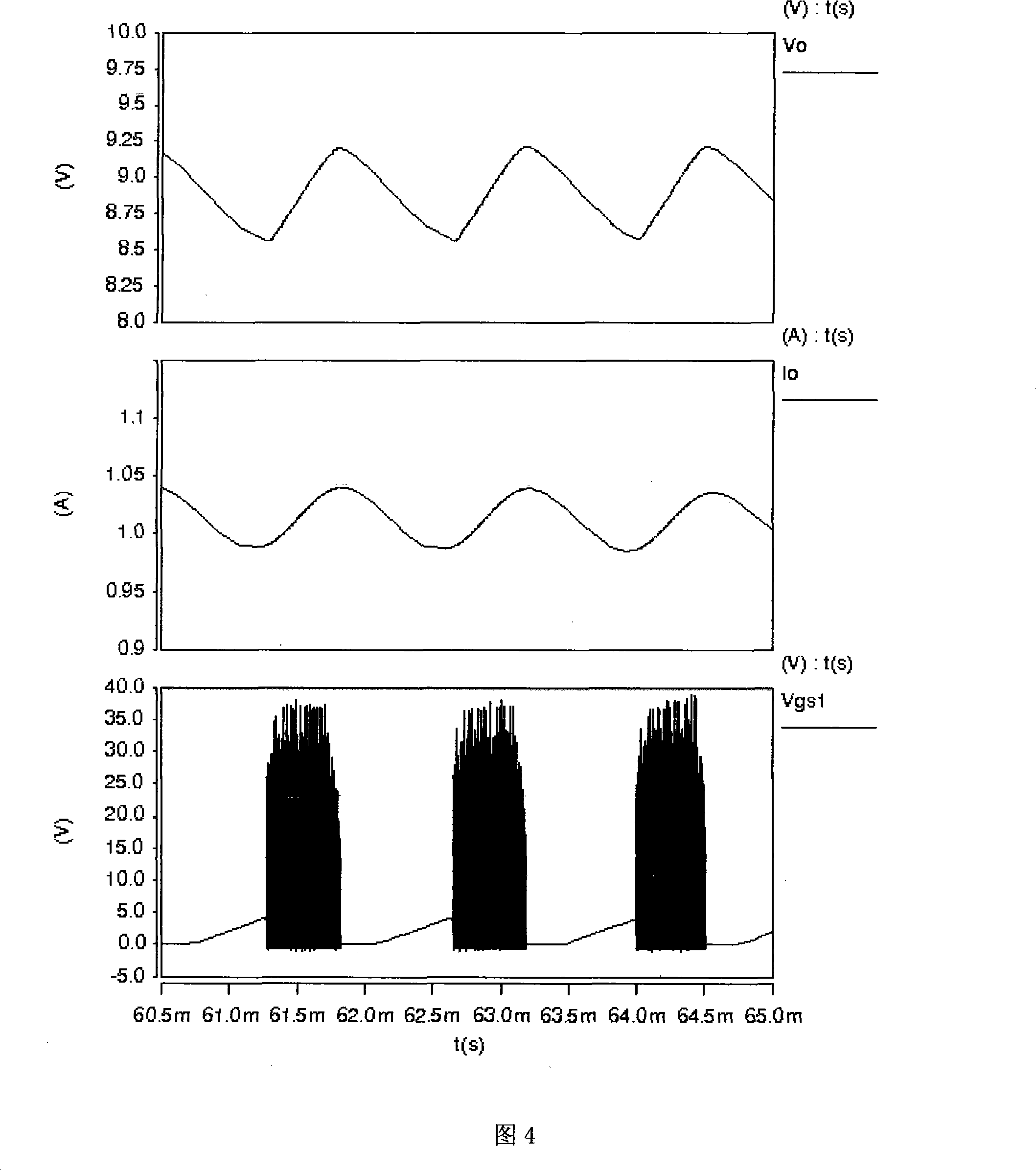

[0025] The rectifying and filtering circuit 1 converts the AC mains power into a relatively stable high-voltage DC signal, and outputs it from the output terminal of the high-voltage DC signal to the input terminal of the high-voltage DC signal of the switch circuit 2, as the energy supply of the whole circuit; the switch circuit 2 will receive the The DC high-voltage signal is converted into a high-frequency AC signal after pulse width modulation by a high-frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com