Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Realistic three-dimensional effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

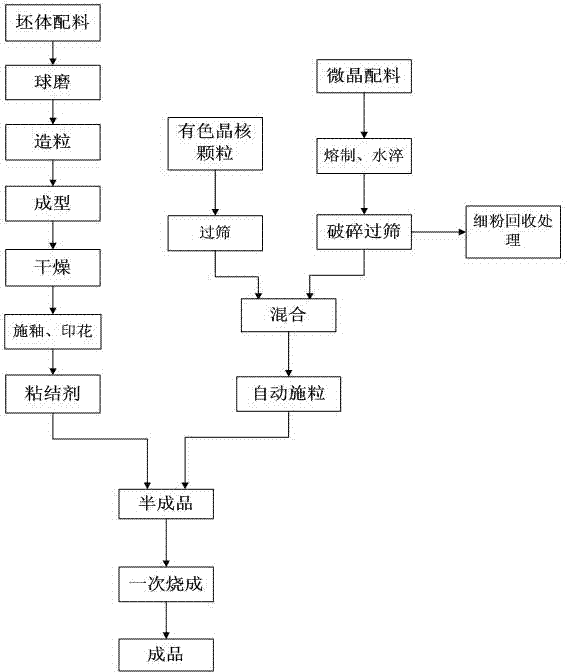

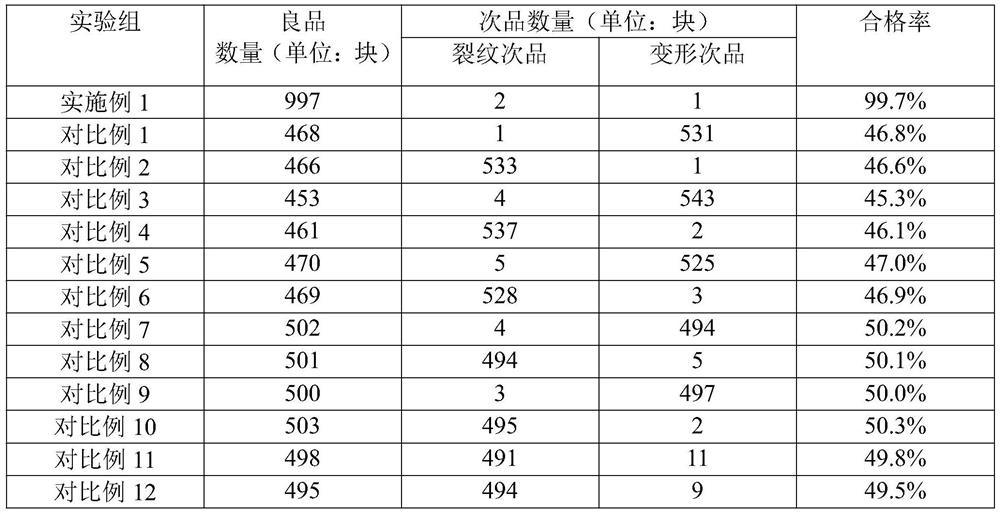

Once-firing colored crystalline glass ceramic composite brick and production method

ActiveCN103030298AImprove efficiencyReduce cost and controllable difficultyCeramic glazeEnergy consumption

The invention discloses a once-firing colored crystalline glass ceramic composite brick and a production method. The once-firing colored crystalline glass ceramic composite brick comprises a blank and a ground coat layer and a colored microcrystal layer that are arranged on the blank sequentially, wherein the colored microcrystal layer consists of a transparent microcrystal layer and colored crystal nucleus particles suspended in the transparent microcrystal layer. The production method comprises the following steps of processing the blank, applying a ground coat, conducting roller printing, applying an adhesive agent on the surface of the blank, uniformly applying transparent microcrystal dry particles and the colored crystal nucleus particles on the surface of the blank to form the colored microcrystal layer, applying a fixing agent, allowing to enter a kiln for once firing, and finishing and edging to form a finished product. The method is low in energy consumption and high in production efficiency, raw materials are saved, and the cost is lowered. The colored crystal nucleus particles suspended in the colored microcrystal layer of the once-firing colored crystalline glass ceramic composite brick are echoed by the roller printing, so that a stereo color effect is more obvious and verisimilar, and the brick has an excellent ornamental effect.

Owner:FOSHAN OCEANO CERAMICS

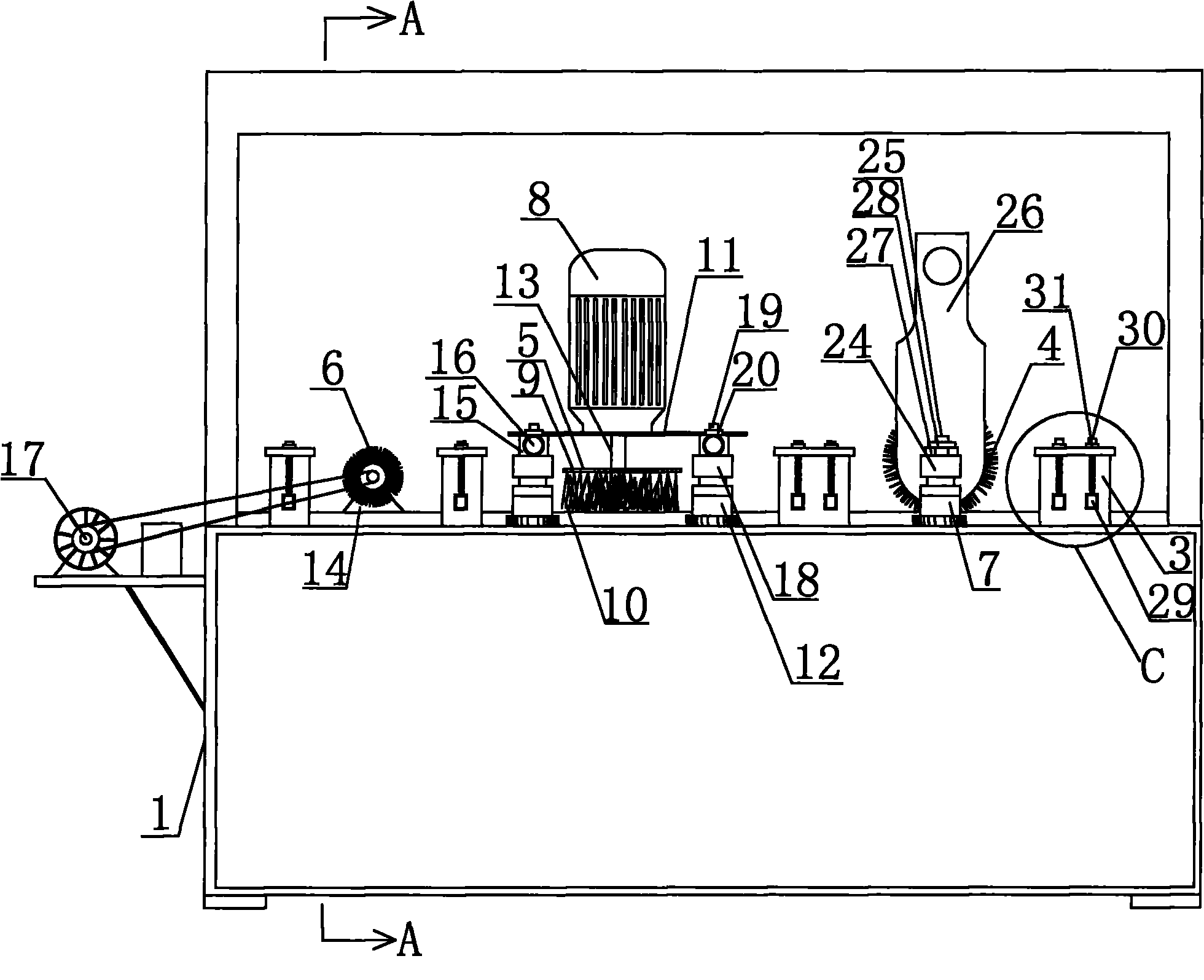

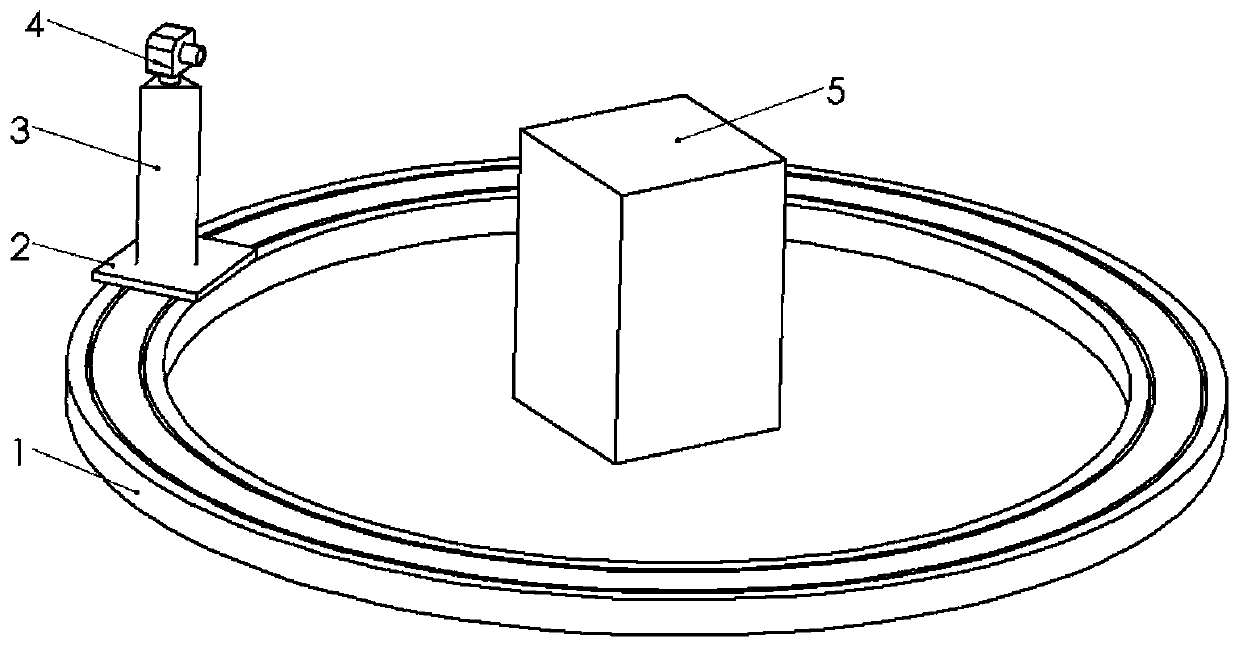

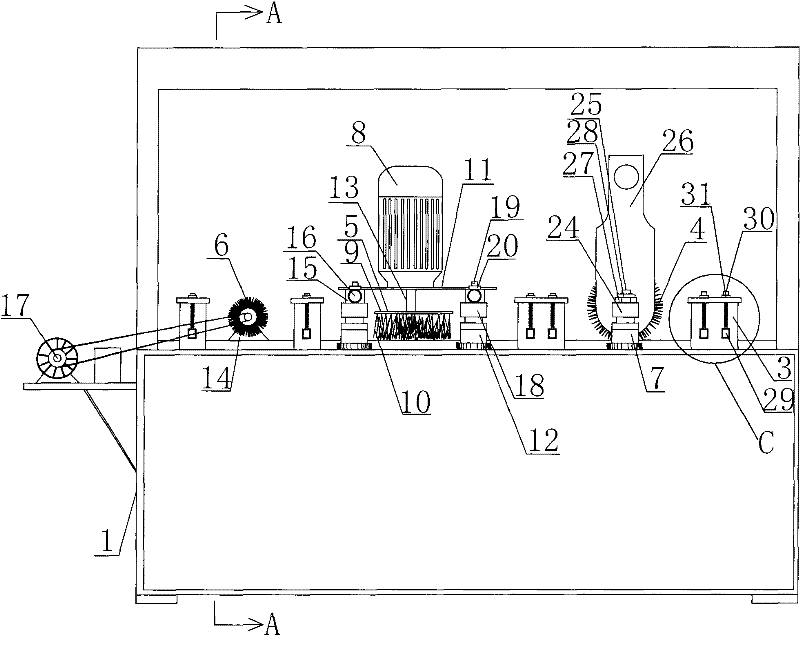

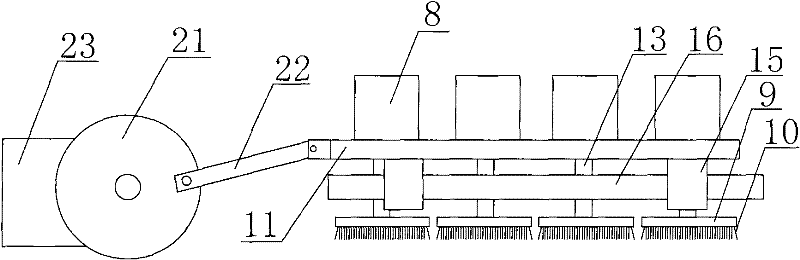

Wire drawing machine

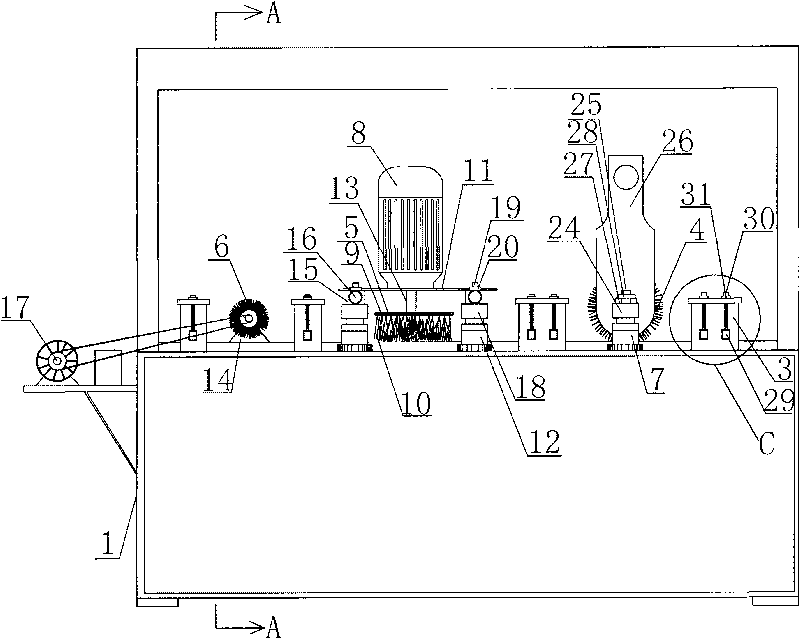

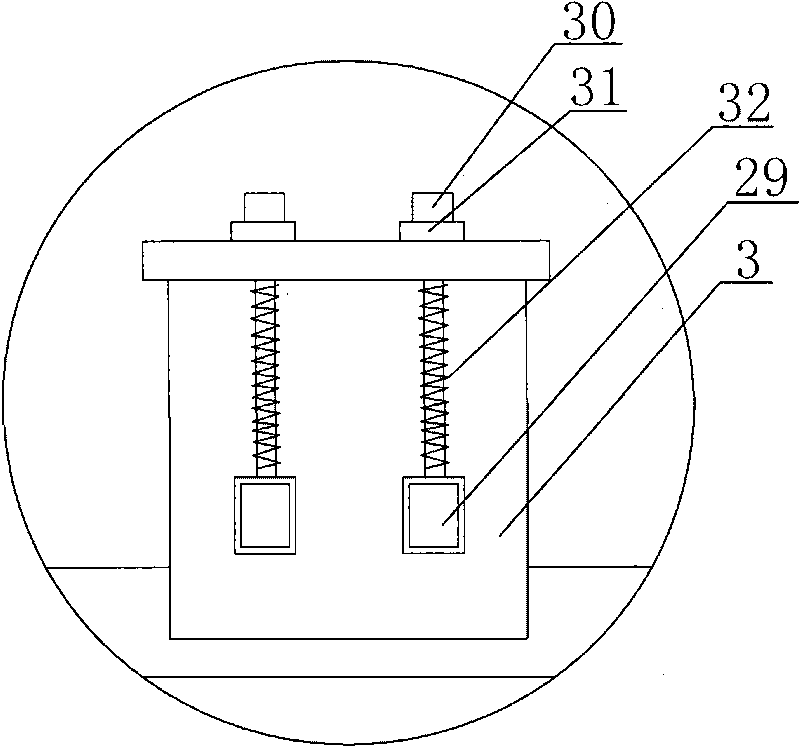

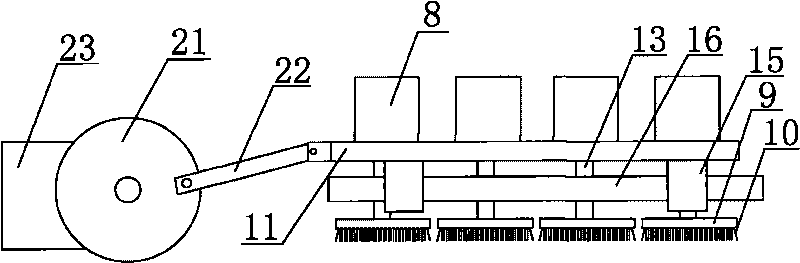

InactiveCN101704206ARealistic three-dimensional effectSmooth texturePlane surface grinding machinesCircular discDrive motor

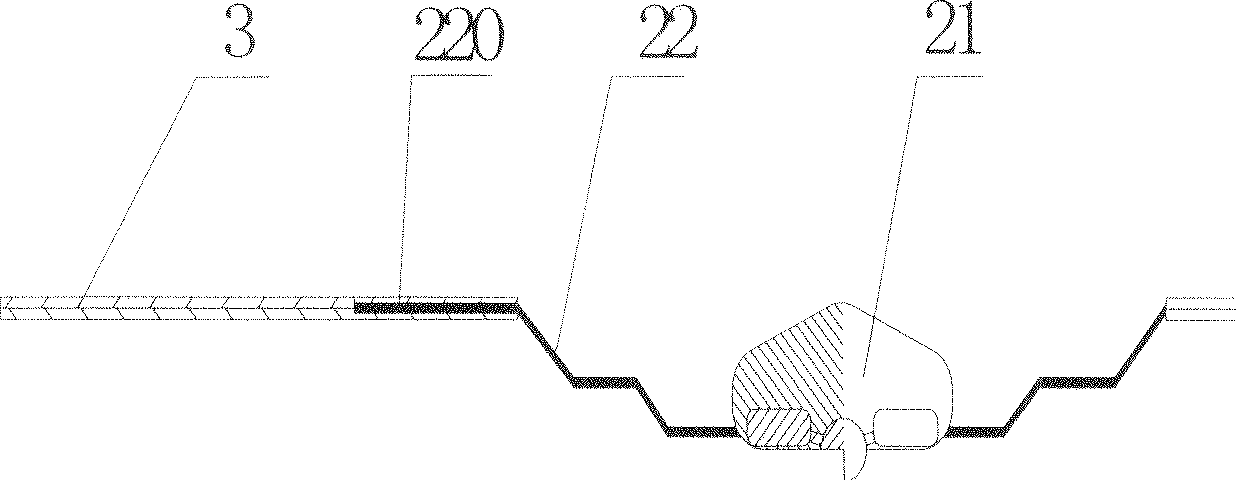

The invention discloses a wire drawing machine. Along a wood board transmission direction, the upper end face of a frame is orderly provided with a front steel wire roller which performs rough grinding on wood boards, a disk brush group which performs wire drawing on the wood boards and a rear steel wire roller which polishes the wood boards, wherein the disk brush group consists of a plurality of disk brushes which are distributed abreast; each disk brush is driven to rotate by a respective transmission motor of each disk brush and comprises a disk and steel wires densely distributed on the lower end face of the disk; the disks are all parallel to the upper end face of the frame and are all arranged on a disk brush mounting platform; a disk brush driving motor is fixedly arranged on the disk brush mounting platform; an output shaft of the disk brush driving motor runs through the disk brush mounting platform to be fixedly connected with the disks; and the disk brush group drives the steel wires to rotate through the disks. Compared with the conventional wire drawing machine, in the wire drawing machine of the invention, grooves and lines are widened, which not only increases the contact areas of the steel wires and the surfaces of the wood boards, but also increases a drawing force when the steel wires are contacted with the wood boards, thus the widening of the lines is benefited and the aim of achieving optimal wire drawing effect is achieved.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

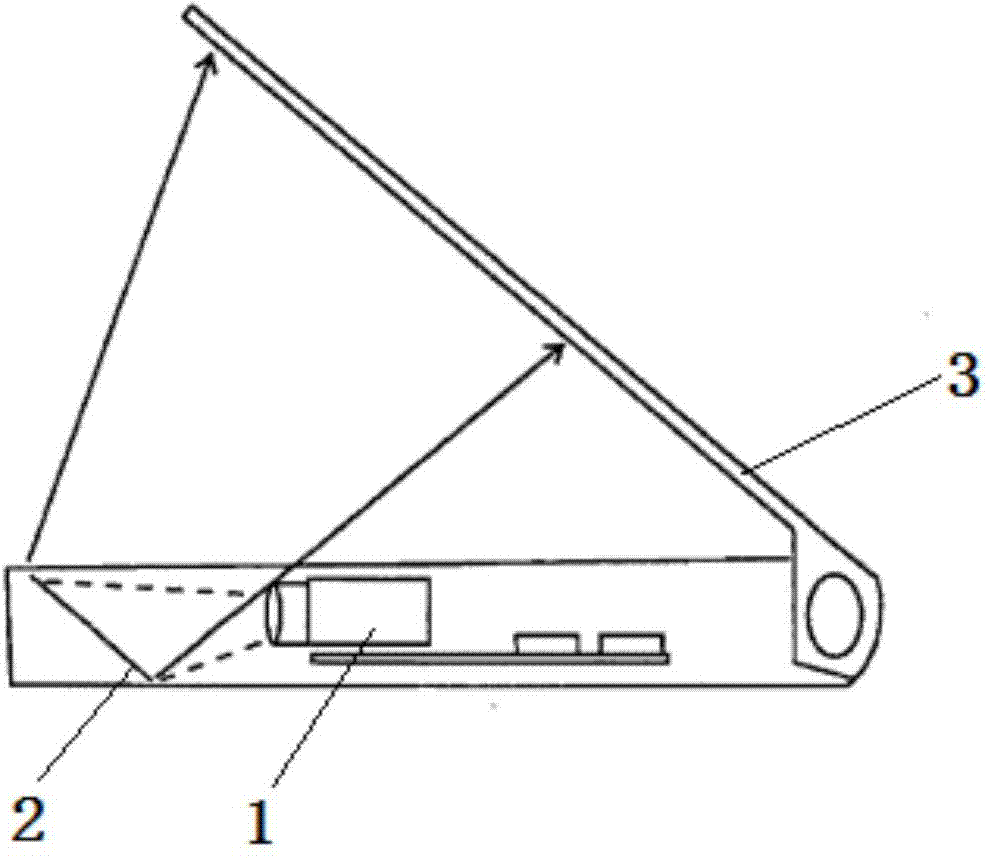

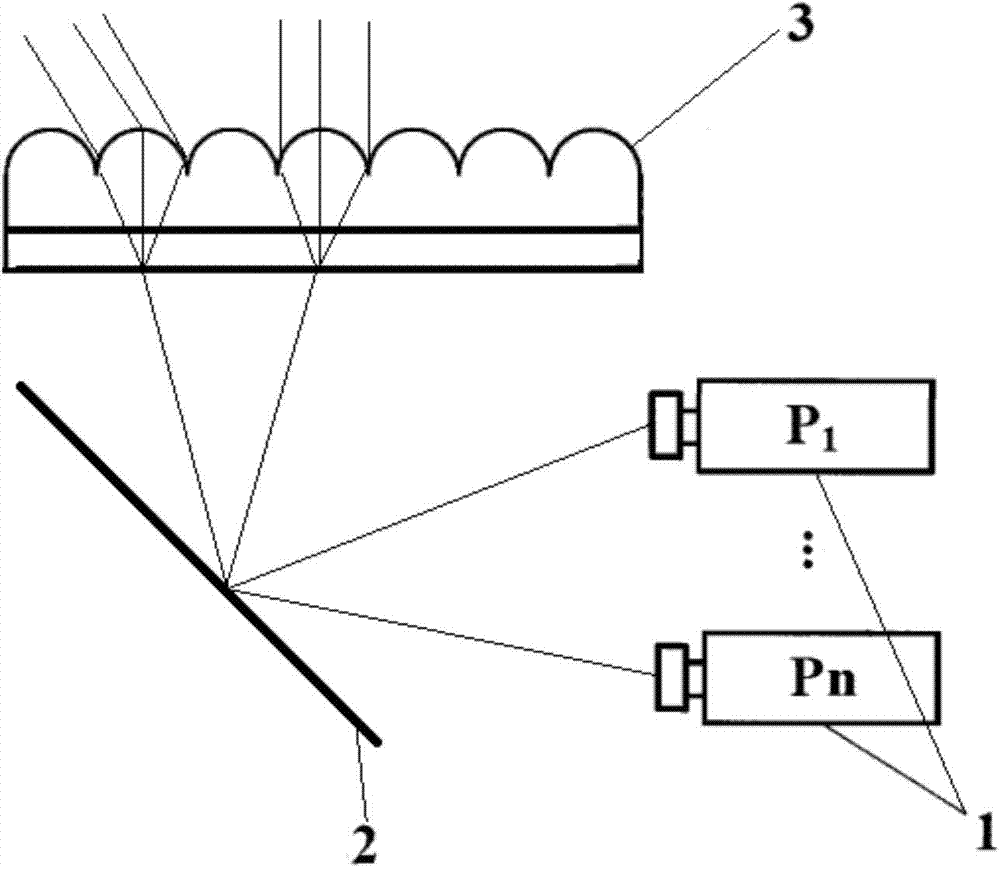

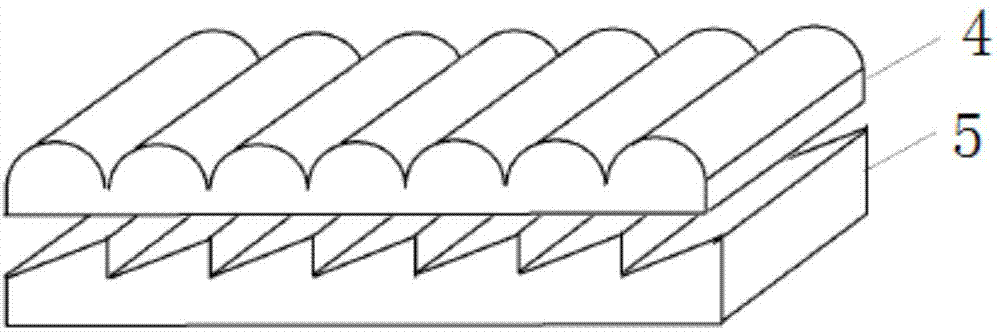

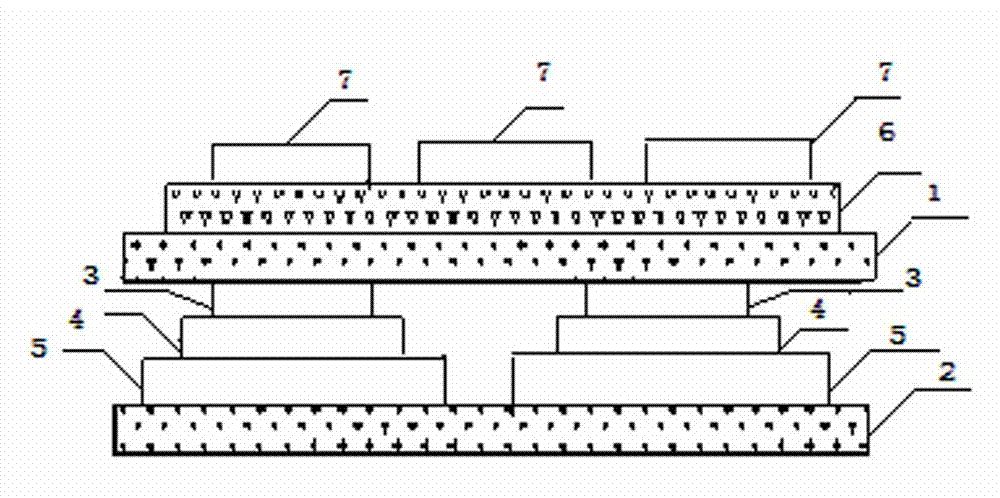

Multi-viewpoint 3D display device

ActiveCN104714361AIncrease the number ofImprove viewing angleStereoscopic photographyOptical elementsViewpointsProjection screen

The invention relates to a 3D display device, in particular to a multi-viewpoint 3D display device. The multi-viewpoint 3D display device comprises a 3D display device body, the 3D display device body comprises a projection screen and a projection unit, and the projection unit comprises at least three projectors for showing different viewpoint scenes. The projectors project to the projection screen which is a transmittance type diffuser screen with different projection angles, and a cylindrical surface grating is arranged on the light-emitting face of the transmittance type diffuser screen. The transmittance type diffuser screen with different projection angles is adopted for being combined with the projectors for showing different viewpoint scenes, in this way, pictures shown by the projectors for showing different scenes are projected in different directions through the transmittance type diffuser screen, and then people can enjoy different pictures from different viewpoints.

Owner:SHANGHAI NOVA OPTICS TECH

Method for preparing embossed decorative veneer

ActiveCN102059730AReduce the number of seamsReduce workloadWood veneer joiningWood layered productsDrive motorWood grain

The invention discloses a method for preparing an embossed decorative veneer, which comprises the steps of selecting, hydrothermal softening, slicing, veneering, cold inspection, rinsing, and wire drawing, wherein the wire drawing step comprises three processes of direct drawing, sweeping and polishing; during direct drawing, a groove is formed on the surface of a board by a front steel wire roller on a wire drawing machine and grains are deepened; during sweeping, a plurality of disc brushes are arranged on the wire drawing machine, each disc brush is driven to rotate by a respective drive motor and comprises a disc and steel wires which are densely arranged on the lower end face of the disc, and the plurality of disc brushes rotate to widen the grains of the groove on the surface of the board, so that the grains on the surface of the board are wider, and the embossed effect is more vivid; and during polishing, first two groups of brushed parts of the board are polished by a rear steel wire roller on the wire drawing machine, so that a finished product has smooth feeling, and the embossed effect is achieved on the surface of the veneer. Compared with the prior art, the method ensures that wood grains are more three-dimensional, vivid and natural.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Angular-type pattern variation simulation decorative film

InactiveCN103192656AImplement Angular ChangesImprove patienceOrnamental structuresSpecial ornamental structuresWood splinterMaterials science

The invention discloses an angular-type pattern variation simulation decorative film, which sequentially consists of a printing stock, a spot color layer, a pattern color layer, a bright coating, a matte coating and a bright coating from bottom to top. The angular-type pattern variation simulation decorative film is characterized in that the bright coating is separated from the pattern color layer, the matte coating and the bright coating are printed in a staggering way, the bright coating adopts a negative image to produce a cylinder, the matte coating adopts a positive image to produce the cylinder, splinters are used for impressing the bright coating, the splinter indentation has a refractive effect, a pattern is enabled to be changed in different angles after being printed, a real fluctuation touch feeling can be realized, and a vivid three-dimensional effect can be realized.

Owner:SUZHOU GUOHAO WALLPAPER

Three-dimensional image reconstruction system and method

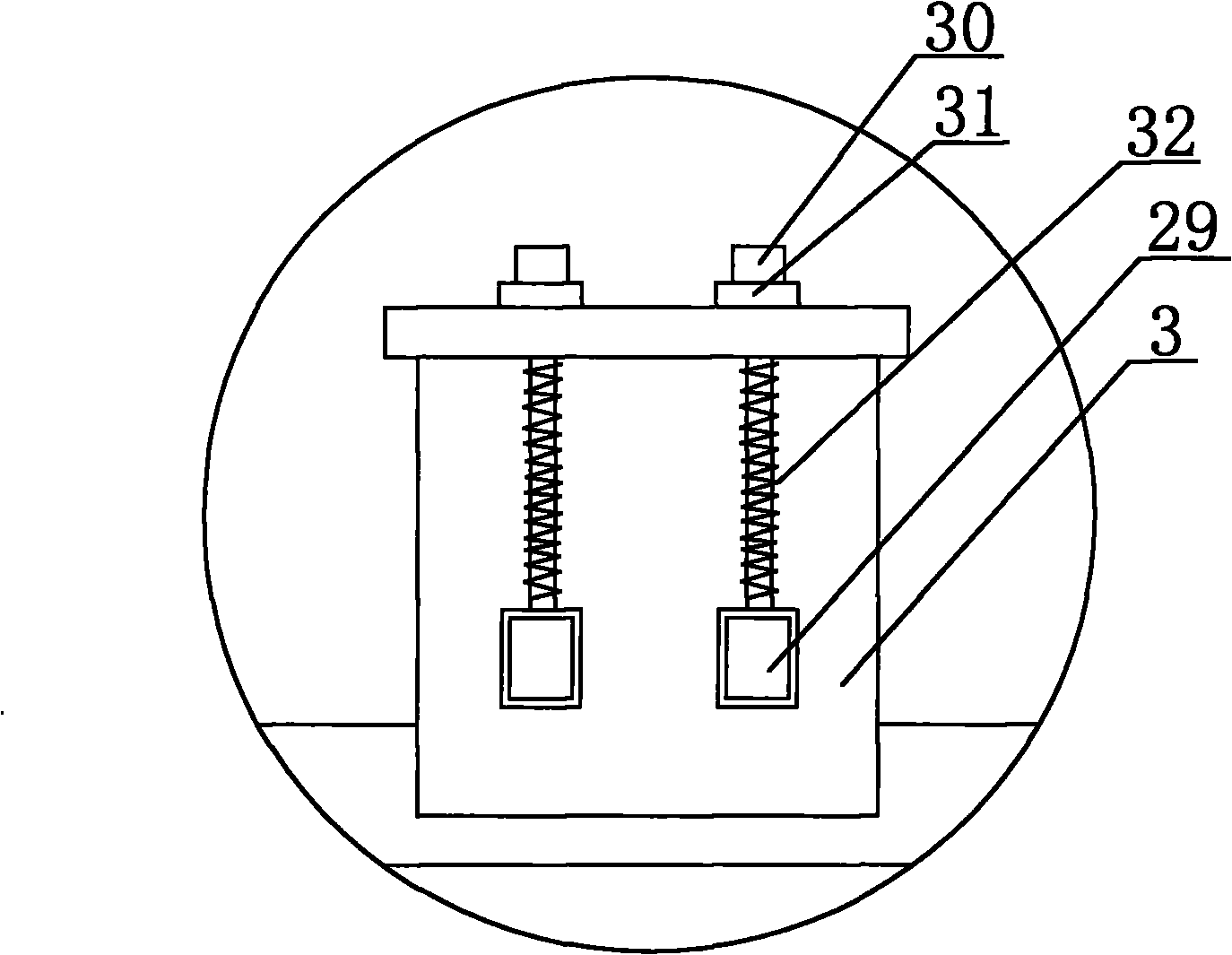

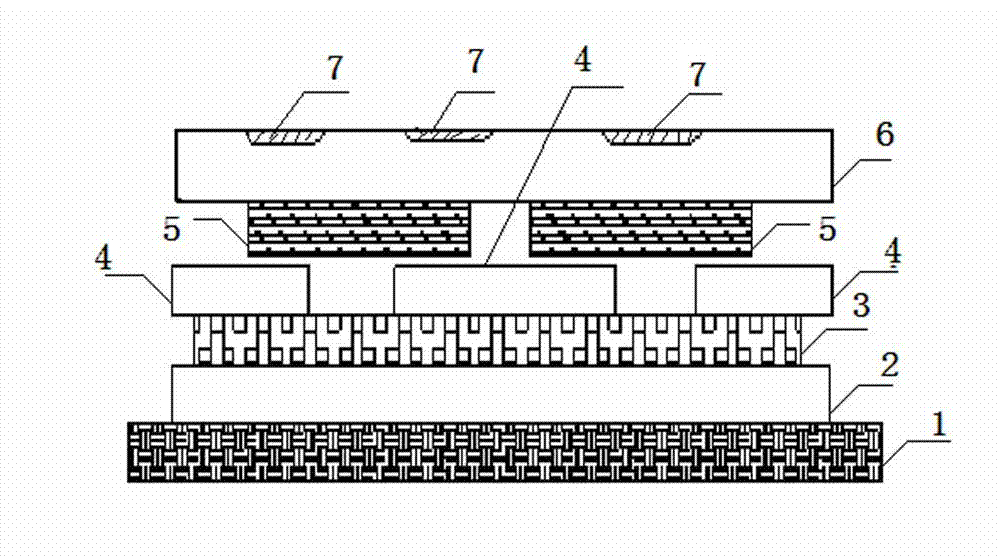

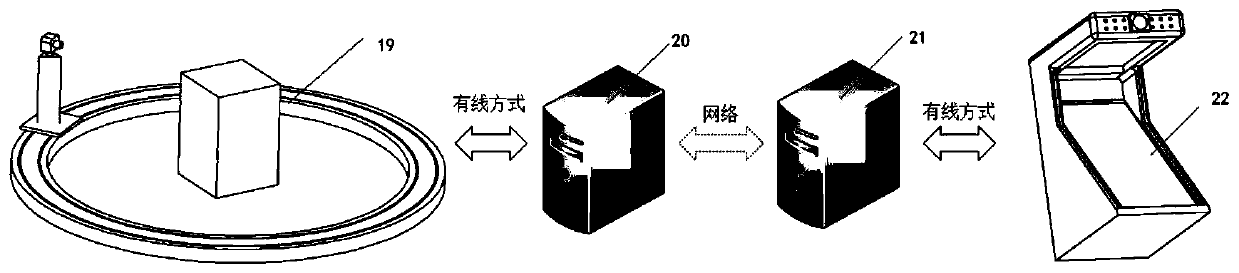

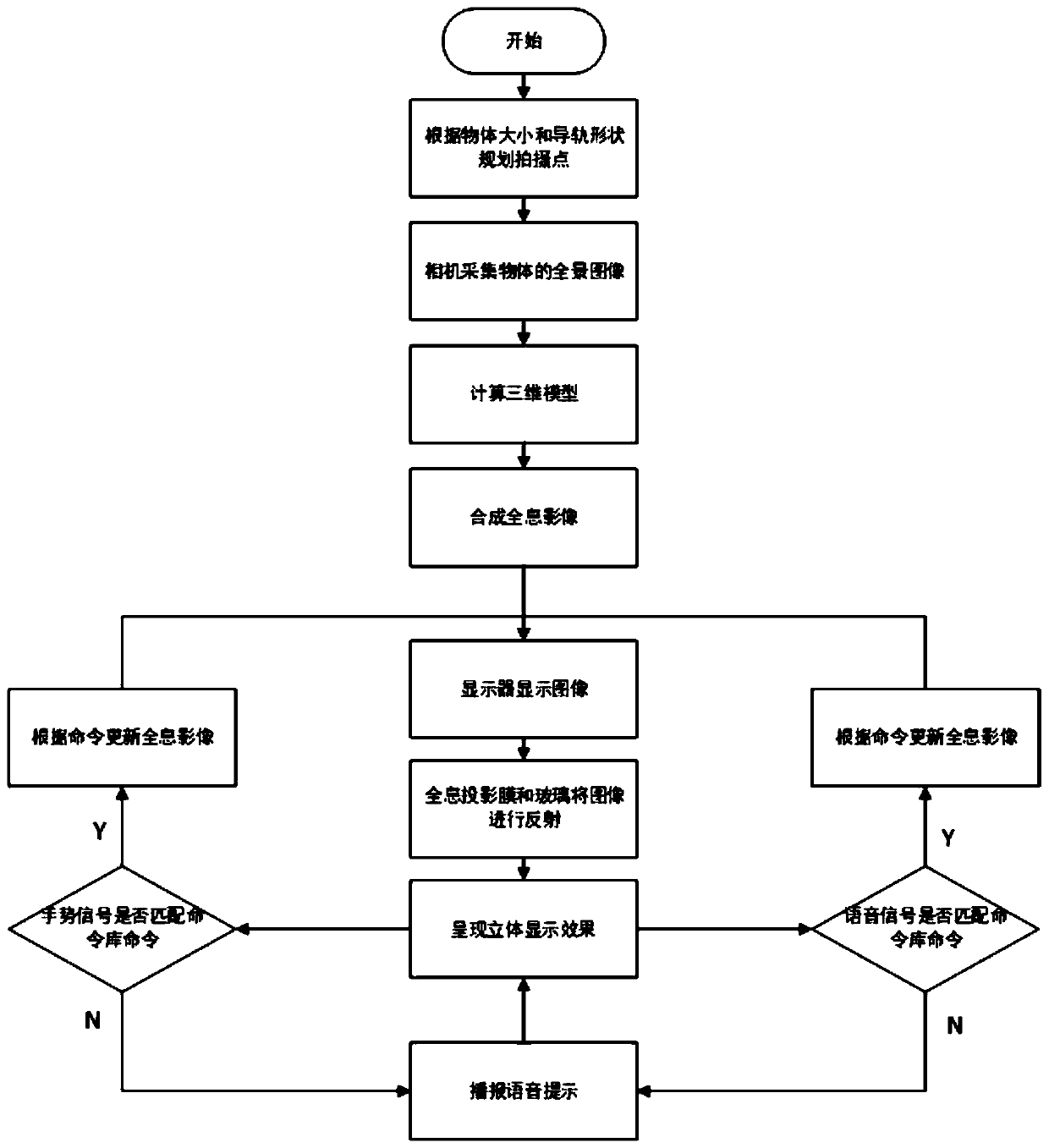

PendingCN110458953AStrong expandabilityRealize panoramic image shootingReconstruction from projection3D-image renderingData connectionImaging processing

The invention discloses a three-dimensional image reconstruction system, which comprises: an image acquisition unit used for acquiring panoramic image data of a target object; an image processing unitwhich is used for planning a collection path, controlling the image collection unit to collect the panoramic image data and processing the panoramic image data to obtain an object three-dimensional model; and a holographic projection unit which is used for projecting and reflecting the two-dimensional image to form a holographic image. The image acquisition unit, the image processing unit and theholographic projection unit are sequentially connected. The image acquisition part and the holographic display system part of the three-dimensional image reconstruction system disclosed by the invention can adopt different implementation schemes according to the space size and capital amount of a scene; the three-dimensional image reconstruction system m is high in flexibility, strong in expansibility, diversified in interaction form, good in experience effect, mature and stable in adopted holographic projection scheme, vivid in three-dimensional display effect and capable of being widely applied to various scenes such as exhibition halls, meeting rooms and laboratories.

Owner:西安宁致信息科技有限公司

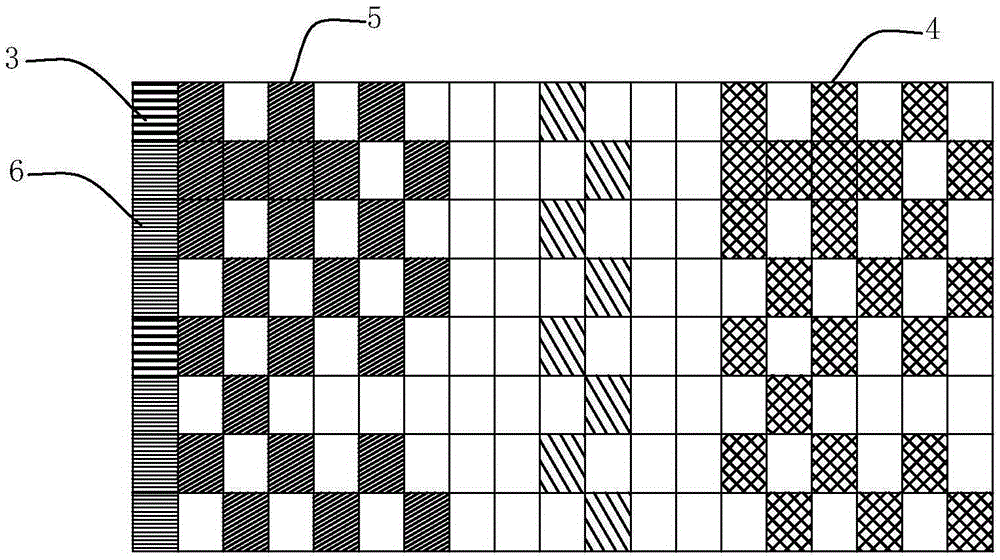

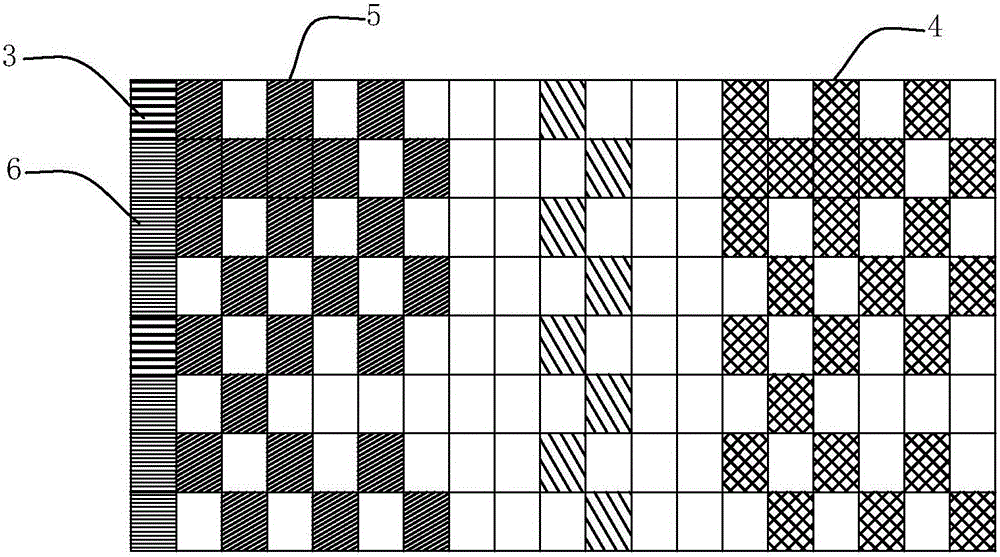

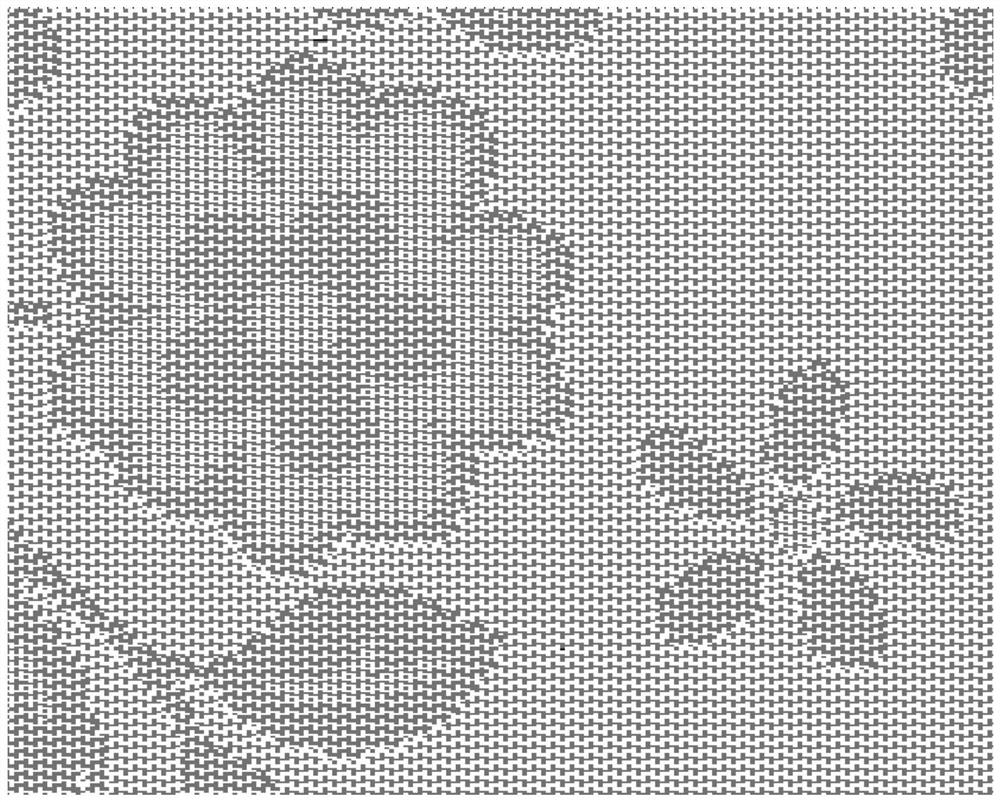

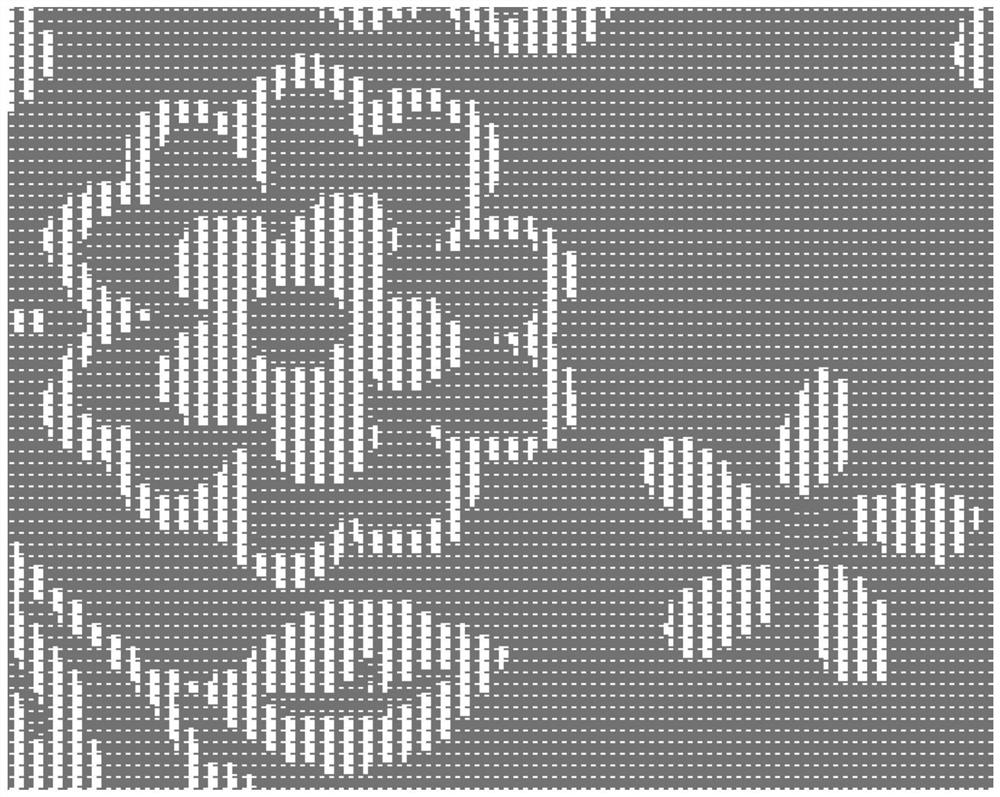

Multicolor multilayer yarn-dyed towel with diversified pattern structures and weaving method of multicolor multilayer yarn-dyed towel

ActiveCN111118705ARich in colorRich pattern contentSwivel-woven fabricsLappet-woven fabricsEngineeringChemistry

The invention discloses a multicolor multilayer yarn-dyed towel with diversified pattern structures and a weaving method of the multicolor multilayer yarn-dyed towel. The towel is a towel product which is woven by wool warps, ground warps and wefts with different colors and at least comprises four layers and four colors; the wool warps at least comprise wool warps with a first color and wool warpswith a second color, the ground warps at least comprise ground warps with a third color and ground warps with a fourth color, and the wefts are divided into at least four layers comprising weft layers of the third color and weft layers of the fourth color; the wool warps with the first color and the wool warps with the second color are respectively interwoven with two layers of weft yarns in thefour layers of weft yarns and the corresponding ground warps to form pile loop patterns; the ground warps with the third color and ground warps with the fourth color are respectively interwoven with the weft layers of the third color and weft layers of the fourth color and the corresponding ground warps to form gauze patterns and / or bottom textures; and the gauze patterns surround the pile loop patterns, and the bottom textures surround the pile loop patterns or the gauze patterns. The multicolor multilayer yarn-dyed towel is a multi-layer towel quilt product which is rich in pile loop surfacecolors, and the colors, patterns and textures of gauze surfaces and pile loop surfaces are combined with one anther.

Owner:SUNVIM GROUP

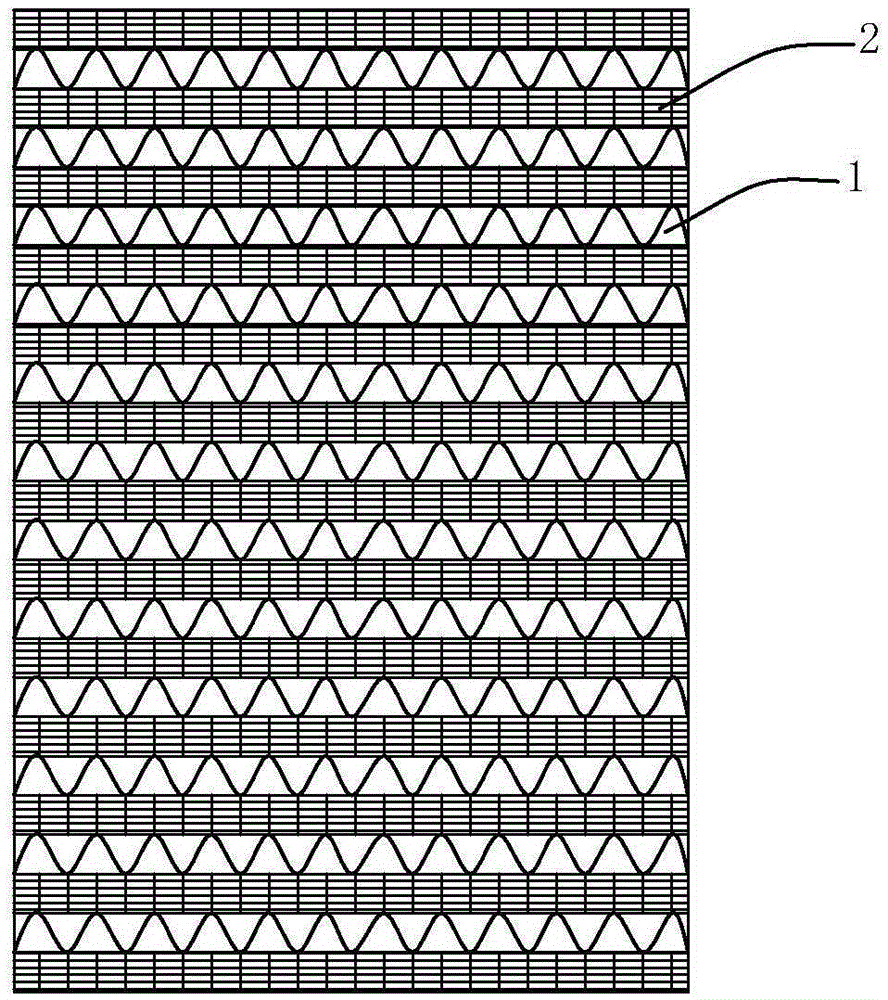

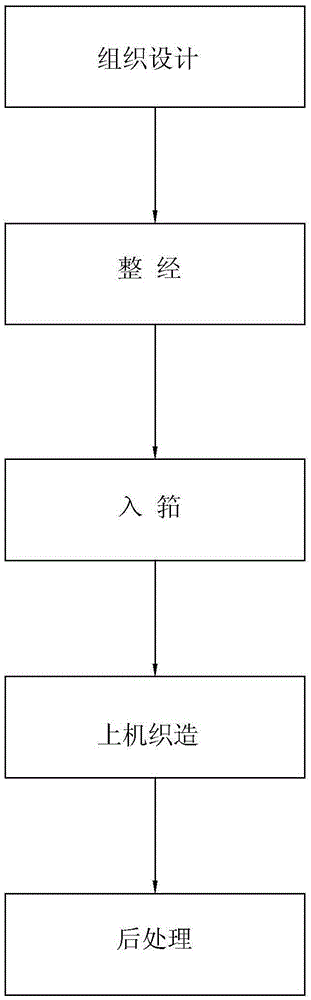

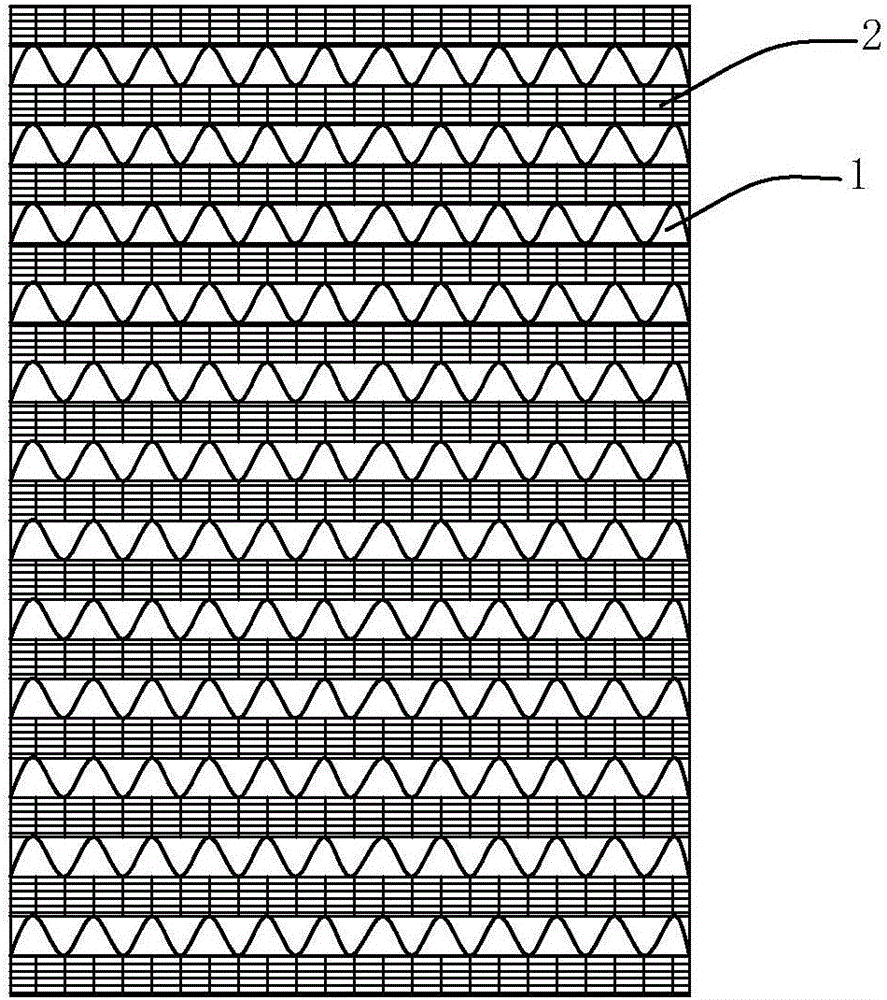

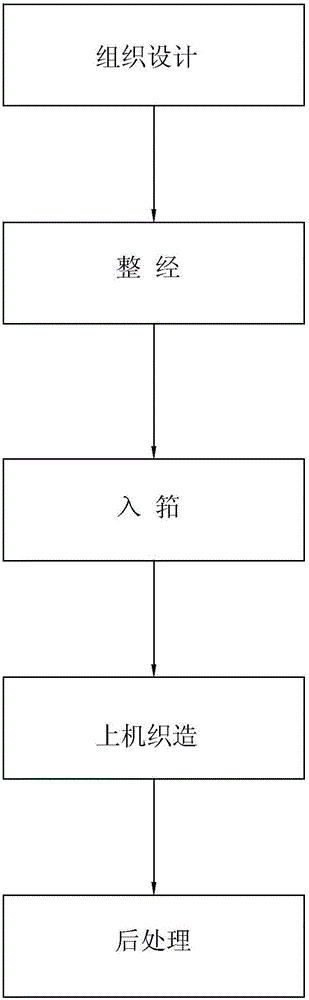

Chenille wash towel and manufacture process thereof

The invention belongs to the technical field of wash towel manufacture and particularly relates to a chenille wash towel and a manufacture process thereof. The chenille wash towel is formed by weaving ground warp, wool warp and weft yarn. The weft yarn comprises chenille yarn and combed cotton yarn. The wash towel has three-dimensional transverse crinkle structures and plain cloth structures. The three-dimensional transverse crinkle structures and the plain cloth structures are arranged alternately to form an undulating fabric. The manufacture process of the chenille wash towel comprises the steps of structure design, warping, denting, heald entry, weaving on a machine and post-processing. The chenille wash towel has better novelty and a three-dimensional sense, the expression form is more flexible, different rubbing effects are achieved on the surface of a product through regulation of the weft yarn and the structures, and breathability is better.

Owner:SUNVIM GROUP

Spray-coating process of honeycomb three-dimensional pattern

ActiveCN103182893AImprove qualityAttractive appearanceDecorative surface effectsSpecial ornamental structuresSpray coatingTransmittance

The invention discloses a spray-coating process of honeycomb three-dimensional pattern. The process comprises the steps that: (1) a workpiece is processed by using a mold, such that a simple honeycomb pattern is formed on the back side of the workpiece; (2) black oil is spray-coated on the back side, such that three-dimensional honeycomb structure is formed; (3) plating silver is spray-coated on the back side, such that a metal effect is enhanced; (4) a black shading is spray-coated on the back side, such that transmittance is avoided, and metal dimensional sense can be enhanced; (5) a topcoat is spray-coated on the back side, such that scratching damages are avoided; (6) a color paint is spray-coated on the front side, such that color and aesthetic effect are adjusted; and (7) surface oil is spray-coated on the front side, such that surface hardness, wear resistance and the like are enhanced. The process provided by the invention has the advantages that: when the honeycomb three-dimensional pattern spray-coating process is applied on a workpiece manufactured by using a transparent material, and front-side and back-side spray-coating is carried out, a three-dimensional honeycomb fading effect is provided on the surface of the workpiece. According to the invention, with multiple times of spray-coating, the three-dimensional effect is better and more realistic, and a charming sense is provided. Viewed from the front side of the workpiece, the three-dimensional effect is looming.

Owner:东莞市旺鑫精密工业有限公司

Printed electrostatic flocking material and digital transfer printing process thereof

InactiveCN109334150AHigh color fastnessHigh color yieldLayered productsDuplicating/marking methodsProduct patternEngineering

The invention provides a digital transfer printing process for a printed electrostatic flocking material. The digital transfer printing process comprises a step of preparing a transfer printing base material, wherein the step of preparing the transfer printing base material comprises the following steps: printing dye color paste onto a transfer printing base material by using a digital ink-jet printer, and forming the transfer printing base material with patterns and decorative designs; the adopted transfer printing base material is transfer printing paper or a transfer printing film. The printing process provided by the invention has the characteristics of being high in color yield, high in fixation rate, vivid in product pattern effect and excellent in batch reproducibility.

Owner:山东领潮新材料有限公司 +2

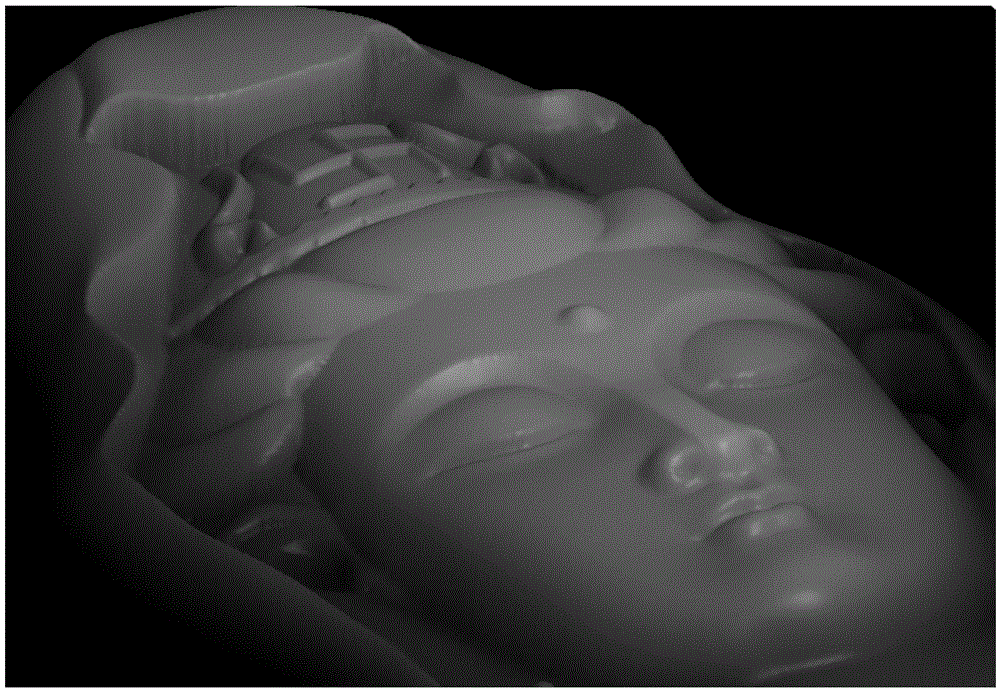

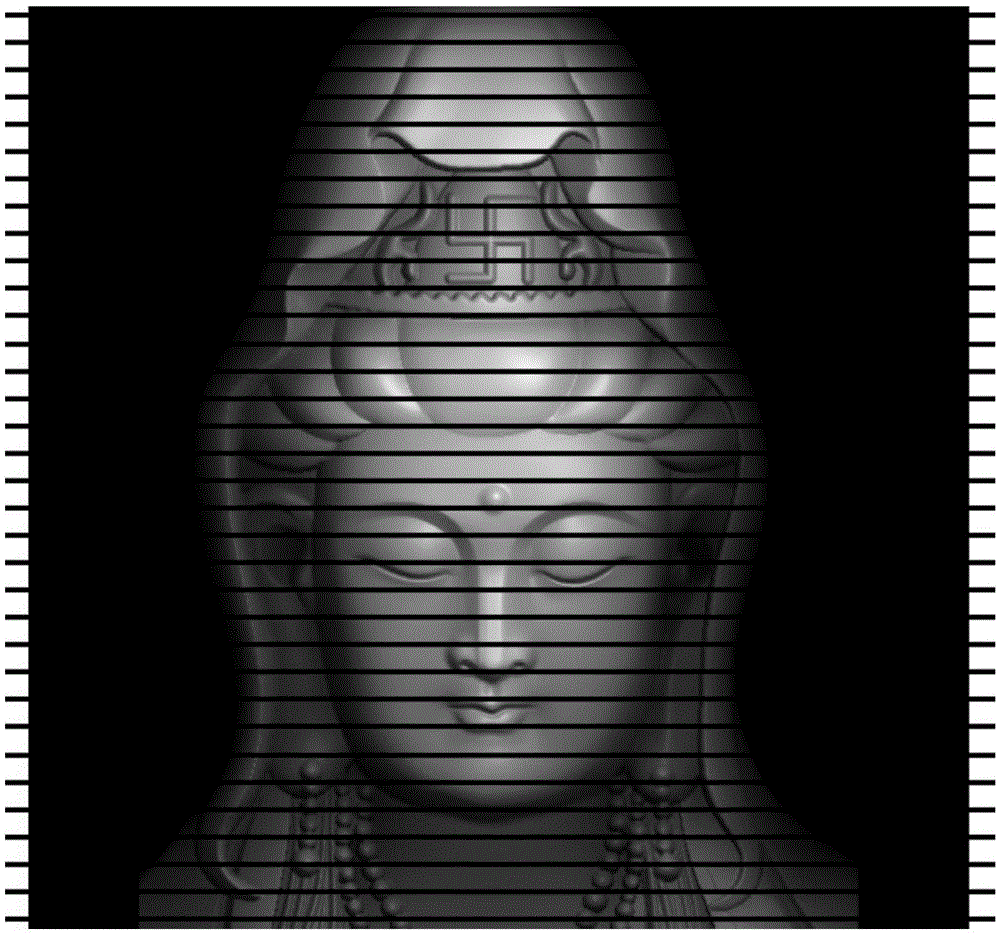

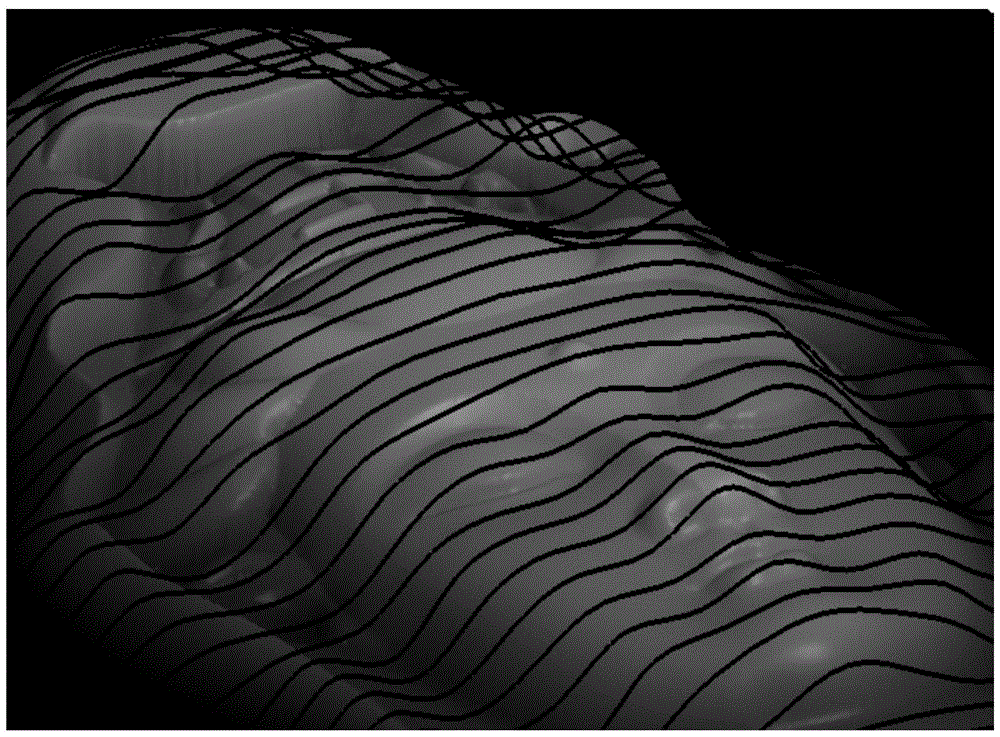

Processing method for forming image with relief sculpture visual effect on planar material and product processed by adopting method

ActiveCN103921610ARealistic three-dimensional effectImprove anti-counterfeiting performanceDecorative surface effectsSpecial ornamental structuresBatch productionCopper

The invention relates to a processing method for forming an image with a relief sculpture visual effect on a planar material and also relates to a product processed by adopting the method, belonging to the technical field of manufacturing of pattern and image products. The method comprises the following steps: sectioning a three-dimensional relief sculpture positioned on a basic plane according to a preset interval, thus obtaining a group of section lines on the surface of the relief sculpture; deflecting the section lines to the basic plane one by one, thus obtaining a group of section deflection projection lines; copying the group of section deflection projection lines to a plane to be imaged; and processing the plane to be imaged along the section deflection projection lines according to the preset depth and width. The effect of displaying images which comprise various complex patterns and have three-dimensional relief sculpture effects on a non-transparent plane is ingeniously achieved, batch production is conveniently performed by means of molds or numerical control, and the space and volume characteristics of the three-dimensional image can be displayed according to the adopted imaging method. Therefore, the three-dimensional effect is vivid, and the image has high anti-counterfeiting performance and the processing method can be applied to manufacturing various metal products such as gold, silver, copper and stainless steel products.

Owner:NANJING BANKNOTE MINTING

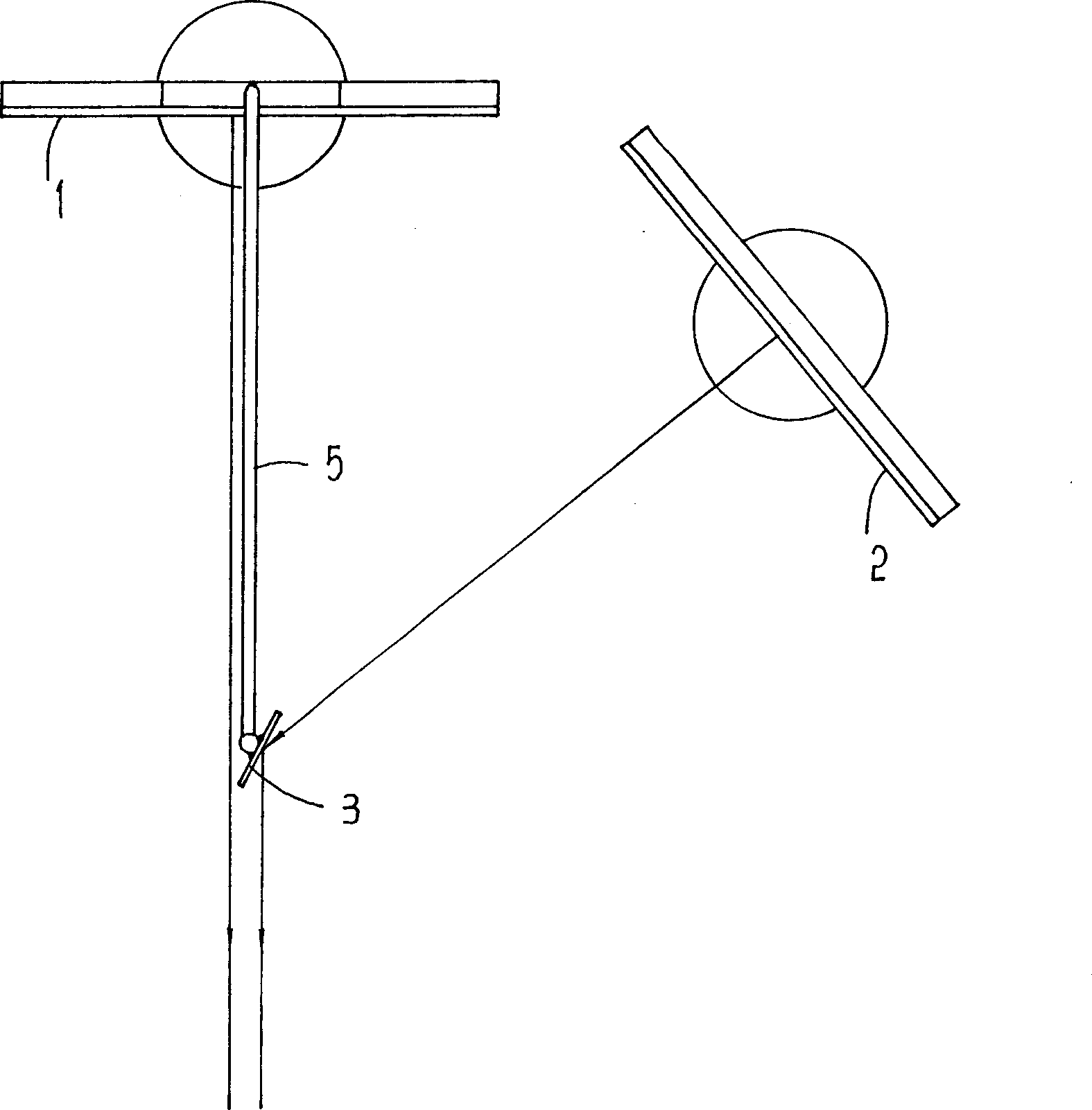

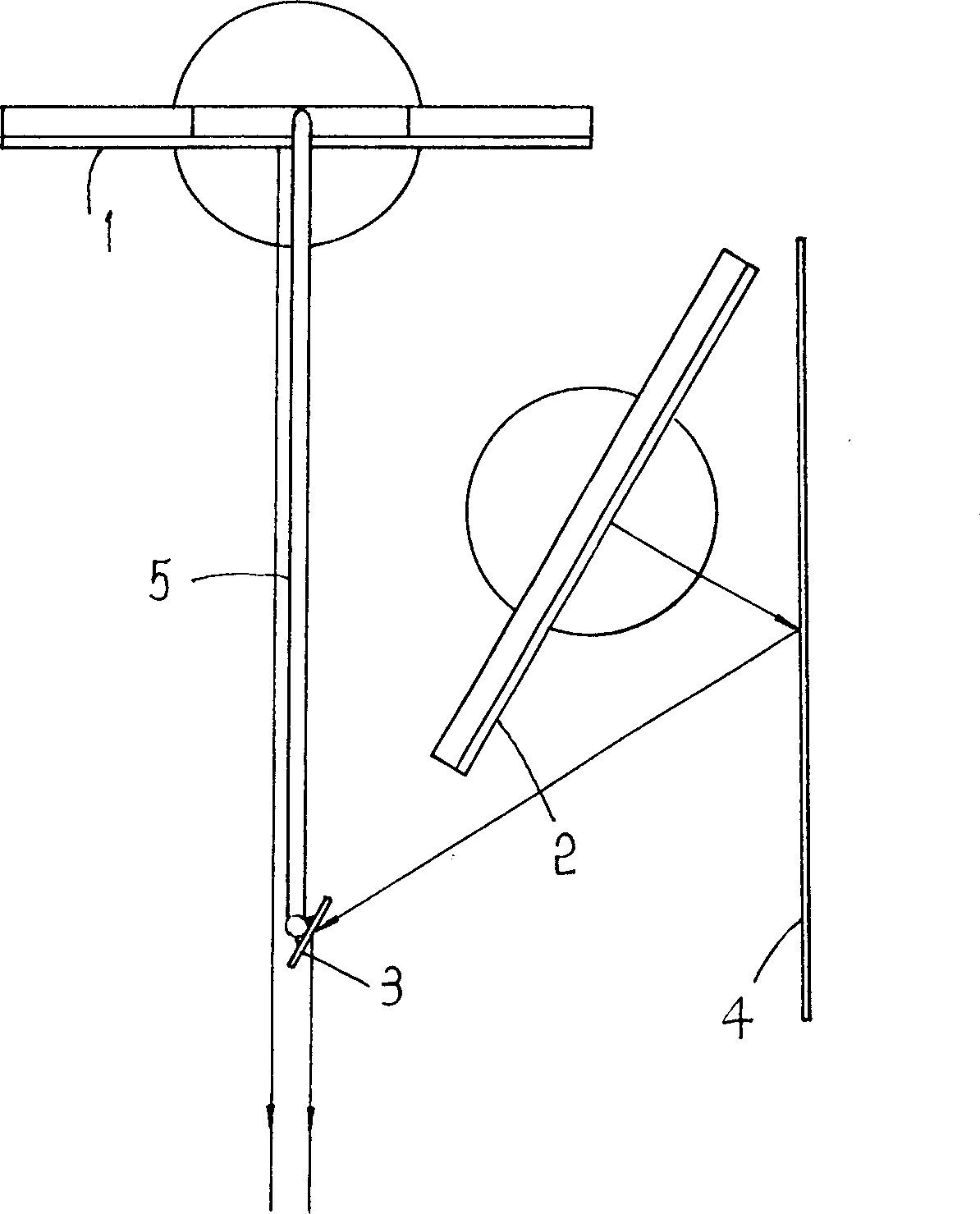

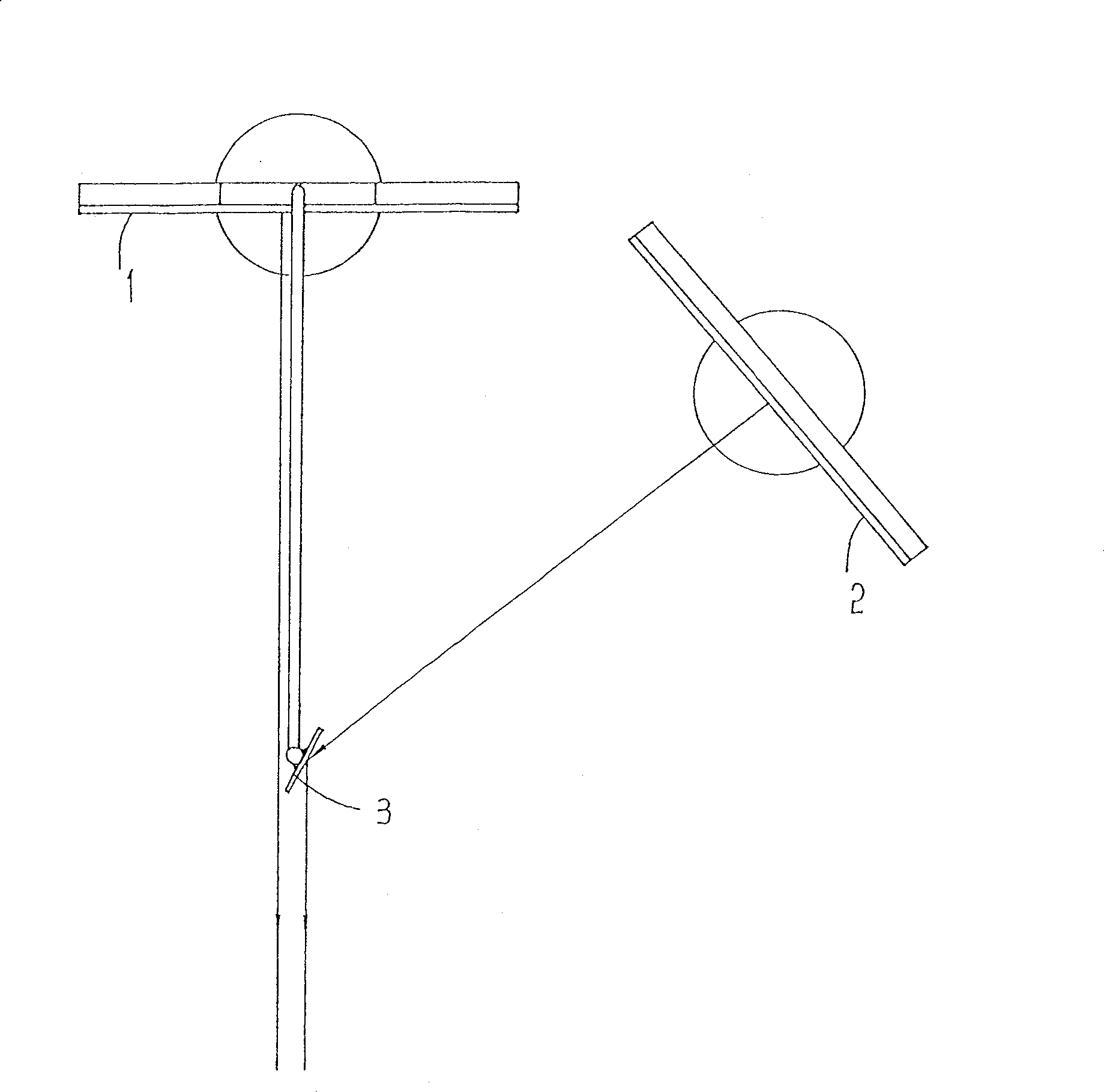

Stereo image display device

InactiveCN1715992ARealistic three-dimensional effectSimple structureProjectorsOptical elementsComputer graphics (images)Imaging quality

The stereo image display device includes two image display screens, including one main image display screen and one auxiliary image display screen, which are set to form some angle and display synchronous images in some visual angel difference suitable for human's eyes. Before the main image display screen, there is one reflector for one eye of human to watch, and the auxiliary image display screen and the reflector have such relative position relationship that the auxiliary image watched in the reflector is superposed with the image the main image display screen displays. The present invention has simple structure, high image quality, low cost, and good stereo effect, and may be used widely.

Owner:胡超

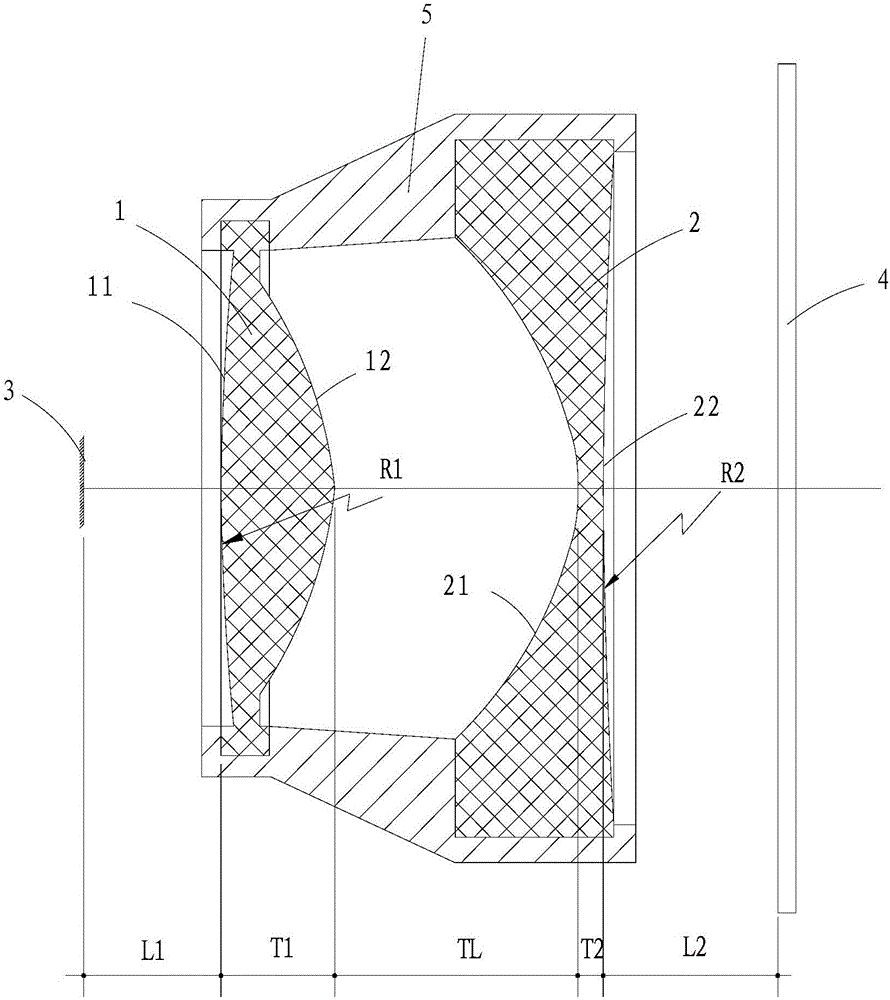

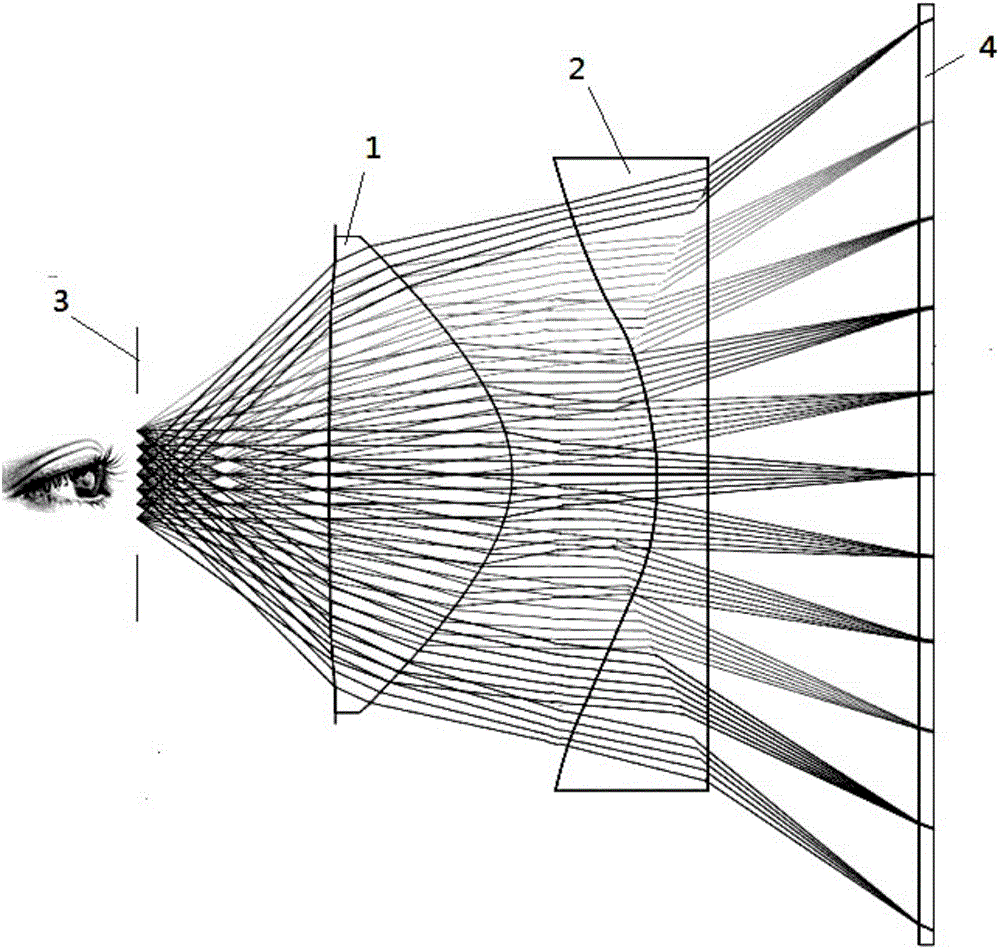

VR/MR optical system of dual-element convex-concave lens and VR/MR device

ActiveCN106371212AShorten the lengthSmall graphic distortionOptical elementsMixed realityAnalog device

The invention provides a virtual reality / mix reality (VR / MR) optical system of a dual-element convex-concave lens. The system comprises a lens group module formed by a first convex lens approaching a diaphragm and a second concave lens at a distance to the first convex lens. The first convex lens is a positive-focal-length lens and the second concave lens is a negative-focal-length; the surface, opposite to the diaphragm, of the first convex lens is a spherical surface and the radius of curvature is R1 that is larger than 18mm and is smaller than 21mm; the surface, opposite to the second concave lens, of the first convex lens is a dual-curve aspheric surface; the surface, opposite to the first convex lens, of the second concave lens is a spherical surface is a dual-curve aspheric surface; and the surface, opposite to the screen, of the second concave lens is a spherical surface and the radius of curvature is R2 that is larger than 24 mm and is smaller than 27 mm. In addition, the invention also provides a VR / MR device having the optical system. Therefore, a problem that the experience is poor because of distortion and dispersion that exist in the optical part of virtual reality equipment or simulation equipment with high immersion and the optical part of mix reality equipment can be solved effectively and thus the good user experience effect can be realized.

Owner:深圳市原点创新有限公司

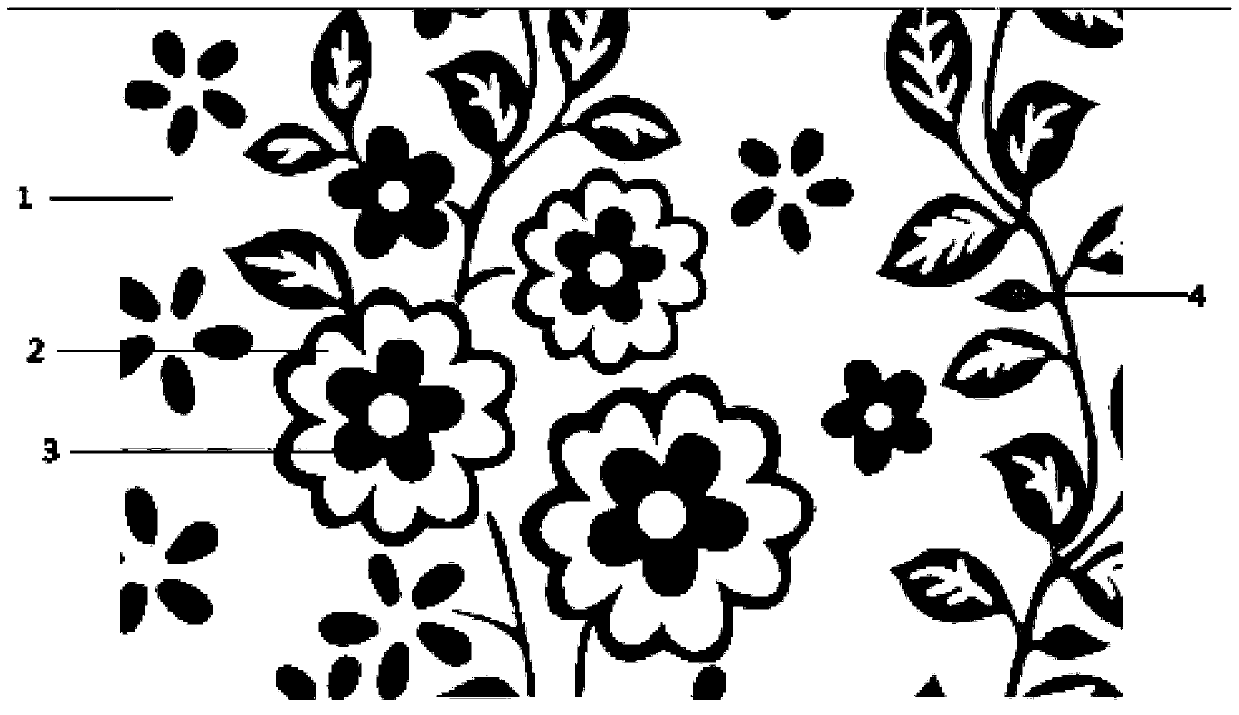

Simulation decorative film of flower

InactiveCN103171360ARealistic three-dimensional effectObvious bumpy touchSpecial ornamental structuresEngineeringCoating

The invention discloses a simulation decorative film of flowers. The simulation decorative film comprises a base film, a third ordinary special color layer, a second ordinary special color layer, a first ordinary special color layer, a printing stock, a matte coating and a bright coating in sequence from the top to bottom. An edition roller printing coating with flower patterns is mainly utilized; because of the different thicknesses of the matte coating self, the matter coating is utilized, so that the coating has the grain feeling, and the whole flower is more vivid in three-dimensional effect; a hollow-out type effect is printed by utilizing the bright coating, so that the flower partially has remarkable convex and concave touch feeling; and the beauty of flowers is better set off by green leaves, so that the three-dimensional and vivid effect of the flower decorative film is achieved.

Owner:SUZHOU GUOHAO WALLPAPER

Method for preparing embossed decorative veneer

ActiveCN102059730BReduce workloadReduce the number of seamsWood veneer joiningWood layered productsCircular discEngineering

The invention discloses a method for preparing an embossed decorative veneer, which comprises the steps of selecting, hydrothermal softening, slicing, veneering, cold inspection, rinsing, and wire drawing, wherein the wire drawing step comprises three processes of direct drawing, sweeping and polishing; during direct drawing, a groove is formed on the surface of a board by a front steel wire roller on a wire drawing machine and grains are deepened; during sweeping, a plurality of disc brushes are arranged on the wire drawing machine, each disc brush is driven to rotate by a respective drive motor and comprises a disc and steel wires which are densely arranged on the lower end face of the disc, and the plurality of disc brushes rotate to widen the grains of the groove on the surface of theboard, so that the grains on the surface of the board are wider, and the embossed effect is more vivid; and during polishing, first two groups of brushed parts of the board are polished by a rear steel wire roller on the wire drawing machine, so that a finished product has smooth feeling, and the embossed effect is achieved on the surface of the veneer. Compared with the prior art, the method ensures that wood grains are more three-dimensional, vivid and natural.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

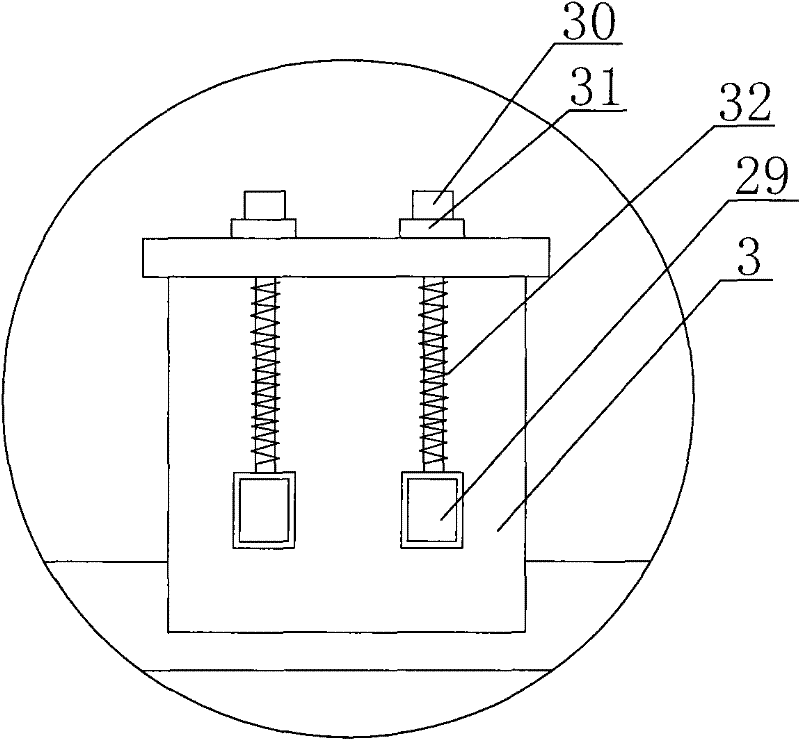

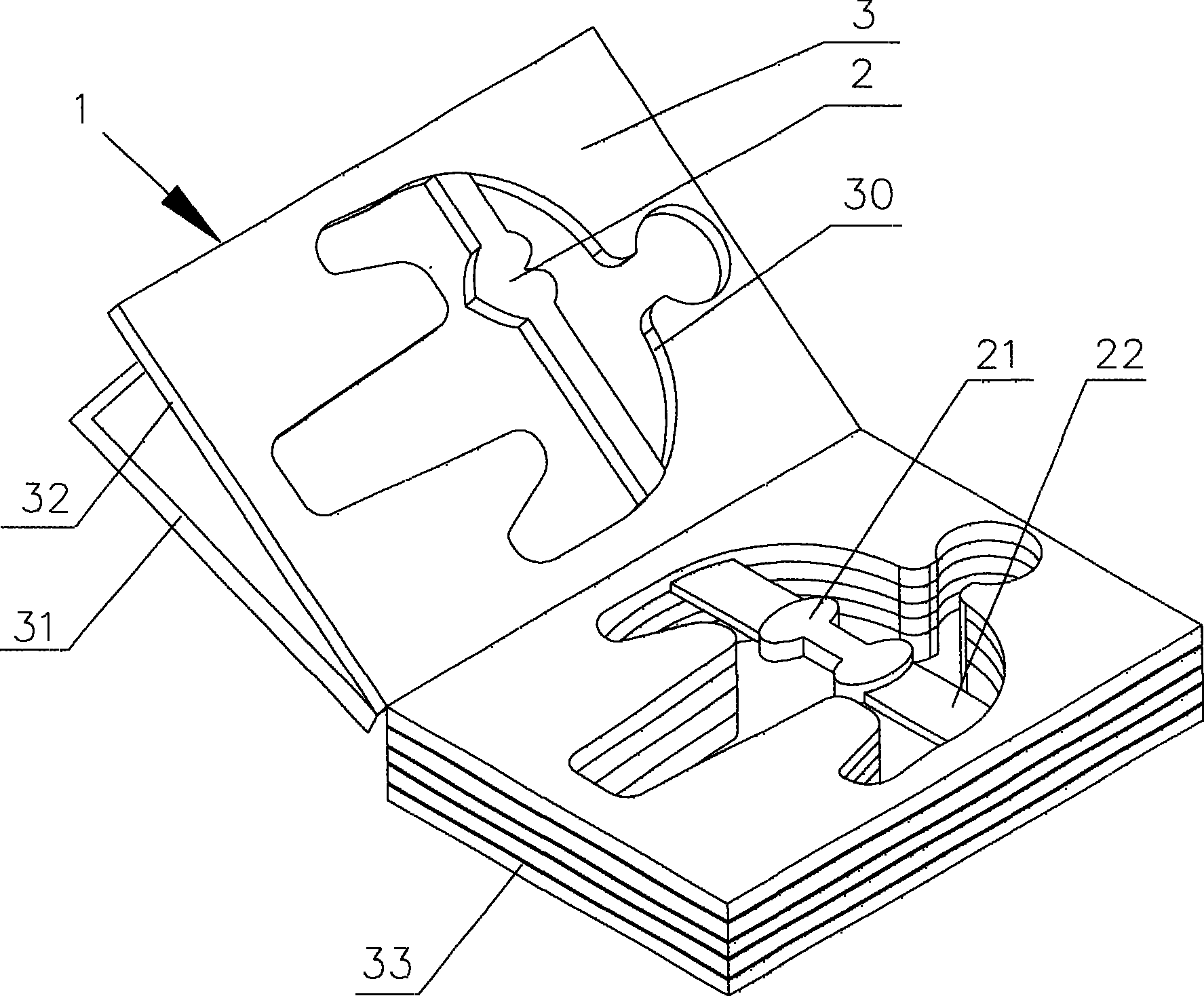

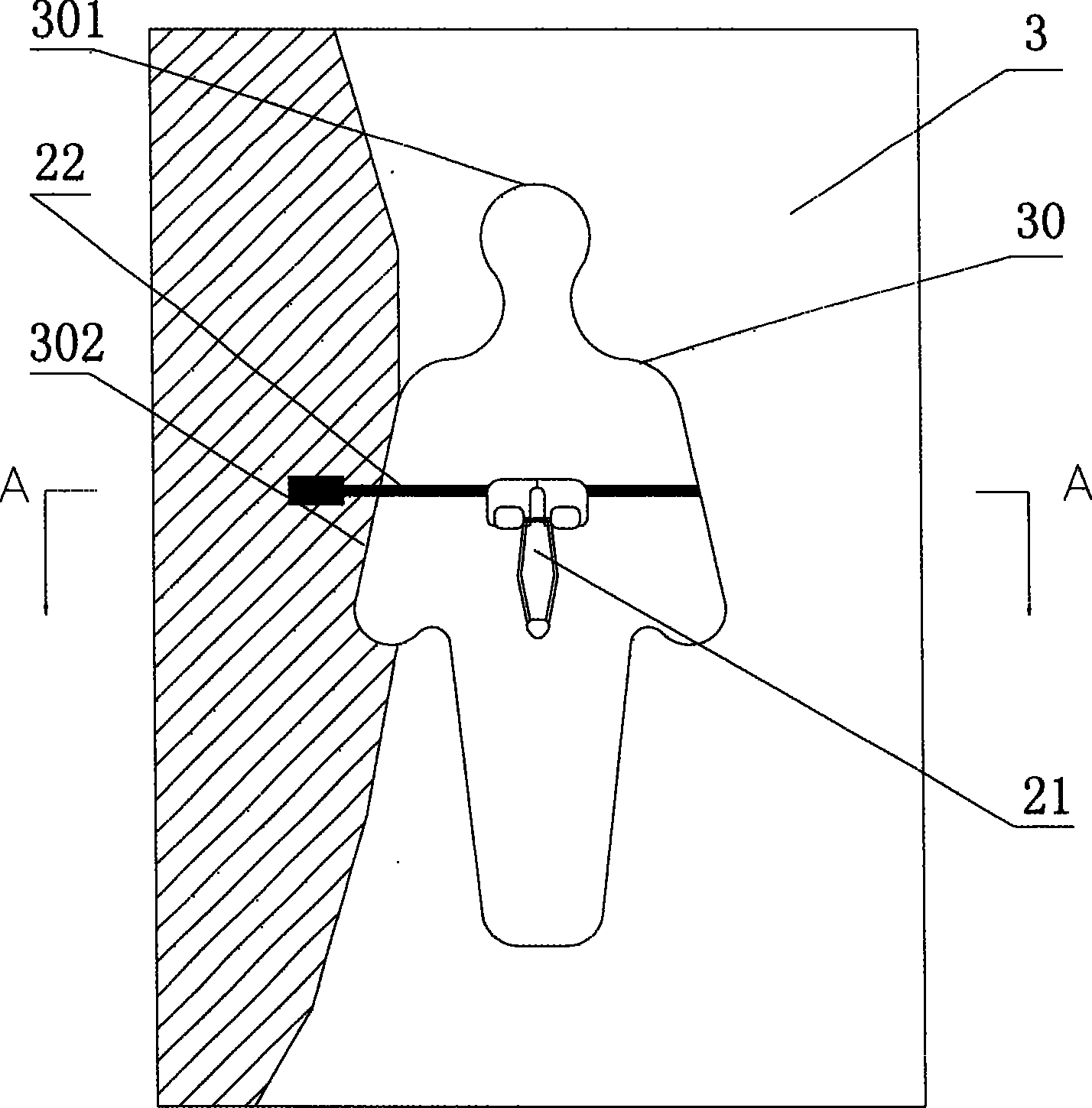

Solid and plane combined model

InactiveCN1909018BRealistic three-dimensional effectStimulate interest in readingTeaching apparatusEngineeringMechanical engineering

The disclosed model combined with multiple solids and planes comprises: arranging a hollow die hole same as profile of model target on same position of every plane model, as well as words or pattern near the hole; combining the solid with molding piece connected by linkage piece to former hole to match with corresponding word or pattern; besides, overlaying these plane models to form the target model. This invention has vivid effect for target description.

Owner:黄建民 +1

Production process for glass

InactiveCN109437589AGood anti-UVRealistic three-dimensional effectCoatingsGlass tempering apparatusChemistryHeavy metals

The invention provides a production process for glass, and relates to the field of glass production and manufacturing. The production process for the glass provided by the invention comprises the following steps: (1) toughening the glass, namely, preserving the heat of a glass block at 720 to 730 DEG C for 220 to 260 seconds, and cooling the glass to 30 to 35 DEG C within 75 to 95 seconds to obtain toughened glass; (2) spraying the surface of the toughened glass with a UV prime coating; (3) spraying the surface of the UV primer coating with a UV coating, and performing UV curing; and (4) spraying primer, a decorative layer and finish paint in sequence, wherein the drying temperature of the primer is 50 to 70 DEG C, and the drying time is 10 to 20 minutes. Through detection, the glass produced by the production process provided by the invention does not have a heavy metal which is harmful to human bodies; and the surface meets a food grade safety test. The glass has high UV resistance and a good anti-oxidation function. The glass has a realistic stereoscopic effect; the product is easy to clean, is not free from oil stain, is non-toxic and harmless, and is strong in antimicrobial property.

Owner:ZHEJIANG ZHONGGANG GLASS

Spray-coating process of honeycomb three-dimensional pattern

ActiveCN103182893BImprove qualityAttractive appearanceLiquid surface applicatorsDecorative surface effectsSpray coatingTransmittance

The invention discloses a spray-coating process of honeycomb three-dimensional pattern. The process comprises the steps that: (1) a workpiece is processed by using a mold, such that a simple honeycomb pattern is formed on the back side of the workpiece; (2) black oil is spray-coated on the back side, such that three-dimensional honeycomb structure is formed; (3) plating silver is spray-coated on the back side, such that a metal effect is enhanced; (4) a black shading is spray-coated on the back side, such that transmittance is avoided, and metal dimensional sense can be enhanced; (5) a topcoat is spray-coated on the back side, such that scratching damages are avoided; (6) a color paint is spray-coated on the front side, such that color and aesthetic effect are adjusted; and (7) surface oil is spray-coated on the front side, such that surface hardness, wear resistance and the like are enhanced. The process provided by the invention has the advantages that: when the honeycomb three-dimensional pattern spray-coating process is applied on a workpiece manufactured by using a transparent material, and front-side and back-side spray-coating is carried out, a three-dimensional honeycomb fading effect is provided on the surface of the workpiece. According to the invention, with multiple times of spray-coating, the three-dimensional effect is better and more realistic, and a charming sense is provided. Viewed from the front side of the workpiece, the three-dimensional effect is looming.

Owner:东莞市旺鑫精密工业有限公司

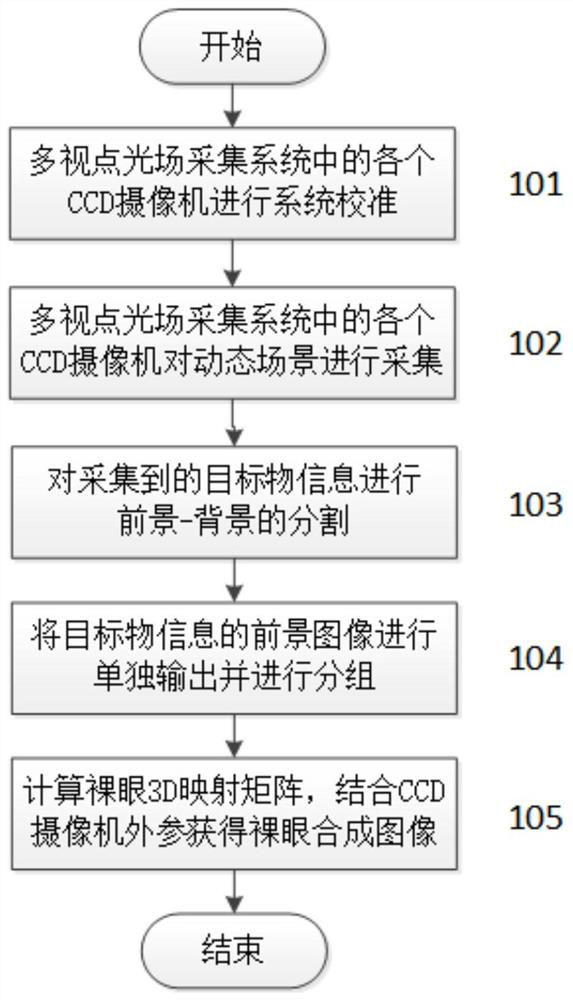

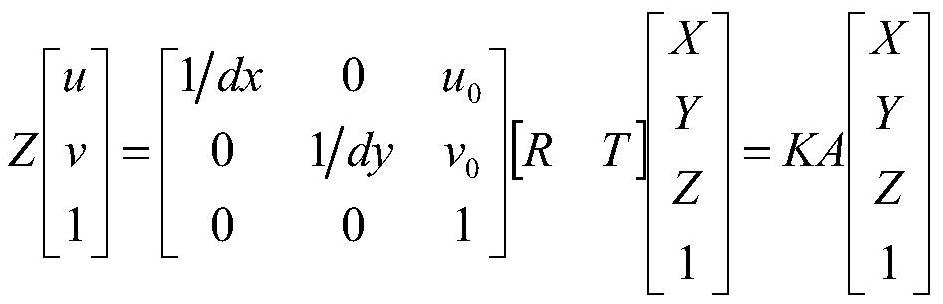

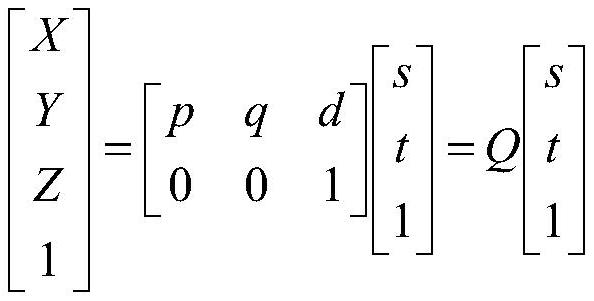

A naked eye 3D image acquisition and generation method

The invention relates to the technical field of naked-eye 3D display, and discloses a naked-eye 3D image acquisition and generation method. The present invention first performs system calibration on each of the CCD cameras in the multi-viewpoint light field acquisition system, then performs dynamic scene acquisition, performs foreground and background segmentation on the acquired target object information, and then separates the foreground image of the target object information Output and group, and finally calculate the naked-eye 3D mapping matrix, and combine the external parameters of the CCD camera to process the foreground image to obtain a naked-eye 3D composite image with the correct proportion. The naked-eye 3D mapping method based on the dynamic light field not only has a more realistic three-dimensional effect, but also is compatible with far and near viewing, so that the viewer will not experience problems such as dizziness and visual fatigue.

Owner:和信光场(深圳)科技有限公司

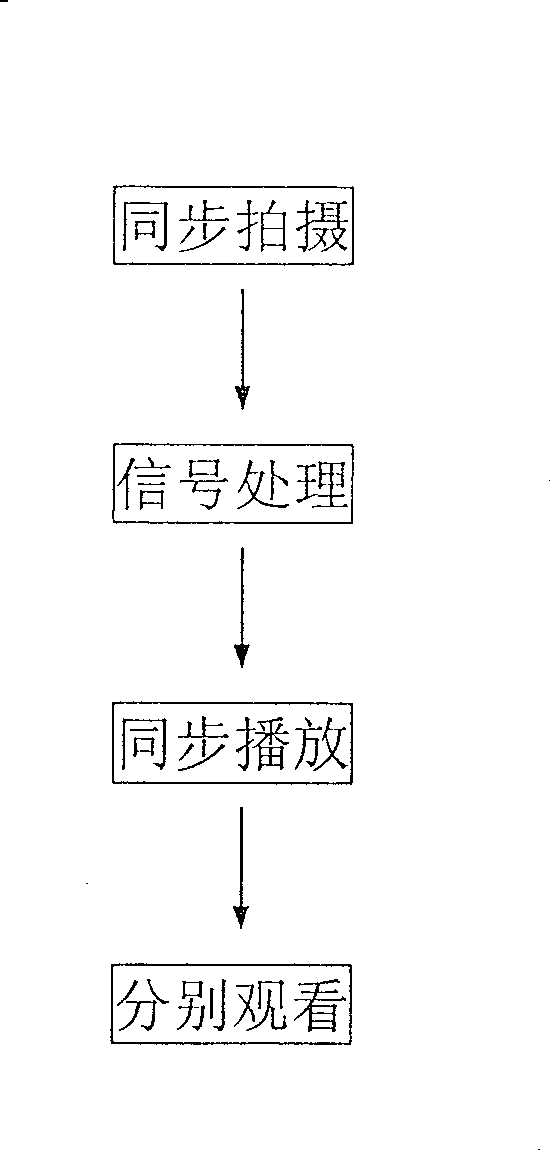

Method of photographing signal treating and broadcasting and viewing stereoimage

ActiveCN100480849CRealistic three-dimensional effectThree-dimensional effect is naturalStereoscopic photographyOptical elementsComputer hardwareBroadcasting

The present invention discloses a stereoscopic picture shooting, signal processing and playback method. Said method includes the following steps: synchronously shooting, signal processing, synchronously playing back and respectively watching. Said method can be extensively used in the fields of television broadcast, family, communication and hospital, etc.

Owner:INLIFE HANDNET CO LTD

A kind of chenille bath towel and its manufacturing process

The invention belongs to the technical field of bath towel manufacturing, in particular to a chenille bath towel and its manufacturing process. The chenille bath towel is woven from ground warp, wool warp and weft yarn, and the weft yarn includes snow Neil yarn and combed cotton yarn, the bath towel has a three-dimensional horizontal wrinkle structure and a flat cloth structure, and the three-dimensional horizontal wrinkle structure and the flat cloth structure are alternately arranged to form a fabric with ups and downs. Its manufacturing process includes weave design, warping, reeding, weaving, machine weaving and post-processing. The present invention has more novelty, three-dimensional effect, and more lively expression form, and forms different friction effects on the surface of the product by adjusting the weft yarn and the structure, and has better air permeability.

Owner:SUNVIM GROUP

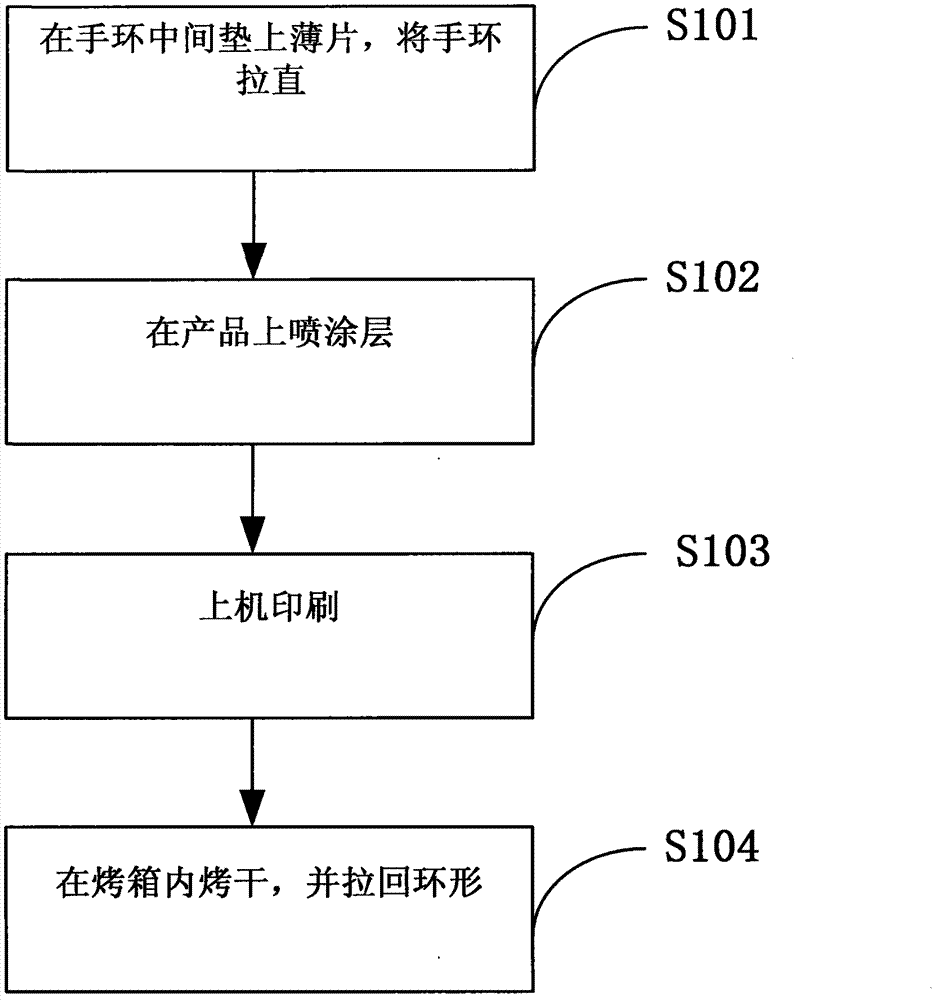

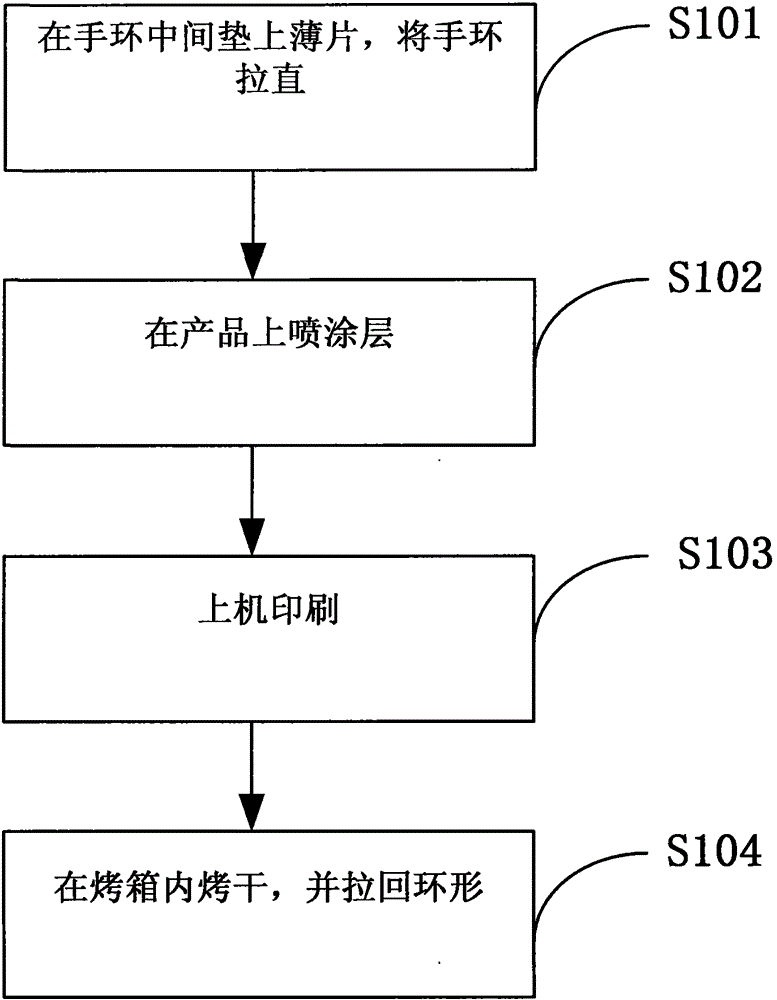

Circular hand ring printing method

ActiveCN103358737ARealistic three-dimensional effectThe printing process is simpleOther printing apparatusCoatingComputer engineering

The invention is applicable to the technical field of printing, and provides a circular hand ring printing method. The printing method comprises the following steps that a sheet is padded in the middle of a hand ring; the hand ring is straightened; a coating is sprayed on the hand ring; and the hand ring is put on a machine for printing, and put in an oven for drying. According to the circular hand ring printing method, the coating is sprayed on the hand ring, and put on the machine for printing, if one half of an area of the hand ring is printed, the printing can be conducted once, if the whole ring is printed, the front, the back and a connector are required to be printed for three times, and finally the hand ring is dried in the oven after printed, so that a printing process is simplified greatly, the method is simple to operate, errors are not easy to make, and a pattern on the hand ring is very lifelike in stereoscopic effect, gorgeous in color, delicate and exquisite.

Owner:GUIZHOU YONGJI PRINTING

A kind of multi-color multi-layer yarn-dyed towel with diversified pattern structure and weaving method thereof

ActiveCN111118705BThree-dimensionalStrong noveltySwivel-woven fabricsLappet-woven fabricsPolymer scienceEngineering

The invention discloses a multi-color multi-layer yarn-dyed towel with various patterns and textures and a weaving method thereof. The towel is a towel product comprising at least four layers and four colors woven from hair warp, ground warp and weft yarns of different colors The wool warp at least includes the wool warp of color 1 and the wool warp of color 2, the ground warp at least includes the ground warp of color 3 and the ground warp of color 4, and the weft yarn is divided into at least four layers, including the weft yarn layer of color 3 and the weft yarn layer of color 4; Wool warp and color 2 wool warp are respectively interwoven with two layers of weft yarns and the corresponding ground warp of the four layers of weft yarns to form a loop pattern; color 3 ground warp and color 4 ground warp are respectively interwoven with color 3 weft yarn layer and color 4 weft yarn layer And correspondingly form gauze pattern and / or bottom weave through interweaving; The invention is a multi-layer towel quilt product with rich loop surface colors and the combination of colors, patterns and textures of the gauze surface and the loop surface.

Owner:SUNVIM GROUP

A kind of circular bracelet printing method

ActiveCN103358737BRealistic three-dimensional effectThe printing process is simpleOther printing apparatusComputer engineeringCoating

The invention is applicable to the technical field of printing, and provides a circular hand ring printing method. The printing method comprises the following steps that a sheet is padded in the middle of a hand ring; the hand ring is straightened; a coating is sprayed on the hand ring; and the hand ring is put on a machine for printing, and put in an oven for drying. According to the circular hand ring printing method, the coating is sprayed on the hand ring, and put on the machine for printing, if one half of an area of the hand ring is printed, the printing can be conducted once, if the whole ring is printed, the front, the back and a connector are required to be printed for three times, and finally the hand ring is dried in the oven after printed, so that a printing process is simplified greatly, the method is simple to operate, errors are not easy to make, and a pattern on the hand ring is very lifelike in stereoscopic effect, gorgeous in color, delicate and exquisite.

Owner:GUIZHOU YONGJI PRINTING

A processing method for forming an image with relief visual effect on a plane material and its product

ActiveCN103921610BEase of mass productionRealistic three-dimensional effectDecorative surface effectsThree-dimensional effectsNumerical controlProjection line

Owner:NANJING BANKNOTE MINTING

Three-dimensional transversely-wrinkled fuzzing towel and weaving process thereof

ActiveCN102660824BStrong three-dimensional senseStrong noveltyHeating/cooling textile fabricsWoven fabricsPolymer scienceEngineering

Owner:SUNVIM GROUP

A kind of manufacturing method of high-temperature bulk relief porcelain plate

The invention provides a method for manufacturing a high-temperature large relief porcelain plate, which comprises the following steps: making relief mud and glaze; creating relief works; making working seed molds; forming a glaze layer on the relief surface of the relief mud; demolding ;Perfect engraving and decoration; Bisque firing treatment of large relief porcelain plates; Grinding and modification of large relief porcelain plates after bisque firing; High-temperature firing treatment of large relief porcelain plates; The porcelain plate is polished to obtain the pre-finished product; the pre-finished product is refired for the third time; the pre-finished product is cooled to the outdoor temperature and then out of the kiln, and then polished and quality inspected to obtain the finished product; a single finished product or multiple The assembled finished products are framed and packaged. The invention has a high qualified rate of finished products and has the advantages of large size specifications of 1.4-1.8m in length, 0.8-1.2m in width, and 1.7-3cm in thickness, and can ensure flatness requirements during assembly operations.

Owner:湖南大球泥瓷艺集团有限公司

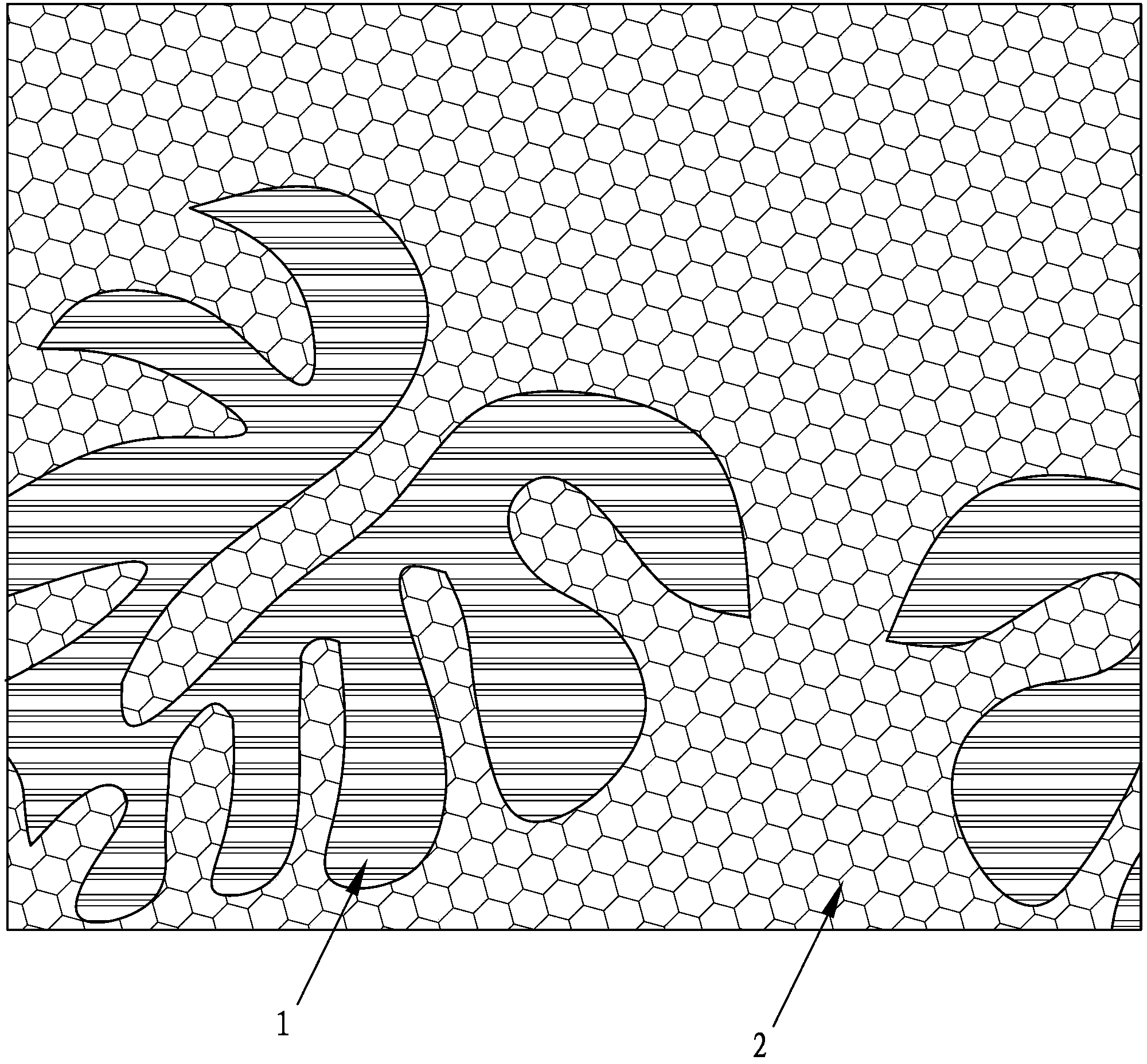

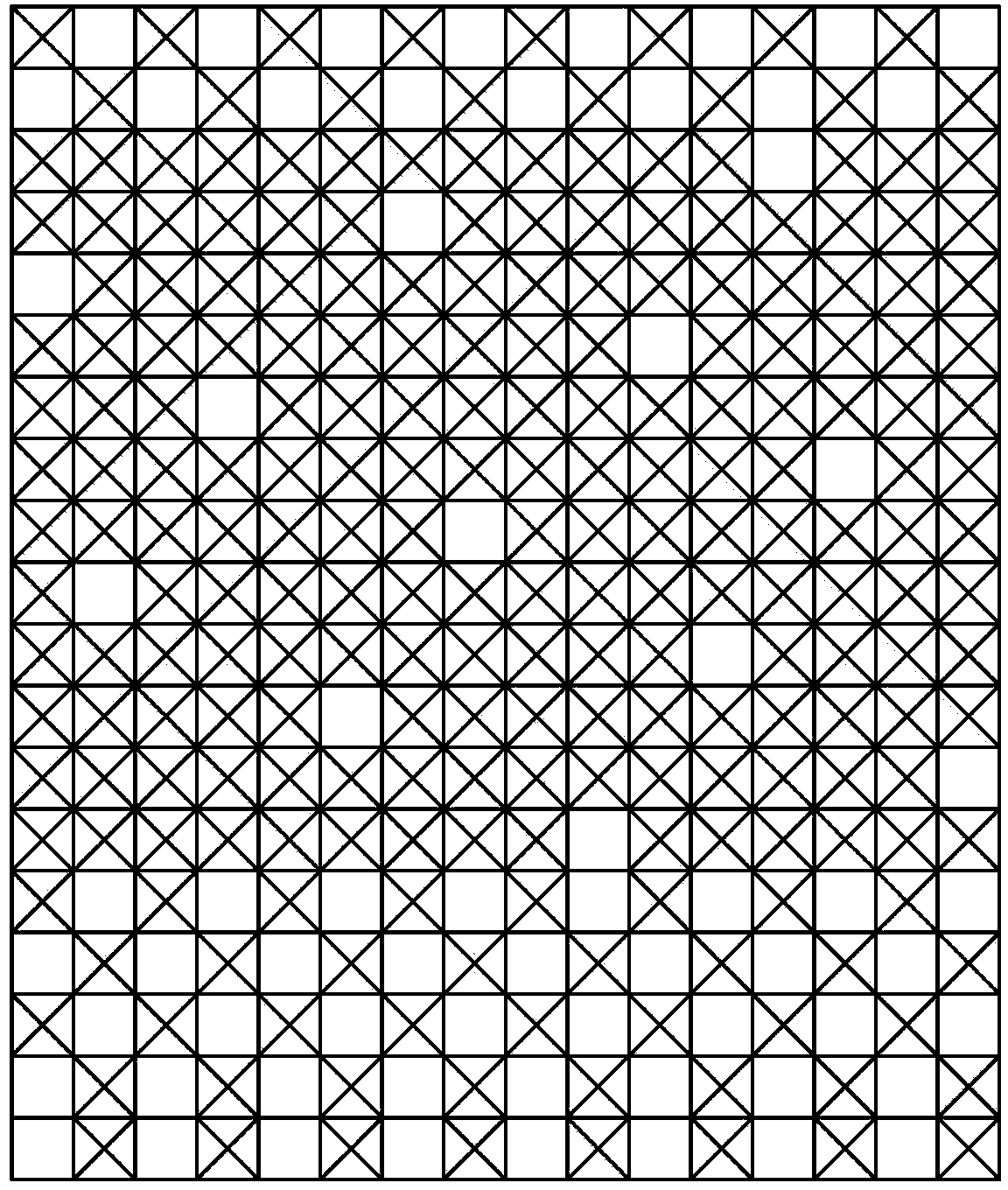

Quasi-stereoscopic picture composing method for material inside organization structure

InactiveCN101271586BRealistic three-dimensional effectImage analysis3D-image renderingImage processing softwareComputer science

The present invention relates to a quasi-three-dimensional image construction method of an internal construction of a material, comprising the following steps: taking a sample; determining viewing planes; shooting a plane photo or image for planes respectively; after inputting the photo or the image into a computer, utilizing a common image processing software to synthesize the quasi-three-dimensional image according to a real position relationship of the plane photo and a perspective principle. Compared with the prior art, the quasi-three-dimensional image construction method provided by the invention has the advantages of lifelike three-dimensional effect, and can reflect actually the information such as an internal constructional feature, a spatial relationship between the internal construction units and a distribution mode in the sample and so on, which can be applied to a three-dimensional characteristic of a macrostructure and a microstructure of various materials such as a metal, a pottery, a macromolecule material, a stone material, the bamboo, a wood and other engineering materials, and used in the fields of material inspection, evaluation, advertisement propaganda the product sample, etc.

Owner:DALIAN JIAOTONG UNIVERSITY

Wire drawing machine

InactiveCN101704206BRealistic three-dimensional effectSmooth texturePlane surface grinding machinesCircular discDrive motor

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

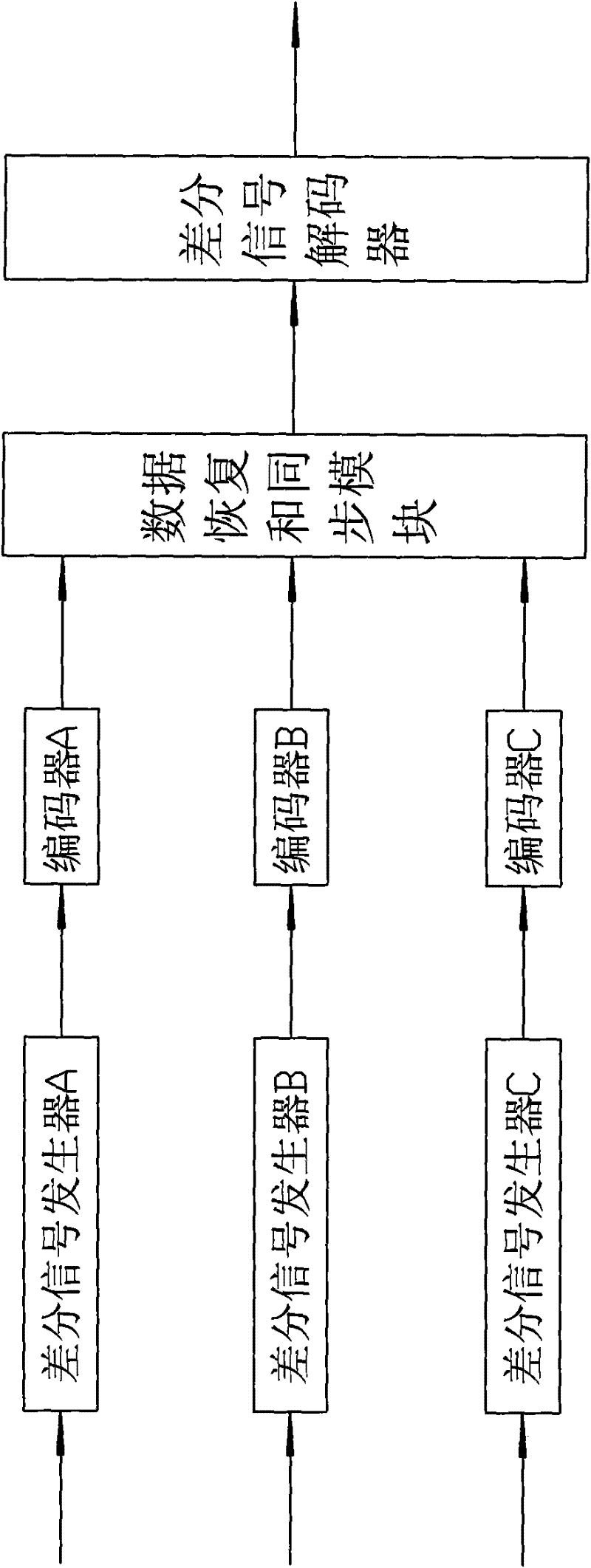

Full high-definition 3D signal transformation system

ActiveCN101742315BIncreased video contentIncrease refresh rateColor signal processing circuitsTelevision systemsProgrammable logic controllerControl store

The invention discloses a full high-definition 3D signal transformation system for processing and transmitting a high-definition video signal with large data quantity to obtain an image with high stereoscopic impression and high definition. The full high-definition 3D signal transformation system comprises a programmable logic controller, a receiving circuit, a transmitting circuit A, a transmitting circuit B, a storage E and a storage F, wherein the receiving circuit is connected with the input end of the programmable logic controller; the transmitting circuit A and the transmitting circuit B are connected with the output end of the programmable logic controller; the storage E and the storage F are connected with the programmable logic controller; the programmable logic controller is internally provided with an input receiving module, a color space transformation circuit, a video buttering circuit, a storage controller, a left and right separation circuit, an output transmitting module A, an output transmitting module B and a system controller, wherein the input receiving module, the color space transformation circuit, the video buttering circuit, the storage controller, the leftand right separation circuit, the output transmitting module A and the output transmitting module B are sequentially connected, and the storage controller and the system controller are both connectedwith the input receiving module, the color space transformation circuit, the video buffer circuit and the left and right separation circuit.

Owner:CHINA HUALU PANASONIC AVC NETWORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com