Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about How to "The printing process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

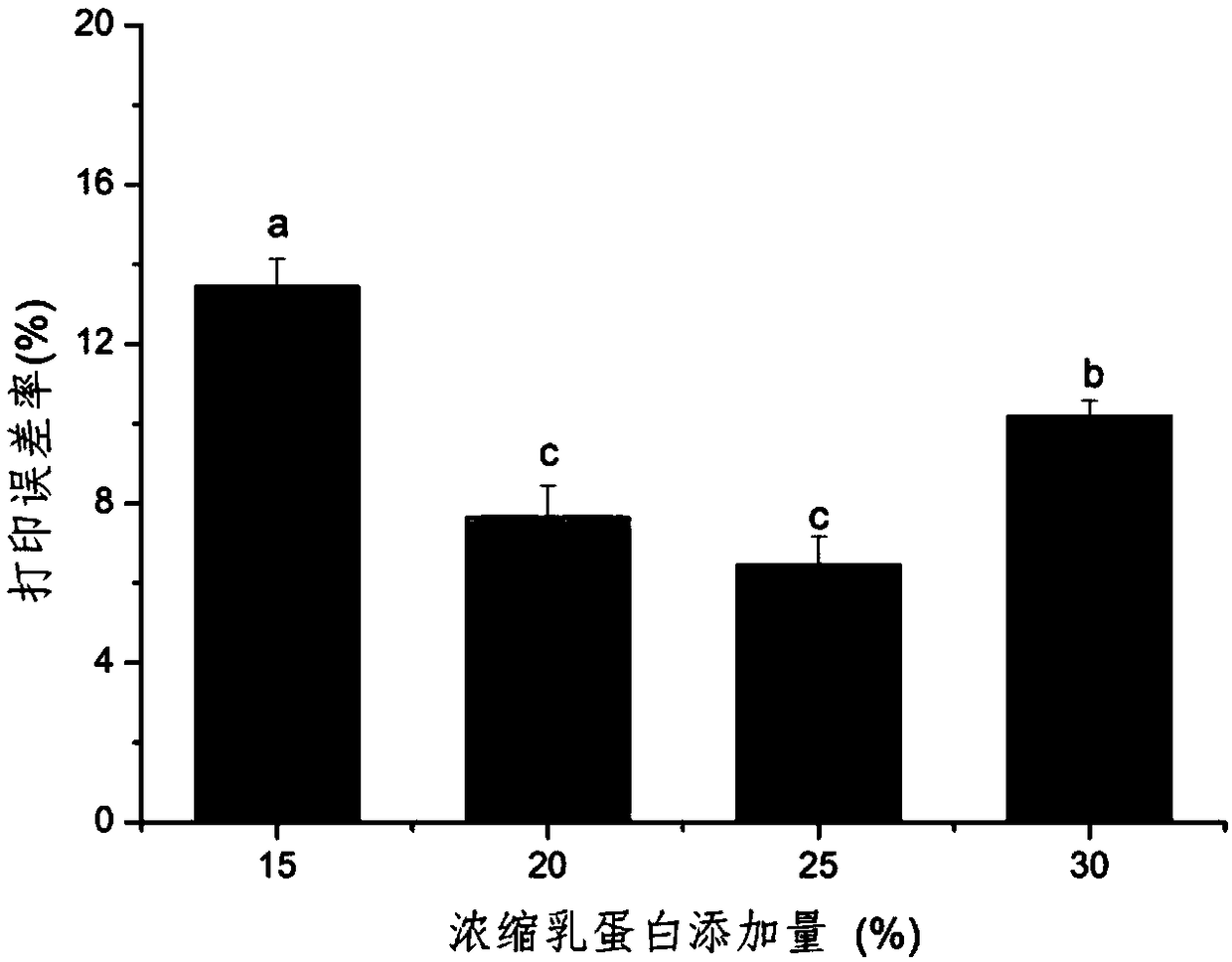

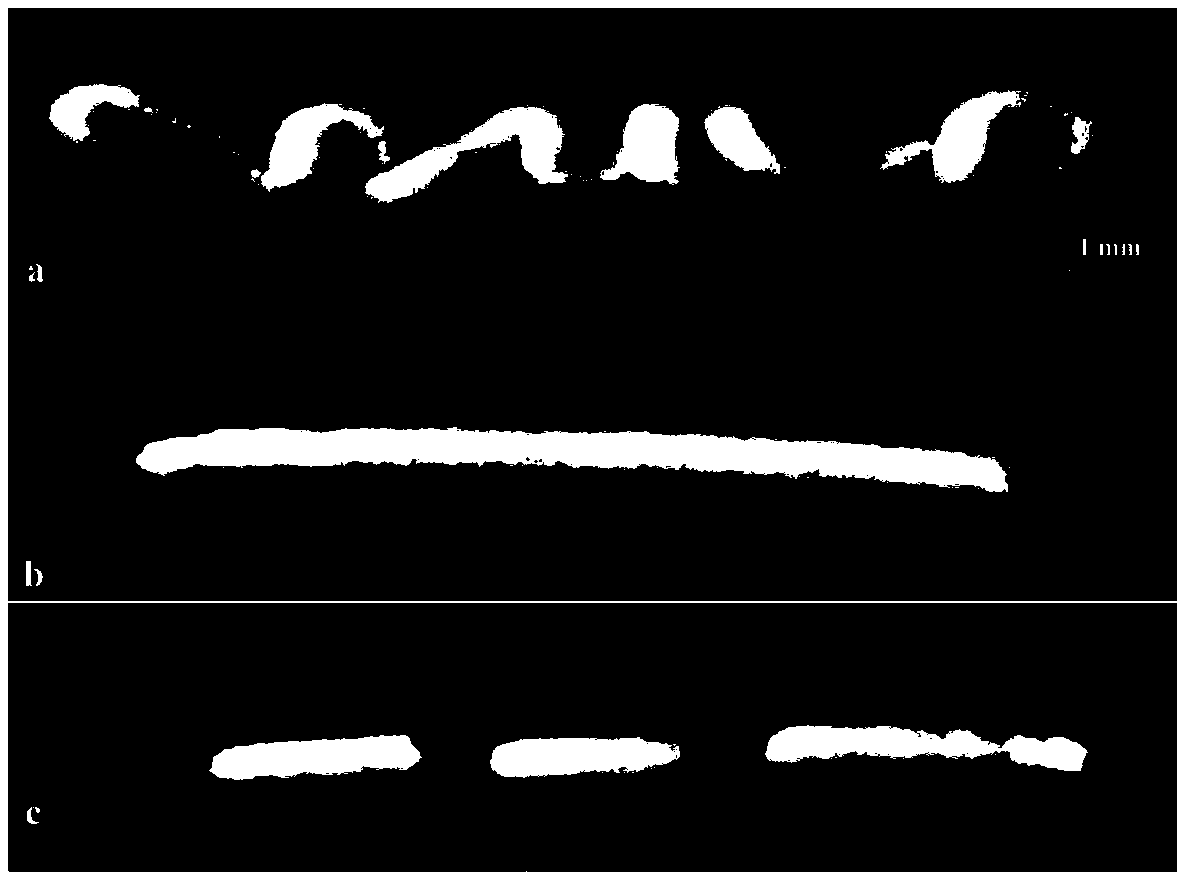

Regulation and control method of improving surimi system unfreezing forming and 3D (three dimensional) accurate printing performance

InactiveCN106798263AModerate viscosityImprove liquidityAdditive manufacturing apparatusFood ingredientsEngineeringGluconic acid

The invention discloses a regulation and control method of improving surimi system unfreezing forming and 3D (three dimensional) accurate printing performance and belongs to the technical field of preparation of 3D printed food materials. The regulation and control method comprises the following steps: unfreezing, mixing, blending, pre-forming, printing, post-setting, cooking frozen surimi and the like. According to the regulation and control method, as for an unfrozen surimi gel system, the printing temperature can be lowered, and the discharge rate and the stereo forming rate are increased; through induction by flaxseed gum and gluconic acid lactonic acid, the surimi gel has stable viscosity and mobility, surimi slurry is fine and smooth, and discharge is smooth without blockage; the surimi gel system can be prepared into fish product dining which maintains original characteristics and taste of a surimi product and has novel appearance and beauty through a 3D accurate printing technology.

Owner:JIANGNAN UNIV

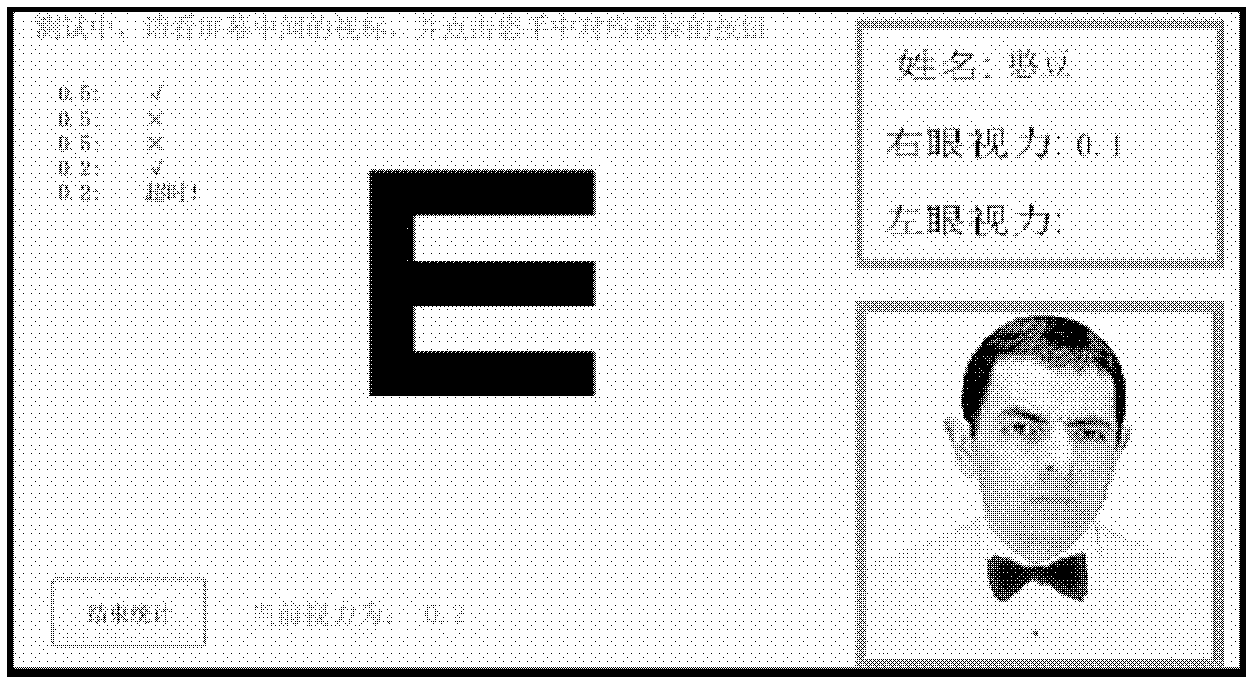

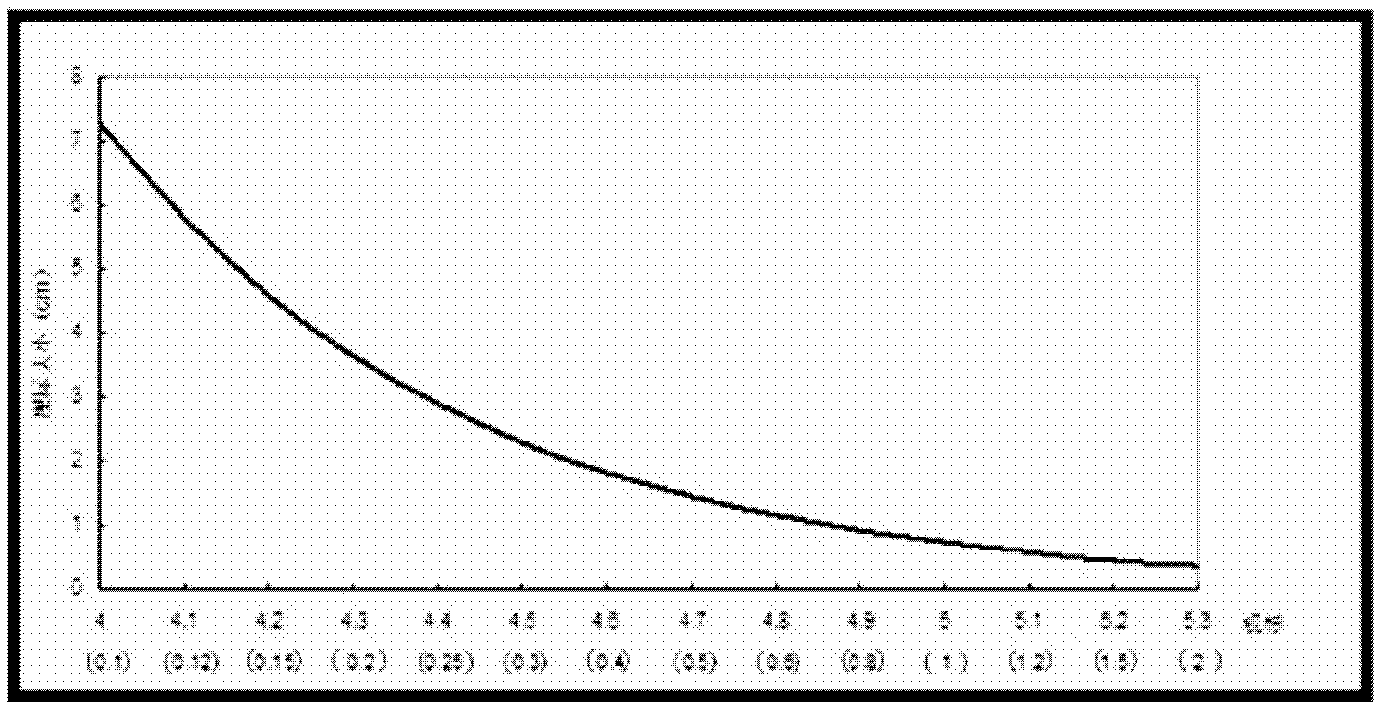

Self-adaptive eyesight test intelligent system and eyesight test method

InactiveCN102599879AReduce the number of medical staffReduce the cost of medical servicesEye diagnosticsSelf adaptiveTarget signal

The invention discloses a self-adaptive eyesight test intelligent system and an eyesight test method. The system comprises a subject recognition unit, a test eyesight target display unit, a direction-selection triggering unit, a test data processing unit and a test information management unit. The core of the system is a self-adaptive cycle processing flow of eyesight test data composed of the test eyesight target display unit, the direction-selection triggering unit and the test data processing unit. An eyesight target signal occurred on the test eyesight target display unit generates random transformation of four directions each time, and the size of the eyesight target matches with the logarithm international eyesight test standard. The subject selects a triggering button according to his own eyesight. The test data processing unit acquires test data through a bluetooth device, and automatically obtains a true eyesight value of the subject after a plurality of cycle processing. The self-adaptive eyesight test intelligent system and eyesight test method lowers the medical service cost of the eyesight test process, and makes the eyesight test flow more accurate, precise, convenient, rapid and intelligent.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

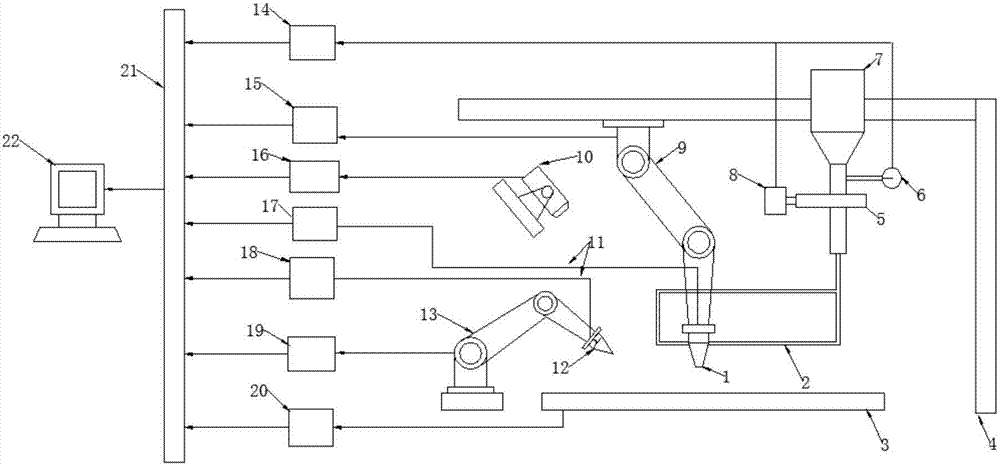

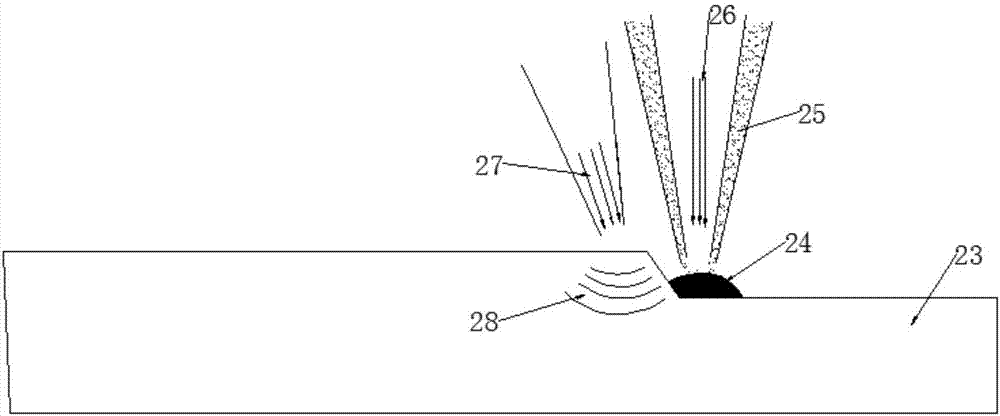

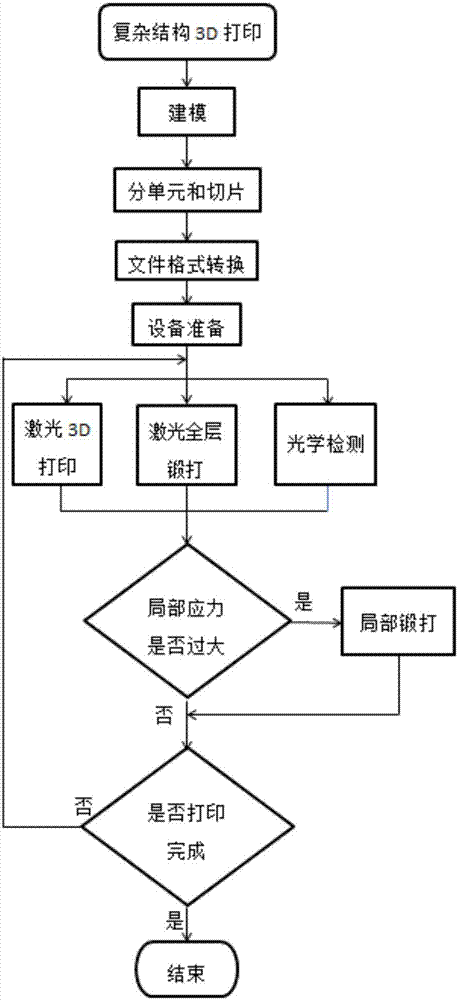

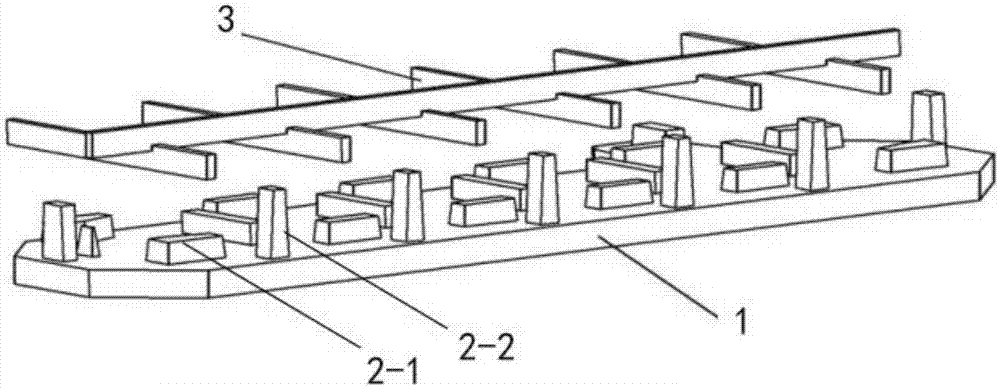

Additive manufacturing method and system for complex structure

InactiveCN107138728AWarpage ControlHigh mechanical strengthAdditive manufacturing apparatusIncreasing energy efficiencyElectricitySpray nozzle

The invention discloses an additive manufacturing system for a complex structure. The additive manufacturing system comprises a workbench, a 3D printing device, a laser forging device and a master control device. The 3D printing device comprises a powder supplying nozzle, a 3D printing mechanical arm used for driving the powder supplying nozzle to move relative to the workbench and a laser generator connected with the powder supplying nozzle. The laser forging device comprises a shot blasting nozzle, a laser shot blasting mechanical arm used for driving the shot blasting nozzle to move relative to the workbench and a pulse laser generator connected with the shot blasting nozzle. The master control device is electrically connected with the 3D printing device and the laser forging device to control moving of the 3D printing mechanical arm and the laser shot blasting mechanical arm. The invention further discloses an additive manufacturing method for the complex structure. By applying the additive manufacturing system and method, the mechanical strength of a part subjected to double-laser printing and forging is greatly improved, and the mechanical comprehensive performance is improved. Thus, the part structure can be further optimized, the structure is improved, the size is reduced, and finally, weight losing is achieved.

Owner:GUANGDONG UNIV OF TECH

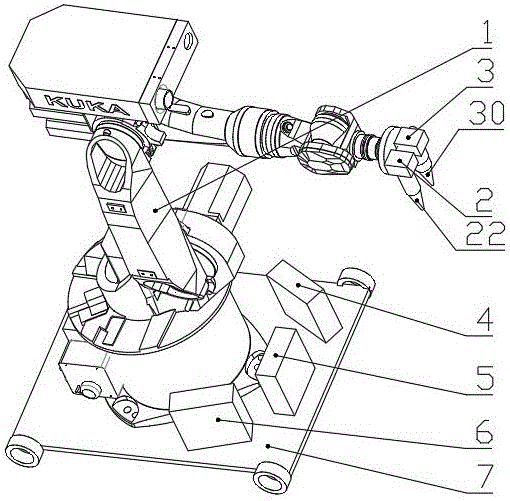

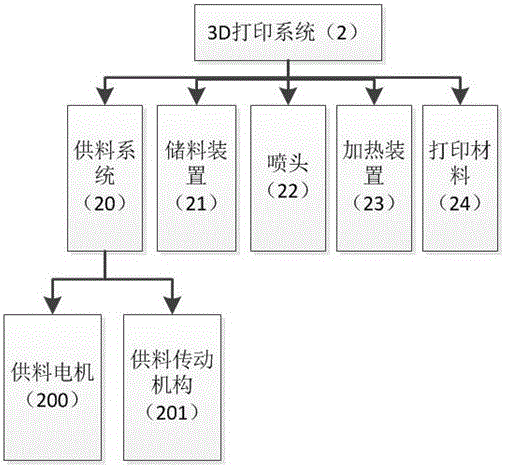

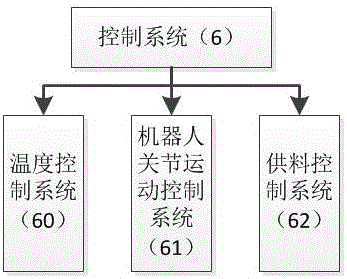

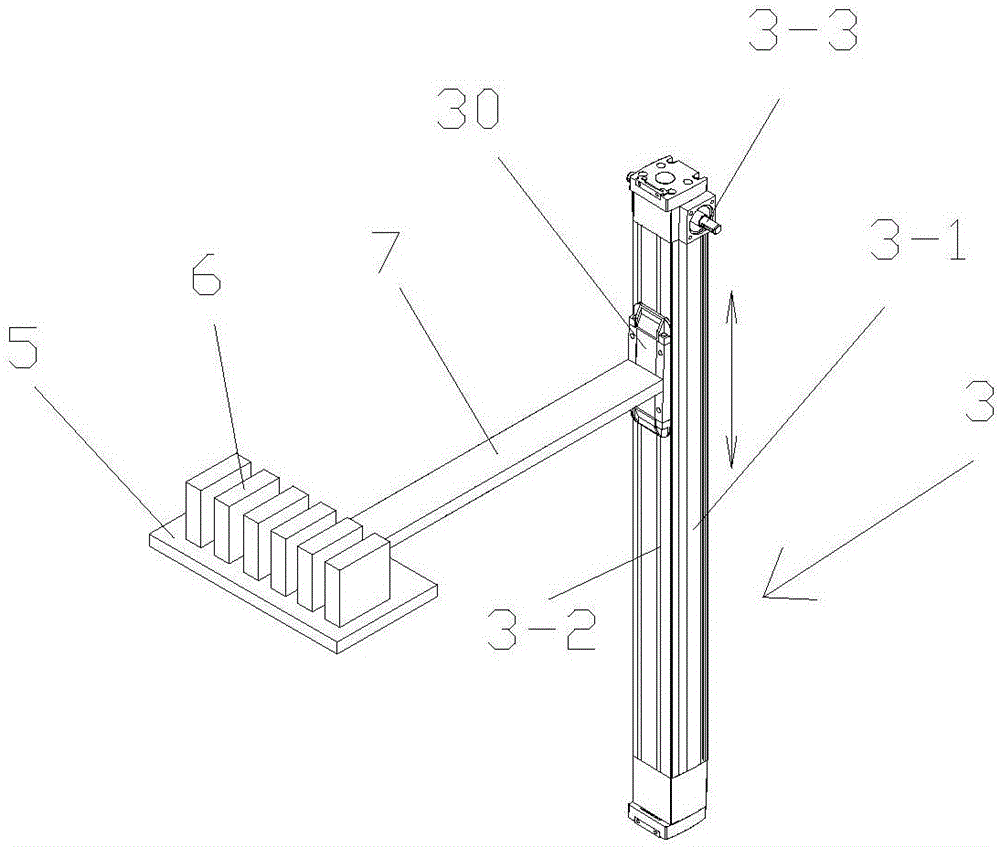

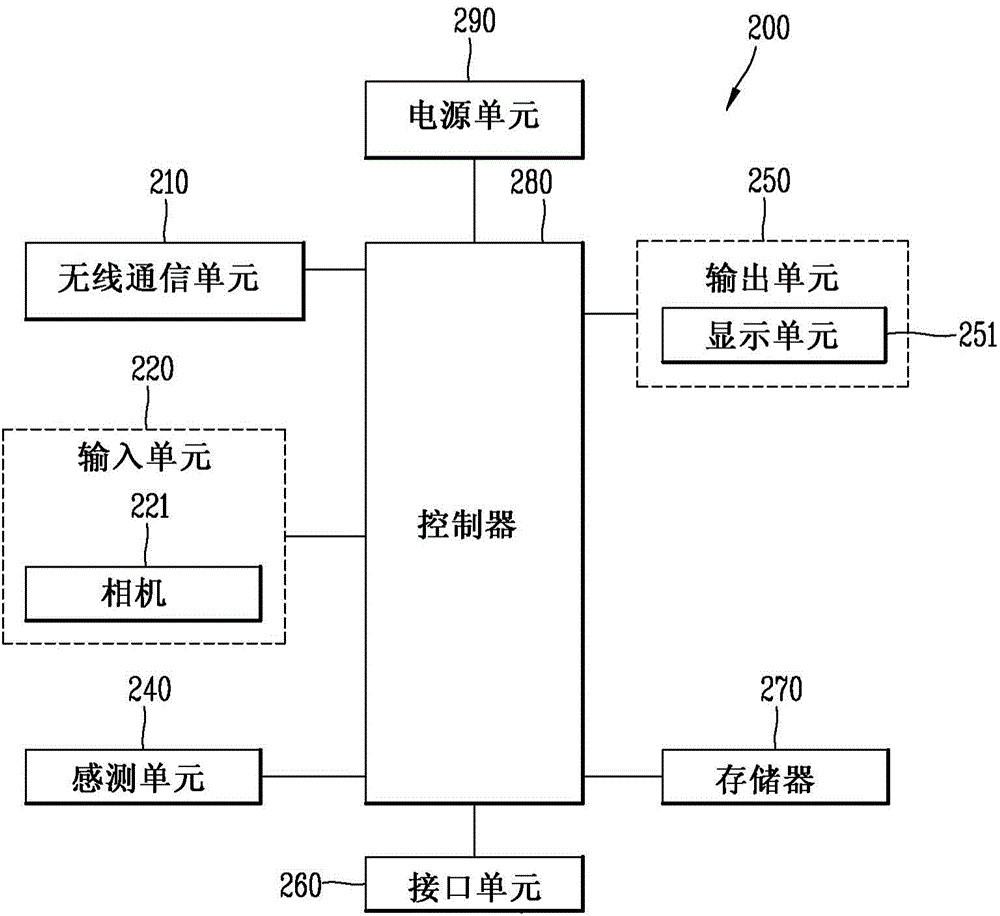

Intelligent robot assisting rapid modeling and 3D printing device

ActiveCN106313513AThe printing process is simpleQuick measurementAdditive manufacturing apparatusManufacturing data aquisition/processingTemperature controlImaging processing

The invention provides an intelligent robot assisting rapid modeling and 3D printing device. Compared with some devices provided before days, the device is more intelligent; compared with traditional reverse engineering, a large amount of unnecessary work can be saved, and the machining efficiency is improved; through an image processing system and a joint control system, the machining process can be monitored and controlled in real time, and the machining accuracy is improved; a mobile platform can achieve all-around movement and obstacle avoidance functions; a temperature control system can monitor the machining temperature in real time, and the surface machining quality is improved; and a feeding control system is used for calculating whether printing materials needed by model printing are sufficient or not, and gives out a corresponding prompt. The overall 3D printing device adopts modularized design, so that manufacturing, maintaining, repairing and replacing are relatively convenient.

Owner:SICHUAN UNIV

Oxygen supply sizing agent groove system and ceramic surface exposure 3D continuous printing method

ActiveCN105034138AUniform air pressureAvoid bondingAdditive manufacturing apparatusCeramic shaping apparatusBonding problemsSizing

The invention discloses an oxygen supply sizing agent groove system and a ceramic surface exposure 3D continuous printing method. The oxygen supply sizing agent groove system comprises an oxygen supply device, a base plate, a connecting pipe, an air-permeable thin film and a sizing agent groove which is of a cylindrical structure; an annular protrusion is horizontally arranged on the inner wall of the sizing agent groove, the upper surface of an annular groove is covered with the air-permeable thin film, the annular groove is formed in the lower surface of the annular protrusion, the base plate is fixed to the bottom of the sizing agent groove, an annular seal structure is defined by the annular groove and the base plate, and a seal chamber is defined by the base plate, the annular protrusion and the air-permeable thin film; multiple through holes are evenly formed in the side wall of the annular protrusion, the annular seal structure is communicated with the seal chamber through the through holes, one end of the connecting pipe is connected with the oxygen supply device, and the other end of the connecting pipe passes through the wall surface of the sizing agent groove and the side face of the annular groove and is inserted into the annual seal structure. By means of the oxygen supply sizing agent groove system, the bonding problem of ceramic biscuits and base plates can be effectively solved, and thereby the continuous ceramic printing is achieved.

Owner:陕西科陶增材智造科技有限公司

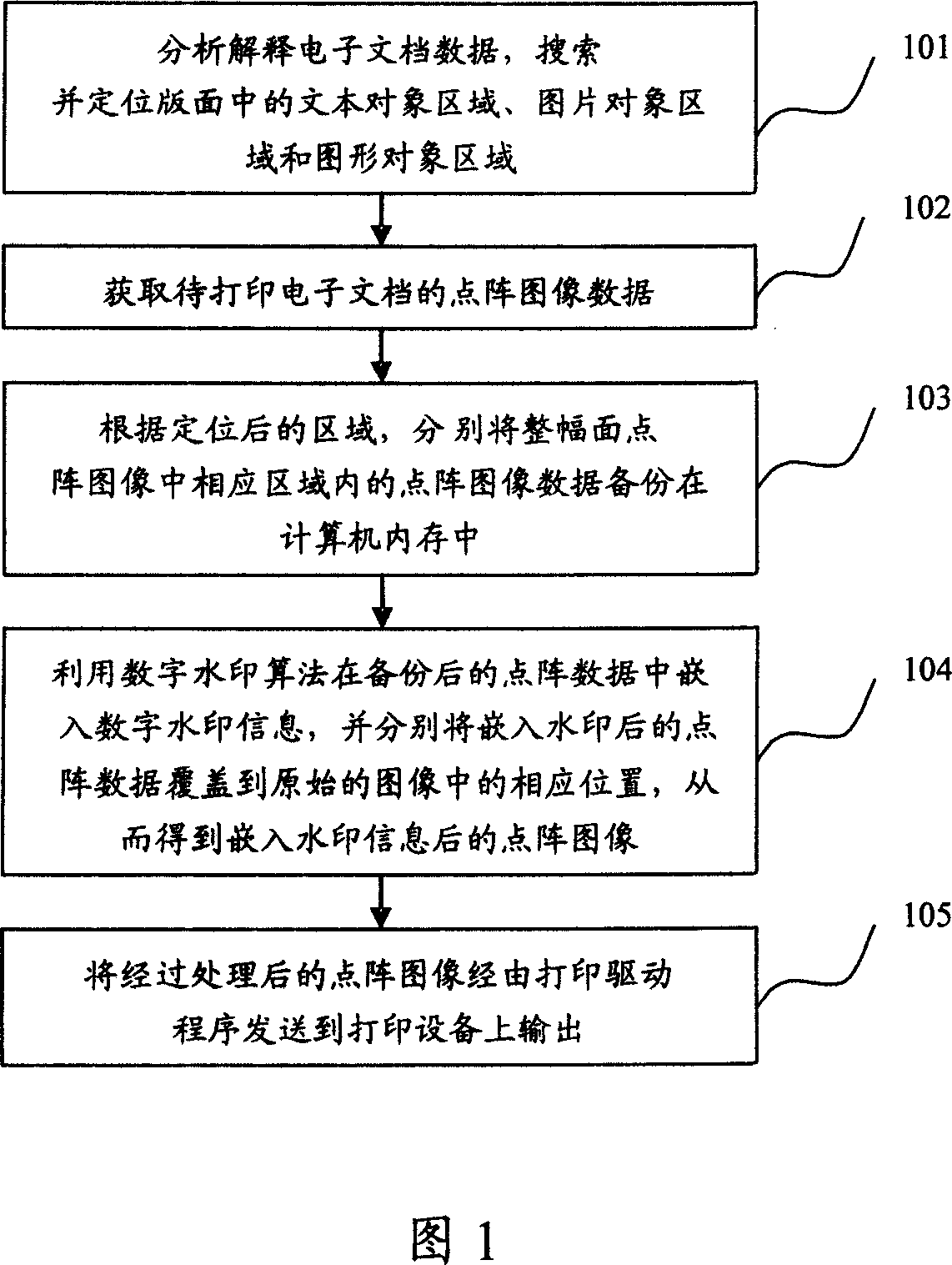

File printing method, device and system

ActiveCN1949818AThe printing process is simpleGood flexibilityImage data processing detailsPictoral communicationElectronic documentSafety coefficient

The invention discloses a method, device and system for implementing document printing by embedded digital watermark information, comprising: obtaining dot array iamge data of a to-be-printed document; embedding digital watermark information into the dot array image data; and printing the dot array image data. And the printing course is simple and the printing has good flexibility; it need not manually separate picture contents from character contents, further raising working efficiency; it has a wide application range and brings about very great convenience to the most common office document printout. Further, it prevents the possibility of modifying and destroying the watermark information inserted in important documents, thus largely enhancing safety coefficient and having important application value.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +2

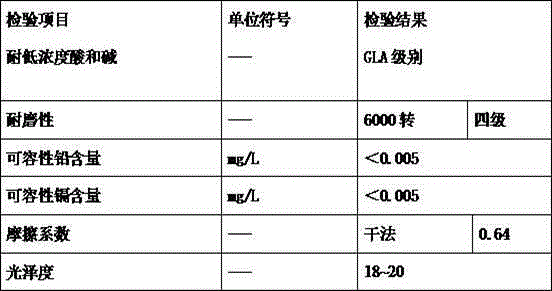

In-glaze decoration embossment base material, in-glaze decoration stained paper manufactured through in-glaze decoration embossment base material and manufacturing technology of in-glaze decoration embossment base material

ActiveCN105293909AIncrease color rangeImprove mechanical propertiesDecorative surface effectsManufacturing technologyMetallurgy

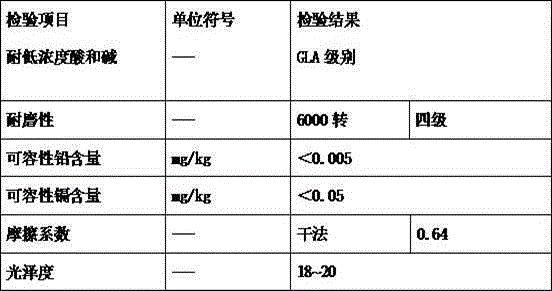

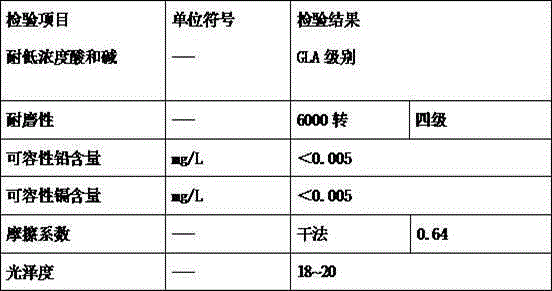

The invention relates to an in-glaze decoration embossment base material, in-glaze decoration stain paper manufactured through the in-glaze decoration embossment base material and a manufacturing technology of the in-glaze decoration embossment base material, and belongs to the technical field of in-glaze decoration stained paper. According to the in-glaze decoration embossment base material, the in-glaze decoration stained paper manufactured through the in-glaze decoration embossment base material and the manufacturing technology of the in-glaze decoration embossment base material, the in-glaze decoration embossment base material is manufactured through the four steps of calcination, ball-milling, drying and pulverizing. The method for manufacturing the in-glaze decoration stained paper through the in-glaze decoration embossment base material includes the four steps of ink grinding, printing, color printing and sealing compound. The method is suitable for different glaze and firing temperatures, the color modulation range of the in-glaze decoration embossment product is widened, the product corrosion resistance and abrasion resistance are improved, zero heavy metal dissolving is achieved, and pigment solubility is high. The three-dimensional effect is good, and brightness is high. The printing technological process is simplified, and the product is high in yield, flawless and more attractive; moreover, the lead and cadmium dissolving-out amount can reach the Europe and America national standard.

Owner:福建省德化铭丰金花纸有限公司

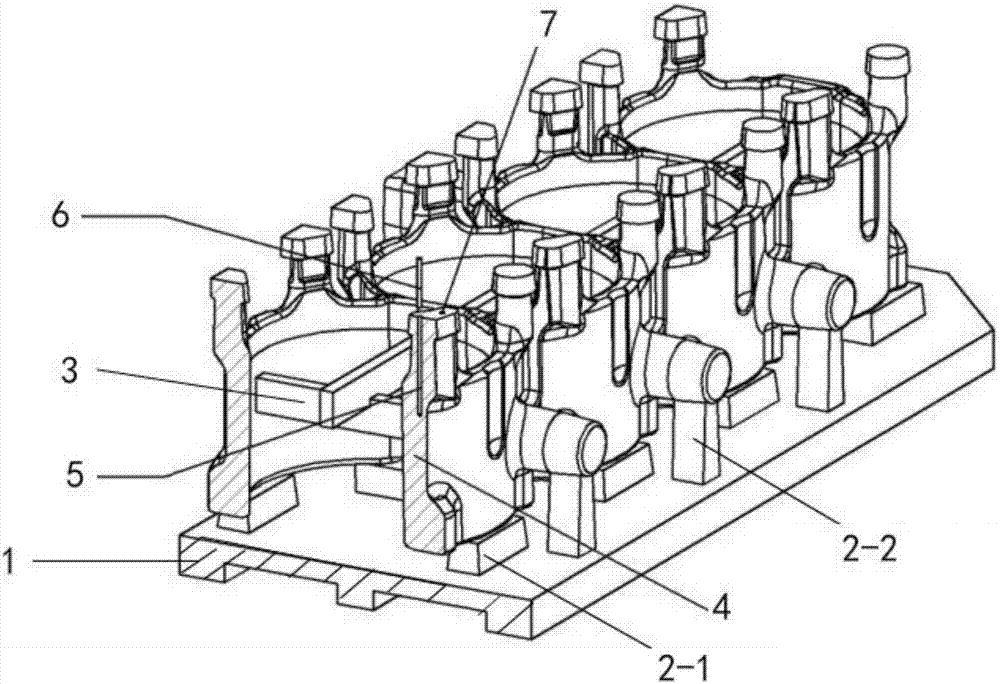

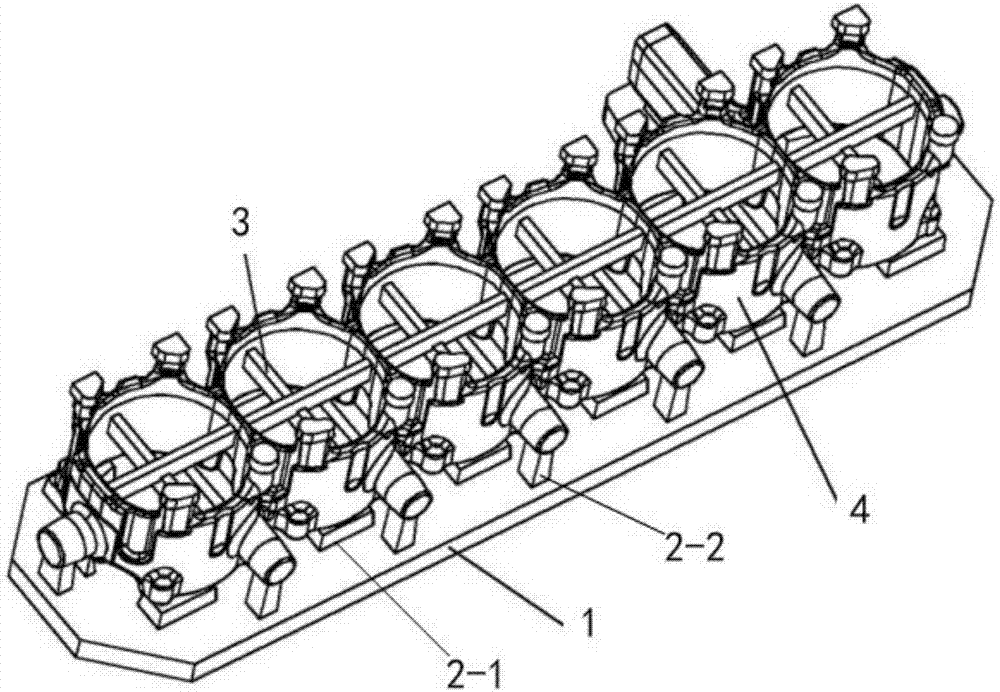

Diesel engine cylinder hole water jacket sand core reinforcing method

ActiveCN107457363AGuaranteed accuracyHigh precisionAdditive manufacturing apparatusFoundry mouldsEngineeringWater jacket

The invention discloses a diesel engine cylinder hole water jacket sand core reinforcing method. The method comprises the following steps that (1) when a cylinder hole water jacket sand core is subjected to 3D printing, a printing supporting mechanism is additionally arranged at first, the cylinder hole water jacket sand core body is printed, and integral forming of the supporting structure and the cylinder hole water jacket sand core is achieved; (2) baking curing is conducted after printing forming; (3) a sand bone hole is longitudinally drilled in a water foot part of the cylinder hole water jacket sand core body; (4) a sand bone matched with the sand bone hole is selected and inserted into the sand bone hole to be fixed; and (5) the supporting structure in the sand core is removed, and the reinforced cylinder hole water jacket sand core with high precision and quality is obtained. The strength of the 3D printed air cylinder block cylinder hole water jacket sand core can be improved, the reinforced sand core can ensure the effect that the positions and shapes of the layers are not changed by dragging during printing, the forming strength and precision of the sand core are ensured, and the practice effect is good.

Owner:GUANGXI YUCHAI MASCH CO LTD

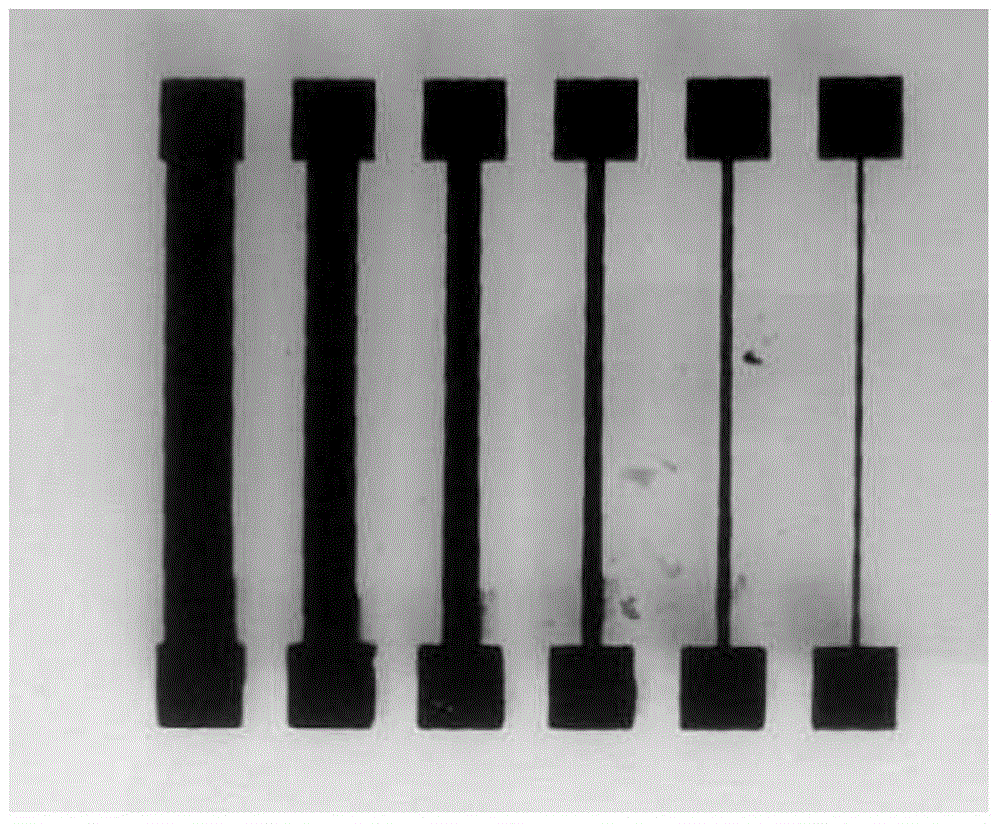

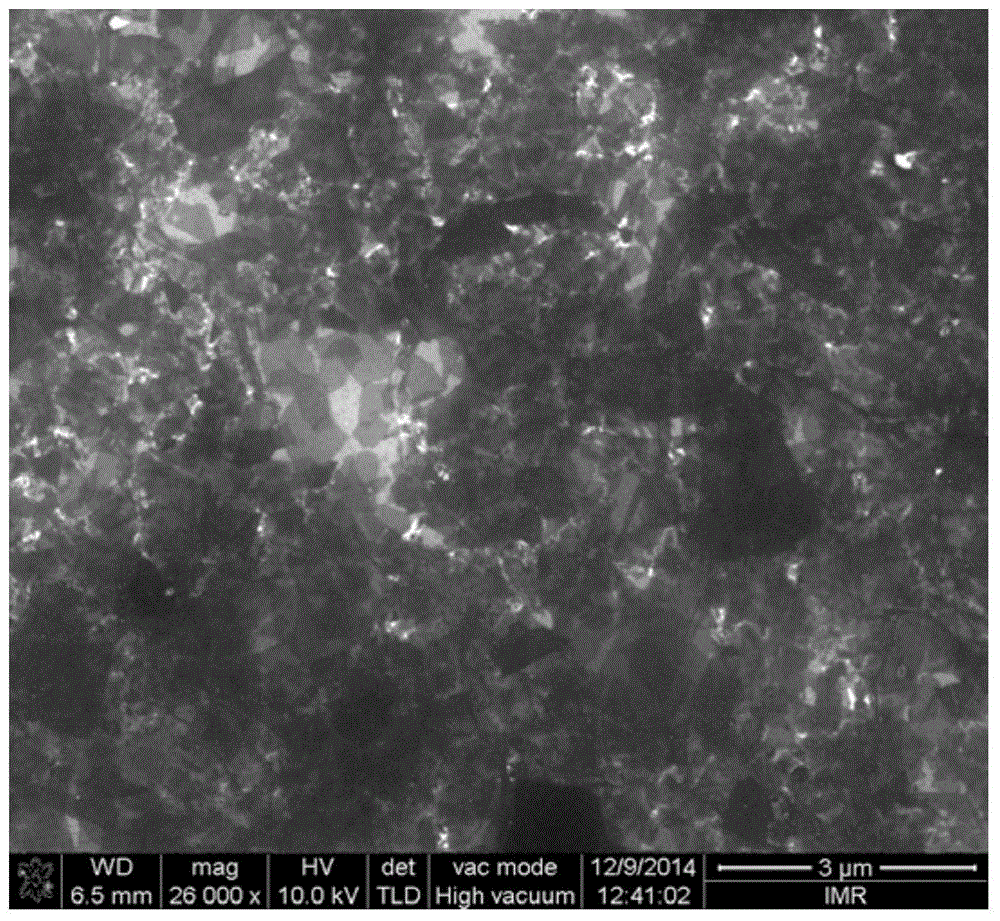

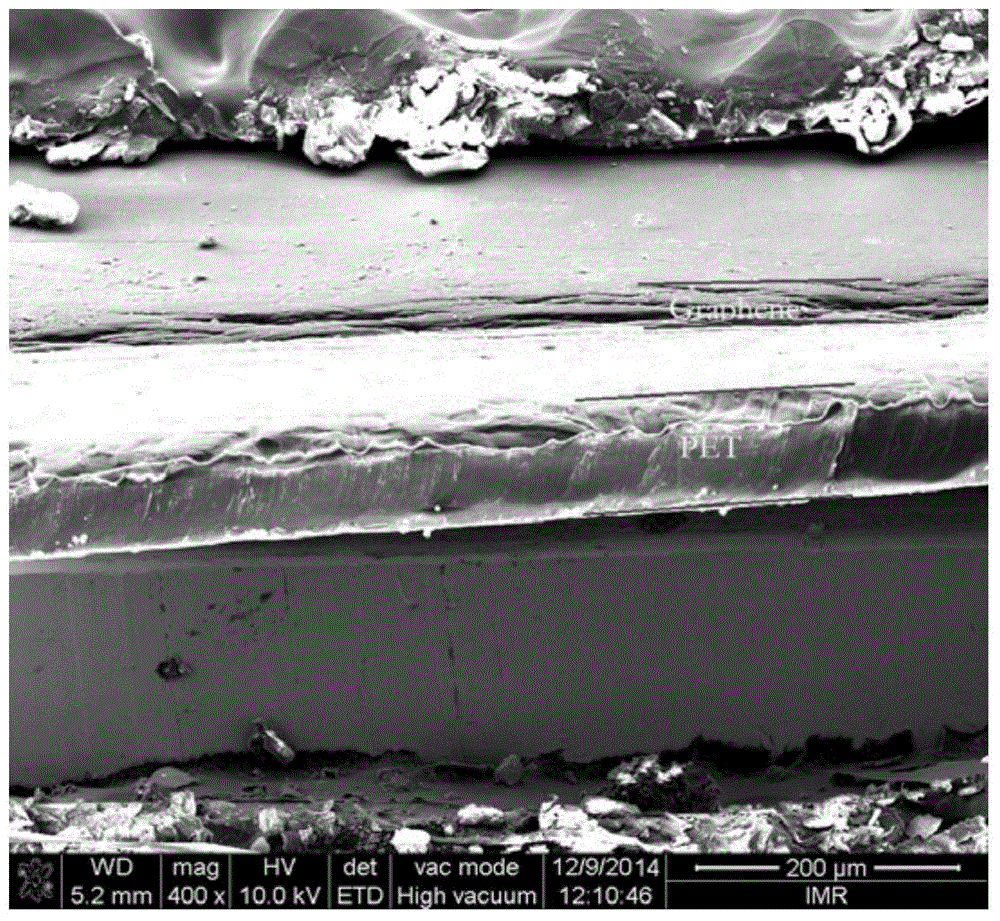

An aqueous graphene conductive printing ink suitable for screen printing and a preparing method thereof

The invention relates to the field of printing electronic materials, and particularly relates to an aqueous graphene conductive printing ink suitable for screen printing and a preparing method thereof. The aqueous graphene conductive printing ink with good impressionability is prepared by mixing graphene water dispersed slurry with a certain graphene content, a thixotropic agent, a defoaming agent and an aqueous solution of a mildew preventive, dehydrating, adding a film forming agent, grinding until fineness is less than 20 [mu]m, and adjusting viscosity of slurry until the static viscosity is 6000-8000 MP.s and the rotary viscosity is 1500-3000 MP.s. Conductivity of films formed by printing ink printing can reach 10<5>-10<6> S / m and is about 100 times of conductivity of carbon based conductive printing ink sold in the market at present. The printing ink adopts water as a solvent, and therefore preparation and printing processes are free of generation of volatile organics. Films can be formed by curing only through low-temperature drying at a temperature lower than 80 DEG C after printing and molding and can achieve the optimum conductive state, thus effectively simplifying a printing process of printing electronic devices, reducing heat resistance requirements on printing base materials, and reducing the preparing cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

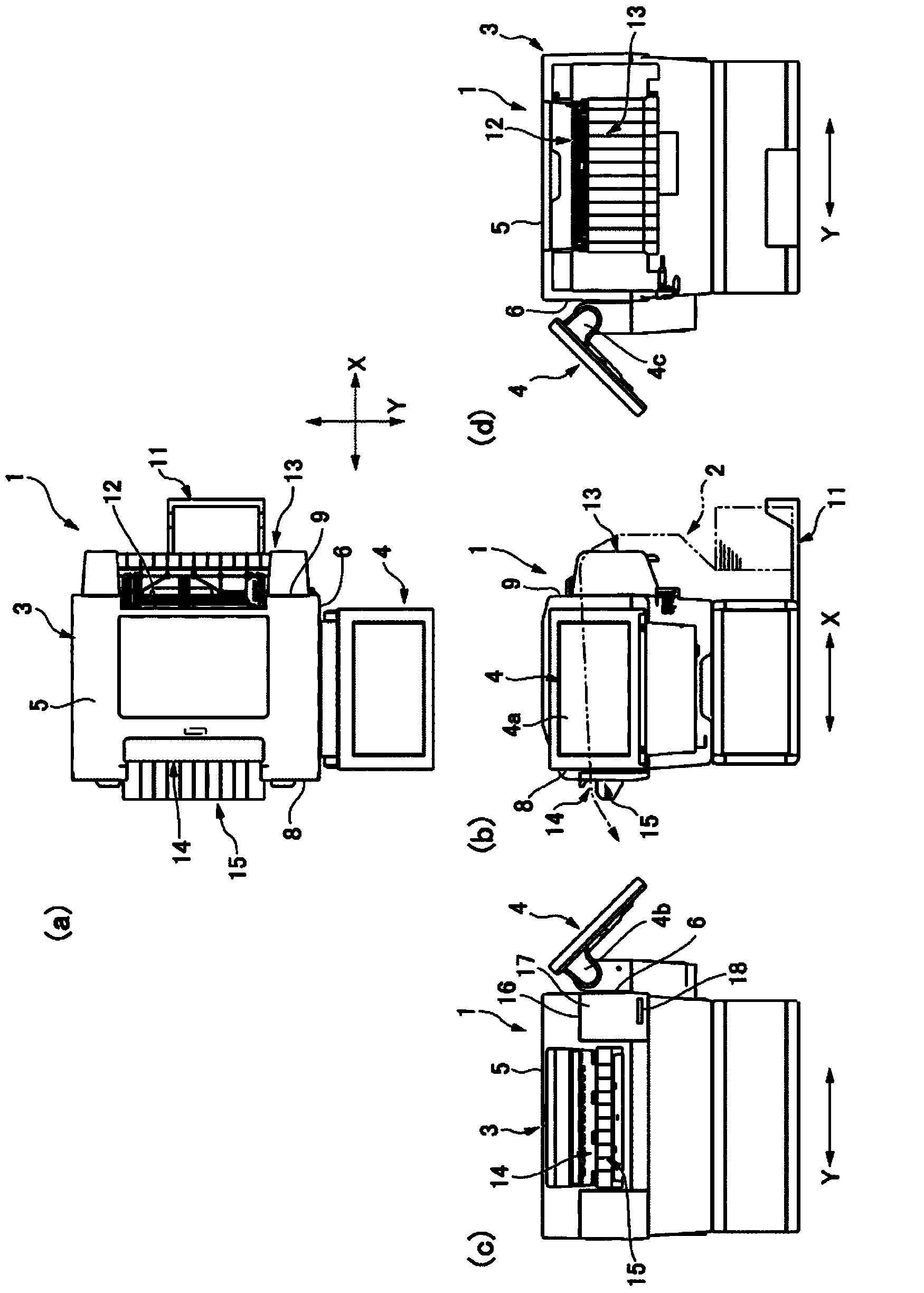

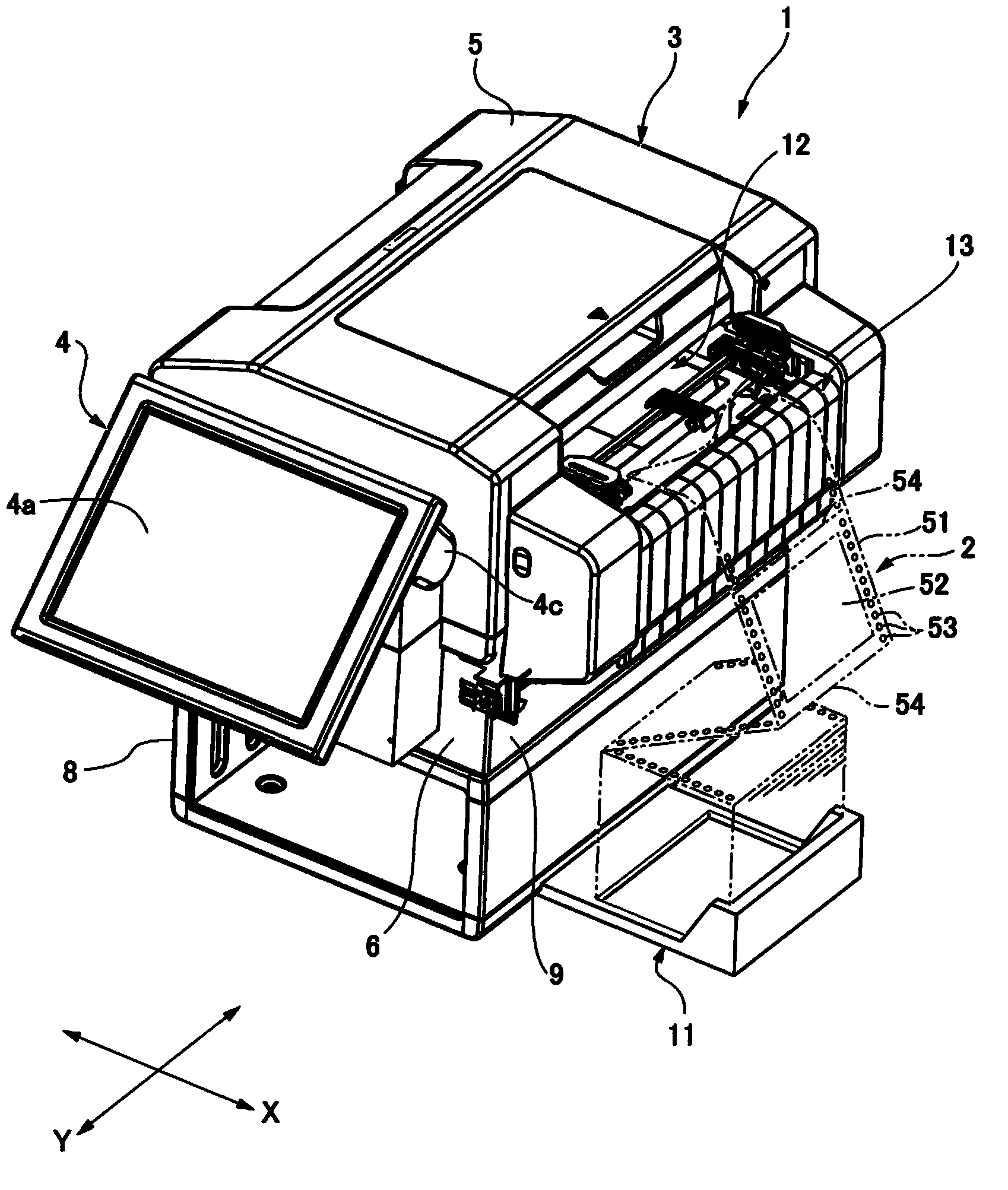

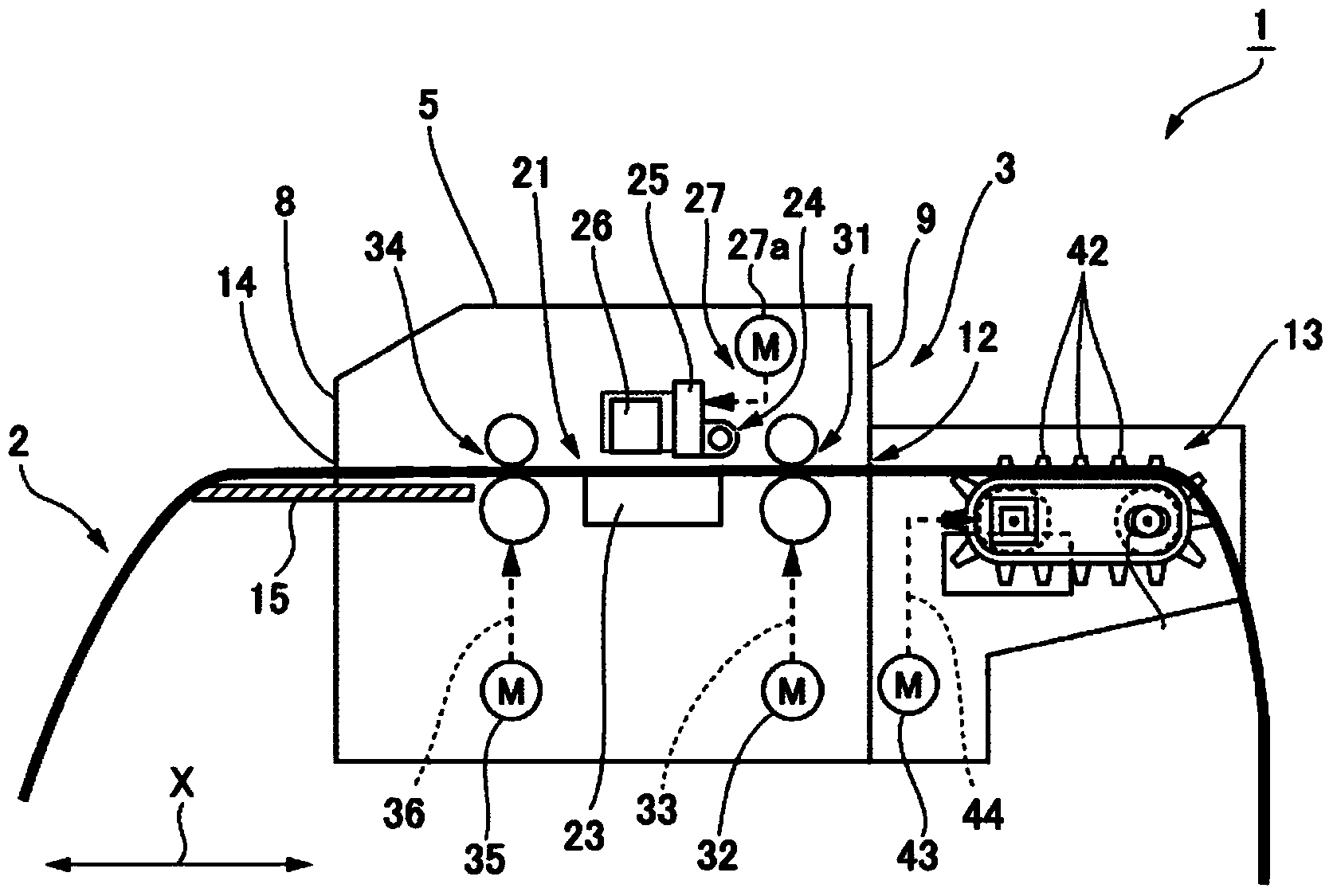

Label printer and label printing system

ActiveCN104364084AThe printing process is simpleTypewritersOther printing apparatusData miningControl unit

This invention proposes a label printer capable of printing an image and attribute information thereof on a label using a suitable format. A label printer (1) has a print head (26), and a control unit (60) for printing an image and attribute information of the image on a label (52) using the print head (26). The label (52) is provided with a half-cut (55), and is attached in a peelable manner to an elongated paper backing (51) in a state of having been separated into a first label piece (56) and a second label piece (57). The control unit (60) of the label printer (1) is provided with an image printing control unit (61) for printing an image on the first label piece (56), and an attribute information printing control unit (62) for printing the image attribute information on the second label piece (57).

Owner:SEIKO EPSON CORP

Preparation process of overglazed famille-rose embossed printing product

The invention discloses a preparation process of an overglazed famille-rose embossed printing product. According to a formula, an overglazed famille-rose embossment pigment comprises the following raw materials by weight percent: 30% of feldspar, 5% of zirconium silicate, 35% of low-temperature lead-free cadmium-free frits and 30% of overglazed transparent white color mixtures. The preparation process comprises the following steps: preparing the famille-rose embossment pigment and printing colored paper. The printing product has the advantages of high capacitability, wide temperature adaptation range, good three-dimensional effect, high brightness and the like; the problem of color mixing limitation of existing printed famille-rose embossed colored paper is solved and a printing process is simplified; the printing product is high in finished product rate when being decorated on a ceramic product, has no flaw, and is relatively attractive and relatively rich in hand feel; in addition, the lead and cadmium dissolving-out quantity can meet the standards of nations such as Europe and America.

Owner:福建省德化铭丰金花纸有限公司

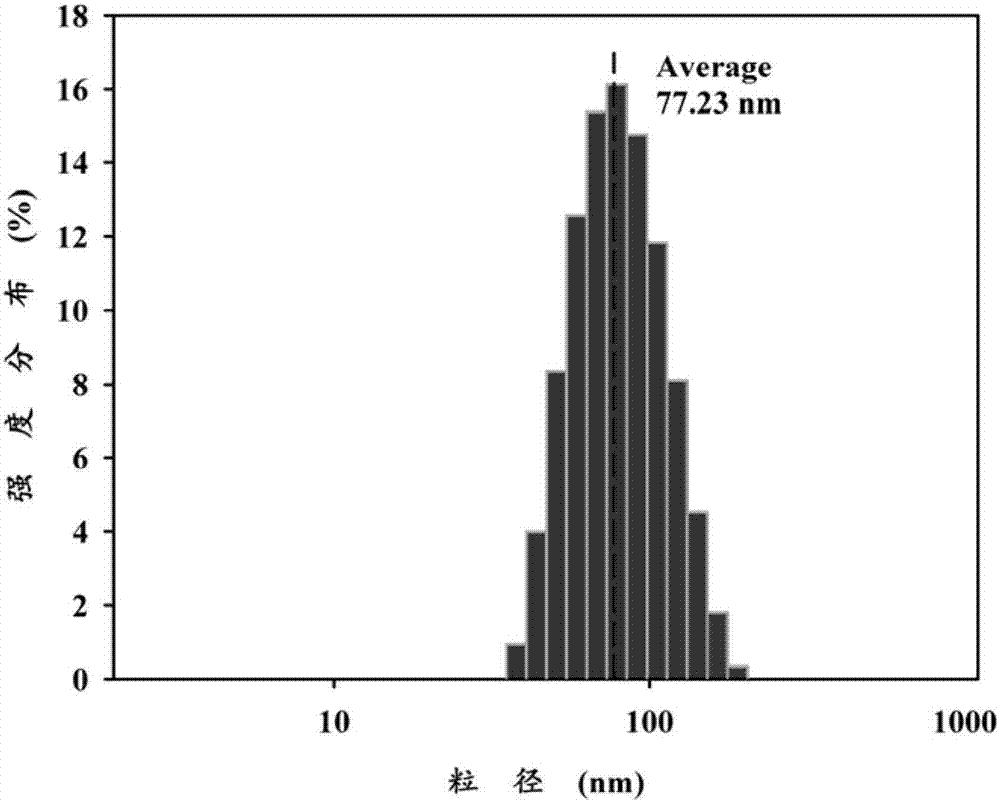

Vanadium dioxide ink for inkjet printing as well as preparation method and application of vanadium dioxide ink

The invention discloses vanadium dioxide ink for inkjet printing. The vanadium dioxide ink is prepared from the following components: nano vanadium dioxide powder, a dispersing agent, a bonding agent and a diluent, wherein the diluent is a mixed solution of dimethylbenzene and ethyl acetate or a mixed solution of the dimethylbenzene and butyl acetate. A preparation method of the vanadium dioxide ink disclosed by the invention comprises the following steps: carrying out mixed ultrasonic dispersion on the nano vanadium dioxide powder and the diluent to obtain vanadium dioxide dispersing liquid; carrying out mixed dispersion and grinding on the vanadium dioxide dispersing liquid and the dispersing agent in a sand mill; then adding the bonding agent, and continuously grinding in the sand mill until the materials are uniformly mixed, thus obtaining the vanadium dioxide ink for the inkjet printing. According to the vanadium dioxide ink disclosed by the invention, by regulating and controlling the particle size, stable dispersion, viscosity and surface tension of the nano vanadium dioxide ink, the vanadium dioxide ink suitable for the inkjet printing is successfully prepared; according to the nano vanadium dioxide ink disclosed by the invention, the smoothness of an inkjet printing process is ensured, a liquid drop shape can be formed during printing, a good printing effect is realized, and the requirement on film forming property of a printer is met.

Owner:NAT UNIV OF DEFENSE TECH

In-mold labeling process

An in-mold labeling process comprises the following steps of: performing pre-treatment including roasting and dust removal on a plastic thin film which is cut previously; performing screen printing on the surface of the thin film to form an image or character LOGO, and then putting the thin film in an oven to solidify ink, wherein the temperature of the oven is set in a range of 80 to 100 DEG C, and the heating time is 1-2 hours; performing 2D (2-Dimensional) or 3D (3-Dimensional) hot pressing or die cutting molding on the thin film; and fixing the thin film in the concave die of an injection molding die for injection molding, wherein an injection molding material is directly bonded to the surface of the thin film so that the screen-printed LOGO is embedded between the thin film and the injection molding material; and the injection molding material and the plastic thin film are the same material. The in-mold labeling process realizes direct bonding of the FILM to the injection molding material through injection molding in the die, so that the printing process procedure is simplified, and labour power, working hours and ink raw material are saved. Besides, the bonding force of the FILM to the injection molded layer is enhanced while the same product appearance effect is achieved.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Preparation of instant milk protein gel and application thereof in 3D printing

ActiveCN108740284A3D printing realizedImprove adaptabilityAdditive manufacturing apparatusAnimal proteins working-upFood additiveSodium Caseinate

The invention discloses preparation of instant milk protein gel and application thereof in 3D printing and belongs to the technical field of 3D printing food material preparation. The preparation disclosed by the invention comprises the steps: firstly, preparing protein suspension of sodium caseinate; then adding milk protein concentrate (MPC) into the protein suspension to prepare milk protein plural gel. According to the preparation disclosed by the invention, a high-quality milk protein ingredient is utilized as a printing food material, and no other food additive is added; thus, the instant milk protein gel has the advantages of high nutritional value, easiness in absorption, good taste, favorability in being swallowed and the like; meanwhile, the instant milk protein gel can meet natural, healthy and zero-addition diet requirements of modern people. According to the preparation disclosed by the invention, when the instant milk protein gel is prepared, accurate temperature controlis avoided, a printing technology is simplified, convenience in operation is achieved, a strict requirement to the environment is avoided, and adaptability and operability of the 3D printing are improved.

Owner:JIANGNAN UNIV

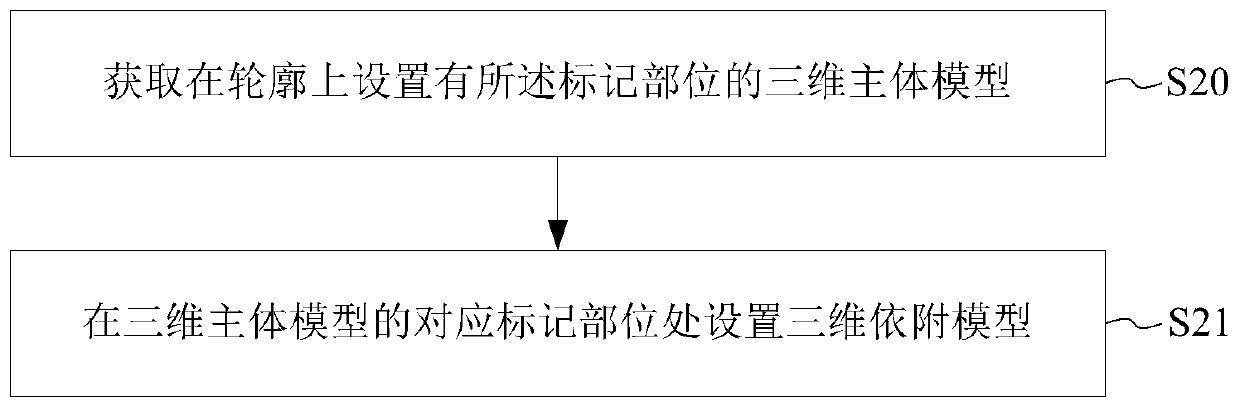

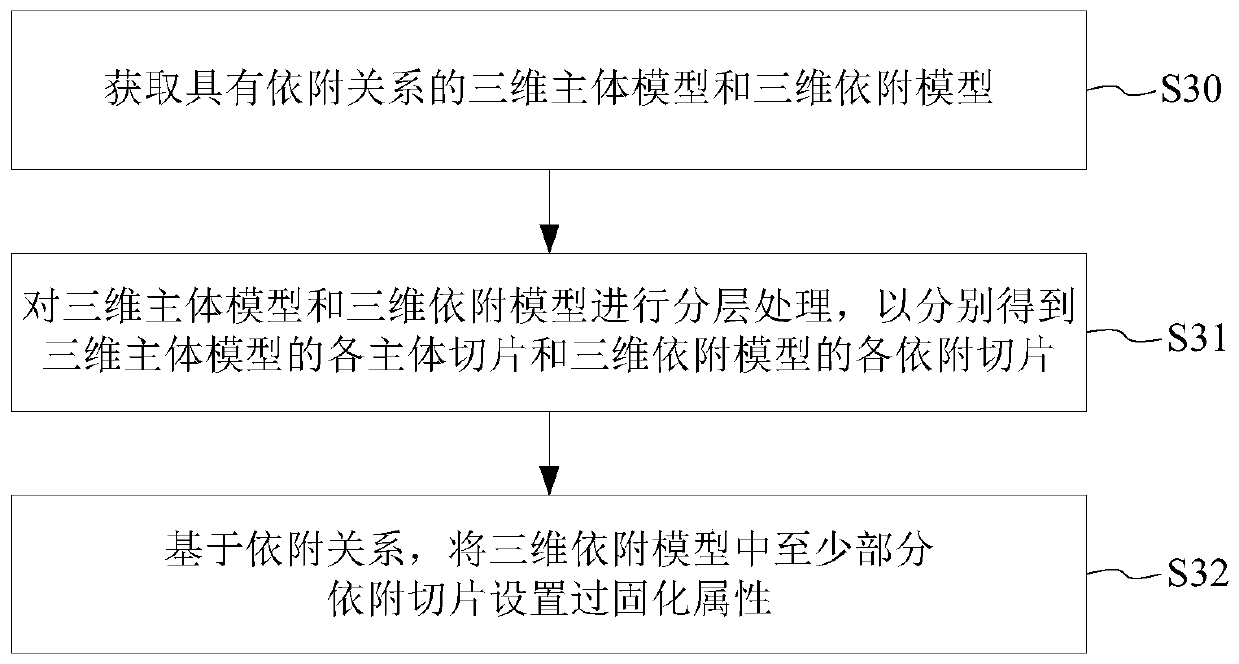

Layering processing method of three-dimensional object data and 3D printing device

ActiveCN110654028AReduced risk of wear and tearThe printing process is simpleAdditive manufacturing apparatus3D object support structuresComputer graphics (images)Process engineering

The invention provides a layering processing method and system of a three-dimensional object data, a 3D printing method and device, a computer device and a computer readable storage medium. Through using the characteristic that a material to be cured can display color appearance with the distinction degree after over-curing, a certain distinction degree such as color and structure sudden change (or the step) is needed in the appearance to recognize the object with the different portions carrying information, in the pretreatment, on the basis of the relations of dependence, the three-dimensional attachment model and the three-dimensional main model are mounted, and are subjected to layering processing, an over-curing property is arranged, in the subsequent printing process, on the basis ofthe obtained slicing data, at least one part is sliced to carry out over-curing with the set rule, in the printing process, different exposure strategies are adopted, in one-time printing, the three-dimensional object with recognized assembling information or configuration information is obtained, the production process is simplified, and the production cost is reduced.

Owner:SHANGHAI UNION TECH

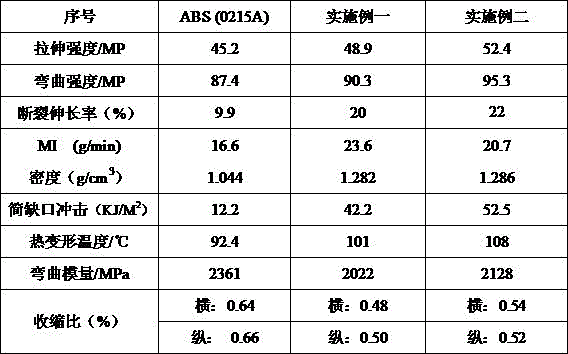

ABS/PC 3D consumable material special material and preparation method thereof

InactiveCN107523001AHigh impact strengthHigh strengthAdditive manufacturing apparatusSurface finishAntioxidant

The invention discloses an ABS / PC 3D consumable material special material and a preparation method thereof. The material comprises the components by the mass percentage: 45% to 65% of ABS, 35% to 45% of PC, 4% to 10% of a toughening agent, 1% to 5% of a compatibilizer, 0.1% to 0.3% of an antioxidant, and 0.1% to 1% of a lubricant. While improving the impact resistance of consumable materials, the prepared ABS / PC 3D consumable material special material reduces the molding shrinkage rate of products, overcomes the shortcomings that ABS consumable materials generate bottom surface warping and large products are easy to fault during a printing process, improves the surface finish degree and the success rate of the printed products, and is new material applied to the technical field of 3D printing.

Owner:四川鑫达企业集团有限公司

Cloth fixing device of printing machine

The invention relates to a cloth fixing device of a printing machine. The cloth fixing device of the printing machine comprises a conveying belt, wherein the conveying belt is arranged on two parallel rotating shafts in a sleeving manner; the surface of the entire conveying belt is uniformly provided with fine and dense adsorption holes penetrating through the conveying belt; an exhaust fan is assembled between the upper and lower layers of the conveying belt; an air inlet of the exhaust fan is provided with a flat cylinder-shaped air inlet box; the upper surface of the air inlet box is provided with fine and dense ventilation holes which are matched with the adsorption holes; particularly, the space between every two ventilation holes is different from the space between every two adsorption holes; an air outlet of the exhaust fan is formed in the tail end of the conveying belt and the opening direction directly faces the adsorption holes in the conveying belt. According to the device, cloth can be firmly fixed to the surface of the conveying belt, meanwhile processes are simplified, and the cloth is not polluted.

Owner:吴江市金都织造有限公司

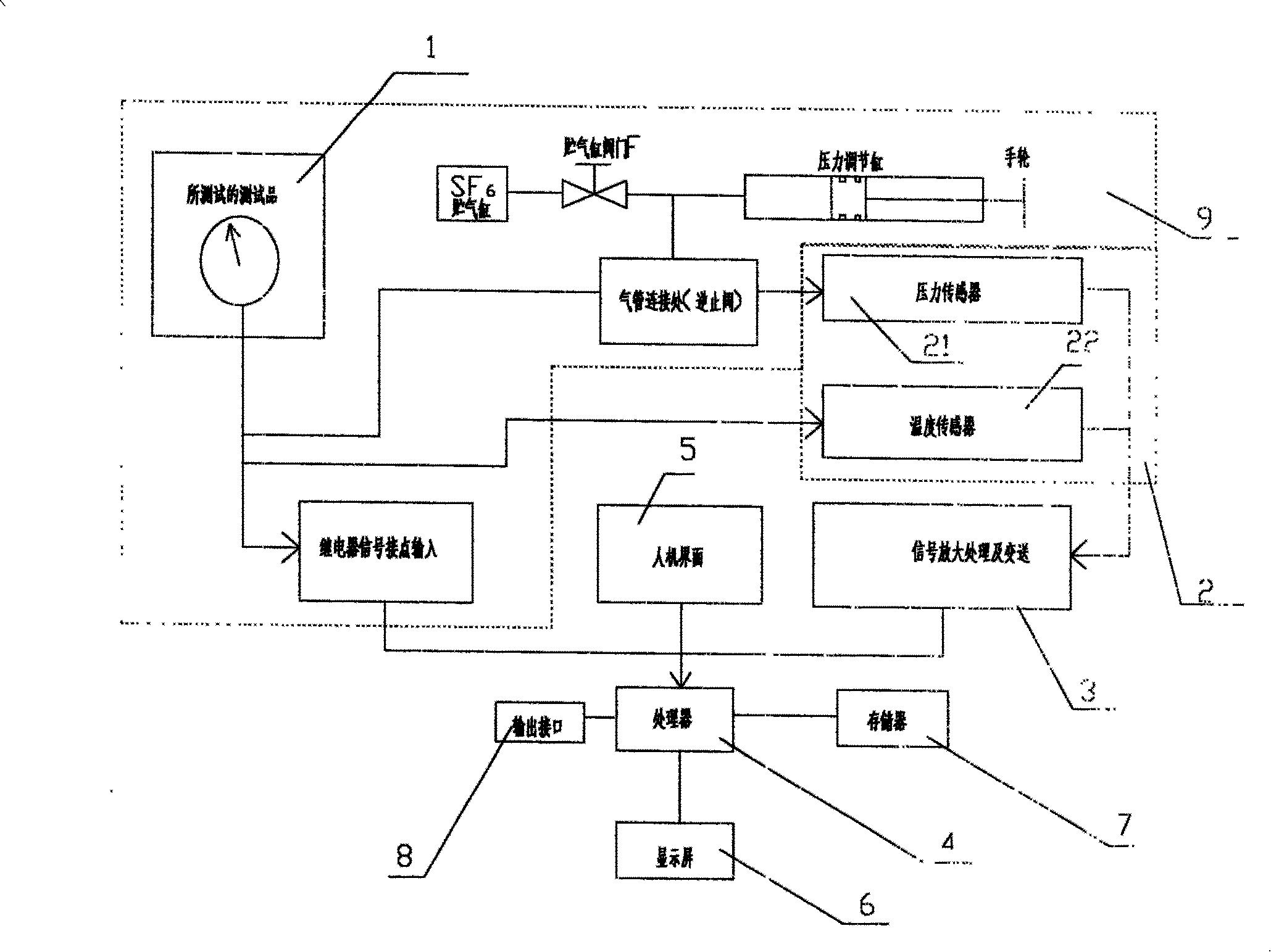

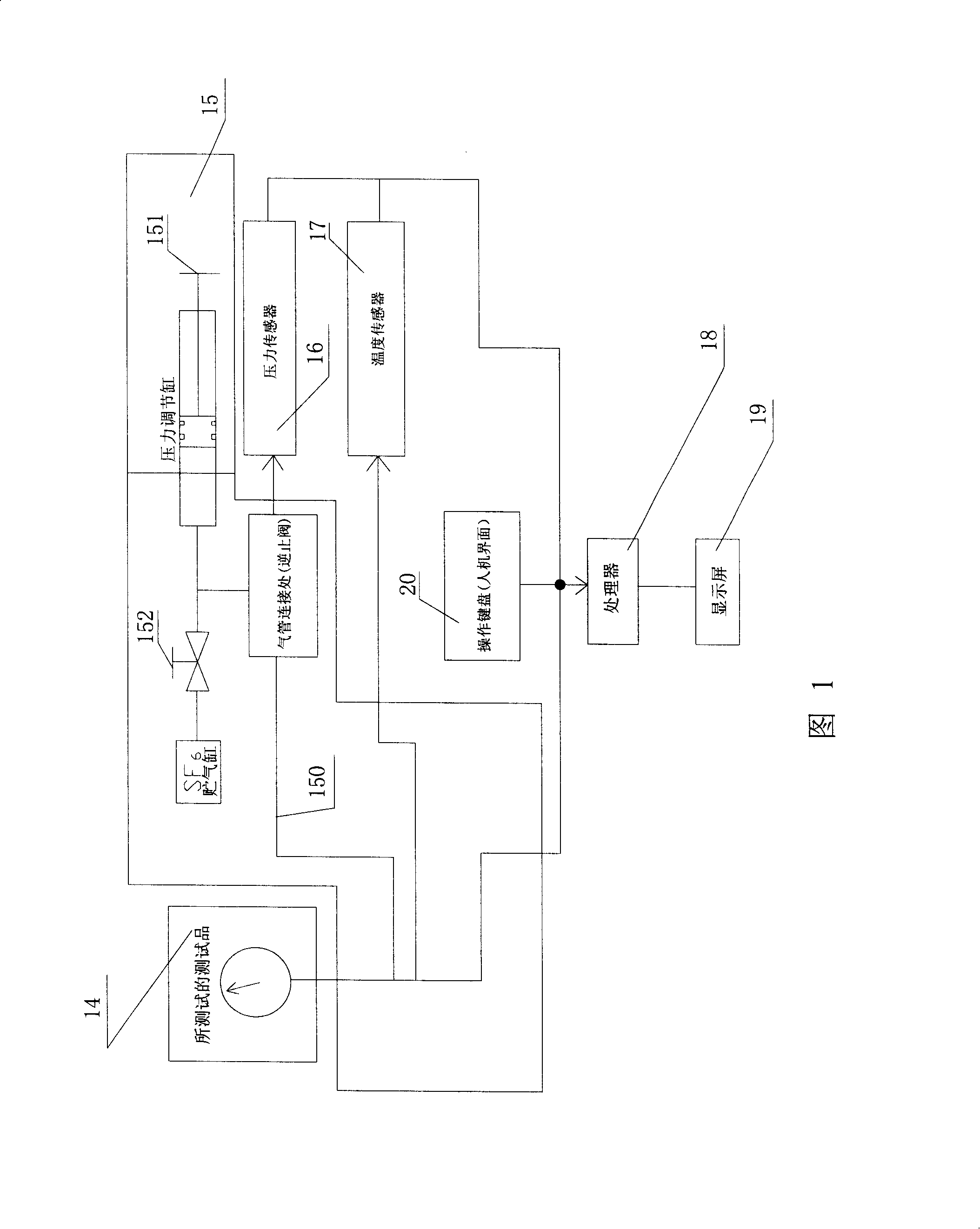

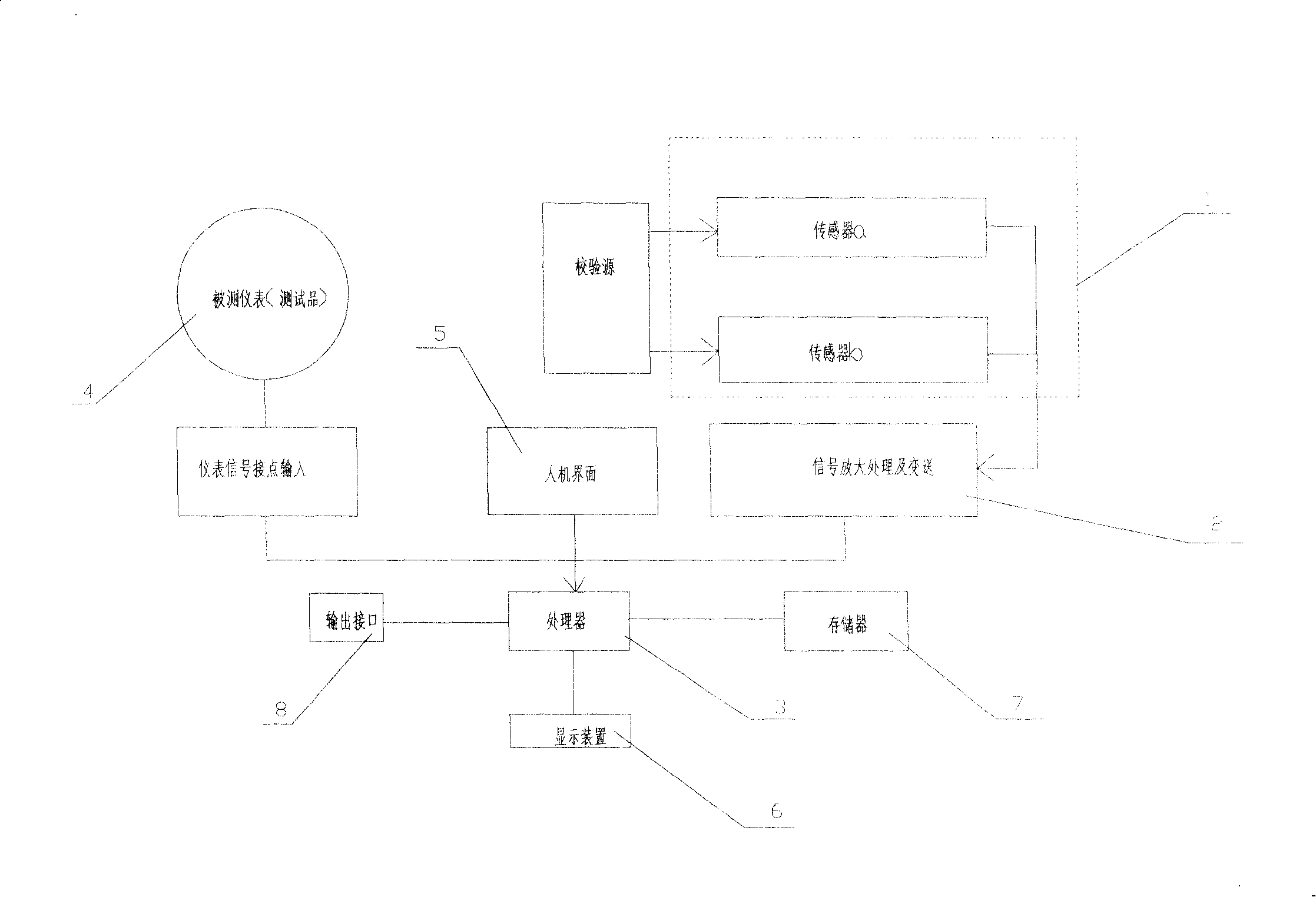

Method for automatically testing and recording rated value of SF6 gas density relay

ActiveCN101221109AEasy to compileVery popularCircuit interrupters testingSpecific gravity measurementComputer data processingLinearity

The invention relates to a method for automatically testing and recording a rated value for an SF6 gas density relay and includes a checking apparatus. The checking apparatus includes a gas source supplying mechanism with adjustable pressure, at least one pressure sensor, a temperature sensor, a computer data processing system and a display screen. The computer data processing system is provided with a relay action signal input port. The method includes the following steps: step 1, the indicating value of a test product is observed according to a pointer of the test product and the pressure is regulated just to a rated value of the test product, namely the pointer of the test product just points at the rated value Pe; step 2, a command key is tested according to the rated value; the checking apparatus automatically records a pressure value P and a temperature value T of the current pressure sensor and the temperature sensor; step 3, corresponding pressure value Pe test is converted automatically at 20 DEG C according to the pressure-temperature characteristic relation of the SF6 gas; step 4, the checking apparatus automatically carries out correcting on the tested Pe test according to the linear relation of the pressure sensor and the temperature sensor and stores the test result.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

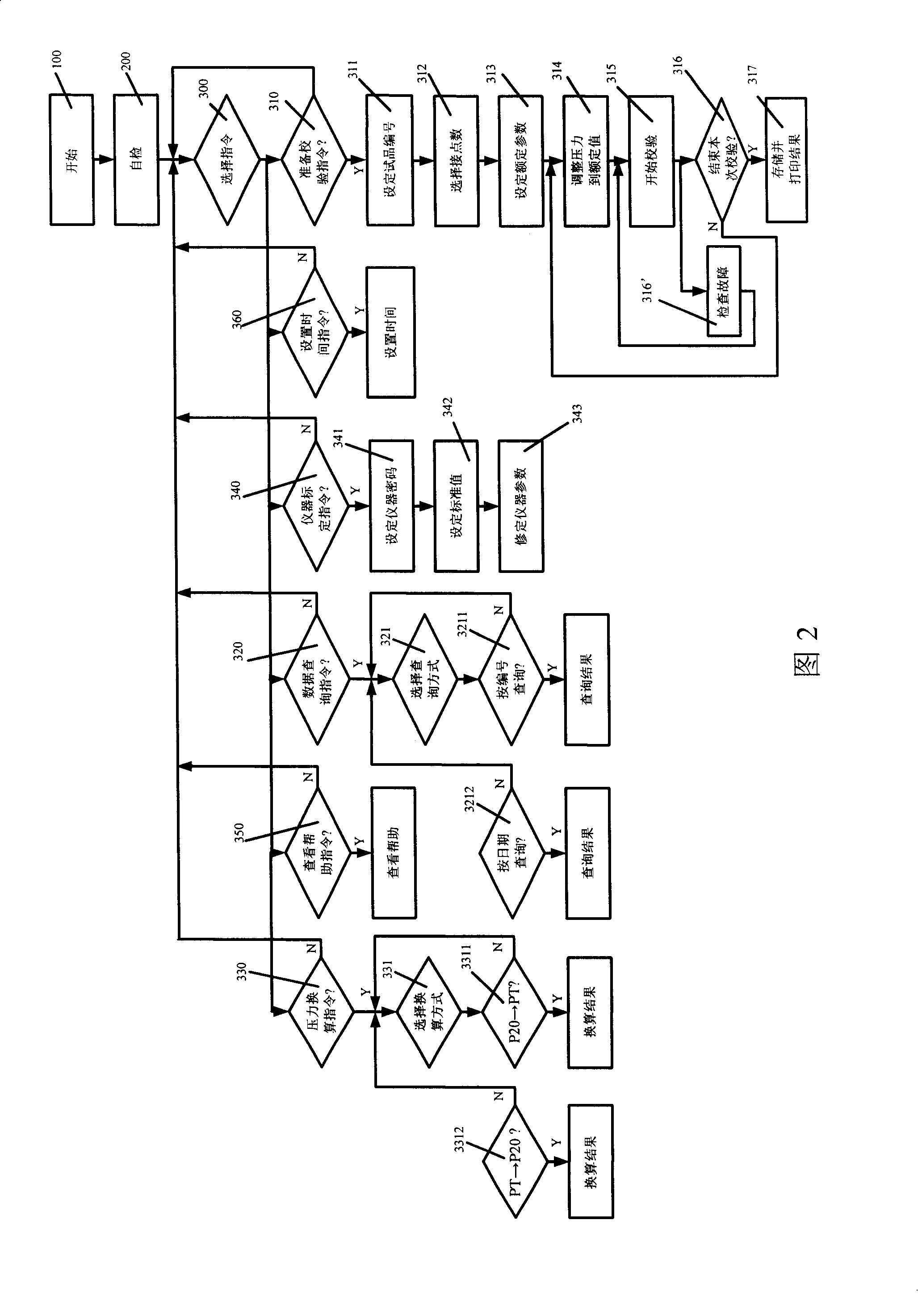

SF6 gas density relay checking instrument and checking process

InactiveCN101221217AEasy to operateEasy to storeCircuit interrupters testingSpecific gravity measurementTest objectComputer science

The invention discloses a calibration process of a calibrator of an SF6 density relay and comprises the following steps: step 1, the process is started; step 2, a self check is carried out; step 3, an instruction is chosen from the choices of calibration preparation, data query, time setting, pressure conversion, help viewing and device marking; if the calibration preparation is chosen, a step 3.1 is carried out, and in the calibration preparation, a step 3.11 is firstly implemented to set a number for the test object; then a step 3.12 is carried out to select a number of contact points; a step 3.13 is carried out after one item is selected, in which a nominal parameter is set; then a step 3.14 is carried out to adjust the pressure to a nominal value; after that, a step 3.15 is carried out to start a calibration; a step 3.16 is carried out after the calibration is finished, which chooses whether to end the calibration or not; if the choice is no, the invention returns to a step 3.14, while if the choice is yes, the invention turns to a step 3.17 to store and print the result. The invention has the advantages of simple operation, fitting for on-site calibration processes, and labor-saving property and convenient using.

Owner:苏丽芳

Self-service printing system

InactiveCN106020746AImprove experienceAvoid disadvantagesSensing by electromagnetic radiationDigital output to print unitsPersonal computerClient-side

The invention discloses a self-service printing system which comprises a client side and terminals. The terminals include an industrial personal computer, a display portion and a printer. The industrial personal computer is used for receiving a cloud printing task and an issuing printing task in the networking status. The printer is used for printing the printing task issued by the industrial personal computer. The display portion displays the status of the terminal. In the networking status, the industrial personal computer firstly receives the cloud task and then issues the task to the printer, and meanwhile, the status is sent to the display portion to be displayed.

Owner:大连印乐科技有限公司

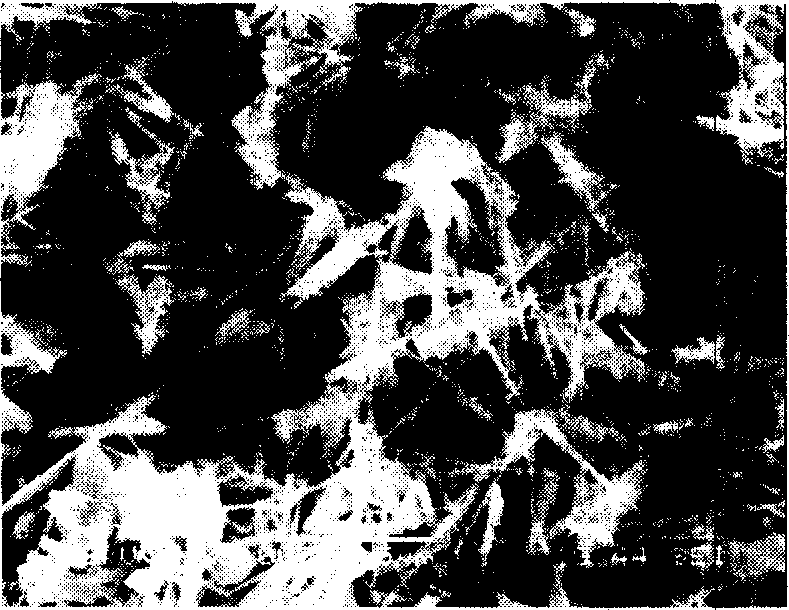

Method for preparing field emission display cathode and ZnO nanowire cathode

InactiveCN1885476AGood field emission characteristicsNo pollution in the processNanostructure manufactureZinc oxides/hydroxidesDecompositionMass ratio

The provided key technique for large-scale ZnO nano line preparation comprises: aerating gas while heating as 50Deg / min to prepare much radial-pattern needle-shape ZnO nano line without catalyst; selecting the nano line and CMC as pulping agent by mass ratio as 1:5~4:5 to prepare the slurry, and controlling the decomposition temperature of the agent and ZnO nano line in 500-800 Deg. This invention is low cost, efficient and environmental friendly, and has wide application.

Owner:XIAN TECHNOLOGICAL UNIV

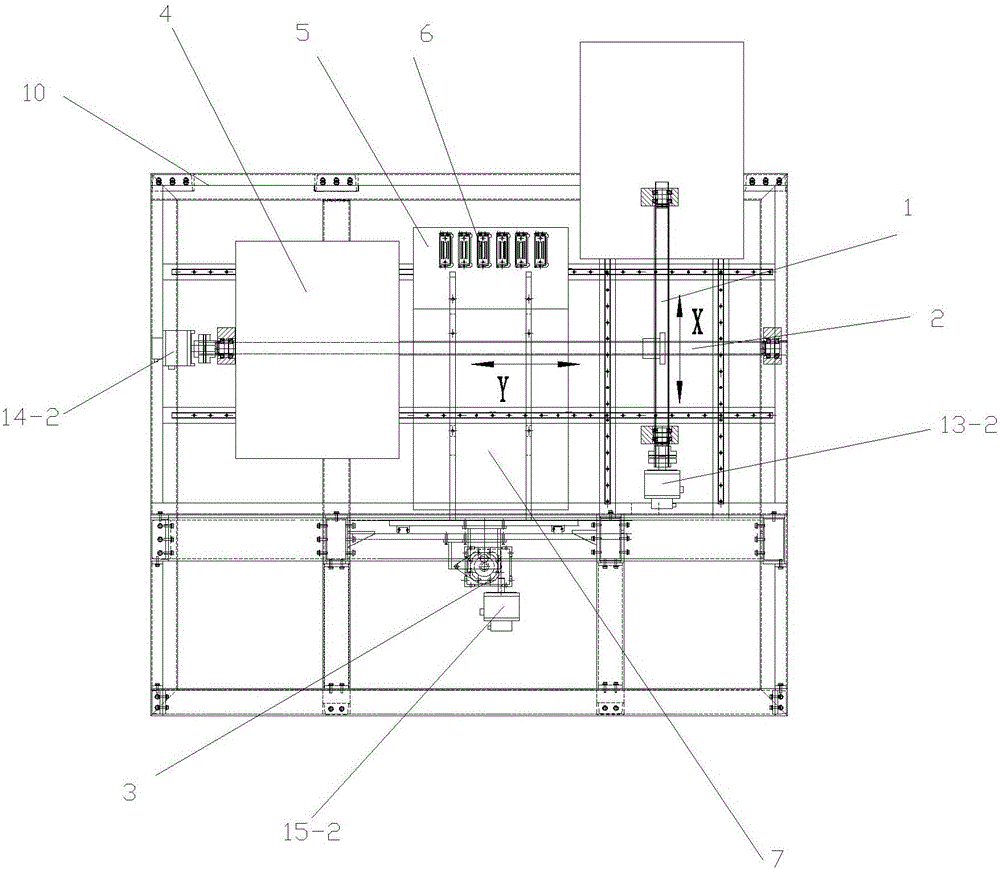

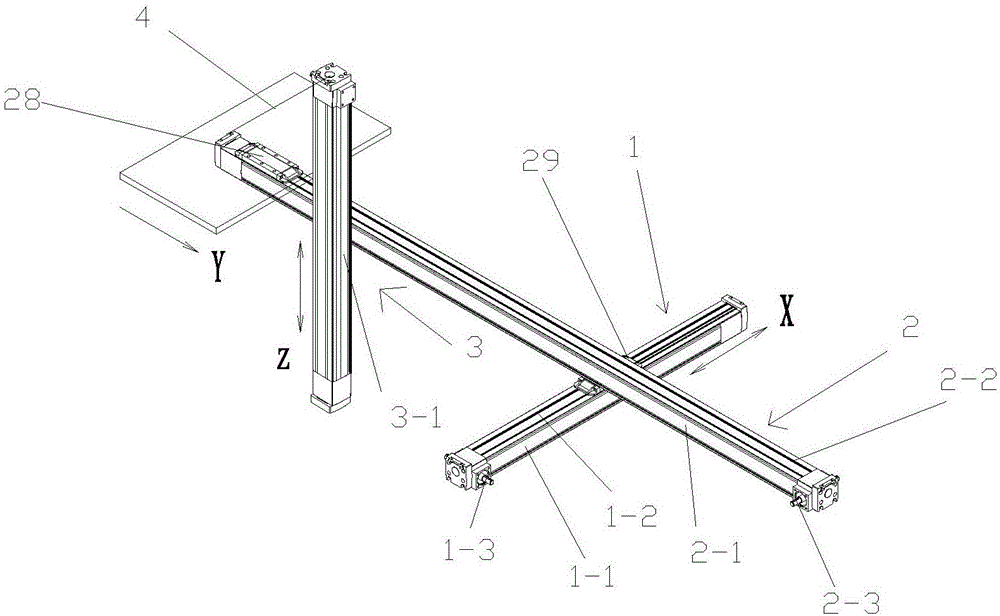

Three-coordinate running table-type digital ink-jet printer

The invention discloses a three-coordinate running table-type digital ink-jet printer, which comprises an ink-jet printing system and a monitoring system, wherein the ink-jet printing system comprises a rack, an ink-jet printing device and a printing running table; the printing running table comprises a printing table board and a printing table position adjuster; the printing table position adjuster comprises a two-dimensional adjusting mechanism and a position adjusting drive module; the ink-jet printing device comprises a spray nozzle, an ink-jet distance adjusting mechanism and an ink supply device; the ink-jet distance adjusting mechanism is a Z-axis adjusting mechanism; the Z-axis adjusting mechanism is provided with a Z-axis drive module; and the monitoring system comprises a data processing control device, a spray nozzle drive module and an ink supply detection device. The three-coordinate running table-type digital ink-jet printer is simple in structure and good in using effect; the spray nozzle can carry out reciprocating motion up and down, and a print substrate can carry out reciprocating motion along an X direction and a Y direction, so that fixed-point printing and die stamping of the print substrate are achieved; the three-coordinate running table-type digital ink-jet printer adapts to the print substrates of different materials and sizes; and the printing quality can be effectively controlled.

Owner:西安德高印染自动化工程有限公司 +1

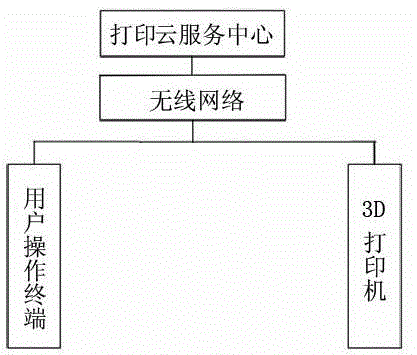

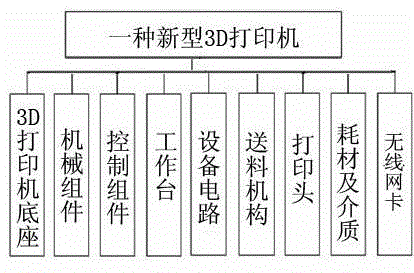

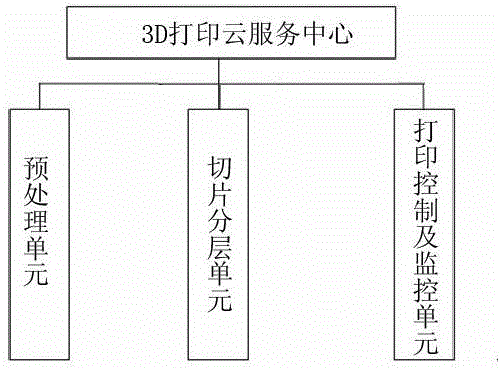

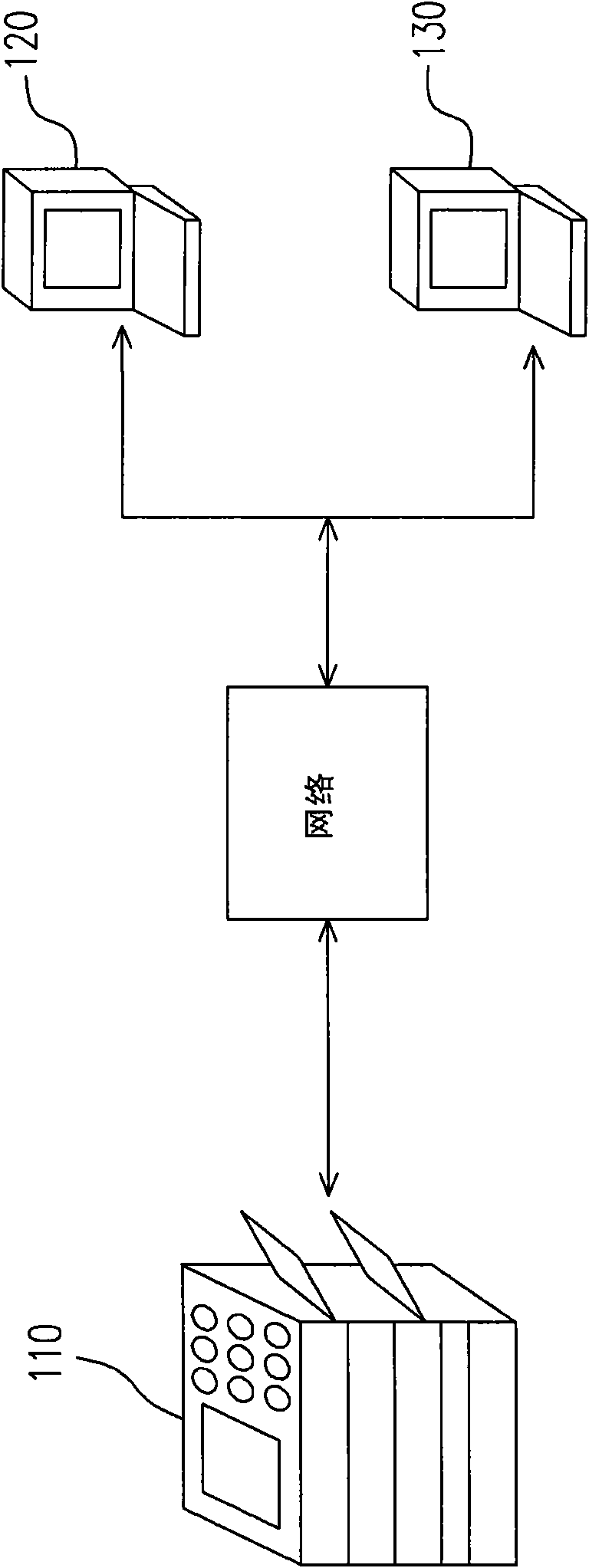

Novel 3D printer

InactiveCN104625047ASimple designThe printing process is simpleAdditive manufacturing apparatusCeramic shaping apparatusTime informationThe Internet

The invention discloses a novel 3D printer. The novel 3D printer comprises a 3D printer base, a mechanical assembly, a control assembly, a working table, an equipment circuit, a feeding mechanism, a printing head, consumables and a medium, wherein the mechanical assembly, the working table, the feeding mechanism and the printing head are arranged on the 3D printer base, and the control assembly controls the mechanical assembly and the feeding mechanism. In addition, a network card which is connected with a printing cloud service center is also installed in the 3D printer, the network card is a wired network card or a wireless network card and can be in information interaction with the cloud service center, and the printing cloud service center is in communication with a user operating terminal and the 3D printer through the Internet or a wireless network, so that data transmission is achieved. According to the novel 3D printer, the 3D printer is connected to the cloud service center, real-time information interaction between a cloud platform and the 3D printer is achieved, the 3D printer can be designed more easily and more conveniently, printing can be easier and more convenient, relevant articles can be printed more rapidly, and the novel 3D printer is convenient to move due to the fact that a portable device is additionally arranged.

Owner:倪俊

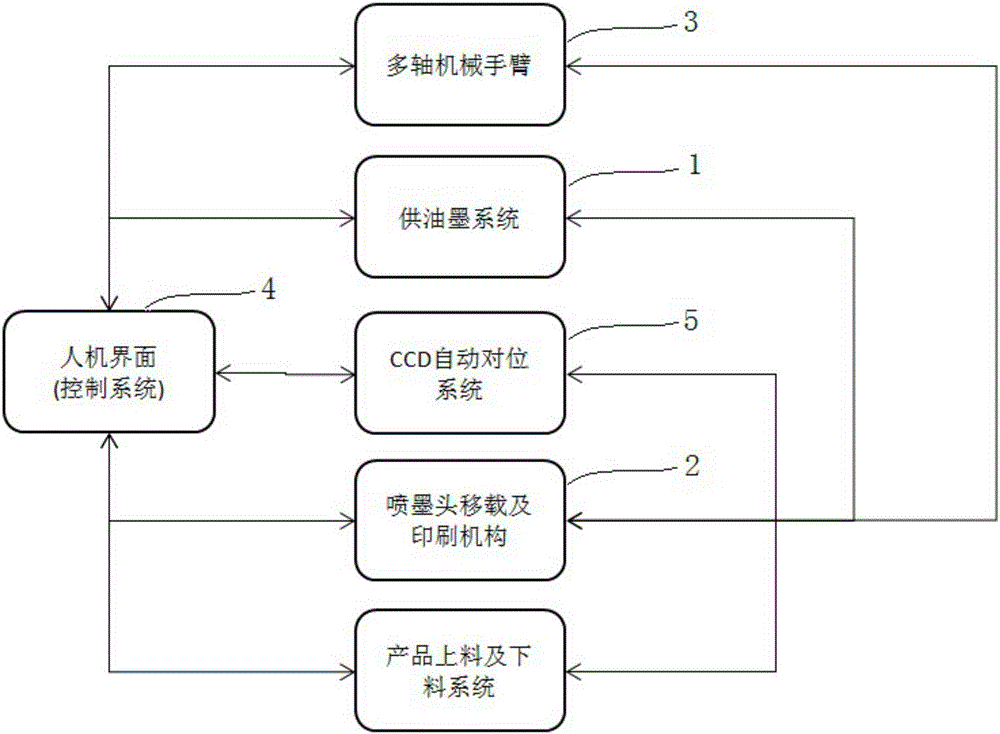

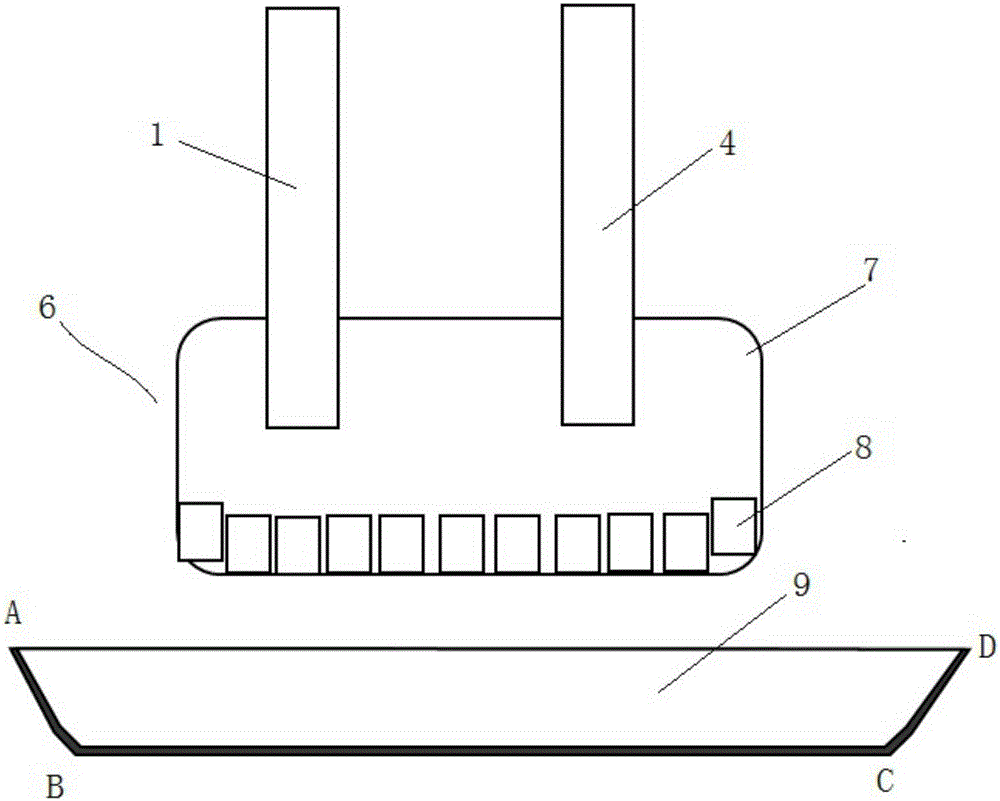

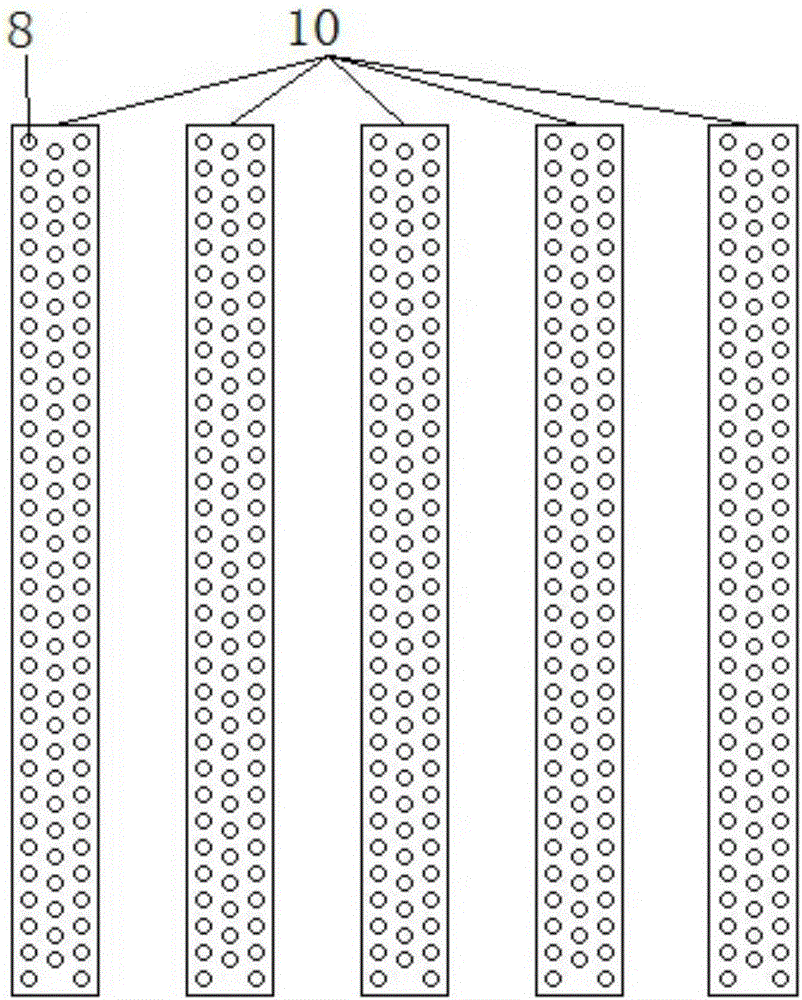

Ink-jet printing system for 3D bent glass cover plate and ink-jet machining method thereof

InactiveCN106626804ANo risk of secondary pollutionOvercoming technical deficienciesTypewritersOther printing apparatusGlass coverData information

The invention discloses an ink-jet printing system for a 3D bent glass cover plate. The ink-jet printing system comprises an ink supply system, an ink jet head transferring and printing mechanism, a multi-shaft mechanical arm and a control system. The ink supply system supplies printing ink to the ink jet head transferring and printing mechanism. The ink jet head transferring and printing mechanism is used for printing the 3D bent glass cover plate. The multi-shaft mechanical arm is used for installing the ink jet head transferring and printing mechanism. The control system sets up data information interconnection with the ink supply system, the ink jet head transferring and printing mechanism and the multi-shaft mechanical arm. The ink jet head transferring and printing mechanism comprises a printing head. The printing head is installed on the multi-shaft mechanical arm. The multi-shaft mechanical arm drives the printing head to steer or move freely, the printing head can be perpendicular to the printing plane of the 3D bent glass cover plate all the time, the printing head is connected with the ink supply system and the control system, and the control system completes printing work of the 3D bent glass cover plate by controlling opening and closing of the printing head. The ink-jet printing system is applicable to printing of the 3D bent glass cover plate, improves machining precision and increases the yield.

Owner:SHENZHEN HJR ELECTRONICS TECH CO LTD

Method for automatic testing linear pointer instrument and recording treatment

The invention relates to a linear pointer-typed instrument with automatic testing and a method for recording the processing; the linear pointer-typed instrument comprises a testing meter of the instrument; the testing meter comprises a sensor (1) which passes through a signal processing amplifier and transmitter (2) and then is input into a CPU (3); the CPU is further connected with a manual input device (5), a display device (7), a storage (8) that is used for storing all testing data and a data output interface (9). The method comprises the following steps: step one, the testing meter is adjusted just to a check point value of a test object to be examined according to an indicated value of the test object, which means that a pointer of the test object points just at a check point P for checking a value N; step two, a testing command key is pressed, thus leading the testing meter to automatically record the value N of the testing point P of the sensor; step three, the value N of the testing point P which is acquired from the testing is automatically calibrated according to the linear relationship between the testing meter and the sensor, and the testing result is stored.

Owner:苏丽芳

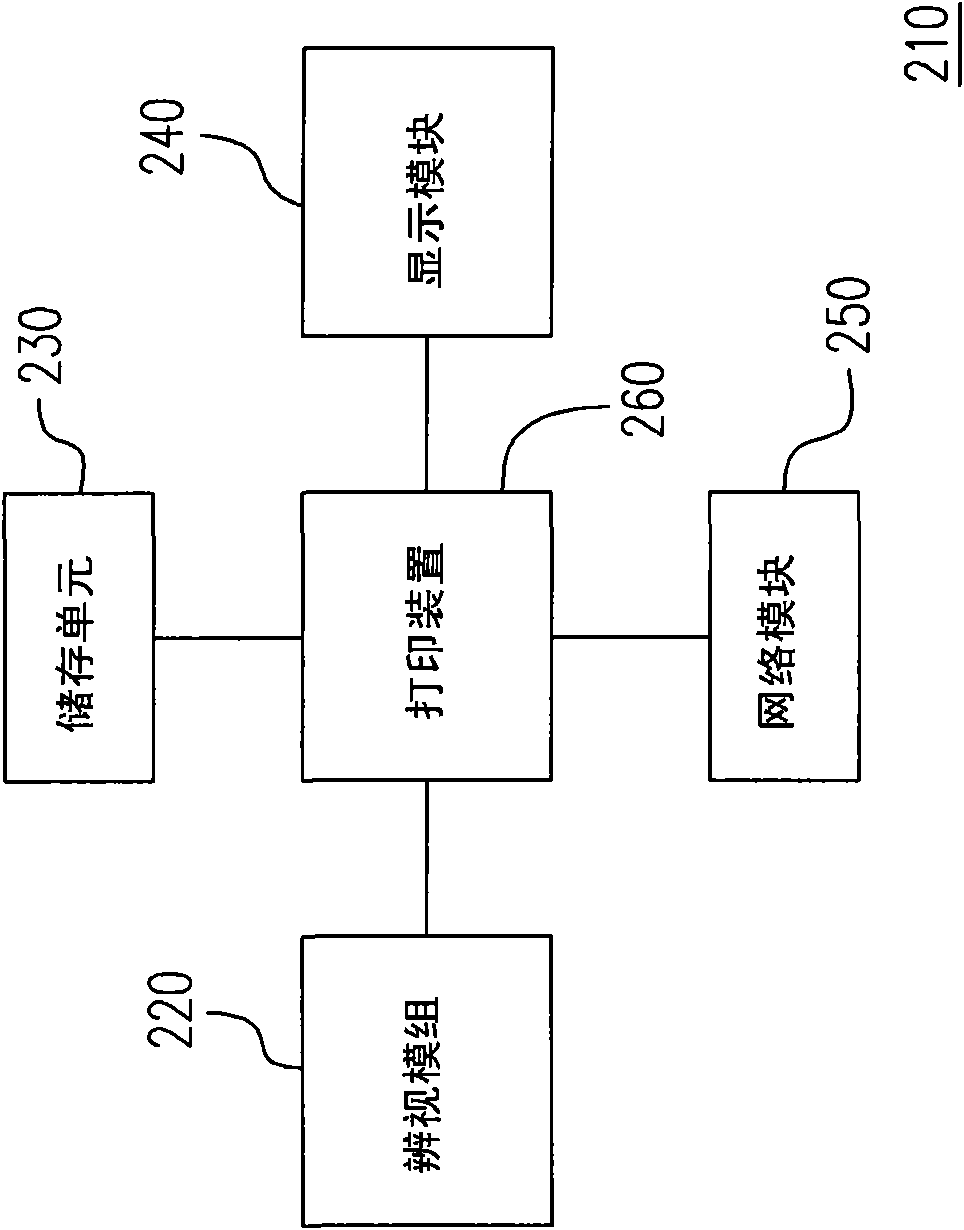

Control device for 3D printer

InactiveCN104972653APrevent waste from increasingPrevent problems caused by inadvertent ingestionAdditive manufacturing apparatusComputer controlObject basedCommunication unit

Disclosed is a control device for a 3D printer, the 3D printer including a supply unit configured to supply a forming material and a degradable agent, and a printing unit configured to print a 3D object. The control device includes a display unit, a controller and a communication unit. The display unit is configured to output screen information enabling a user to set a use period of the 3D object. The controller is configured to determine an amount of the degradable agent to be added to the 3D object based on the set use period and configured to generate a control signal for controlling the 3D printer, the control signal being indicative of the determined amount of the degradable agent. The communication unit is configured to transmit the control signal to the 3D printer.

Owner:LG ELECTRONICS INC

Office equipment and printing method thereof

InactiveCN101556530AImprove securityImprove convenienceSpeech analysisCharacter and pattern recognitionEngineeringWireless network

The invention relates to office equipment and a printing method thereof, which can improve convenience for printing a file by a user. The equipment comprises an identifying module and a printing device. Because the printing equipment can be connected with a user computer by a connecting mode, such as a wireless network, a local area network or a connecting wire, during printing, a user only needs to stay in front of the printing device, the identifying information of the user is authenticated by an identifying system, after comparison is passed, the data to be printed can be automatically printed for the user directly by the printing equipment.

Owner:KINPO ELECTRONICS

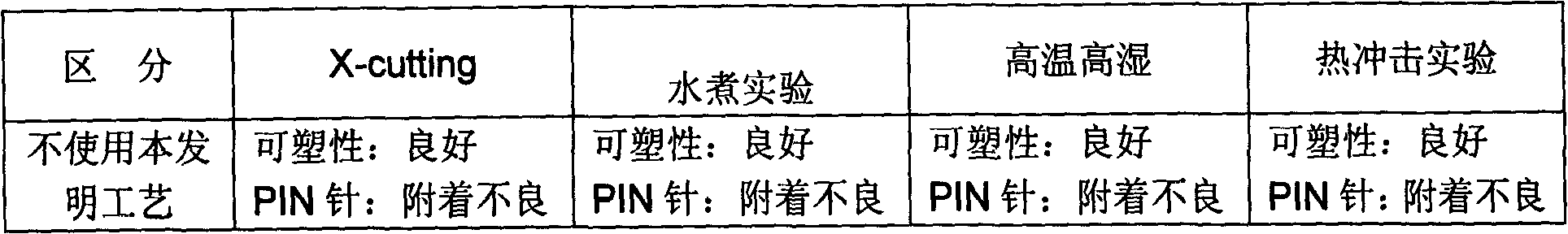

Technological method used for printing mobile phone antenna

ActiveCN103568611AShorten the printing timeShorten the timeAntenna supports/mountingsDuplicating/marking methodsPins needlesPrinting ink

The invention relates to a technological method used for printing a mobile phone antenna. The technological method comprises following steps: (1) PIN needles are printed with an ink with high adhesive force; (2) the PIN needles are dried at a temperature of 60 to 200 DEG C; (3) the PIN needles, which are printed with the ink and obtained in step (2), are inserted into a frame or a casing of the mobile phone antenna which is to be printed; and (4) the frame or the casing is printed with the mobile phone antenna using a conductive printing ink; and (5) the mobile phone antenna is dried at a temperature of 60 to 200 DEG C so as to obtain the mobile phone antenna. Compared with existing technology, printing times of the technological method are reduced, production yield is increased, and production cost is reduced.

Owner:SHENZHEN HAIDEMEN ELECTRONICS CO LTD

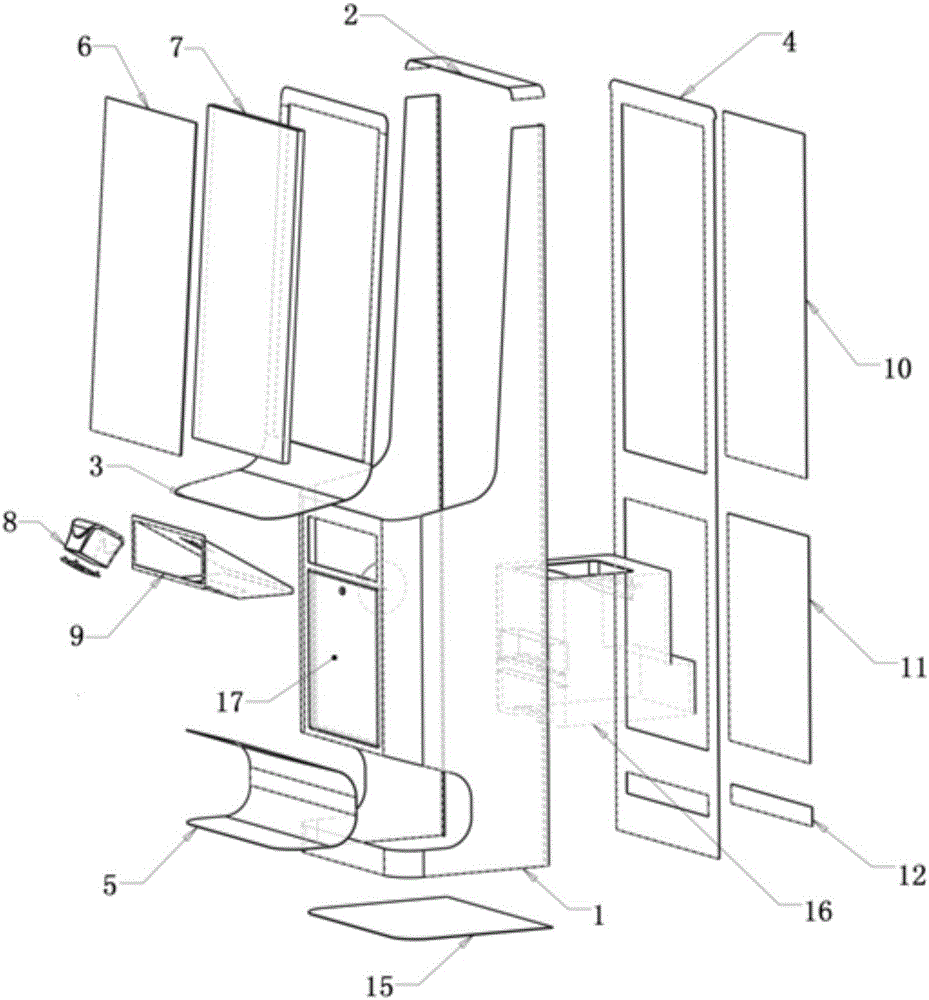

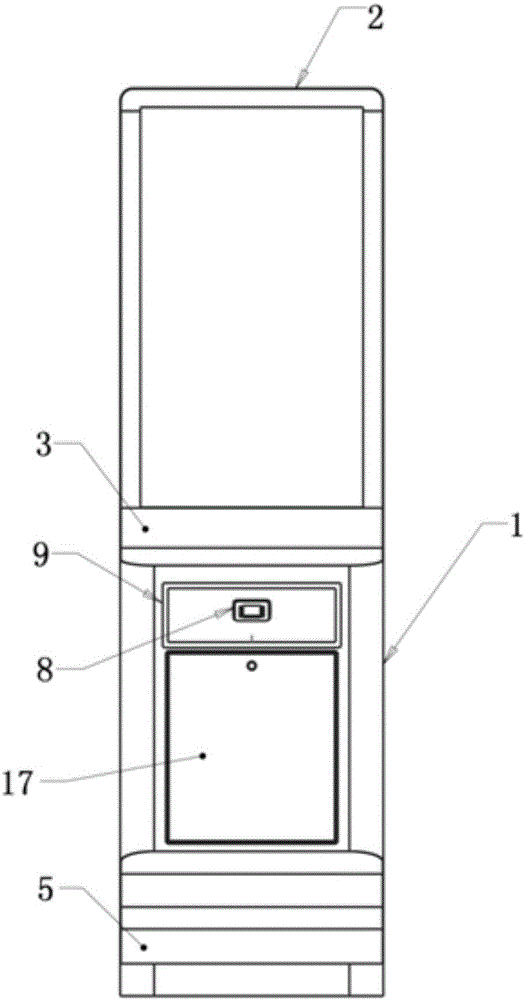

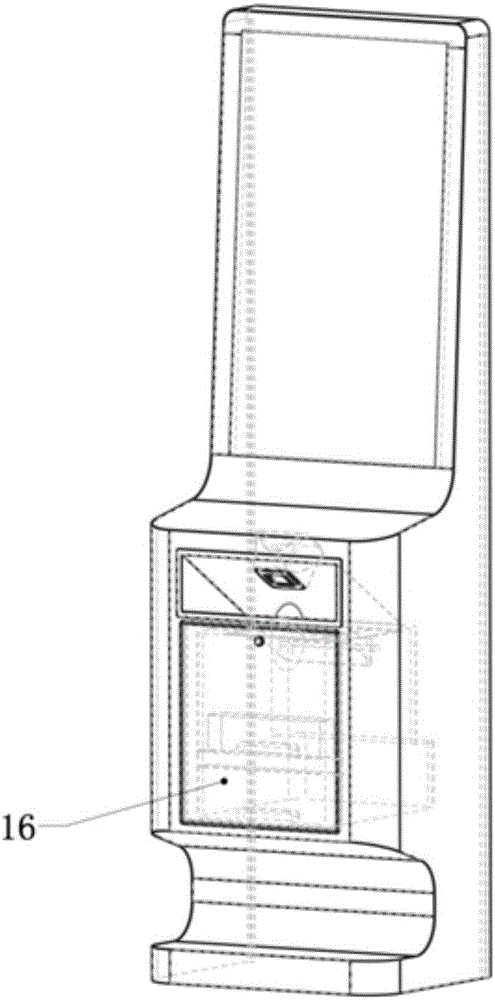

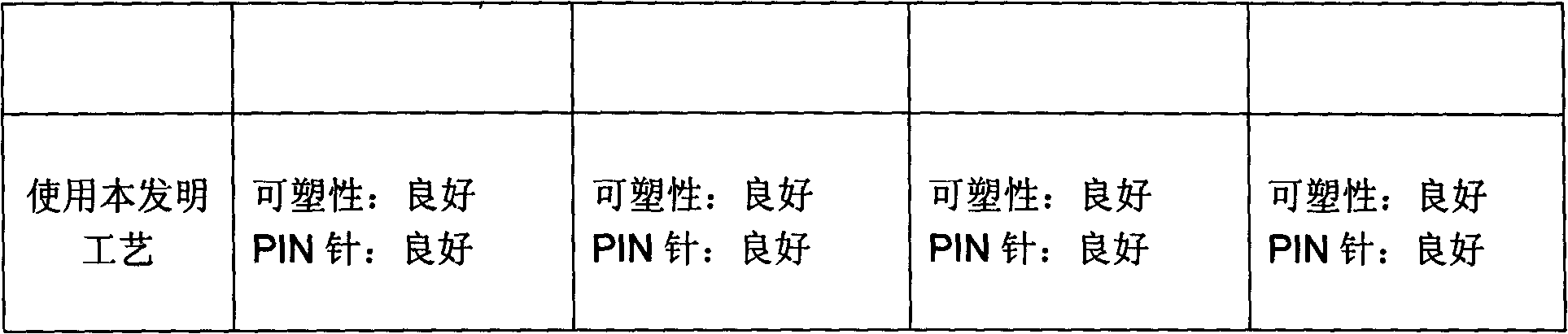

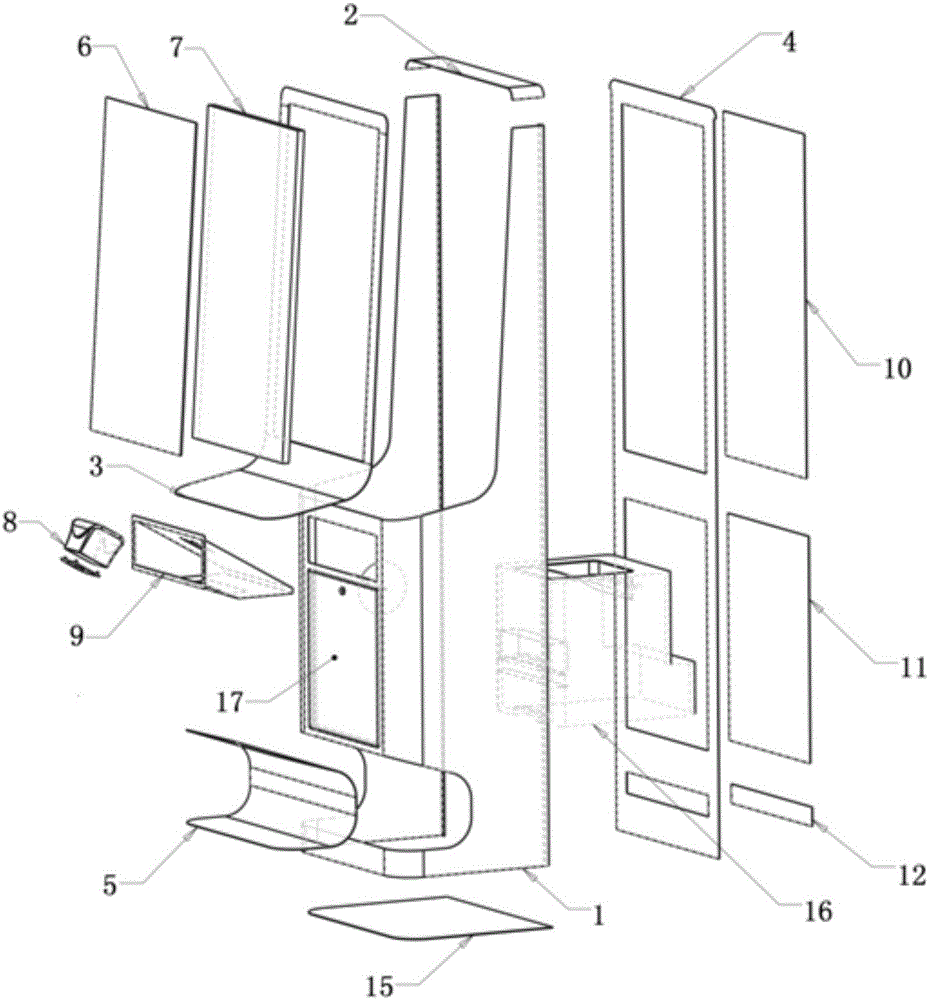

Lost and found system

InactiveCN106067153ASolve the limitation of real-time release of locationSolve the defect of lack of offline displayData processing applicationsApparatus for meter-controlled dispensingClient-sideComputer engineering

The invention discloses a lost and found system which is composed of a client side and a terminal. The shell of the terminal is composed of a main body (1), an upper structure chamfering plate (2), an upper baffle plate (3), a rear baffle plate (4) and a lower baffle plate (5). The upper baffle plate (3) is L-shaped. A glass layer (6) is clamped and fixed through the vertical surface of the upper baffle plate (3) and a screen (7). The terminal is divided into an industrial control computer and a display part. The industrial control computer is used for receiving cloud-side lost information under the networked state. The display part is used for displaying the lost information received by the machine. The industrial control computer firstly receives the cloud-side lost information and then displays the lost information on the display part under the networked state.

Owner:DALIAN POLYTECHNIC UNIVERSITY

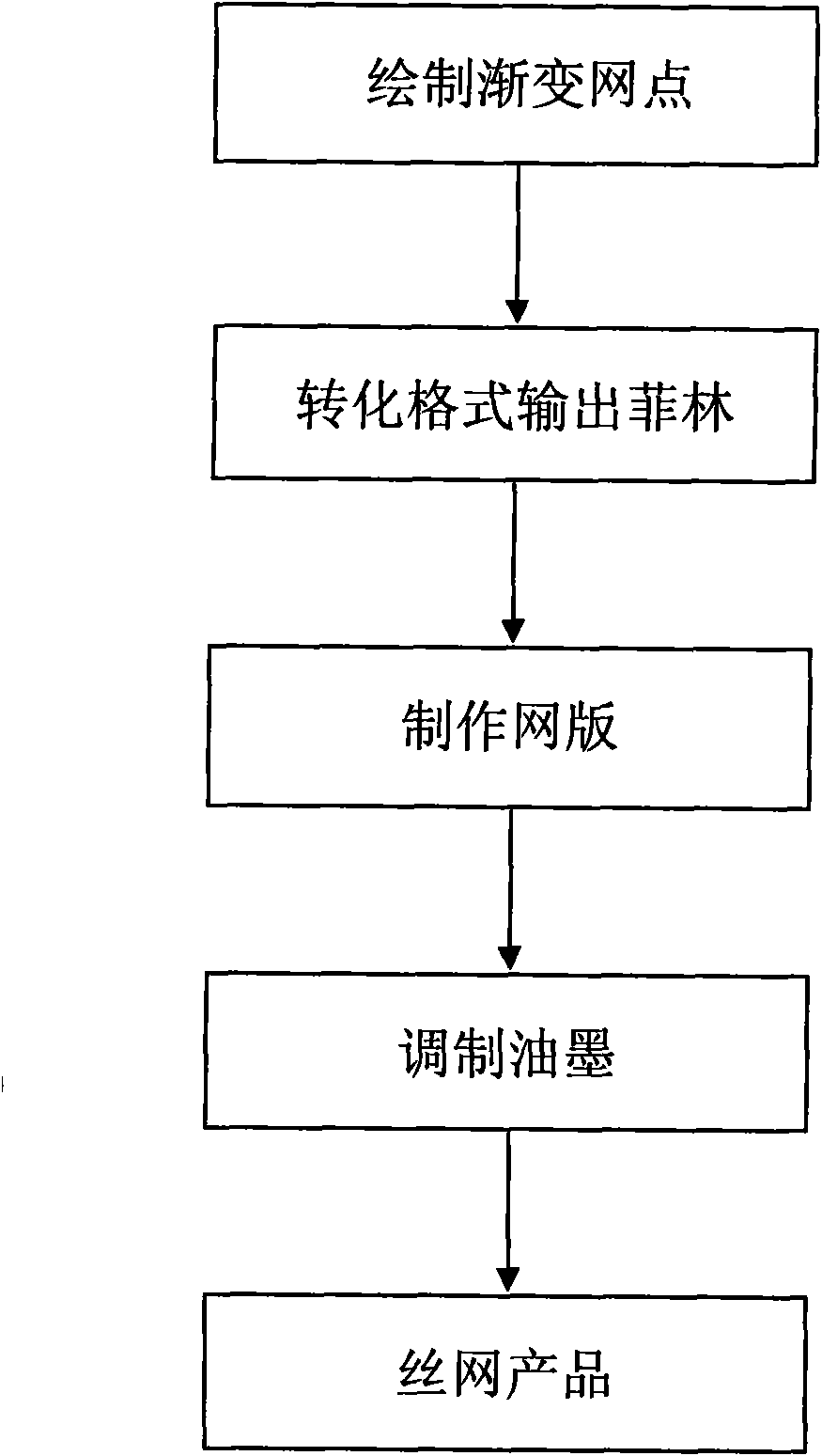

Printing method for realizing vignetting effectof automobile instrument dial

InactiveCN101576710AThe printing process is simpleLow costScreening processesScreen printingPrinting ink

The invention provides a printing method for realizing the vignetting effect of an automobile instrument dial. The printing method comprises the following steps: (1) drawing annular dots with gradually changed sizes in engineering drawing software; (2) converting the drawing into graphic design software, arranging a plurality of crossing angular lines around Film and outputting the Film, wherein the angular lines are as thick as 0.2-0.35 mm; (3) producing a printing screen according to the Film; and (4) mixing printing ink for coloring, printing and then obtaining the automobile instrument dial with the vignetting effect. The vignetting effect of the automobile instrument dial is obtained by combining the engineering software drawing by a dot-printing technology in the screen printing process. By arranging the annular dots on the automobile instrument dial and under the co-effect of printing ink color mixing and inside instrument illumination, when the inside instrument illumination is started, the visual effect of gradual brightness change of an inner circle and an outer circle at a vignetting position can be achieved. The adoption of the printing method can simplify printing procedures and has the advantages of low cost, short time period, flexible product data adjustment, obvious effect, and the like.

Owner:SHANGHAI DELCO ELECTRONICS & INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com