In-mold labeling process

An in-mold insert injection molding and process technology, which is applied in the field of IML, can solve the problems of complicated printing process, high product defect rate, distortion and deformation, etc., and achieve the same excellent molecular diffusion bonding, simplified printing process, and strong bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

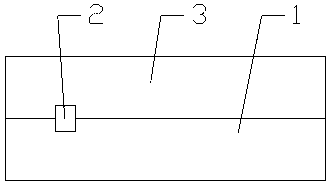

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

[0020] An injection molding process for in-mold inserts, the steps of which are as follows:

[0021] Step 1, cutting the roll-shaped film FILM into a square block with a designed size for printing and forming processes, and performing pretreatment including baking and dust removal on the cut plastic film;

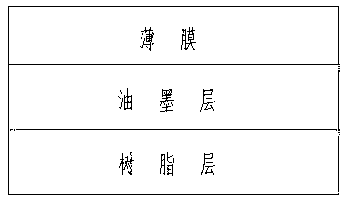

[0022] Step 2: Screen printing is performed on the surface of the film to form an image or text LOGO. The mesh size of the screen printing screen is 100-150 mesh, and then the screen-printed film is placed in an oven for ink curing. The purpose is to fix the IML ink , the oven temperature is set to 80-100°C, and the heating time is 1-2 hours;

[0023] Step 3: Perform 2D or 3D hot pressing and die-cutting on the film. After heating the printed film, fix the film in the 2D or 3D forming mold and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com