SF6 gas density relay checking instrument and checking process

A gas density and relay technology, applied in circuit breaker testing, instruments, scientific instruments, etc., can solve the problems of large temperature influence, troublesome use, poor accuracy, etc., and achieve the effect of simple operation, labor-saving use, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

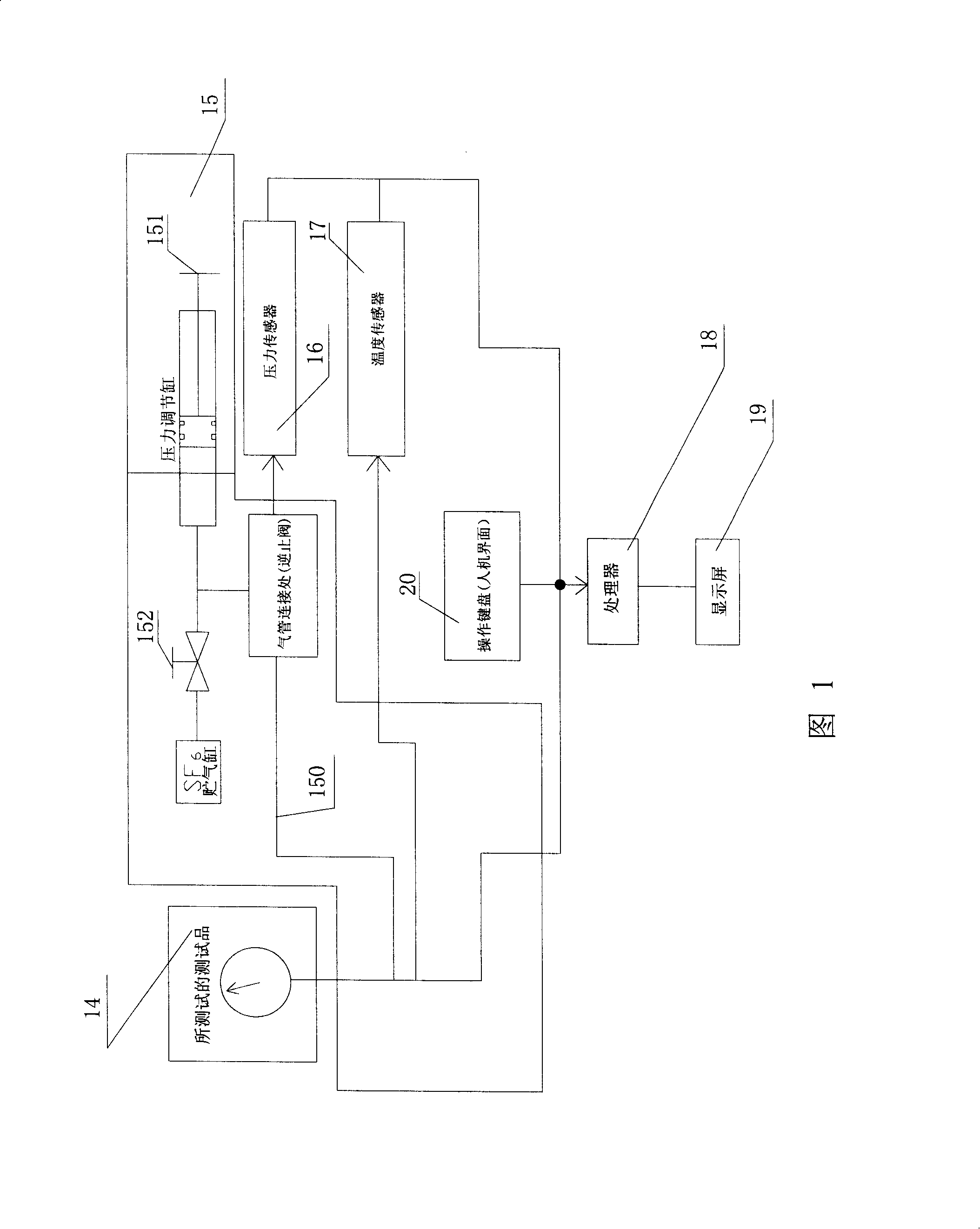

[0020] Please refer to Figure 1, the SF of the present invention 6 The calibration process of the gas density relay calibrator can use the following SF 6 Gas density relay calibrator to complete, the calibrator includes an adjustable pressure gas supply mechanism 15, a pressure sensor 16, a temperature sensor 17, a computer data processing system 18 and a computer data processing system connected The display screen 19, the computer data processing system is provided with the action signal input port of the tested relay 14, and the air supply mechanism 15 communicates with the check valve on the tested relay 14 check port and the gas supply mechanism 15 by a connecting air pipe 150 , the pressure sensor 16 transmits the pressure signal to the computer data processing system 18 , and the temperature sensor 17 transmits the temperature signal of the tested relay 14 to the computer data processing system 18 .

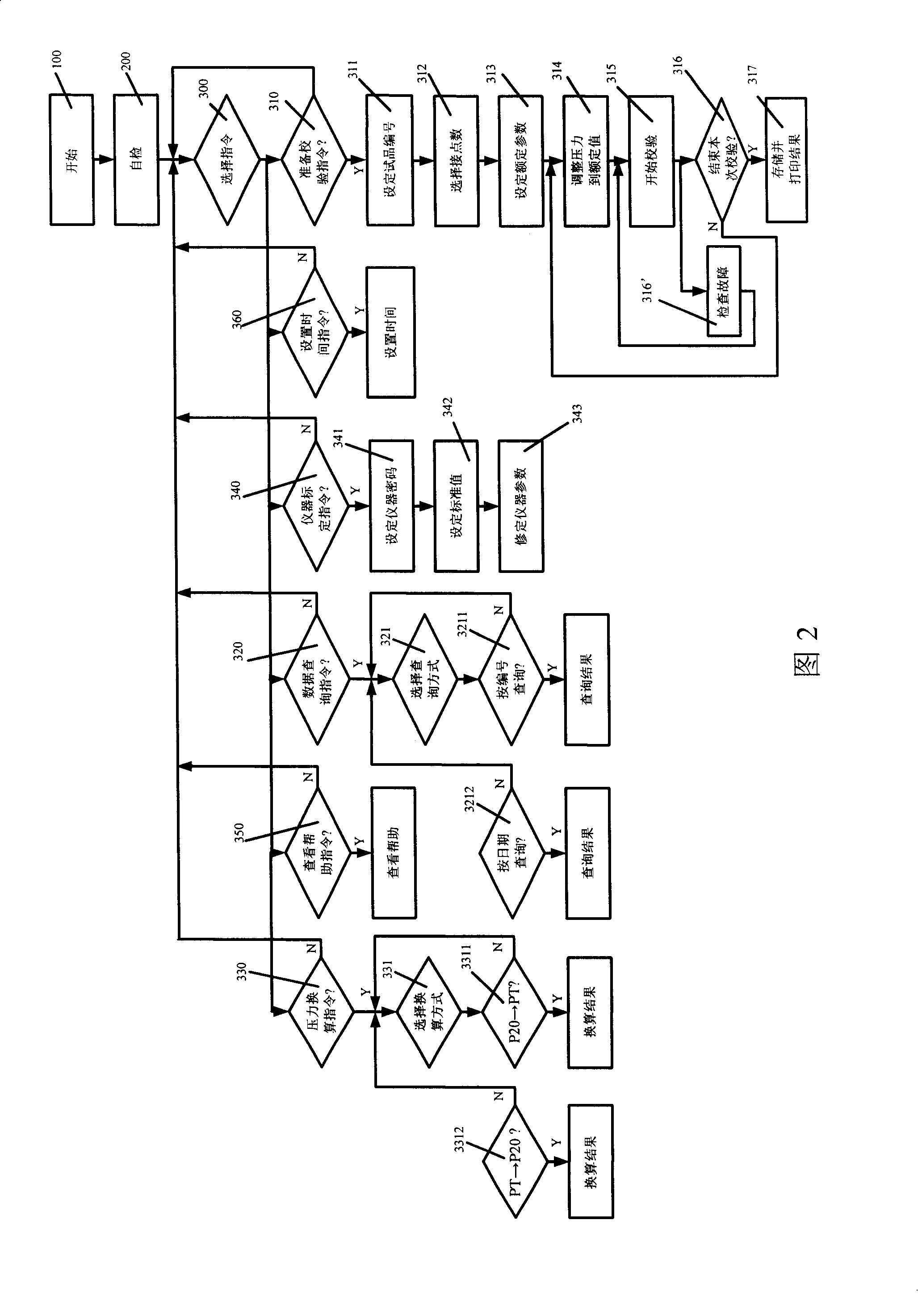

[0021] Please refer to Fig. 2 again, SF of the present invention 6 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com