Vanadium dioxide ink for inkjet printing as well as preparation method and application of vanadium dioxide ink

A vanadium dioxide and inkjet printing technology, which is applied in the field of ink, can solve research problems and achieve the effects of improving printing performance, satisfying film formation, and ensuring fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

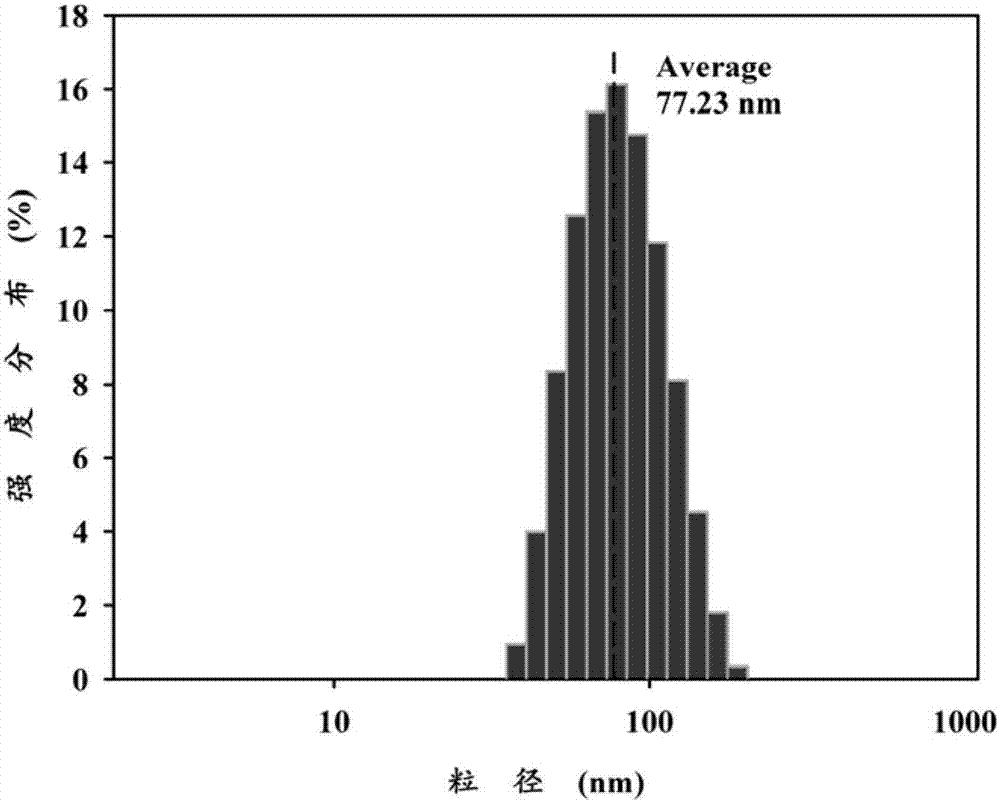

[0036] A vanadium dioxide ink for ink-jet printing of the present invention comprises the following components: 8g average particle diameter is 50nm nano-vanadium dioxide powder, 0.4g dispersant DISPERBYK-110, 24g binder fluorocarbon resin And 120g of diluent (a mixture of xylene and butyl acetate in a volume ratio of 4:1).

[0037] The preparation method of the vanadium dioxide ink that is used for inkjet printing of the present embodiment specifically comprises the following steps:

[0038] (1) 8g of vanadium dioxide nano-powder and 120g of diluent (a mixture of xylene and butyl acetate in a volume ratio of 4:1) were mixed and ultrasonically dispersed for 30min to obtain a vanadium dioxide dispersion;

[0039] (2) Add 0.4 g of dispersant DISPERBYK-110 to the vanadium dioxide dispersion obtained in step (1), and mix, disperse and grind in a sand mill for 8 hours;

[0040] (3) Add 24 g of fluorocarbon resin to the dispersion after step (2), and continue mixing in a sand mill ...

Embodiment 2

[0048] A vanadium dioxide ink for ink-jet printing of the present invention comprises the following components: 8g particle diameter is the nanometer vanadium dioxide powder of 50nm, 0.5g dispersant DISPERBYK-110, 48g binding Fluorocarbon resin and 320g diluent (mixture of xylene and butyl acetate with a volume ratio of 3:1).

[0049] The preparation method of the vanadium dioxide ink that is used for inkjet printing of the present embodiment specifically comprises the following steps:

[0050] (1) 8g of nano-vanadium dioxide powder and 320g of diluent (a mixture of xylene and butyl acetate in a volume ratio of 3:1) were mixed and ultrasonically dispersed for 10 minutes to obtain a vanadium dioxide dispersion;

[0051] (2) Add 0.5 g of dispersant DISPERBYK-110 to the vanadium dioxide dispersion obtained in step (1), and mix, disperse and grind in a sand mill for 12 hours;

[0052] (3) Add 48 g of fluorocarbon resin to the dispersion after step (2), and continue mixing in a sa...

Embodiment 3

[0058] A vanadium dioxide ink for ink-jet printing of the present invention comprises the following components: 8g average particle diameter is 50nm nano-vanadium dioxide powder, 0.25g dispersant DISPERBYK-110, 36g binder fluorocarbon resin And 120g of diluent (a mixture of xylene and butyl acetate with a volume ratio of 5:1).

[0059] The preparation method of the vanadium dioxide ink of the present embodiment specifically comprises the following steps:

[0060] (1) 8g of nano-vanadium dioxide powder and 120g of diluent (a mixture of xylene and butyl acetate in a volume ratio of 5:1) were mixed and ultrasonically dispersed for 20min to obtain a vanadium dioxide dispersion;

[0061] (2) Add 0.25 g of dispersant DISPERBYK-110 to the vanadium dioxide dispersion obtained in step (1), and mix, disperse and grind in a sand mill for 24 hours;

[0062] (3) Add 36 g of fluorocarbon resin to the dispersion after step (2), and continue mixing in a sand mill for 4 hours to obtain a vana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com