ABS/PC 3D consumable material special material and preparation method thereof

A technology of special materials and consumables, which is applied in the field of special materials for ABS/PC3D consumables and its preparation. It can solve the problems of material shrinkage, poor impact strength of molded products, and easy fracture of large-scale printed products, achieving stable printing and improving shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

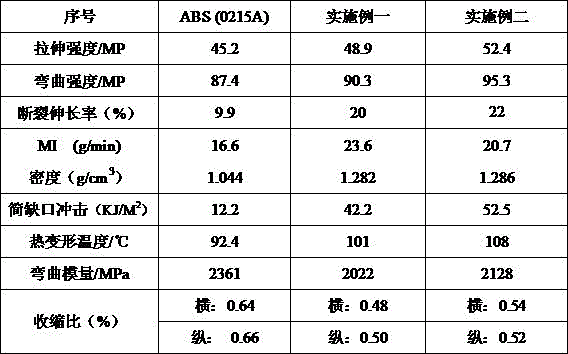

Examples

Embodiment 1

[0015] (1) Dry ABS and PC in a constant temperature drying oven at 100°C for 2 hours;

[0016] (2) Configure the experimental materials according to the following composition ratio: ABS65%, PC 25%, toughening agent 5%, compatibilizer 5%, lubricant 0.5%, antioxidant 0.3%;

[0017] (3) Put the above-mentioned experimental raw materials in a high-speed mixer and mix them thoroughly for 2 minutes to obtain uniformly mixed experimental materials. The temperature of the high-speed mixer is set to 40°C and the speed is 1600r / min;

[0018] (4) Put the mixed materials into the twin-screw extruder, melt and extrude, and granulate; the production process conditions are: the temperature of each zone of the twin-screw extruder is: the temperature of the first zone is 190 ° C, the temperature of the second zone 240°C, 240°C in zone 3, 240°C in zone 4, 240°C in zone 5, 230°C in zone 6, 230°C in zone 7, 220°C in zone 8, 245°C in machine head, of which the vacuum is on in zone 7 The port is v...

Embodiment 2

[0020] (1) Dry ABS and PC in a constant temperature drying oven at 100°C for 3 hours;

[0021] (2) Configure the experimental materials according to the following composition ratio: ABS 55%, PC 35%, toughening agent 5%, compatibilizer 5%, lubricant 0.5%, antioxidant 0.3%;

[0022] (3) Put the above-mentioned experimental raw materials in a high-speed mixer and mix them thoroughly for 3 minutes to obtain uniformly mixed experimental materials. The temperature of the high-speed mixer is set at 40°C and the speed is 2000r / min;

[0023] (4) Put the mixed materials into the twin-screw extruder, melt and extrude, and granulate; the production process conditions are: the temperature of each zone of the twin-screw extruder is: the temperature of the first zone is 190 ° C, the temperature of the second zone 240°C, 240°C in zone 3, 240°C in zone 4, 240°C in zone 5, 230°C in zone 6, 230°C in zone 7, 220°C in zone 8, 245°C in machine head, of which the vacuum is on in zone 7 The port is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com