Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

434 results about "Mobile phone antenna" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile phone antenna

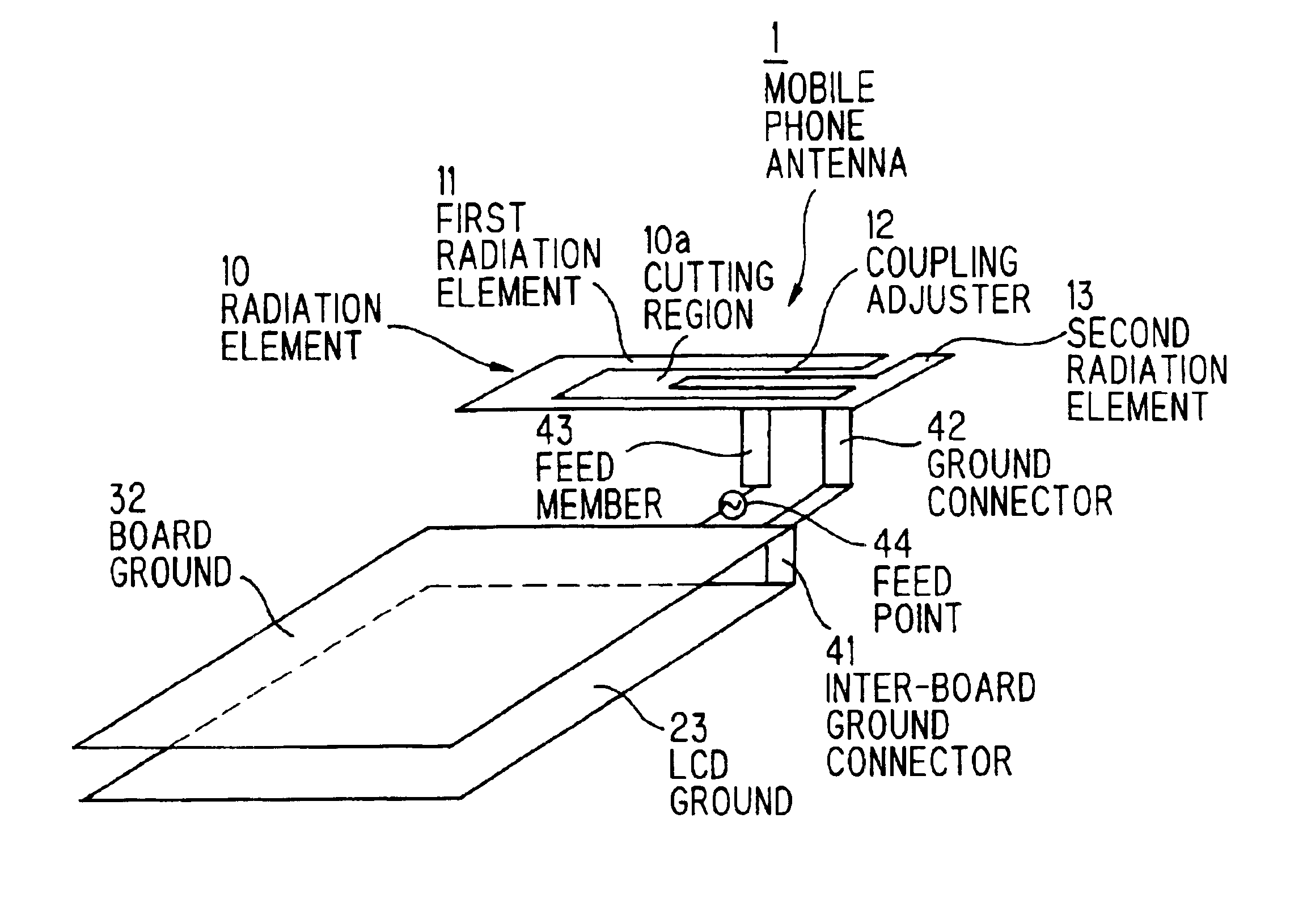

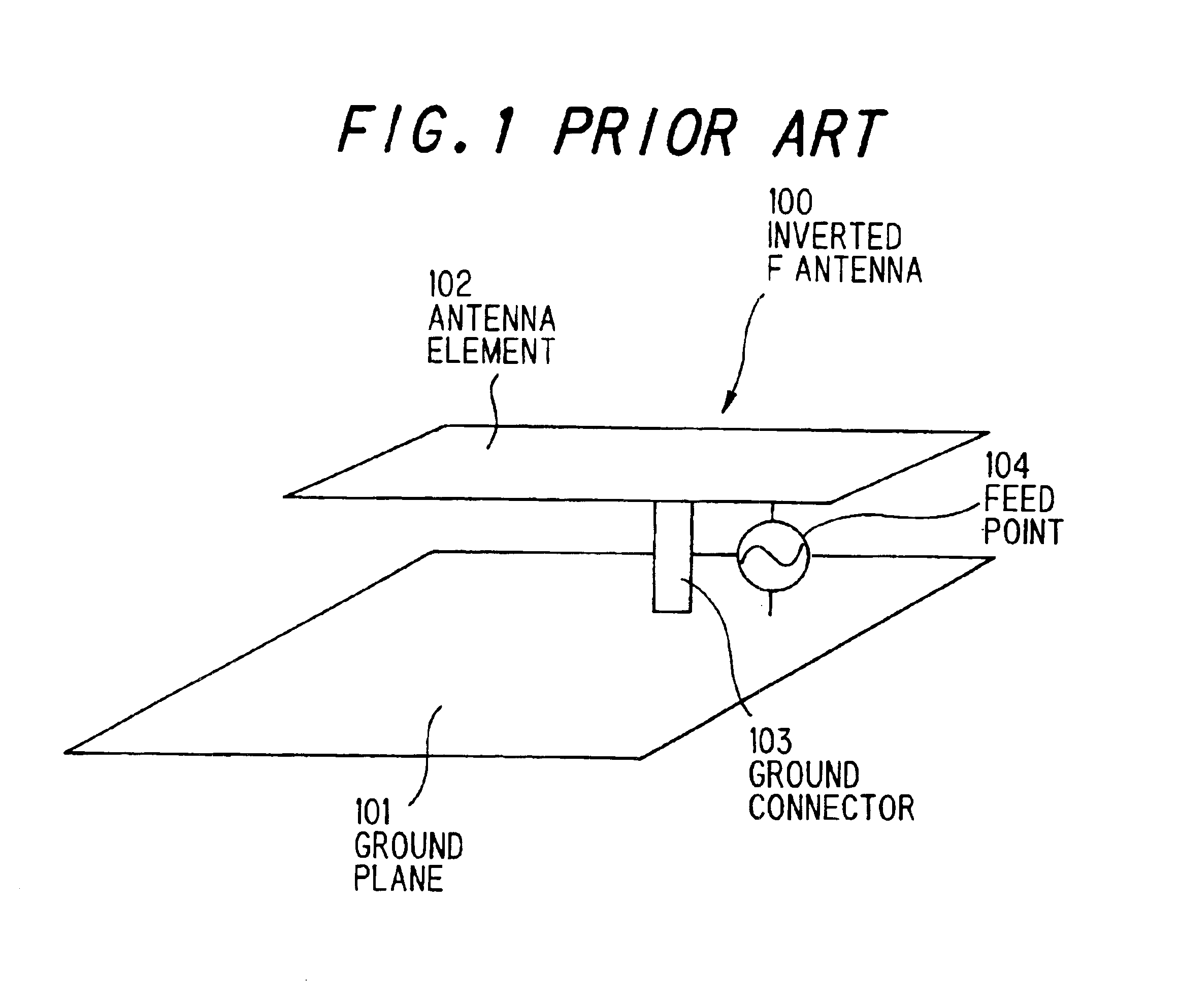

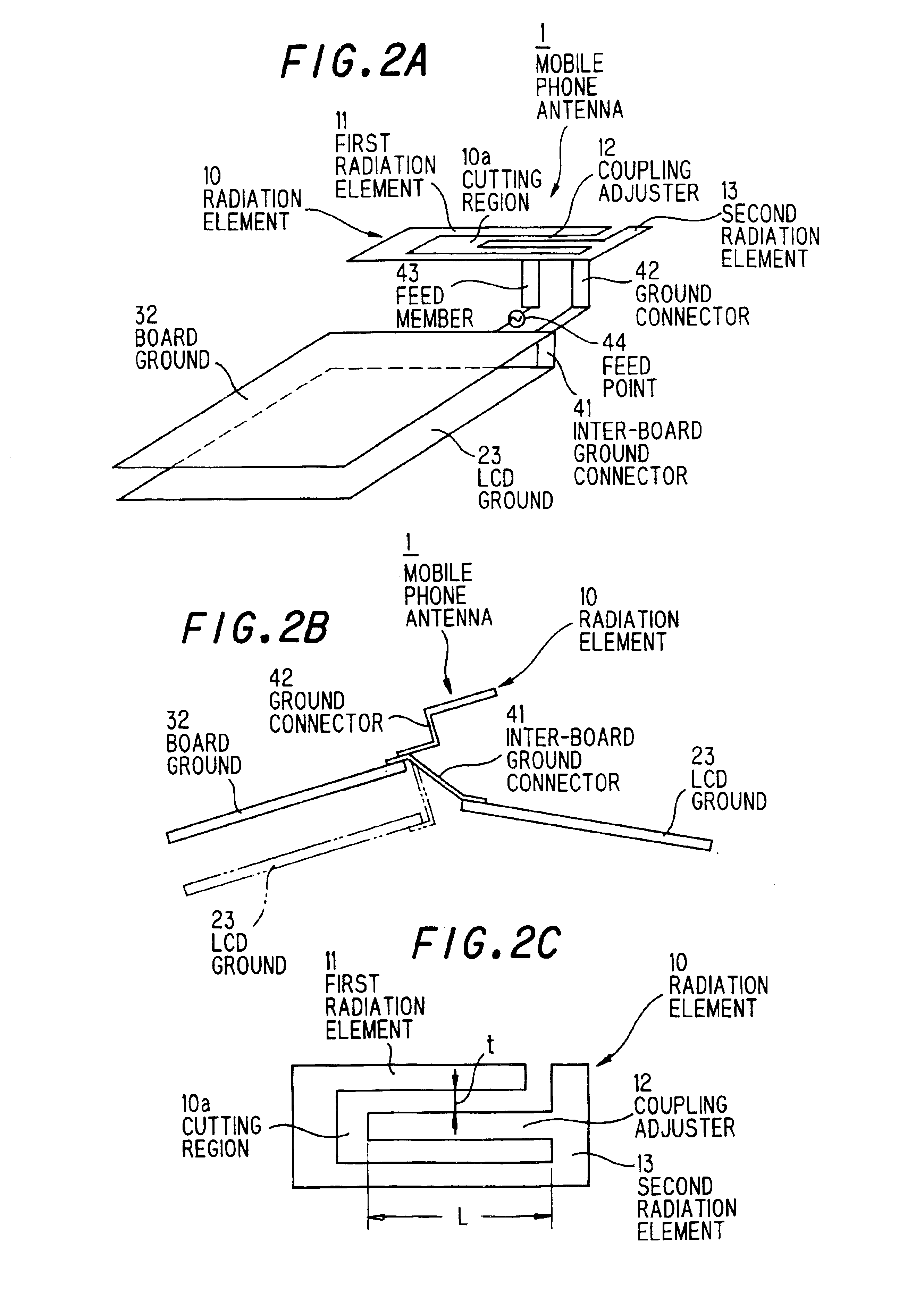

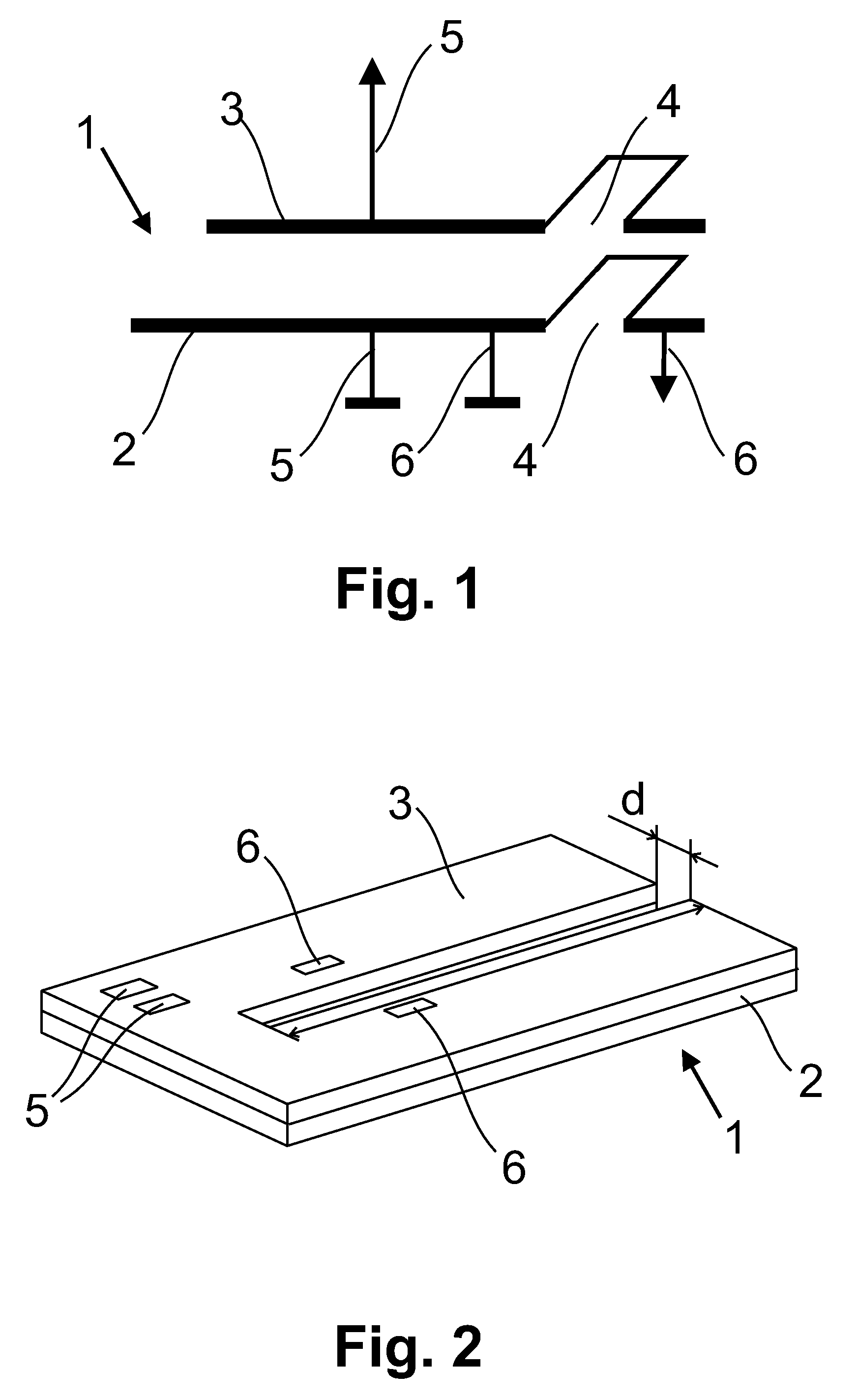

InactiveUS6963310B2High bandwidthAvoid displacementCollapsable antennas meansSimultaneous aerial operationsElectrical conductorResonance

A mobile phone antenna has: a first conductive radiation element that is formed in a sheet metal conductor and resonates at a predetermined resonance frequency; a second conductive radiation element that is formed in the sheet metal conductor and resonates at the predetermined resonance frequency; and a ground that is connected through a conductive ground connector with the second conductive radiation element. The ground is placed such that the ground is not opposed to the first and second conductive radiation elements.

Owner:HITACHI CABLE

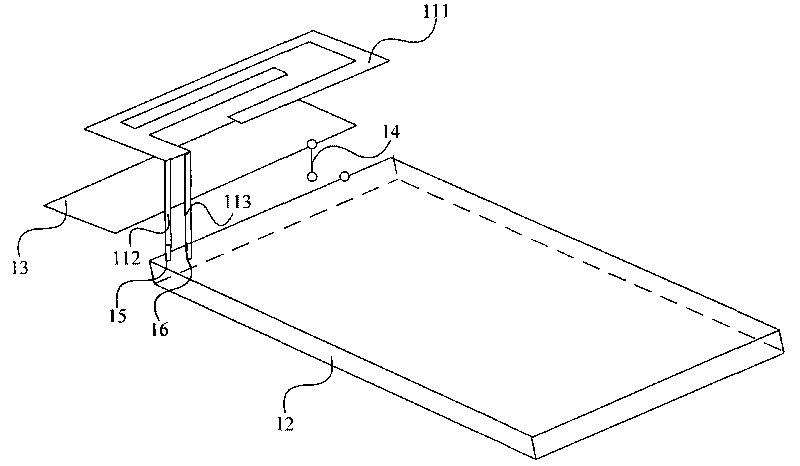

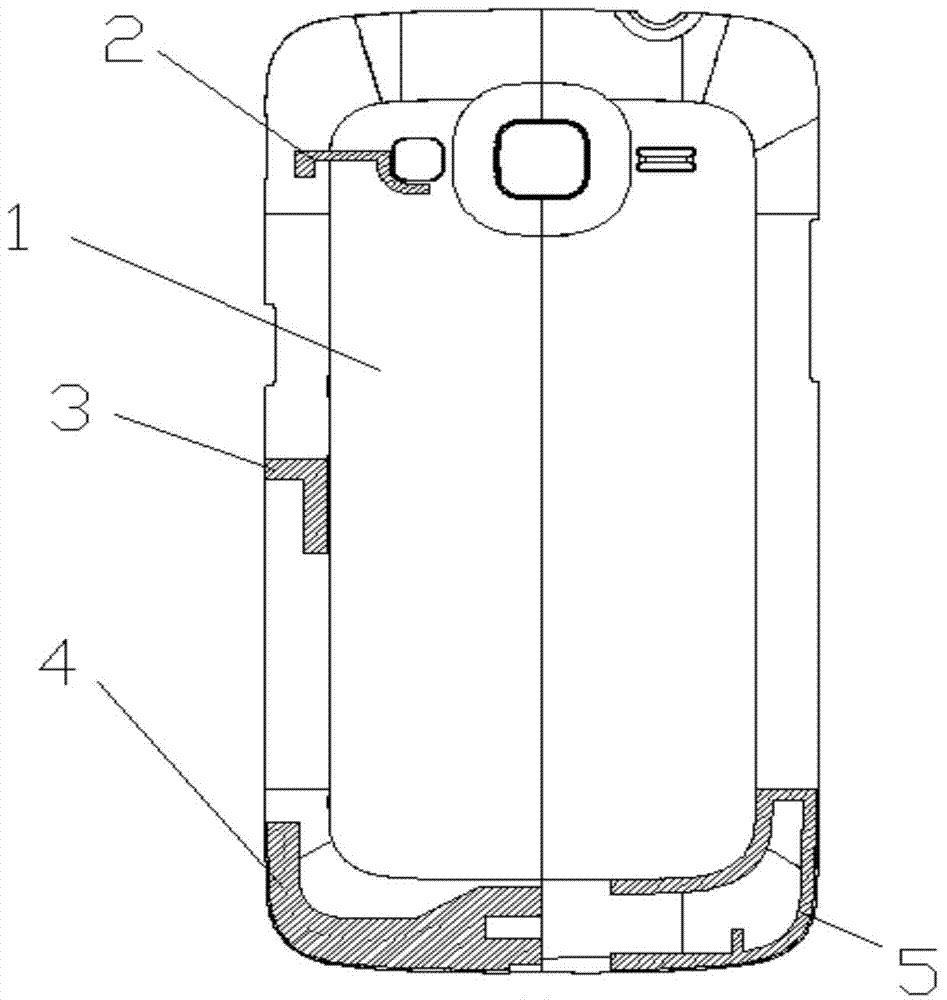

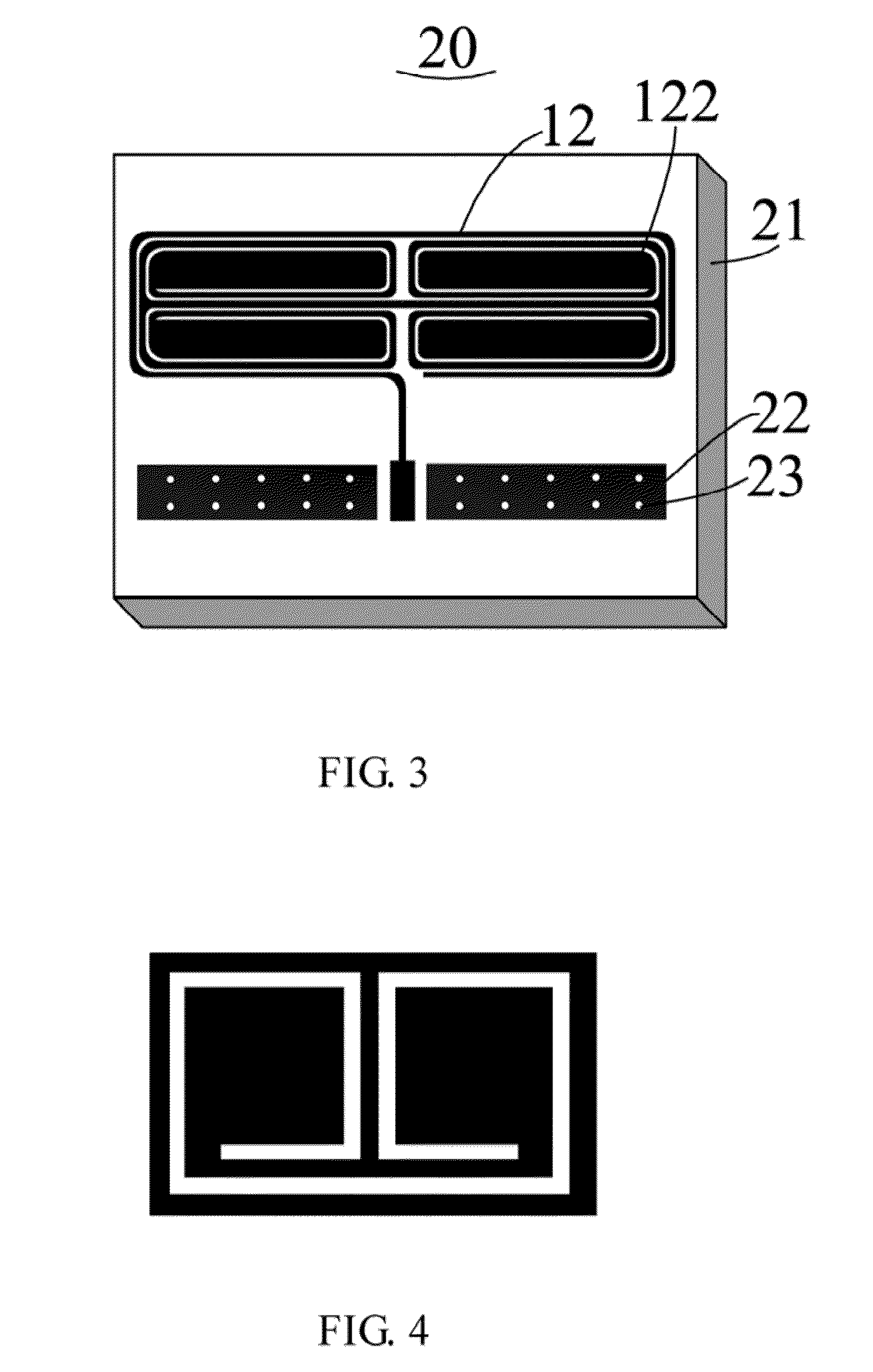

Multi-frequency-band rear metal cover mobile phone antenna

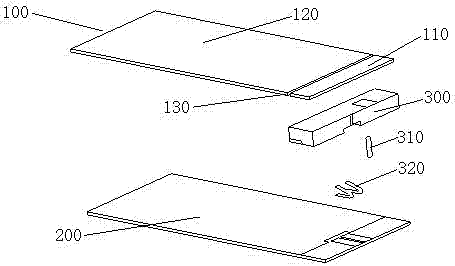

InactiveCN103178344AEffective radiationEfficient receptionSimultaneous aerial operationsAntenna supports/mountingsRadio frequencyPrinted circuit board

The invention aims at disclosing a multi-frequency-band rear metal cover mobile phone antenna which comprises a mobile phone rear metal cover, a printed circuit board and an antenna bracket, wherein the antenna bracket is positioned between the mobile phone rear metal cover and the printed circuit board; the mobile phone rear metal cover comprises a first rear metal cover and a second rear metal cover which are positioned on a same plane; a narrow gap is formed between the first rear metal cover and the second rear metal cover; the first rear metal cover is connected with an antenna part of the antenna bracket; the second rear metal cover is connected with a ground phase of the printed circuit board; a radio-frequency line of the printed circuit board is connected with the first rear metal cover; and the first rear metal cover and the ground phase of the printed circuit board are mutually connected. Compared with the prior art, the multi-frequency-band rear metal cover mobile phone antenna disclosed by the invention has the advantages that the antenna can effectively radiate or receive an electromagnetic signal in a way that the first rear metal cover of the rear metal cover is taken as a high-frequency or low-frequency radiating body of the antenna and other parts are arranged on the antenna bracket, thereby overcoming the defects of the prior art and realizing the purpose.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO +1

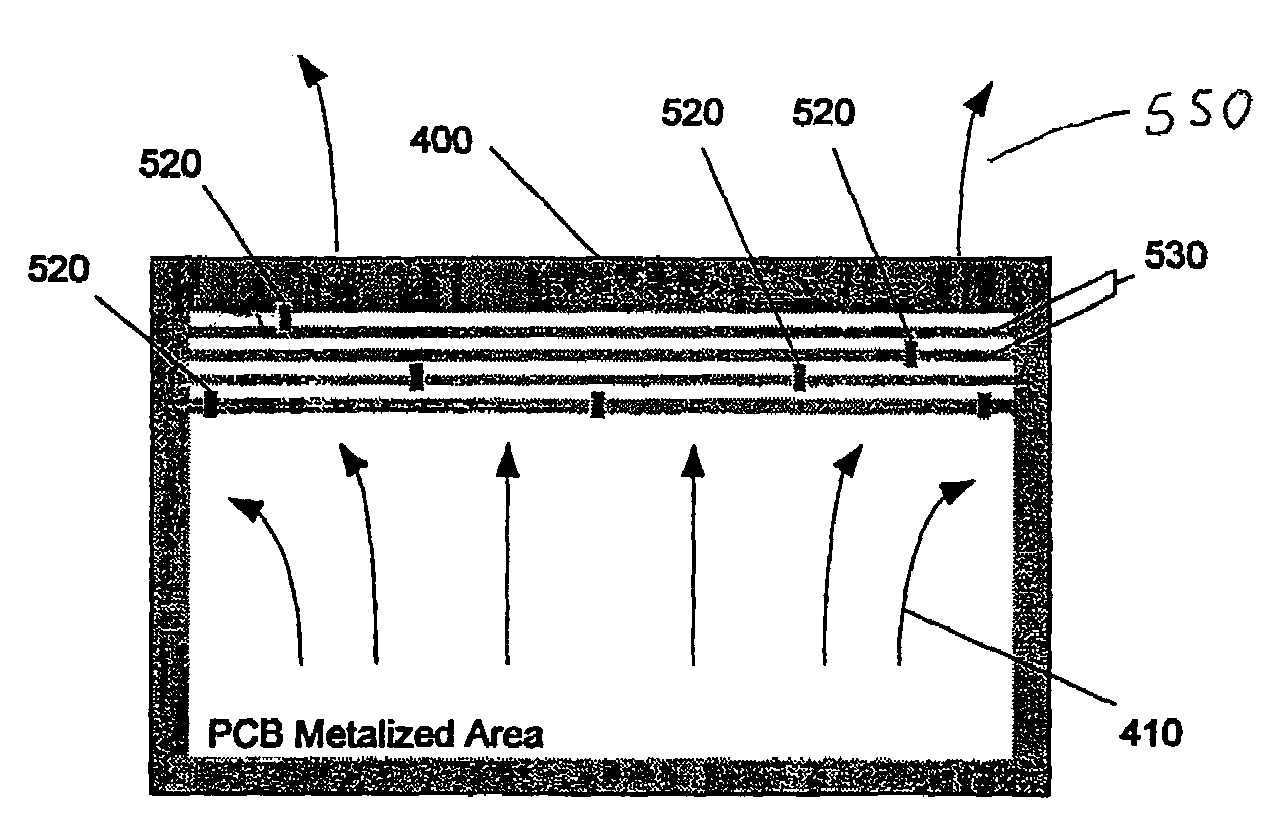

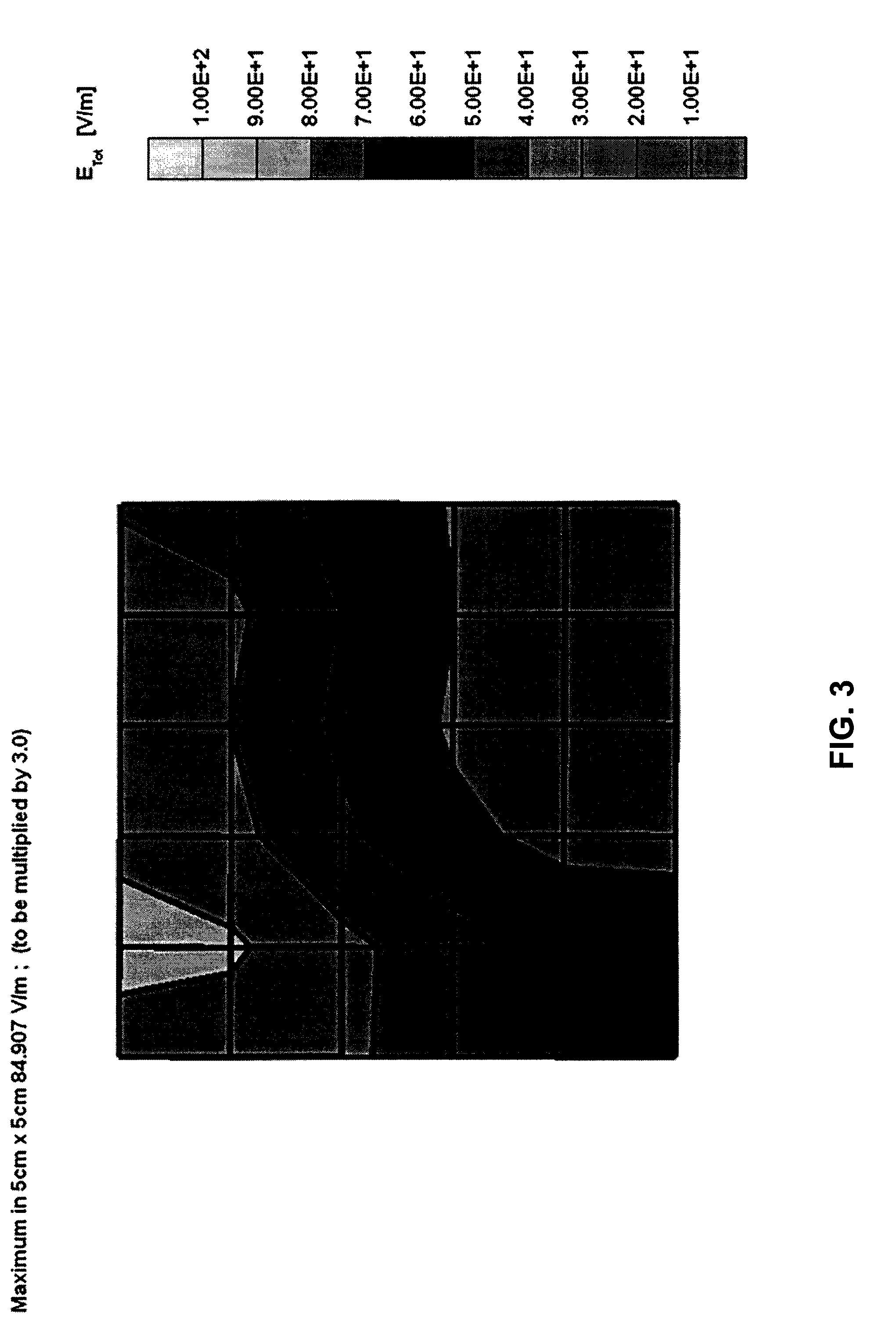

Reduction of near field electro-magnetic scattering using high impedance metallization terminations

ActiveUS7376408B2Reduce the electro-magnetic field scatteringHigh areaMagnetic/electric field screeningCurrent interference reductionInelastic scatteringGradual transition

The present invention uses metallization termination techniques to reduce the electro-magnetic field scattering at the edges of metallized areas. The metallization termination techniques provide a gradual transition from high conductivity areas to high impedance areas. The mobile phone antenna illuminates the PCB allowing currents to flow on the PCB. When the currents reach edges of the PCB they flow through a region of increasingly high impedance without reflecting back or scattering.

Owner:SNAPTRACK

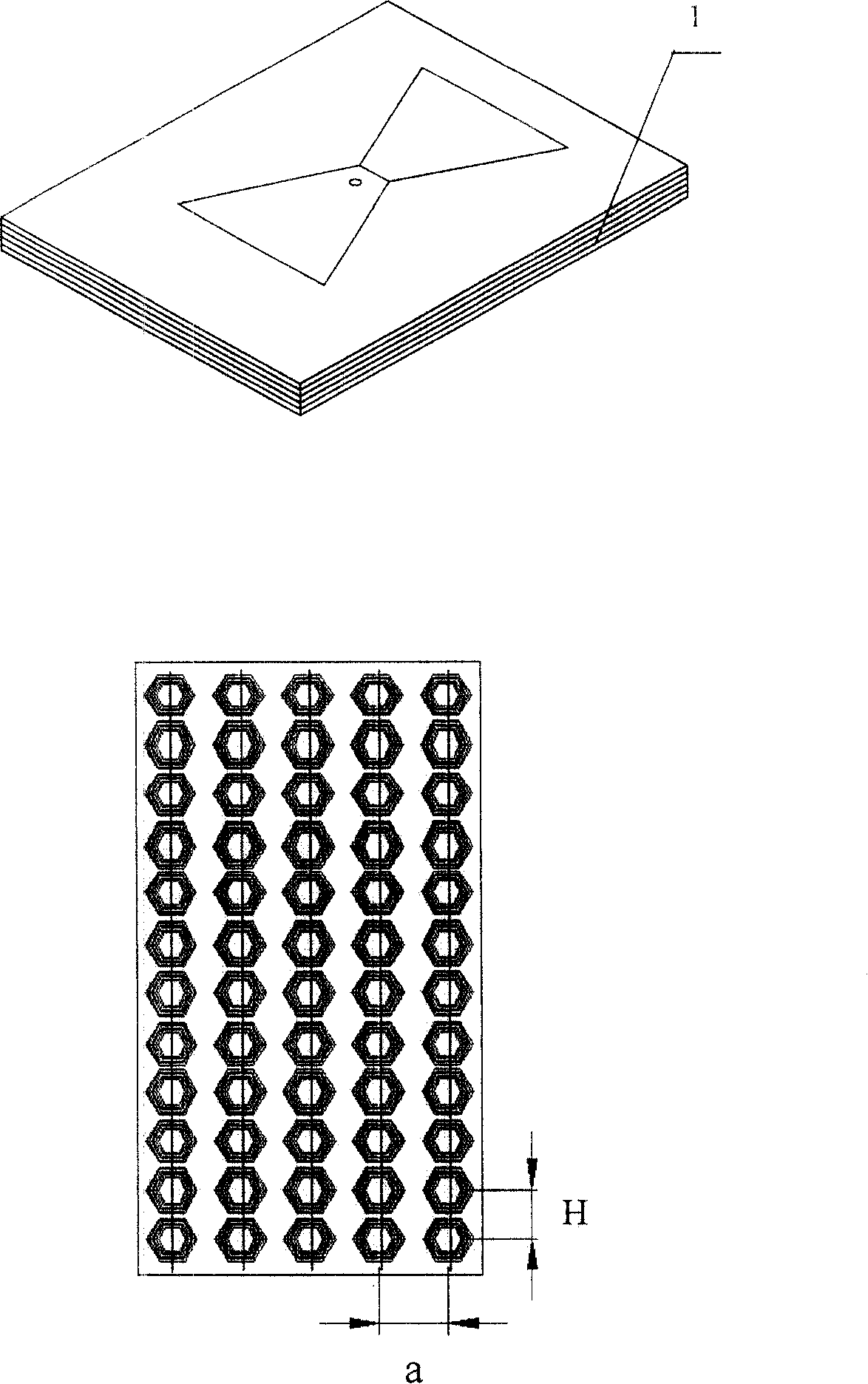

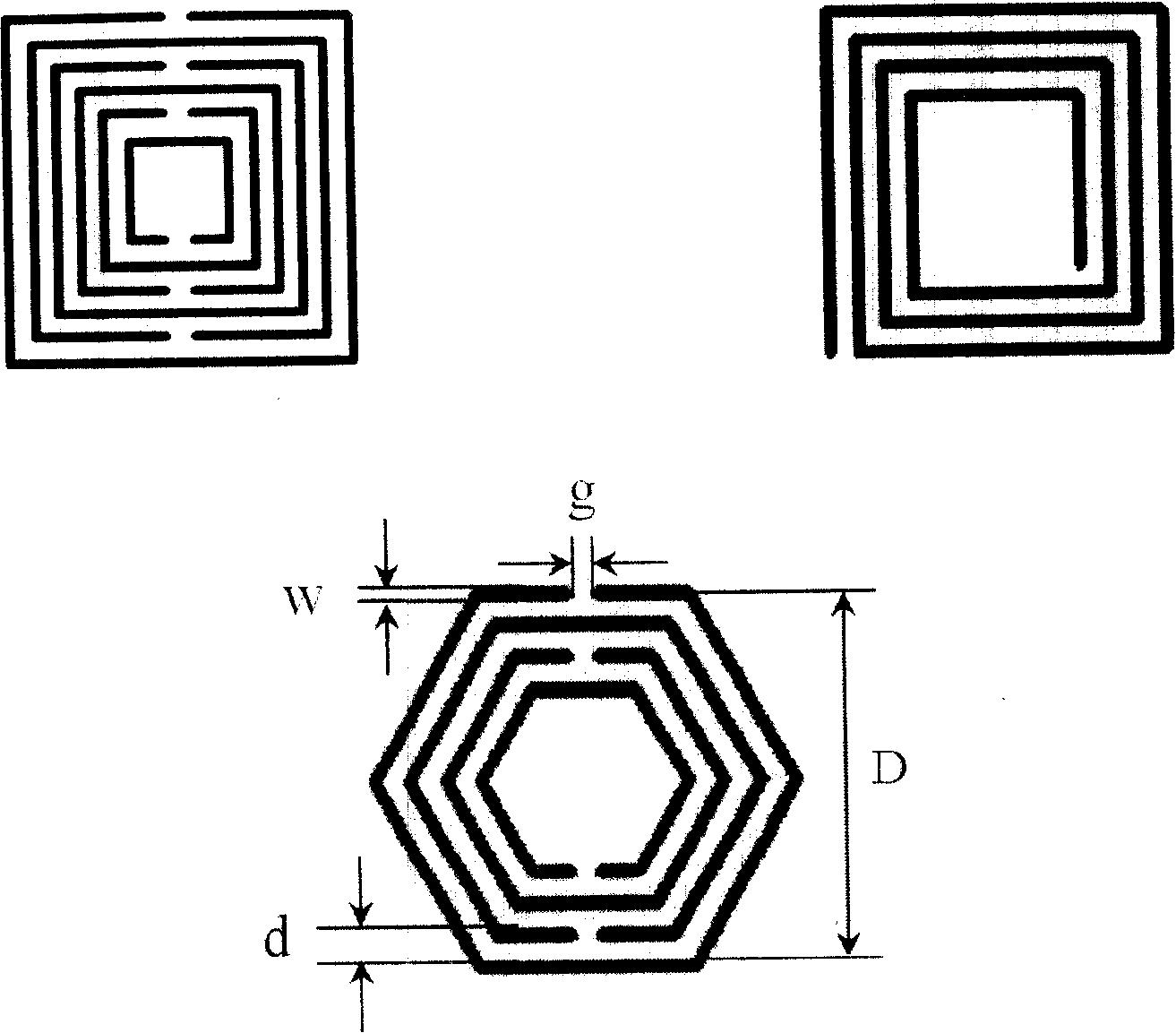

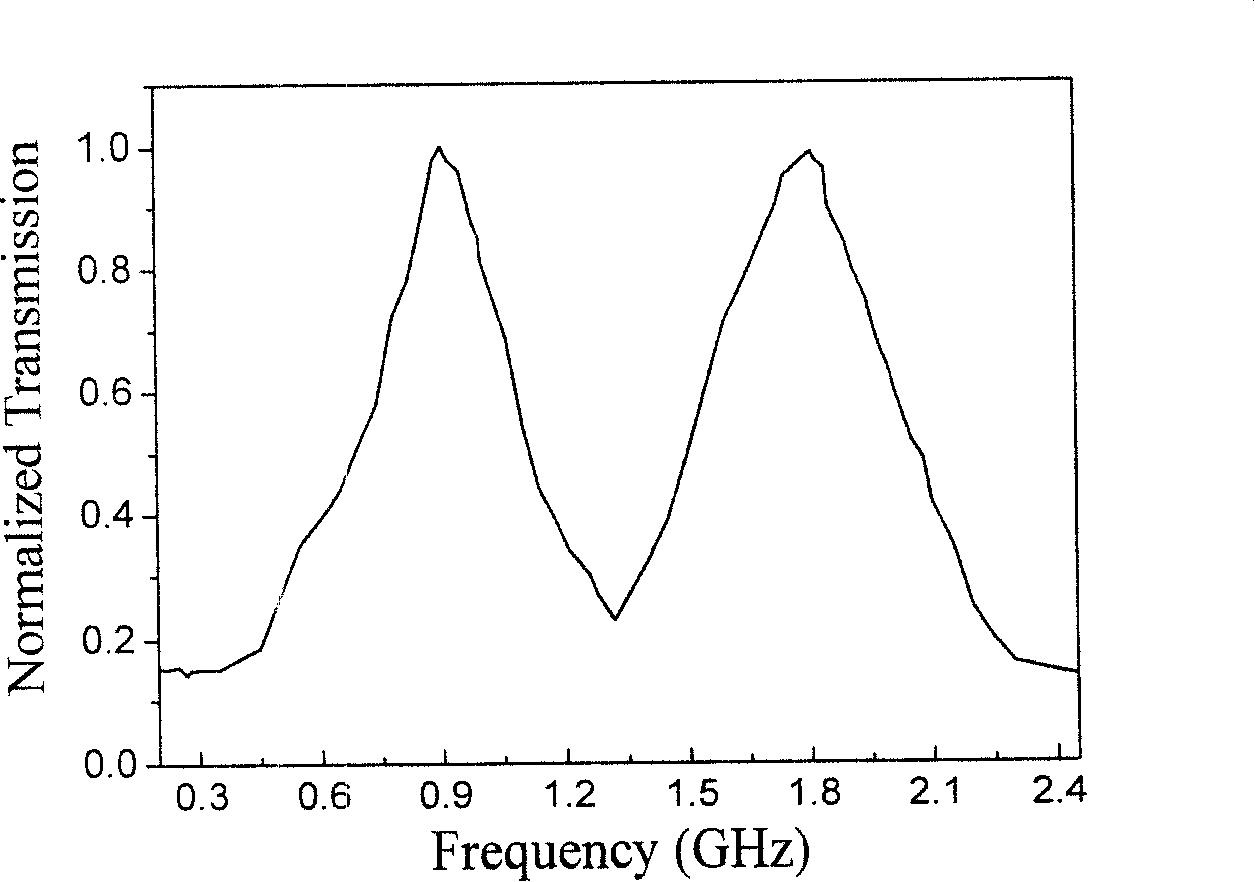

Mobile phone antenna medium substrates with anti-symmetric structure left hand material

The present invention relates to a cellphone antenna medium placode, in particular to a double frequency cellphone antenna medium placode with asymmetric structure left hand material, wherein, the left hand material has double left hand transmission band which is made by introducing the metal resonant ring of non-equal line space. The present invention uses the double left hand band with the asymmetric structure left hand material to realize effective amplification for the evanescent wave in electromagnetic wave in two power frequency sections of low frequency 900MHz and high frequency 1800MHz in cellphone antenna, and the evanescent wave participates in the radiation and receiving work of the antenna to signal, thereby improving radiation efficiency of the cellphone antenna and gains of the cellphone antenna.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

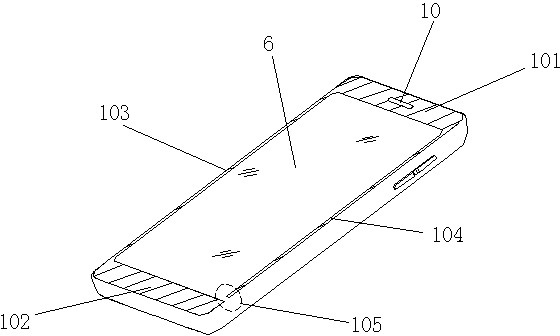

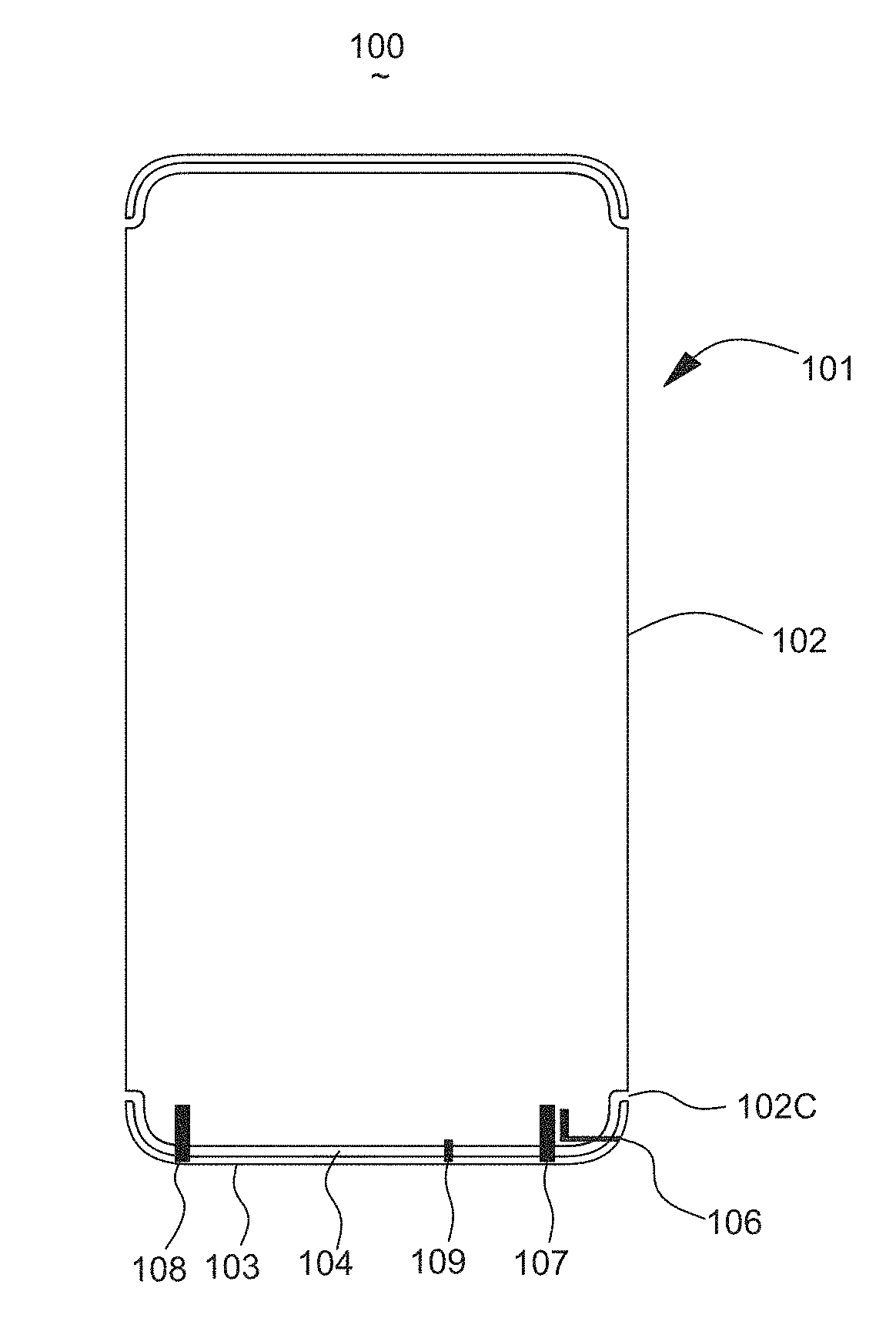

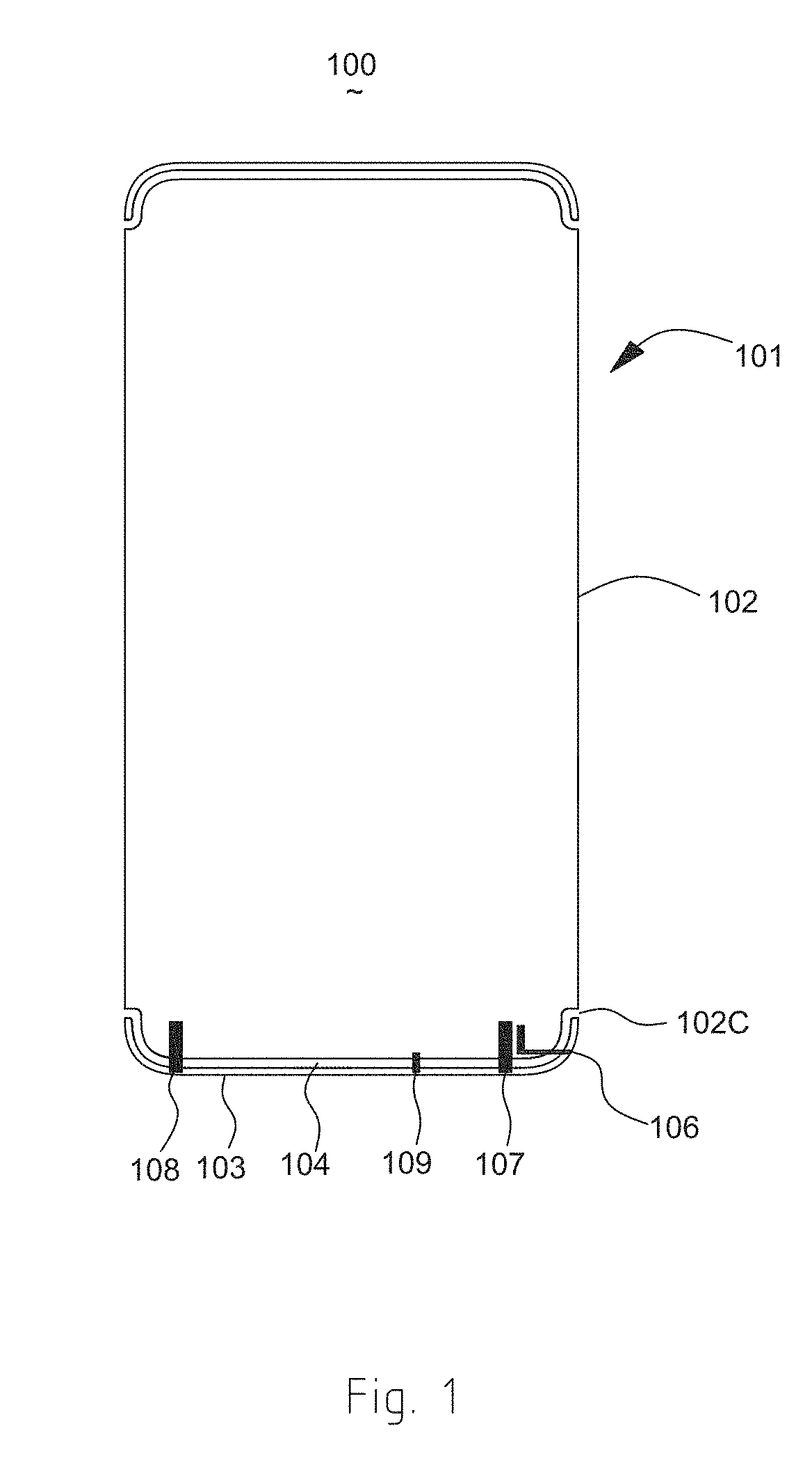

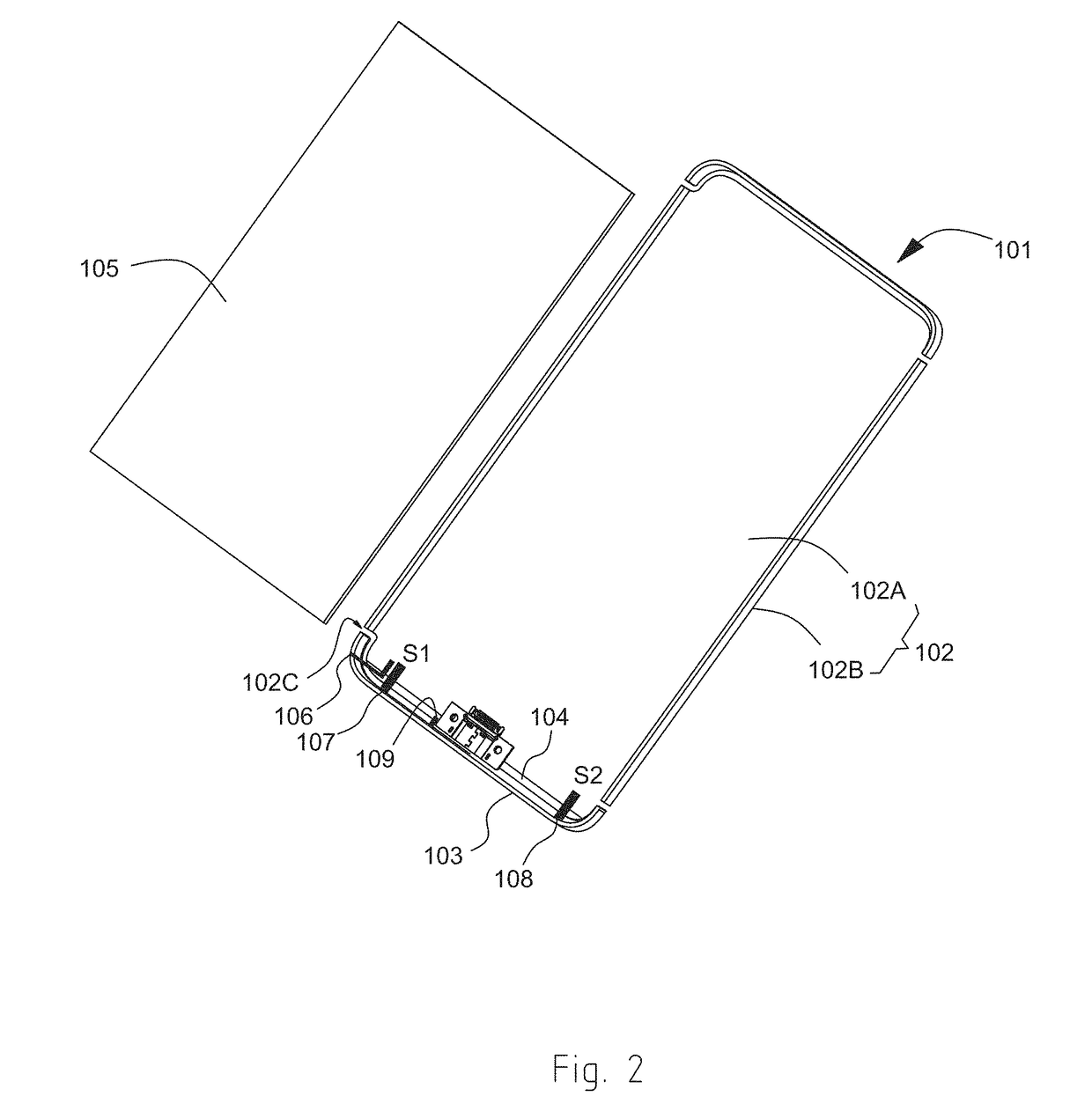

Coupling feed-in type antenna device for mobile phone

ActiveCN102593578AImprove expressivenessIncrease wireless communication capabilitiesAntenna arraysAntenna supports/mountingsCouplingRadio frequency

The invention discloses a coupling feed-in type antenna device for a mobile phone. The antenna device comprises a main board arranged in the mobile phone, a metal decorative piece shaped like two squares sleeved together and mounted on the front surface of the mobile phone, an antenna carrier mounted on the mobile phone housing, and an antenna branch I and an antenna branch II which are arranged on the antenna carrier, wherein a gap is formed on the antenna branch II; a radio frequency feed source is arranged on the main board and connected with the antenna branch II through an antenna connector; the main board is connected with the antenna branch I and the metal decorative piece through antenna connectors; and the metal decorative piece is communicated with the antenna branch II through an antenna connector. The antenna device has the advantages that the metal decorative piece on the front surface of the mobile phone is ingeniously adopted as a part of the antenna, so the metal texture of the whole phone is greatly enhanced in the aspect of modeling; and meanwhile, the coupling feed-in manner is adopted by the antenna device, so that the antenna sensitive problem that the antenna performance is severely worsened when a human hand tightly holds the gap on the metal frame is well solved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Structure and manufacturing method for selectively forming metal on plastic substrate

InactiveCN103088321AElectroless plating process shortenedGood value for moneySynthetic resin layered productsLiquid/solution decomposition chemical coatingChemical platingManufacturing technology

The present invention relates to a structure and a method for selectively forming a compact and precise metal pattern on a plastic substrate surface. The structure comprises three layers of materials such as a plastic substrate, nickel or zinc or an indium tin oxide material, and a metal subsequently deposited on the material, wherein the nickel or the zinc or the indium tin oxide material is formed through adopting laser to irradiate the plastic substrate, decomposing an additive previously added to the plastic, and adopting reductive chemical plating to treat. The manufacturing method comprises: adopting laser to selectively scan the plastic substrate. According to the present invention, the additive does not adopt a copper-containing oxide, a copper chelate, a copper complex and a metal oxide having a spinel structure, and adopts the environmentally friendly non-toxic inorganic salt containing nickel and zinc, and the indium tin oxide material, the coupling agent is adopted to carry out coating modification to prepare the additive having a core-shell structure, and the additive is added to the plastic to prepare the laser composite plastic; the laser is adopted to decompose the shell part of the additive so as to release active ingredients in the core; the present invention belongs to a new material based advanced assembly and manufacturing technology in the field of electronic and electric apparatuses; and the structure and the method are used for manufacturing mobile phone antennas, transparent lamp parts, automobile parts, three-dimensional circuits and other products.

Owner:深圳市微航磁电技术有限公司

Mobile phone antenna

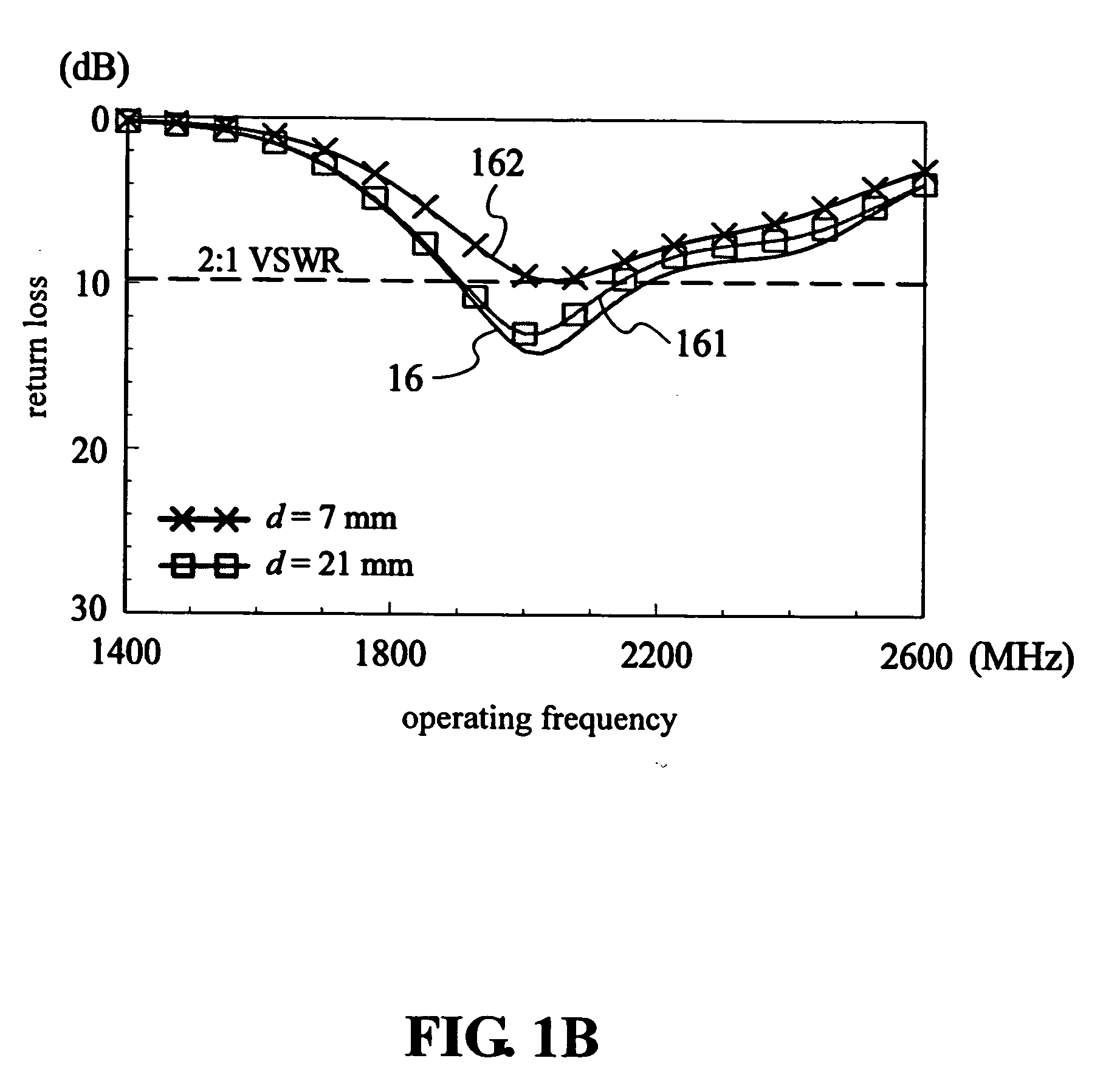

ActiveUS7209087B2Simultaneous aerial operationsAntenna supports/mountingsGround planeMobile phone antenna

The present invention provides a mobile phone antenna, which comprises an antenna ground plane, a radiating conducting plate, a feeding conducting strip, a shorting conducting strip, and a system ground plane. Using the antenna ground plane as a shielding metal wall, the present invention advantages itself of making the antenna and a shielding metal box easier to be integrated without a need for an isolation distance. The present invention thus makes the best use of the internal spacing of a mobile phone. This antenna is suitable for application as an embedded antenna for both folded-type and bar-type mobile phones. The operating bandwidth of this antenna can cover the required bandwidth for a Universal Mobile Telecommunication System operation.

Owner:NAT SUN YAT SEN UNIV +1

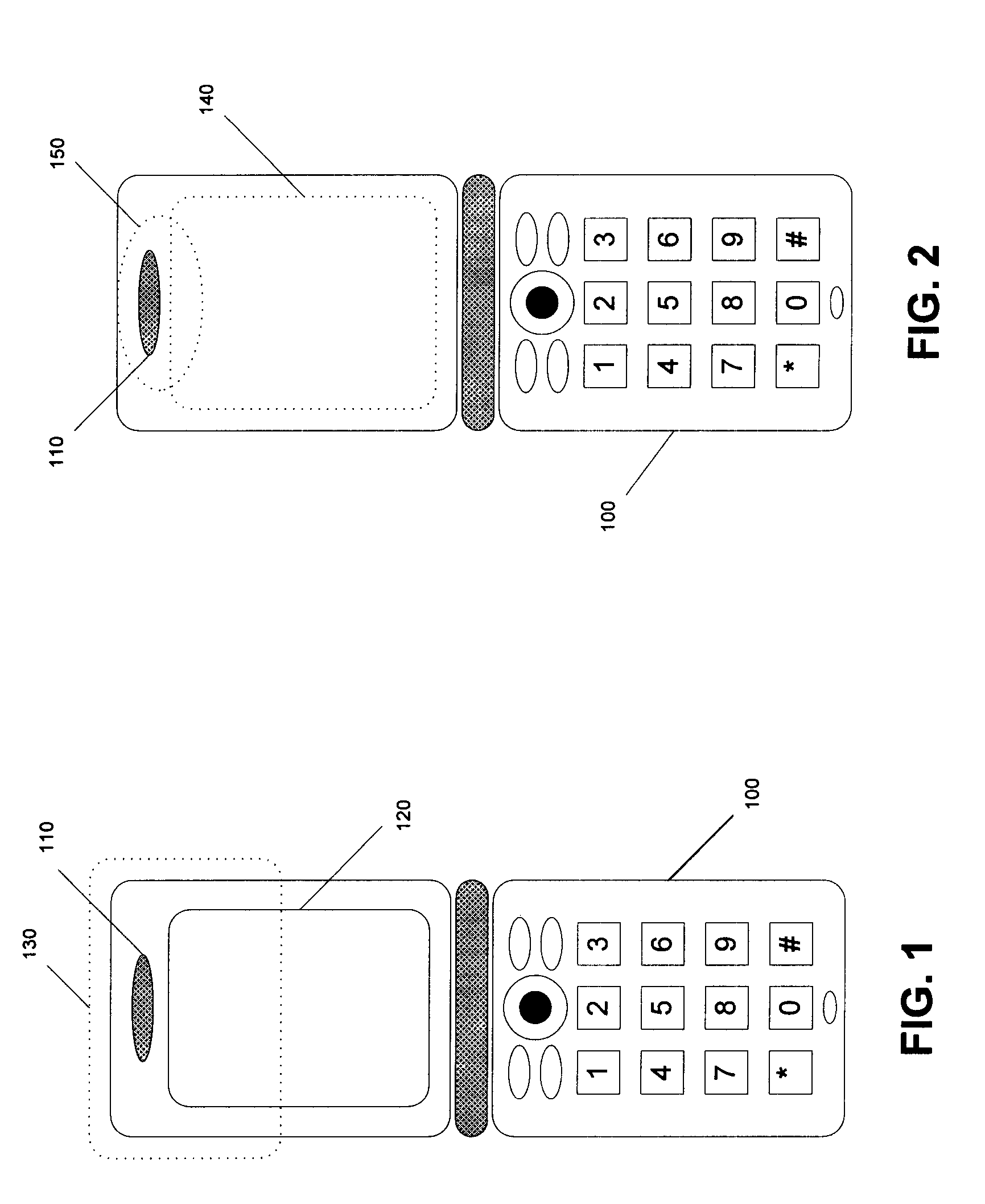

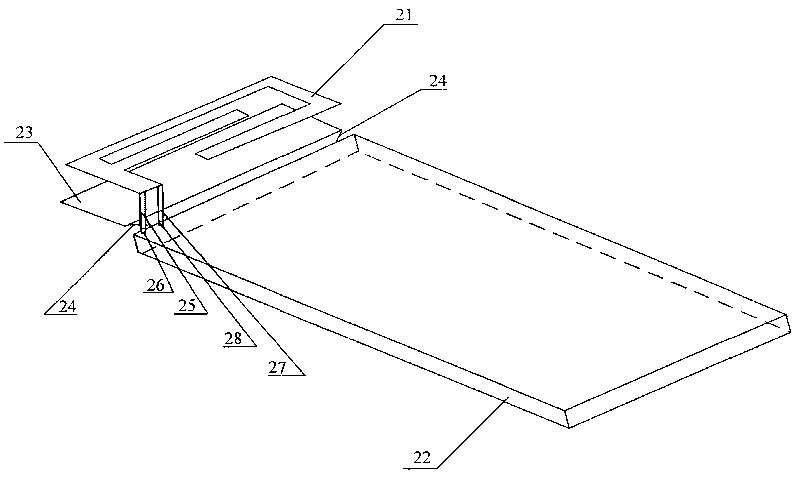

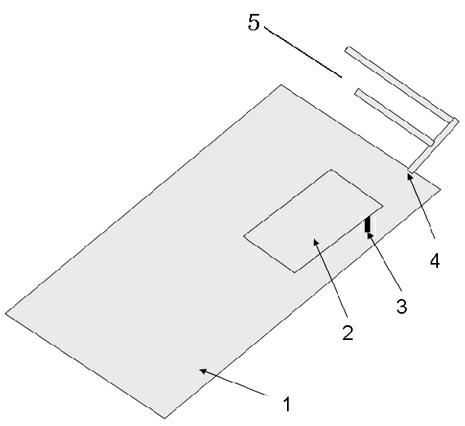

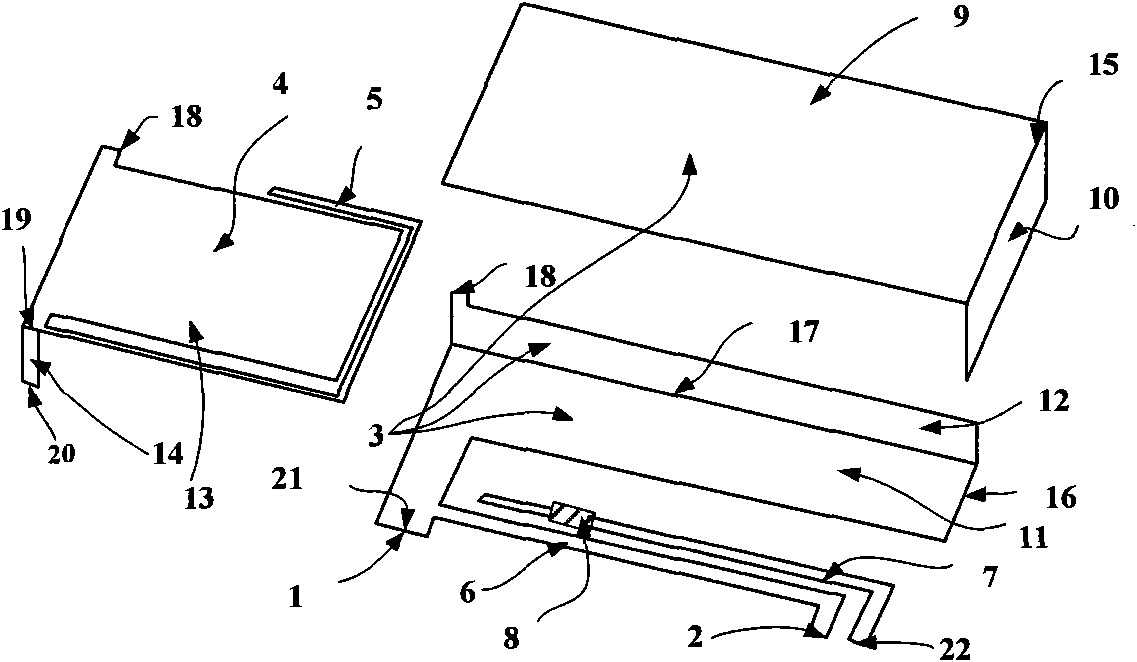

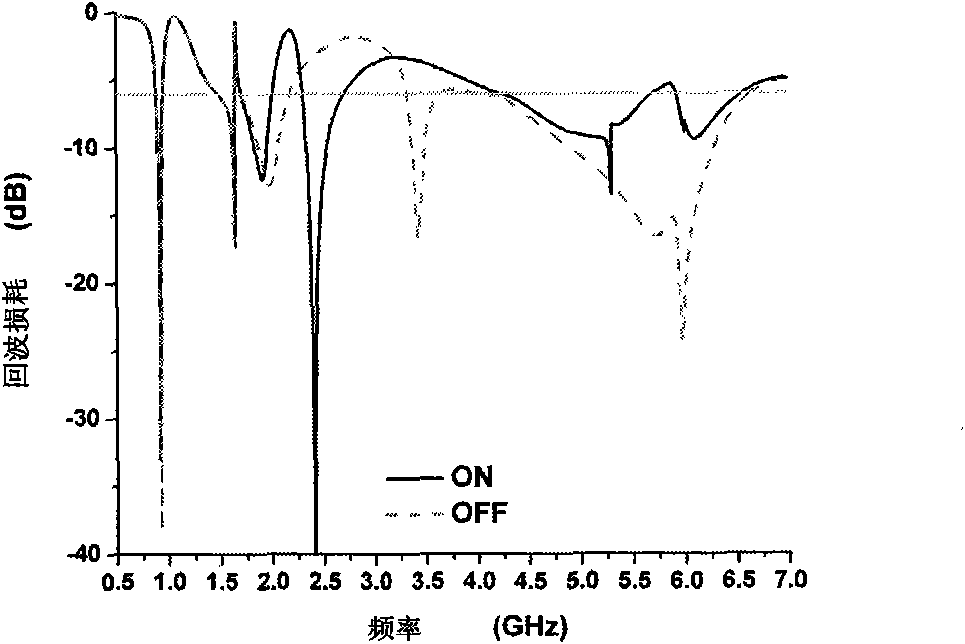

Reconfigurable mobile phone built-in antenna and implementation method thereof

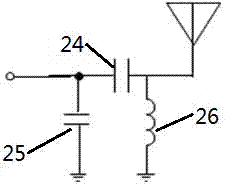

ActiveCN101719584AImprove performanceReduce SAR valueSimultaneous aerial operationsAntenna supports/mountingsElectronic switchEngineering

The invention provides a reconfigurable mobile phone built-in antenna and an implementation method thereof. The reconfigurable mobile phone built-in antenna comprises an antenna main structure, an additional ground area, a ground area printed on one surface of a printed board, an electronic switch and an antenna feeding point and a grounding point printed on the other surface of the printed board, wherein the antenna main structure comprises a wiring structure of the antenna, a feeding spring piece which is in contact with the antenna feeding point and a grounding spring piece which is in contact with the grounding point, and the additional ground area is positioned under the wiring structure; the electronic switch is used for disconnecting the additional ground area with the ground area on one surface of the printed board when the antenna works at low-frequency frequency band and connecting the additional ground area with the ground area on one surface of the printed board when the antenna works at high-frequency frequency band. The reconfigurable mobile phone built-in antenna can lead the mobile phone antenna to acquire the optimal wireless performance in finite space.

Owner:HUAWEI DEVICE CO LTD

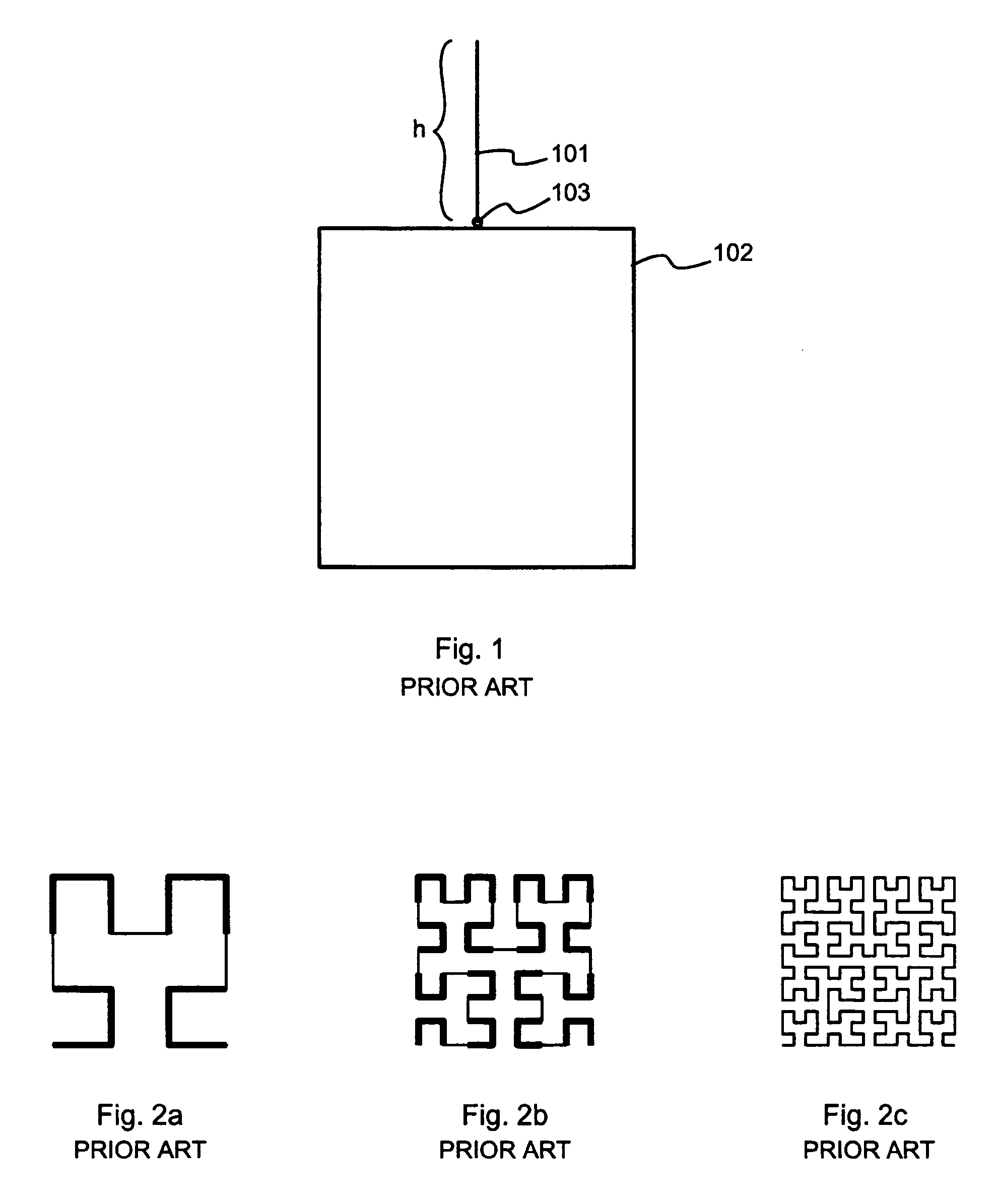

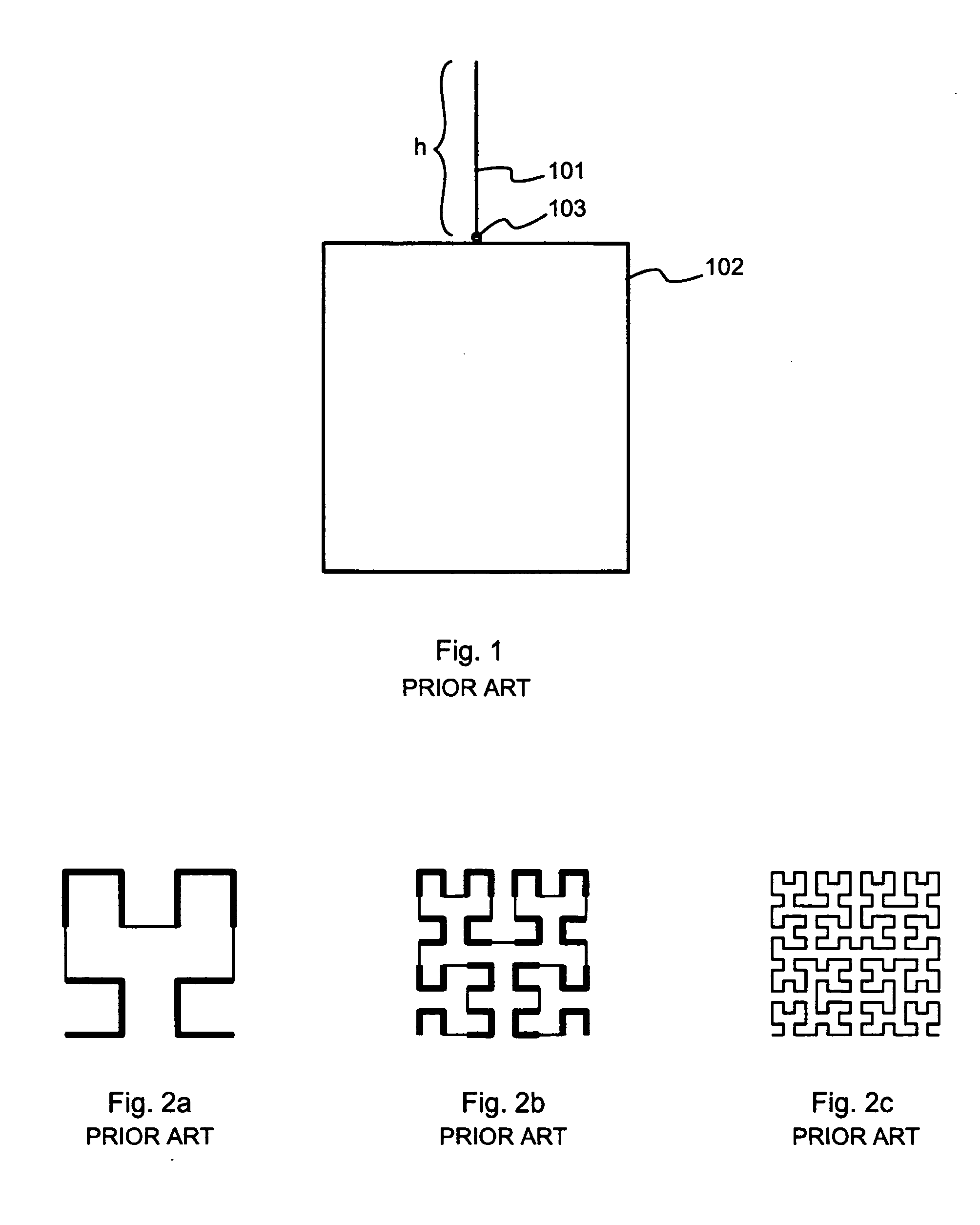

Modified space-filling handset antenna for radio communication

InactiveUS7026997B2Simultaneous aerial operationsAntenna supports/mountingsCurrent distributionAntenna element

Owner:NOKIA CORP

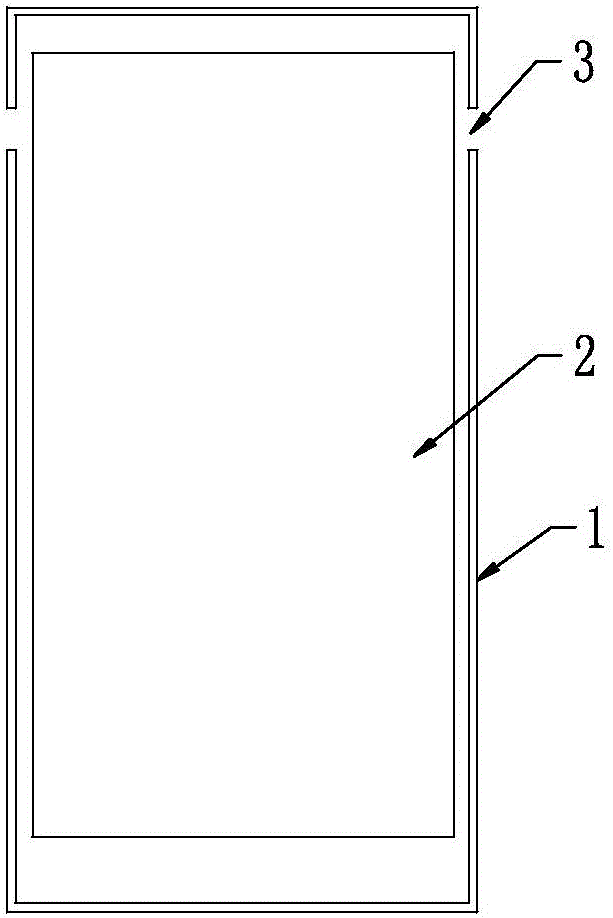

Non-breakpoint metal frame based mobile phone antenna

InactiveCN105932402AIntegrity guaranteedReduce processing difficultySimultaneous aerial operationsAntenna supports/mountingsFrame basedAntenna feed

The invention relates to a non-breakpoint metal frame based mobile phone antenna. The mobile phone antenna structure comprises a completely-closed metal frame and a main board arranged in the metal frame, wherein a main antenna clearance region, a sub antenna clearance region and a three-into-one antenna clearance region are formed between the closed metal frame and the main board; and a main antenna feeding point, a sub antenna feeding point and a three-into-one antenna feeding point are arranged in the corresponding main antenna clearance region, the sub antenna clearance region and the three-into-one antenna clearance region respectively; the feeding points are electrically connected with the metal frame through connecting points respectively; and the three side edges of the closed metal frame are electrically connected to the corresponding side edges of the main board through grounding points. According to the mobile phone antenna, the metal frame is adopted for radiation, so that the complexity of the mobile phone structure is effectively reduced, the cost of the mobile phone is lowered, and the performance of the antenna is improved; and in addition, the mobile phone antenna is simple and attractive in structure and excellent in performance, and can be widely applied to the mobile phones with the completely-closed metal fames, as well as can satisfy the high-quality demands of the mobile phones.

Owner:SHANGHAI TRANSSION CO LTD

Antenna module for mobile phone

InactiveUS20060017626A1Increase costReduce the required powerAntenna supports/mountingsAntenna equipments with additional functionsA d converterElectronic component

An antenna module for use with a mobile telecommunication device such as a mobile phone. The antenna module includes an antenna element and, preferably, an RF (radio frequency) chain having receive circuitry and perhaps an analog-to-digital converter or other electrical components. Transmit circuitry may be present as well. The antenna module has a housing, in one or more parts, for supporting these components, and a jack through which power and data links can be formed. The jack may provide a means for adjusting the antenna so that its orientation relative to the mobile phone antenna may be altered.

Owner:NOKIA CORP

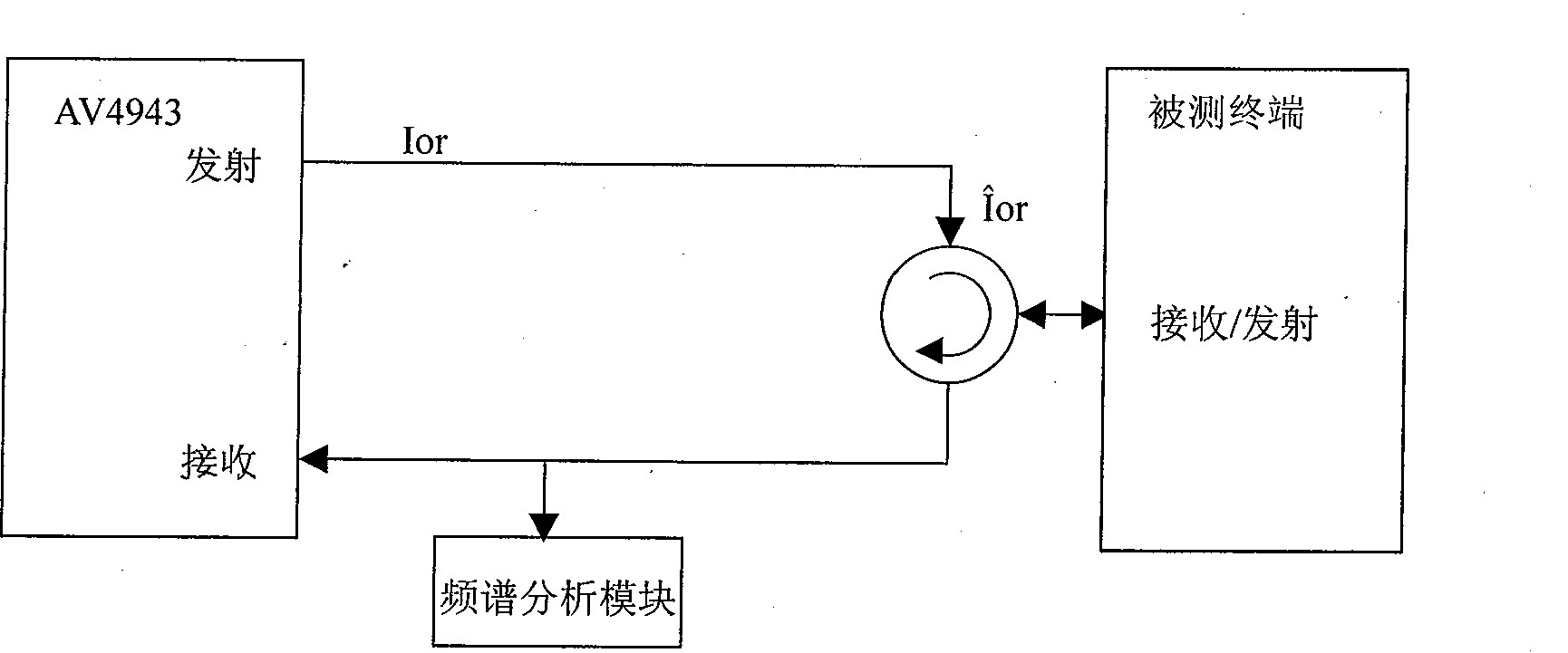

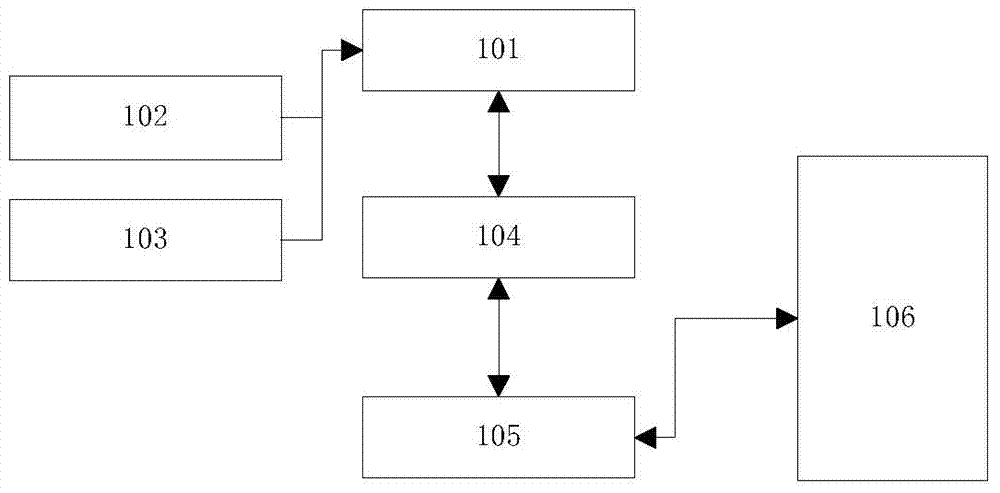

Automatic test method for mobile phone antenna radiation performance

InactiveCN101459477AWon't disconnectImprove test efficiencyTransmitters monitoringReceivers monitoringTest efficiencyAutomatic test equipment

The invention belongs to the technical field of 3G mobile phones, in particular to a test method for mobile phone antenna radiation performances, which comprises firstly testing the total radiation power of a mobile phone, calculating the gain of a mobile phone antenna according to the total radiation power, setting the gain value of the mobile phone antenna as the loss value of up link and down link of a terminal all-purpose tester, setting a reference power value as a critical reference power value of the omnidirectional sensitivity measurement, wherein the set reference power value will be extremely close to the critical reference power value therefore, thereby guaranteeing the chain path in the test process connecting. The test method can be used to find the reference power value meeting the requirement only by testing twice, simultaneously, and can test the total radiation power of the mobile phone antenna, thereby increasing the test efficiency and the test stability.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

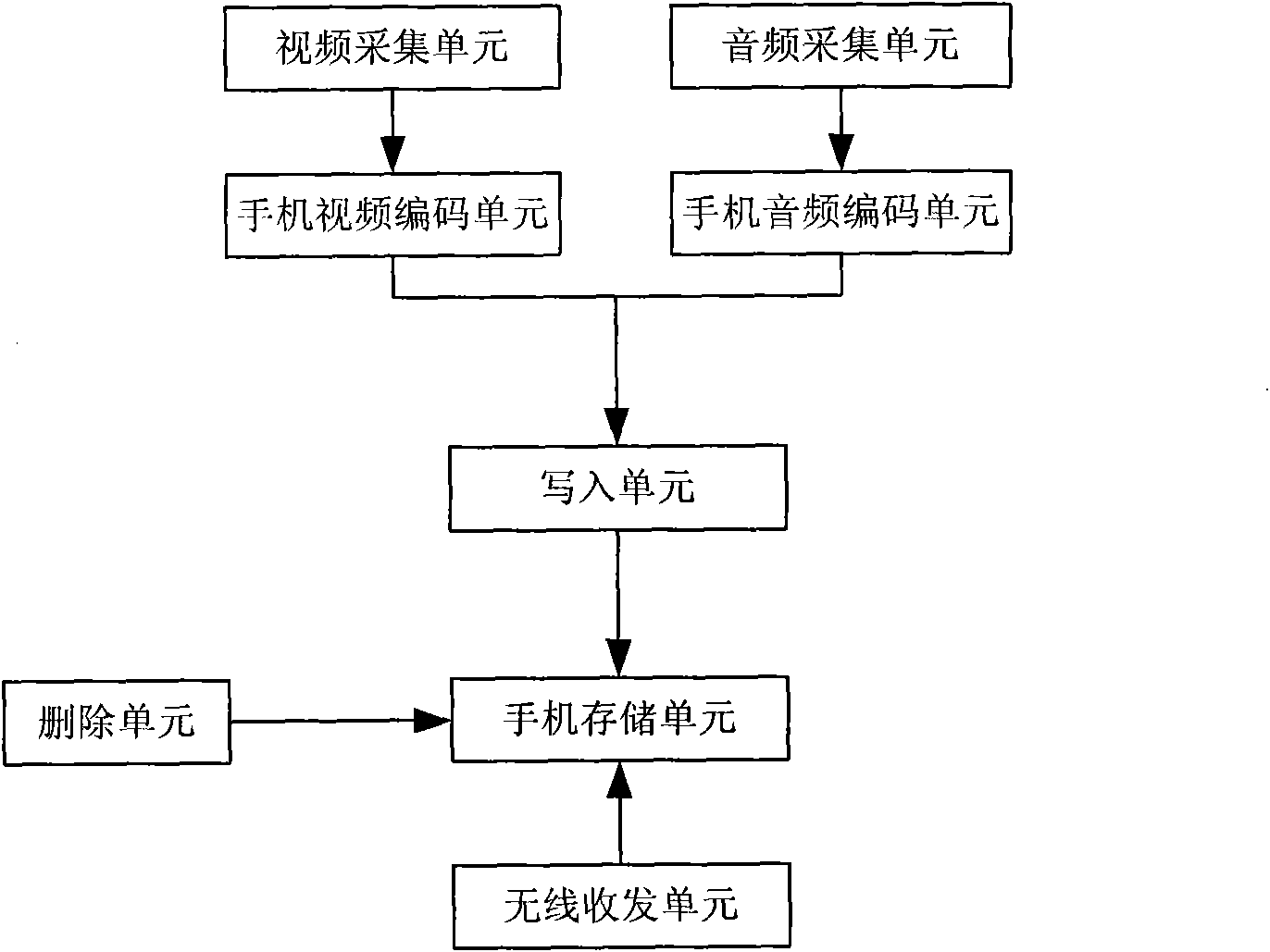

Video live broadcast system facing to set-top box and PC of mobile phone and working method thereof

ActiveCN101945096AIncrease selling pointMeet needsColor television detailsTelevision systemsVideo transmissionThird generation

The invention discloses a video live broadcast system facing to a set-top box and a PC of a mobile phone and a working method thereof and relates to the technical field of network multimedia television, the field of video transmission and the field of mobile phone communication, the system comprises a mobile phone as a video source of the video live broadcast system and a video server which is connected with a mobile phone antenna, wherein the mobile phone comprises a video acquisition unit, a mobile phone video encoding unit, an audio acquisition unit, an audio encoding unit, a writing unit,a mobile phone storage unit, an antenna transceiving unit and a deleting unit; and the video server comprises a network communication unit, a video decoding unit, an audio decoding unit, a data buffer unit, a server storage unit, an audio and video synchronization unit, a live broadcast command processing unit, a server video encoding unit, a server audio encoding unit, a live broadcast data transmitting unit and the like. The system and the working method thereof can realize the function of acquiring a video by applying the mobile phone and carrying out live broadcast facing to a variety of types of terminals, in particular to the set-top boxes through 3G wireless network, WIFI or GPRS wireless communication network.

Owner:SHANGHAI BROADBAND TECH

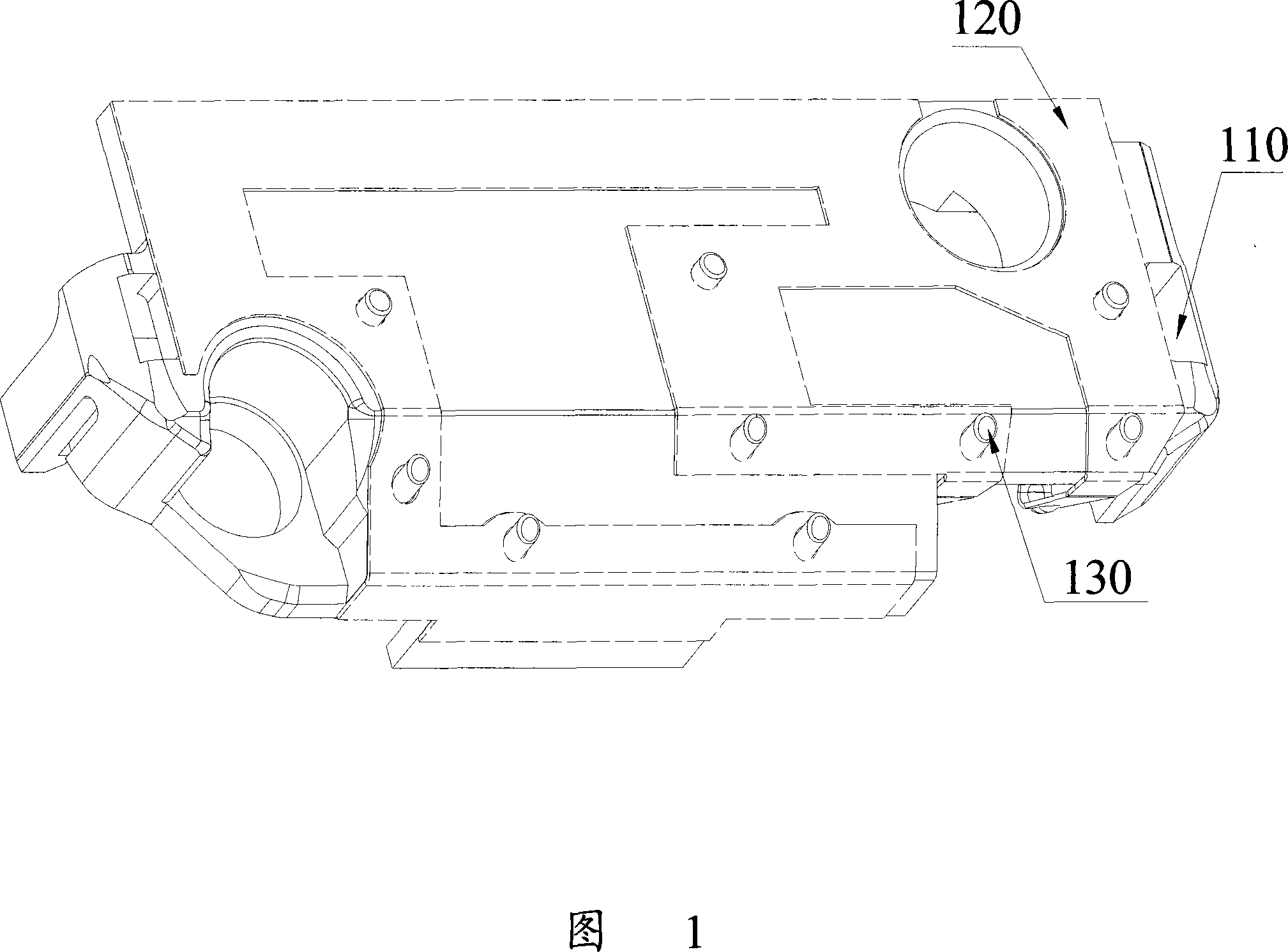

A built-in mobile phone antenna and its making method

InactiveCN101145633AIncrease production capacityReduce manufacturing costAntenna supports/mountingsRadiating elements structural formsAgricultural engineeringCoating

The invention discloses a built-in mobile phone antenna, which comprises a bracket made from non-electroplated material, a radiation fin part made from electroplated material and a coating layer of the radiation fin part. Meanwhile, the invention further discloses a manufacturing method of the built-in mobile phone antenna. The built-in mobile phone antenna and the manufacturing method thereof reduce the production cost, improve the production efficiency, and remarkably improve the production capacity of the mobile phone antenna.

Owner:ZTE CORP

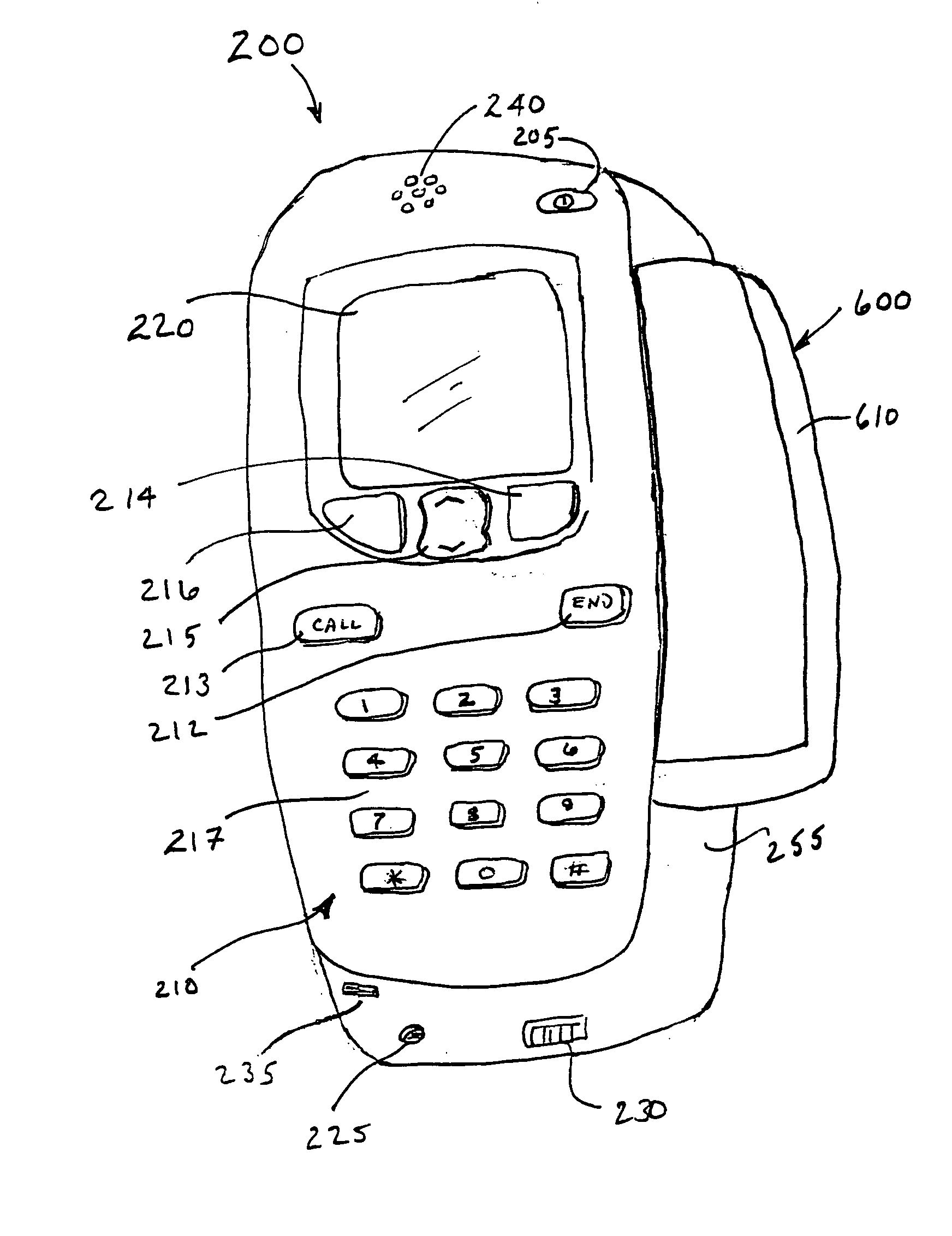

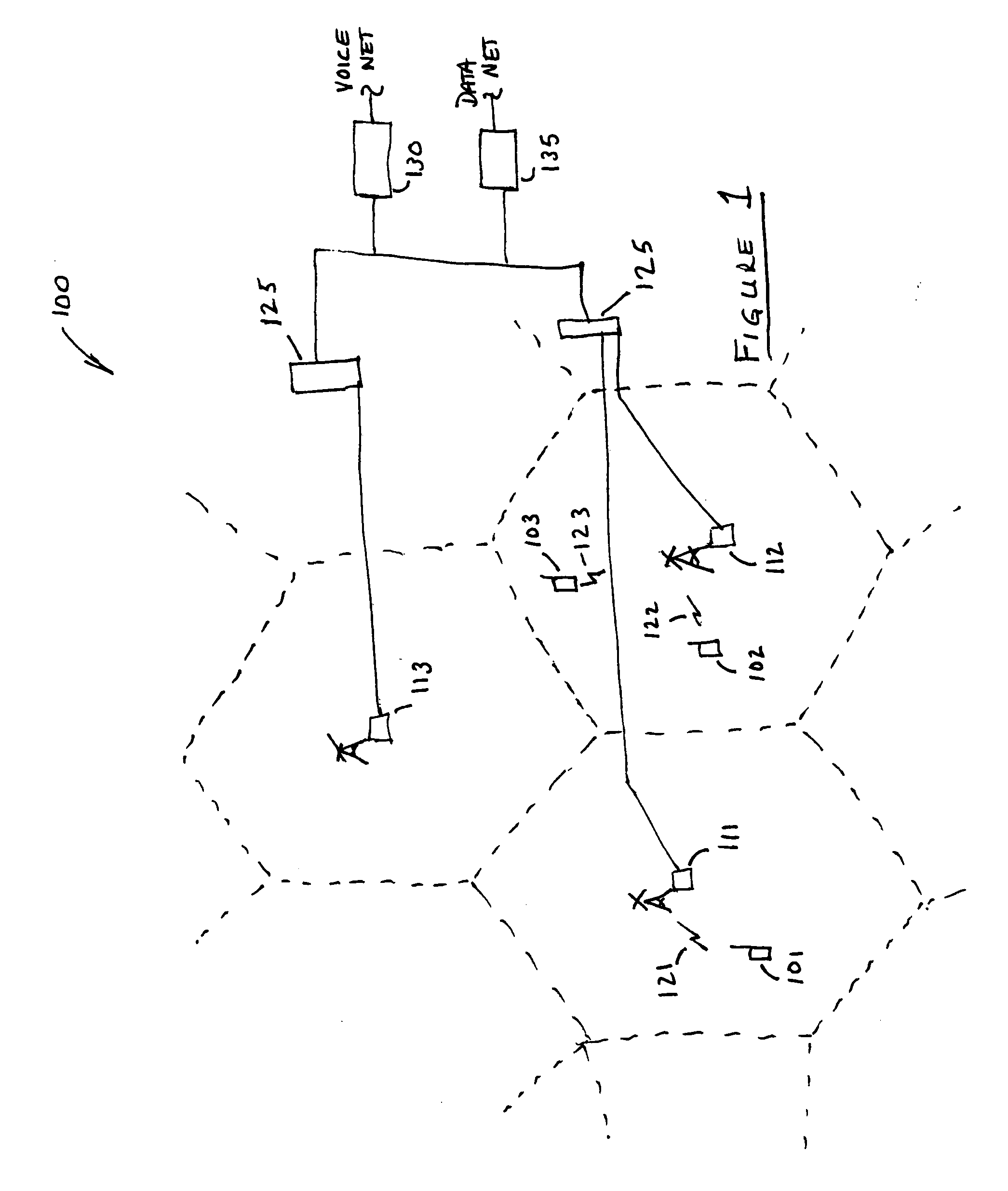

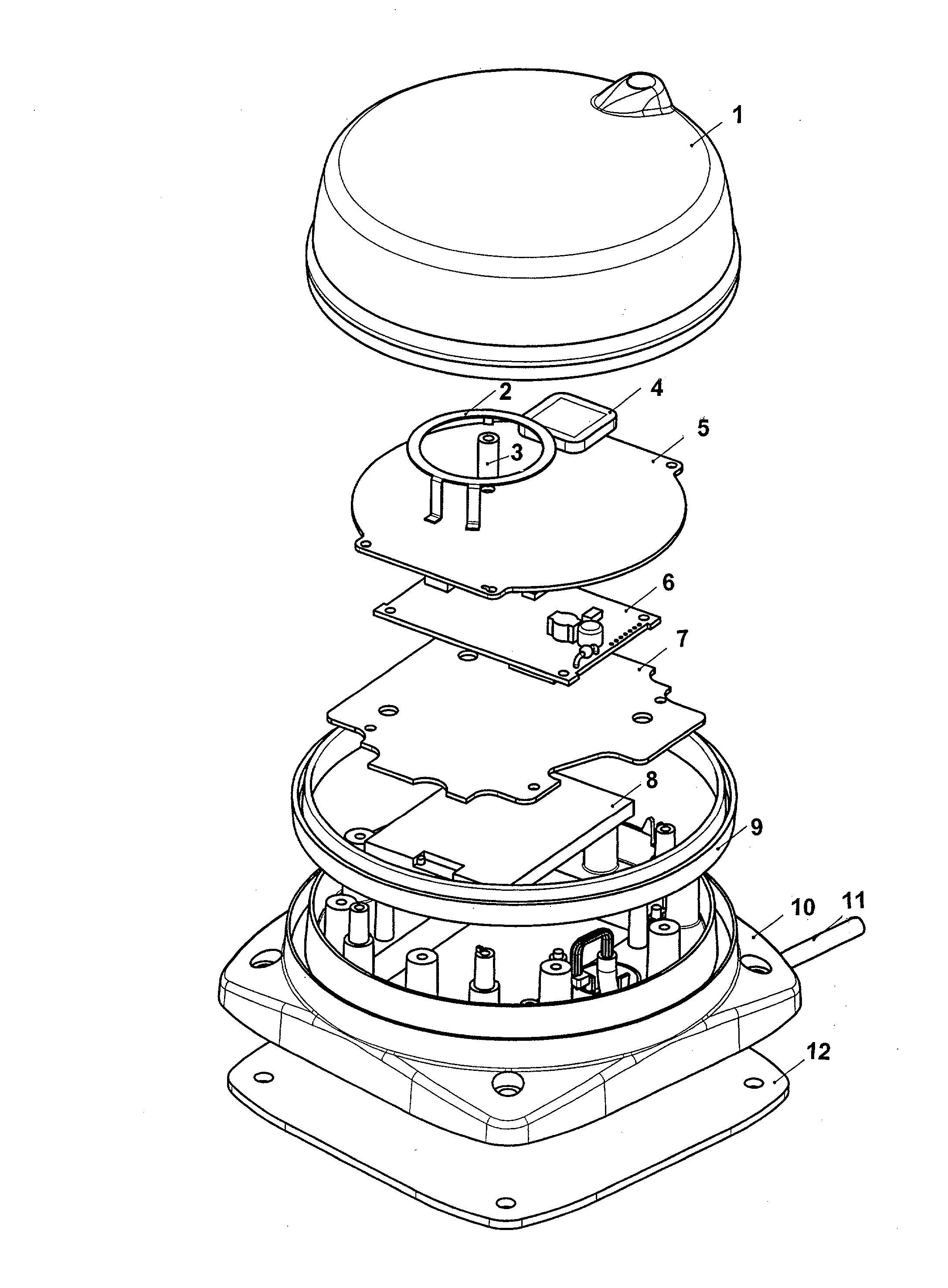

Vehicle activity tracking

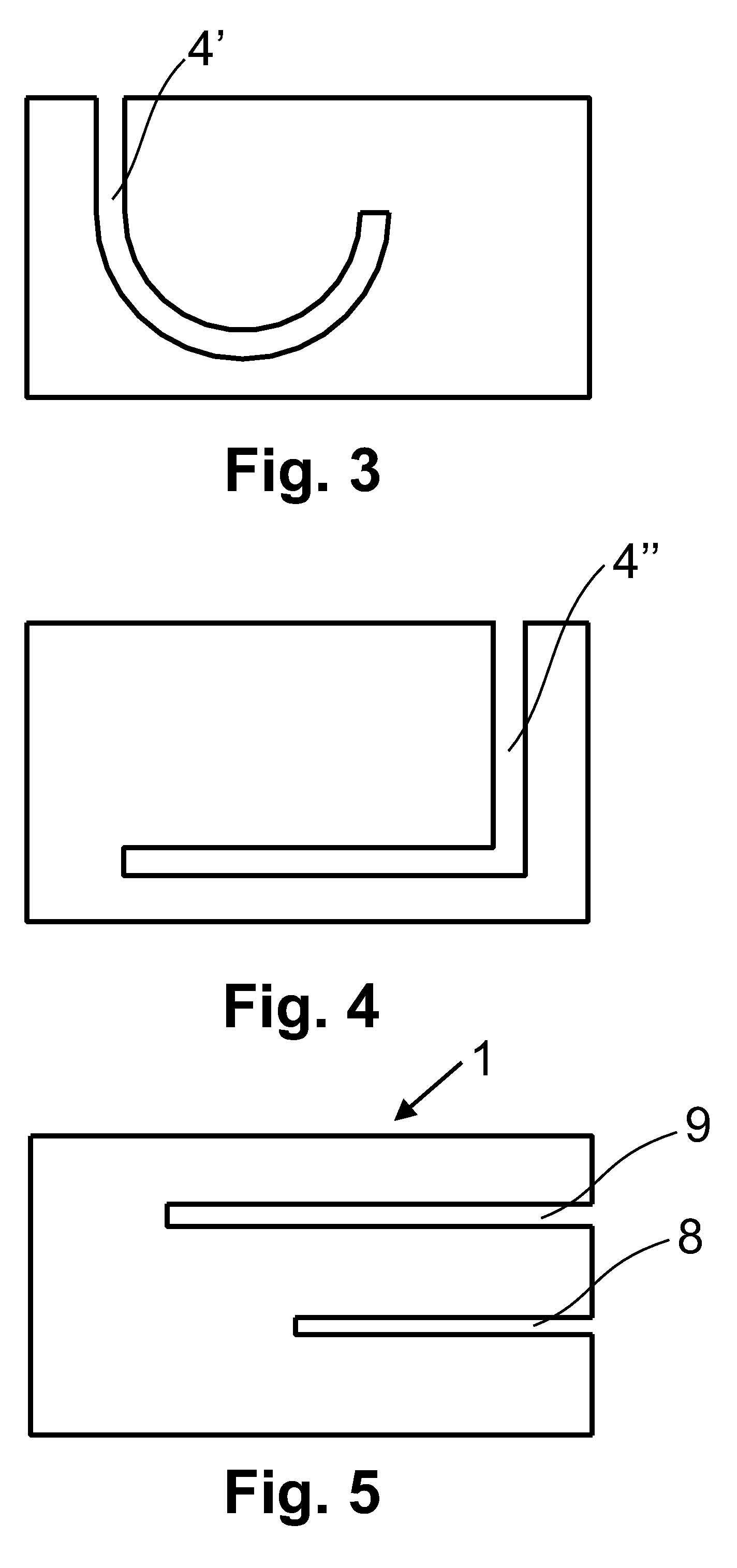

InactiveUS20020156576A1Physical and radio interferenceInstruments for road network navigationAntenna arraysModem deviceGps receiver

A unitary vehicle tracking device having a GPS receiver, a radio transmitter, which preferably is a mobile phone modem integrated within a single waterproof housing suitable for mounting on the top exterior of the vehicle. The housing is transparent to radio signals and the GPS and mobile phone antennas are mounted on a common board above the other components. Preferably the mobile phone antenna is of the halo type and is mounted above and in registration with the GPS antenna so as not to interfere with the field of view of the GPS antenna.

Owner:TELETRAC NAVMAN US LTD

Method for manufacturing shell of electronic product

ActiveCN103702529ASimilar or consistent flatnessAvoid problems that affect appearanceElectrical apparatus casings/cabinets/drawersManufacturing cost reductionFile design

The invention discloses a method for manufacturing a shell of an electronic product. The method comprises the following steps of A, generating of 3D (Three-Dimensional) drawing file design of an injection mold: reserving an antenna groove by the injection mold when a mold opening 3D drawing file design is generated; B, injection mold processing: carrying out shape processing on the antenna groove when a mold core is processed so as to ensure the integrated forming of an antenna and the shell of the product when the antenna is subsequently processed, and enabling the shell of the product not to be subjected to poor appearance when surface processing is carried out; C, injection molding machine molding: completing the injection molding of the product by utilizing the injection mold, which is already designed and processed in a mold, of the antenna groove; D, mobile phone antenna processing: directly processing a mobile phone antenna in the antenna groove on the surface or the inner wall of a mobile phone plastic piece; E, mobile phone surface processing and coating. According to the method disclosed by the invention, the bottlenecks of a surface decoration technology that the surface of the product is rugged when the mobile phone antenna is assembled or printed on the surface of the product, and the surface of the product needs to be sanded when the mobile phone antenna is produced can be broken through, highly-textured appearance on the surface of the product can be generated, the manufacturing cost can be reduced, and the yield of the product can be increased.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO

Broadband 5G MIMO mobile phone antenna based on orthogonal mode pair

ActiveCN110061349AImprove isolationSmall headroomSimultaneous aerial operationsAntenna supports/mountingsCouplingMimo antenna

Disclosed is a broadband 5G MIMO mobile phone antenna based on an orthogonal mode pair. The antenna comprises a metal floor, a metal frame, and one or more orthogonal antenna pairs, wherein one or more floor gaps are formed in the long edge of the metal floor; the four sides of the metal frame are closed, and an even number of frame gaps are formed in the metal frame; and each group of orthogonalantenna pairs comprises two antenna units, wherein the antenna unit comprises a central feeding branch, a first side feeding branch, a second side feeding branch, a first coupling branch and a secondcoupling branch. The two antenna units in the orthogonal antenna pair are in an orthogonal mode, so that high isolation characteristics can be realized under the integration of double antennas. In addition, the metal frame and the multi-mode cooperative work and the like are adopted for further broadening the bandwidth of the antenna units. The antenna has the advantages of being wide in broadband, compatible with the metal frame, high in isolation degree, small in clearance, integrated in a double-antenna mode and the like, and is suitable for the 5G MIMO antenna of various small mobile terminals with mobile phones as representatives.

Owner:TSINGHUA UNIV

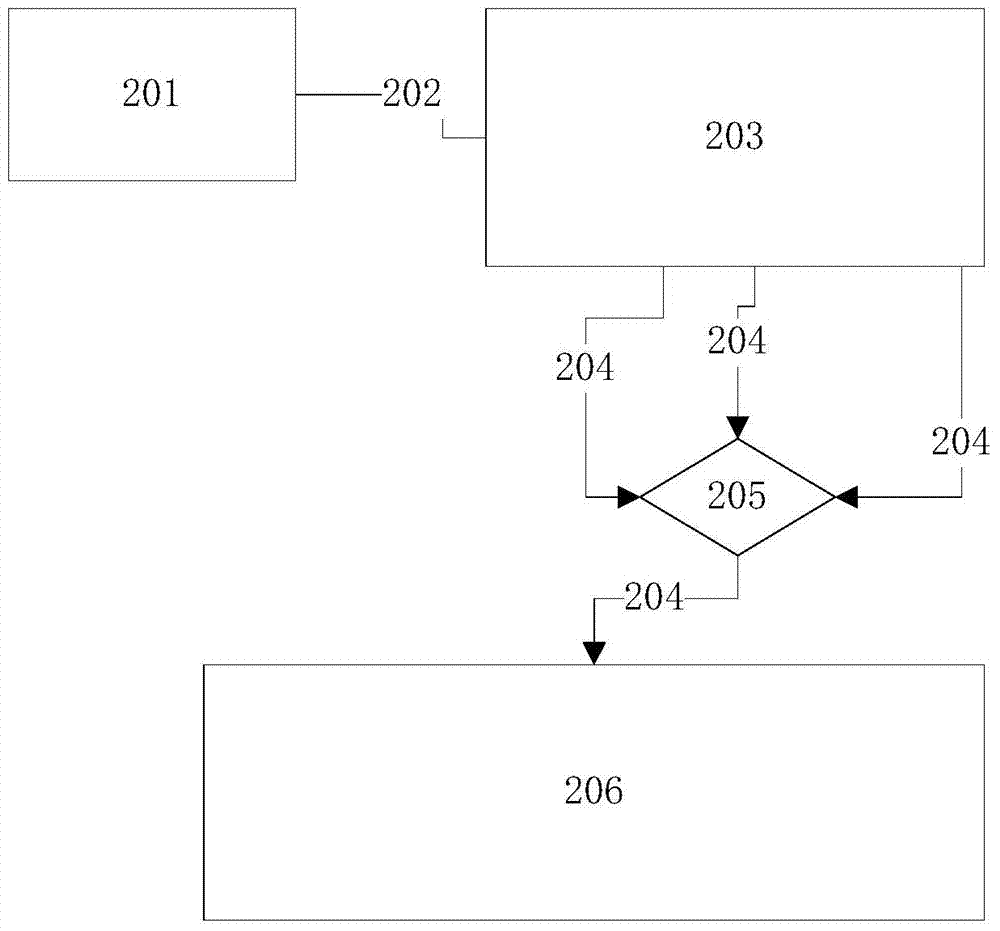

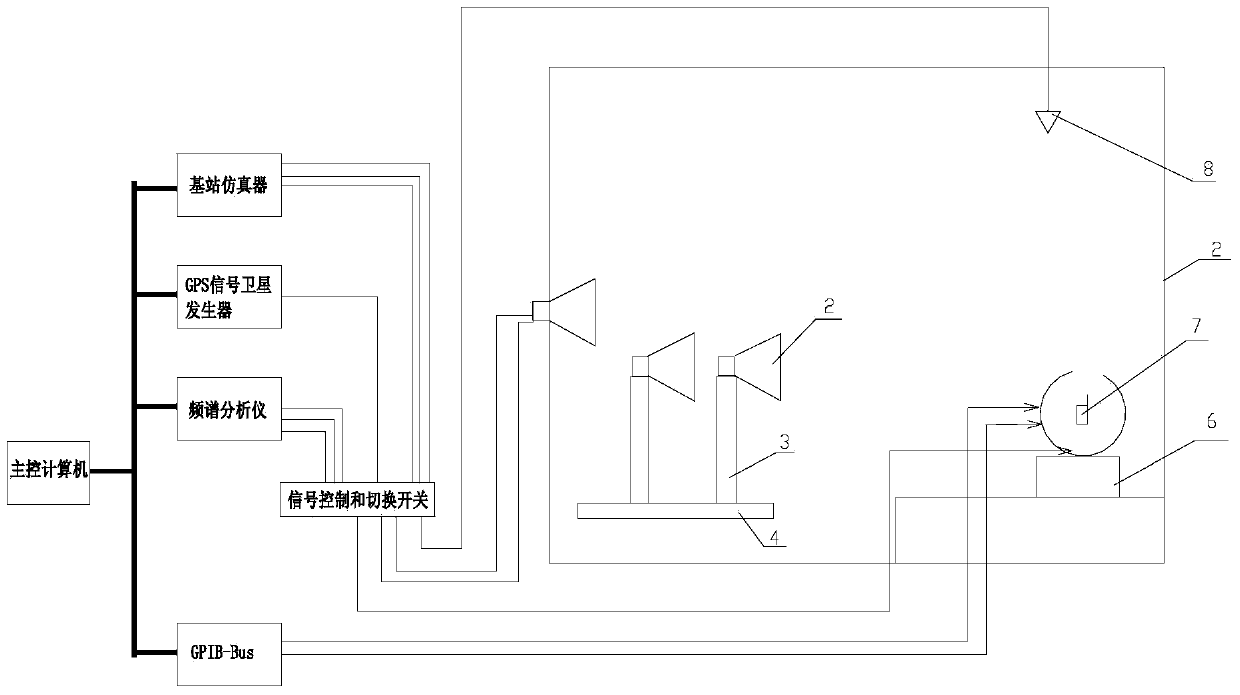

Method and system for mobile phone antenna coupling test on production line

ActiveCN104506252AImprove qualityIncrease intensificationTransmitters monitoringElectromagentic field characteristicsTest efficiencyProduction line

The invention discloses a method and a system for mobile phone antenna coupling test on a production line. The system comprises a coupling test module, an industrial personal computer, a multi-signal-source device, radio-frequency cables, a combiner and a coupling shielding box. The coupling test module comprises mobile internal test software for coupling test of a to-be-tested mobile phone in set process; the industrial personal computer is connected with the multi-signal-source device and used for configuration of parameters of the multi-signal-source device and controlling a transmission channel of the multi-signal-source device to open or close; the multi-signal-source device under control of the industrial personal computer is used for generating radio-frequency signals with multiple frequency points for mobile phone antenna coupling; the radio-frequency cable is arranged between the multi-signal-source device and the combiner and between the combiner and the coupling shielding box respectively; the coupling shielding box is used for placement of at least one mobile phone and used for broadcast type parallel coupling test of mobile phones. The method and the system for mobile phone antenna coupling test on a production line have the advantage that test efficiency and precision can be improved.

Owner:上海鑫测信息技术有限公司

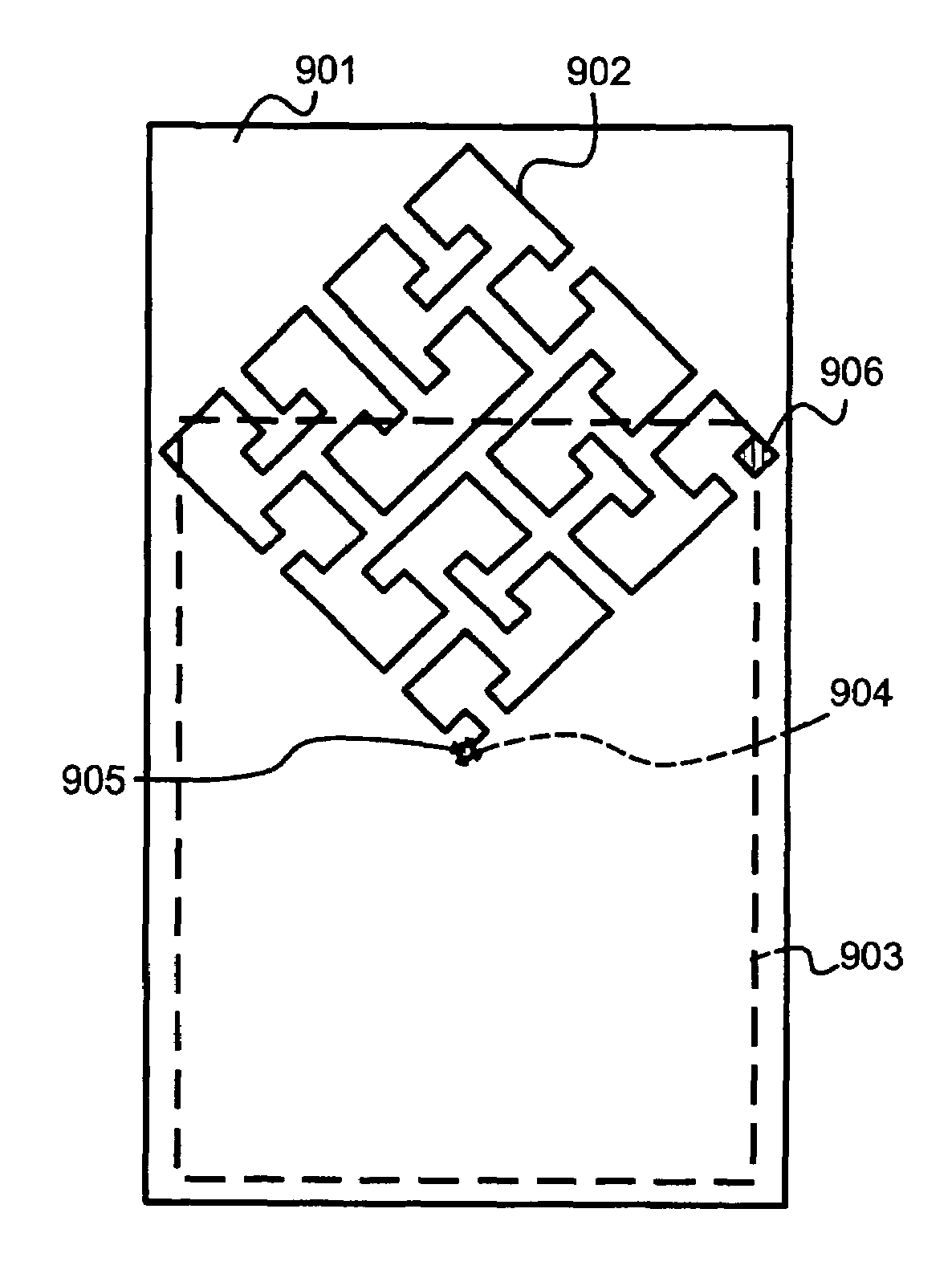

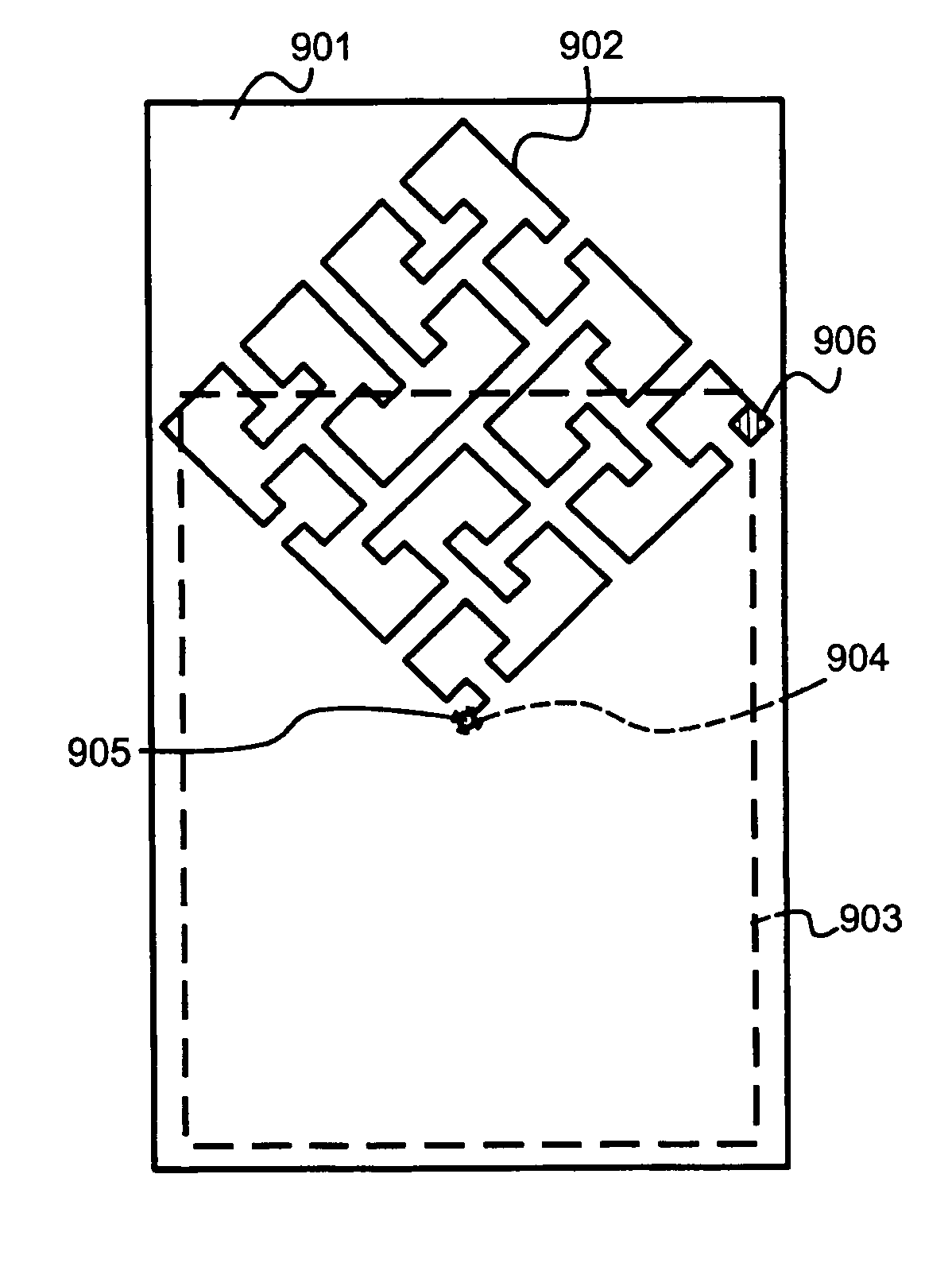

Modified space-filling handset antenna for radio communication

InactiveUS20050237238A1Simultaneous aerial operationsAntenna supports/mountingsCurrent distributionEngineering

For manufacturing an antenna there is first defined a meandering shape. A simulated current distribution is determined for a conductive line having said meandering shape. First and second segments of said meandering shape are identified, at which said simulated current distribution exhibits first and second currents respectively, so that a vector sum of said first and second currents is essentially zero. A bend containing said first and second segments is replaced with a direct connection in said meandering shape, thus producing a pruned meandering shape. The antenna will have a radiating antenna element that has a shape equal to said pruned meandering shape.

Owner:NOKIA CORP

Mobile phone antenna structure supporting long term evolution (LTE) multiple input multiple output (MIMO) technology

InactiveCN102856645AImprove Radiation PerformanceImprove isolationAntenna arraysAntenna supports/mountingsMimo antennaLow frequency band

The invention relates to a mobile phone antenna structure supporting the LTE MIMO technology. The structure comprises a metal ground, a main antenna and a diversity antenna. The metal ground comprises a first side and a second side which are a pair of opposite sides. The main antenna is arranged on the first side of the metal ground, and the diversity antenna is arranged on the second side of the metal ground. The diversity antenna comprises a diversity antenna feeder line, a diversity antenna feeder port and a plurality of diversity antenna bending branch wires, wherein the plurality of the diversity antenna bending branch wires are connected with the metal ground respectively. One end of the diversity antenna feeder line is connected with the diversity antenna feeder port, and the other end is connected with one of the plurality of the diversity antenna bending branch wires. According to the mobile phone antenna structure supporting the LTE MIMO technology, the antenna is a high-performance LTE MIMO antenna capable of covering low frequency bands and suitable for being placed and mounted on mobile terminals of mobile phones and the like so as to solve the technical problems that good segregation and low relevance cannot be achieved simultaneously in a plurality of wide frequency bands in the prior art.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

Vehicle activity tracking

A unitary vehicle tracking device having a GPS receiver, a radio transmitter, which preferably is a mobile phone modem integrated within a single waterproof housing suitable for mounting on the top exterior of the vehicle. The housing is transparent to radio signals and the GPS and mobile phone antennas are mounted on a common board above the other components. Preferably the mobile phone antenna is of the halo type and is mounted above and in registration with the GPS antenna so as not to interfere with the field of view of the GPS antenna.

Owner:TELETRAC NAVMAN US LTD

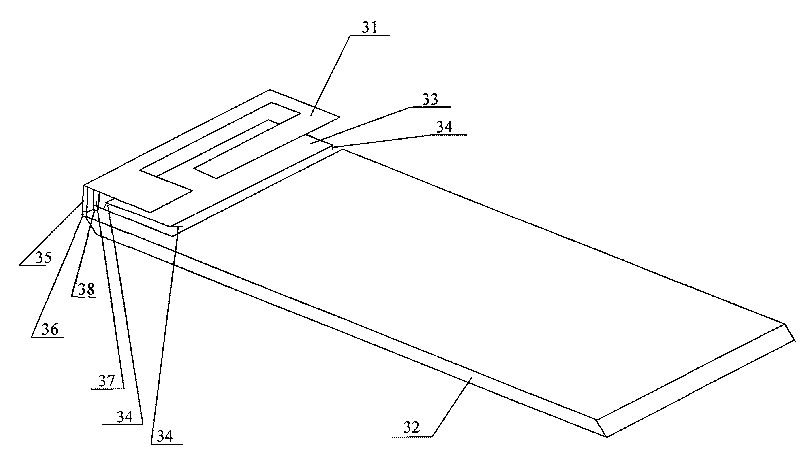

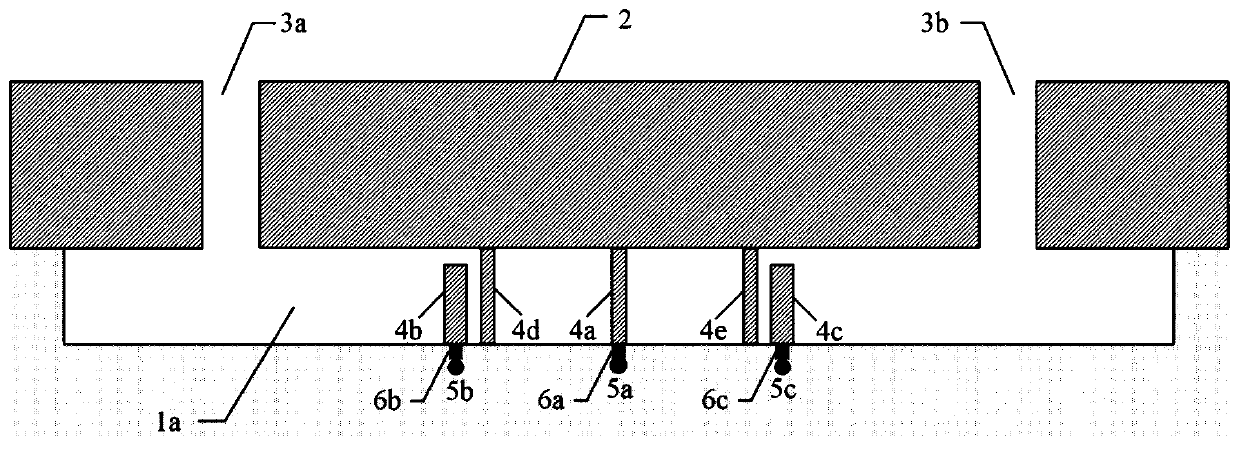

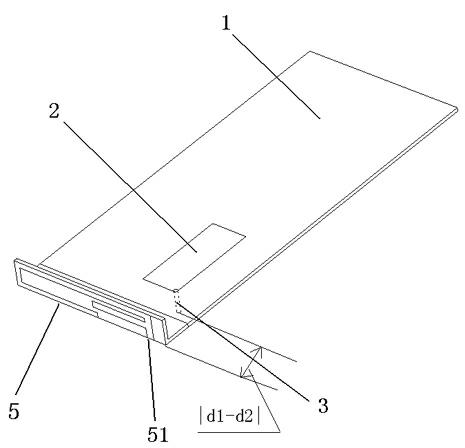

Communication terminal capable of effectively reducing HAC/SAR of antenna

InactiveCN102098070AReduce the valueAntenna supports/mountingsTransmissionElectrical conductorResonance

The invention relates to a communication terminal capable of effectively reducing the hearing aid compatibility / specific absorption rate (HAC / SAR) of an antenna. The communication terminal comprises a printed circuit board (PCB) mainboard, an antenna bracket which is arranged on the PCB mainboard, and an antenna which is arranged on the antenna bracket, and also comprises at least one metal conductor piece; the metal conductor piece generates at least one resonance frequency point, and the resonance frequency point is positioned in an operating frequency range which can improve the HAC / SAR; a gap exists between the metal conductor piece and the PCB mainboard; the metal conductor piece is connected with the PCB mainboard through a connecting piece and then earthed; the metal conductor piece can be arranged at a position near an antenna feed point and also can be arranged at an adverse position near the antenna feed point; the metal conductor piece can be transversely arranged and also can be vertically arranged relative to the PCB mainboard; and the metal conductor piece and a mobile phone antenna are arranged on the same side of the antenna feed point. By arranging the metal conductor piece, current is concentrated on the metal conductor piece, so that the current on the PCB mainboard is weakened, the aim of reducing the HAC is fulfilled; and similarly, a value of the SAR also can be reduced.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

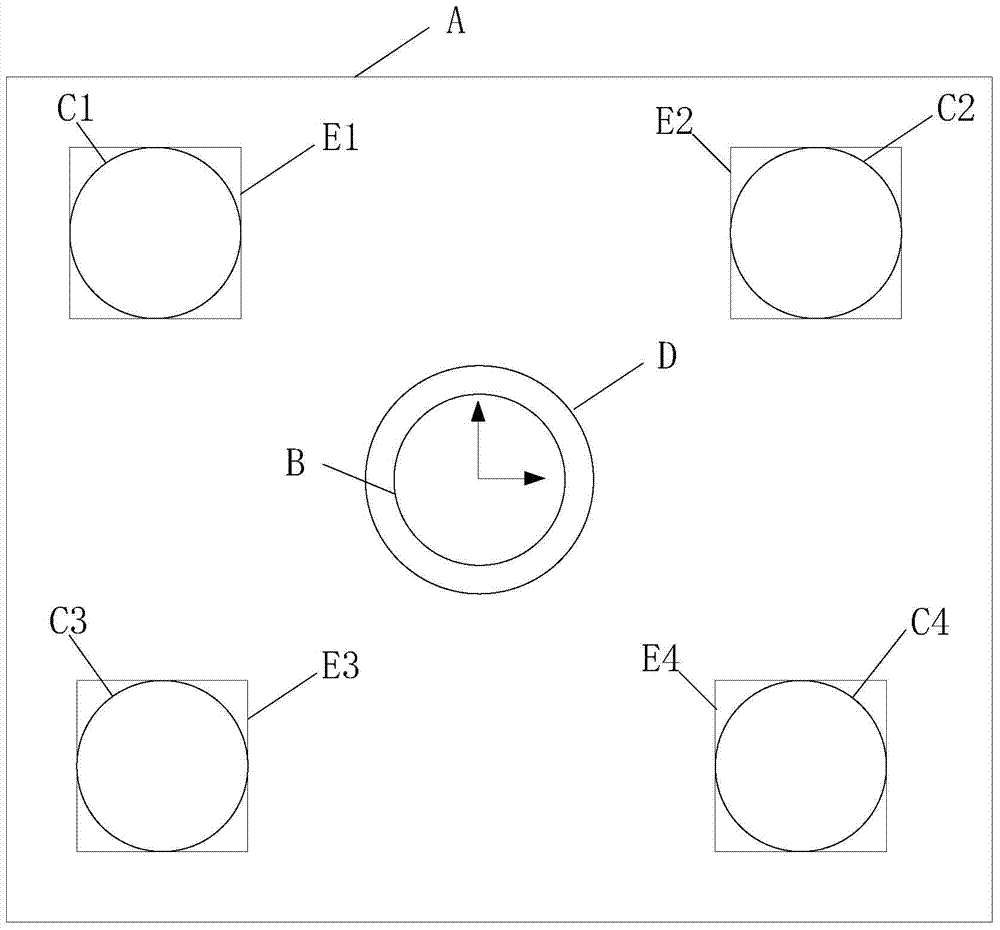

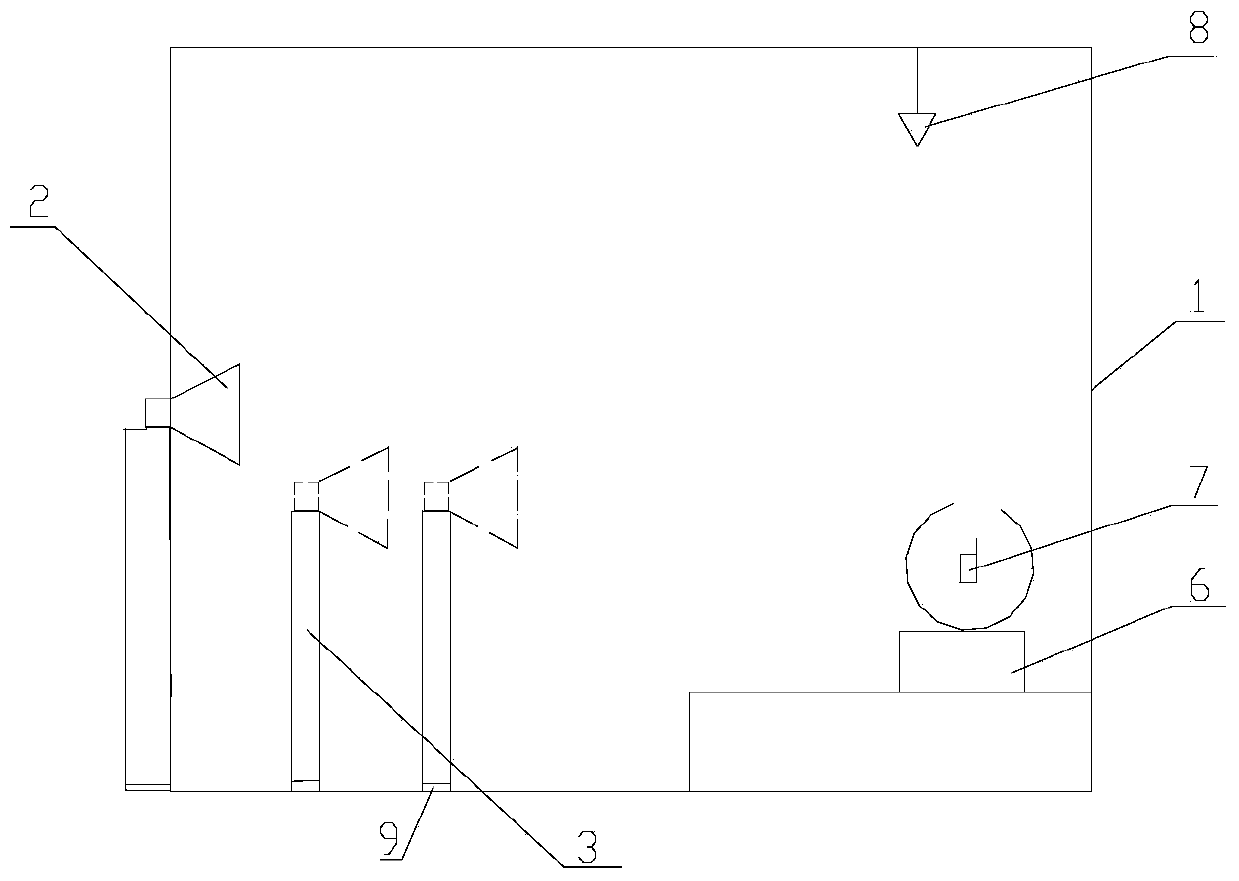

Measuring distance adjustable OTA (over-the-air) test darkroom

InactiveCN104215855AOvercome the defect of fixed positionTest coherenceElectrical testingMeasurement instrument housingCommunications systemTest fixture

The invention relates to a measuring distance adjustable OTA (over-the-air) test darkroom and belongs to the technical field of mobile phone antenna OTA, namely over-the-air transmission test devices. The test darkroom comprises a test darkroom body as well as a measuring turntable and a darkroom communication antenna arranged in the test darkroom body. The test darkroom is characterized in that position-changeable measuring antennas are arranged in the test darkroom body, and each measuring antenna is arranged on one measuring antenna support; each measuring antenna support comprises a supporting foot, a supporting rod and an antenna fixing device; each supporting foot is located at the lower end of each supporting rod, and each antenna fixing device is arranged on the corresponding supporting rod. The defect that the position, corresponding to the measuring antennas, of a measuring turntable in an OTA test darkroom in the prior art is fixed and unchanged is overcome, positional changing of the measuring antennas in the test darkroom is realized, the most appropriate measuring distance is provided for each operating frequency and each communication system so as to ensure smoothness in testing, and most stable and reliable testing is provided.

Owner:SHENZHEN SINOPOW COMM TECH

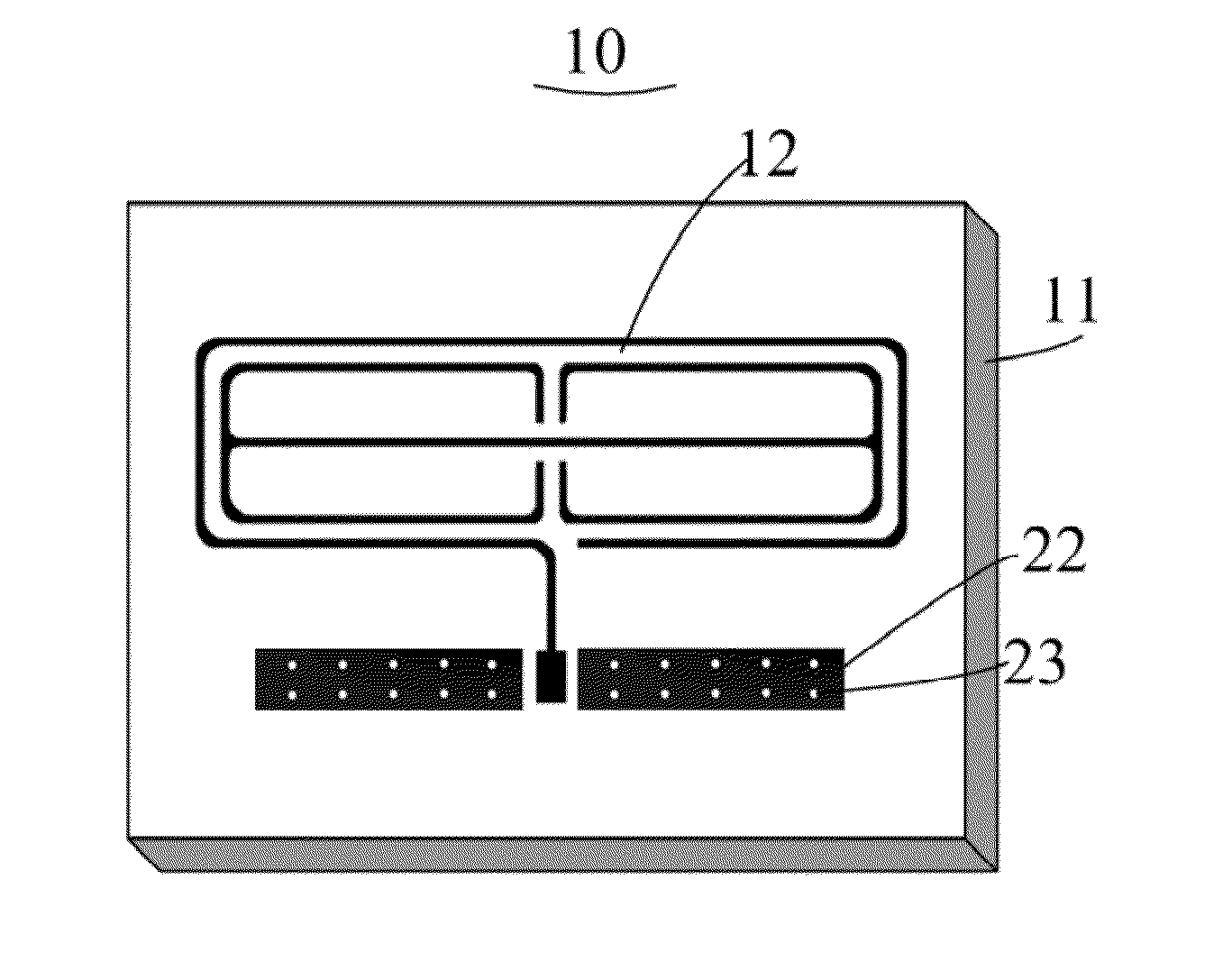

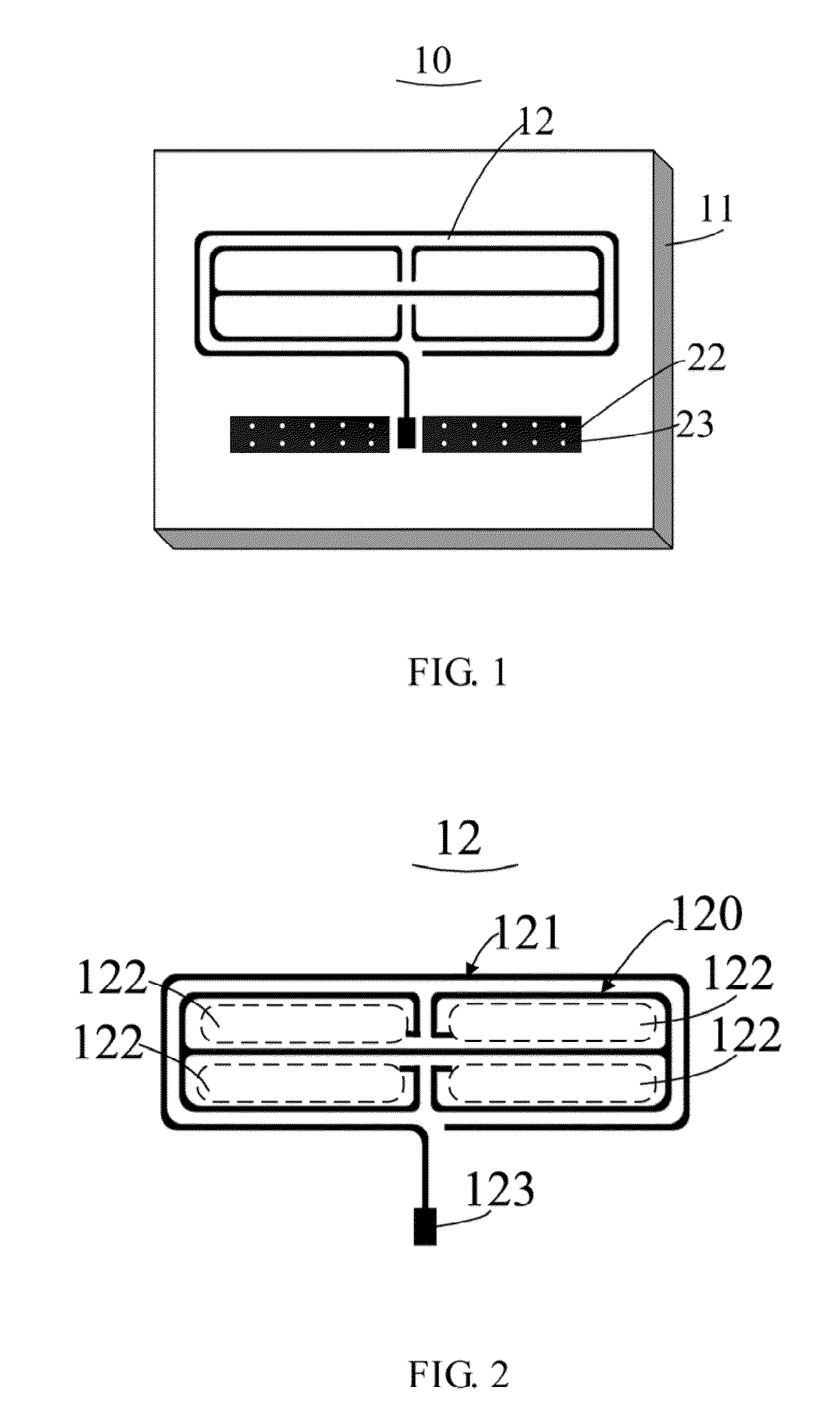

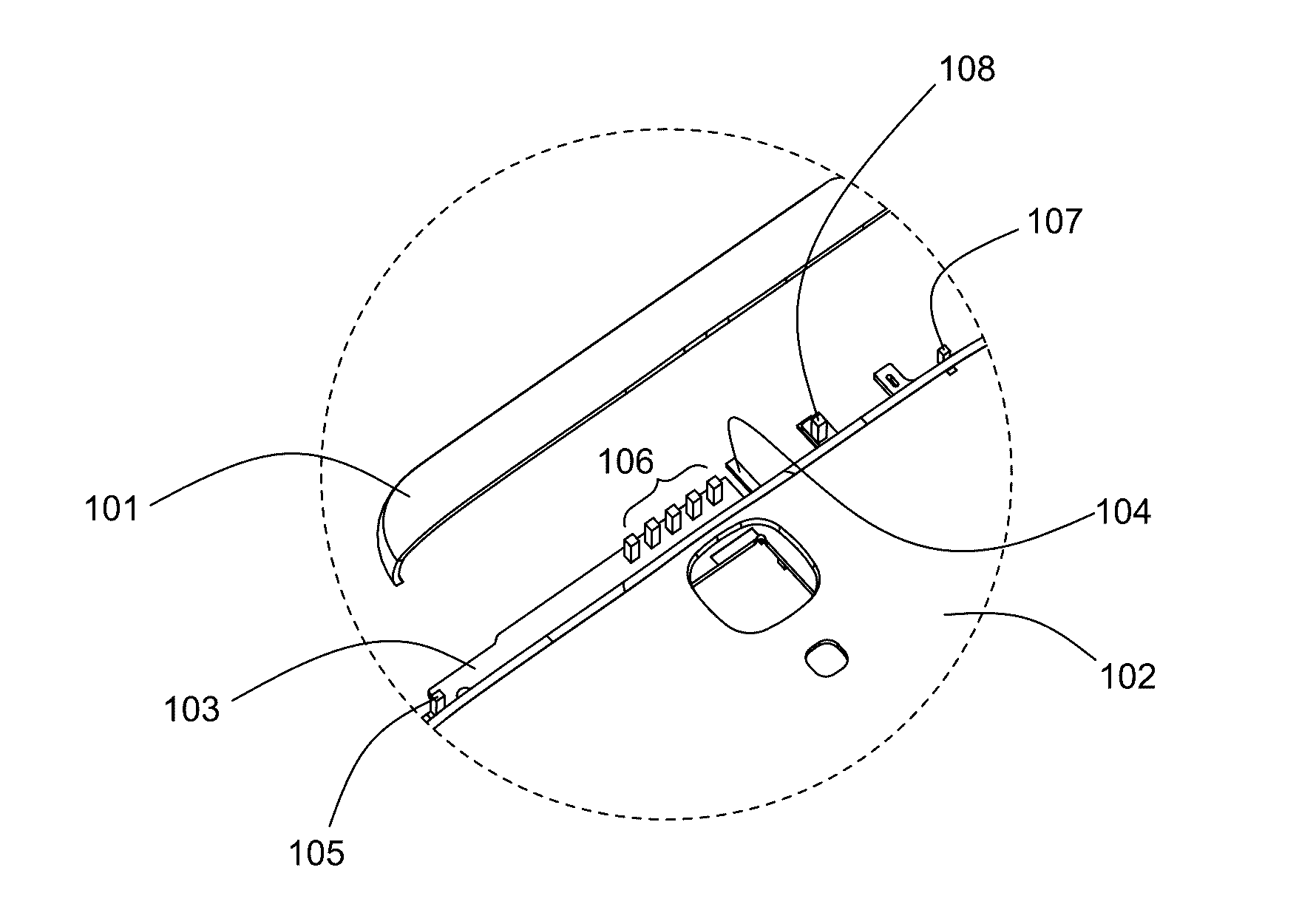

Antenna and wireless communication apparatus

ActiveUS20130002490A1Increases physical length of antennaLow costSimultaneous aerial operationsRadiating elements structural formsElectromagnetic responseEngineering

An antenna comprises a medium substrate and grounding units attached on the medium substrate. The antenna further comprises a metal structure attached on the medium substrate. The metal structure comprises an electromagnetic response unit, a metal open ring enclosing the electromagnetic response unit and a feeding point connected to an end of the metal open ring. The electromagnetic response unit comprises an electric-field coupling structure. This design increases the physical length of the antenna equivalently, so an RF antenna operating at an extremely low frequency can be designed within a very small space. This can eliminate the physical limitation imposed by the spatial area when the conventional antenna operates at a low frequency, and satisfy the requirements of miniaturization, a low operating frequency and broadband multi-mode services for the mobile phone antenna. Meanwhile, a solution of a lower cost is provided for design of the antenna of wireless communication apparatuses.

Owner:KUANG CHI INTELLIGENT PHOTONIC TECH

Mobile Phone Antenna Structure with Full Spectrum Band

InactiveUS20180006361A1Simultaneous aerial operationsAntenna supports/mountingsFrequency spectrumEngineering

An antenna structure includes a metal shell including a grounded middle frame provided with a main body and sides bent and extending from two sides of the main body and a radiating part serving as an antenna radiating body. The radiating part forms an insulation filled gap with the middle frame. Two ends of the radiating part are arranged opposed to each other for forming an insulation filled breaking joint. A circuit board is arranged below the metal shell, and one side of the circuit board adjacent to the radiating part forms a clearance zone between the circuit board and the radiating part. The antenna further includes a feeding point, at least one ground point, and a tuning circuit. The feeding point is close to the breaking joint, and the ground point includes a first ground point and a second ground point.

Owner:AAC TECH PTE LTD

Mobile phone antenna integrated with battery

InactiveUS20090256766A1Antenna equipments with additional functionsSlot antennasEngineeringDielectric layer

A mobile phone antenna integrated with a battery, comprising: a plurality of battery electrodes; a dielectric layer separating the battery electrodes from one another; and a slot formed in the battery electrodes; wherein walls of the slot are parallel to each other and the electrodes with said slot are adapted to emit and receive electromagnetic waves.

Owner:BURY

Mobile Phone Antenna System

InactiveUS20160351997A1Simultaneous aerial operationsAntenna supports/mountingsTop capMobile telephony

A mobile phone antenna system includes a metal rear cover, a circuit board, a first antenna module and a second antenna module connected electrically with the circuit board. The metal rear cover includes a top cover, a middle cover with a distance from the top cover, and a connector used for connecting electrically the top cover and the middle cover. The circuit board is provided with several grounding points. The top cover takes the connector as dividing point. The first antenna module and the second antenna module are connected electrically with the top cover at one side of the connector. A number of second match circuits are connected electrically with the grounding points, and the mobile phone antenna system has better adjusting ability.

Owner:AAC TECH PTE LTD

Mobile phone antenna

ActiveUS20070063901A1Simultaneous aerial operationsAntenna supports/mountingsGround planeMobile communication systems

The present invention provides a mobile phone antenna, which comprises an antenna ground plane, a radiating conducting plate, a feeding conducting strip, a shorting conducting strip, and a system ground plane. Using the antenna ground plane as a shielding metal wall, the present invention advantages itself of making the antenna and a shielding metal box easier to be integrated without a need for an isolation distance. The present invention thus makes the best use of the internal spacing of a mobile phone. This antenna is suitable for application as an embedded antenna for both folded-type and bar-type mobile phones. The operating bandwidth of this antenna can cover the required bandwidth for a Universal Mobile Telecommunication System operation.

Owner:NAT SUN YAT SEN UNIV +1

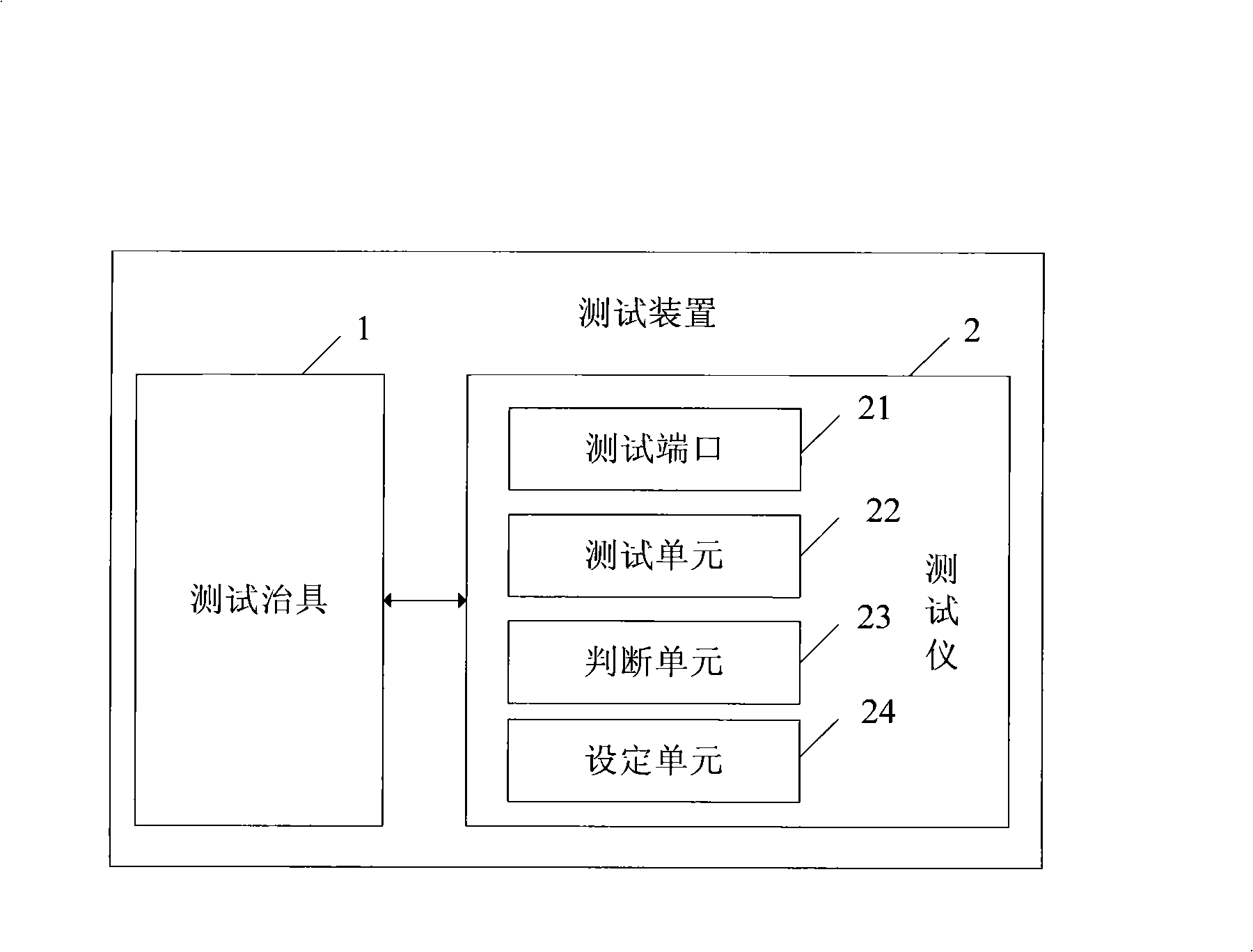

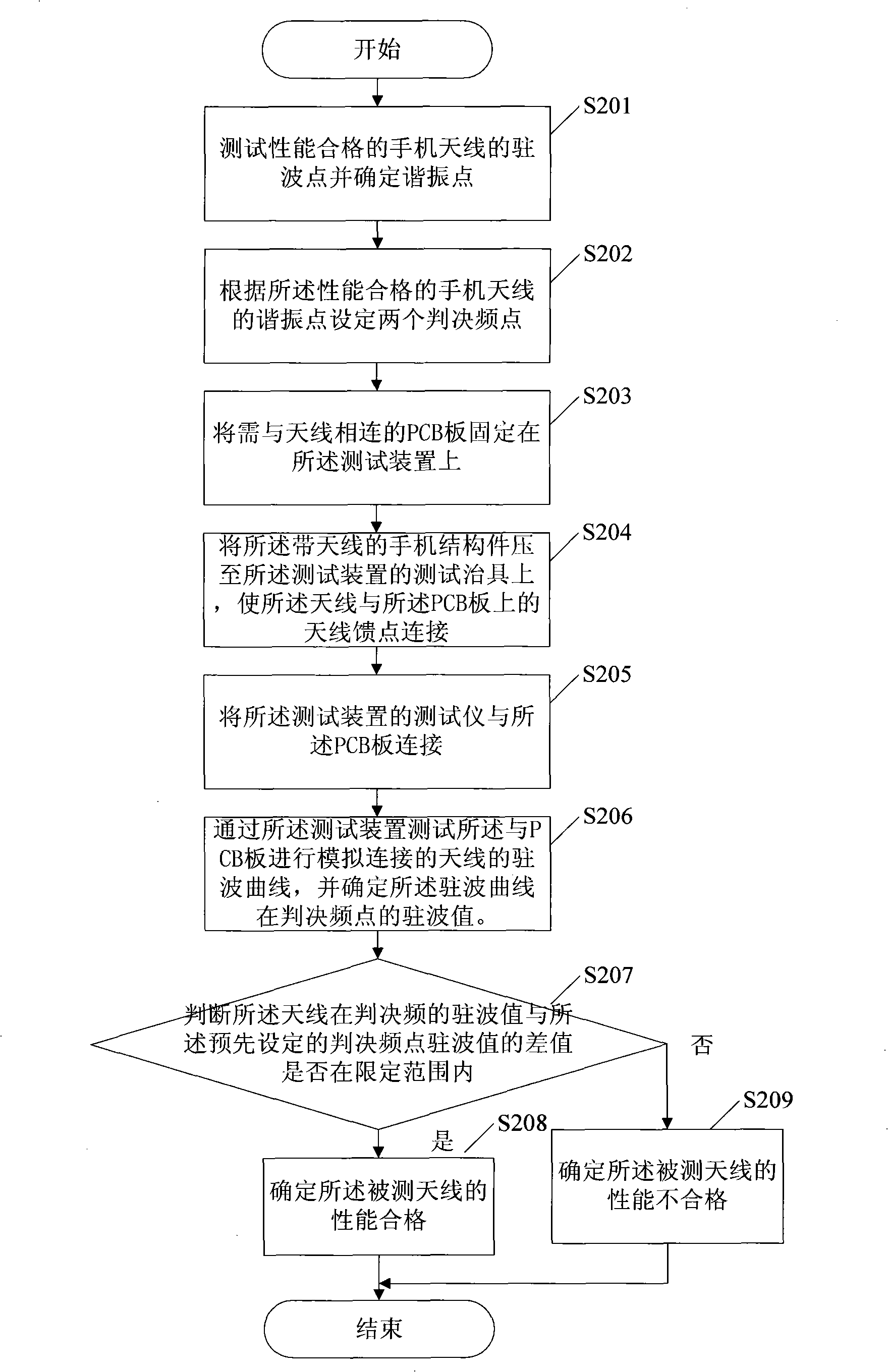

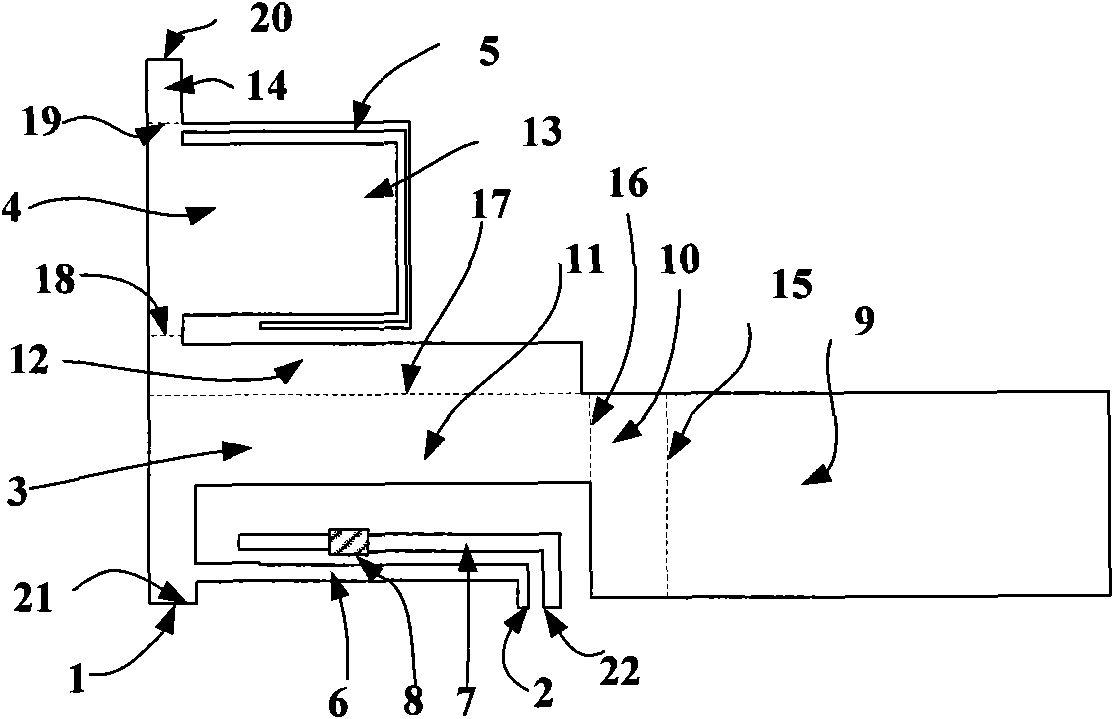

Method for testing mobile phone antenna performance and test device

ActiveCN101321023AEasy to operateImprove test efficiencyRadio/inductive link selection arrangementsSubstation equipmentTest fixtureStanding wave

The embodiment of the invention discloses a method for testing the antenna performance of the mobile phone and a testing device, wherein the method includes: performing the analog connection of the mobile phone structure with the antenna with the PCB board; testing the standing wave value of the antenna at the adjusting frequency point on the structure piece through the testing device, and adjusting whether the difference of the preestablished adjusting frequency point is in the limited range, if true, determining the performance of the antenna is eligible, otherwise the determining the performance of the antenna is not eligible. Through the invention to test the performance of the antenna, the factors including the material of the antenna and the change of the antenna forms on the performance of the antenna are controlled, and the operation is simple, which effectively advances the producing efficiency.

Owner:HUAWEI DEVICE CO LTD

Multi-frequency multi-mode reconfigurable mobile phone antenna

InactiveCN101562274ASmall sizeSatisfy built-in needsSimultaneous aerial operationsAntenna supports/mountingsElectrical conductorTD-SCDMA

The invention relates to a multi-frequency multi-mode reconfigurable mobile phone antennas, which comprises a metallic conductor part, a carrier for bearing the metallic conductor part, and a radio frequency switch, wherein the metallic conductor part comprises an antenna main body and a feeding point and a grounded point below the antenna main body; the feeding point and the grounded point are connected with a feeding point and a GND of a main board of a mobile communication terminal device respectively; the antenna main body comprises five conductor branches including a reversed L-shaped conductor part with width variation, a non isometric stretched conductor part, a thread conductor part which is bent for three times, a short circuit tuning branch and an inductive coupling reversed L-shaped conductor part; the radio frequency switch is arranged in the left center of the inductive coupling reversed L-shaped conductor part; and the antenna main body is bent and folded through five fold lines in turn to form a solid structure. The antenna can meet the radio communication requirement of systems such as EGSM, GPS, DCS, PCS, TD-SCDMA, TD-LTE, Bluetooth, WiMAX2.5, IMT-Advanced, WLAN5.2, WiMAX5.8 and the like, and simultaneously has the advantages of low profile, small volume and high gain.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com