Method for automatically testing and recording rated value of SF6 gas density relay

A gas density, automatic testing technology, applied in the direction of measuring electrical variables, circuit breaker testing, instruments, etc., can solve the problems of inconvenient, difficult to test accurately, troublesome, etc., and achieve the effect of easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

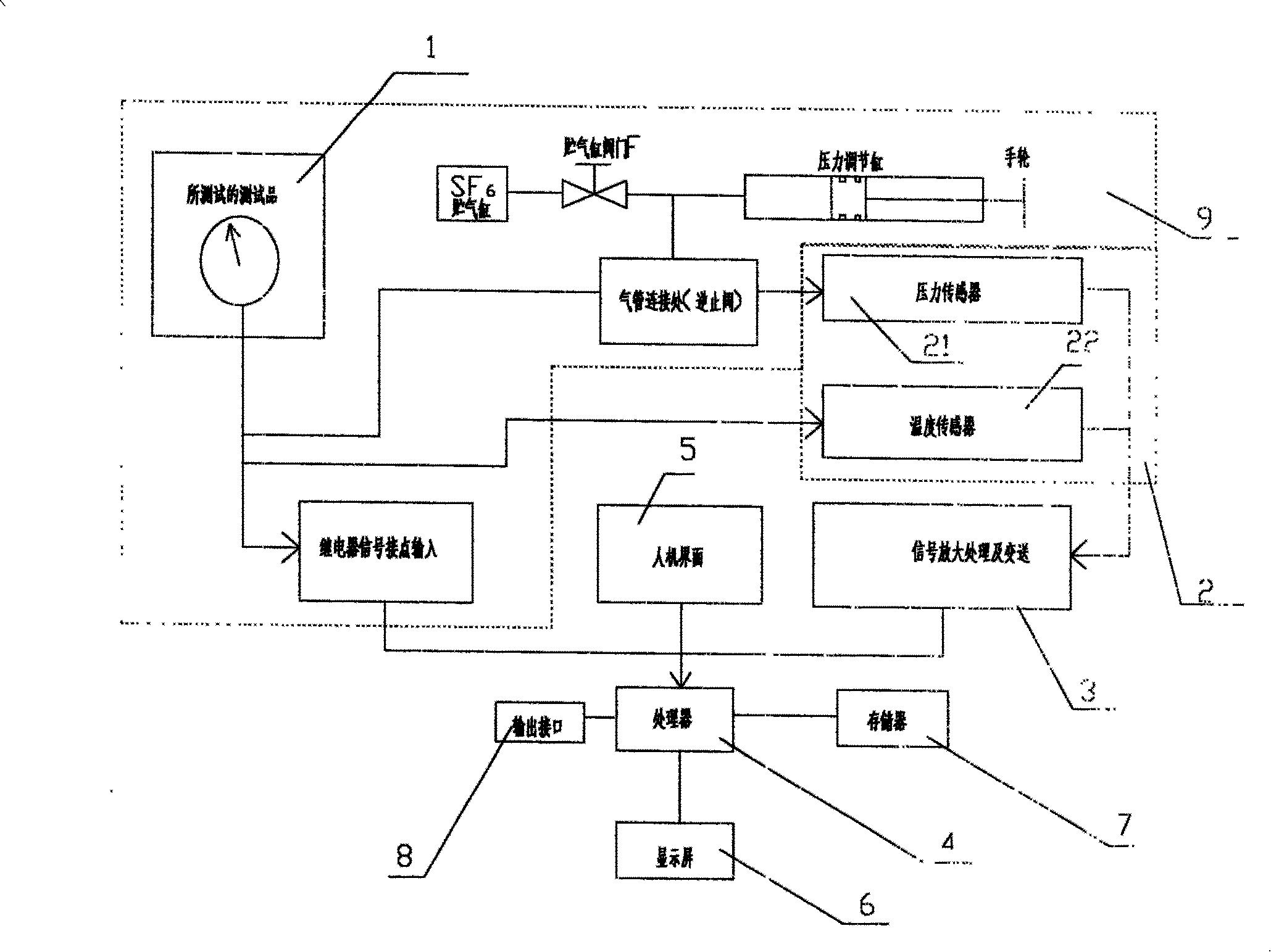

[0025] According to the use requirements of the calibrator, first connect the peripheral gas circuit and circuit, and start to enter the calibration state. Use the man-machine interface 5 of the calibrator to first input the rated value parameter value of the relay to be tested: the rated value Pe and its accuracy ΔP; enter the test number of the relay being tested. Enter the menu (status) of 'Validation Rating': According to the pointer of the test product, observe the indicated value of the test product, and first adjust the pressure to just the rated value of the test product, that is, the pointer of the test product just points to the rated value Pe, Then press the rated value test command key, the present embodiment is to press the 'ENTER' key, (the rated value test command key form can be flexible and diverse, not limited, for example, an external selection button, keyboard or switch can be used; the keyboard on the LCD can be used , you can also use the touch screen on ...

Embodiment 2

[0027] According to the use requirements of the calibrator, firstly connect the peripheral air circuit and the circuit, and start to enter the calibration state. Use the man-machine interface 5 of the calibrator to first input the accuracy requirement ΔP of the rated value Pe of the density relay to be tested; Then enter the test number of the relay being tested. Enter the menu (status) of 'Validation Rating': According to the pointer of the test product, observe the indicated value of the test product, and first adjust the pressure to just the rated value of the test product, that is, the pointer of the test product just points to the rated value Pe, Then press the rated value test command key, the present embodiment is to press the 'ENTER' key, (the rated value test command key form can be flexible and diverse, not limited, for example, an external selection button, keyboard or switch can be used; the keyboard on the LCD can be used , you can also use the touch screen on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com