Cloth fixing device of printing machine

A technology for fixing devices and printing machines, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of cloth pollution, cumbersome fixing process, etc., and achieve the effects of easy collection, no need for sizing, and simplified printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

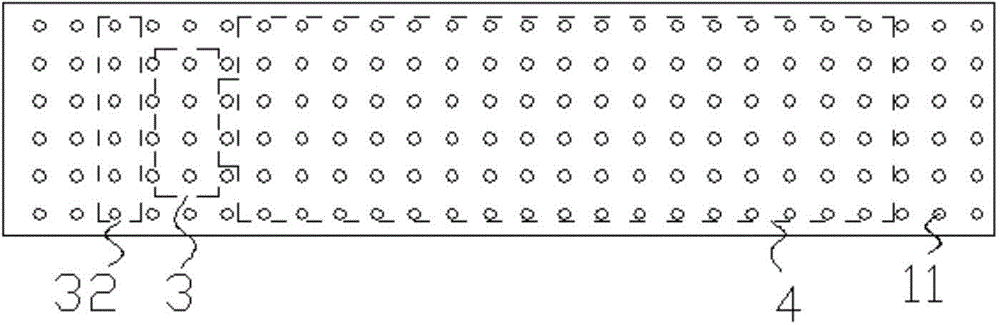

[0013] exist figure 1 , figure 2 In the shown embodiment, the cloth fixing device of the printing machine includes a conveyor belt 1; the conveyor belt 1 is sleeved on two parallel rotating shafts 2; A suction fan 3 is installed between the upper and lower layers of the conveyor belt 1, and a flat column-shaped air intake box 4 is installed at the air inlet of the exhaust fan 3, and a device is also installed at the air inlet. There is a filter screen 31; the upper surface of the air inlet box 4 is close to the lower surface of the conveyor belt 1, and the gap between the two is 0.5-1.5mm; the upper surface of the air inlet box 4 is provided with the adsorption hole 11 Matching fine air holes 41; the spacing between the air holes 41 is different from that between the adsorption holes 11; the air outlet device of the exhaust fan 3 is at the tail end of the conveyor belt 1, and the opening direction of the air outlet Vertical to the surface of the conveyor belt 1 and facing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com