Multicolor multilayer yarn-dyed towel with diversified pattern structures and weaving method of multicolor multilayer yarn-dyed towel

A technology of patterns and towels, which is applied in the direction of flower-digging fabrics, textiles, papermaking, fabrics, etc., can solve problems such as lack of novelty, unobtrusive visual effects, and insufficient color and pattern expressions, so as to improve grades and market competition. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

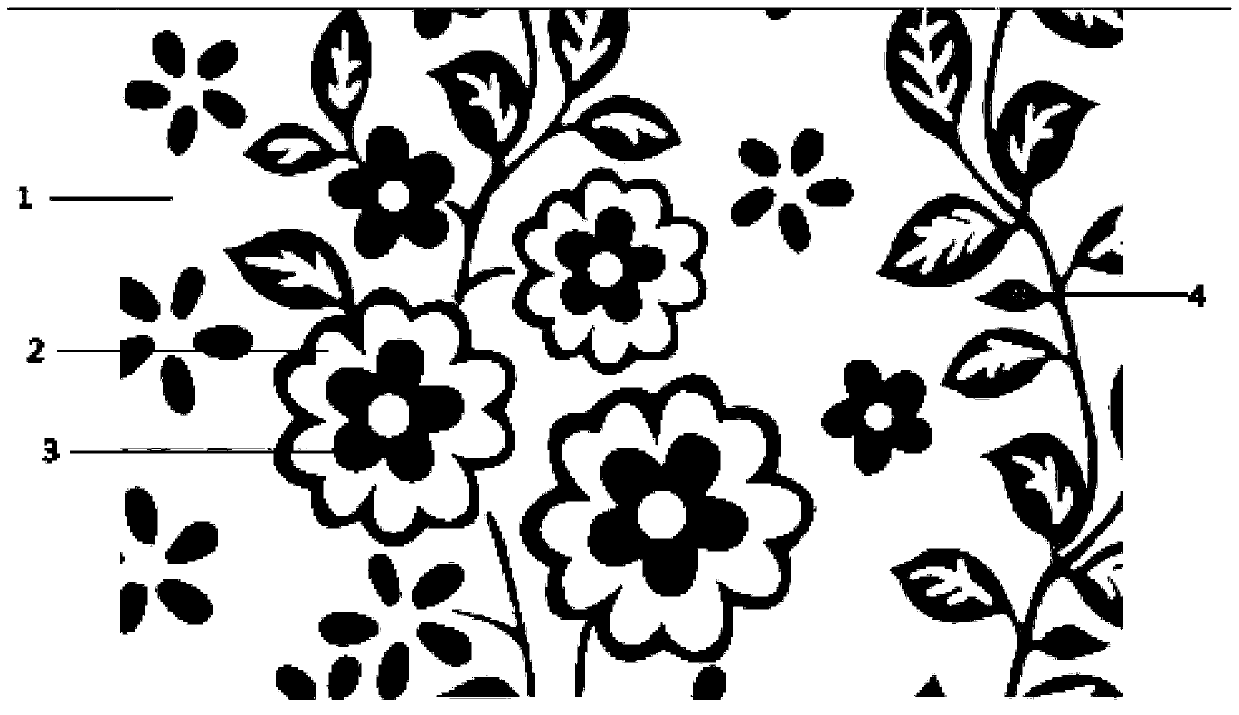

Embodiment 1

[0041] A multi-color multi-layer yarn-dyed towel with various patterns and textures, the towel is a four-layer four-color towel product woven from wool warp, ground warp and weft yarn of different colors; the wool warp includes wool of color 1 Warp and color 2 wool warp, the ground warp includes color 3 ground warp and color 4 ground warp, the weft yarn is divided into four layers, including color 3 weft yarn layer and color 4 weft yarn layer; the color 1 wool warp and color 2 wool warps are respectively interwoven with two layers of weft yarns in the four layers of weft yarns and the corresponding ground warp to form a loop pattern; the color 3 ground warp and the color 4 ground warp are respectively mixed with the color 3 weft yarn layer and the color 4 weft yarn layer and corresponding The ground warp is interwoven to form a gauze pattern and / or a bottom weave; the gauze pattern surrounds the terry pattern, and the bottom weave surrounds the terry pattern or the gauze patter...

Embodiment 2

[0043] The satin loom is preferably a Swiss Sulzer G6200 satin rapier loom for weaving. The speed of the satin loom is 330 rpm, and the twist value of the ground warp tension is 100 degrees; the twist value of the wool warp tension is 40 degrees. Menopause tablets in 0.65g.

[0044] Use color 1 wool warp and color 2 wool warp for the wool warp, choose color 3 ground warp and color 4 ground warp for the ground warp, divide the weft yarn into four layers: the first layer of weft yarn, the second layer of weft yarn, and the third layer of color 3 weft yarn layer And the fourth layer of color 4 weft yarn layers; the warp density of the product is preferably 80 threads / 5cm, and the weft density is designed at 100cm / 2.54cm.

[0045] According to the pattern design, every 12 weft yarns are a cycle unit, wherein the wool warp of color 1 and 6 weft yarns form pattern unit 1, the wool warp of color 2 and the remaining 6 weft yarns form pattern unit 2; The raising method of warp and col...

Embodiment 3

[0049] The satin-lifting loom is preferably G6300 satin-lifting rapier loom. The speed of the satin-lifting loom is 345 rpm, the twist value of the ground warp tension is 102 degrees; g.

[0050] Use color 1 wool warp and color 2 wool warp for the wool warp, choose color 3 ground warp and color 4 ground warp for the ground warp, divide the weft yarn into four layers: the first layer of weft yarn, the second layer of weft yarn, and the third layer of color 3 weft yarn layer And the fourth layer of color 4 weft yarn layers; the warp density of the product is preferably 80 threads / 5cm, and the weft density is designed at 100cm / 2.54cm.

[0051] According to the pattern design, every 12 weft yarns are a cycle unit, wherein the wool warp of color 1 and 6 weft yarns form pattern unit 1, the wool warp of color 2 and the remaining 6 weft yarns form pattern unit 2; The raising method of warp and color 2 hair warp is six-weft raising, 2-weft plain cloth, and 4-weft raising loop. When w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com