Simulation decorative film of flower

A technology for decorative films and flowers, applied in special decorative structures, decorative arts, etc., can solve the problems of no protective coating, damage, easy aging, etc., and achieve a realistic three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

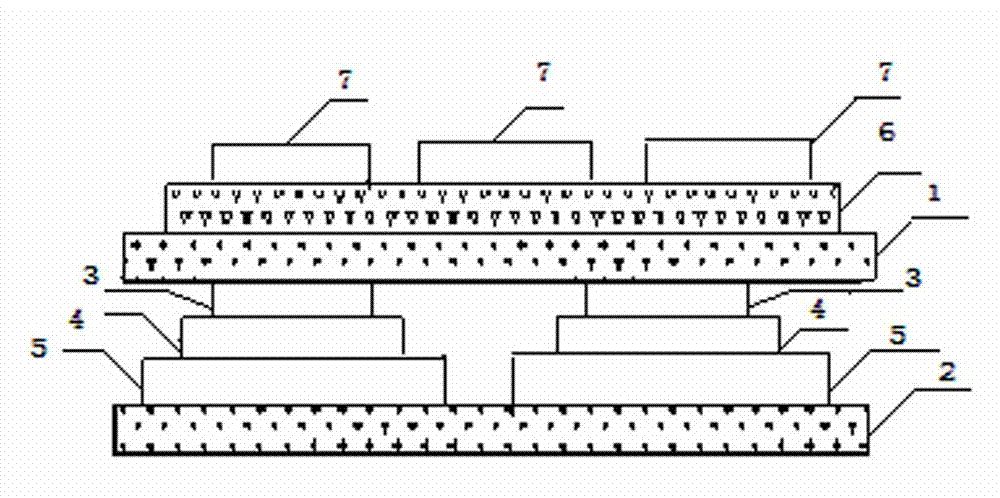

[0010] As shown in the figure, in the flower simulation decorative film according to the present invention, the first common spot color layer 3 is printed on the lower surface of the substrate, and the second common spot color layer 4 is printed on the lower surface of the first common spot color layer 3 surface, the third ordinary spot color layer is printed on the lower surface of the second ordinary spot color layer 4, the bottom film 2 is printed on the lower surface of the third Ouyang spot color layer, and the matte coating is fully printed on the upper surface of the substrate, glossy The coating is printed on the upper surface of the matte coating.

[0011] After the printing is completed, due to the uneven thickness of the matte coating 6, it has obvious concave-convex touch, and the plate roller is a positive image, which makes the petals of flowers look more vivid and vivid. The matte coating is full-page printing , The gloss coating is printed into a hollow effect,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com