Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96 results about "Coolmax" patented technology

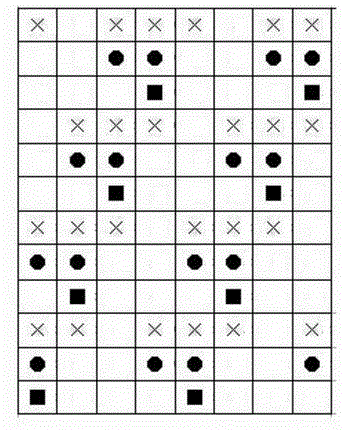

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coolmax is the brand name for a series of polyester fabrics developed and marketed by Invista (formerly Dupont Textiles and Interiors). Coolmax is marketed as "moisture-wicking" and "breathable". As a polyester, it is moderately hydrophobic, so it absorbs little fluid and dries relatively quickly (compared to absorbent fibers such as cotton). The cross-section is non-round, increasing surface area by an estimated 20% (over round fibers) in order to produce a wicking effect via capillary action.

Coolmax fiber/pearl fiber blending knitted fabric with moisture absorption and perspiration health care functions

InactiveCN101608378AMaintain sweat-wicking and quick-drying propertiesSmooth textureWeft knittingWarp knittingYarnPerspiration

The invention relates to a Coolmax fiber / pearl fiber blending knitted fabric with moisture absorption and perspiration health care functions, the fabric is knitted by blending yarns containing pearl fiber, the blending yarns are one or more than one of tencel fiber, modal fiber and viscose, the mass ratio of pearl fiber in the blending yarns is 15-50%, the blending yarns are spun to be 16-60. The fabric of the invention has the health care efficacies of promoting microcirculation of human body blood, preventing ultraviolet rays and protecting skin, keeps the feature of fast perspiration and simultaneously has the advantages of smooth texture, good wearability and comfort wearing.

Owner:DONGHUA UNIV +1

Moisture-absorbing and perspiring anti-bacterial fabric and preparation technology thereof

InactiveCN105421055AImprove antibacterial propertiesSoft and wear-resistantBiochemical fibre treatmentLiquid/gas/vapor removalWater basedMoisture

The invention relates to a moisture-absorbing and perspiring anti-bacterial fabric and a preparation technology thereof. The moisture-absorbing and perspiring anti-bacterial fabric is blended and weaved by the following raw materials in parts by weight: 40 to 80 parts of bamboo fibers, 40 to 80 parts of long staple, 10 to 30 parts of ramie, 10 to 30 parts of coolmax fibers, 10 to 20 parts of corn fibers, 10 to 20 parts of Delight fibers, and 5 to 20 parts of Tancel, and then is treated by anti-bacterial finishing liquid; the anti-bacterial finishing liquid comprises 5 to 10 parts of chitosan, 5 to 10 parts of silk fibroin, 0.5 to 3 parts of butyl ricinoleate sodium sulfate, 0.5 to 3 parts of lemon acid, 0.5 to 2 parts of butyl methacrylate, 5 to 8 parts of dodecyl diphenyl ether sodium disulfonate, 5 to 10 parts of hydroxypropyl methyl cellulose, 5 to 10 parts of polyhexamethylene biguanidine, 5 to 15 parts of organosilicon quaternary ammonium salt, 3 to 8 parts of dodecyl trimethyl ammonium chloride, and 5 to 10 parts of water-based polyurethane. The moisture-absorbing and perspiring anti-bacterial fabric has the advantages that the anti-bacterial property is higher, the moisture-absorbing, perspiring, anti-pilling and air-ventilation properties are realized, the softness is realized, and the abrasion is resisted; the moisture-absorbing and perspiring anti-bacterial fabric is particularly suitable for being applied to the fields of underwear, overwear, sportswear and bedding articles.

Owner:杜名胜

Moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and production method thereof

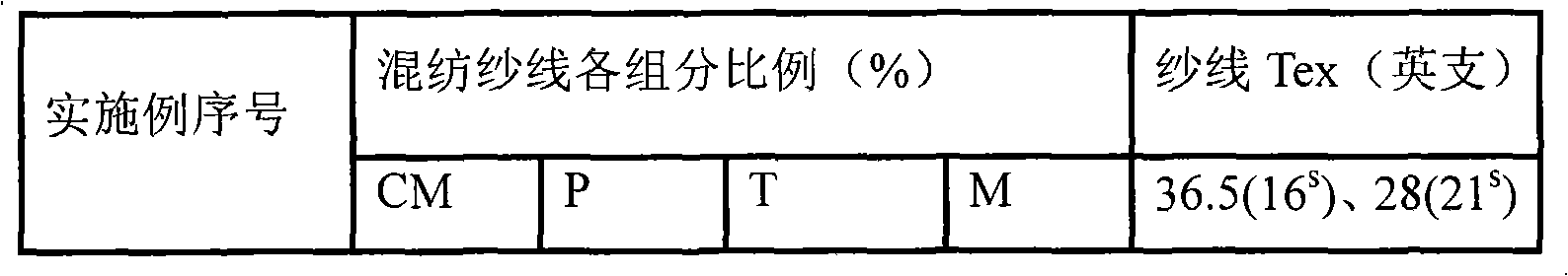

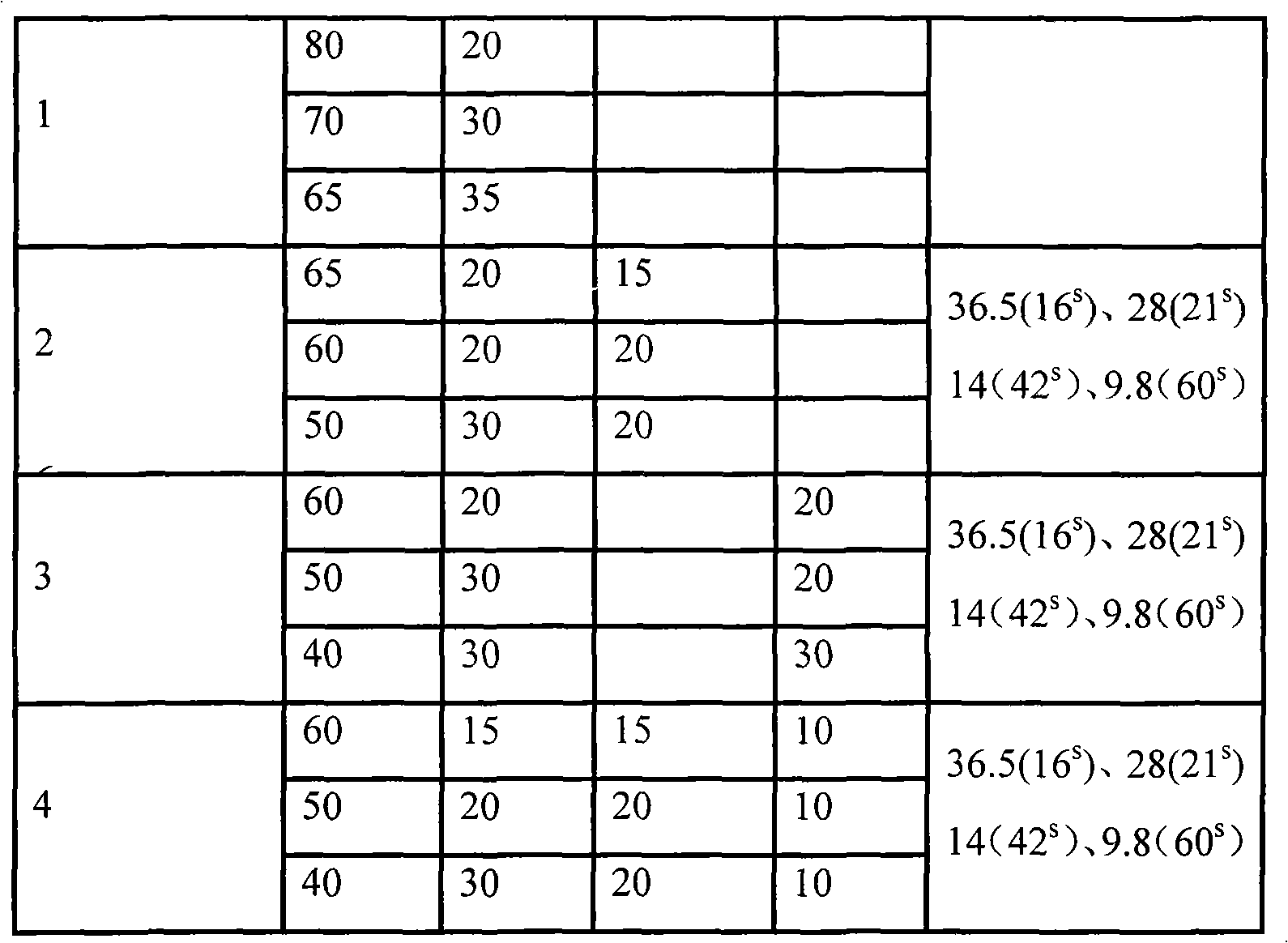

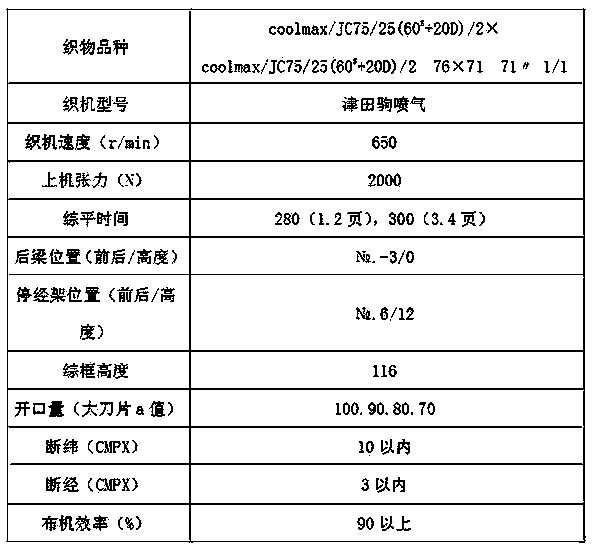

The invention provides moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and a production method of the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric and belongs to the technical field of textile. 75% of coolmax moisture-absorbing and sweat-releasing modified polyester fibers and 25% of cotton fibers are used as coated fibers, and 20D common polyester filament yarn is composed of covering yarn. Cotton opening and picking, cotton carding and pre-drawing are performed on the coolmax moisture-absorbing and sweat-releasing modified polyester fibers, and primary drawing, secondary drawing, roving, spinning, single yarn winding, yarn twisting and plied yarn winding are performed on the cotton fibers undergoing cotton opening and picking, cotton carding and combing to generate coolmax / JC75 / 25(60S+20D) single yarn and coolmax / JC75 / 25(60S+20D) / 2 plied yarn; the moisture-absorbing, sweat-releasing, washable and quick-drying shirt fabric is produced through beaming, slashing, denting, weaving and weave repairing. By means of reasonable scotching and cotton carding processes, two-time drawing mixing and appropriate slashing and weaving processes, the fabric has good moisture-absorbing, sweat-releasing, washable and quick-drying effects and good boney feel.

Owner:JIHUA 3542 TEXTILE CO LTD

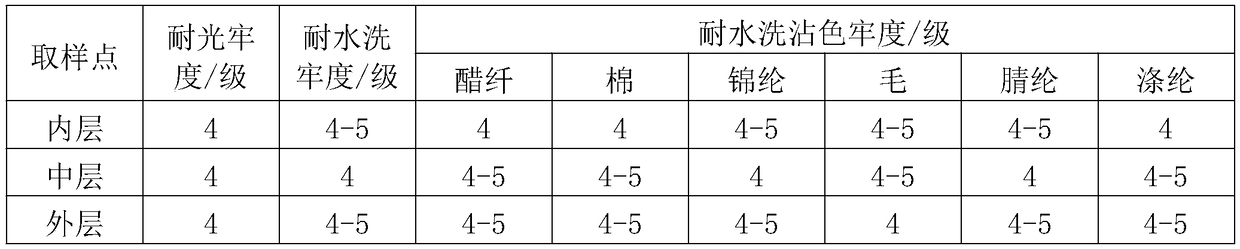

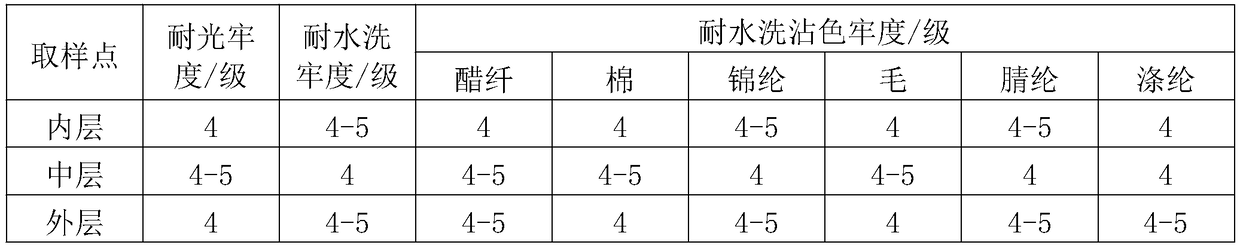

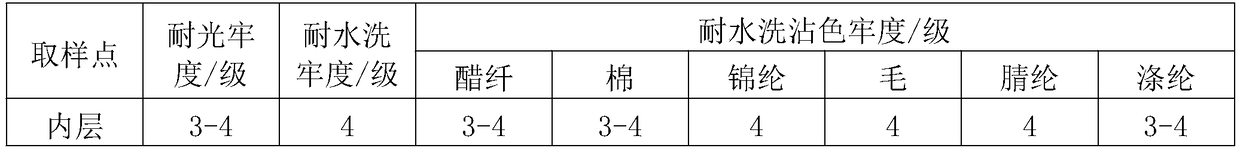

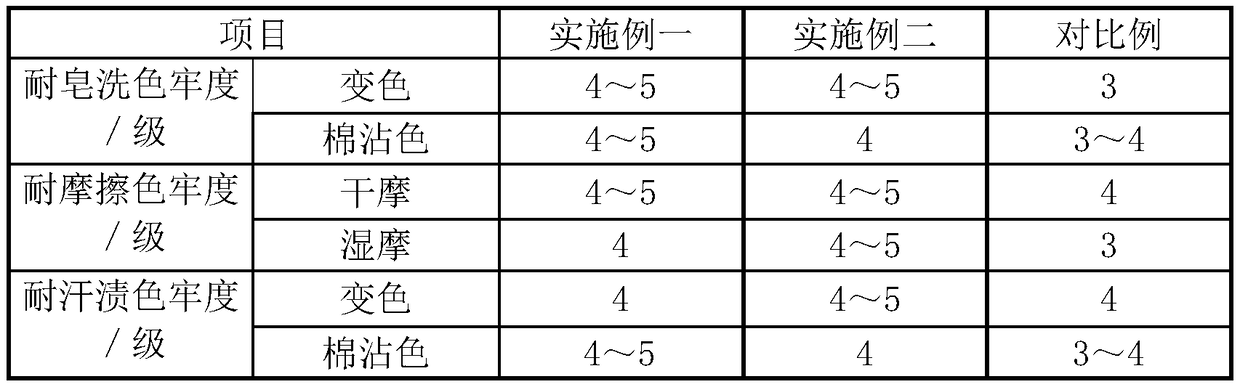

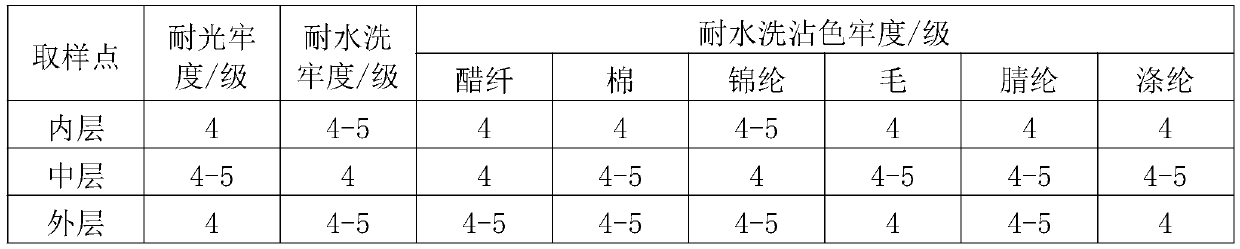

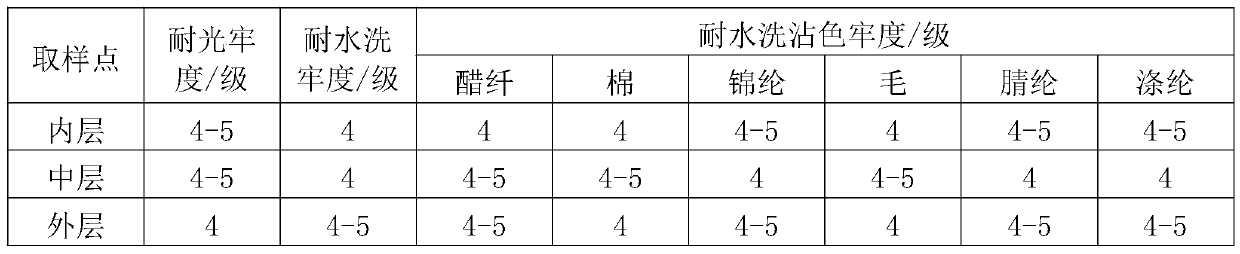

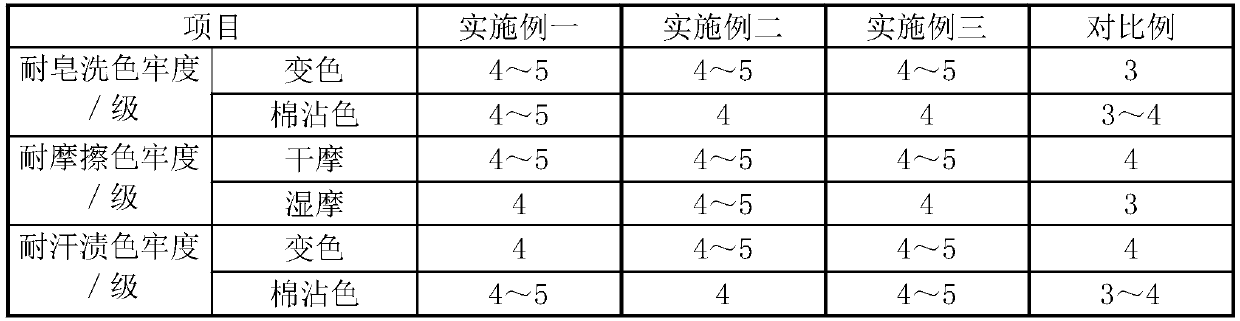

Preparation method of coolmax fiber/wool blend moisture absorbing/releasing tweed

The invention relates to a preparation method of coolmax fiber / wool blend moisture absorbing / releasing tweed. The preparation method is characterized in that the tweed comprises the raw materials of 50% of wool and 50% of coolmax fibers in terms of mass percentage; the preparation method comprises the steps of dyeing and re-combing, spinning, weaving and post-treating; the coolmax fibers and the wool are respectively dyed in the process of dyeing and re-combing, wherein the coolmax fibers are dyed at 120 degrees centigrade by using mesothermal dyestuffs; the pH value is controlled at 3-5, the time for 60 minutes in the dyeing process; and the highly active cleaning agent ECO is employed for washing after the dyeing process. The tweed produced by the preparation method provided by the invention has the advantages of moisture absorbing and releasing, good strength, high fastness and uniform color.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

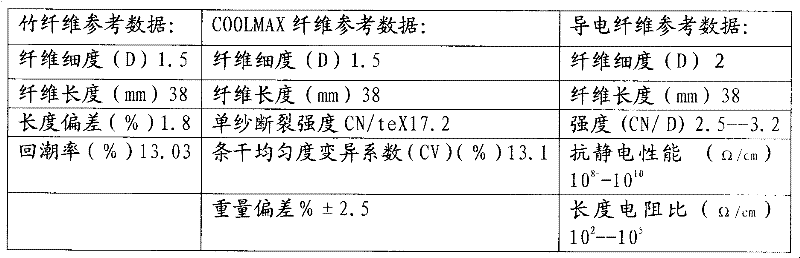

Bamboo fiber, Coolmax fiber and conductive fiber blended yarn and method for producing same

The invention discloses a bamboo fiber, Coolmax fiber and conductive fiber blended yarn and a method for producing the same. The bamboo fiber, Coolmax fiber and conductive fiber blended yarn has functions and characters of the three types of fibers, has complementary advantages, and has unique nobility by being spun by siro-spinning technology. The functional yarn can be used for knitting and tatting. A fabric made of the bamboo fiber, Coolmax fiber and conductive fiber blended yarns has the functions and characters of high strength, fine shape retention, high breathability, high moisture absorption, high sweat releasing, antibiosis, dust proofing, electrostatic resistance, ultraviolet resistance, environment-friendliness, easiness in caring, resistance to washing, stable size, softness and smoothness in touch and the like, is especially suitable for being made into knitted sports underwear, underpants, T-shirts, sportswear, shirts, hats and the like, and contributes to clothing grade increase and improvement on people's life quality, and commercial opportunities are supplied to textile enterprises. Therefore, great social benefit and economic benefit are achieved.

Owner:SHAOXING HENGMEI FANCY SILK +1

Moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric and preparation method thereof

InactiveCN107419438AImprove performanceLong-lasting and stable effectNon-woven fabricsPolyesterViscose

The invention relates to an antibacterial health-care spunlaced faric, in particular to a preparation method and application of a moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric. The moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric is prepared from, by weight, 10-70% of moisture-absorption and sweat-discharge fiber (including Coolmax, Coolplus, Cooldry and Topocool), 0-50% of pearl fiber, 0-50% of mint fiber, 0-60% of antibacterial viscose fiber (or viscose fiber) and 0-60% of antibacterial polyester fiber or polyester fiber. The moisture-absorption and sweat-discharge fiber spunlaced nonwoven fabric has the advantages that the developed moisture-absorption and sweat-discharge fiber spunlaced nonwoven face towel base fabric has the effects of disinfection, cleaning, maintenance, moisturizing nourishing and the like and also has the effects of corrosion prevention, inflammation diminishing, hygiene, health care and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

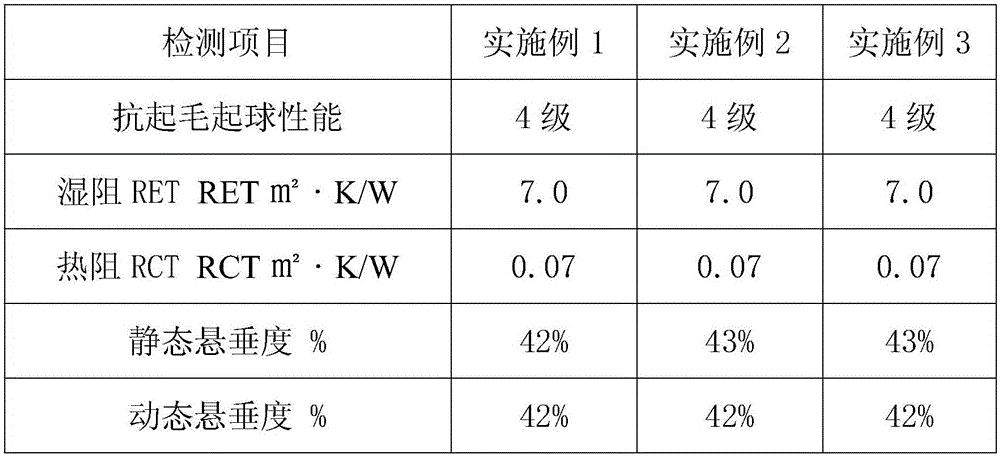

Sweat discharge underwear fabric

ActiveCN105286096AFeel smoothSoft touchVegetal fibresUndergarmentsHigh volume manufacturingEngineering

The invention discloses a sweat discharge underwear fabric which is woven from the following raw materials in parts by weight: 20-40 parts of Thermocool or Coolmax fiber, 60-80 parts of regenerated cellulose fiber and 1-5 parts of spandex. In the post finishing process, the hand feeling, the color and the moisture absorbing effect of the sweat discharge underwear fabric are compared, moisture absorbing and sweat discharge additives are screened and compared, and a set of optimal post finishing process and optimal moisture absorbing and sweat discharge additive formula which is applicable to different ratios of raw materials and fabric products of different qualities and colors is developed; the sweat discharge underwear fabric disclosed by the invention is smooth and soft in hand feeling and good in drapability, is very good in moisture absorbing and sweat discharge effect, is pure in gloss and excellent in quality, can completely meet the requirements of wearers on comfort, breathability and coolness, and is optimal option of fabrics in summer. The process is convenient to operate and applicable to large-scale production process.

Owner:浙江剑利美针织服饰有限公司

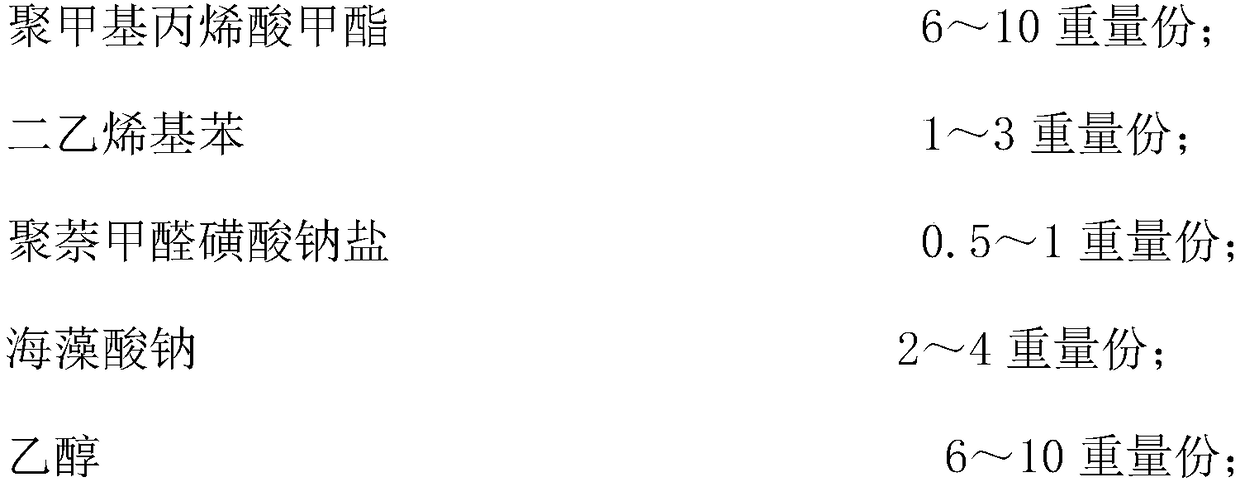

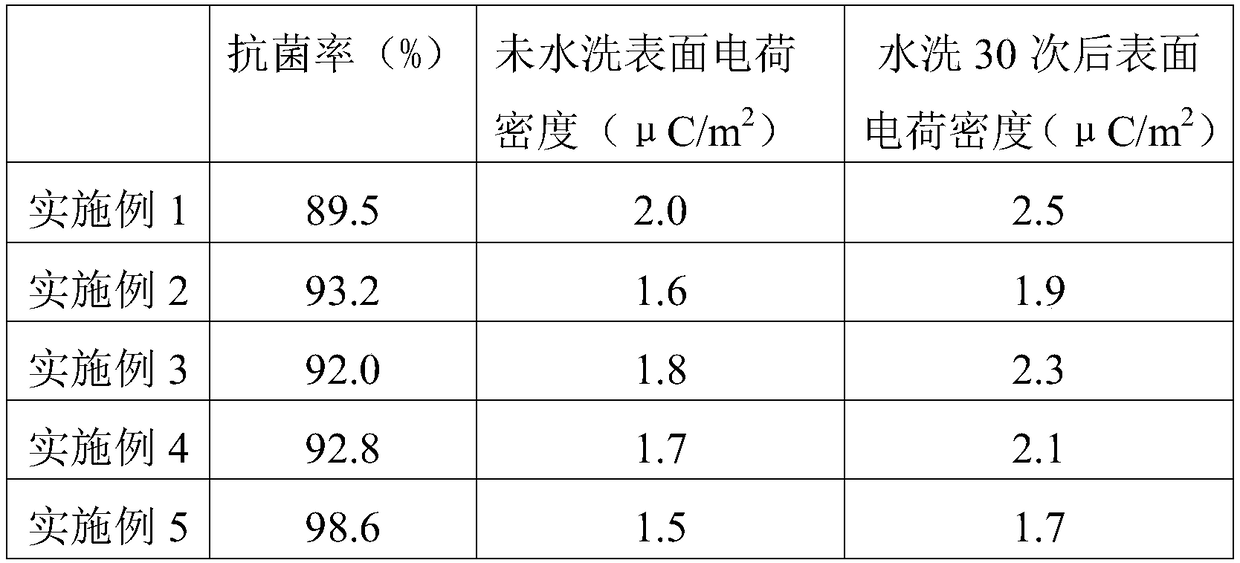

Moisture-absorbing and sweat-releasing antibacterial fabric and preparation method thereof

ActiveCN108950842AMoisture wicking and antibacterial propertiesImprove wearing comfortWeft knittingBiochemical fibre treatmentMoisturePromotion effect

The invention discloses a preparation method of moisture-absorbing and sweat-releasing antibacterial fabric, which comprises the following steps: soaking and rolling antibacterial treatment solution of grey cloth, moisture-absorbing and sweat-releasing finishing solution, and obtaining moisture-absorbing and sweat-releasing antibacterial fabric; the grey cloth is woven from the following weight ingredients: Coolmax fiber 12-14 weight; regenerated cellulose fiber 40-50 weight; polyacrylonitrile fiber 6-8 weight. Through the compatibility of the antibacterial treatment solution and the specificcomposition and content of the moisture-absorbing and sweat-releasing finishing solution, the antibacterial treatment solution and the moisture-absorbing and sweat-releasing finishing solution have asynergistic promotion effect; the fabric has the moisture-absorbing and sweat-releasing antibacterial properties, and improves the clothing comfort.

Owner:广东国色婚纱礼服有限公司

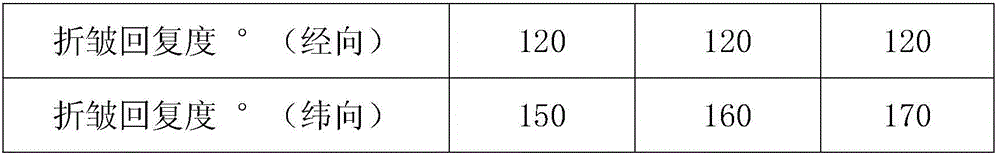

Design method and production process of double-layer quick-drying three-proofing fabric

The invention discloses a design method and a production process of double-layer quick-drying three-proofing fabric. Quick-drying fiber is selected as the inner layer of the fabric, and warm-keeping fiber is selected as the outer layer of the fabric, so that the fabric has excellent moisture permeation and warm keeping functions; in order to improve comfort of the fabric, modal and coolmax blendedyarn is used in the inner layer; after three-proofing finishing, the quick-drying performance of the fabric is slightly reduced, but water-proof, oil-proof and anti-fouling functions are greatly enhanced. The produced double-layer quick-drying three-proofing fabric is most suitable for infant clothing, infants are lively and active and can produce a lot of sweat during playing, the fabric can quickly absorb sweat produced by the human body, keep the human body dry and clean, when infants have rests quietly, the fabric has the excellent warm keeping function and can effectively prevent loss ofheat of the human body and protect infants against wind cold attack, after three-proofing treatment, clothing is easy to wash clean, and the fabric is excellent functional fabric.

Owner:IANGSU COLLEGE OF ENG & TECH

Antistatic fabric and preparation method thereof

ActiveCN108642691AImprove antistatic performanceEliminate hazardsWeft knittingLiquid/gas/vapor removalAntistatic agentGram

The invention discloses an antistatic fabric and a preparation method thereof. The preparation method of the antistatic fabric comprises the following steps of: (1) blending 35-40 parts by weight of Coolmax fiber and 58-62 parts by weight of bamboo fiber into blended yarns; weaving the blended yarns with 2-4 parts by weight of spandex to obtain a plain weave fabric with a gram weight of 150 to 300gram per square meter; (2) tidying the plain fabric after being subjected to antistatic treatment. The antistatic fabric has good antistatic performance, can eliminate the harm of static electricityto the human body, eliminate the uncomfortable feeling generated by static electricity during movement, can eliminate the tangling caused by static electricity, is dust-resistant, is resistant to dirty and easy to wash. After the grapheme is improved, the adhesive force on the fabric is increased, and the antistatic property and the antibacterial property are improved.

Owner:珠海鑫康源新材料科技有限公司

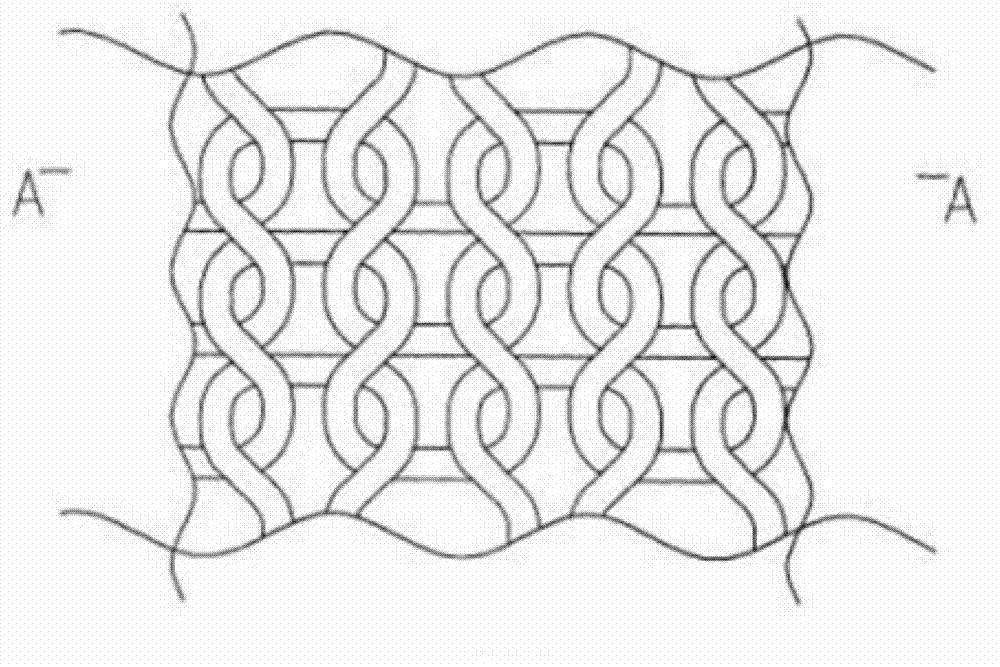

Multi-component weft triple fabric and weaving process thereof

InactiveCN105568473AStrong moisture wickingImprove antistatic performanceLoomsWarping machinesWear resistantEngineering

Provided are a multi-component weft triple fabric and a weaving process thereof. The fabric is formed y five components of cotton, Coolmax modified polyester fibers, China-hemp, conductive fibers, and polyester filament yarns. Four kinds of yarns are used, and warps are combed cotton / Coolmax modified polyester fibers, and weft yarns are combed cotton / Coolmax modified polyester fibers, terylene low-elastic interlaced yarns, combed cotton / China-hemp and terylene, and conductive fibers. Fabric weave structure is a weft triple structure. The front surface is combed cotton / Coolmax modified polyester fiber warps and wefts, the middle layer is the terylene low-elastic interlaced yarns, and the back surface is the combed cotton / China-hemp blended yarns. The face weave is cross grain, the intermediate weave is cross grain, and the inner weave is cross grain. The fabric is cool and crisp in hand feeling, novel in style, and is firm and wear-resistant. The fabric has good moisture absorption and sweat releasing property, and is comfortable in wearing. The fabric has good healthcare and functionality, and is especially suitable for professional uniform in spring and autumn.

Owner:JIHUA 3542 TEXTILE CO LTD

Multifunctional radiation-proof woven fabric and production method thereof

The invention provides multifunctional radiation-proof woven fabric and a production method, wherein the multifunctional radiation-proof woven fabric is woven by a warp and weft machine, the warp is blended by coolmax fiber and bamboo charcoal fiber by the weight ratio of 1:1-0.5, the fineness of the wrap is 45<s>-50<s>, the weft contains yarn I and yarn II which are arranged at intervals in the ratio of 2:1 or 3:1, the components of the yarn I are the same as that of the warp, i.e. the yarn I is blended by the coolmax fiber and the bamboo charcoal fiber by the weight ratio of 1:1-0.5, the fineness of the yarn I is 45<s>-50<s>, and the yarn II is formed by cabling by the coolmax two fold yarn with the fineness of 30s-40s and stainless steel metal filament with 68-72D. The electromagnetic shielding effect of the multifunctional radiation-proof woven fabric is good and durable, at the same time, has good functions of humidity-absorbing, breathability, shape-memory, bacteriostasis, antiultraviolet, and good wearability.

Owner:YANCHENG INST OF IND TECH

Radiation-proof garment and its making method

InactiveCN102488333AGood electromagnetic shielding effectPrevent affecting the performance of radiation protection clothingWoven fabricsYarnYarnCarbon fibers

The invention discloses a radiation-proof garment and a method of making shell fabric of the radiation-proof garment. The shell fabric of the garment is woven with warps and wefts and is characterized in that the warps are formed by blending Coolmax fibers and bamboo carbon fibers according to a weight ratio 1:1-2:1, and fineness of the warps is 35-45S. The wefts are formed by arranging first yarns and second yarns at intervals according to a proportion 2:1 or 3:1, the first yarns are the same as the warps, and the second yarns are formed by doubling and twisting Coolmax two-fold-yarns with fineness 30-40S and stainless steel filaments. The radiation-proof garment has the advantages that firstly, the radiation-proof garment has fine electromagnetic shielding effect; secondly, processibility and wearability of the shell fabric are enhanced; thirdly, comfort of the shell fabric is improved; and fourthly, the radiation-proof garment has a great health function.

Owner:HANGZHOU HECHUANG FASHION

Production process of thin side-stretch fabric

InactiveCN109505049AImprove comfortHigh color fastnessSingeingHeating/cooling textile fabricsPolyesterFiber

The invention discloses a production process of a thin side-stretch fabric. The production process comprises the following steps of S1 warping, S2 beam dyeing pretreatment, S3 beam dyeing, S4 soapingand color fixing, S5 foam slashing, S6 weft yarn unwinding, S7 weft yarn pretreatment, S8 weft yarn dyeing, S9 weft yarn soaping, S10 weaving and S11 after treatment. According to the production process of the thin side-stretch fabric, warp yarn is dacron spandex core-spun yarn, beam dyeing and sizing are adopted, weft yarn is subjected to cone yarn dyeing, stain fabric weave is adopted, and therefore polyester fibers are arranged on one face of the fabric, and blended tencel and Coolmax fibers are presented on the other face of the fabric. The polyester fibers have the advantages of being resistant to wear, high in brute force and the like, the face, in contact with the skin, of the tencel and Coolmax fibers has the functions of being good in hygroscopicity, resistant to static and bacteria and the like, and the comfort of the fabric is improved. Beam dyeing and sizing are adopted, fluff and nep on warp yarn can be reduced, and weaving is conducted smoothly.

Owner:浙江鸣春纺织股份有限公司

COOLMAX SIROFIL yarn and production method thereof

The invention discloses a COOLMAX SIROFIL yarn, comprising the following components according to percent by weight: 40-60% of wool, 25-50% of COOLMAX fiber, 10-20% of lustrous polyester filament yarn. The production steps of the COOLMAX SIROFIL yarn include: step 1), wetting and storing; step 2), mixing slivers; step 3), gilling; step 4), roving; step 5), spinning; step 6), steaming yarns; step 7), automatically spooling; step 8), steaming the yarns. The yarn of the invention can be produced into light thin worsted fabric and has good moisture-absorbing, quick-drying and breathing performances and is highly fashionable.

Owner:ZHANGJIAGANG DONGYA WOOL TEXTILE CO LTD

Manual tufting carpet with moisture absorption and moisture guide functions and weaving method of manual tufting carpet

ActiveCN102783892AImprove moisture absorption and moisture conduction functionIncrease contact areaEmbroidering machines apparatusFloor carpetsFiberHigh humidity

The invention discloses a piece of manual tufting carpet with moisture absorption and moisture guide functions and a weaving method of the manual tufting carpet. The carpet is woven by Coolmax fiber subjected to alkali weight reducing processing, after the Coolmax fiber is subjected to the alkali weight reducing processing, the cross section of the Coolmax fiber has special groove structures, the surface area is increased, the moisture absorption and moisture guide functions are further improved, fiber broken end and loop end alternate arrangement at intervals is adopted in the weaving method, the loop end and broken end height difference is regulated, the three-dimensional effect of veins is enhanced, the contact area between the Coolmax fiber and the air is increased, the moisture absorption and moisture guide speed is accelerated, and the function is enhanced. Bottom cloth with nonuniform warp and weft yarns, thick warp yarns, thin weft yarns and low density is used at the bottom of the carpet, so gap passages are formed on contact surfaces between the bottom and the ground, air with high humidity can be fast guided out from the bottom of the carpet, the moisture absorption and moisture guide effects of the carpet are promoted, the use comfort of the carpet is improved, the Coolmax cheese weight reducing time is controlled in the weaving process, and the twist degree of the weight reducing fiber is properly increased, so the softness of the carpet is enhanced, and the falling cannot easily occur.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Production technology of beam-dyed double-layer two-way stretch fabric

The invention discloses a production technology of beam-dyed double-layer two-way stretch fabric. The production technology comprises the following steps: preparation of a surface beam, dyeing pretreatment of the surface beam, dyeing of the surface beam, soaping of the surface beam, foam slashing of the surface beam, preparation of a lining beam, pretreatment of the lining beam, dyeing of the lining beam, soaping of the lining beam, foam slashing of the lining beam, weaving and after finishing. According to the production technology of the beam-dyed double-layer two-way stretch fabric, the surface is formed by interweaving nylon fiber core spun yarn, and the lining is formed by interweaving corn spun yarn taking tencel and Coolmax as a coating layer. According to the double double-layer two-way stretch fabric, the surface has wear resistance of nylon fiber, the lining has moisture absorption and removal effect of the tencel and the Coolmax fiber, and the creativity and durability of the fabric are improved. Besides, yarn hairiness and neps on warp can be reduced by beam dyeing sizing, so that weaving is performed smoothly. The process of the production technology can be shortened and production efficiency can be improved.

Owner:浙江鸣春纺织股份有限公司

Health-fitness home textile fabric rich in grape seed extract procyanidine and manufacturing method thereof

ActiveCN104120534AProlong the effective timeImprove protectionFibre treatmentWoven fabricsBiotechnologySpinning

The invention discloses health-fitness home textile fabric rich in grape seed extract procyanidine and a manufacturing method of the health-fitness home textile fabric. The health-fitness home textile fabric comprises warp yarn and weft yarn, the warp yarn is Siro spinning yarn formed by spinning Coolmax moisture adsorption and sweat releasing fibers and modal fibers, and the weft yarn is Siro spinning yarn formed by spinning bamboo charcoal fibers and TENCEL fibers. The grape seed extract procyanidine of the home textile fabric with the health-fitness function is printed on the home textile fabric in a microcapsule mode, and components of the grape seed extract procyanidine have the effect of beautifying skin, resisting wrinkles, removing beverage, preserving moisture, improving the sleeping and the like on the human body.

Owner:ZHONGFU HAT DECORATION CREATIVE RES & DEV NANTONG CO LTD

Sweet-free T-shirt fabric

The invention discloses sweet-free T-shirt fabric. The sweet-free T-shirt fabric is formed by weaving of raw material including 20-40 parts by weight of Coolmax fibers, 60-80 parts by weight of cotton fibers, and 1-5 parts by weight of spandex. The sweet-free T-shirt fabric has following beneficial effects: a comparative test is made to fabric feeling, color and moisture absorption effect during afterfinish of fabric based on characteristics of moisture-adsorbing and sweat-removing fibers Coolma, cotton fibers and spandex; comparative tests are made as to varieties of moisture-adsorbing and sweat-removing additives so that the set of formulas suitable for optimal afterfinish process of fabric products with different proportions of raw material, different quality, and different colors and best moisture-adsorbing effect functional additives is made; the sweet-free T-shirt fabric feels smooth, soft and shows great drapability and fine moisture-adsorbing and sweat-removing effect and bright in color and good in quality; the physical indicators of the fabric are in accord with the standard so that a user can feel comfortable, breathable and cool when wearing T-shirt; the T-shirt is the best choice for moisture-adsorbing and sweat-removing fabric; and operation is performed conveniently; and the sweet-free T-shirt fabric is suitable for a volume-produce process.

Owner:WUJIANG XINJINHUA TEXTILE

Novel moisture-absorbing and breathable blend fabric

InactiveCN104207387ASoft and comfortable to wearWith health careTextiles and paperProtective garmentKapok fiberMoisture

The invention discloses a novel moisture-absorbing and breathable blend fabric. The novel moisture-absorbing and breathable blend fabric is blended and woven of Coolmax fibers, Shengfeng pearl fibers, bamboo charcoal fibers and kapok fibers. The novel moisture-absorbing and breathable blend fabric comprises the following fabric fiber components in percentage by weight: 25-29 percent of Coolmax fibers, 17-21 percent of Shengfeng pearl fibers, 20-24 percent of bamboo charcoal fibers and 26-38 percent of kapok fibers. The novel moisture-absorbing and breathable blend fabric is blended and woven of the Coolmax fibers, the Shengfeng pearl fibers, the bamboo charcoal fibers and the kapok fibers; the woven fabric is soft, comfortable, moisture-absorbing and breathable to wear and has the characteristics of health care, beauty maintaining and skin care.

Owner:刘喜

Preparation method of outdoor sportswear fabric

ActiveCN105951424AGood hygroscopicityStrong moisture wickingBiochemical treatment with enzymes/microorganismsVegetal fibresFiberPolyester

The invention discloses a preparation method of outdoor sportswear fabric. The fabric adopting ultrafine polyester fibers has better moisture absorption, more excellent moisture absorption and sweat releasing properties and better breathability and drapability than conventional silk-like fabric. Through appropriate twisting, the polyester fibers have a diffuse reflection phenomenon on light and have the luster of almost real silk, and the drapability of the fabric can be increased; Coolmax fibers and cottongrass fibers are added for blending, and the antibacterial performance and the moisture absorption and sweat releasing properties of the fabric are enhanced; through pretreatment of the cottongrass fibers, the effective antibacterial ingredients of the cottongrass fibers are prevented from being damaged as far as possible.

Owner:东阳新东煌服饰有限公司

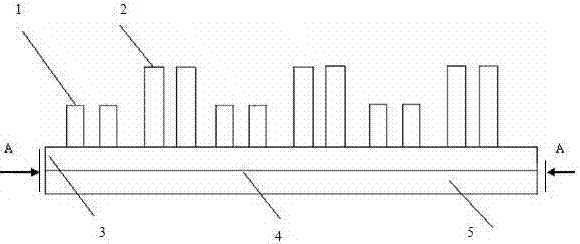

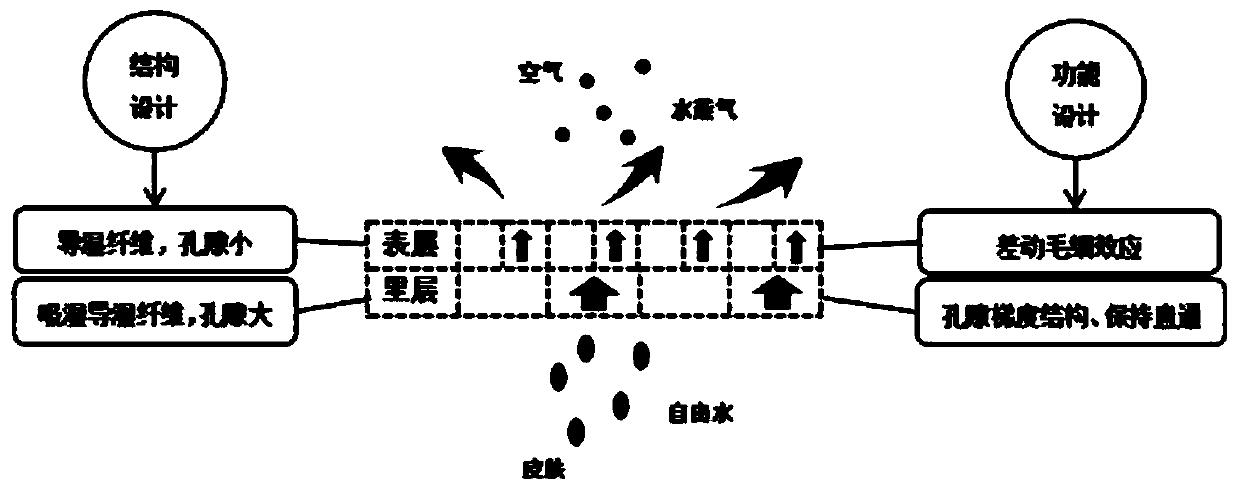

Method for producing unidirectional moisture absorption and guiding fabric

InactiveCN110438624AGood one-way moisture absorption and moisture conduction functionWith one-way moisture absorption and moisture conduction functionMulti-ply fabricsYarnCotton fibre

The invention discloses a method for producing a unidirectional moisture absorption and guiding fabric. The method comprises the steps of interweaving yarns with moisture guiding performance and yarnswith moisture absorption performance to prepare a fabric, wherein the yarns with the moisture guiding function are prepared by blending jutecell fibers and cotton fibers, and the yarns with the moisture guiding function are coolmax pure yarns. The fabric can feel comfortable when people wear the fabric inside under the two conditions that people perspire and do not perspire. By adopting a single-layer fabric structure and a double-layer fabric structure, the fabric has functions of moisture absorption and moisture guiding with different thicknesses and degrees, can meet different requirementsof people in different seasons, and is high in practicability and wide in application range.

Owner:XI'AN POLYTECHNIC UNIVERSITY

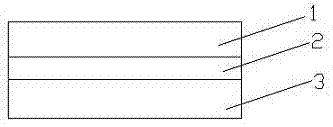

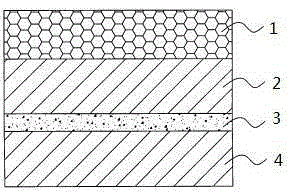

Whitening and breathable health care fabric

InactiveCN102501487APlay a role in whiteningPlay a role in health careSynthetic resin layered productsFiberSurface layer

The invention provides whitening and breathable health care fabric, which comprises a surface layer, a middle layer and an inner layer, the middle layer is clamped between the surface layer and the inner layer, the surface layer is a whitening layer, the middle layer is a breathable layer, and the inner layer is a health-care layer. The whitening layer is made of aloe fibers, the breathable layer is made of COOLMAX fibers, and the health care layer is made of polyvinyl chloride fibers. The fabric made of the materials has a whitening function and further has health care and breathable functions when being worn.

Owner:CHANGSHU FUJIALI WEAVING

Production process of nylon side-stretch yarn-dyed fabric

InactiveCN109505045AImprove comfortHigh color fastnessSingeingHeating/cooling textile fabricsFiberNylon 6

The invention discloses a production process of a nylon side-stretch yarn-dyed fabric. The production process comprises the following steps of S1 yarn preparation, S2 warp dyeing, S3 weft dyeing, S4 warp preparation, S5 knitting and S6 after finishing. According to the production process of the nylon side-stretch yarn-dyed fabric, warps are nylon core-spun yarns formed by dyeing cheese yarns, wefts are tencel fiber and Coolmax fiber core-spun yarns formed by dyeing cheese yarns, satin weave is adopted to show nylon yarns one face of the fabric and show the blended tencel and Coolmax fiber on the other face of the fabric, the nylon yarns have the characteristics of abrasion resistance, high strength and the like, the tencel and Coolmax fiber face in contact with the skin has good hygroscopicity and antistatic and antibacterial functions, and the comfort of the fabric is improved. The warps and the wefts are obtained by dyeing cheese yarns, dipping with assistants and then executing standing so that the warps and the wefts can be easily colored during dyeing and are high in color fastness.

Owner:嘉兴市鸣竣纺织有限公司

Sleepwear not making people catch cold and preparation method thereof

ActiveCN105780482AGood moisture wicking effectAvoid coldVegetal fibresCross-linkCis-Butenedioic Acid

The invention discloses sleepwear not making people catch cold and a preparation method thereof.The sleepwear not making people catch cold is woven from, by weight, 0-100 parts of Coolmax fibers, 0-100 parts of regenerated cellulose fibers and 0-10 parts of spandex.The sleepwear not making people catch cold is dipped in a moisture-absorbing and sweat-releasing finishing agent.The moisture-absorbing and sweat-releasing finishing agent is prepared from, by mass, 0.3-0.7% of polyvinyl pyrrolidone, 0.1-0.5% of a cross-linking agent, 0.1-0.5% of a penetrating agent and the balance water.The penetrating agent is composed of 40-60 wt% of dioctylsulfosuccinate sodium salt and 40-60 wt% of sodium diethylhexyl sulfosuccinate.The sleepwear not making people catch cold is also called anti-cold sleepwear, has good moisture-absorbing and sweat-releasing effects, is not attached to skin when people sweat, prevents people from catching cold, and particularly has an anti-cold effect.

Owner:上海小蓝象服装有限公司

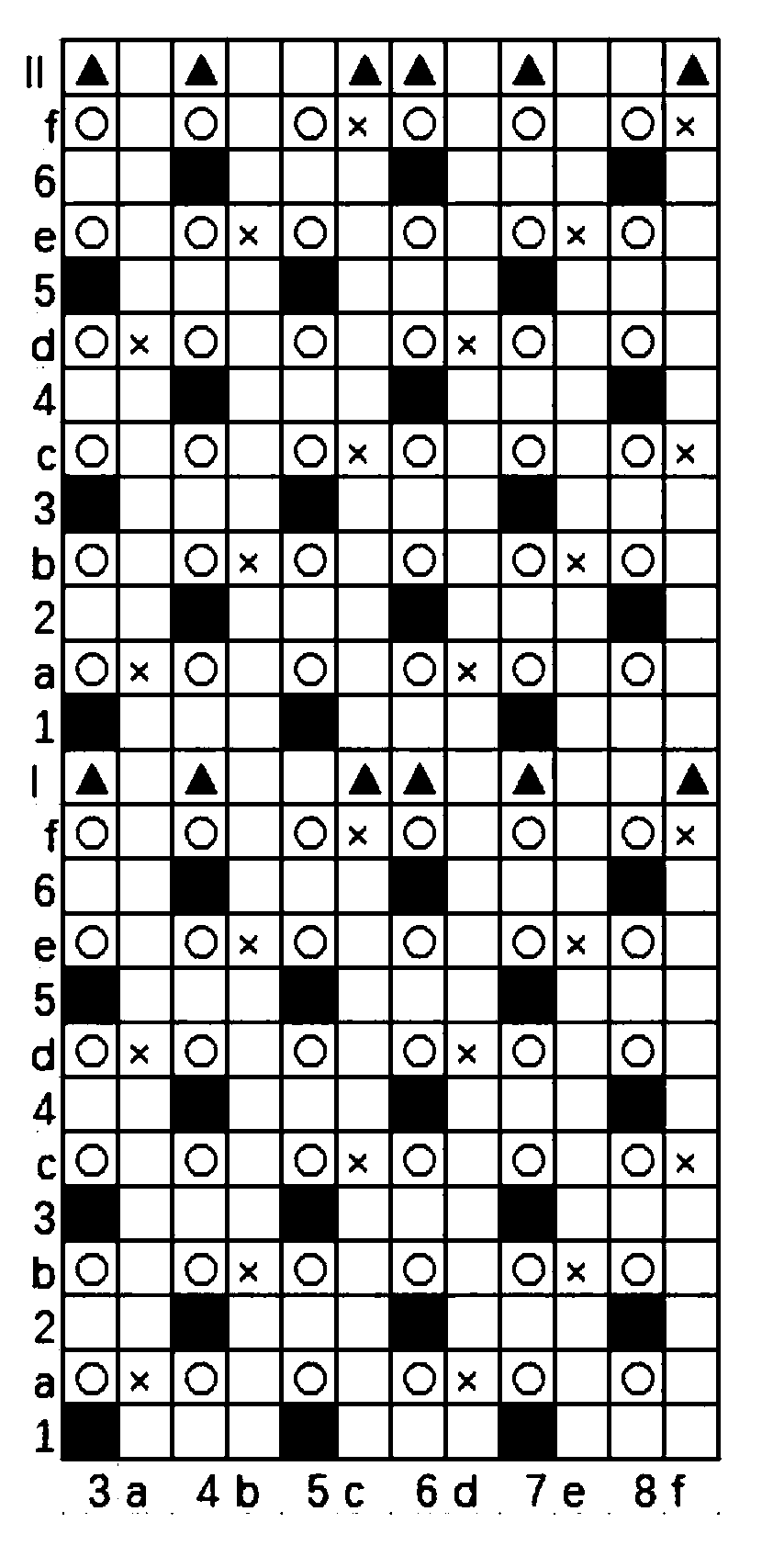

Blended fabric of COOLMAX fiber, bamboo fiber and electroconductive fiber

InactiveCN102358978AMeet functional needsSolve the defects caused by the singleness of fibersWoven fabricsYarnFiberYarn

The invention discloses a blended fabric of COOLMAX fiber, bamboo fiber and electroconductive fiber. The blended fabric is formed by interweaving warp and weft, wherein both the warp and weft are selected from blended yarn of COOLMAX fiber, bamboo fiber and electroconductive fiber, and the warp and weft are in swansdown twill weaves. Because the selected blended yarn of COOLMAX fiber, bamboo fiber and electroconductive fiber has special ultra-strong and durable functions, the woven fabric has the functions and characteristics of ultra-strong moisture absorption, air permeation and sweat discharge properties (the drying rate of the fabric is 5 times of that of pure cotton), bacterial resistance, bacterial inhibition, odor prevention, ultraviolet resistance, wrinkle resistance, coolness, soft touch feeling, smoothness, static electricity resistance and the like, and is especially suitable for manufacturing military hats, police hats, travelling hats and working hats, or manufacturing sport underwear, knickers, shirts, bags and the like.

Owner:SHAOXING SHULILE TEXTILE PROD

Production process of weft-elastic peach skin fabric

ActiveCN109763241ASolve the shortcomings of poor moisture absorption and drainageGood moisture absorption and dehumidification functionFibre typesSingeingYarnPolyester

The invention discloses a production process of weft-elastic peach skin fabric. The production process comprises the following steps: S1 preparation of warp, S2 warping, S3 beam dyeing pretreatment, S4 beam dyeing, S5 beam soaping, S6 foam sizing, S7 weft yarn loosening, S8 weft yarn pretreatment, S9 weft yarn dyeing, S10 weft yarn soaping, S11 weaving and S12 after finishing. According to the production process of the weft-elastic peach skin fabric, warp yarn adopts combined yarn prepared from cotton-like filaments and POY (polyester pre-oriented yarn) by intermingled two-for-one twisting, tencel and Coolmax fiber are adopted as a coating layer and spandex is adopted as warp yarn of core yarn. Satin weaving is adopted, so that one side of the fabric is combined yarn and the other side iswarp yarn, after posttreatment such as washing, the washing effect can be formed on one side of wet yarn, and one side of the warp yarn has better moisture absorption and removing functions, so that the defects of poor moisture absorption and removing performance of traditional peach skin fabric are overcome.

Owner:JIAXING MINGYE TEXTILES CO LTD

Production process of double-layer four-surface elastic fabric

InactiveCN109652895AImprove comfortImprove wear resistanceTwo or more solvent application treatmentMulti-ply fabricsFiberSurface layer

The invention discloses a production process of a double-layer four-surface elastic fabric. The production process includes the steps: S1 yarn selection; S2 warping; S3 weaving; S4 gray fabric pretreatment; S5 mechanical softening; S6 gray fabric presetting; S7 dyeing by a two-bath method; S8 post-finishing and setting. Nylon filaments serve as a coating layer, spandex serves as a first covering yarn of a core yarn, the first covering yarn serves as wrap yarns and weft yarns of a surface layer of the double-layer fabric, the content of the spandex is 6%, natural silks and Coolmax fibers serveas a coating layer, spandex serves as a second covering yarn of a core yarn, and the second covering yarn serves as wrap yarns and weft yarns of a inner layer of the double-layer fabric. According tothe production process of the double-layer four-surface elastic fabric, the surface layer is provided with a nylon covering yarn, the inner layer is provided with a covering yarn of the natural silksand the Coolmax fibers, so that the surface layer of the double-layer elastic fabric has the advantages of good abrasion resistance, high strength and the like of nylon wires, the inner layer of the elastic fabric has the advantages of good moisture absorption and perspiration and the like, and comfort of the fabric is improved.

Owner:浙江鸣春纺织股份有限公司

Antibacterial compound non-woven cloth

InactiveCN105196626AImprove antibacterial propertiesHygroscopicSynthetic resin layered productsCompound aBiochemical engineering

The invention discloses antibacterial compound non-woven cloth which is characterized by being prepared by compounding a breathable layer, an antibacterial layer, an elastic layer and a bottom layer in sequence from top to bottom, wherein the breathable layer is prepared from a coolmax fiber fabric; the antibacterial layer is prepared from a hemp warp-weft interwoven fabric, and is added with silver ions; the elastic layer adopts a meshed structure formed by interweaving high-elasticity fibers; the bottom layer is a pure cotton fabric. The antibacterial compound non-woven cloth is high in elasticity, good in antibacterial effect, breathable, soft, skin-friendly and wide in application range, and the comfortableness of a user can be greatly improved.

Owner:TAICANG YIFEI CHEM FIBER WEAVING CO LTD

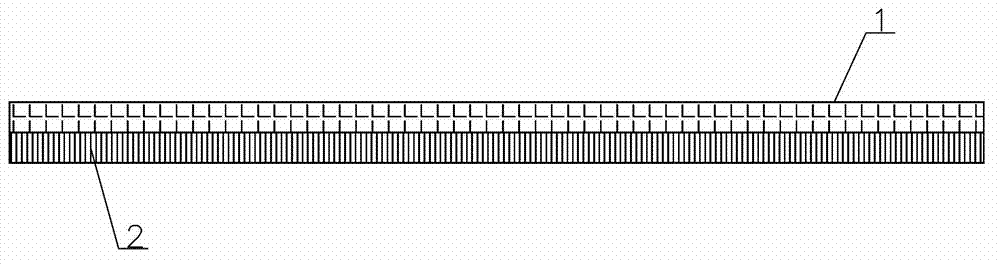

Indigo knitted thickened jean

InactiveCN103070505AIncreasing the thicknessImprove breathabilityWeft knittingProtective garmentFiberYarn

The invention relates to the technical field of the clothes fabric, in particular to indigo knitted thickened jean, and the jean is of a two-layer structure comprising a surface layer and a bottom layer, wherein the surface layer is formed by weft knitting of indigo pure cotton yarns and high-conductivity wet polyester yarns, the bottom layer is a poly spun velour layer formed by napping, ironing and cutting the back surface of the surface layer. The indigo knitted thickened jean has the beneficial effects that the poly spun velour is added in the inner layer, so that the heat preservation performance is improved; and four pipeline specially-shaped polyester fibers Coolmax are adopted, so that good ventilation can be guaranteed while the thickness of the jean is increased, and the indigo knitted thickened jean can meet the climate changing requirement.

Owner:李雪明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com