Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198 results about "Crêpe paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crêpe paper is tissue paper that has been coated with sizing (a glue-like substance). It can then be creased in a way similar to party streamers to create gathers, giving it a crinkly texture like that of crêpe. This creasing process is called creping or crêping.

Methods for creping paper

ActiveUS7744722B1Reduce accumulationPrevent adhesive build-upNatural cellulose pulp/paperMechanical working/deformationAdhesiveCrêpe paper

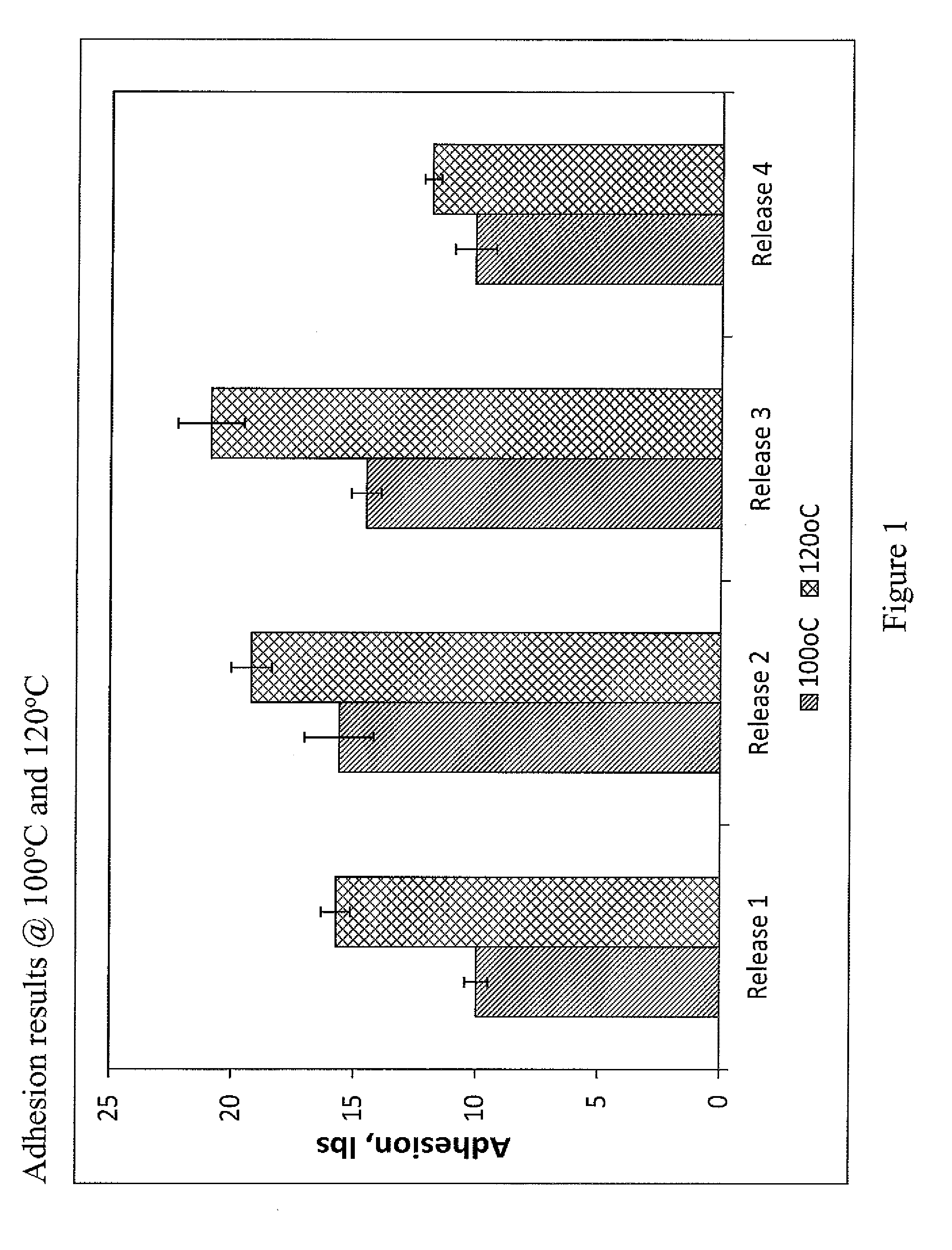

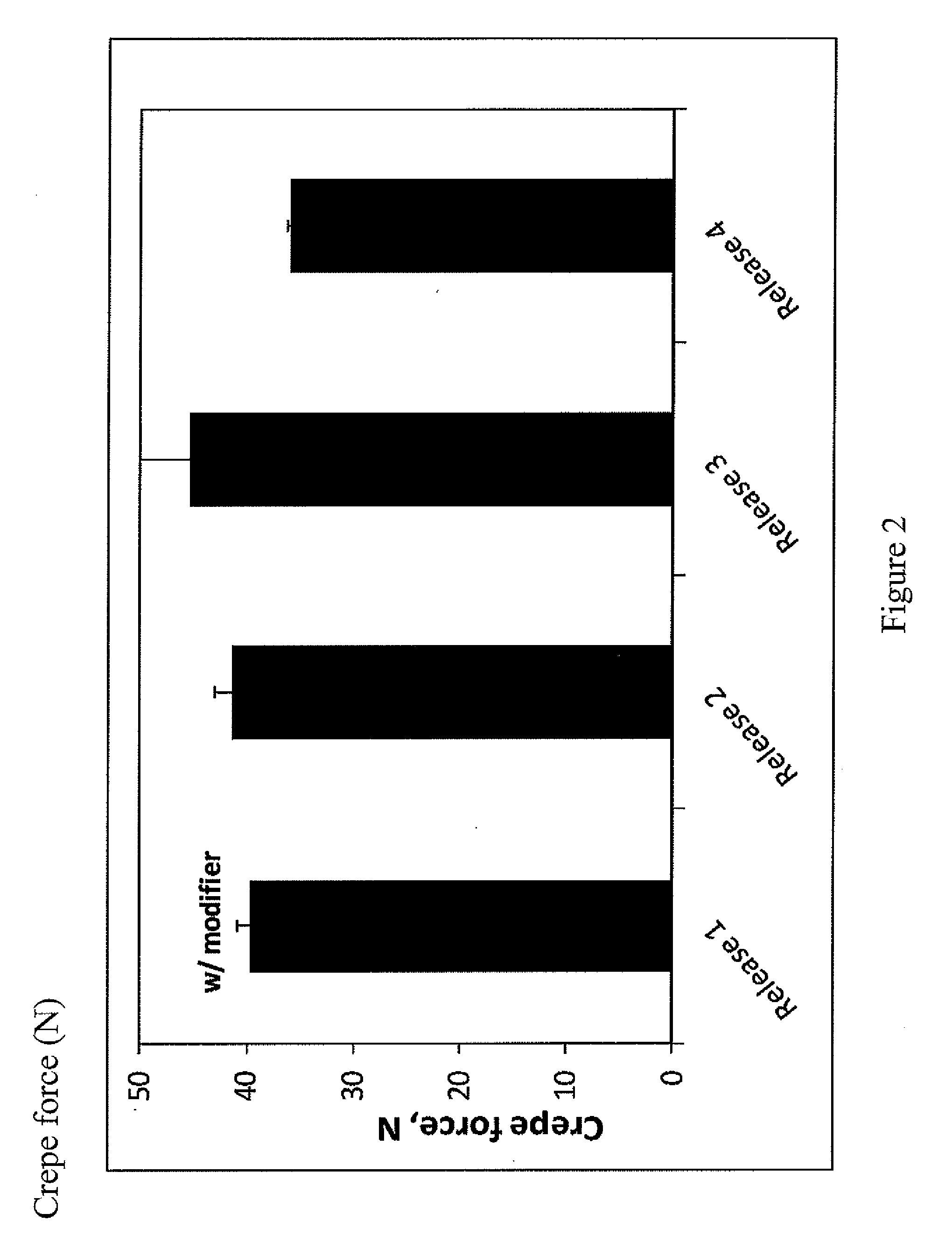

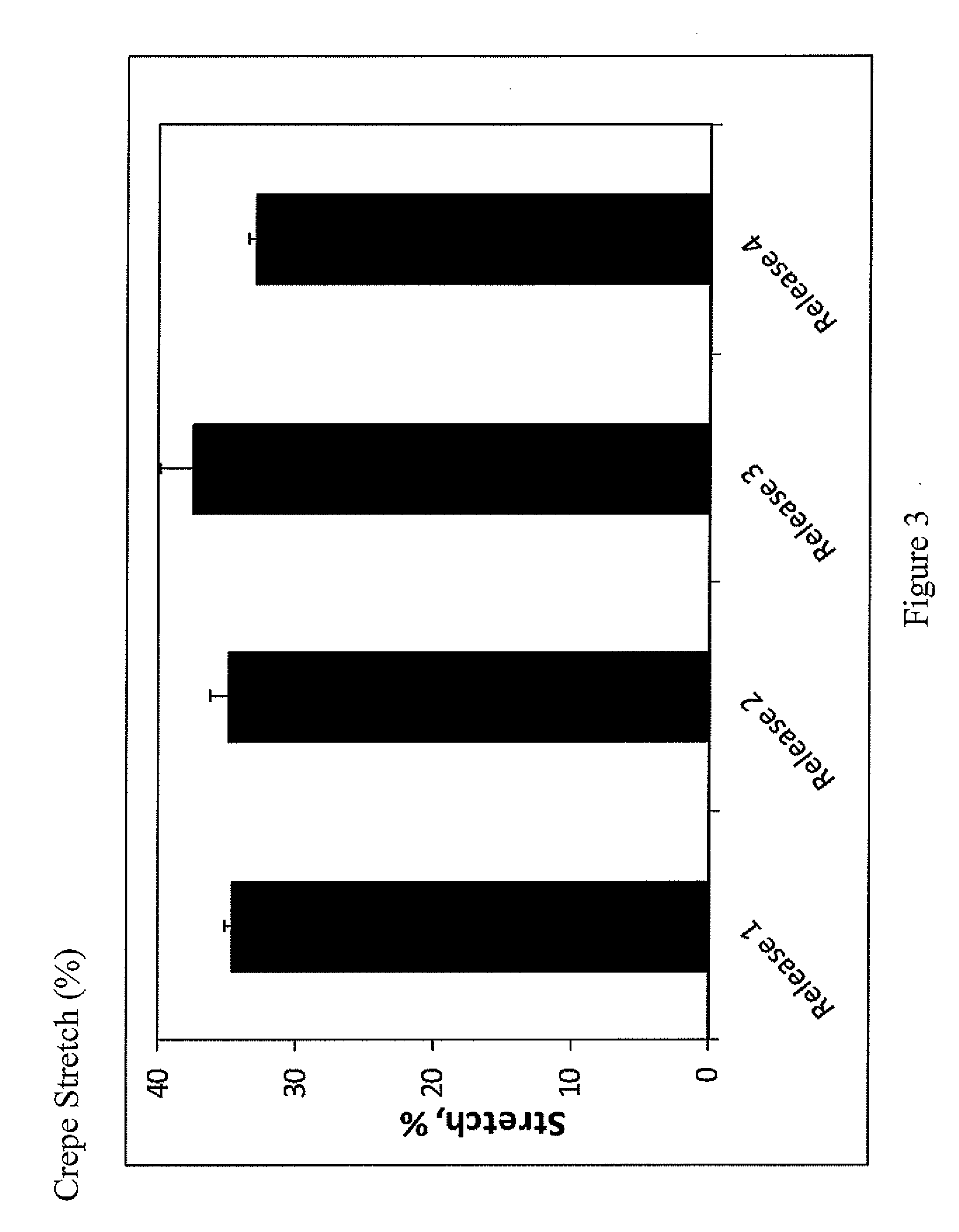

A creping aid system for use on a creping cylinder, for example, a Yankee dryer, comprises a creping adhesive and a creping modifier, the combination comprising polyethylene.

Owner:SOLENIS TECH CAYMAN

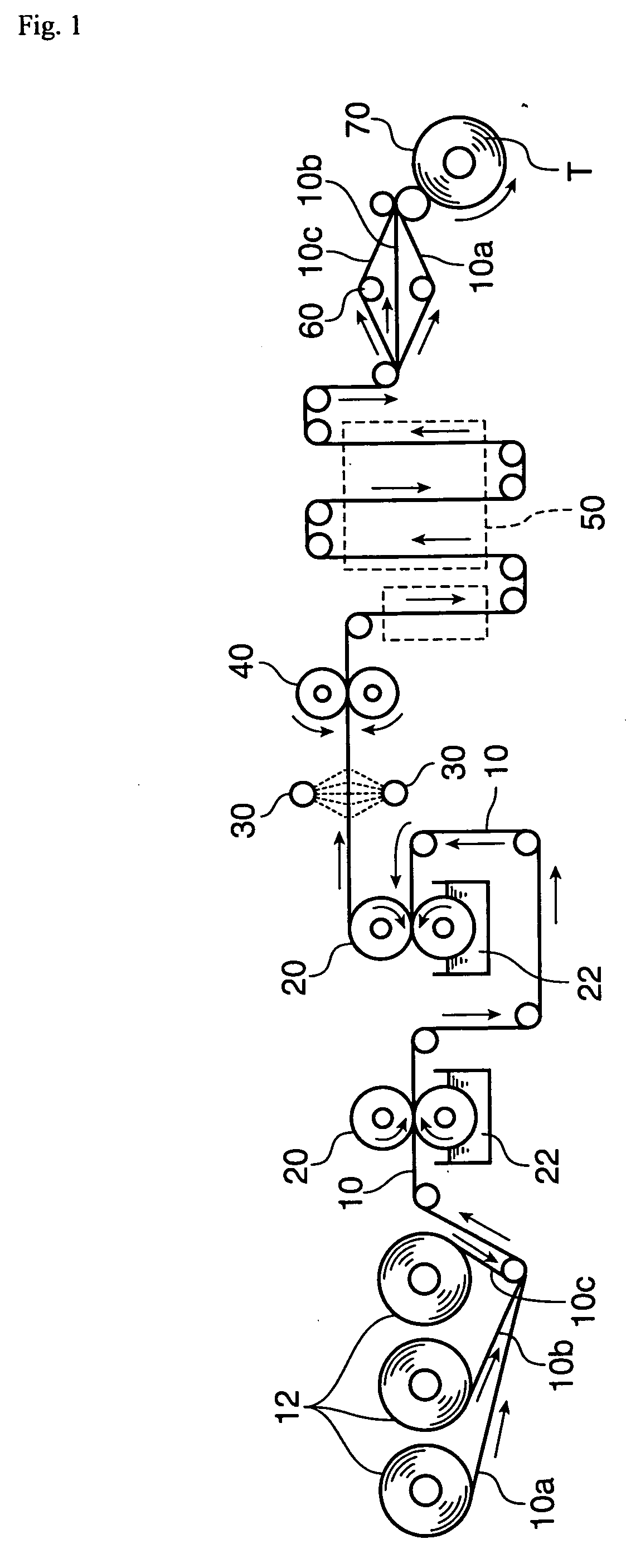

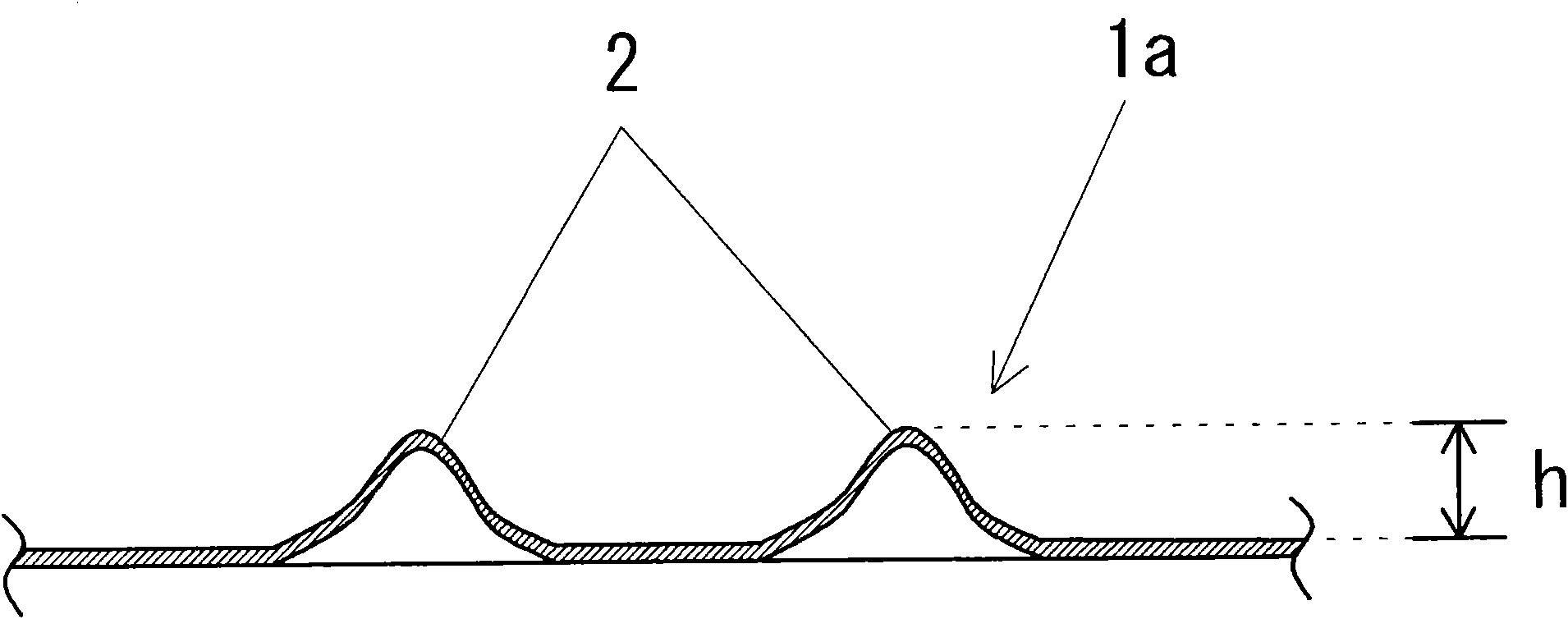

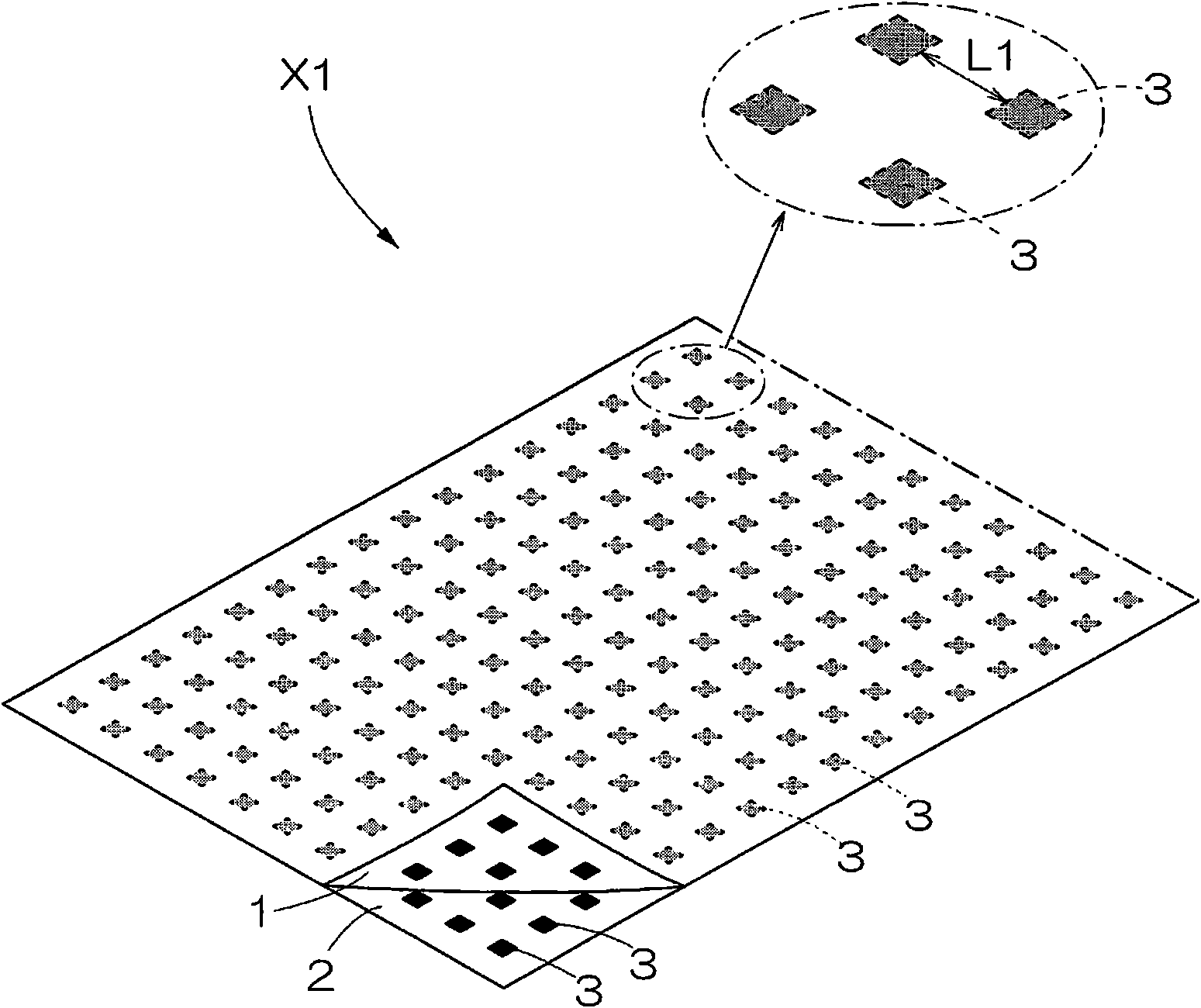

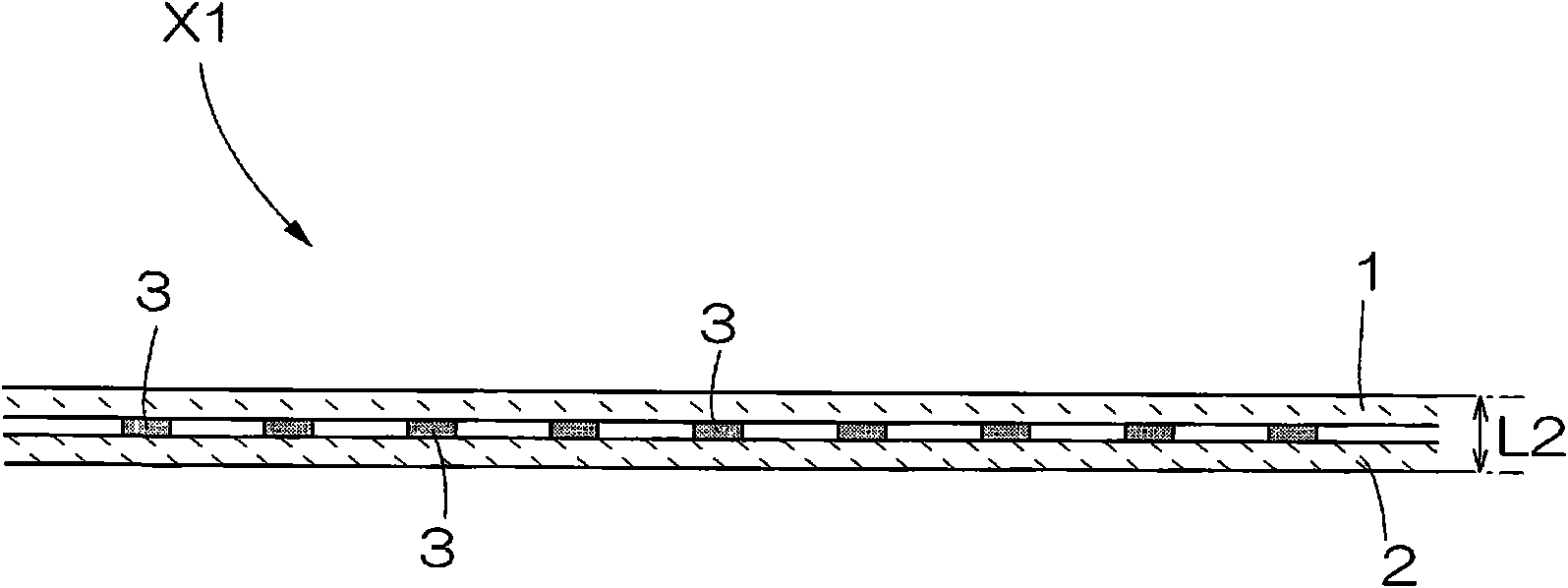

Embossed crepe paper and its manufacturing method

ActiveUS20060278357A1Property is spoiled littleDestruction of hydrogen bondingNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperPulp and paper industry

An object of the present invention is to provide an embossed crepe paper which can clearly be formed into fine embossed shapes, and is excellent in the fluffy feel and therefore excellent in such as absorbency for fats. As a means of achieving this object, the method for manufacturing an embossed crepe paper, according to the present invention, is a method for manufacturing an embossed crepe paper comprising a step of embossing a raw crepe paper, wherein: a raw paper having a basis weight of 6 to 28 g / m2 is used as the raw crepe paper; and the embossing step includes the steps of: (a) supplying the raw crepe paper with water in an amount of 0.1 to 100 weight % based on the basis weight to thereby put the raw crepe paper in a wet condition; (b) embossing the wet-conditioned raw crepe paper; and (c) drying the embossed wet-conditioned raw crepe paper.

Owner:KAWANO PAPER

Paper machine and press section thereof

InactiveUS6998022B2Simple partsLower capital expenditureNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperEngineering

A soft crepe paper machine comprises a wet section with a press section having a press defined by first and second press elements forming a press nip through which a press felt runs with a paper web. A suction roll is arranged in the loop of the press felt before the press nip at a distance from the second press element, and the felt with the web thereon runs around the suction roll with a large wrap angle. A drying cylinder forms the second press element. The first press element is either a solid press roll, a suction press roll, or a variable crown press roll.

Owner:METABO PAPER KARLSTAD

Creped paper product and method for manufacturing

ActiveUS20060207735A1High tear strengthNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperPulp and paper industry

A creped paper product is provided according to the invention. The creped paper product comprises a result of creping a web of fibers comprising synthetic fibers to provide a creped paper product having a stretch of at least 3% in the machine direction according to TAPPI test T494. The web of fibers can include about 0.5 wt. % to 100 wt. % synthetic fibers based on the total weight of the fibers. In addition, the web of fibers can contain about 0.5 wt. % to about 10 wt. % of synthetic fibers and about 90 wt. % to about 99.5 wt. % of cellulosic fibers. When the web of fiber includes a mixture of synthetic fibers and cellulosic fibers, the creped paper product can be provided having a tear strength in the machine direction according to TAPPI test T494 at least 10% greater than an otherwise identical creped paper product that does not contain synthetic fibers. A method for forming a creped paper product is provided according to the invention.

Owner:AHLSTROM MUNKSJO NA SPECIALTY SOLUTIONS LLC

Creping adhesives comprising blends of polyaminoamide epihalolhydrin resins and polyamides

A composition comprising one or more polyaminoaminde epihalohydrin resins and one or more polyamides in a ratio of about 1:99 to about 99:1 based on polymer actives and use of the composition for creping paper webs.

Owner:ECOLAB USA INC

Creping adhesives comprising blends of polyaminoamide epihalolhydrin resins and polyamides

A composition comprising one or more polyaminoaminde epihalohydrin resins and one or more polyamides in a ratio of about 1:99 to about 99:1 based on polymer actives and use of the composition for creping paper webs.

Owner:ECOLAB USA INC

Creping adhesives comprising blends of high and low molecular weight resins

A composition comprising one or more high molecular weight resins and one or more low molecular weight resins in a ratio of about 1:99 to about 99:1 based on polymer actives, wherein said high molecular weight resins are selected from the group consisting of glyoxylated polyacrylamide, crosslinked polyaminoamide and polyaminoamide-epihalohydrin resins having a molecular weight of about 100,000 to about 5,000,000 Dalton and the low molecular weight resins are selected from the group consisting of glyoxylated polyacrylamide, crosslinked polyaminoamide and polyaminoamide-epihalohydrin resins having a molecular weight of less than about 100,000 Dalton and wherein the mole ratio of epihalohydrin to secondary nitrogen atoms in the high and low molecular weight polyaminoamide-epihalohydrin resins is less than about 0.5. and use of the composition for creping paper webs.

Owner:ECOLAB USA INC

Method for producing paper towel

InactiveCN102912676AReduce intensityHigh strengthWater-repelling agents additionReinforcing agents additionFiberPaper towel

The invention relates to a manufacturing method of a crepe paper product. A method for producing a paper towel comprises the following steps of: selecting 70-80 % of bleached softwood pulp and 20-30 % of straw pulp as raw materials; pulping the pulp by using a pulper, after beating the pulp by using a disc mill and adding auxiliary materials of an expanding agent, a softening agent and a wet strength agent to the pulp, molding, dehydrating and squeezing the pulp by using a Harper fourdrinier system; creping a wet paper sheet in a creping cylinder when the dryness of the wet paper sheet is 30-45 %, wherein an angle between a creping knife and the tangential line of a cylinder surface is 20-30 degrees, the cutting edge angle of a scraping knife sticking to the cylinder surface is 60-85 degrees, and the speed ratio of the creping cylinder and a heating cylinder is 1.15-1.18:1; and then drying the wet paper sheet by using the heating cylinder; and winding, rewinding and slicing the paper sheet so as to obtain a finished product. The method for producing the paper towel, provided by the invention, has the advantages as follows: through fiber variety and proportion selection and through the adoption of a wet creping process, the paper towel are produced; and the produced the paper towel has the advantages of tensile strength and proper air permeability; and the strength, wet strength, hydrophobicity, air permeability, flexibility and the like of the paper towel all reach higher standards; therefore, high quality and low cost are achieved.

Owner:QUANZHOU HUAXIANG PAPER IND

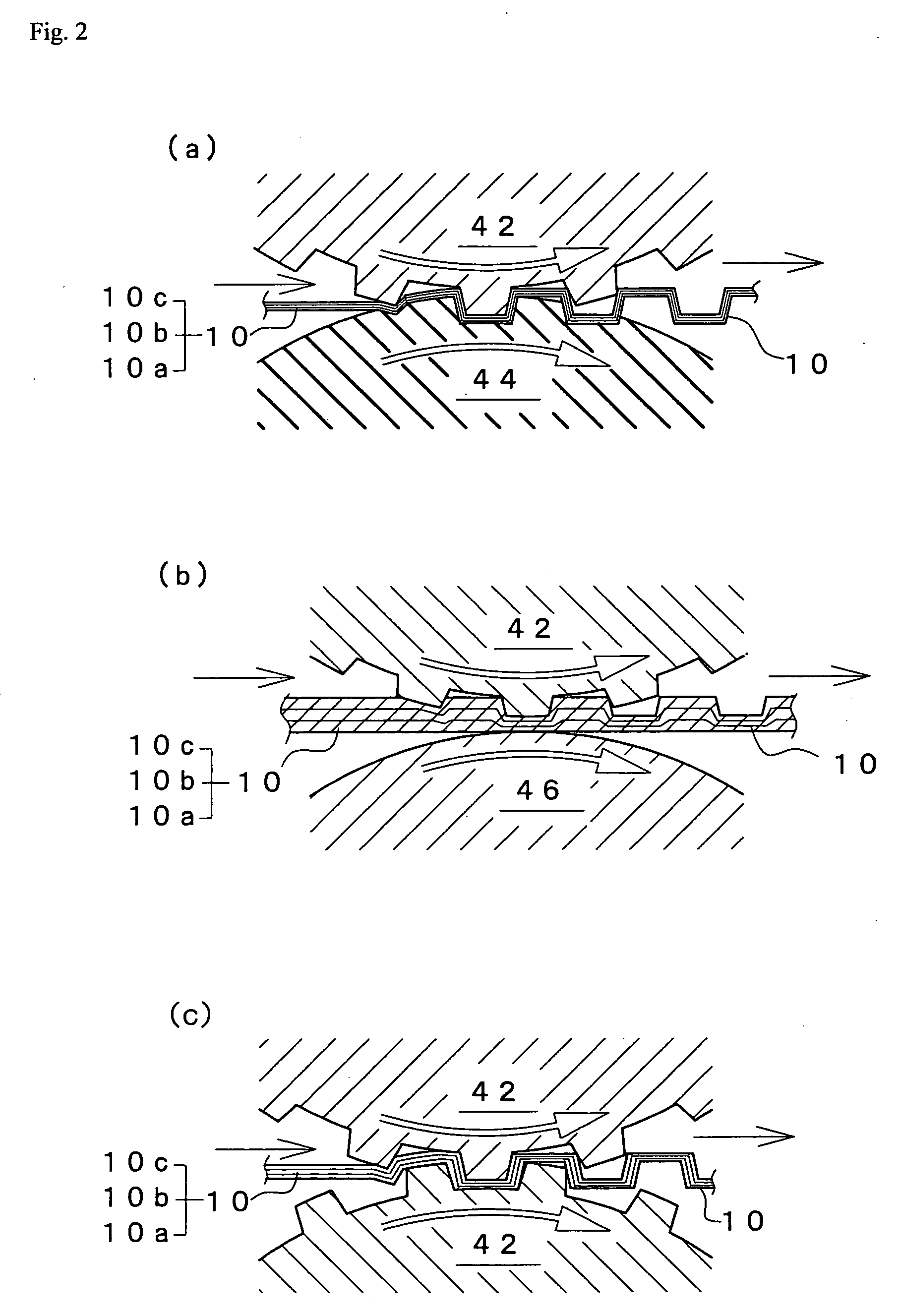

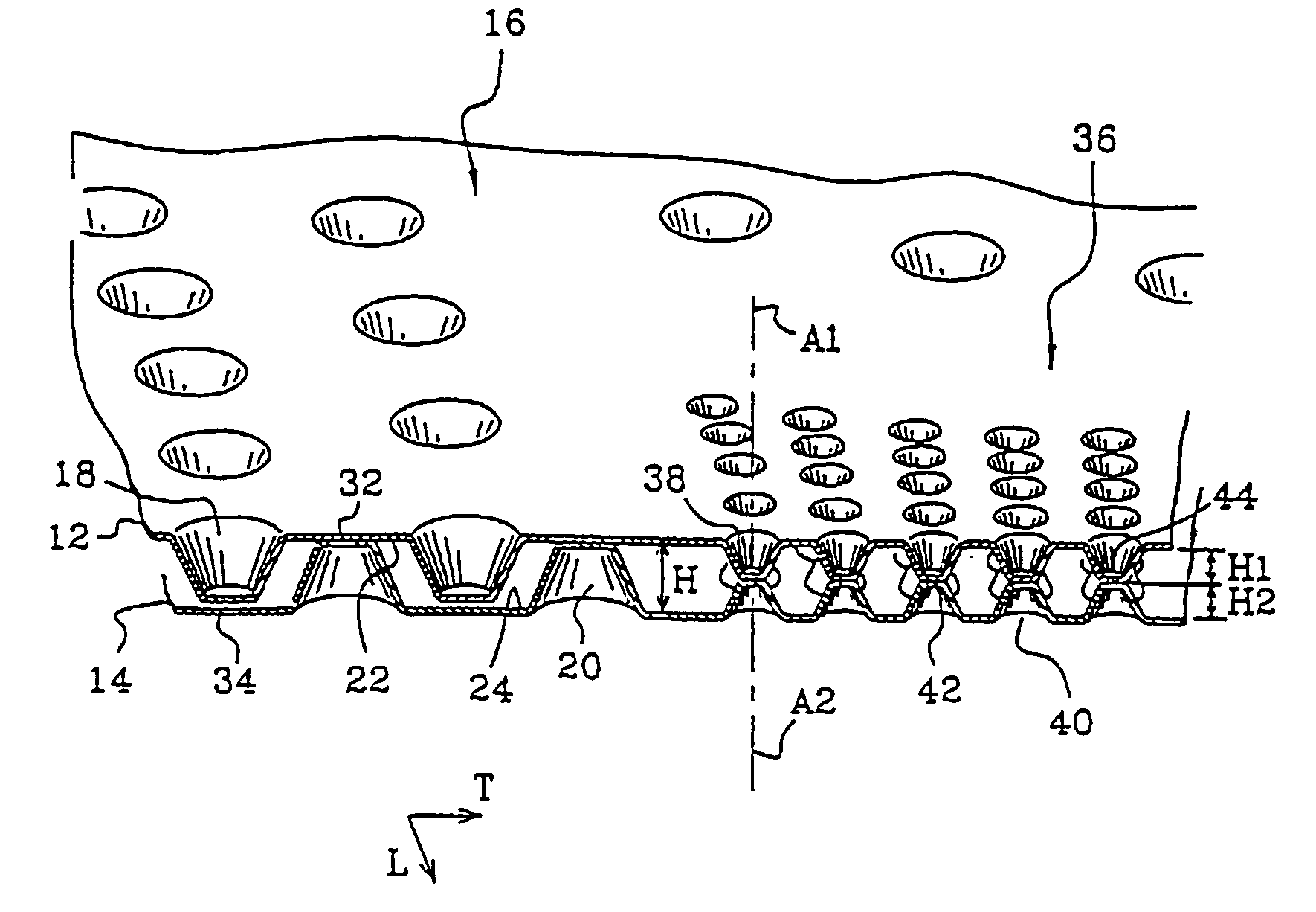

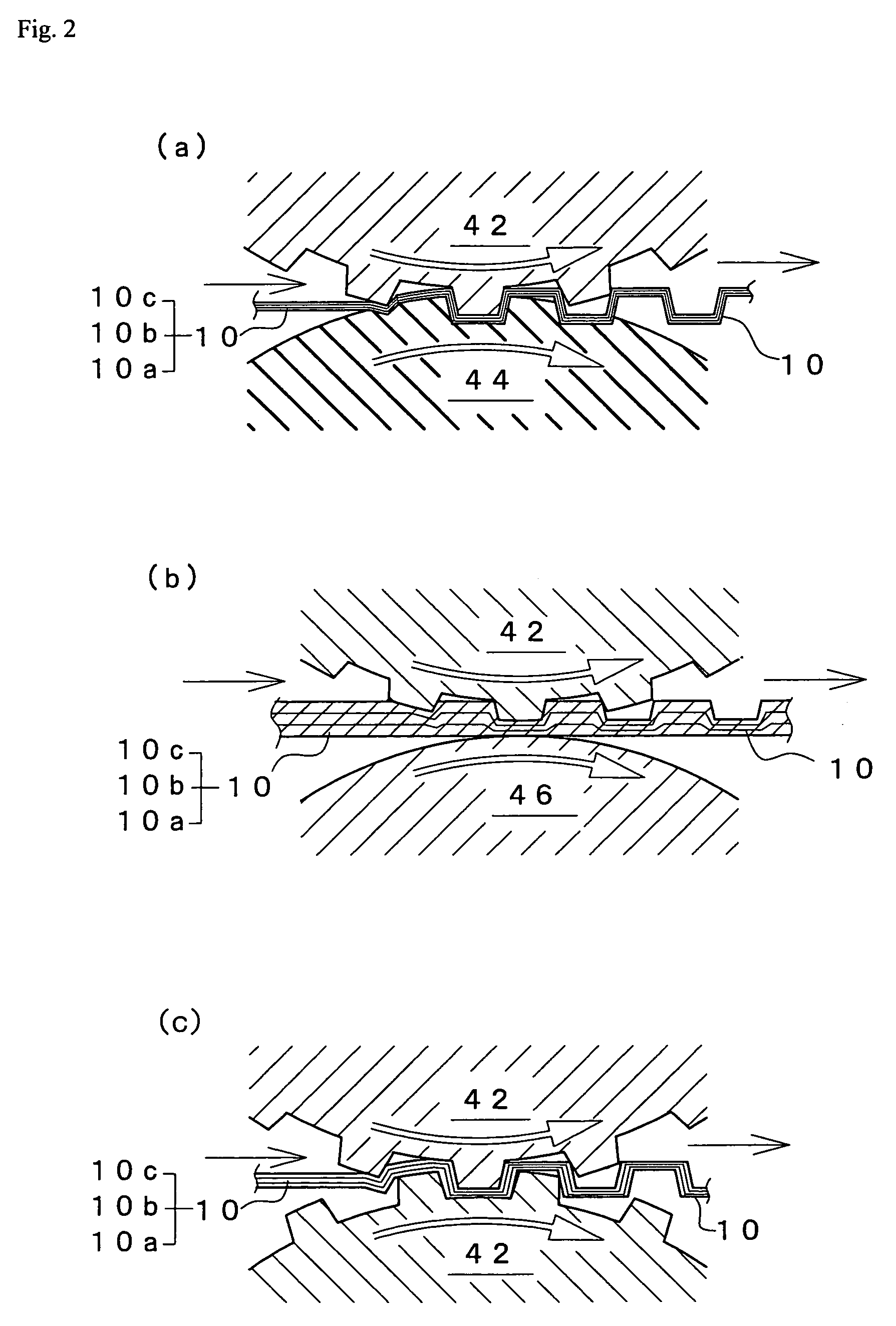

Sheet of absorbent creped paper, cylinder for embossing such a sheet and an embossing process

InactiveUS7083845B2Suppleness of the sheet to be increased without diminishing its mechanical characteristicsNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperEngineering

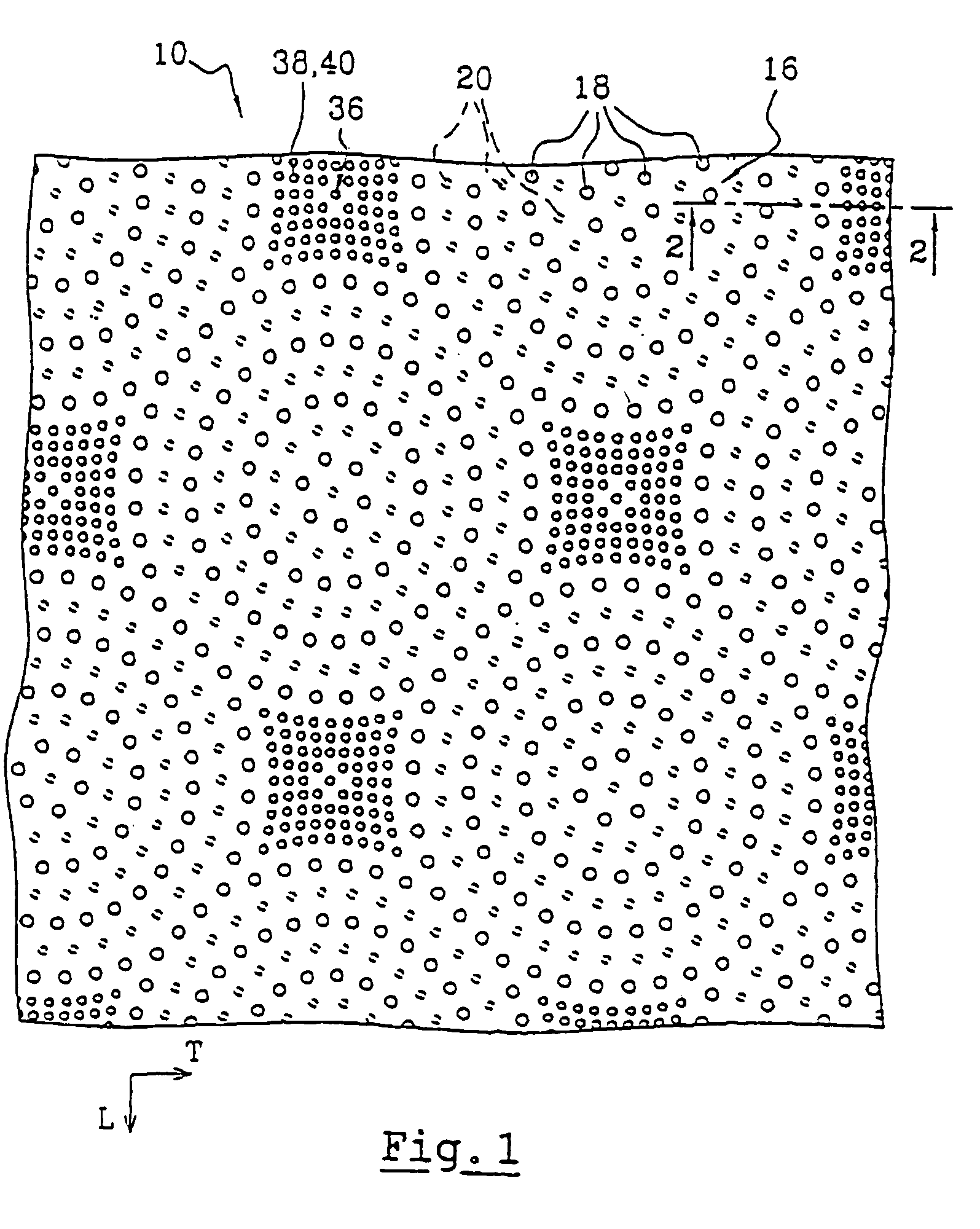

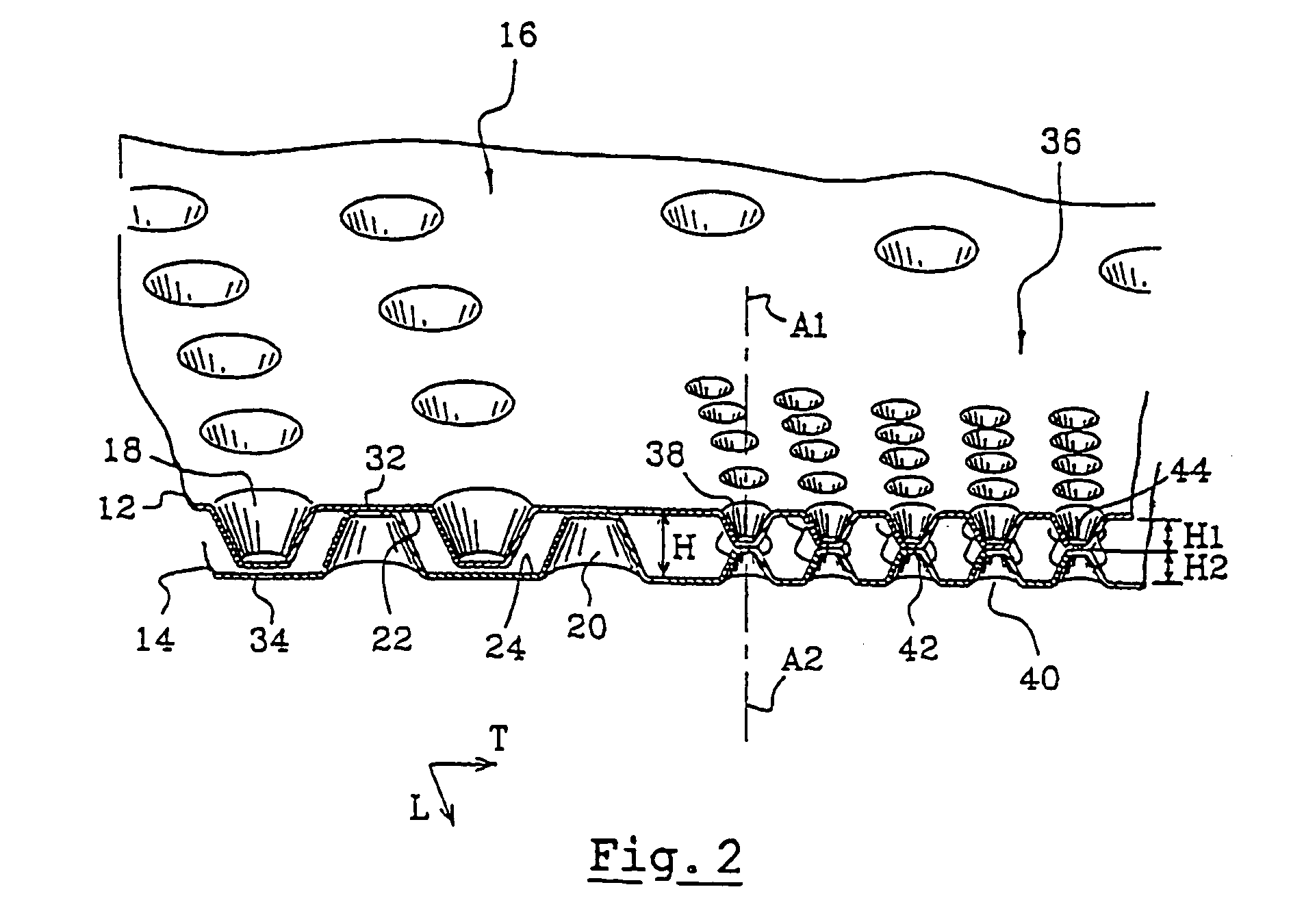

The invention relates to an embossed sheet 10 made up of at least a first and a second ply 12, 14 of creped cellulose cotton of the type in which the first ply 12 has an embossed design 16 involving a first series of first projections 18 that form in particular first alignments and in which the apexes 32 are connected to the internal face 24 of the facing second ply 14 characterized in that these two plies 12, 14 each have a second embossed design 36 involving a second series of second projections 38, 40, and by the fact that the apexes 42, 44 of the second projections 38, 40 of a ply 12, 14 extended outward and are facing and near apexes 44, 42 of the second projections 40, 38 of the other ply 14, 12.

Owner:GEORGIA PACIFIC FRANCE SAS

Manufacturing method of crepe paper

InactiveCN101760993AGood flexibilityGood high temperature resistanceSpecial paperWater-repelling agents additionCrêpe paperWet strength

The invention relates to a manufacturing method of crepe paper, which comprises the steps of preparing wood pulp, beating, papermaking, corrugating, drying and the like. The wood pulp formed by mixing 5-30% of (w / w) hardwood pulp and 70-95% of (w / w) softwood pulp is matched with 0.5-10% of (w / w) wet strength agent, 1-10% of (w / w) sizing agent and more than 5% of (w / w) softening agent for use in the beating process, and the manufactured crepe paper is not damaged under the conditions of 125 DEG C, 5 atmospheres and more than 30 minutes and is especially suitable for the use in steam sterilization.

Owner:PINGHU SANMA PLASTIC & PAPER PACKAGING

Disposable cutting sheet

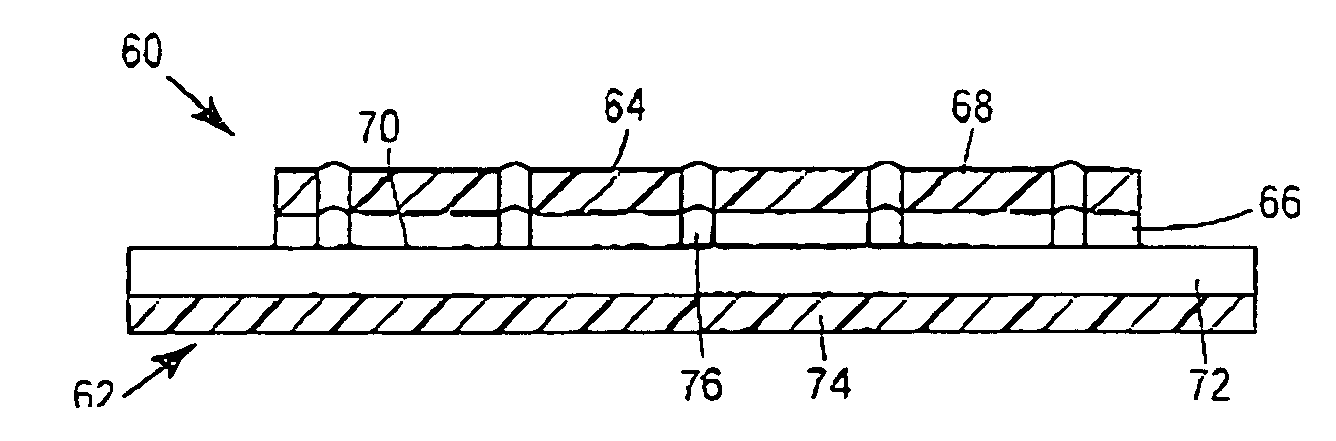

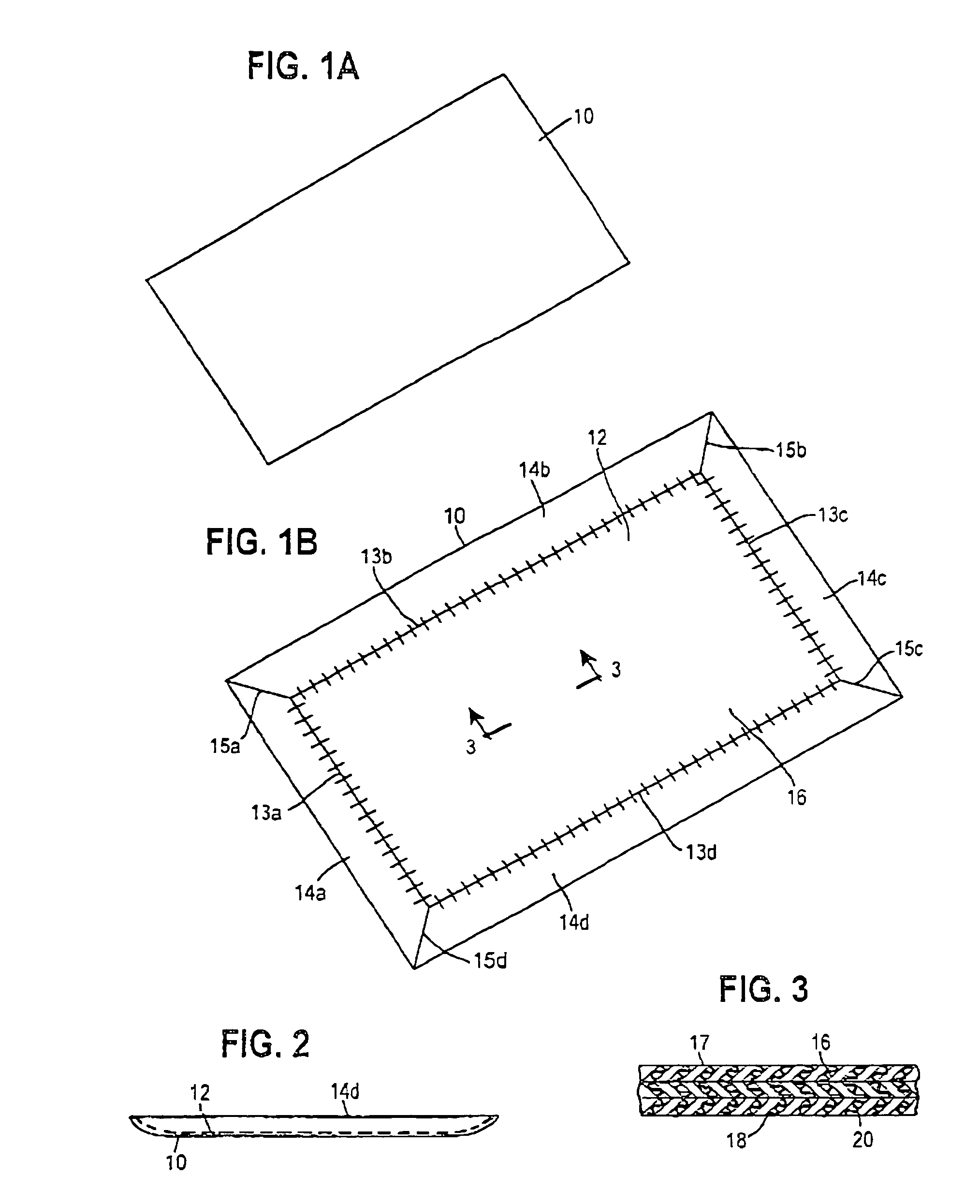

InactiveUS6991844B2Lamination ancillary operationsSynthetic resin layered productsCrêpe paperAbsorbent material

A disposable cutting sheet for cutting and preparation of food items thereon includes a first cut-resistant layer having a first surface area and including an absorbent ply and a thermoplastic material ply, wherein the thermoplastic ply of the first layer includes a plurality of apertures therein. The cutting sheet further includes a second layer having a second surface area and including an absorbent ply and a thermoplastic material ply. The first layer is disposed on and secured to the second layer such that portions of the thermoplastic and absorbent plies of the second layer extend beyond the surface area of the first layer to form a border completely surrounding the first layer. At least one of the absorbent plies is crepe paper, a roughened absorbent material, and / or includes an odor absorbing material therein.

Owner:SC JOHNSON HOME STORAGE INC

Medical crepe paper body paper

ActiveCN103161092AImprove the finishTissue is delicate and softReinforcing agents additionFiberWrinkly skin

The invention belongs to the technical field of special paper manufacturing, and particularly relates to medical crepe paper body paper which is used for protecting a sterilization instrument to carry out sterile storage or conveying in a sterile state. The medical crepe paper body paper is characterized in that cotton pulp and needle-point leaf wood pulp are used as fibrous materials, and a traditional papermaking technology is used for manufacturing the body paper, namely beating, rinsing, pulp rectifying, papermaking, slitting and packaging. The cotton pulp is used as the main raw material, the needle-point leaf wood pulp is used as the auxiliary raw material, the characteristics that cotton fibers are tough in property, fine and smooth and soft in texture, good in folding resistance and abrasion resistance and absorption performance are used, and therefore produced paper is fine and soft and good in smoothness. Polyphenylene oxide polyphenyl ether (PPE) wet strength agents are added in pulp, and the strength, the stiffness, the smoothness and the water resistance of the crepe paper body paper are further improved. The medical crepe paper body paper is soft in hand feel, good in air permeability, high in strength, high in tensile strength, good in smoothness and good in water resistance.

Owner:杭州特种纸业有限公司

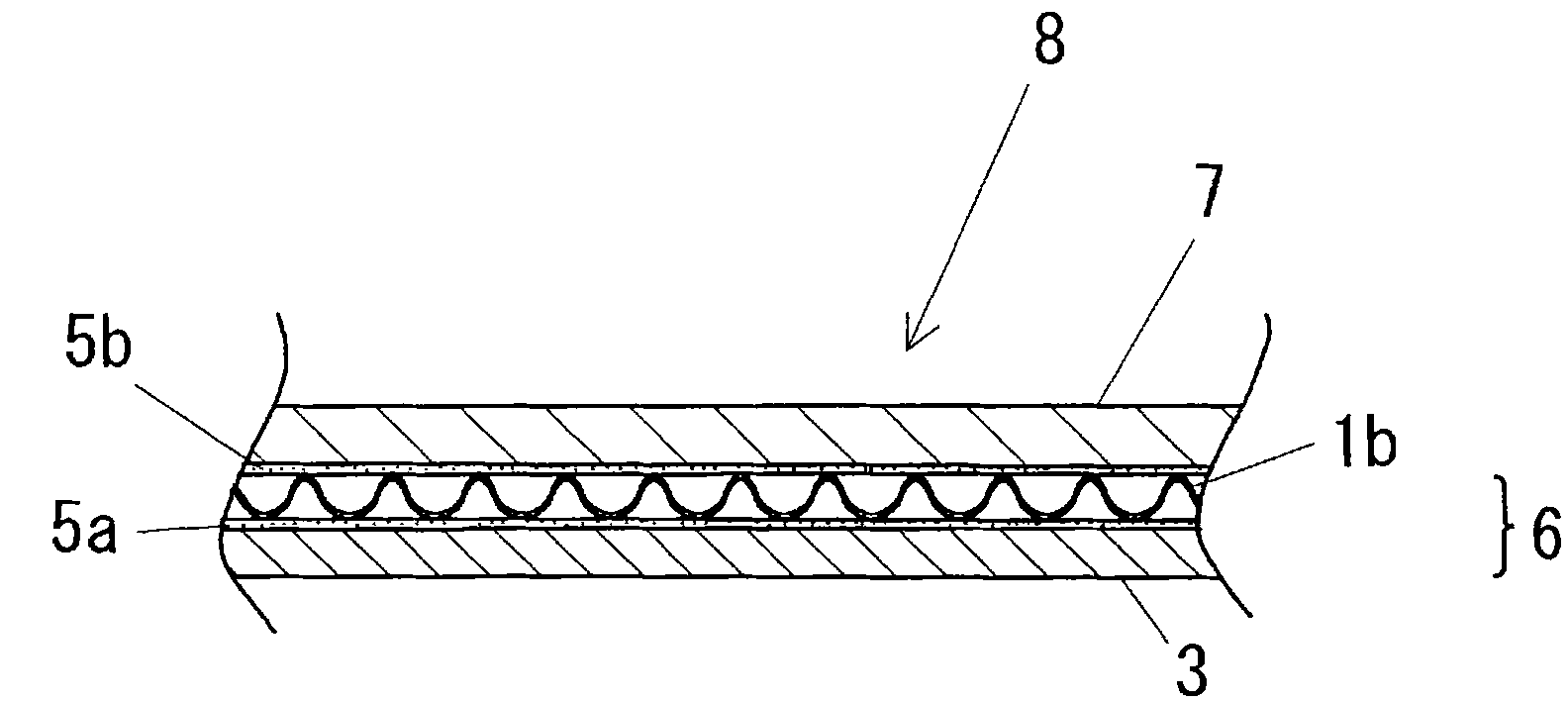

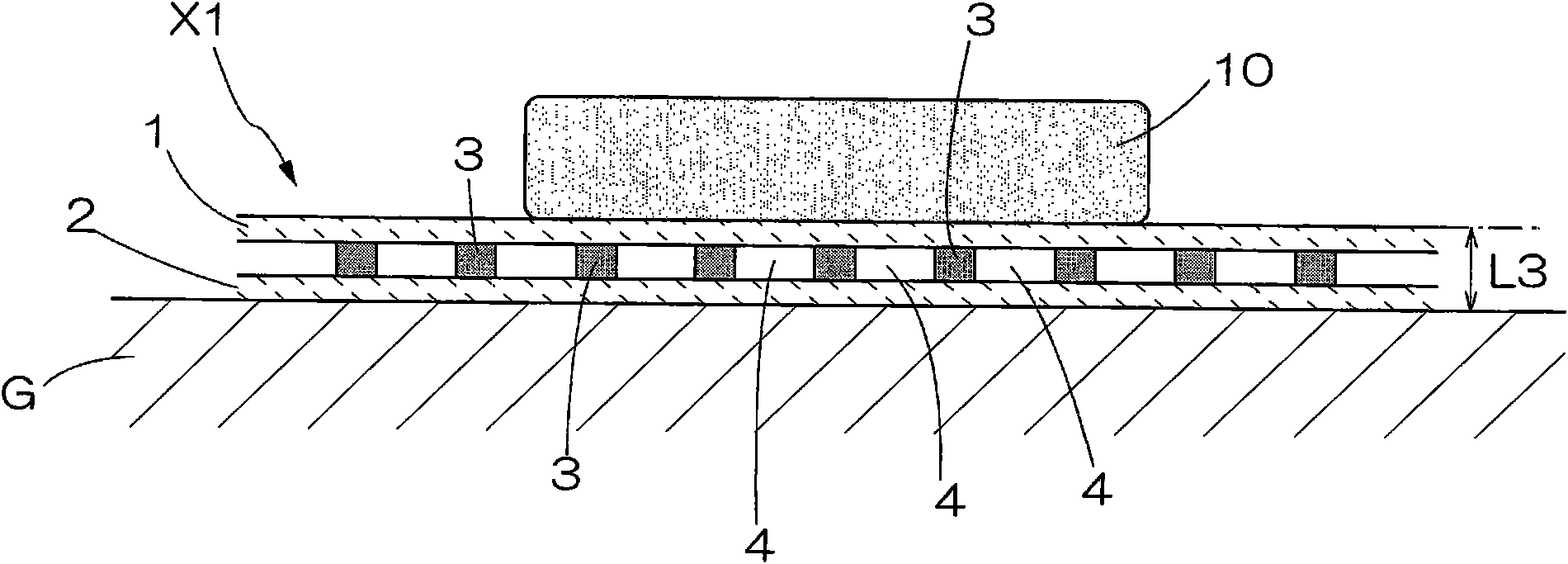

Sound absorbing skin material and sound absorbing material utilizing the same

ActiveCN101945762AAppropriate sound absorptionGood formabilityPaper/cardboard layered productsFloor coveringsFiberCrêpe paper

A lightweight sound absorbing skin material that excels in sound absorption and moldability; and a sound absorbing material utilizing the same. A fiber sheet (3) on its one major surface or both major surfaces is laminated with a creped and / or embossed drawn paper material (for example, creped paper (1b)) to thereby obtain a sound absorbing skin material (6). The drawn paper material has a crepe ratio of 10 to 50%, a projection height of 0.02 to 2.00 mm and a projection count of 20 to 200 projections / cm2. The sound absorbing skin material (6) is laminated with a sheetlike breathable porous material (7) to thereby obtain a sound absorbing material (8).

Owner:NAGOYA OIL CHEM CO LTD

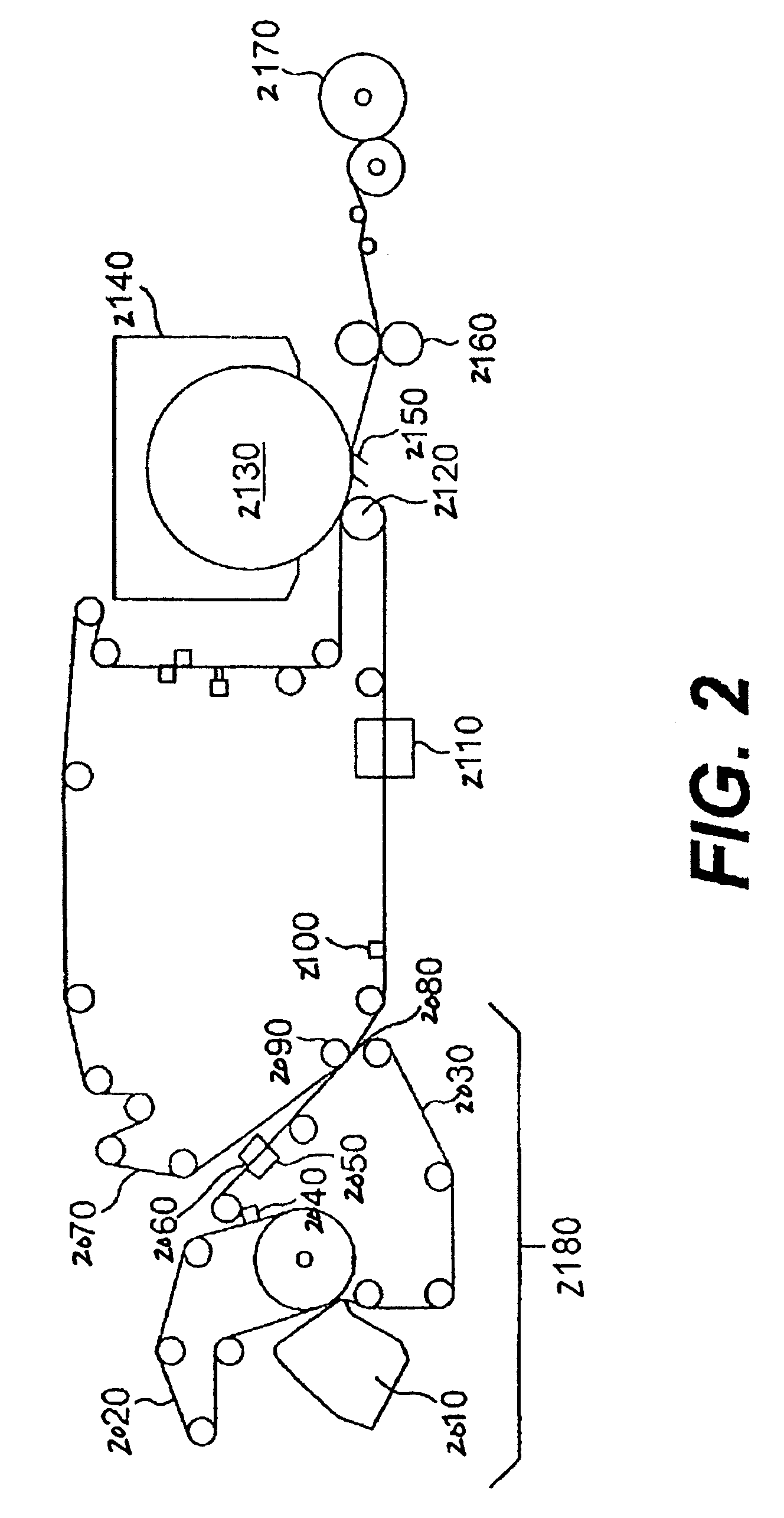

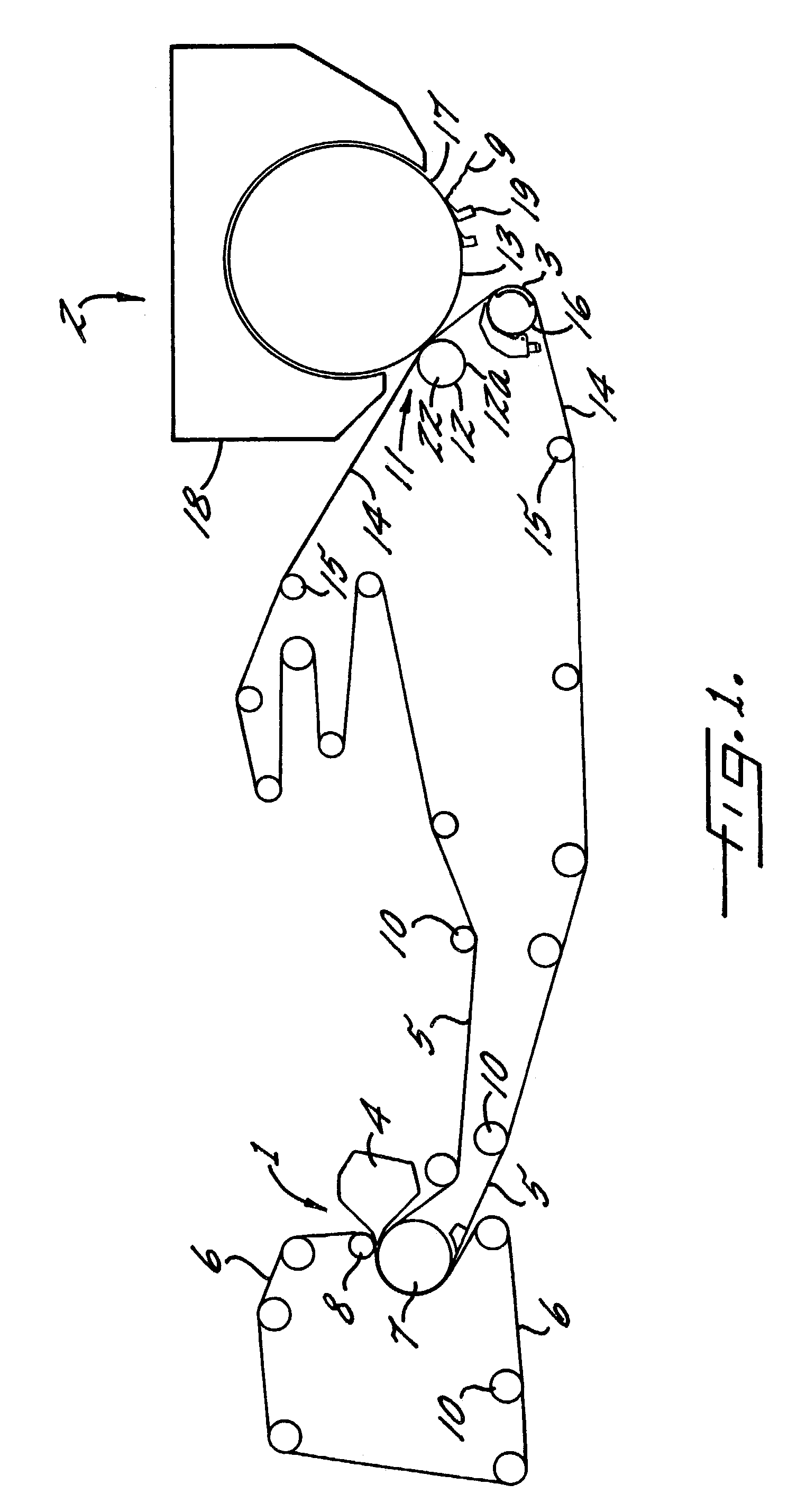

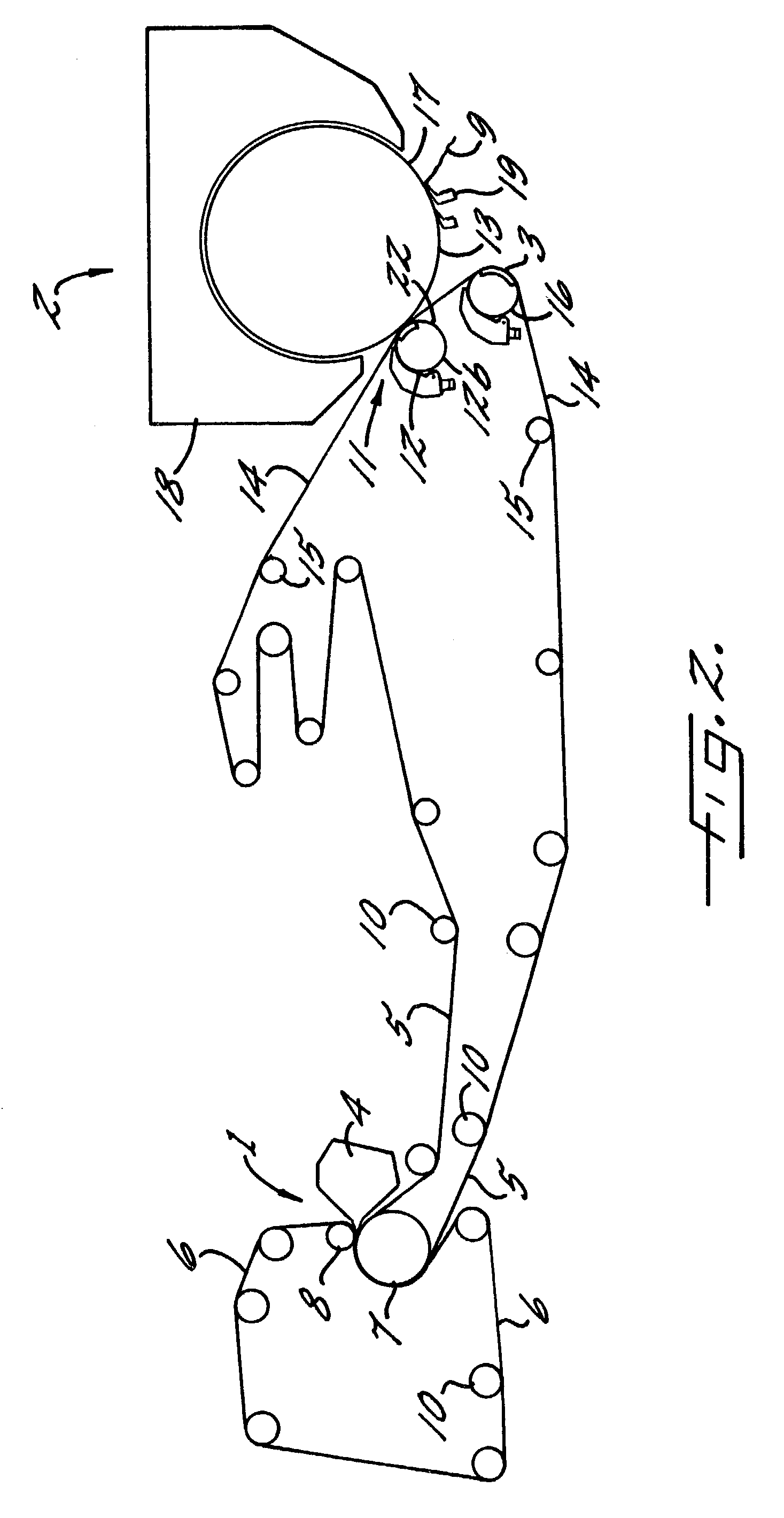

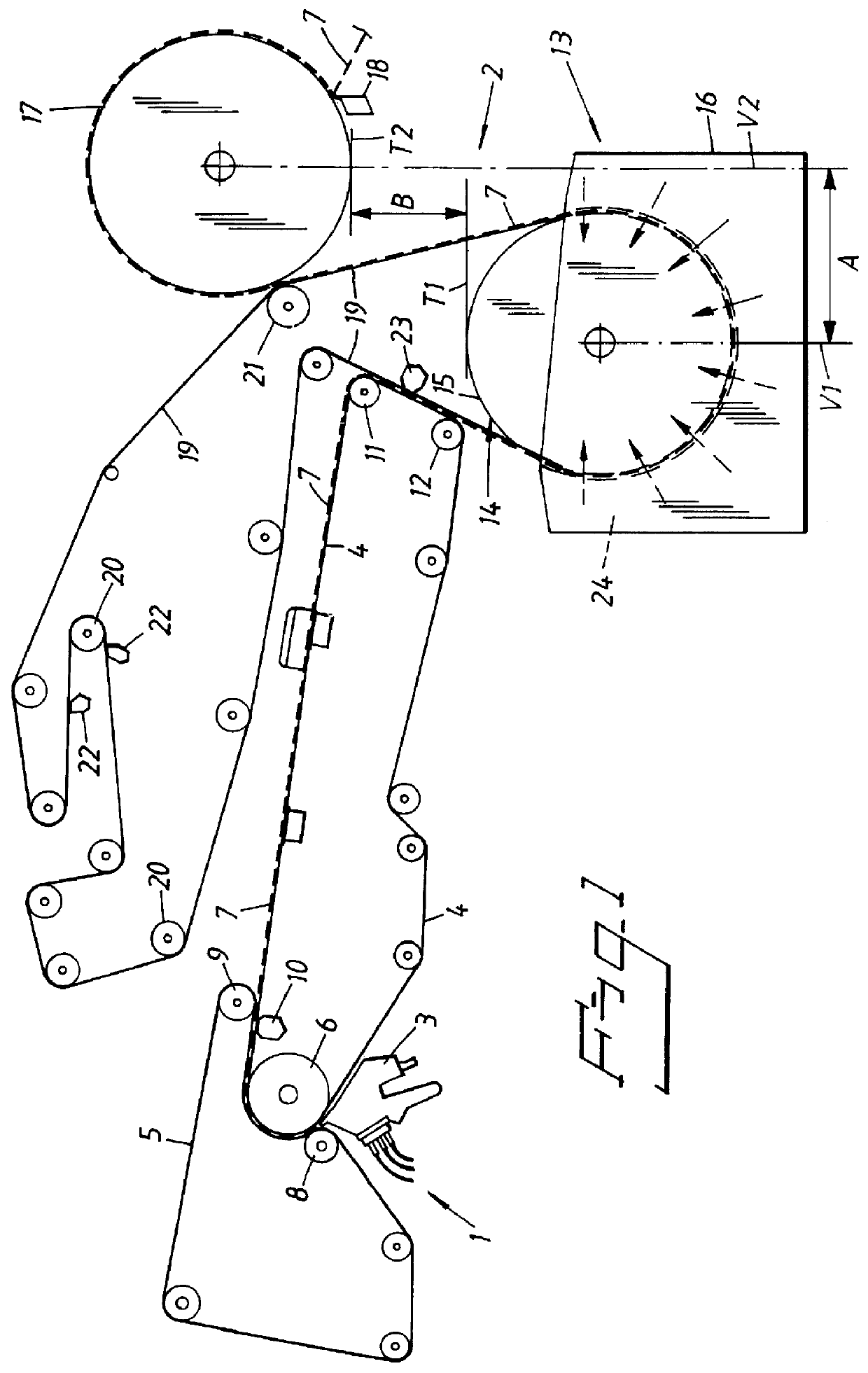

Paper machine for manufacturing a web of soft crepe paper

A paper machine for manufacturing a web of soft crepe paper comprises a wet end (1) having at least one forming wire (4) for forming and supporting a web (7), and a drying section (2) with a through drying machine (13), a drying cylinder (17) and a perforated belt (19) running around a through-blow cylinder of the through drying machine and a transfer roll (21) at the drying cylinder, the web running through the through drying machine being exposed to drying air after its transfer from the forming wire. The belt (19) and the web (7) move from the through drying machine (13) to the drying cylinder (17) in a run that is free from mechanical means which would compress the web, whereby in said run the surface of the web which is exposed to the drying air faces away from the belt and remains free from contact with such means up to the drying cylinder.

Owner:VALMET KARLSTAD

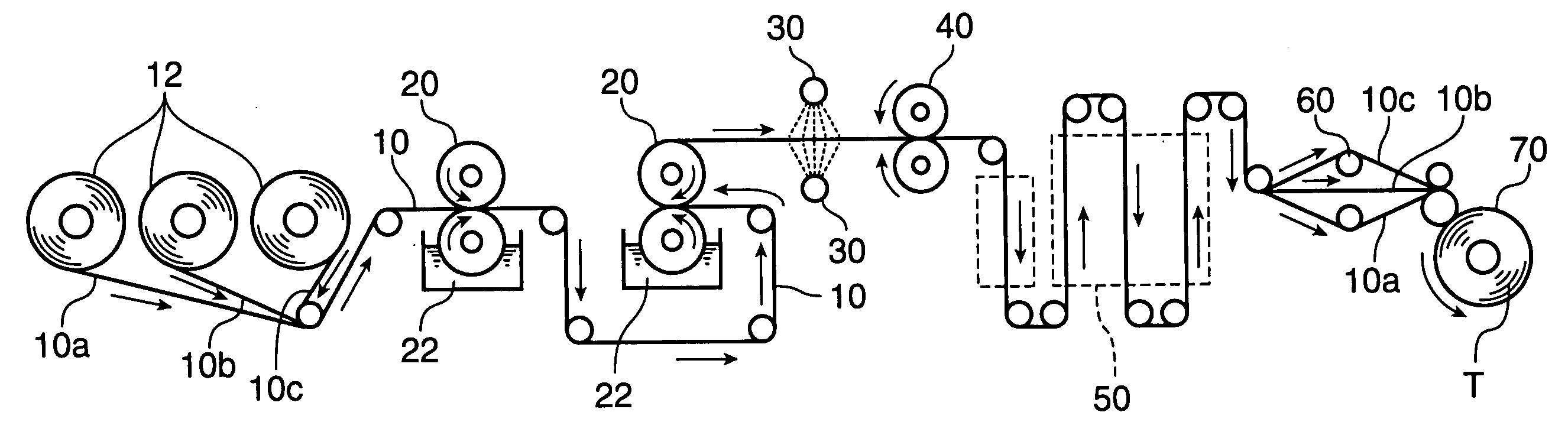

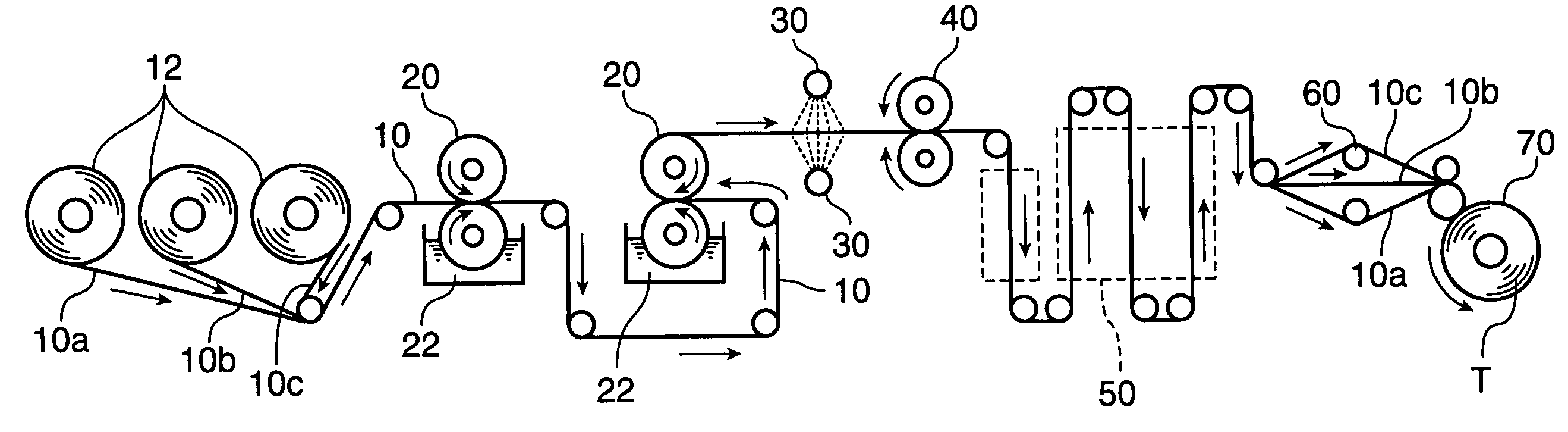

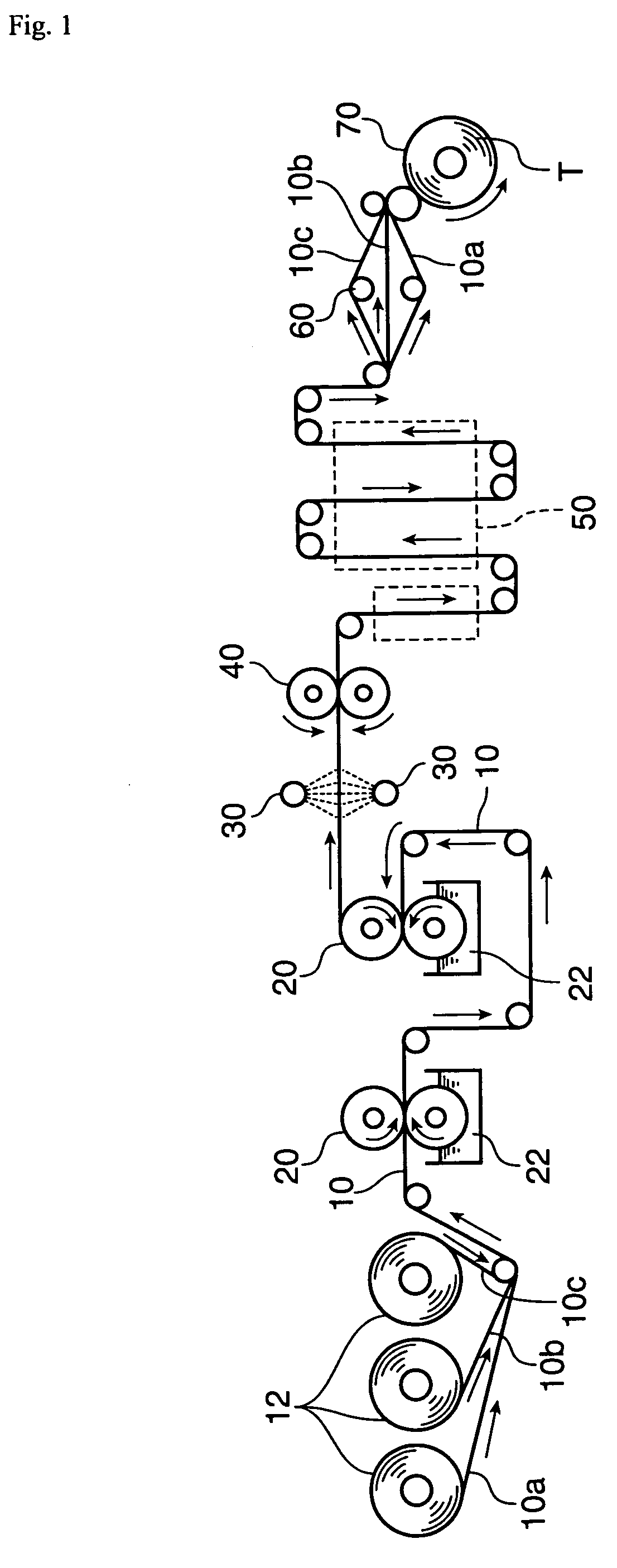

Embossed crepe paper and its manufacturing method

ActiveUS7799167B2Property is spoiled littleDestruction of hydrogen bondingNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperPulp and paper industry

An object of the present invention is to provide an embossed crepe paper which can clearly be formed into fine embossed shapes, and is excellent in the fluffy feel and therefore excellent in such as absorbency for fats. As a means of achieving this object, the method for manufacturing an embossed crepe paper, according to the present invention, is a method for manufacturing an embossed crepe paper comprising a step of embossing a raw crepe paper, wherein: a raw paper having a basis weight of 6 to 28 g / m2 is used as the raw crepe paper; and the embossing step includes the steps of: (a) supplying the raw crepe paper with water in an amount of 0.1 to 100 weight % based on the basis weight to thereby put the raw crepe paper in a wet condition; (b) embossing the wet-conditioned raw crepe paper; and (c) drying the embossed wet-conditioned raw crepe paper.

Owner:KAWANO PAPER

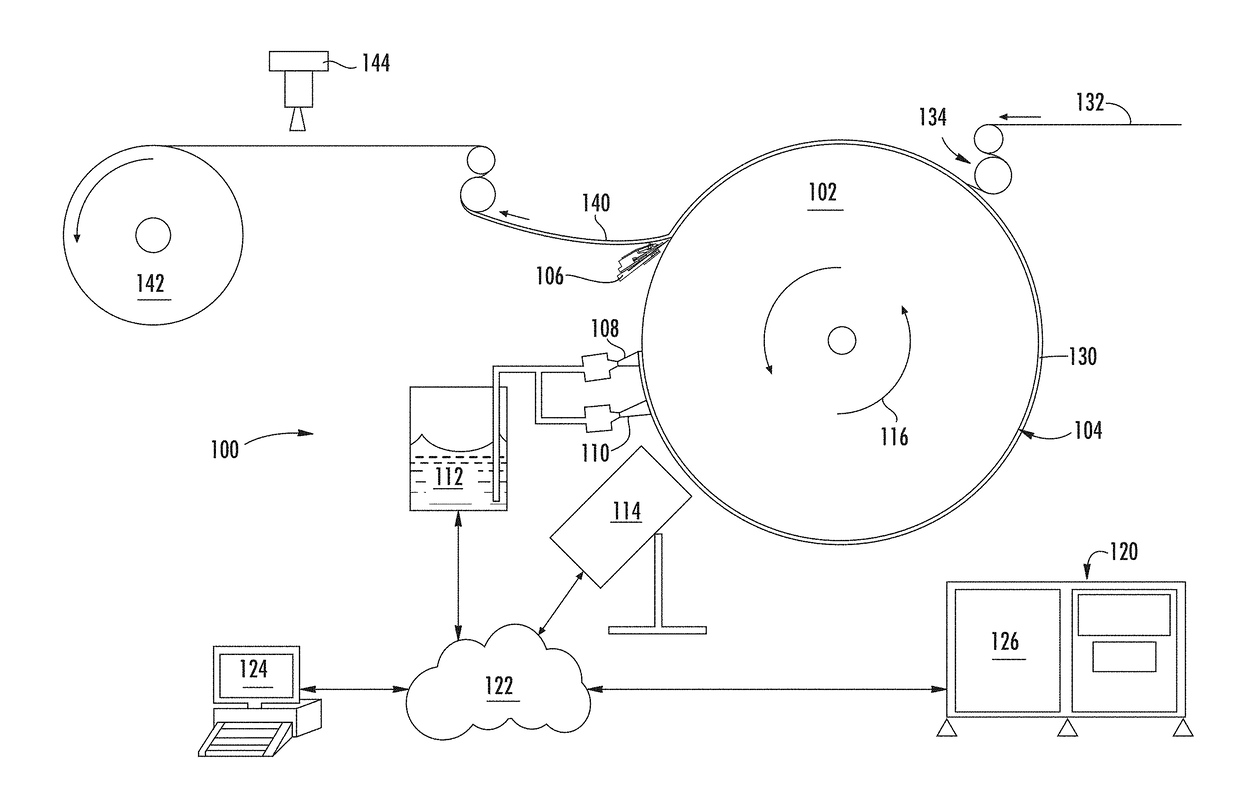

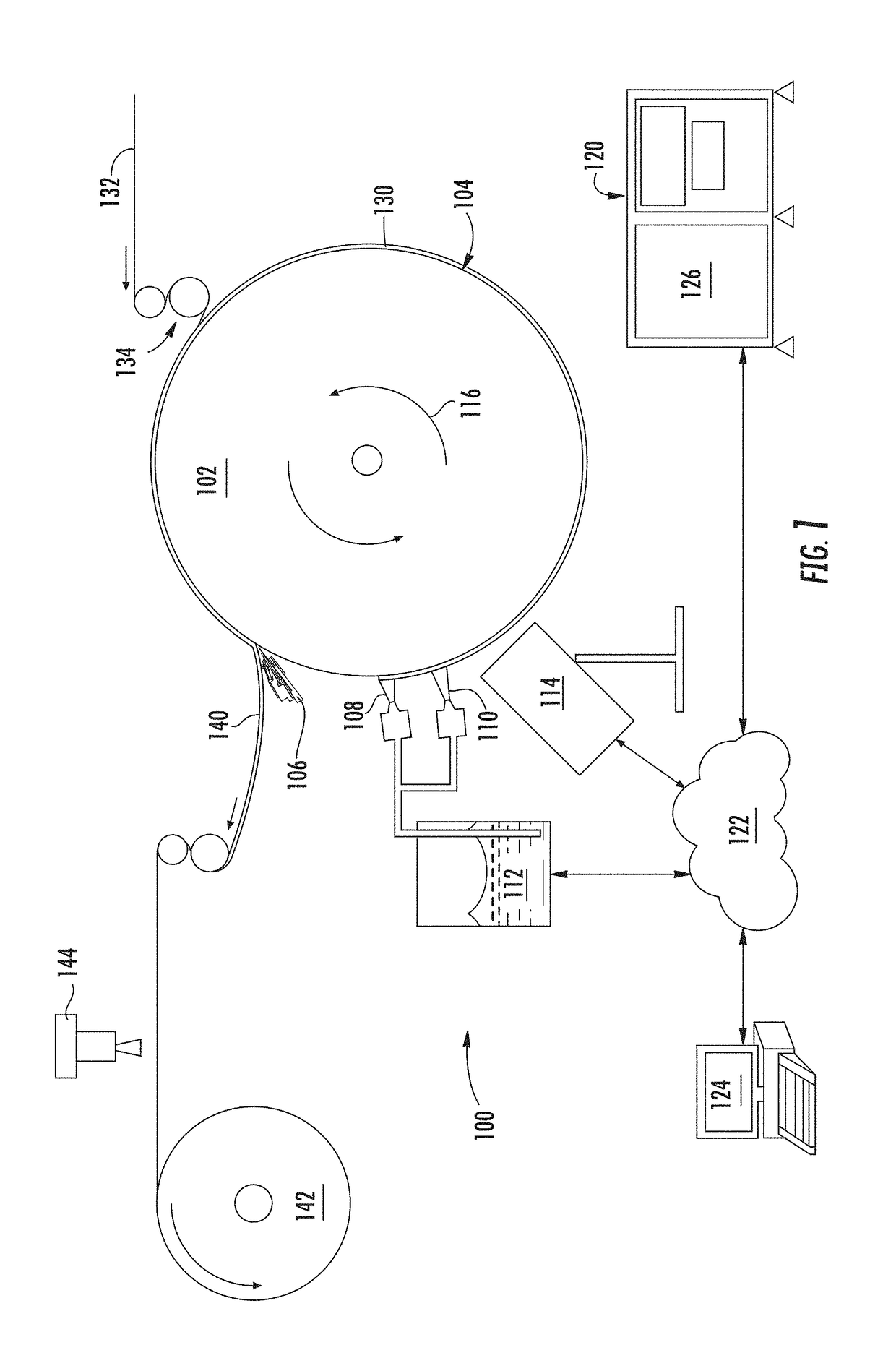

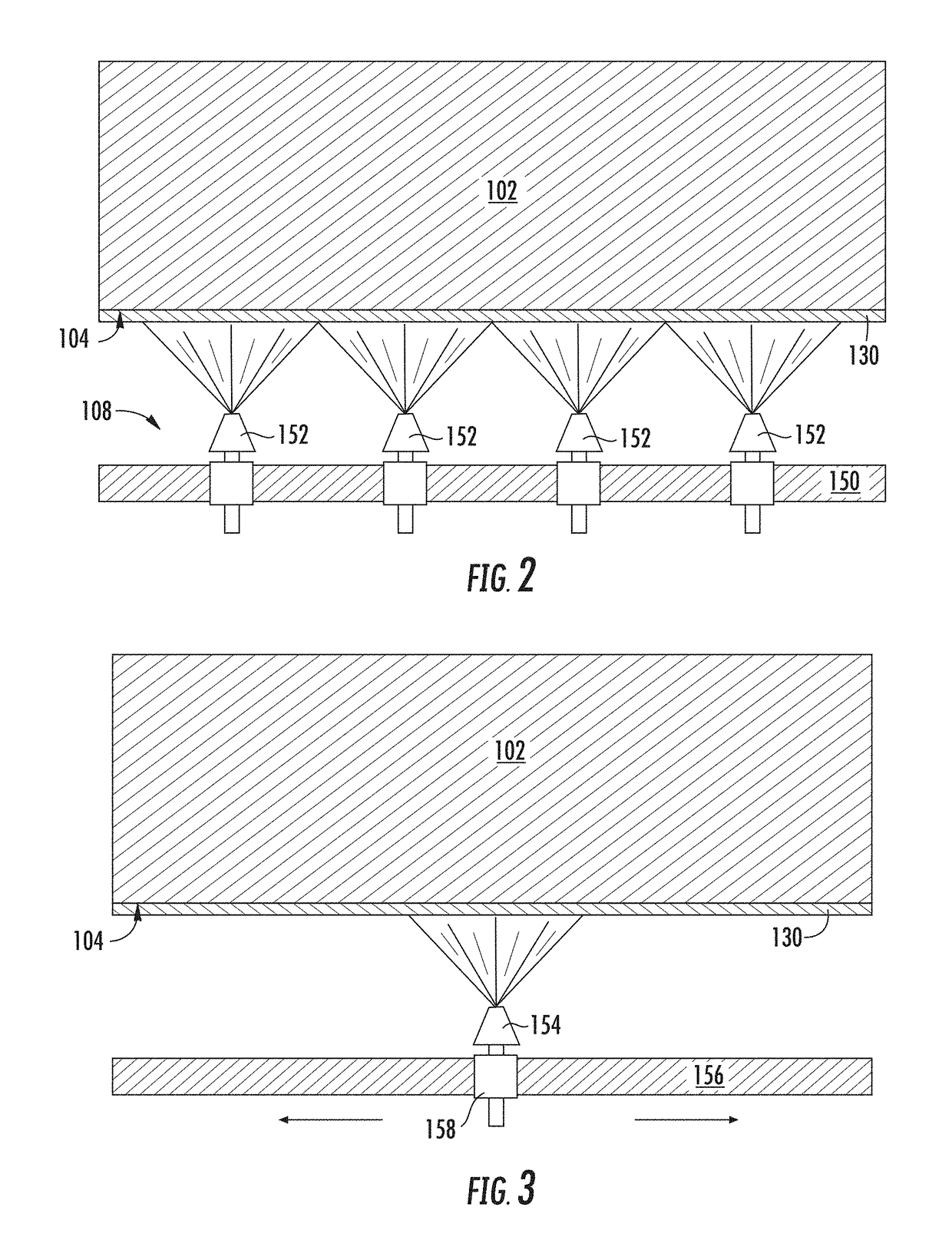

Yankee dryer profiler and control

ActiveUS20180119359A1Influence qualityQuality improvementMechanical working/deformationCoated paper substrateCrêpe paperYankee

A method for creping paper includes applying an adhesive composition to an outer surface of a creping cylinder (Yankee cylinder) to form an adhesive coating, contacting paper with the adhesive coating, removing the paper and adhesive coating from the creping cylinder, and determining a quality of the adhesive coating. Determining the quality of the adhesive coating may include measuring a degree of cross-linking of the adhesive polymer, a concentration of the adhesive polymer in the adhesive coating, a water content of the adhesive coating, an ash content of the adhesive coating, or combinations thereof. Determining the quality of the adhesive coating may also include determining a thickness of the adhesive coating by measuring light absorbed by the coating and calculating the thickness using Beer's Law. Systems and apparatuses for determining the quality of the adhesive coating and for creping paper are also disclosed.

Owner:GORDEN MICHAEL

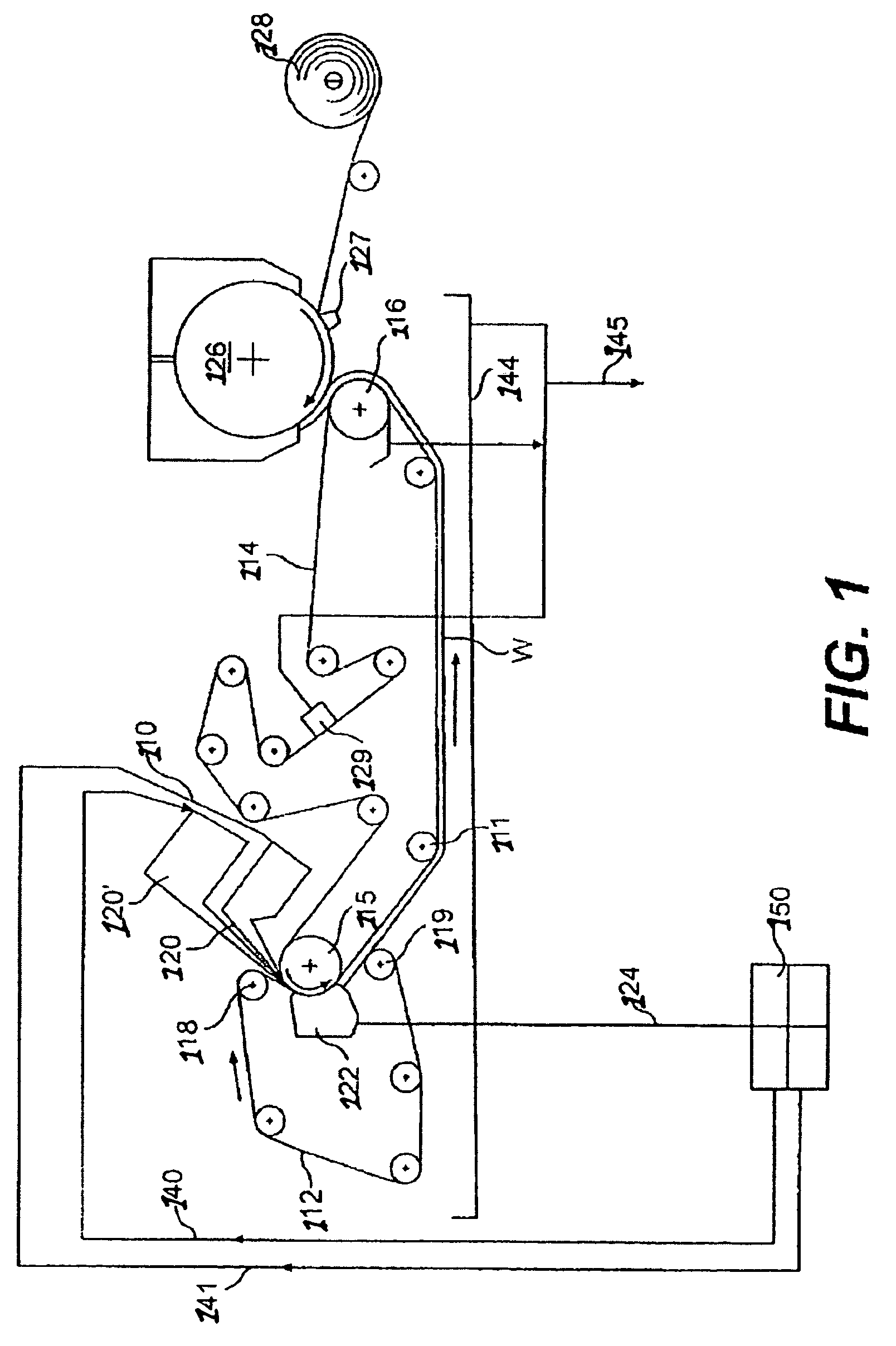

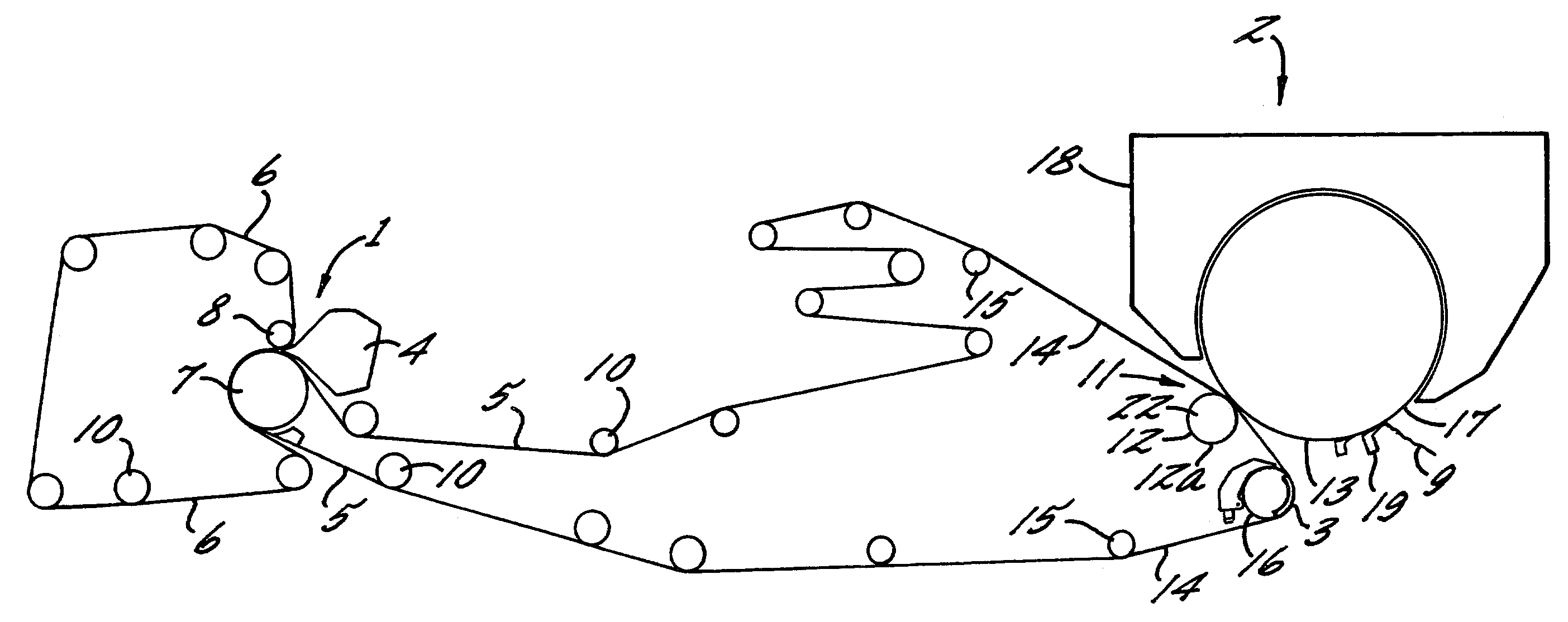

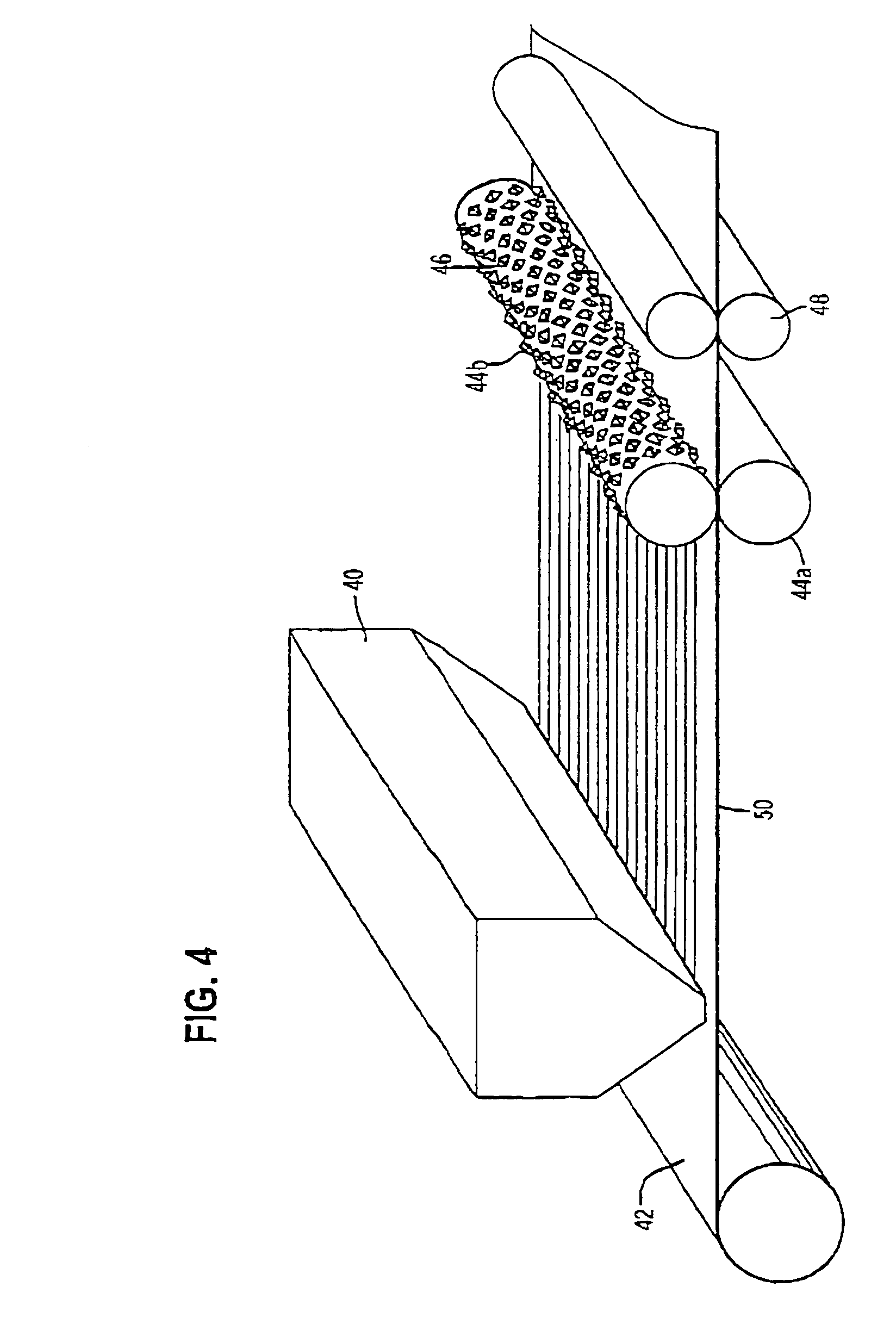

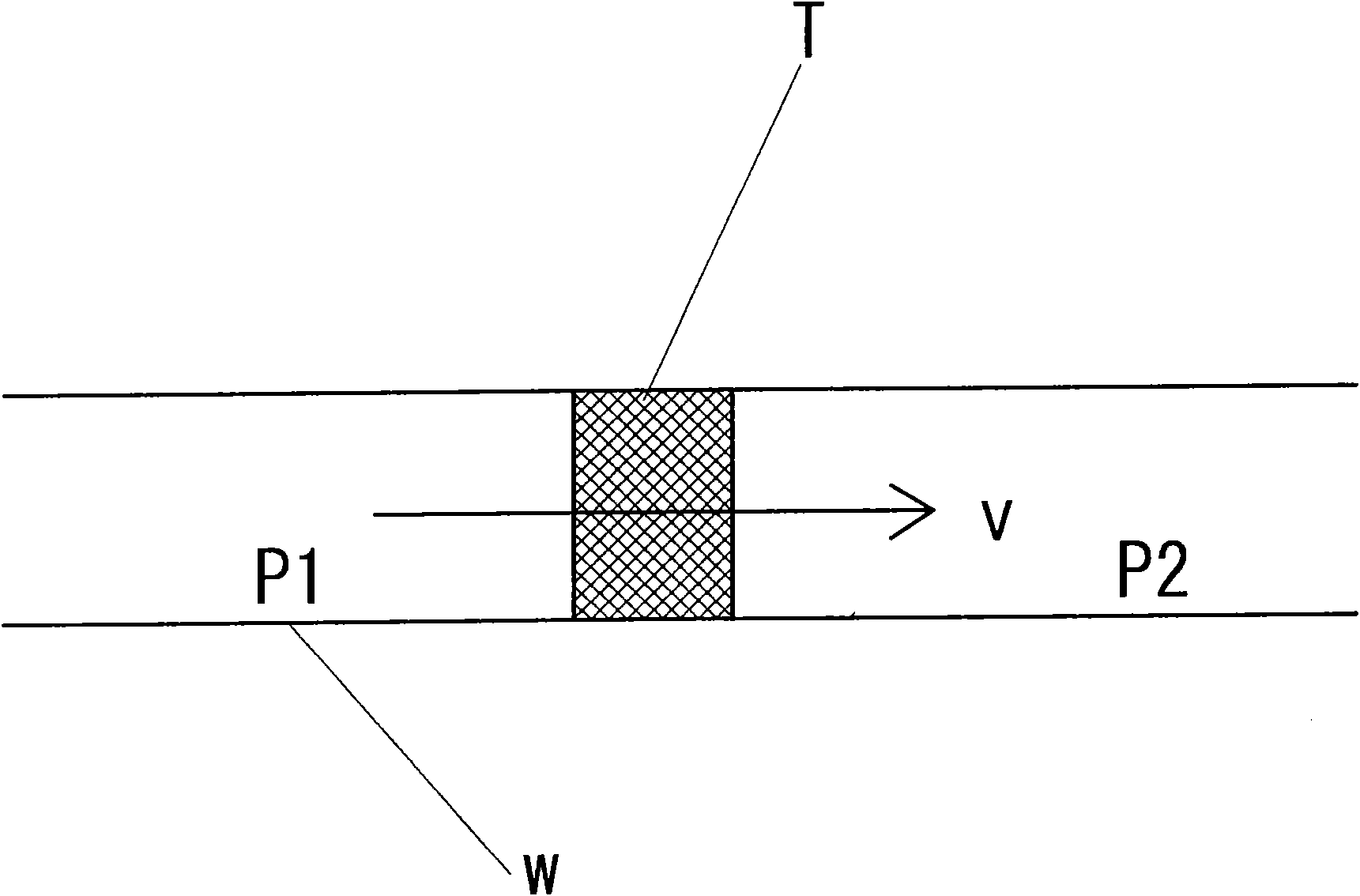

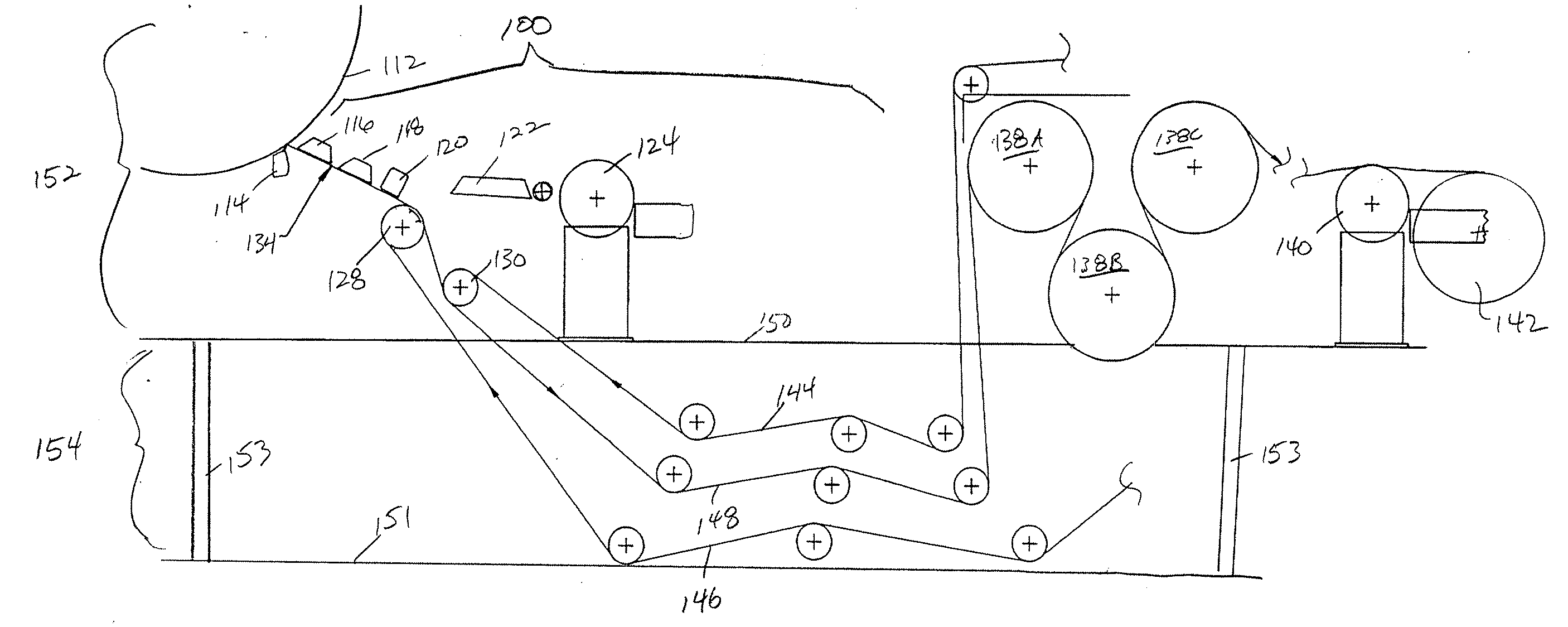

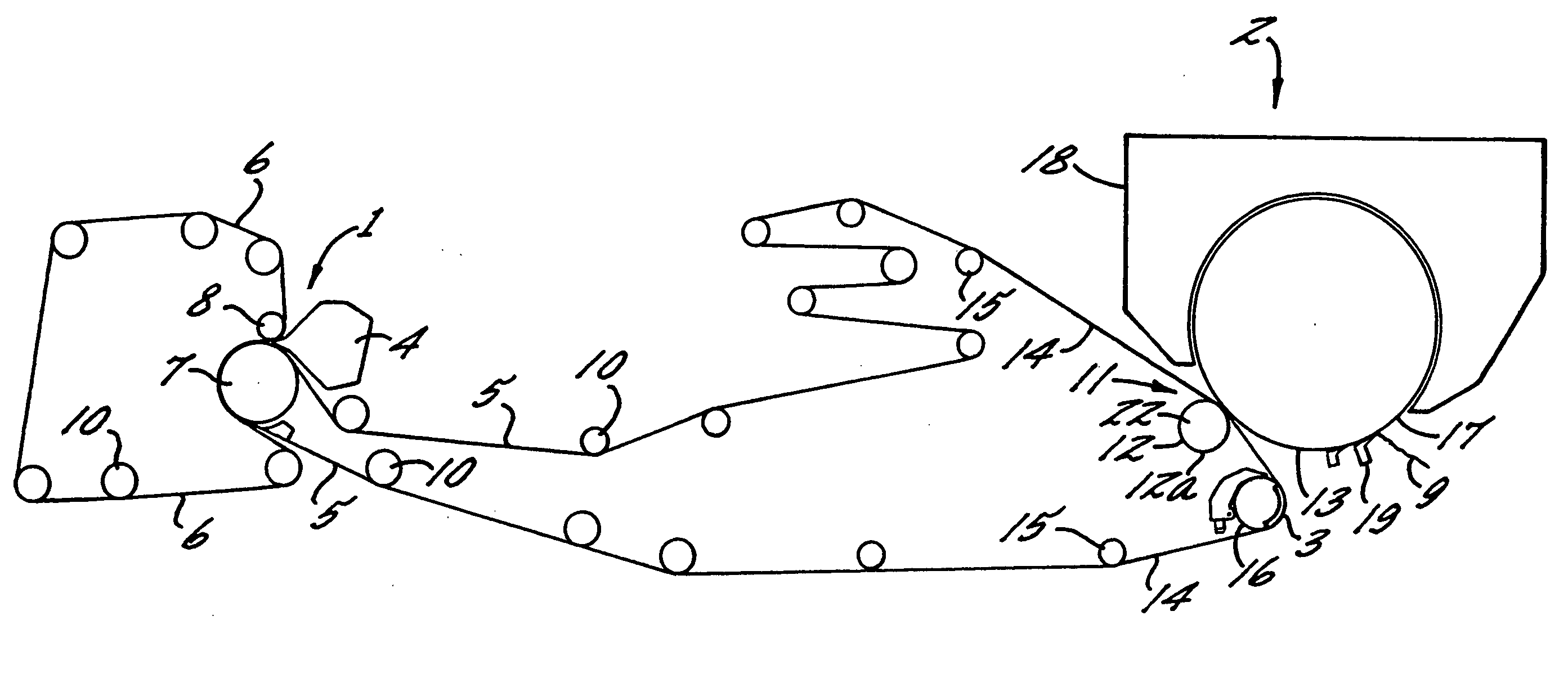

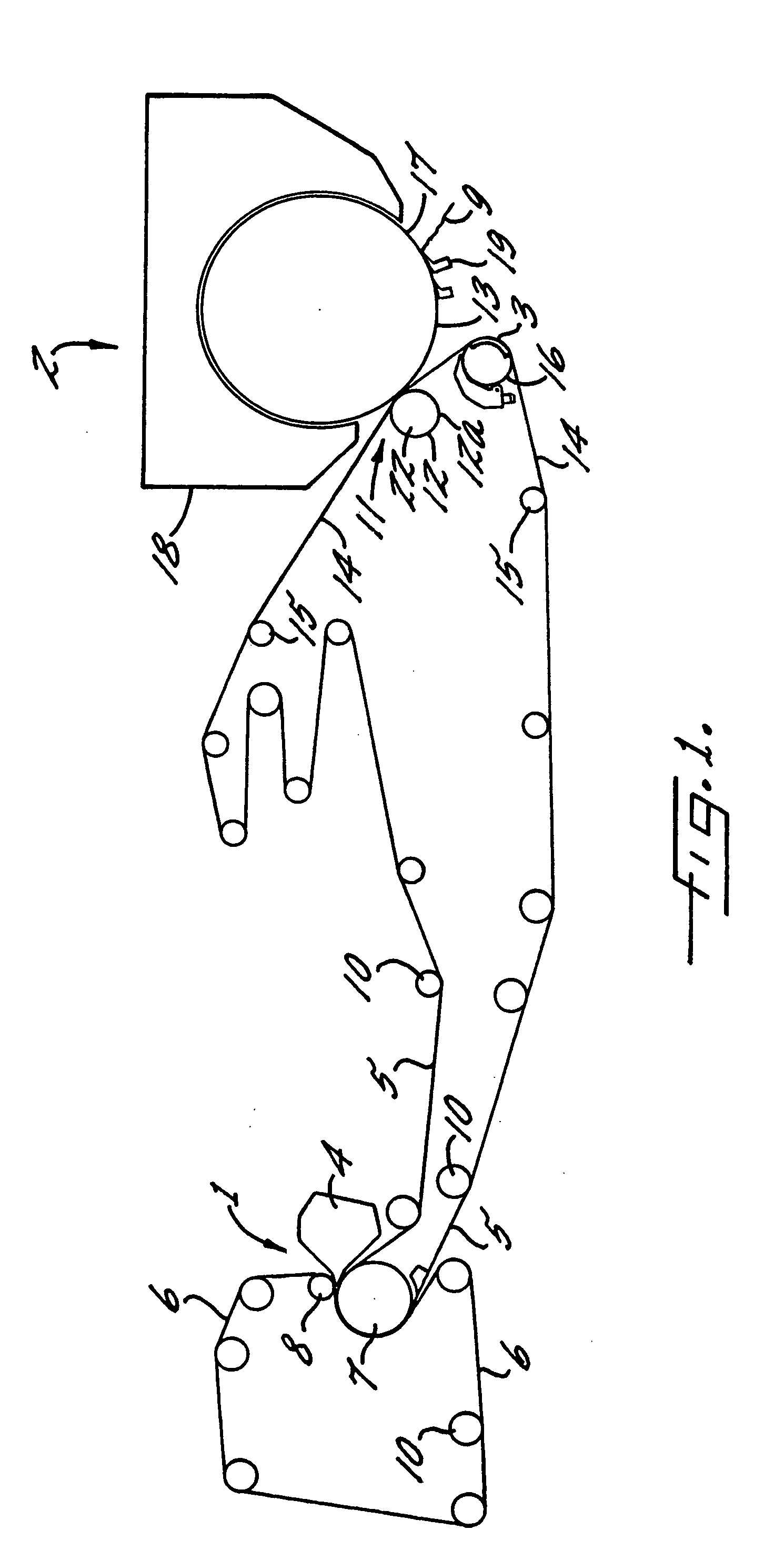

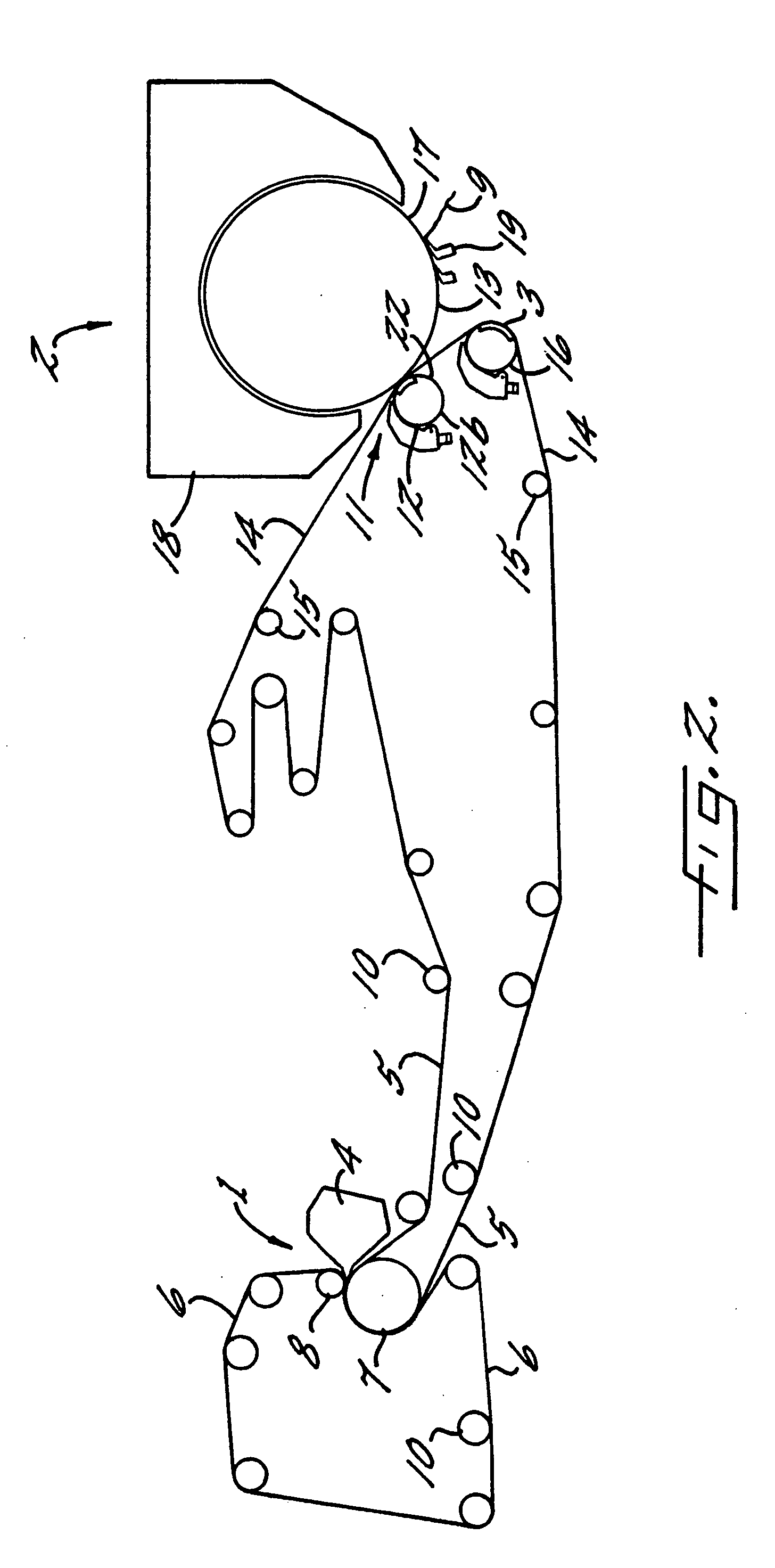

Wet/dry crepe swing paper machinery

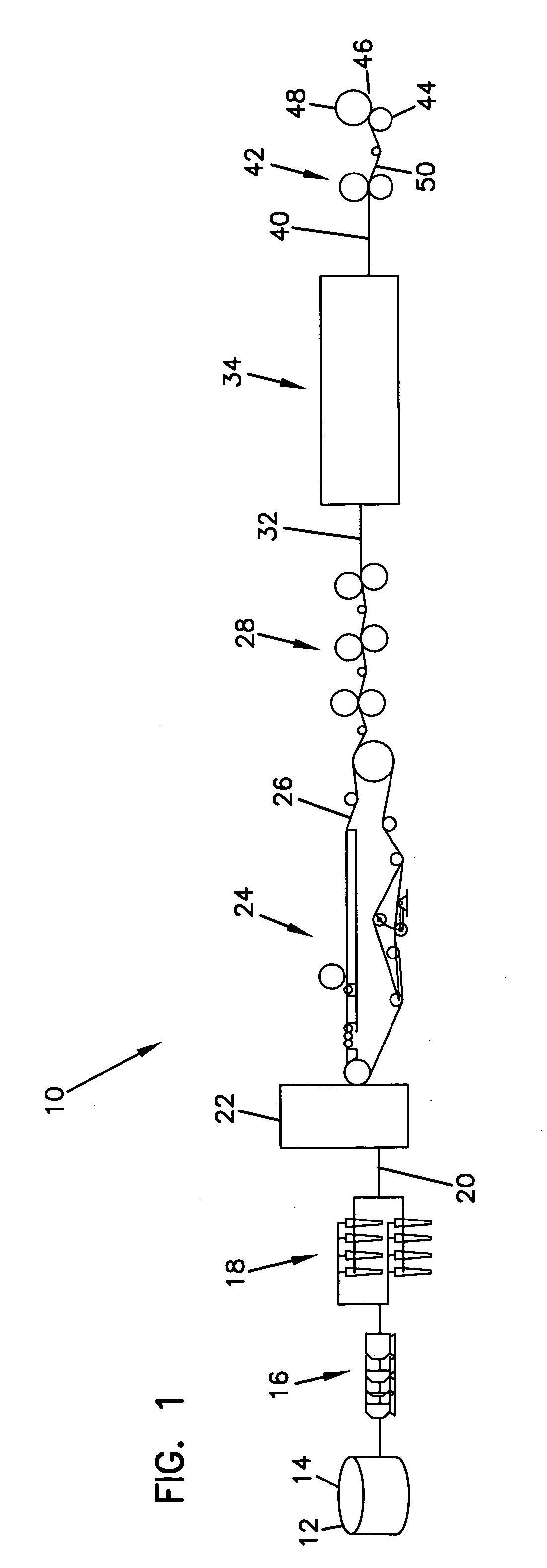

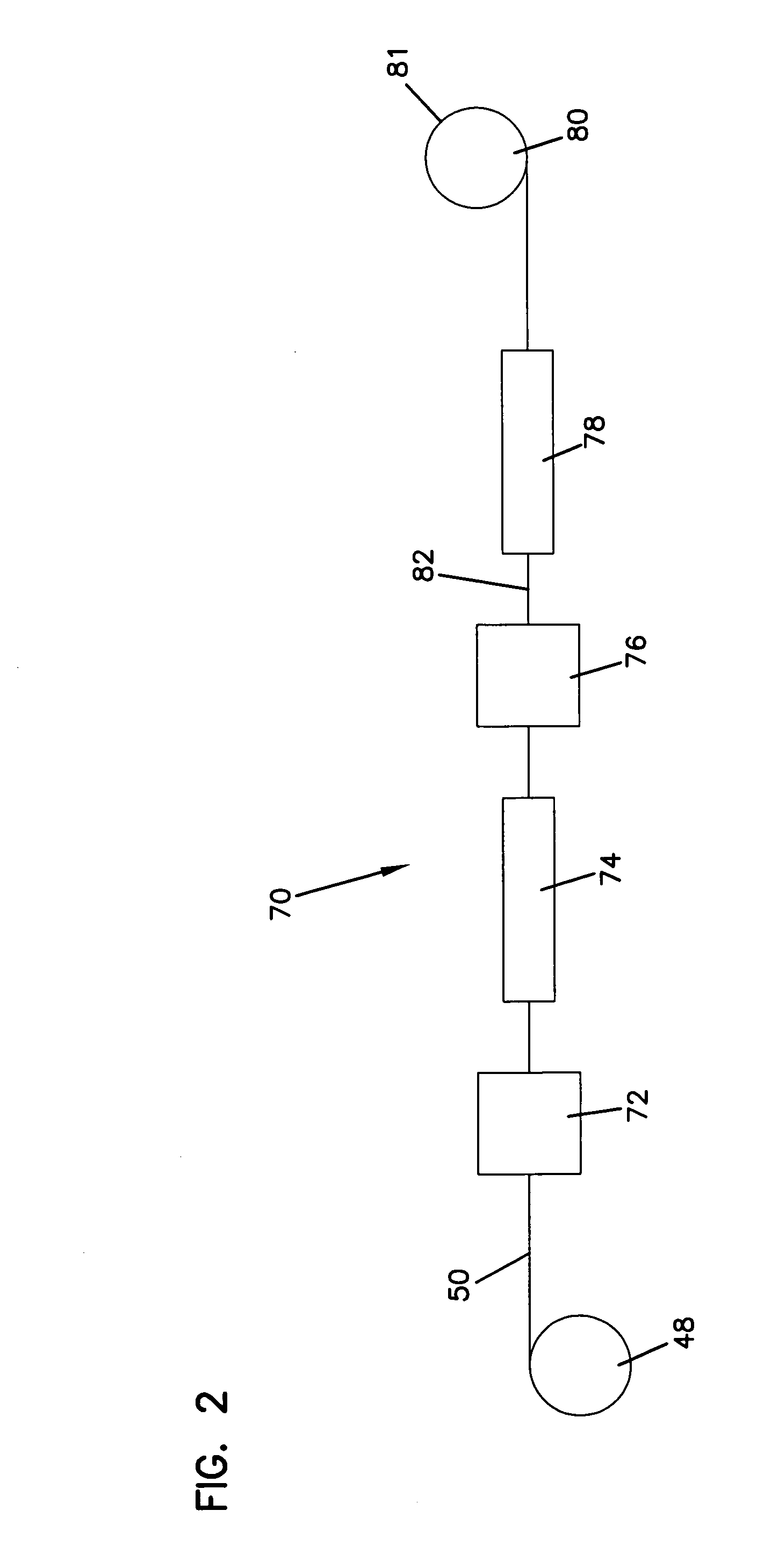

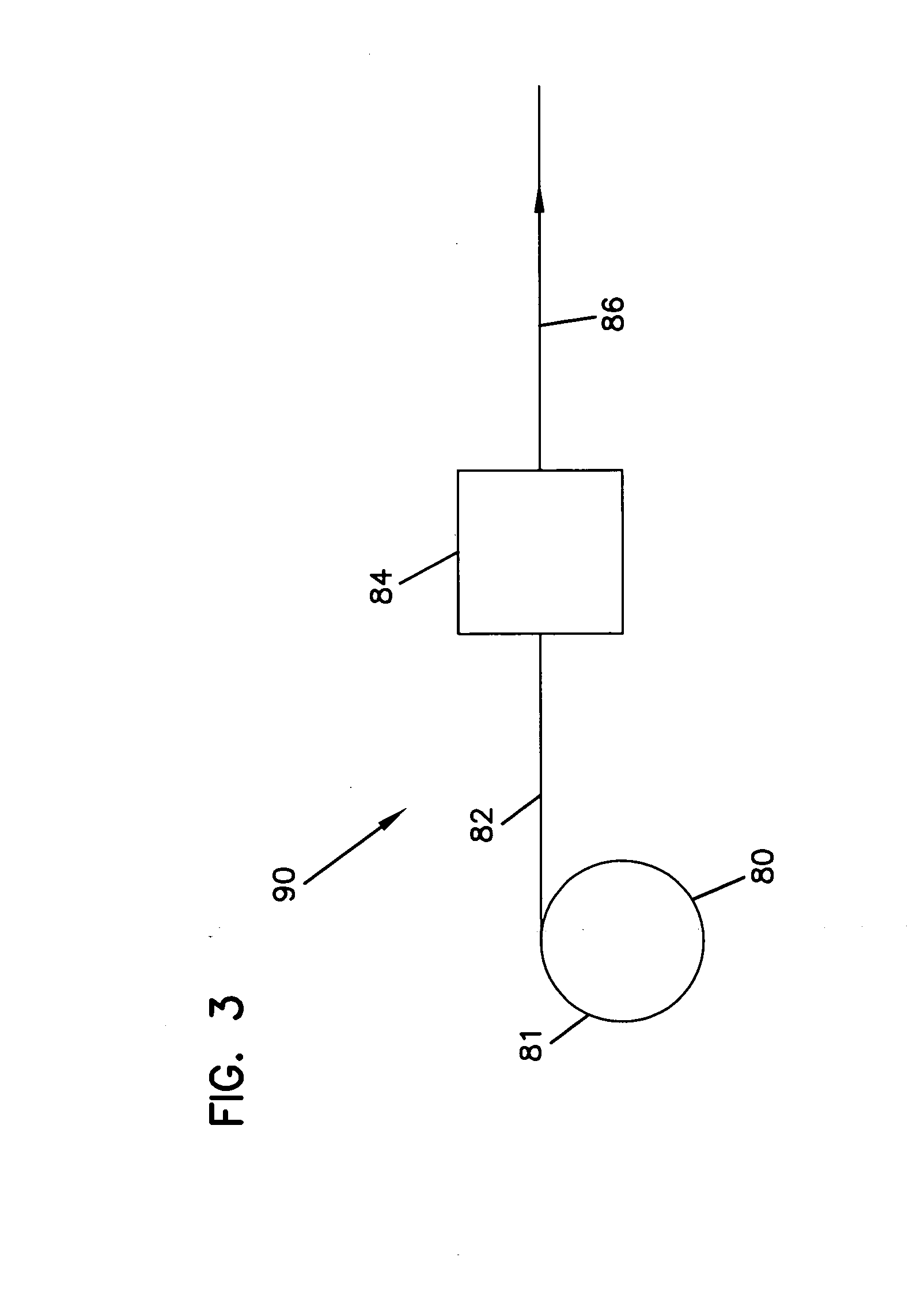

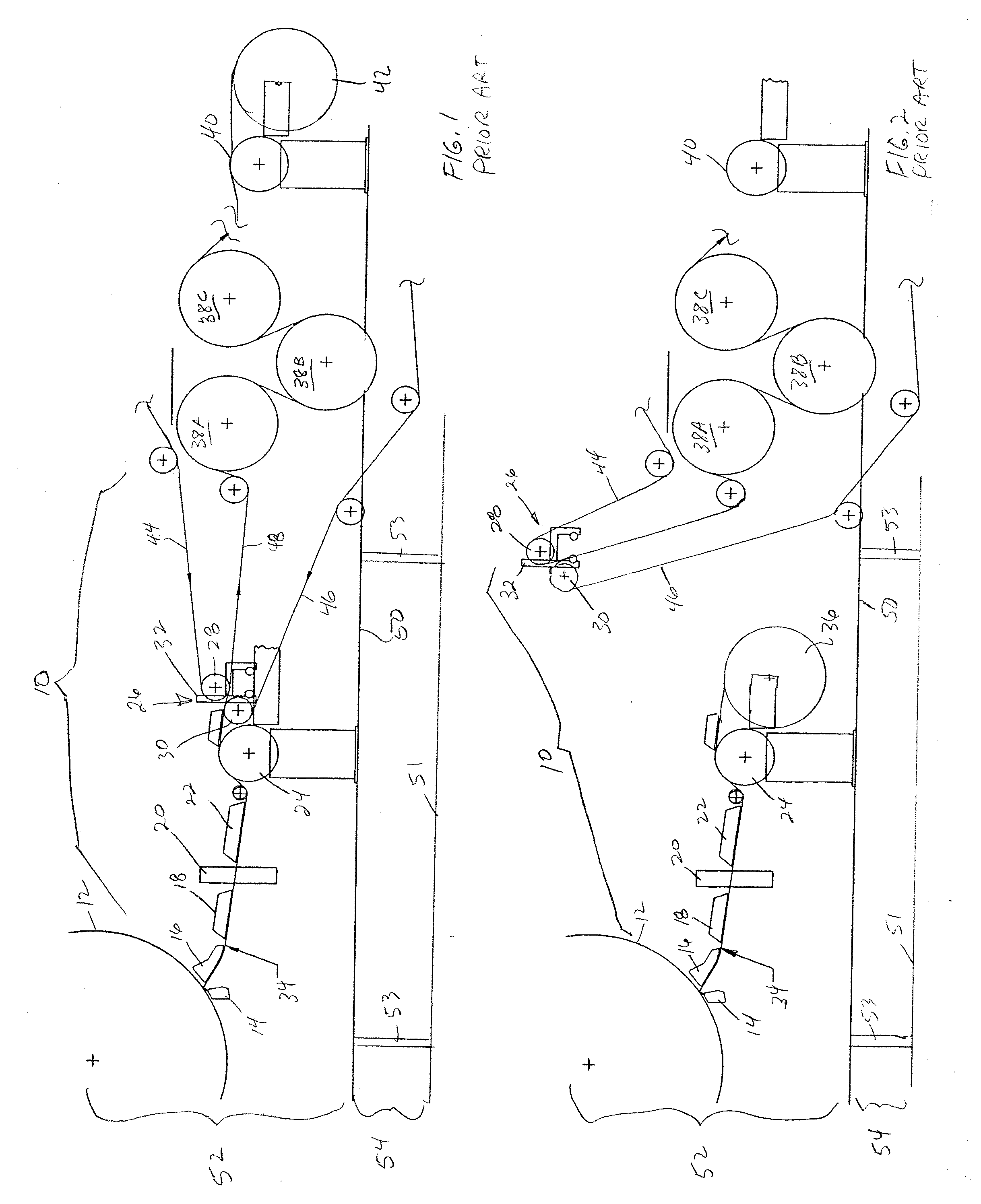

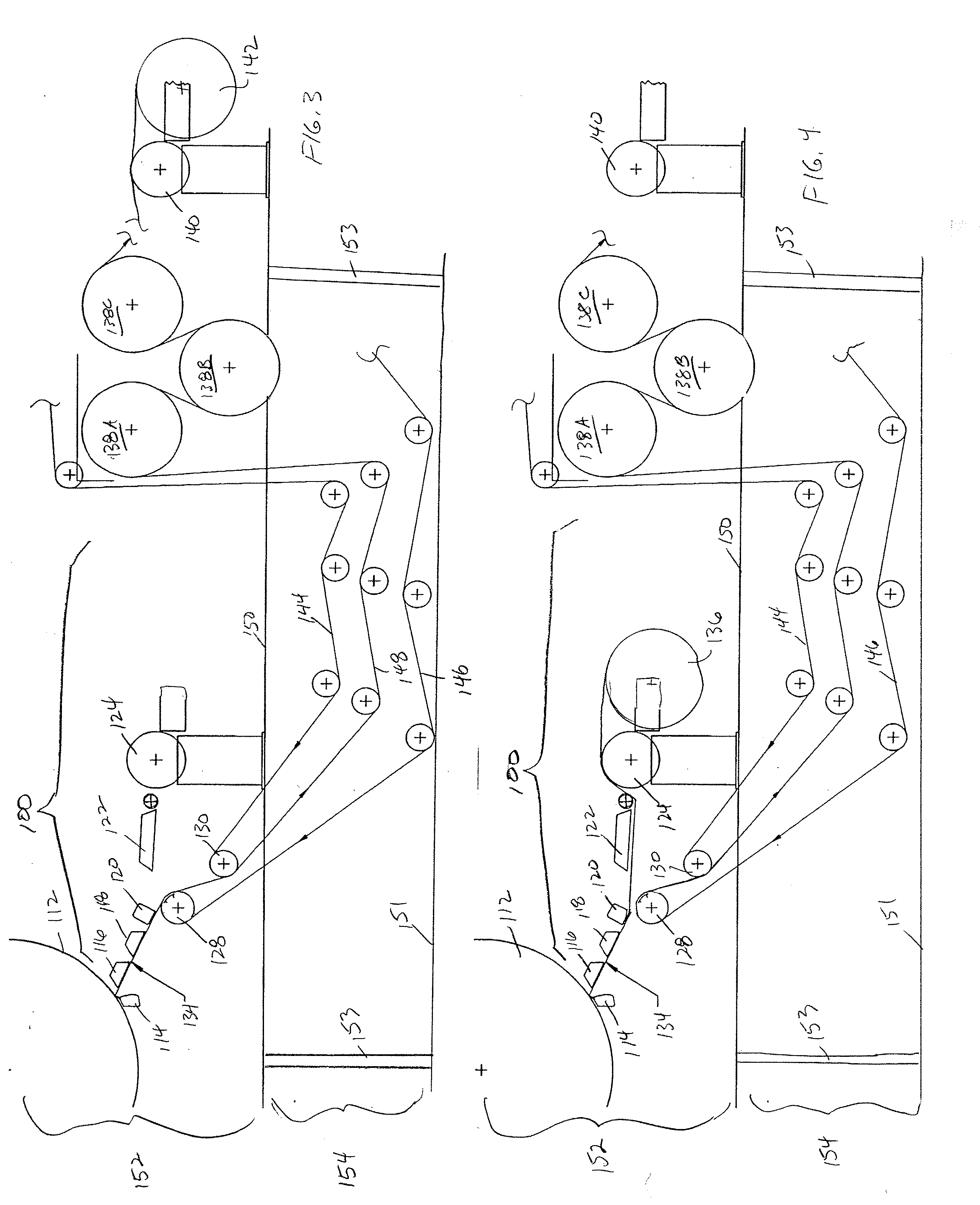

InactiveUS20080029237A1Required changingTime requiredMechanical working/deformationPaper/cardboard wound articlesCrêpe paperMoisture

A swing paper machine configured to manufacture both wet crepe paper web having a moisture content of at least 20% and dry crepe paper web having a moisture content less than about 15%. The paper machine includes a Yankee dryer having a paper web positioned thereon, a creping doctor blade configured to remove the paper web from the Yankee dryer as either the wet crepe paper web or the dry crepe paper web, a first reel, at least one carrier web, and at least one dryer. The wet crepe paper web is carried by the at least one carrier web to the at least one dryer for reducing a moisture content of the wet crepe paper web. The wet crepe paper web bypasses engagement with the first reel. The dry crepe paper web engages the first reel and is wound into a parent roll. The paper machine is changeable between manufacture of wet and dry crepe paper web without altering a position of the first reel and the at least one carrier web relative to the Yankee dryer.

Owner:WAUSAU PAPER TOWEL & TISSUE

Pyemotes spraying structure as well as manufacturing method and release device thereof

InactiveCN101911926ASolve the problem of biological controlImprove breeding efficiencyAnimal huntingForest industryCrêpe paper

The invention particularly discloses a pyemotes spraying structure as well as a manufacturing method and a release device thereof for solving the problem that the traditional pyemotes can not be used for biologically preventing and controlling pests with great population density. The manufacturing method of the pyemotes spraying structure comprises the following steps of: (a) breeding pyemotes to obtain pyemotes physogastry bodies and offspring adult pyemotes; (b) making foamed plastics or gauze or crepe paper into sheets, or making a cotton thread into a strip as a spraying carrier; and (c) crawling the spraying carrier with the offspring adult pyemotes, or sticking the pyemotes physogastry bodies to the glued surface of the spraying carrier to obtain the spraying structure. The pyemotes not only can be applied to the prevention and control of small stem boring pests, but also can be applied to the prevention and control of piercing and sucking pests, leaf-eating pests and the like in the fields of agriculture, parks, forestry and the like. The application range of the pyemotes is greatly expanded, various new alternative hosts are simultaneously used for breeding the pyemotes, so that the breeding efficiency of pyemotes is greatly improved, and the breeding cost is greatly reduced.

Owner:段东红 +2

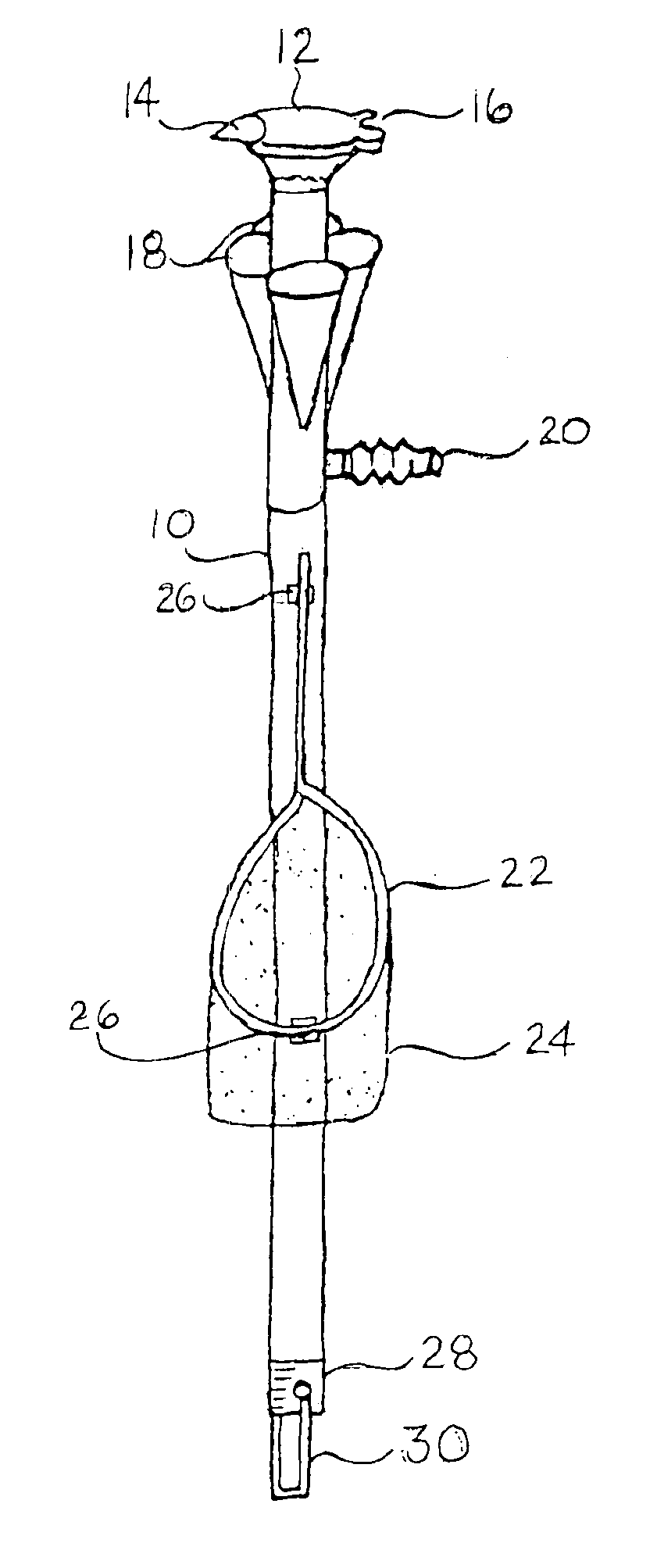

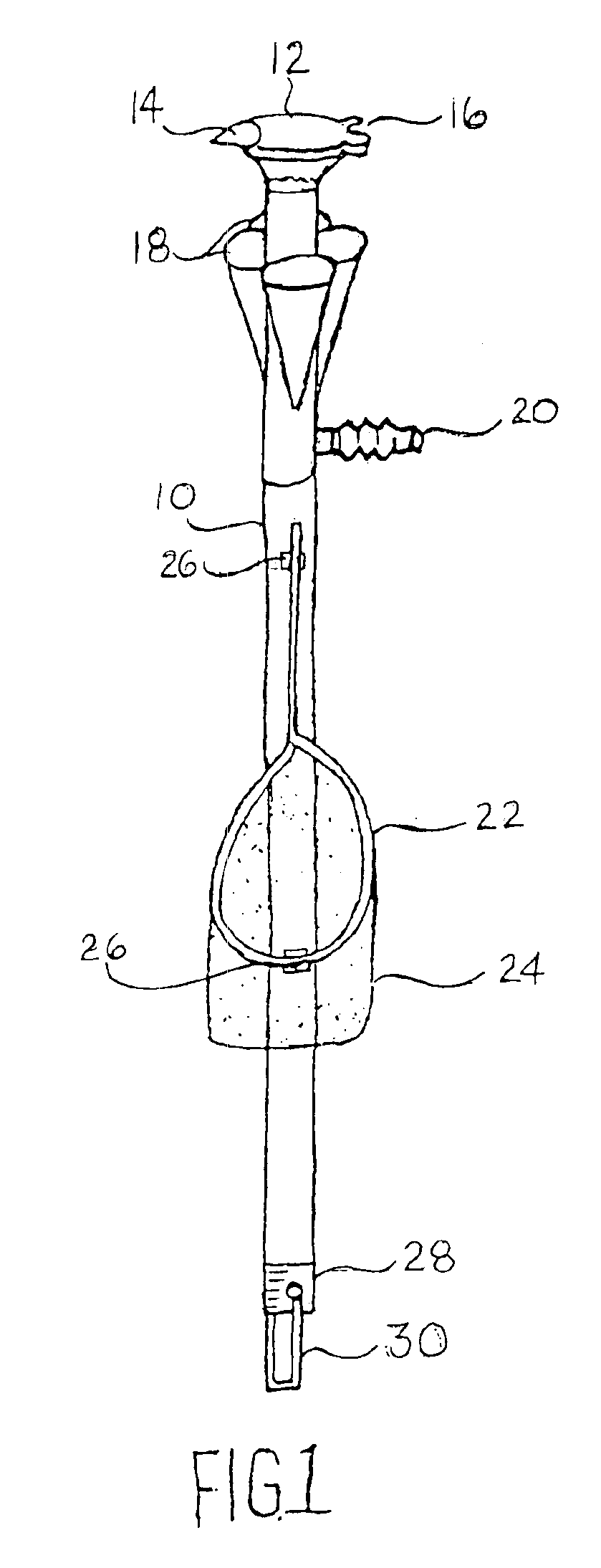

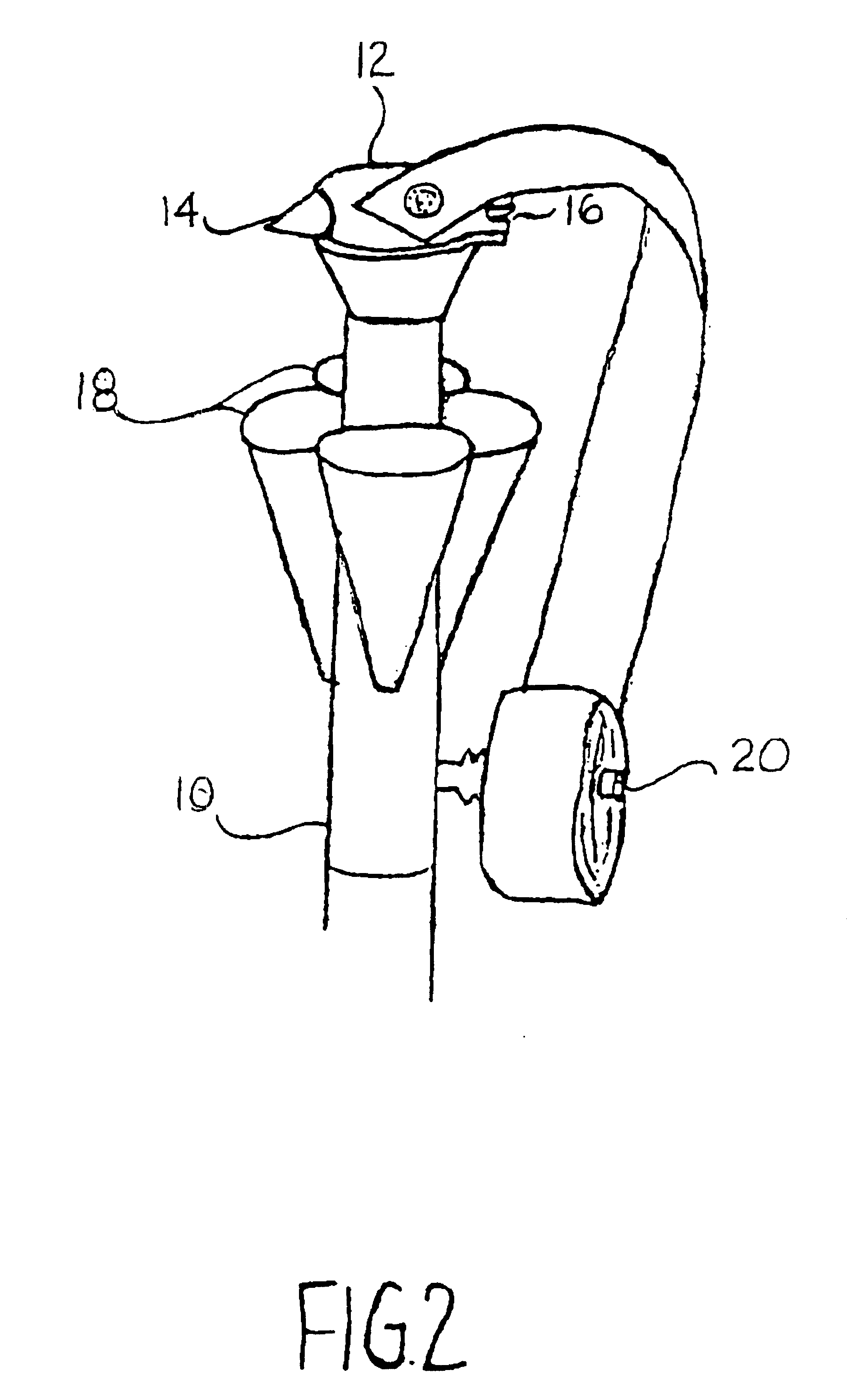

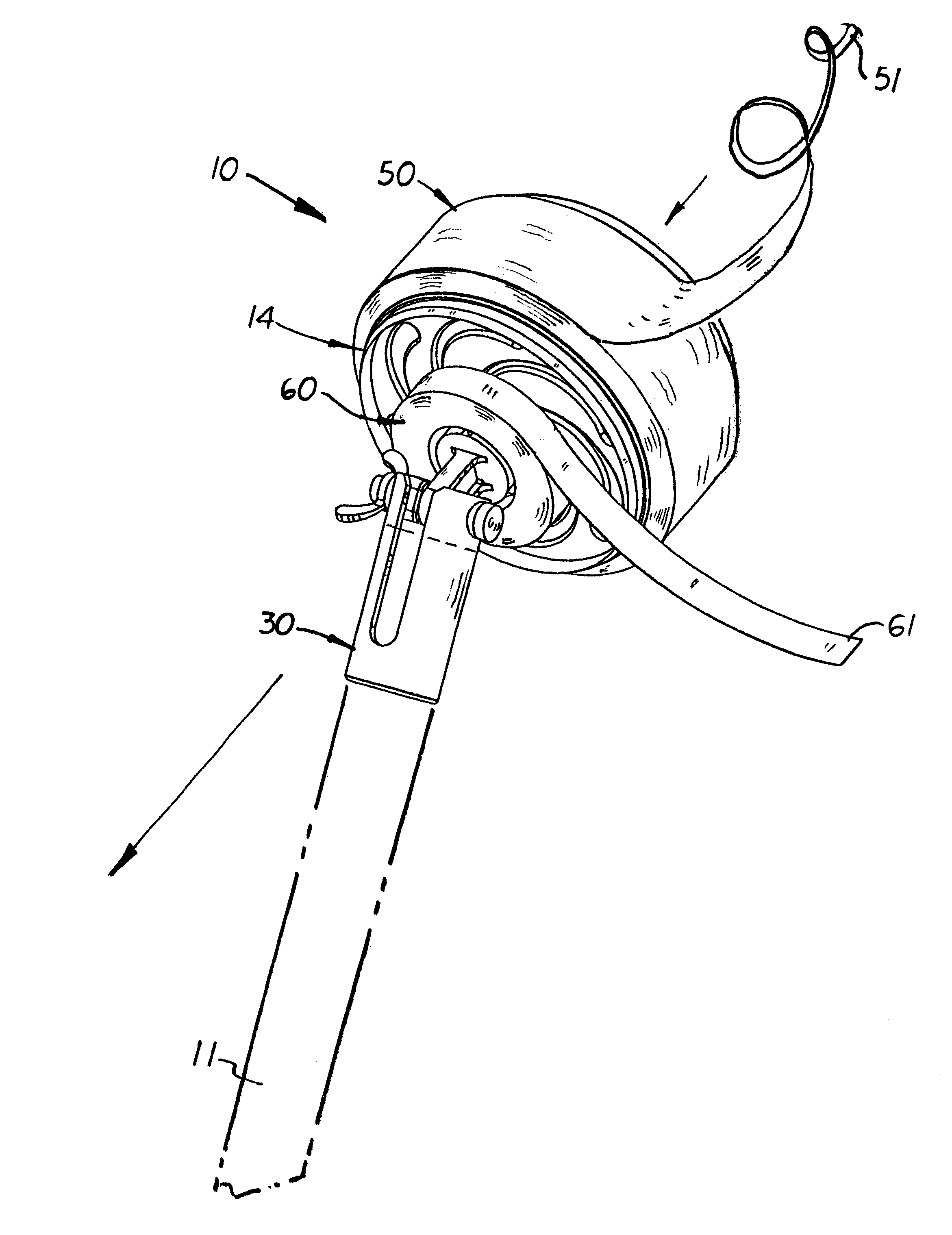

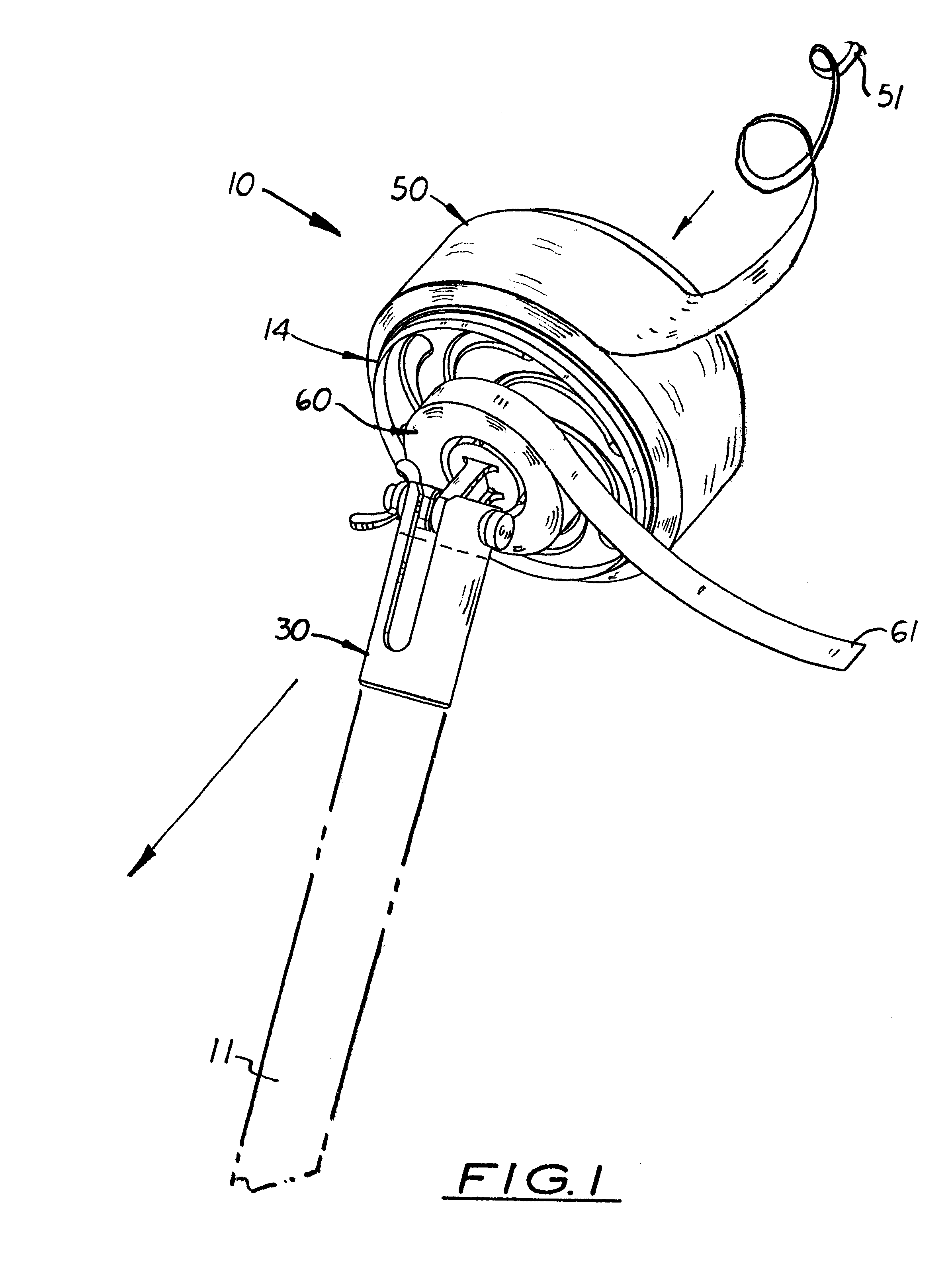

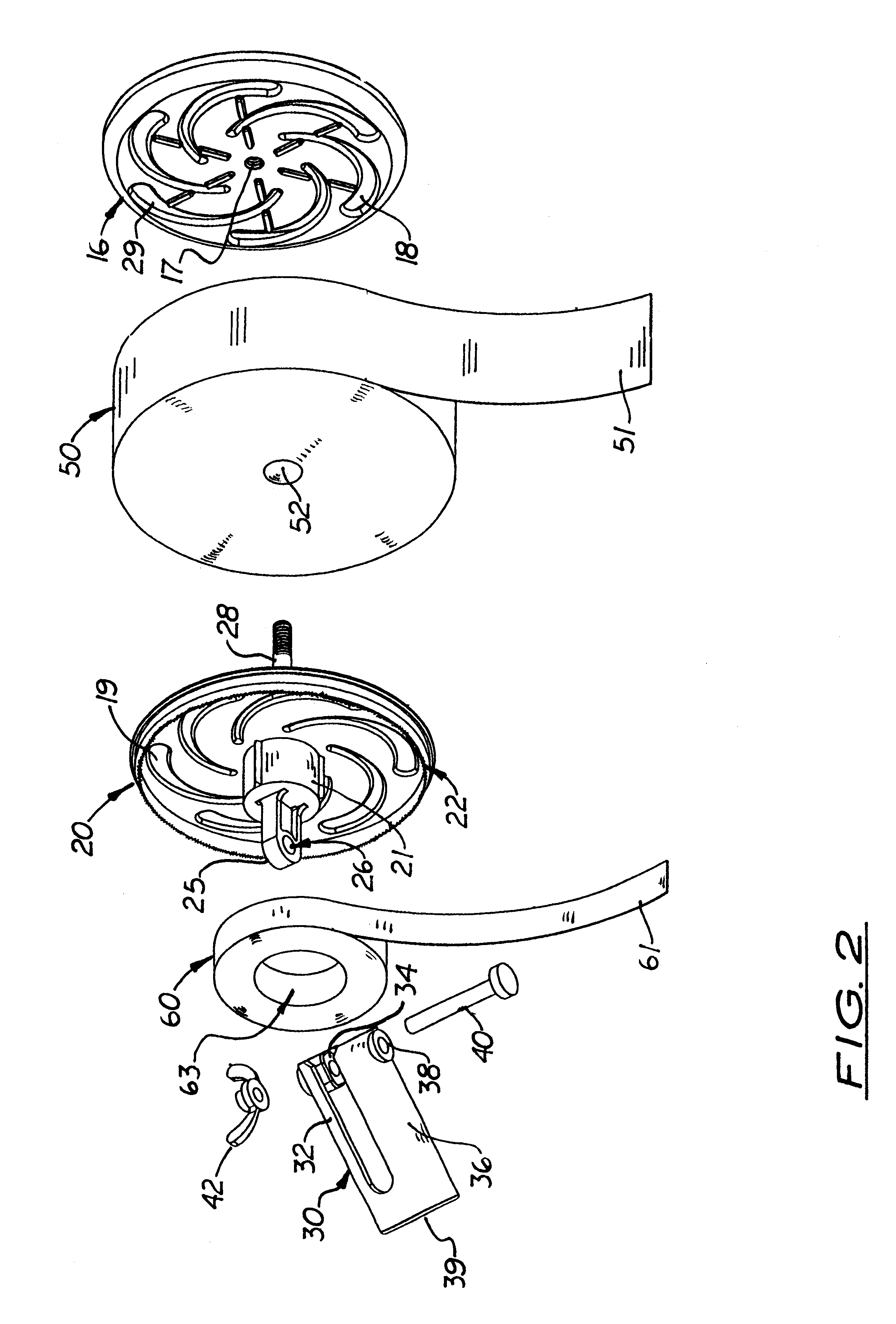

Extendable pole for hanging decorations overhead

An elongated, extendable pole(10) having a plurality of holding devices. A flexible platform(12) of predetermined circumference sits atop the pole(10) to press the adhesive end of a decoration to the ceiling. A sharp pointed lip(14) attached to the platform(12) removes the decoration. Opposite the lip(14) is a lead in slit(16) on the platform(12) which steadies ribbons or string placed upon the platform(12). Beneath the platform(12) are a set of contiguous containers(18) to hold the curling ribbon and tiny light weight decor being hung. Below the containers(18), to one side of the pole(10), is an extensible spindle(20) upon which crepe paper streamers are placed and dispensed. Held against the lower portion of the pole(10) is a removable book(22) which inserts into the spindle(20) thereby providing a place for balloons and larger light weight decor to be elevated to the ceiling and hung. When not in use the pole (10) may be hung by the strap (30) connected to its distal end.

Owner:VARNER VICTORIA

Soft crepe paper machine and press section thereof

InactiveUS20050133186A1Simple partsLower capital expenditureNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paper

A soft crepe paper machine comprises a wet section with a press section having a press defined by first and second press elements forming a press nip through which a press felt runs with a paper web. A suction roll is arranged in the loop of the press felt before the press nip at a distance from the second press element, and the felt with the web thereon runs around the suction roll with a large wrap angle. A drying cylinder forms the second press element. The first press element is either a solid press roll, a suction press roll, or a variable crown press roll.

Owner:METABO PAPER SWEDEN

Sterilized packaging self-sealing bag for goffered paper

InactiveCN101486394AIncreased load-bearing capacityTurn on securitySynthetic resin layered productsBagsAnti virusEpoxy

The invention relates to a disposable medical sterilization packaging self-sealing bag, which comprises an upper layer plastic film and a lower layer plastic film which are sealed together by heat, and one side is provided with an opening, wherein, the upper layer plastic film is provided with air holes, the outer surface of the upper layer plastic film is also provided with a layer of creped paper, and the lower layer plastic film is a stripping composite film of epoxy polyester (PET) plus polyethylene (PE). The disposable medical sterilization packaging self-sealing bag has better packaging bearing effect and no paper scraps in the opening process of the package, thus achieving more secure opening. The packaging self-sealing bag can be widely used for sterilization anti-virus packaging of medical instruments, and provide protection after sterilization.

Owner:SHANGHAI JIANZHONG MEDICAL PACKAGING

High temperature resistant crepe paper adhesive tape used for shoes

InactiveCN105331301AKeep dryImprove versatilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkCrêpe paper

The invention provides a preparation method of a high temperature resistant crepe paper adhesive tape used for shoes. The preparation method comprises a step of pressure sensitive adhesive preparation and a step of coating; according to the step of pressure sensitive adhesive preparation, methylbenzene is used for removing water in cross-linking agent dibenzoyl peroxide, and dibenzoyl peroxide is mixed with an organic silicon pressure sensitive glue at a certain ratio for uniform stirring, cross-linking agent diisocyanate of acrylic ester pressure sensitive glue is dissolved in methylbenzene, and is mixed with acrylic ester pressure sensitive glue; and at last crepe paper is coated with the mixtures of the two pressure sensitive glues so as to obtain a final product; wherein the final product possesses high temperature resistance, and no glue is left after removing from shoe materials.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Party streamer dispenser

A party streamer dispenser for decorating a room. The dispenser includes a body which holds a roll of crepe paper, a roll of adhesive tape, and an adjustable handle that selectively attaches to an elongated pole. The body comprises a cap and a frame that are disposed and compressed against opposite sides of the roll of crepe paper. A threaded bolt extends transversely between the cap and frame and through the center bore on the roll of crepe paper. Integrally formed on the frame is a laterally extending neck around which a roll of adhesive tape is placed. Extending laterally from the distal end of the neck is an extension. During assembly, an end cap is pivotally attached to the lateral extension. An elongated pole may be placed into the end cap so that the user may use the elongated pole to elevate the dispenser to a desired elevated location in the room. During use, the dispenser is held so that the crepe paper unravels transversely from the roll as the dispenser is held perpendicular to the direction of travel and moved across the room thereby simultaneously dispensing and twisting the crepe paper into a streamer.

Owner:CRAINE DEAN A

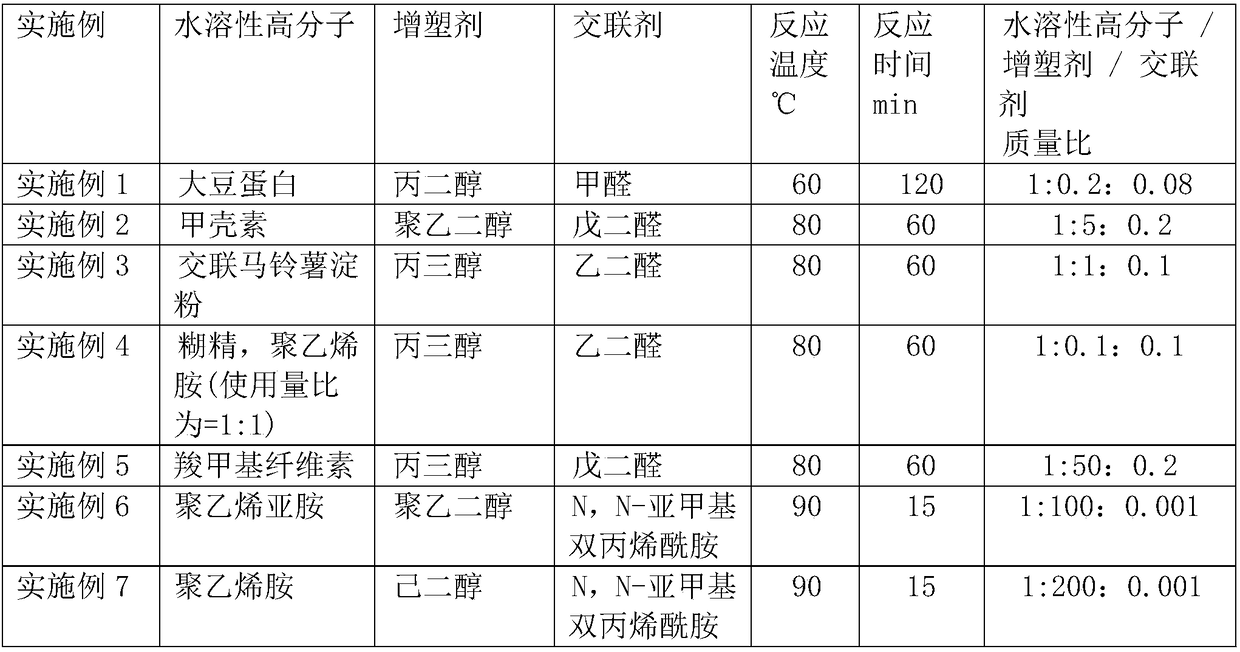

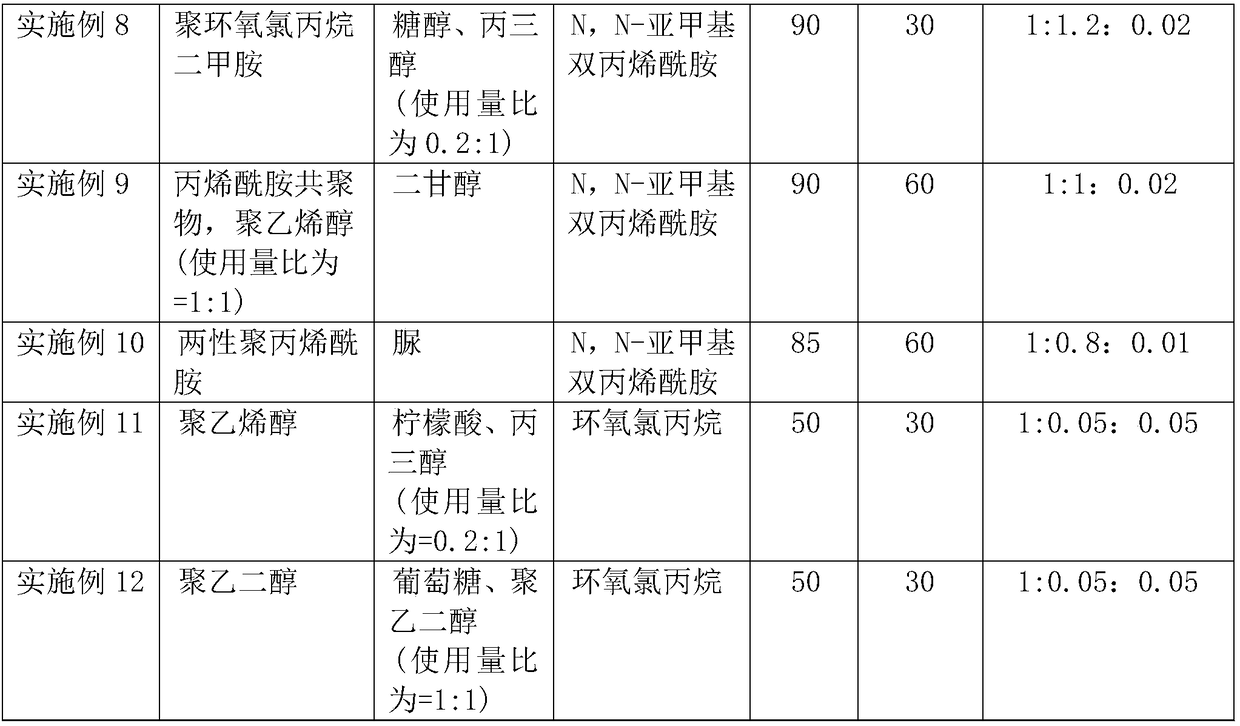

Preparation method of cylinder adhesive for crepe paper

ActiveCN108148502AChange film formationChange the cohesivenessStarch coatingsPolyether coatingsCross-linkPolymer science

The invention relates to a preparation method of cylinder adhesive for crepe paper. The existing cylinder adhesive generally has defects such as poor film forming performance, poor film forming elasticity and poor remoistening performance and the like. By utilizing a water-soluble macromolecular polymer in a water phase, by adding a cross-linking agent and a plasticizer, the cylinder adhesive is prepared by virtue of local cross-linking of macromolecules and the compounding of the plasticizer. The cylinder adhesive prepared by the invention is stable in performance, has good adhesive force andfilm forming performance, can adjust the remoistening performance and softness of a film and can well improve the wrinkling performance of the crepe paper.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

Method of producing a creping paper and the creping paper thereof

ActiveUS20160168798A1Improve performanceImprove efficiencyNatural cellulose pulp/paperMechanical working/deformationFiberCrêpe paper

The present invention provides for a method of producing a creped paper and the crepe paper products made using this method. The method includes treating the surface of a crepe fiber web and / or surface of a Yankee drum dryer or cylinder with compositions containing a combination of hydrophobes and surfactants and wherein these compositions have been subjected to physical treatments to reduce the mean particle size to about 1 micron (μm) or less.

Owner:SOLENIS TECH CAYMAN

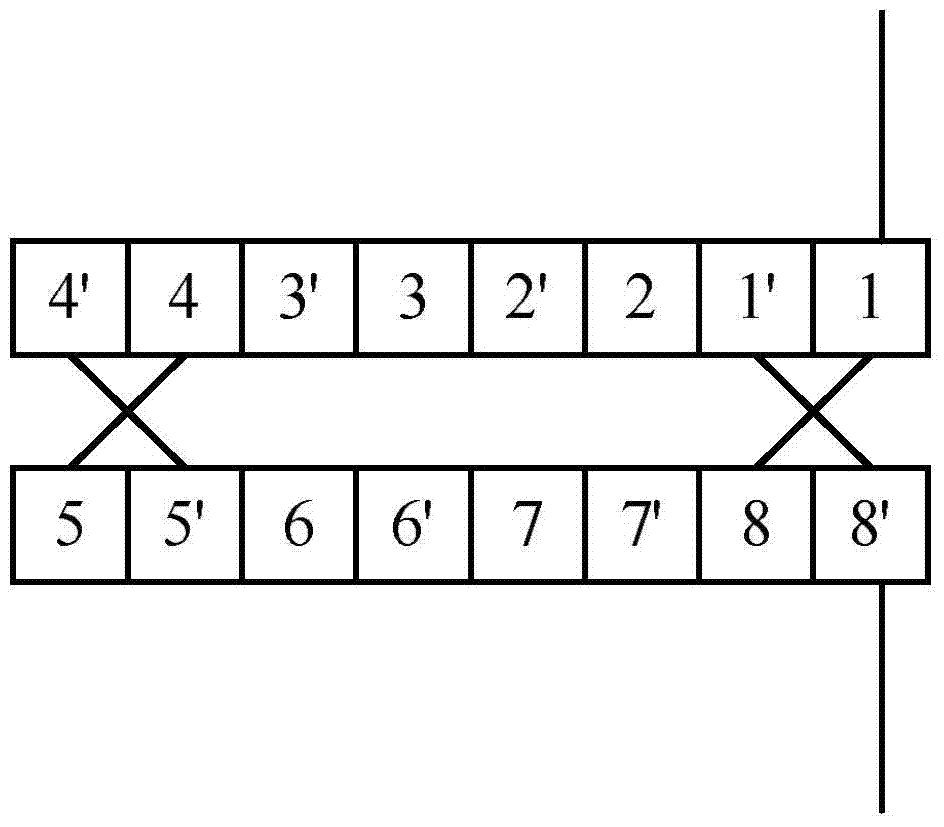

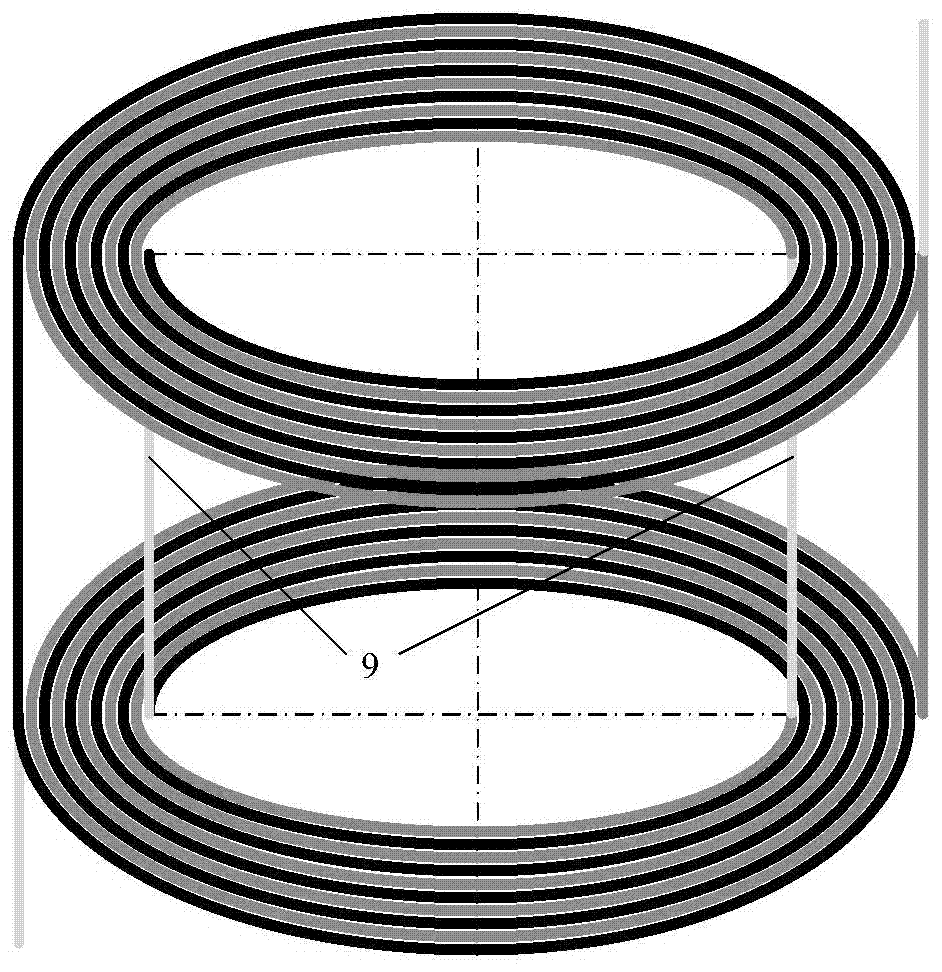

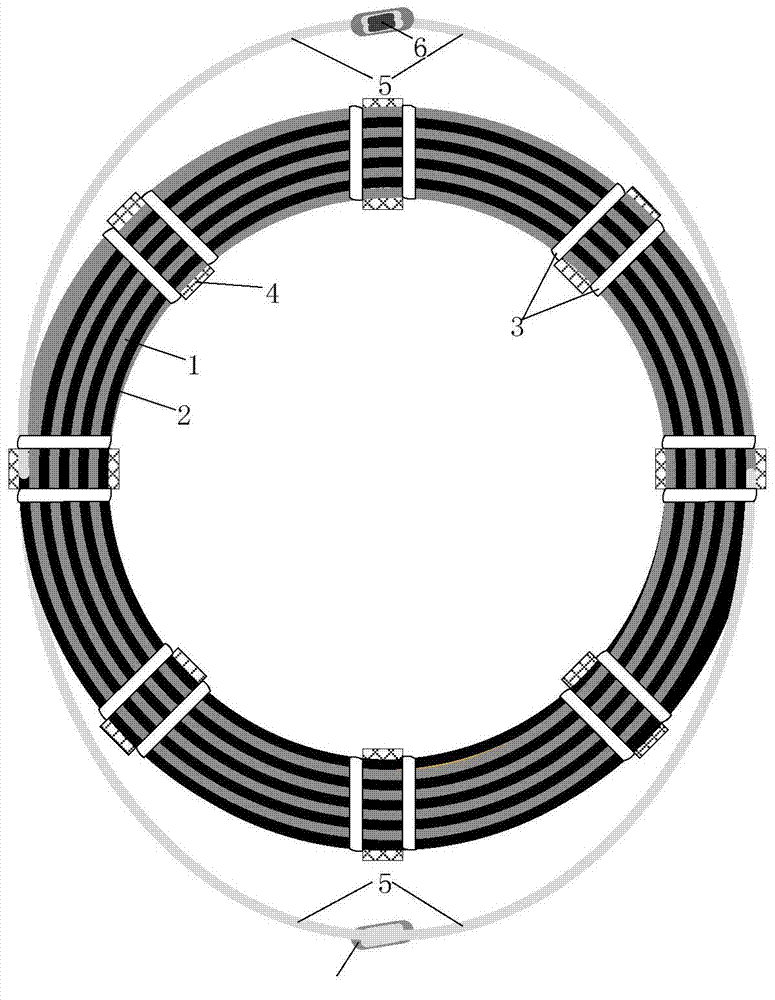

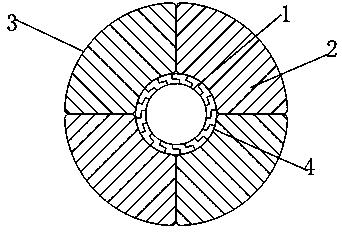

Model coil of interturn insulation test of oil-immersed power transformer and manufacturing method of model coil

ActiveCN104777406AEffective analog characteristicsEffectively simulate the development process of electrical and thermal agingTesting dielectric strengthTransformers/inductances coils/windings/connectionsTransformerEllipse

The invention relates to a model coil of an interturn insulation test of an oil-immersed power transformer and a winding method of the model coil. Specification parameters of the coil and a category of insulation paper are the same as those of the transformer. The coil is divided into an upper cake and a lower cake, wherein each cake is subjected to parallel winding by two paper wrapped wires A and B; two first tangling positions of a connecting part of the two cakes are wrapped with at least six layers of insulation paper; the two first tangling positions are located on an inner ring of the coil; a distance between the two first tangling positions is half perimeter of a lead wire of the inner ring; the head end and the tail end of each paper wrapped wire are connected together; the two paper wrapped wires serve as a high-voltage outgoing wire and a low-voltage outgoing wire respectively; an ellipse is defined by four leading-out terminals of the paper wrapped wires; the high-voltage outgoing wire and the low-voltage outgoing wire of the coil are arranged at the two ends of a long axis respectively; a short axis is coincided with a straight line formed by the two first tangling positions of the two paper wrapped wires and is equal to the diameter length of an excircle of the coil; and each of the paper wrapped wires from tangent points to end points of the leading-out terminals is additionally wrapped with at least six layers of crepe paper to reinforce insulation. The coil can effectively simulate breakdown characteristics of an interturn oil paper compound insulation system and a development process of electrical aging and thermal aging under a working condition of the large transformer, and is simple to manufacture.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

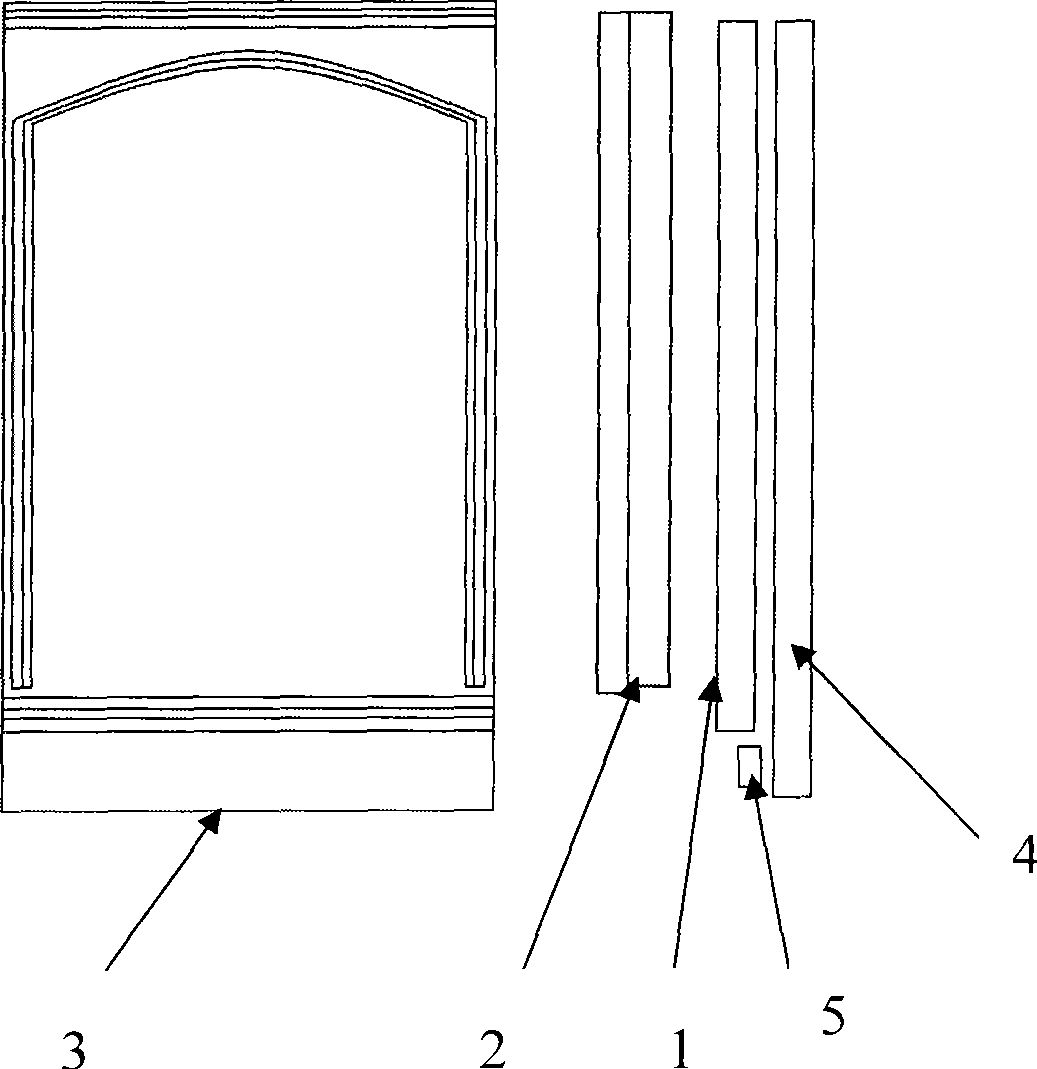

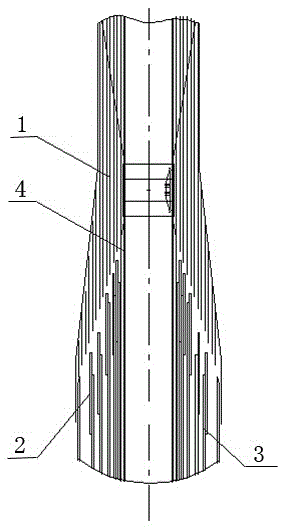

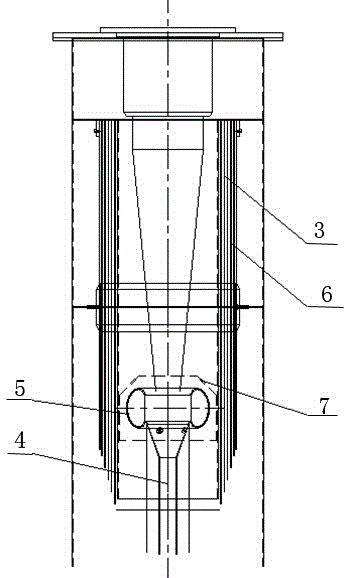

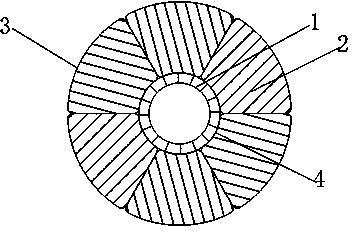

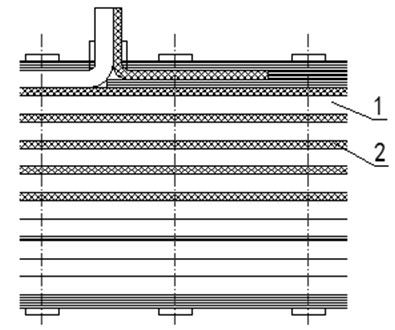

Novel valve side wire-outlet structure for converter transformer

ActiveCN105609270AAlleviate supply tensionReasonable structureTransformers/inductances coils/windings/connectionsCardboardTransformer

The invention relates to a novel valve side wire-outlet structure for a converter transformer, and belongs to the technical field of an extra-high voltage converter transformer. According to the technical scheme, multiple layers of insulating paper sleeves and corrugated boards are arranged on the exterior of an aluminum pipe in the wire outlet; the insulating paper sleeves in each layer are arranged from inner to outer in a stepped and overlapped manner; the lengths of the insulating paper sleeves in the inner layer are greater than that of the insulating paper sleeves in the outer layer; the corrugated boards are arranged between adjacent two layers of the insulating paper sleeves; the lengths of the corrugated boards are greater than that of the insulating paper sleeves in the upper layer and less than that of the insulating paper sleeves in the lower layer; flat paper boards (2) are arranged in the junctions of the insulating paper sleeves; the insulating paper sleeves and the corrugated boards on the exterior of the aluminum pipe are gradually thinned to be converted into a crepe paper (1) structure in a transitional manner; the exterior of the aluminum pipe far from the wire outlet is wrapped with the crepe paper (1); the crepe paper wraps for insulation until the flat paper boards (2) are wrapped, and then the crepe paper continuously wraps for insulation until the insulating paper sleeves in the outermost layer are wrapped. The novel valve side wire-outlet structure has the positive effects that the novel valve side wire-outlet structure is reasonable in structure, easy to implement, and capable of effectively relieving tension supply of valve side leads and capable of promoting the rapid development of the direct current power transmission and transformation industries.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

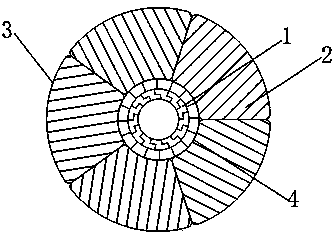

Oversized-section hollow corrugated split conductor

InactiveCN104347152ALarge sectionImprove transmission capacityNon-insulated conductorsPower cablesElectrical conductorCrêpe paper

The invention discloses an oversized-section hollow corrugated split conductor, which is of a combined type hollow segmentation conductor structure. The center of the conductor is combined by multiple layers of conductor single-line layers; conductor strand block layers integrated by a plurality of corrugated conductor strand blocks are arranged out of the conductor single-line layers; insulated crepe paper is arranged between the conductor strand block layers and the self-supporting external conductor single-line layers. The Z-shaped or corrugated conductor single lines are of a stable self-supporting structure, no gaps are formed between the conductor single lines, and therefore, requirements on tighter connection between the conductor single lines can be met without compression. Strength is guaranteed by the hollow self-supporting structure, a metal spiral pipe, a drawing copper pipe or a supporting pipe made of plastic and the like are replaced a small gap exists between the hollow self-supporting structure and segmentation conductor strand blocks, and the flexibility of the whole conductor is not lowered. According to the hollow structure, the section of the conductor is utilized to a maximum degree, and adverse effects brought by a 'skin effect' are lowered to a larger extent.

Owner:WUXI JIANGNAN CABLE

Kitchen paper

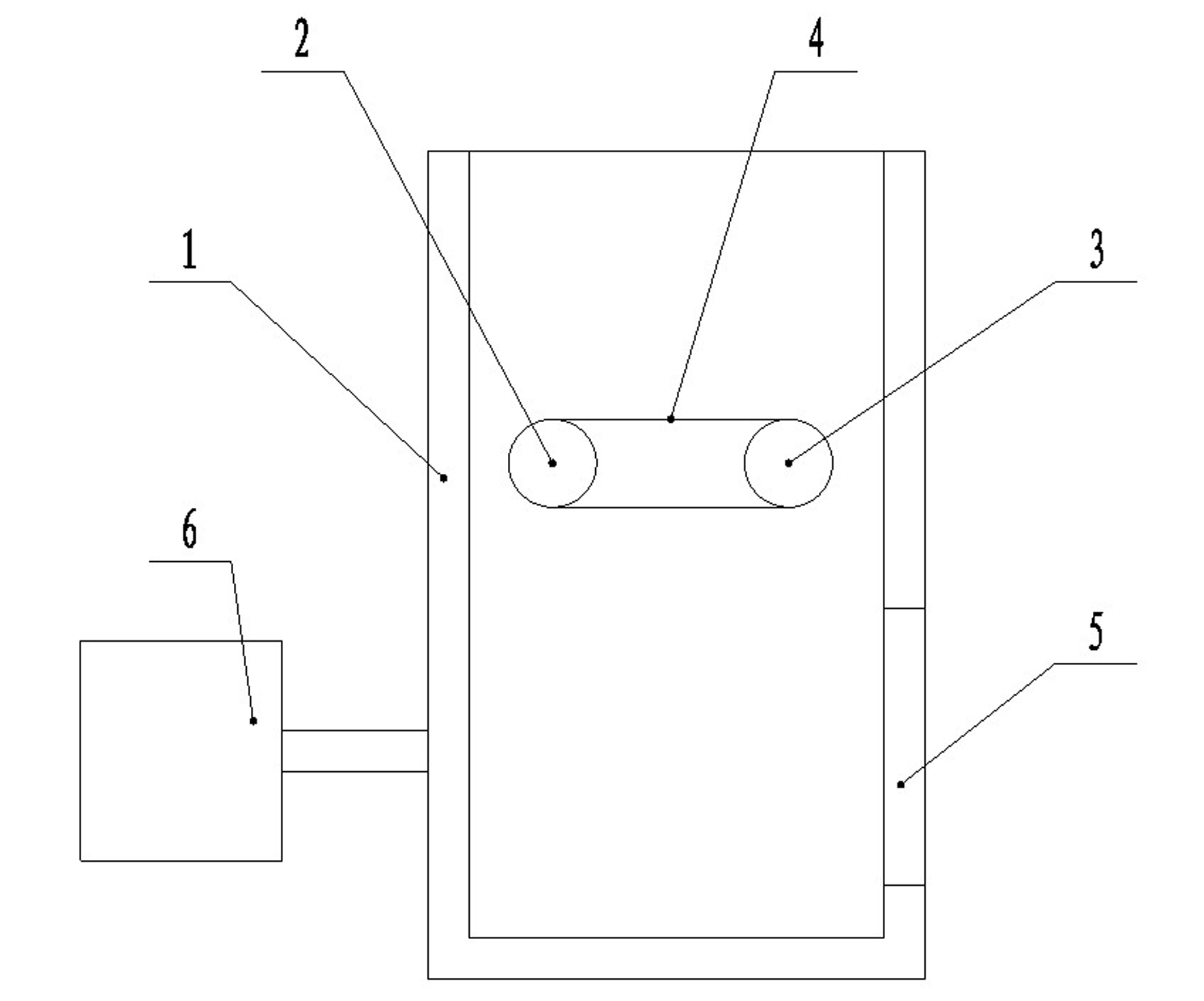

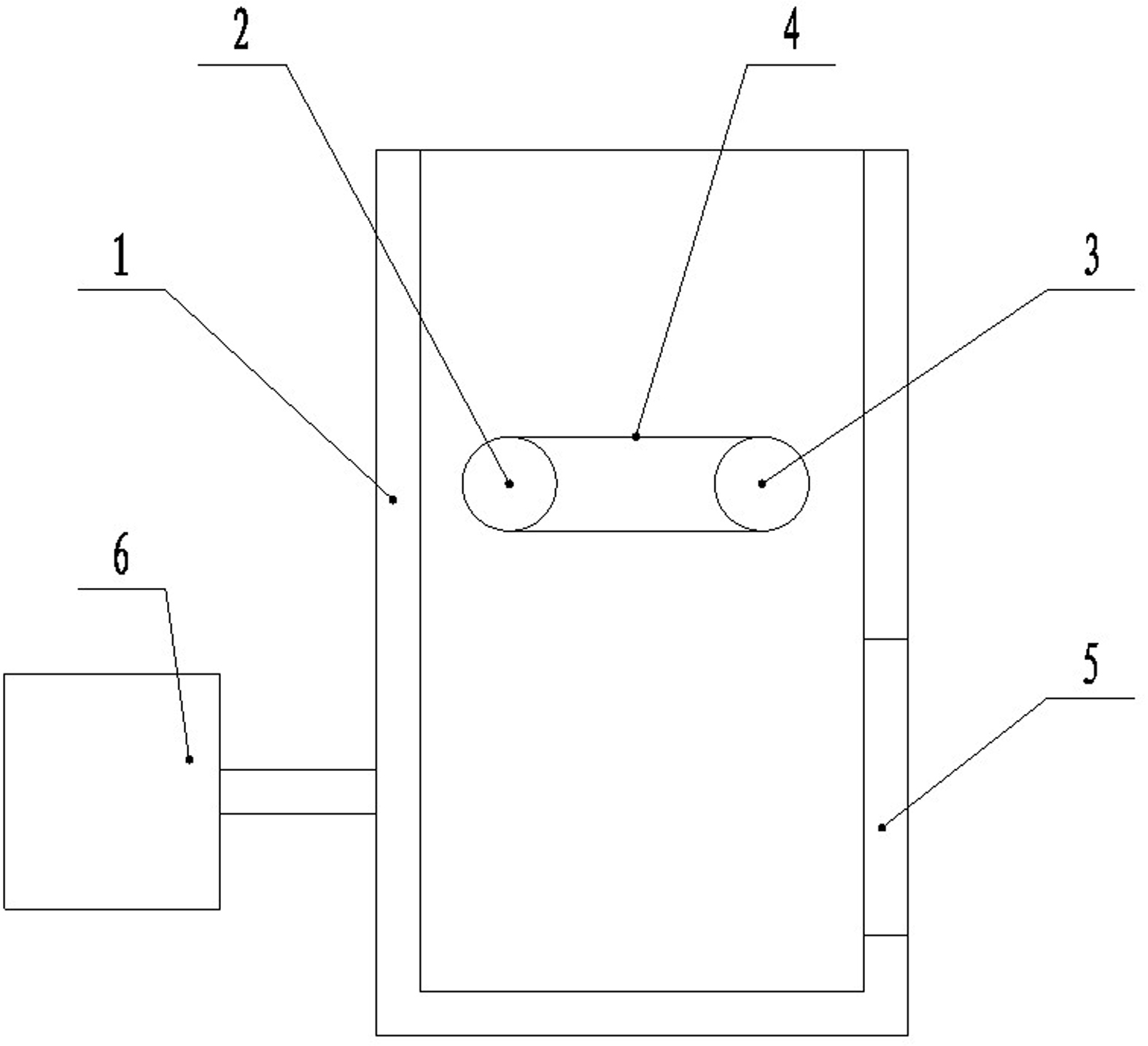

ActiveCN102031725ALarge intervalUse without hindranceMechanical working/deformationPaper/cardboardCrêpe paperPulp and paper industry

Owner:DAIO PAPER CORP

Suspension end insulation structure with transformer coil inserted with shielding wire

InactiveCN102543393ASmall sizeExtended service lifeTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerCrêpe paper

The invention discloses a suspension end insulation structure with a transformer coil inserted with a shielding wire. The suspension end insulation structure comprises a coil current carrying wire and a coil shielding wire distributed at an interval. An end part of the coil shielding wire is connected to a paperboard strip; aluminum metallization crepe papers are covered at outer sides of a suspension end of the coil shielding wire and the contact part of the coil shielding wire and the paperboard strip; a Denison paper is covered at the outer side of the paperboard strip; and the suspension end of the coil shielding wire is in a round corner structure. The invention has the advantages that an existing shielding suspension end which is not treated or is subjected to simple wrapping is changed into a standard insulation structure, so that a local discharge initial voltage at the suspension end is effectively increased, simultaneously the electric field intensity of two adjacent oil conduits at the shielding suspension end and a horizontal oil conduit size between two adjacent shielding suspension ends are reduced; the service life of the transformer is prolonged; and the production cost is lowered.

Owner:SHANDONG DACHI ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com