Preparation method of cylinder adhesive for crepe paper

A technology of sticking agent and crepe paper, applied in starch coatings, polyether coatings, coatings, etc., can solve the problems of film-forming, film-forming elasticity and insufficient re-wetting, and achieve good wrinkling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

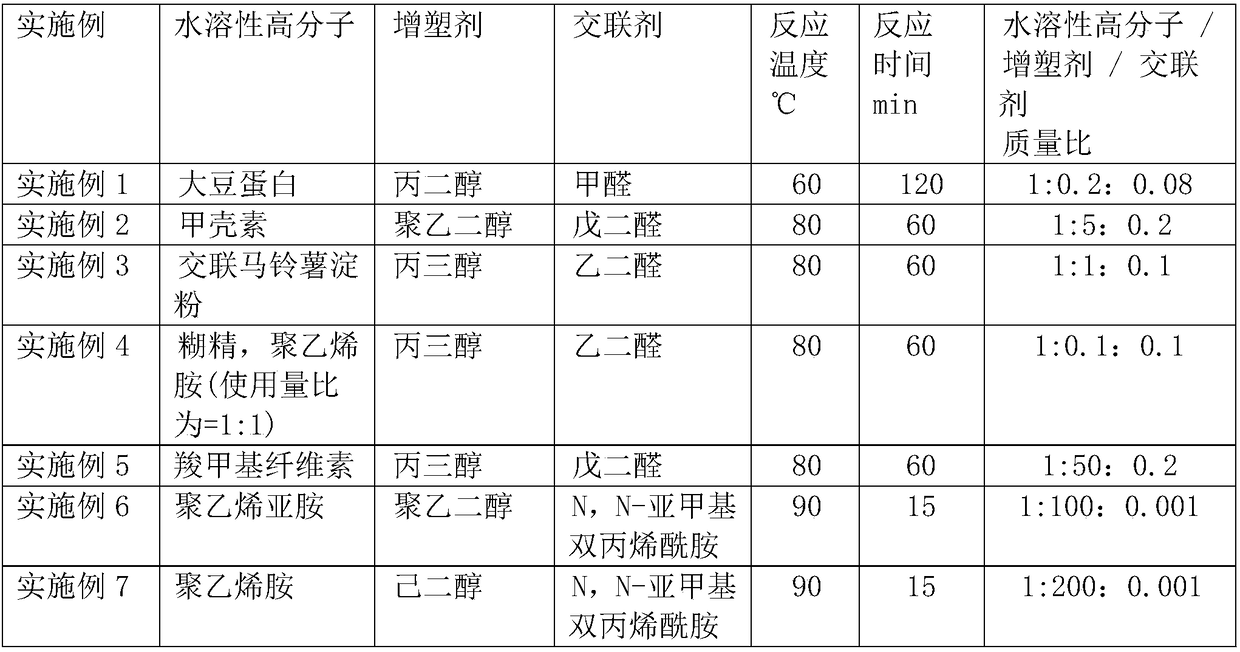

[0021] The present invention will be described in more detail below in conjunction with the examples, but the present invention is not limited thereto.

[0022] Take a certain amount of water-soluble polymer, calculate the amount of plasticizer that needs to be added according to the ratio between it and the plasticizer, and calculate the reaction time and the ratio according to the effective content and ratio of the water-soluble polymer and plasticizer. Solid content, finally uniformly diluted with water to 15% solid content. The following formula, through the addition of plasticizers and cross-linking agents, changes the film-forming properties of water-soluble polymers, polymerizes suitable adhesion and film-forming properties, and can be used as a crepe agent in toilet paper dryer coatings.

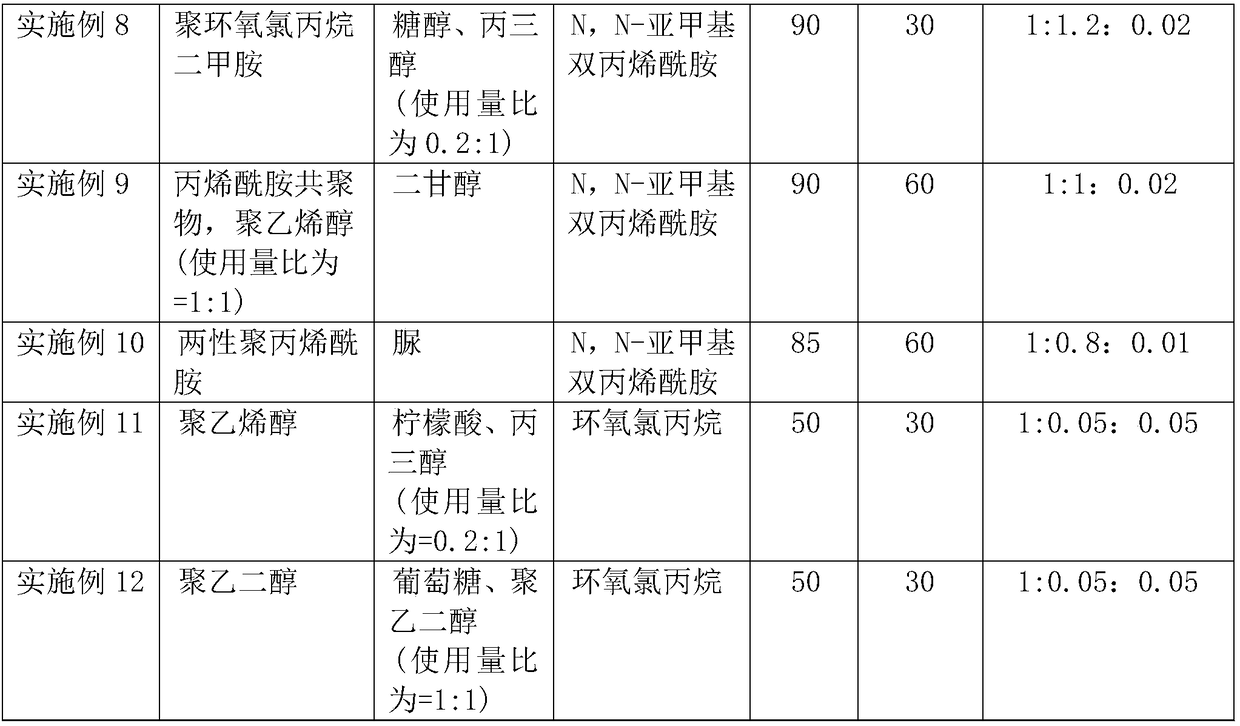

[0023] Table 1 embodiment design

[0024]

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com