Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

376results about How to "Improve transmission capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

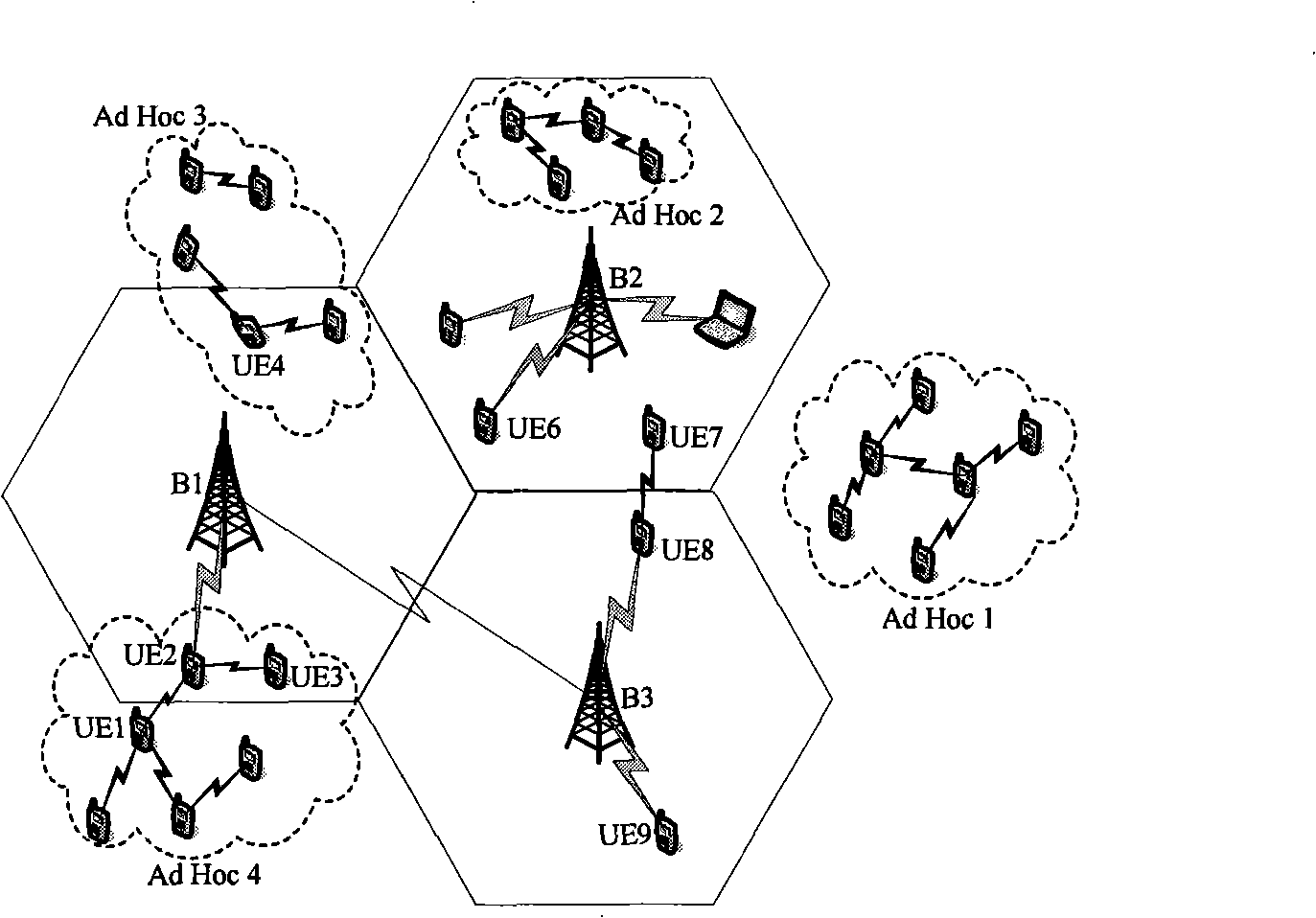

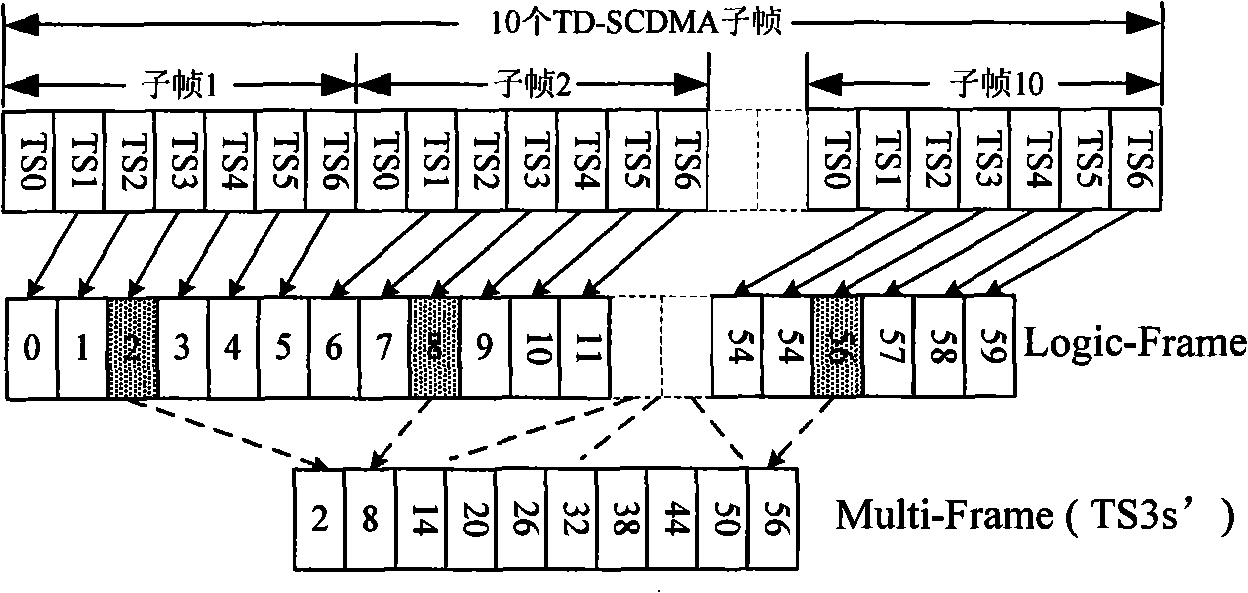

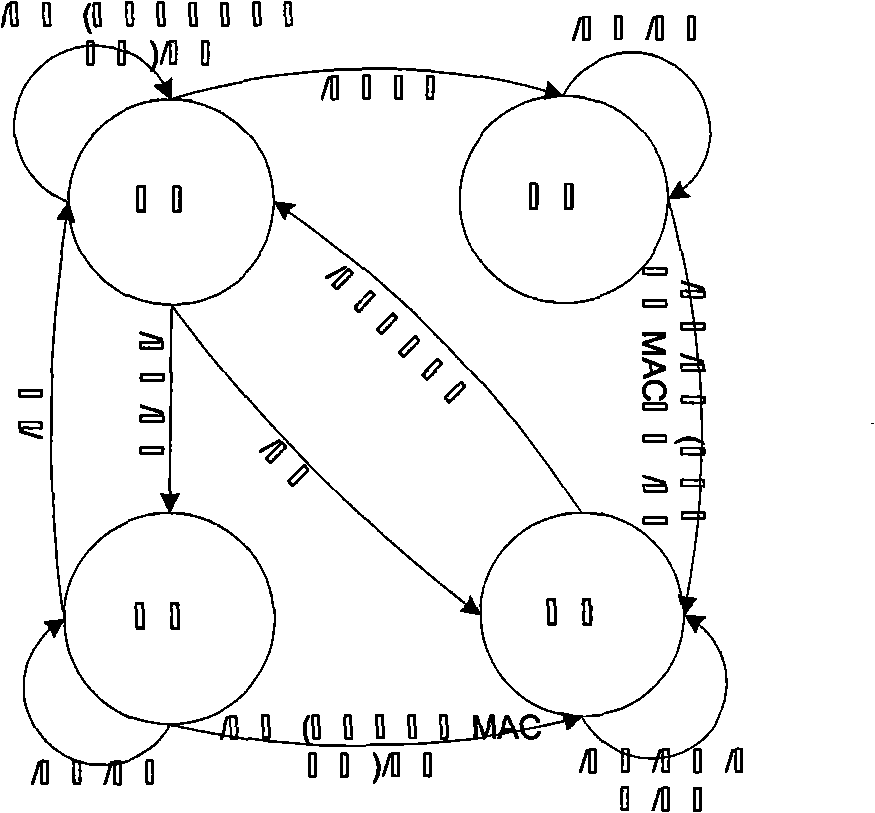

Access control method fusing TD-SCDMA cell phone network and self-organizing network

InactiveCN101360339AAchieve conflict-free wireless accessFast decodingConnection managementRadio/inductive link selection arrangementsAir interfaceEngineering

A connection controlling method of integrating a time synchronous code division multiple access with a automatic-organizing network belongs to the mobile communication field of the communication technology, based on keeping the unitive air interface of TD-SCDMA honeycomb network physic frame invariable construction, the method is a multi-channel synchronization connecting control method based on the preset pattern and distributing pattern control, the time span resource is divided into the control channel and the data channel by the OVSF (Orthogonal Variable Spreading Factor), thus improving the time span reusability through terminal to terminal status to expose the terminal problem, the method maintains the time span status of node within two jumps time span, and realizes the conflict-free wireless connection within two jumps time span; thereby solving the problems of realizing the conflict-free visit time span and performing the reliable alternation communication under integrating network and multi-communication modes.

Owner:PANDA ELECTRONICS GROUP +3

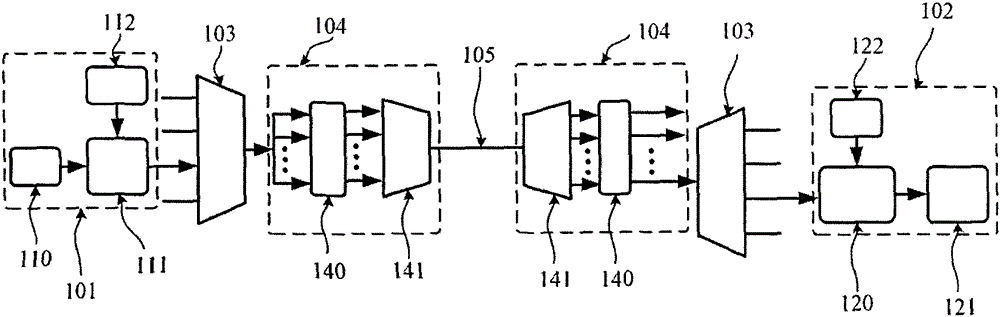

System, method, apparatus, and computer program for wireless communication

ActiveUS20050249303A1Improve transmission performanceImprove transmission efficiencySpatial transmit diversitySecret communicationMimo communicationSelf adaptive

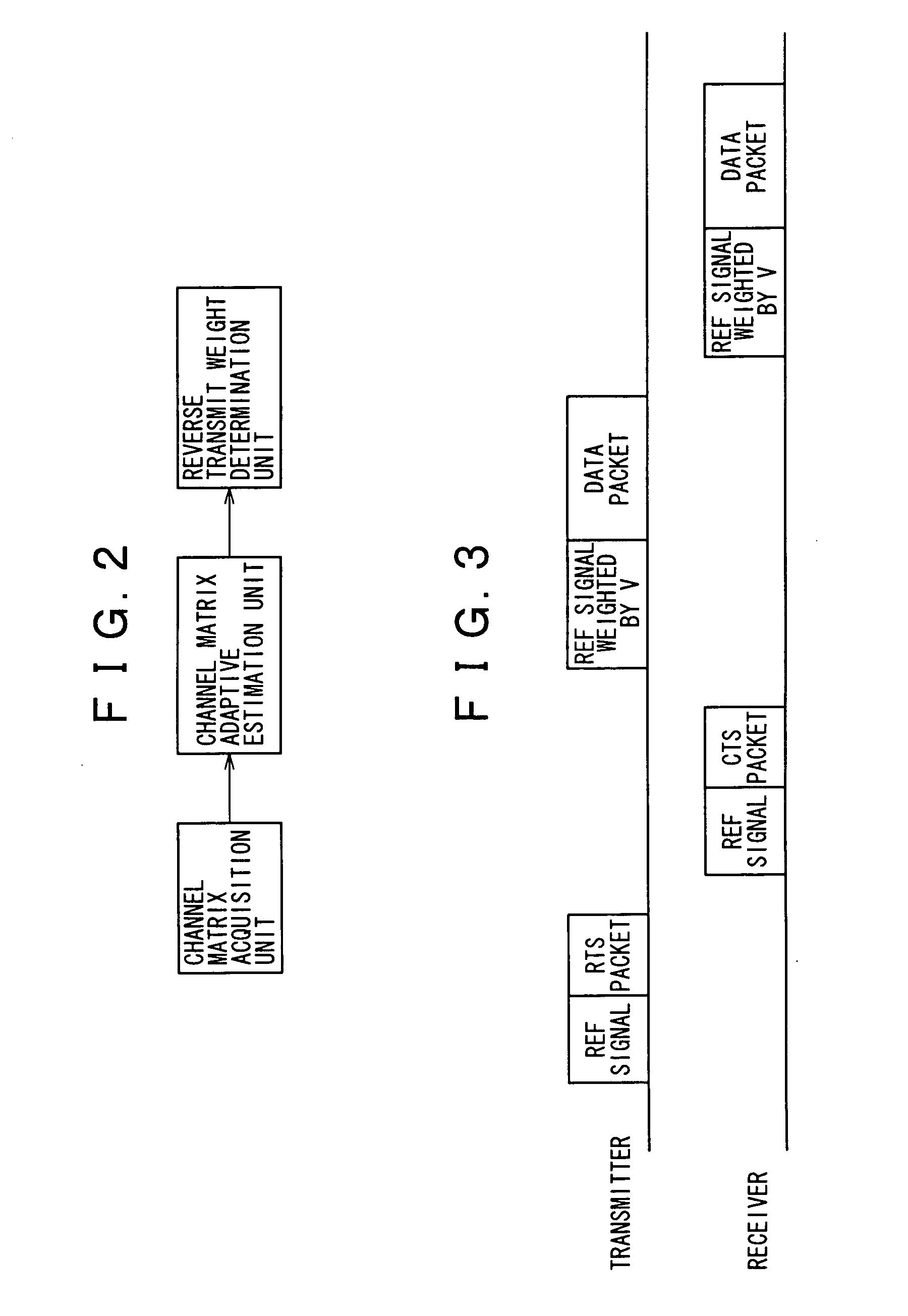

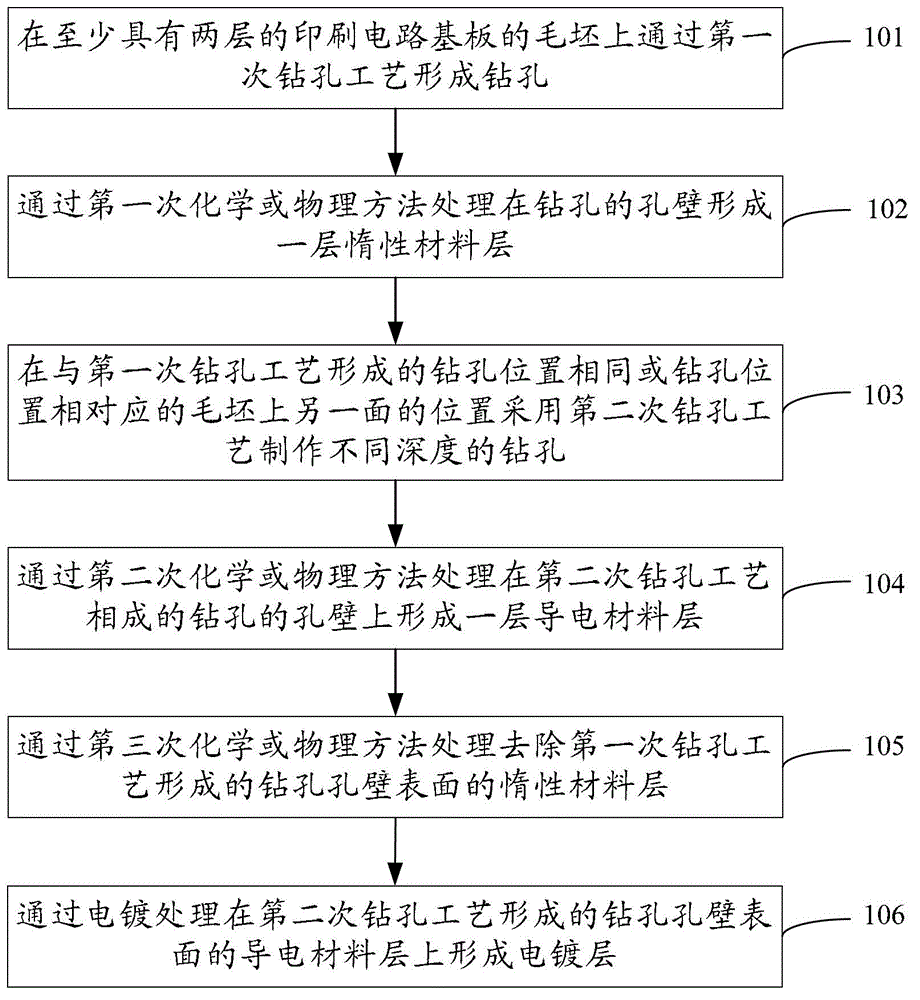

The disclosed invention enhances transmission efficiency by decreasing regions of reference signals which are attached to transmit packets from a transmitter during bidirectional SVD-MIMO communication. The transmitter transmits user data following a reference signal. At the other end, the receiver acquires a channel matrix, based on the reference signal attached preceding the user data, receives the user data, while weighting the data with receive weights derived from the channel matrix, adaptively estimates the channel matrix H as long as the user data is being received, and obtains transmit weights V′ for transmitting user data in the reverse direction from an adaptively estimated channel matrix H′.

Owner:REDWOOD TECHNOLOGIES LLC

Control method, system and equipment for down data link of TDD HSDPA system

InactiveCN101414901AImprove transmission capacitySupport transport characteristicsError prevention/detection by using return channelData switching networksNetwork packetControl system

The invention discloses a downlink data transmission control method, a system and equipment in a time division duplex high-speed downlink packet access system, which reduce the control overhead of a base station and further improve the transmission capacity of the downlink data. The method which controls the transmission of the downlink data comprises the following steps: after initial transmission of a data packet is carried out to user equipment on a pre-appointed initial transmission code channel, confirmed feedback information after the user equipment correctly receives the data packet iswaited for being received on a initial transmission feedback channel corresponding to the pre-appointed initial transmission code channel; moreover, when the confirmed information is not received on the initial feedback channel, retransmission control information is sent to the user equipment on a control channel which is configured for the user equipment, and the data packet is retransmitted. The downlink data transmission control system comprises user equipment and a base station. The embodiment of the invention also discloses a base station and user equipment.

Owner:CHINA ACAD OF TELECOMM TECH

Through hole structure, printed circuit board, and manufacture method of through hole structure

ActiveCN102946695AReduce manufacturing difficultyImprove processing efficiencyElectrical connection printed elementsPrinted element electric connection formationEngineeringPrinted circuit board

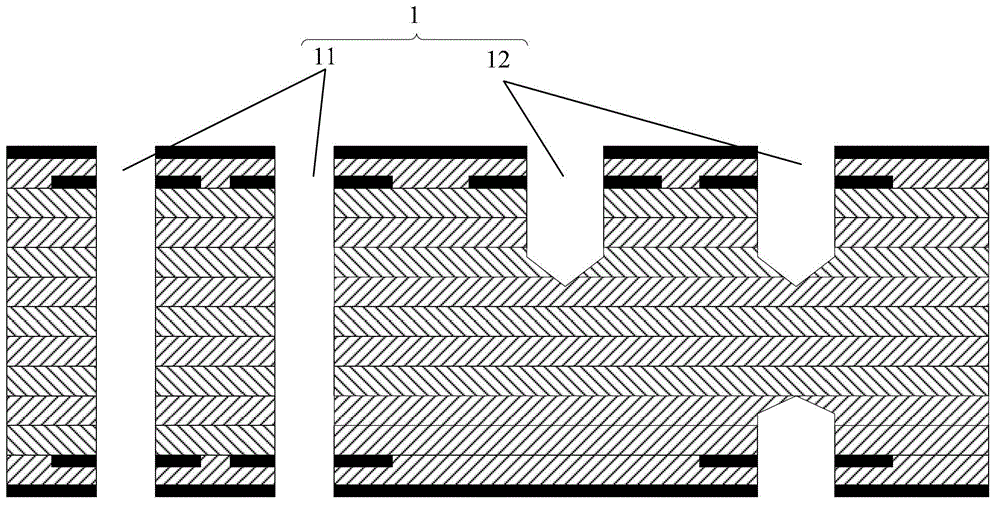

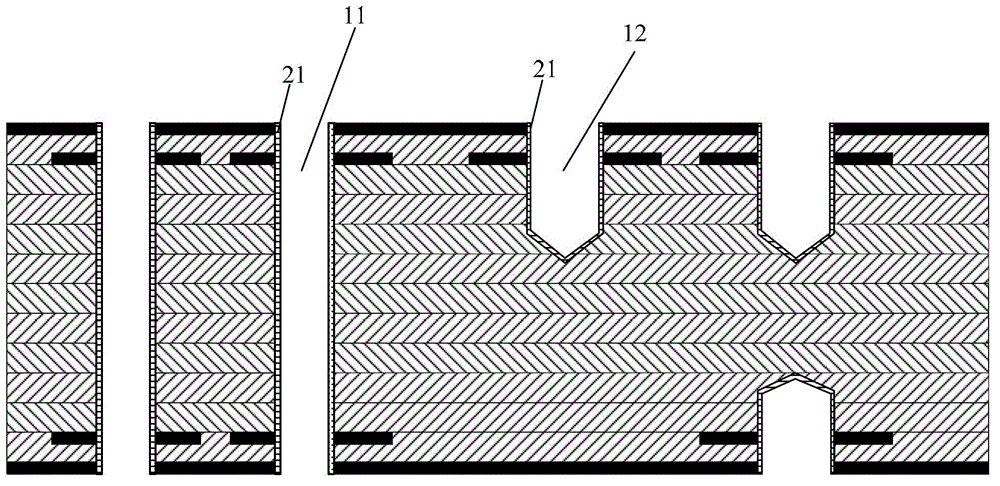

The embodiment of the invention provides a through hole structure, a printed circuit board and a manufacture method of the through hole structure, and relates to the field of printed circuit boards. According to the invention, the density of an outgoing line is increased, the transmission capacity of a signal is increased, the manufacture difficulty is lowered, and the product reliability is improved. The through hole structure is surrounded by hole walls and comprises at least two through hole parts which are formed through division along the axial direction of the through hole structure and at least one step part which is formed through division along the axial direction, wherein the at least two through hole parts are surrounded by the hole walls, the at least one step part is surrounded by the hole walls, each step part of the at least one step part is located between two adjacent through hole parts of the at least two through hole parts and is connected with the two adjacent through hole parts; and the hole walls of the at least two through hole parts and the hole walls of the at least one step part at least comprise one insulated hole wall and one metalized hole wall. The example of the invention is applied to manufacturing the printed circuit board.

Owner:XFUSION DIGITAL TECH CO LTD

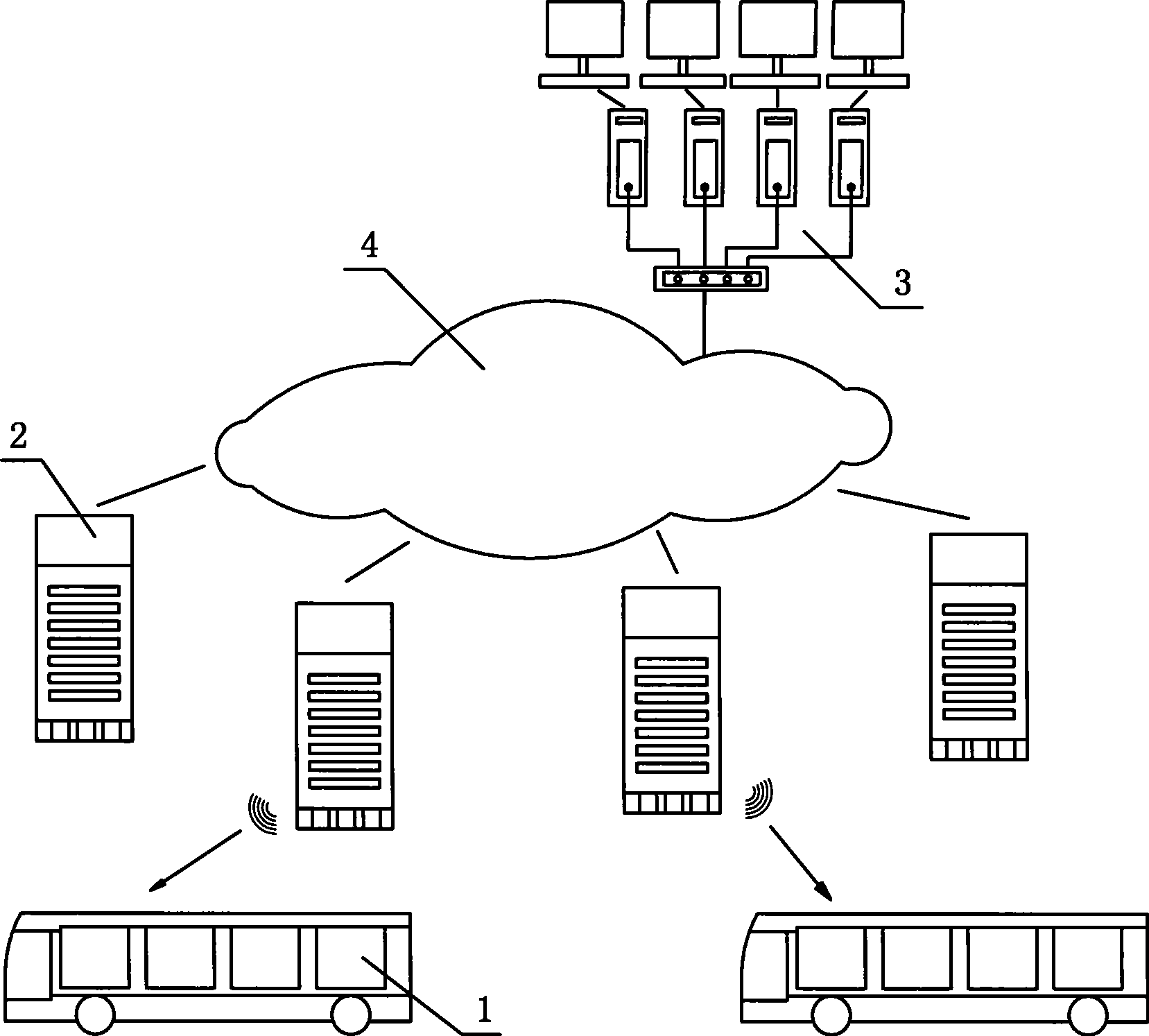

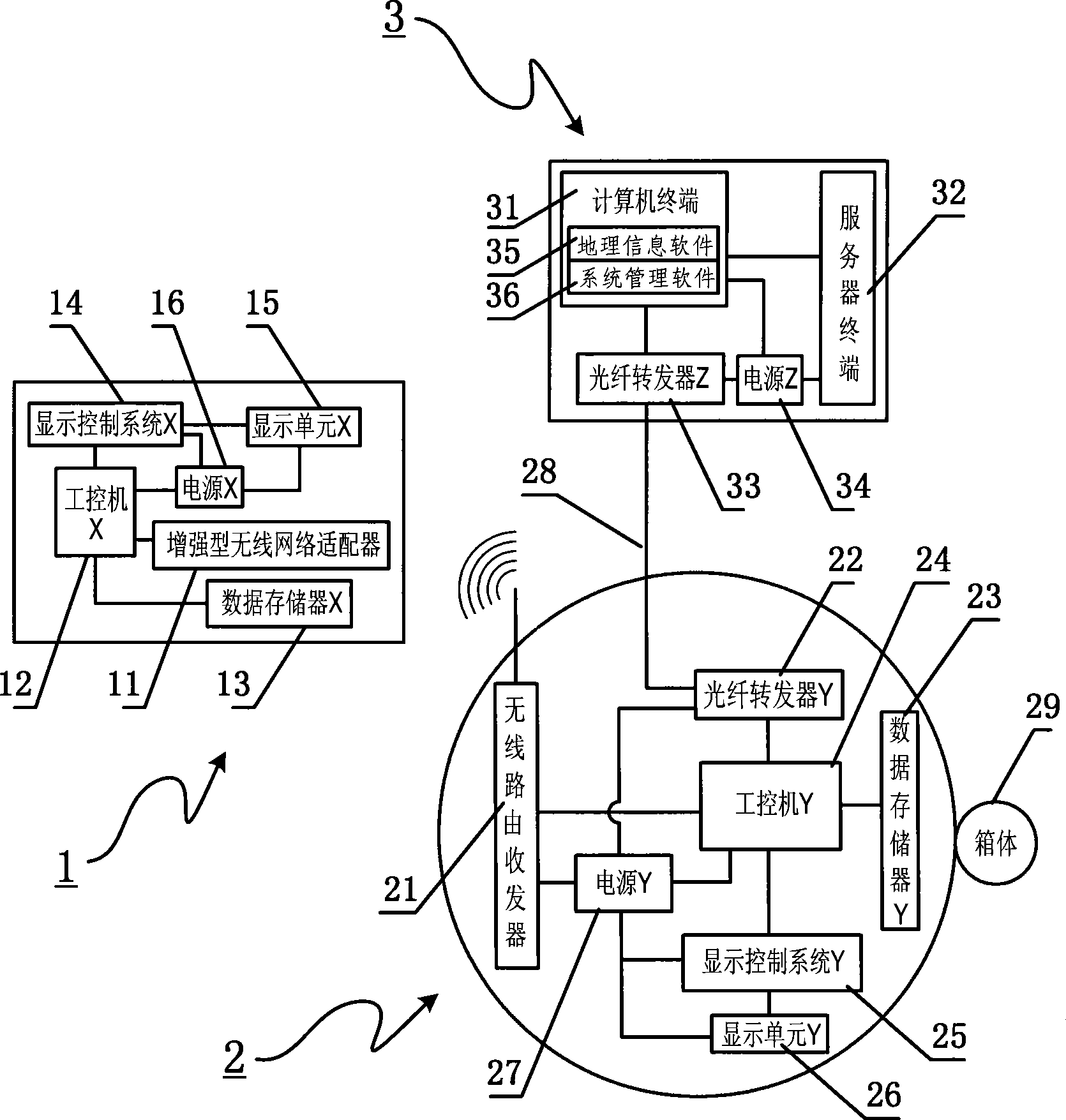

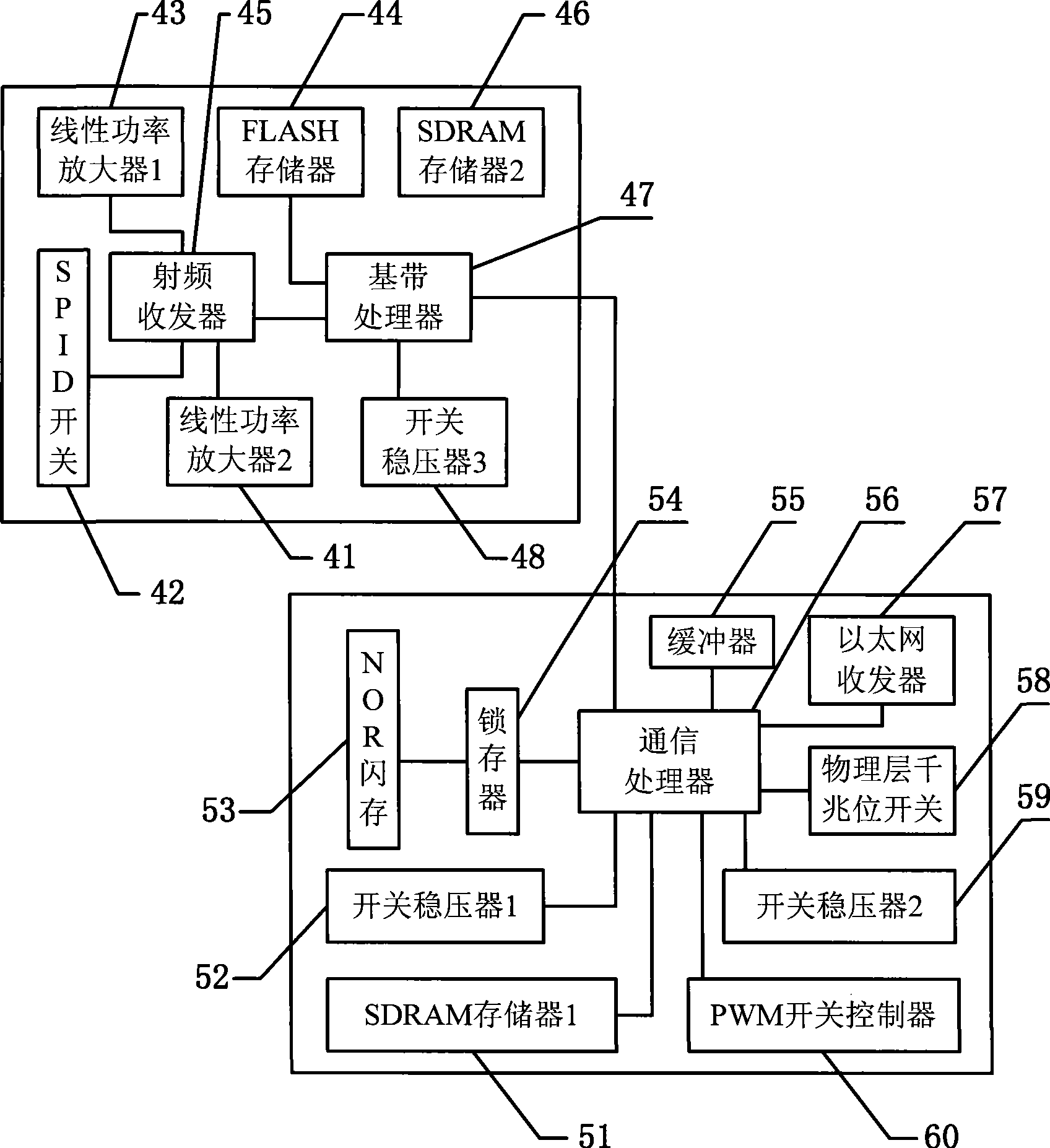

Digital public transport information publishing and cluster controlling method and device

InactiveCN101398975AWide coverageIntegrity guaranteedDetection of traffic movementTelecommunications linkEngineering

The invention relates to a method used for digital bus information releasing and group control and a device thereof. The technical measure comprises the following steps: a vehicle terminal system, an electronic station board system and a vehicle technical information management centre are arranged, the electronic station board system is the vehicle technical information management centre are connected into a bi-directional communication network by line link, the vehicle terminal system transmits the vehicle information to the electronic station board system in a wireless communication, the electronic station board system reports the information to the vehicle technical information management centre, the bus coming to station at each station can be found out by inquiring a database, the station arriving time of the bus is calculated according to experimental data including average running speed, average running time between the stations and the like, finally, the arriving time is fed back to the electronic station board system, and the arriving time is displayed to the waiting passengers in a digital way. The method can effectively solve the problems of bus reduction in city and dispatching, information releasing, passenger facilitation, intelligent management control and the like. Therefore, the method realizes intelligent bus dispatching.

Owner:JIANGSU HANDSON INTELLIGENT TECH CO LTD

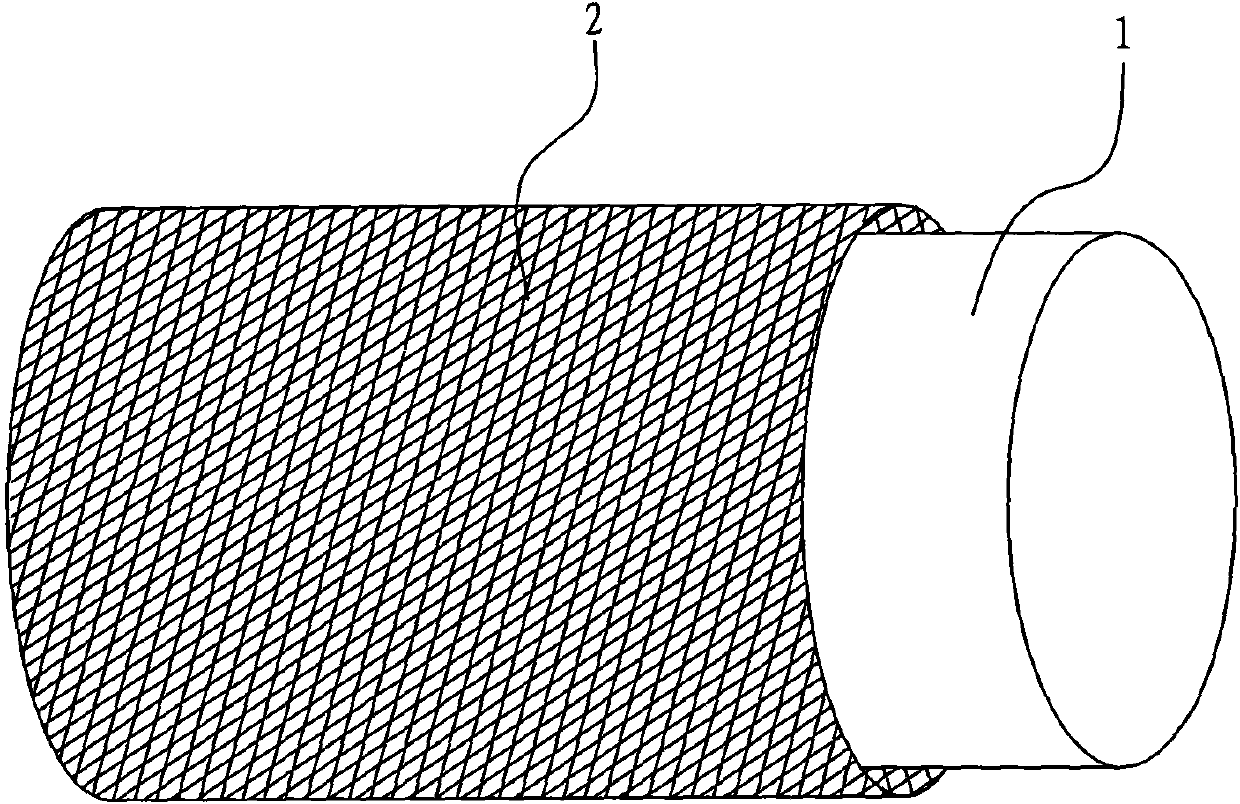

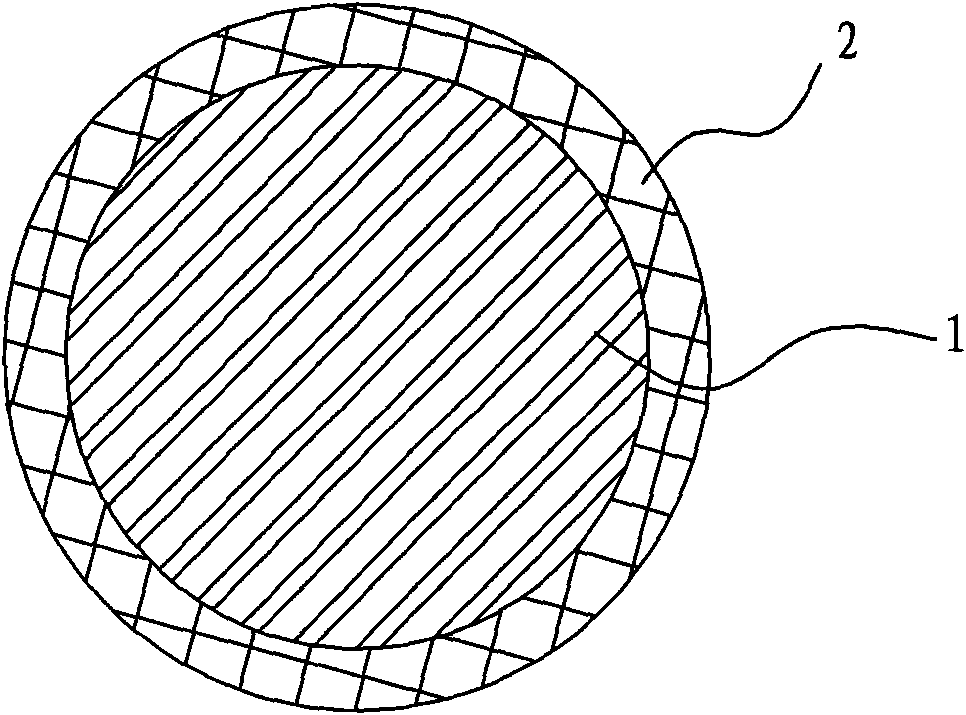

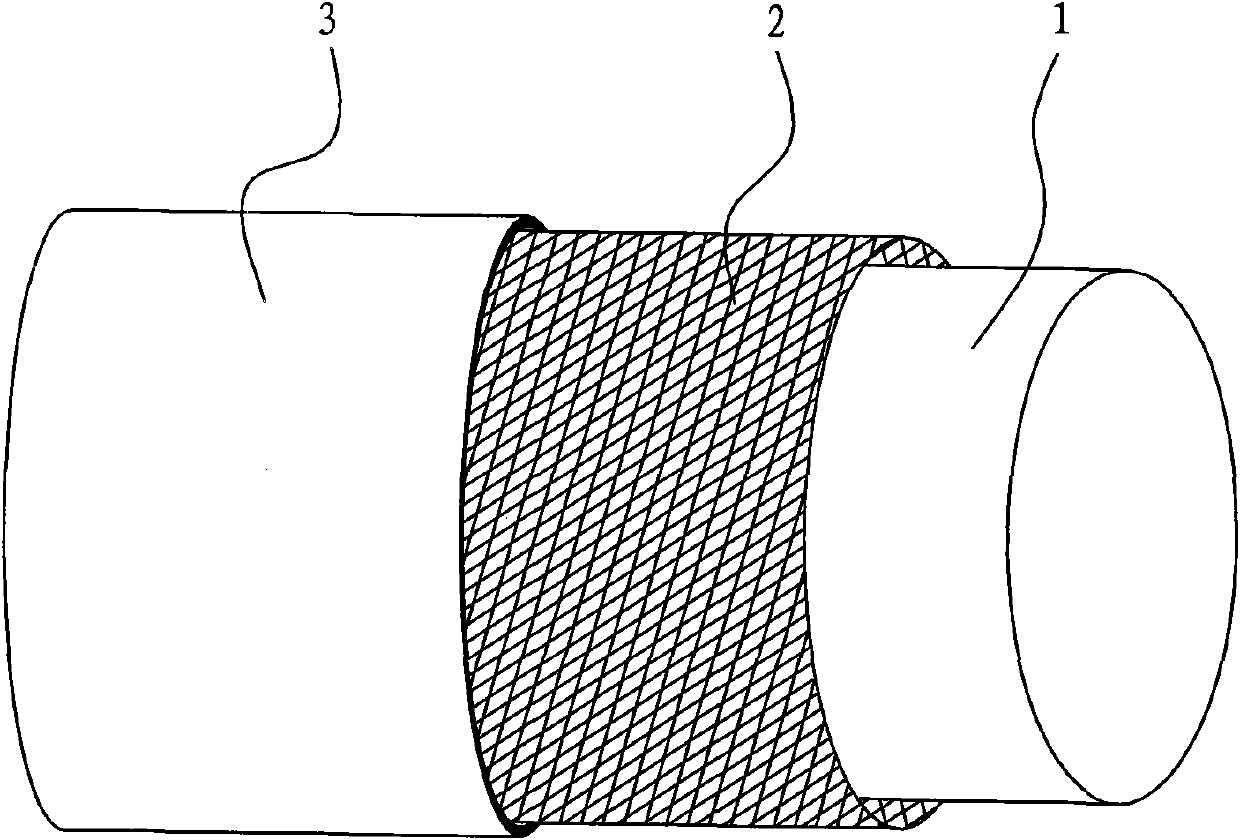

Composite material core used for enhanced cable, preparation process thereof and enhanced cable

InactiveCN102024517AImprove lateral strengthImprove fatigue resistance and fatigue resistanceInsulated cablesCable/conductor manufactureElectrical conductorFiber bundle

The invention relates to a composite material core used for an enhanced cable, a preparation process and the enhanced cable. The composite material core comprises an inner core and an outer layer, wherein the inner core is composed of fiber and thermosetting resin; the outer layer comprises a fiber woven pipe and thermosetting resin which are composited to form the outer layer; and the fiber woven pipe of the outer layer is a network structure which is woven by interlacing a plurality of fiber bundles. The transversal strength of the composite material core is greatly improved by the interlaced network structure, the fatigue resistance of the composite material core is greatly improved, and the service life of the composite material core and a power transmission cable is prolonged; and the problem that the composite material core is broken when the composite material core is stranded, wound and extruded by a conductor in the manufacturing process of the cable is completely avoided. As the fiber woven pipe is adopted by the outer layer, the flexibility of the outer layer is greatly increased by the interlaced and woven structure, thereby meeting the requirement of manufacturing composite material core with major diameter.

Owner:JIANGSU JIATAI TECH MATERIAL

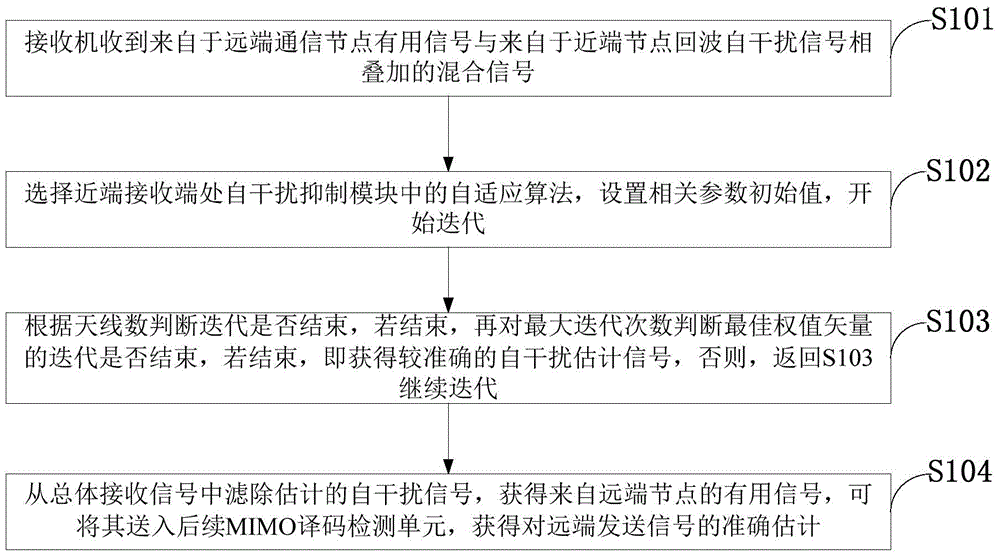

Echo self-interference self-adaption suppression method for broadband wireless full-duplex MIMO communication system

ActiveCN104468055ABER performance improvementImprove transmission capacityError prevention/detection by diversity receptionSelf interferenceSystem configuration

The invention discloses an echo self-interference self-adaption suppression method for a broadband wireless full-duplex MIMO communication system. According to the suppression method, the iterative thought of a self-adaption filtering method is applied to an echo self-interference suppression method, accurate estimation of self-interference signals and promotion of bit error rate performance of the system are achieved through a self-adaption iterative algorithm, and non-ideal fading channel transmission conditions and multi-antenna MIMO system configuration are fully considered to put forward the echo self-interference self-adaption suppression method for the broadband wireless full-duplex MIMO communication system based on a normalized least mean square (NLMS) error algorithm. While the high-intensity self-interference signals can be suppressed significantly, the bit error rate loss of the system is effectively reduced, the transmission capacity of system channels is promoted, the implementation complexity of self-interference suppression is reduced, and the overall comprehensive performance of the wireless full-duplex system is comprehensively improved.

Owner:XIDIAN UNIV

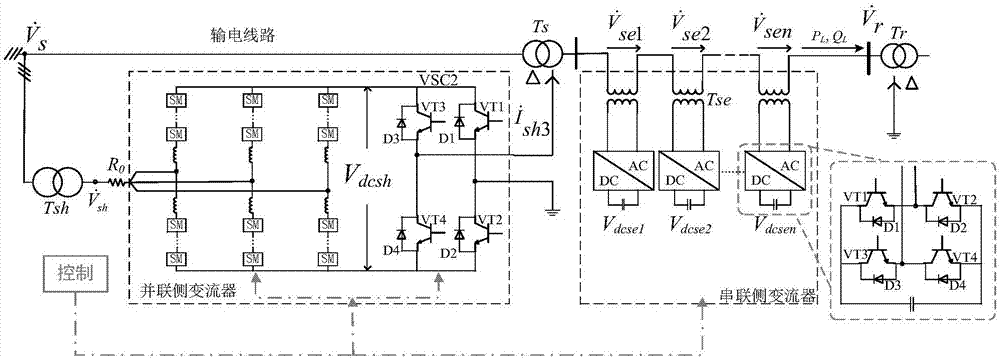

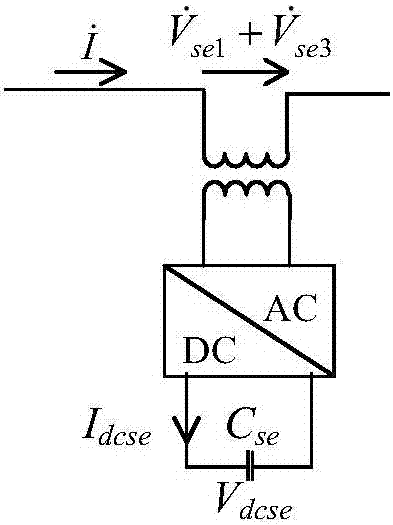

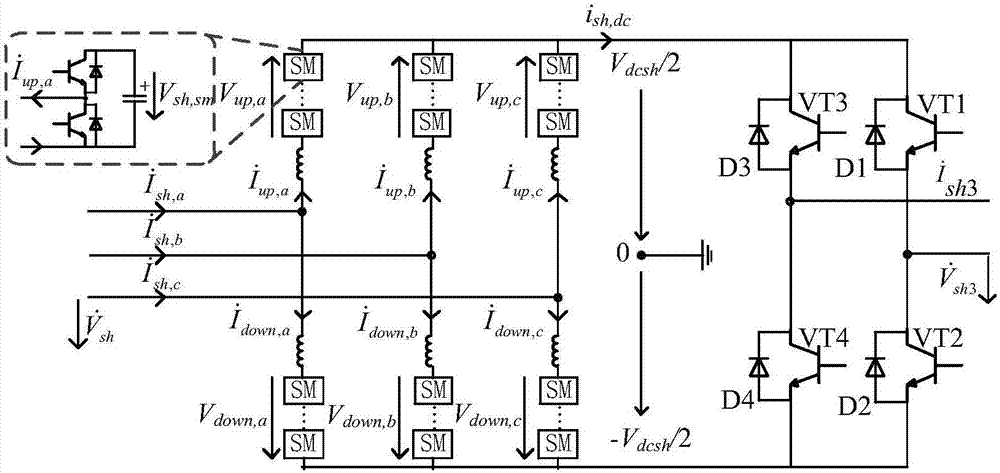

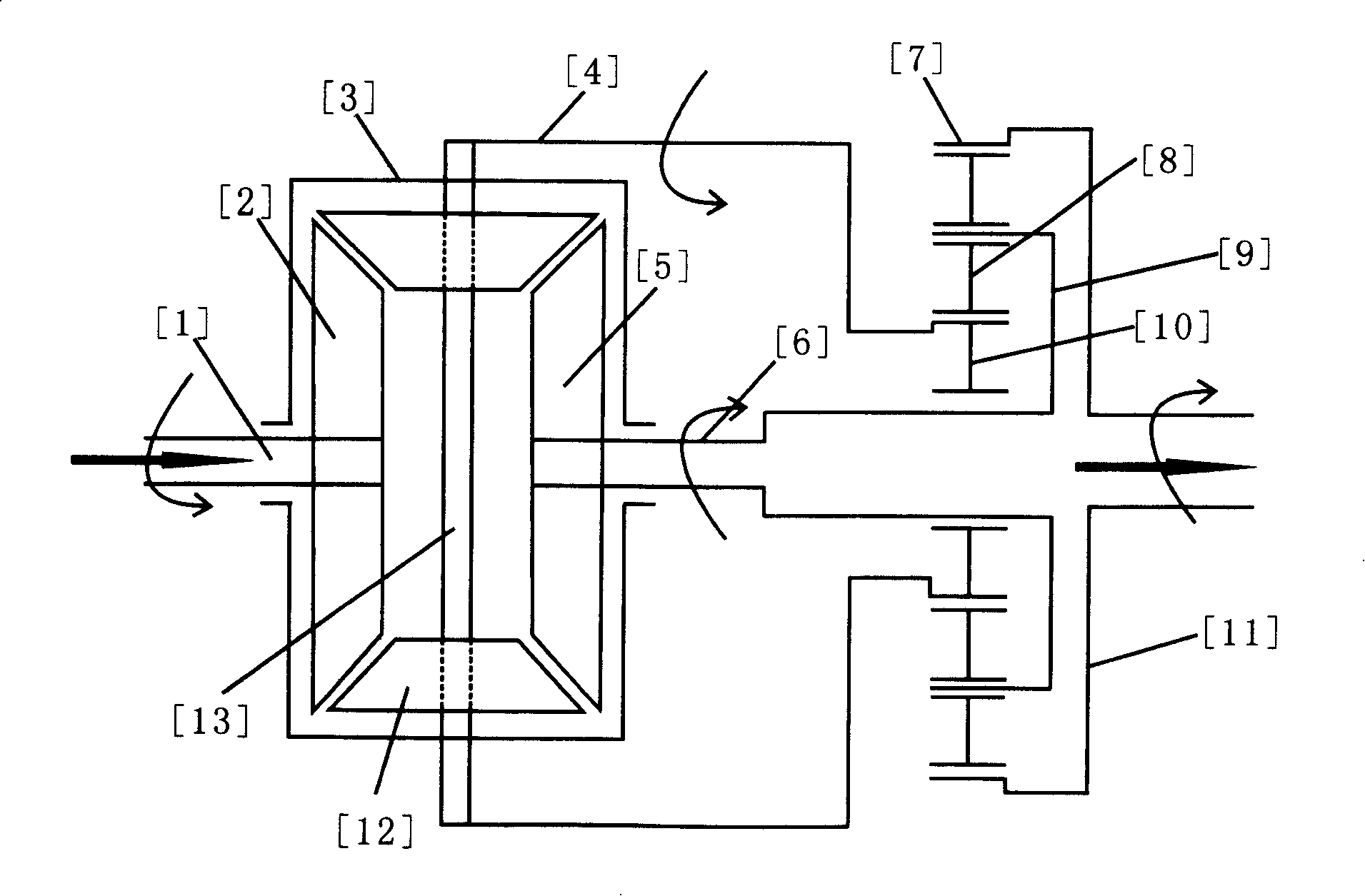

Electromagnetic transient mathematical model of distributed power-flow controller based on MMC, control system and modeling method

ActiveCN106911132AImprove harmonic characteristicsEasy to Modular DesignAc networks with different sources same frequencyMathematical modelThree phase converter

The invention discloses an electromagnetic transient mathematical model of a distributed power-flow controller based on an MMC, control system and a modeling method. The distributed power-flow controller comprises a parallel connection side converter composed of a three-phase converter based on the MMC at the parallel connection side and a parallel connection side single-phase converter and a series connection side converter composed of multiple sets of series connection side single-phase converter; the electromagnetic transient mathematical model mainly comprises a parallel connection side converter model and a series connection side converter model; the control system comprises a parallel connection side control model and a series connection side control model, the parallel connection side control model comprises a three-phase converter control module based on the MMC at the parallel connection side and a parallel connection side single-phase converter module, and the series connection side control model comprises a series connection side third harmonic control module and a series connection converter active power reactive power control module. The electromagnetic transient mathematical model is designed by adopting modularization, the sub module switch-on and switch-off frequency is lowered, and the loss is lowered; the control system adapts to different voltage grades, and is applicable to flexible alternating current transmission occasions.

Owner:WUHAN UNIV OF TECH +3

Method for selecting optimum relay in communication between wayside device and vehicle

ActiveCN102625237AImprove transmission capacityImprove performanceBroadcast service distributionLocation information based serviceNetwork performanceReal-time computing

The invention provides a method for selecting optimum relay in communication between a wayside device and a vehicle. The method comprises the following steps that: predicting a future track according to position and speed information updated by the vehicle in a vehicle-mounted network; selecting another wayside device as an optimum relay node according to the future track; firstly sending data to the relay node by a source wayside device; and then sending the data to a target vehicle by the relay node. With the help of the relay node, the source wayside device is capable of communicating with the further target vehicle, so that the transmission capacity of the network is efficiently increased according to the method provided by the invention and the performance of the network is improved.

Owner:SHANGHAI JIAO TONG UNIV

Alternating current electrified railway in-phase continous power supply system based on multi-port direct current transmission

ActiveCN104410095ASmall amount of workLess investmentElectric power transfer ac networkDc source parallel operationContact networkLow voltage

The invention discloses an alternating current electrified railway in-phase continous power supply system based on multi-port direct current transmission. The system comprises more than one three-phase high-voltage alternating current power supply, direct current converters used for converting three-phase high-voltage alternating current into high-voltage direct current, a high-voltage direct current transmission loop used for transmitting the high-voltage direct current to a loop of each traction transformer, alternating current converters used for converting the high-voltage direct current into low-voltage single-phase alternating current, and a contact network system connected with an output end of the alternating current converter, wherein the contact network system is divided into an alternating current bus and a return line which takes power by a locomotive and then flows back from a steel rail. The system has the advantages that the system is simple in structure principle, high in safety and reliability, and easy to realize and popularize.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Optical communication system based on hybrid mode multiplexing

InactiveCN106411452AImprove transmission capacityImprove transmission performanceWavelength-division multiplex systemsOptical mode multiplex systemsData informationEngineering

The invention relates to an optical communication system based on hybrid mode multiplexing, specifically an optical communication method and device based on hybrid mode multiplexing. The method comprises the steps that optical signal modulation units generate single-wavelength fundamental mode modulation output optical signals under modulation of a baseband data signal; hybrid mode multiplexing optical signals are formed; the hybrid mode multiplexing optical signals are transmitted in a transmission medium, and hybrid mode multiplexing output optical signals are generated; single-wavelength channel or wavelength division multiplexing multichannel fundamental mode output optical signals are formed according to the hybrid mode multiplexing output optical signals; multi-way single-wavelength channel fundamental mode output optical signals are formed according to the wavelength division multiplexing multichannel fundamental mode output optical signals; each single-wavelength channel fundamental mode output optical signal passes an optical signal modulation unit, thereby outputting transmitted data information. According to the method and the device, mode resources of a free space or communication transmission few-mode optical fibers are utilized fully, mode utilization rates can be improved to the greatest extent, and the transmission capability and transmission performance of an optical communication system are increased.

Owner:JINAN UNIVERSITY

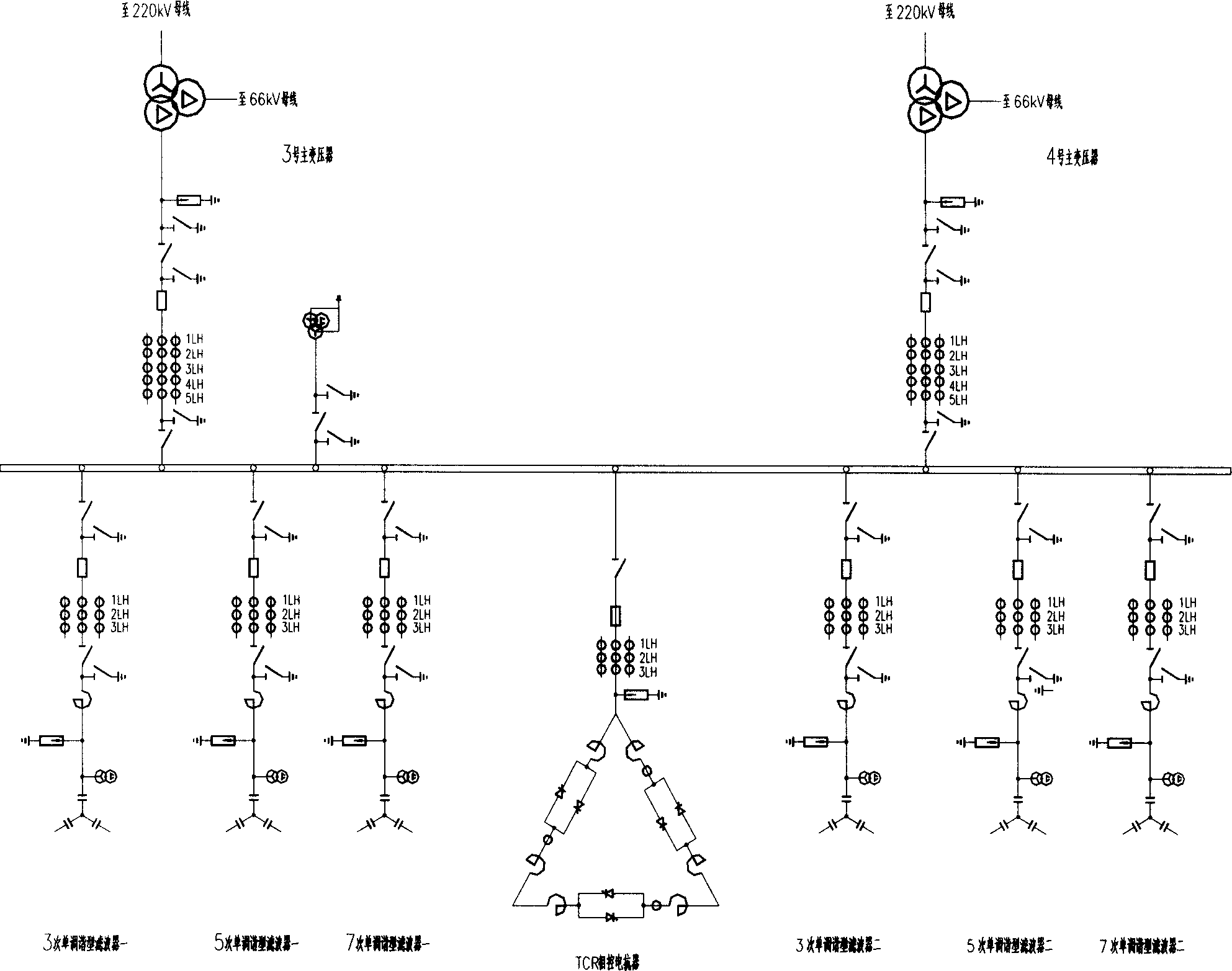

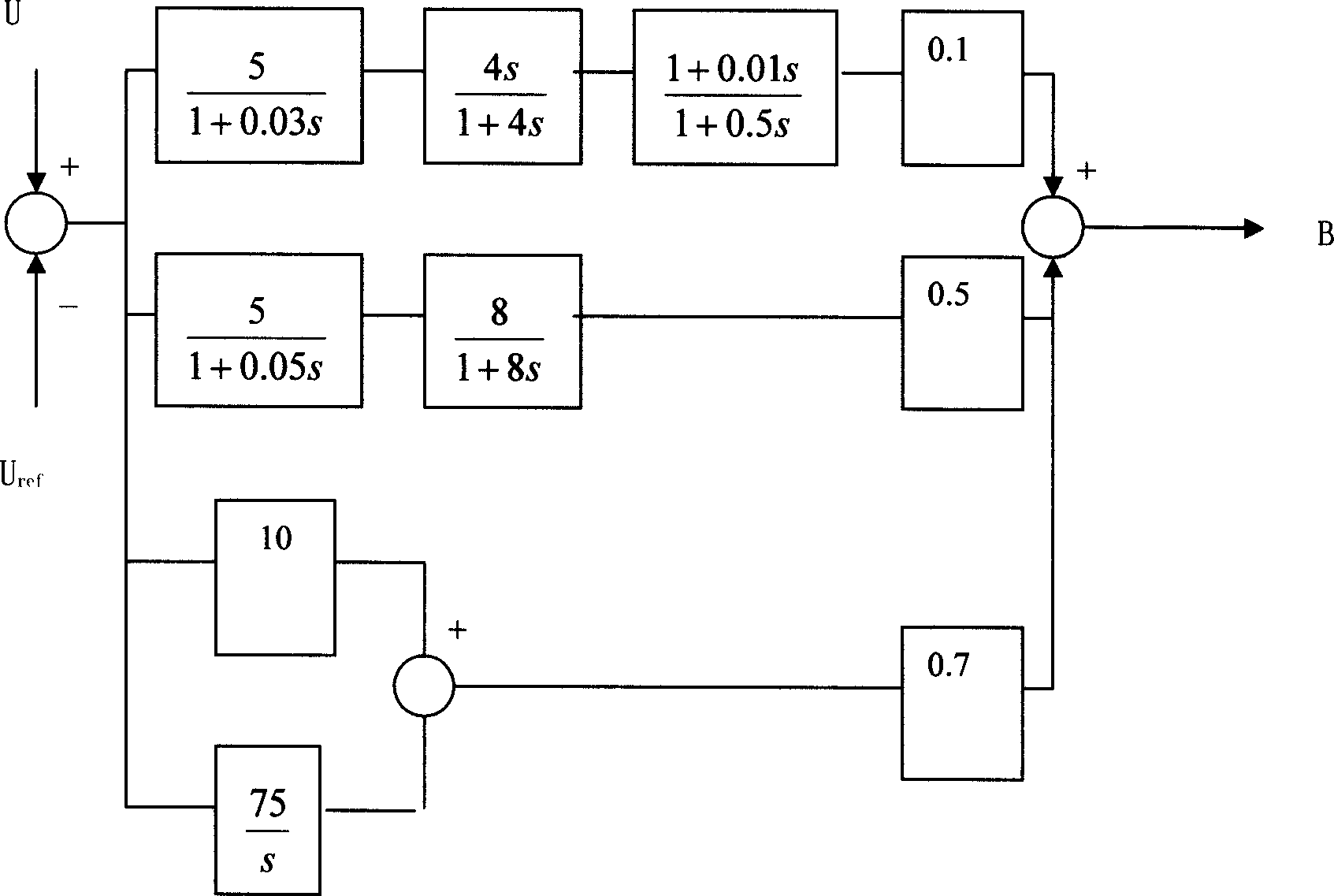

Method for regulating static var compensator of electricity transmission system

ActiveCN1766774AImprove stabilityImprove securityFlexible AC transmissionReactive power adjustment/elimination/compensationElectric power systemTransformer

The invention relates to a static reactive power compensator adjusting method used in power transmission system. It comprises three combined regulation control tactics: it controls the reactor (TCR) antennal organs which is controlled by the bus wire thyristor to do perceptual reactive-load power constant adjustment; it controls the power filter device group (FC) and the fixed condenser band to do condenser reactive-load power interval adjustment; it controls the load transformer tapping switch (LTC) to do bus wire adjustment.

Owner:CHINA ELECTRIC POWER RES INST +1

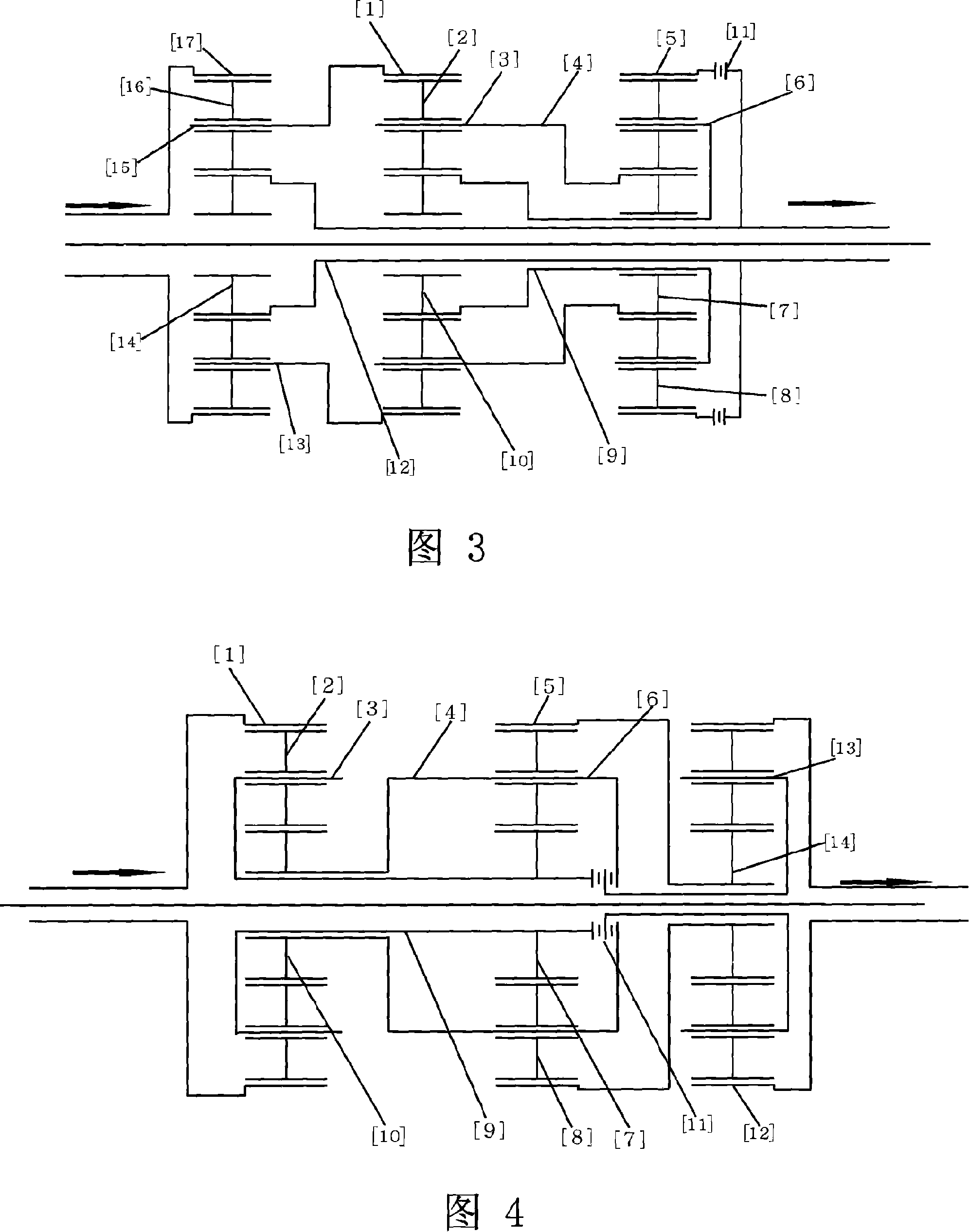

Planetary gear multipath transmission stepless speed changer

InactiveCN101235878ARealize the task of continuously variable speed and torqueImprove transmission efficiencyToothed gearingsDifferential gearingsAutomatic transmissionGear wheel

The invention discloses a stepless transmission for planetary gear multi-path drive, which is designed according to the principle of differently distributing the moment and revolution rate because the planetary gear provides rotation and revolution to different extent under different environment and control. The invention is composed of two rotating members with planetary gear component, one set of the rotating members is used as input step and a rotating member is used to serve as a main input gear for connecting an input moment, and the other set is used as output step and a rotating member serves as a main output gear for driving rear-step driving mechanism. The middle of the other two rotating members of the input step and the output step are connected in pair by different drive ratio, thereby respectively forming two drive paths for reducing speed and increasing moment and increasing speed and reducing moment. Stepless change to driving of input moment is accomplished by forward and reverse rotation modes of the drive path for increasing speed and reducing moment, constantly variable rotating speed of the two moment driving paths and proper control to rotation speed of the two movement driving paths. The stepless transmission for planetary gear multi-path drive is a stepless transmission for gears with fixed number of teeth, has high drive efficiency and strong drive capacity, which is produced with prior art and products with low device investment, and has manufacturing cost much lower than existing stepless transmission and automatic transmission.

Owner:龙宏元

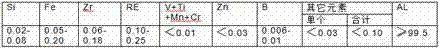

Manufacture method of high electric superalloy conductor and product thereof

ActiveCN1924053AImprove heat resistanceImprove conductivityMetal/alloy conductorsHeat resistanceTitanium

The invention discloses a preparing method of high-conductive thermal tolerance aluminum alloy wire, which comprises the following steps: 1. adding Zr and Fe in the electric aluminium liquid (0.3-0.6% Zr, 0.10-0.25 Fe, not more than 0.08% Si, not more than 0.01% element sum of Ti, V, Mn and Cr); 2. manufacturing thermal tolerance aluminium alloy rod material through continuous aluminium casting manufacturing line; 3. setting the heading temperature at 400-430 deg.c for 50h; 4. drawing and stranding to manufacture high-conductive thermal tolerance alloy wire.

Owner:QINGDAO HANHE CABLE

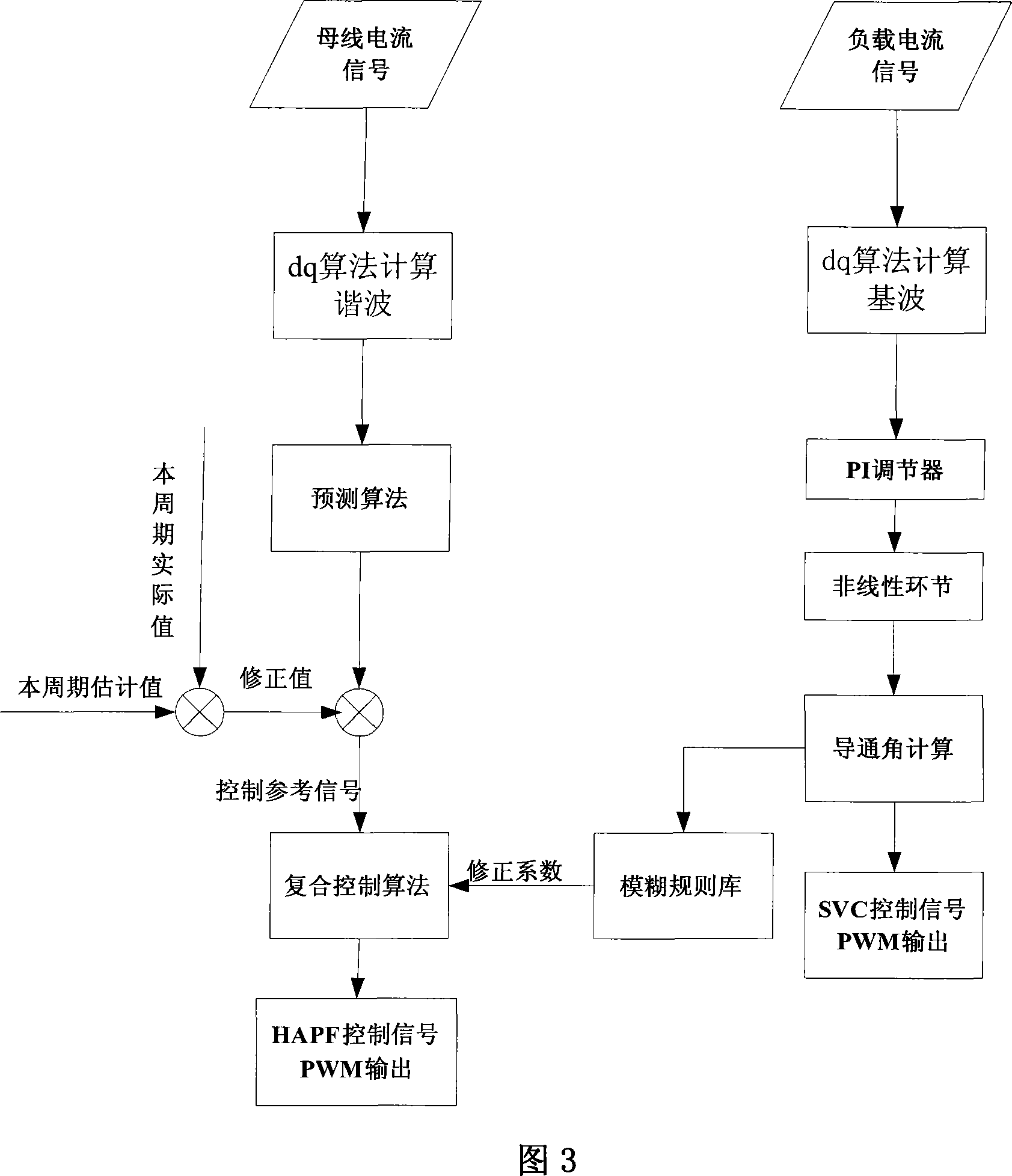

Method for eliminating and controlling SVC specific times harmonic advanced research and apparatus realizing the same

InactiveCN101202447AImprove dynamic performance indicatorsImprove stabilityFlexible AC transmissionReactive power adjustment/elimination/compensationElectric power systemPower factor

The invention discloses an SVC selected harmonic number prediction elimination control method and the devices for implementing thereof. The invention predicts the harmonic numbers of 2, 5, 7, 11 and 13 of the SVC system by adopting an adaptive control algorithm which is based on fuzzy prediction; the prediction result is used for modifying the PWM output, which is controlled by load current feedforward, of an injection-typed active filter HAPF; the HAPF outputs the harmonic current which is identical to the SVC selected harmonic time current and has reverse phase, thus reaching the objects of harmonic filtering, improving the dynamic performance of the device and improving the stability of the system. The invention implements the optimum control to power network reactive and power factor, provides a plurality of dynamic reactive storage for the power system, has an important effect in stabilizing the voltage of the generatrix and compensating the reactive power of the distribution network, and effectively improves the transmission capacity of the power system.

Owner:HUNAN UNIV

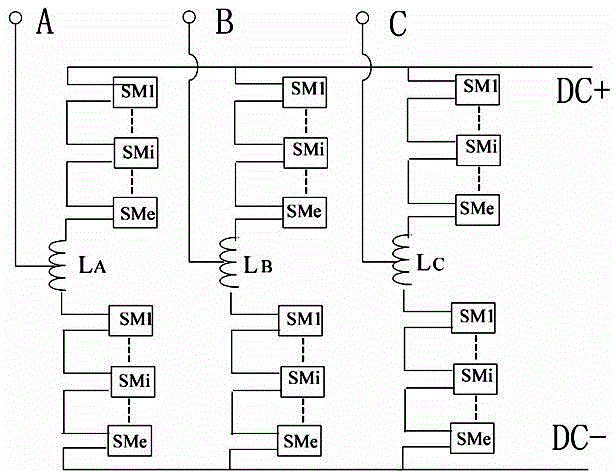

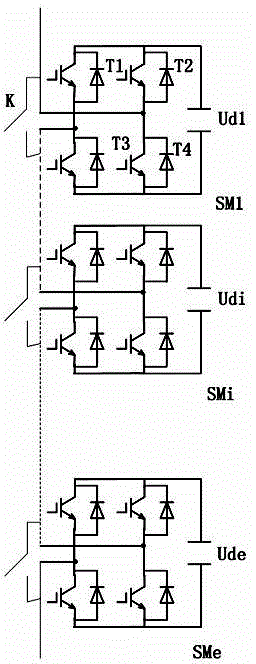

Method for increasing capacity of flexible direct-current power transmission system and apparatus thereof

ActiveCN103715930AImprove transmission capacityIncrease the voltage valueDc-ac conversion without reversalTransverterFull bridge

The invention relates to the technical field of flexible direct-current power transmission, particularly to a method for increasing the capacity of a flexible direct-current power transmission system and an apparatus thereof. According to the invention, by adding a full-bridge sub-module (FBSM) which can generate negative voltage into a bridge arm of a modular multilevel converter (MMC), direct-current output voltage of a transverter is balanced while alternating-current output voltage of the transverter is adjusted, thereby increasing the transmission capacity of the transverter. The method does not have higher requirements on the through-current capability of IGBT elements and proceeding from conventional engineering technologies, the application of flexible direct-current power transmission technologies in practical engineering is substantially optimized.

Owner:STATE GRID CORP OF CHINA +2

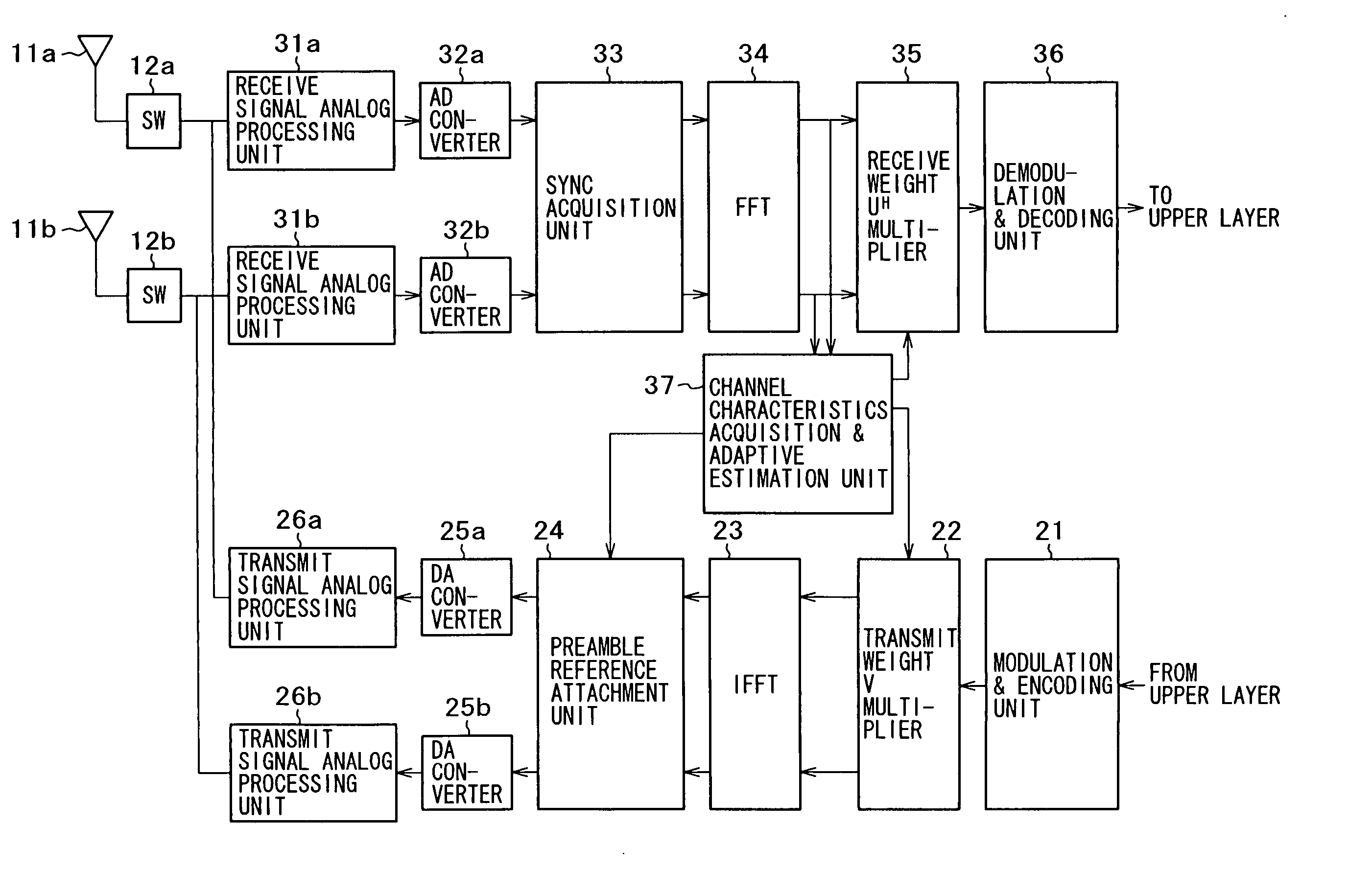

Wireless communications system, wireless communications apparatus and wireless communications method

ActiveCN1614906AInconsistency compensationImprove transmission capacitySpatial transmit diversityError prevention/detection by diversity receptionSingular value decompositionCommunications system

In SVD-MIMO transmission using singular value decomposition, the amount of information fed back from the receiver to the transmitter is reduced. The receiver does not feed back the transmission weight vector V to the transmitter, which is obtained by the receiver through singular value decomposition of the channel information matrix, but sends reference symbols to the transmitter, and the transmitter obtains the channel information matrix and Singular value decomposition is performed to produce the vector V necessary to send the data. In the process of obtaining the vector V, the inconsistency between the channel matrices in opposite directions is compensated by calibration, which can compensate the errors between the transmitting and receiving analog devices of both the transmitter and the receiver.

Owner:WI FI ONE TECH INT LTD

Polarization-independence direct detection system and method based on light intensity modulation signal

ActiveCN105553560ANo significant increase in costImprove transmission capacityPolarisation multiplex systemsElectromagnetic transmittersMultiplexingSignal on

The invention discloses a polarization-independence direct detection system and method based on a light intensity modulation signal, and relates to the field of optical fiber communication. The method comprises the following steps that: a sending send divides light signals into two beams of perpendicular signals in a polarization state, the two signals in the polarization state are respectively modulated in an intensity modulation mode, and polarization multiplexing signals are formed after the two signals pass through a polarization coupler; two beams of lasers perpendicular in polarization direction are used as two pilot signals used for carrying out frequency beating with the polarization multiplexing signals on a receiving end so as to realize polarization-independence light signal receiving; and the receiving end divides the received signals into two beams of perpendicular signals in a polarization state, the two beams of signals respectively are subjected to re-sampling changing into doubled sampling, then a conventional constant modulus algorithm is utilized for processing, and recovered signals are directly judged. According to the invention, the transmission capacity of the system is doubled without increasing the cost of the system.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

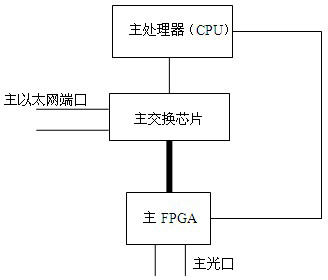

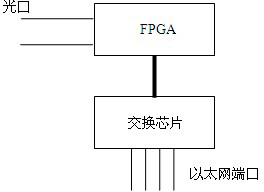

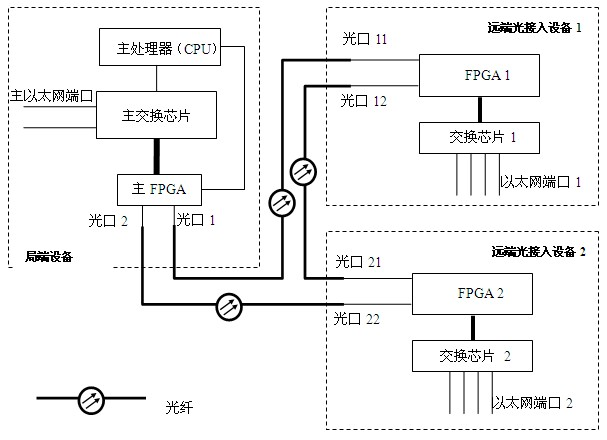

Common public radio interface (CPRI) frame-based wavelength division multiplexing-passive optional network (WDM-PON) mobile and fixed integrated access system

ActiveCN103281599AMeet transfer requirementsSimple structureMultiplex system selection arrangementsWavelength-division multiplex systemsFiberFrame based

The invention discloses a common public radio interface (CPRI) frame-based wavelength division multiplexing-passive optional network (WDM-PON) mobile and fixed integrated access system, and relates to the field of PON access. The mobile and fixed integrated access system comprises a mobile and fixed integrated access optical line terminal (OLT), an optional distribution network (ODN) and a plurality of mobile and fixed integrated access optional network units (ONUs); the mobile and fixed integrated access OLT is connected with the mobile and fixed integrated access ONUs through the ODN; the mobile and fixed integrated access OLT comprises a local end relay framing module, N parallel local end WDM-PON optical modules and a coupler, wherein N is a positive integer and N is greater than or equal to 8 and is less than or equal to 64; the local end relay framing module is connected with the coupler through the N parallel local end WDM-PON optical modules; each mobile and fixed integrated access ONU comprises a far end framing module and a far end WDM-PON optical module; and the coupler is connected with each WDM-PON optical module through the ODN. By the CPRI frame-based WDM-PON mobile and fixed integrated access system, mobile service and fixed network service can be transmitted at the same time; deep coverage of mobile radio signals of an operator can be realized; and the trunk fiber resources accessed in a network can be saved.

Owner:FENGHUO COMM SCI & TECH CO LTD

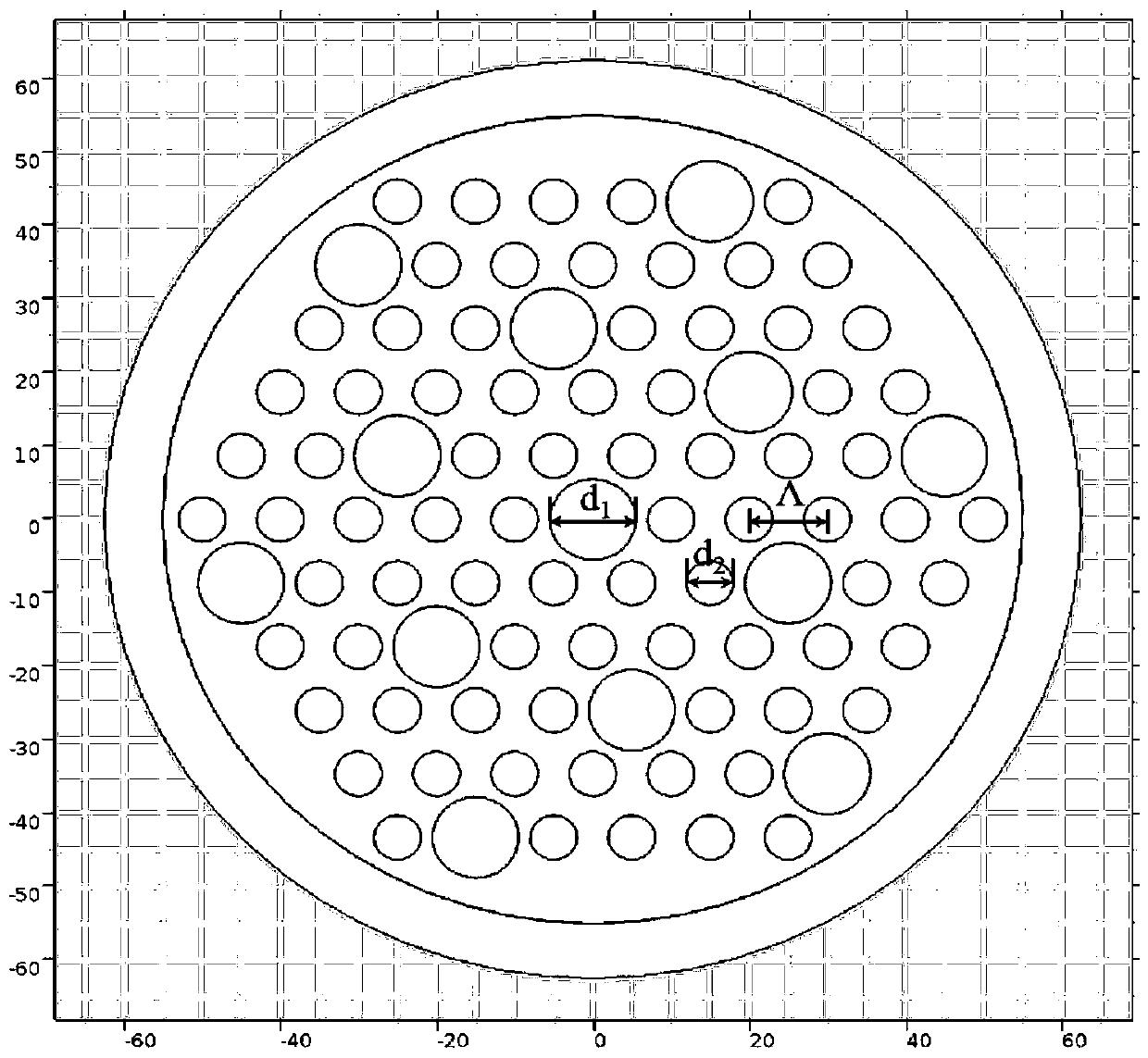

Multi-core few-mode microstructure optical fiber for field of space division-mode division multiplexing

ActiveCN110927863ASmall sizeControl the refractive index differenceCladded optical fibreOptical waveguide light guideRefractive indexEngineering

A multi-core few-mode microstructure optical fiber for the field of space division-mode division multiplexing comprises a central area and an outer cladding area, and the outer cladding area is arranged on the periphery of the central area. The central area comprises few-mode fiber cores and an air hole inner cladding, and a plurality of few-mode fiber cores are arranged in the central area. The number of degenerate transmission modes of a single few-mode fiber core is greater than or equal to 2. One few-mode fiber core is arranged in the center of the central area, the other few-mode fiber cores are uniformly distributed around the few-mode fiber core in the center, any three adjacent few-mode fiber cores are equidistant, and an air hole inner cladding is arranged between the periphery ofeach few-mode fiber core and the two adjacent few-mode fiber cores. According to the optical fiber, the number of degenerate transmission modes of each fiber core can be ensured to be more than two by designing and adjusting the diameters of the air holes and the distances between the holes and controlling the refractive index difference of materials, the size of the optical fiber is reduced as much as possible, inter-core / inter-mode crosstalk and differential mode group delay are controlled on the basis to meet the communication requirement, and the communication capacity is improved.

Owner:NORTHEASTERN UNIV

Method for preparing high-strength, high-conductivity and heat-resistant aluminum alloys

The invention discloses a method for preparing high-strength, high-conductivity and heat-resistant aluminum alloys. The method for preparing the high-strength, high-conductivity and heat-resistant aluminum alloys comprises the following steps: putting pure aluminum powder into a ball mill, ball milling, then putting the aluminum powder after ball milling into a cold isostatic pressure encapsulation sleeve and carrying cold isostatic pressure treatment, and putting pressure blanks after carrying out cold isostatic pressure treatment in a protective atmosphere to carry out sintering densification at a sintering temperature of 600-640 DEG C; and carrying out hot squeezing and cold drawing on sintered aluminum bars to obtain the high-strength, high-conductivity and heat-resistant aluminum alloys. The high-strength, high-conductivity and heat-resistant aluminum alloys prepared by the method are free of other alloy metals and just contain a nano-sized tiny oxide substance point which is used as a strengthening phase, and the strengthening phase is tiny and uniform, so that the strength of the material is improved, and the influence on the conductivity of the material is small; the oxide strengthening phase can stably exist at the high temperature, so that the recovery and re-crystallization of the material can be remarkably avoided, and the growth of crystal grains is avoided; therefore, the strength can be retained at the high temperature; the heat resistance of the material is remarkably improved.

Owner:UNIV OF SCI & TECH BEIJING

Photon probability shaping signal transmission method based on few-mode multi-core optical fiber

ActiveCN111064514AImprove transmission capacityFlexible transfer rateFibre transmissionElectromagnetic receiversData streamEqualization

The invention discloses a photon probability shaping signal transmission method based on a few-mode multi-core optical fiber. The method comprises the following steps: carrying out probability shapingconstellation mapping on multiple paths of parallel bit data streams to obtain a 16QAM signal; enabling a modulator to modulate a 16QAM signal to laser, and then converting the 16QAM signal into a signal in a high-order mode after mode conversion; enabling a few-mode multi-core optical fiber entry mode multiplexer to realize different-mode transmission and space division multiplexing of differentprobability signals; enabling a receiving end to carry out demultiplexing through a space division mode division multiplexer, decomposing the optical signal into multiple signals, sending the signalsto a photoelectric detector for detection, converting the optical signal into an electric signal to obtain multiple 16QAM signals, and carrying out dispersion compensation on the converted 16QAM signals; carrying out MIMO equalization processing on the 16QAM signal symbol in an MIMO equalizer by applying an adaptive step length equalization algorithm so as to carry out compensation mode couplingand modal delay; and finally, performing corresponding probability shaping constellation de-mapping and digital signal processor processing to obtain initial bit data.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

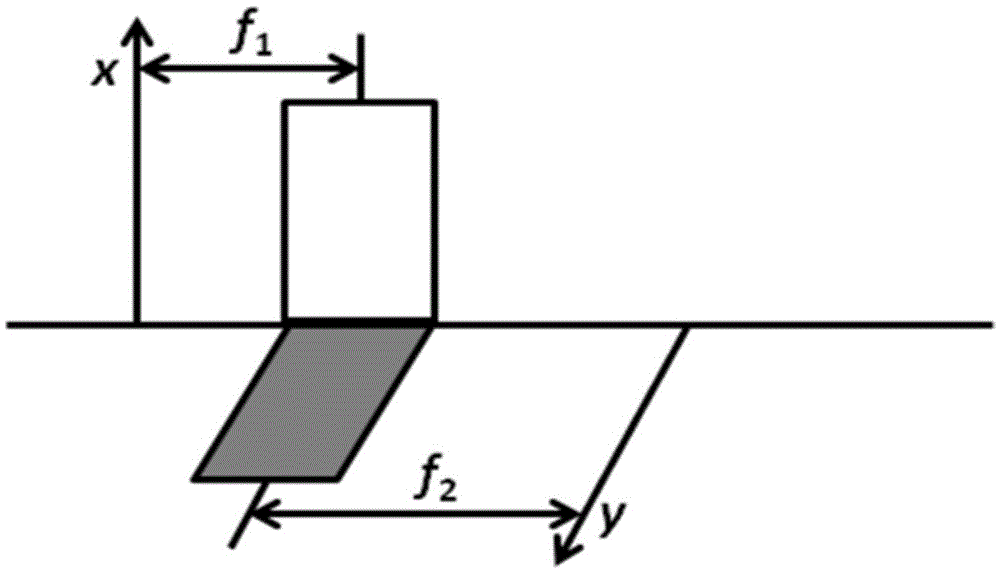

Non-orthogonal polarization multiplexing phase modulation signal transmission plan based on phase tracking

InactiveCN105071894ABreaking strict orthogonalityImprove spectral efficiencyWavelength-division multiplex systemsElectromagnetic transmissionDigital signal processingNon orthogonal

The invention discloses a non-orthogonal polarization multiplexing phase modulation signal transmission plan based on phase tracking. In a transmitting end with the serial number of 101<1> to 101<N>, one or N non-orthogonal polarization multiplexing (NPDM) phase modulation (m-PSK) signals with different wavelengths are generated; the NPDM phase modulation signals are combined into a wavelength division multiplexing NPDM signal via a wavelength division multiplexer (102); the multiplexed optical signal is transmitted in an optical fiber (103); an optical amplifier (104) is used for performing power compensation to the transmitted optical signal; an electrical signal received by a receiving end is used to realize demodulation output of non-orthogonal phase modulation signals in a digital signal processing unit (108). Compared with a traditional orthogonal polarization multiplexing (PDM) phase modulation signal plan, a non-orthogonal multiplexing phase modulation signal whose polarization multiplexing angle is greater than a certain specific small angle could be adaptively recovered in the invention, and the signal transmission plan has larger tolerance to polarization dependent loss and is suitable for the field of backbone networks for long-distance transmission. Simultaneously, the plan is compatible with the traditional PDM solution, thereby greatly improving the transmission flexibility of a future backbone network.

Owner:SOUTHWEST JIAOTONG UNIV

Video monitor data transmission system

ActiveCN102097001ASimplify the transmission lineImprove transmission capacityNon-electrical signal transmission systemsClosed circuit television systemsEmbedded systemMonitoring data

The invention belongs to the field of video monitor and discloses a video monitor data transmission system which comprises an optical fiber, a local end equipment and a plurality of remote optical access equipments, wherein the optical fiber, the local end equipment and the plurality of remote optical access equipments form an open serial link or a ring network link used for transferring compressed video service data or other ethernet service data. In the video monitor data transmission system, a time division multiplexing technology is adopted to transfer ethernet data of the plurality of remote optical access equipments through a same optical fiber, thereby greatly simplifying a transmission line; and the video monitor data transmission system can realize automatic distribution of time slots and coordinate a plurality of remote optical access units to normally work with the local end equipment.

Owner:深圳市诺龙技术股份有限公司

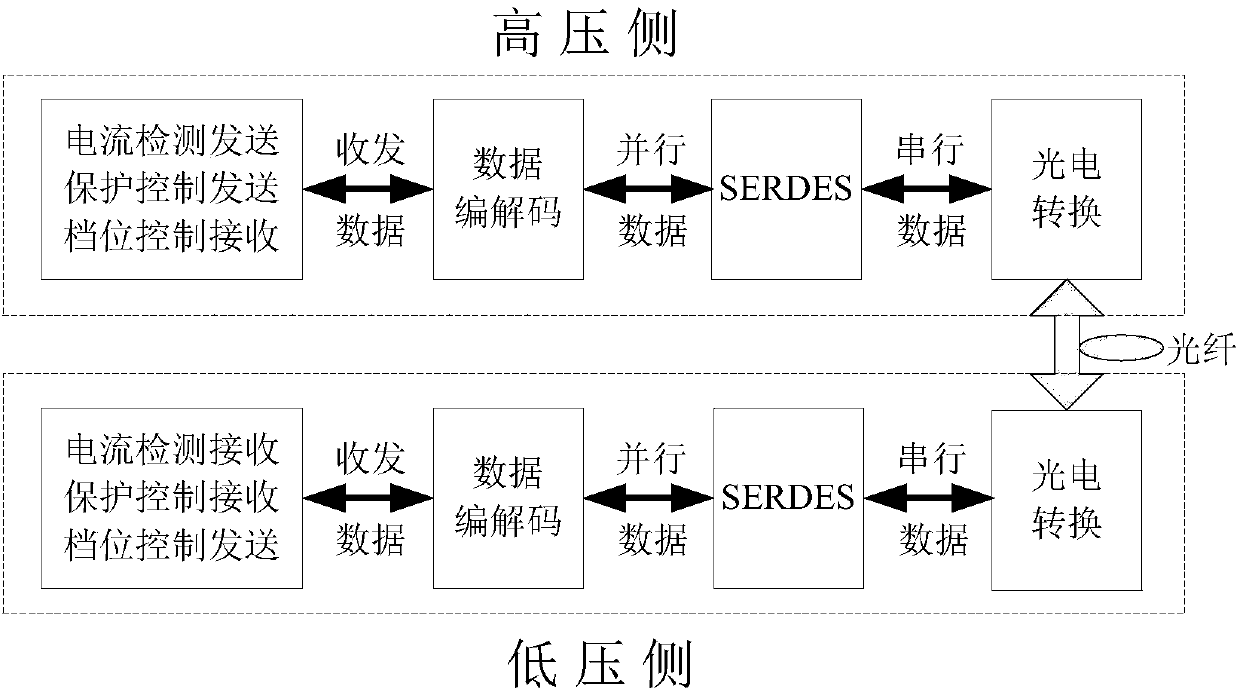

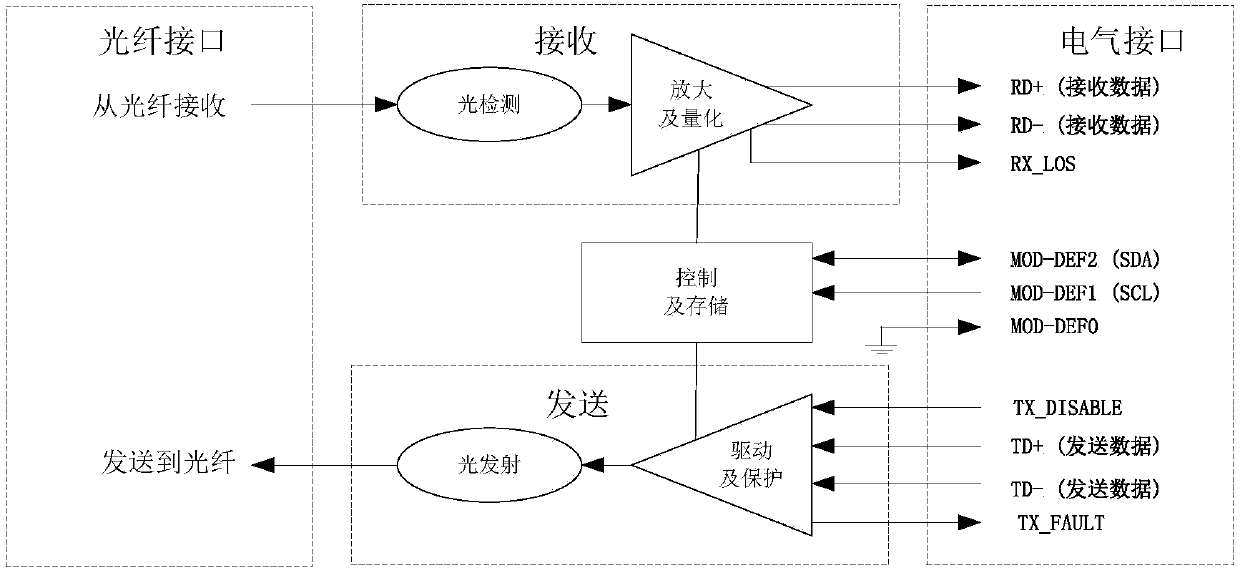

High-speed digital optical fiber isolation transmission device and method

InactiveCN107800481AImprove data transfer performanceHigh speed transmissionFibre transmissionAnti jammingLow speed

The invention discloses a high-speed digital optical fiber isolation transmission device and method, and belongs to the field of high-speed digital isolation transmission control. A digital technologyand an optical fiber transmission technology are combined, so that the data transmission performance is excellent; an optical fiber is used for transmission, the device and the method have the advantages of high isolation voltage level, high anti-jamming capability, large input dynamic range, high response speed and the like, and high-speed and high-precision signal transmission can be realized in the high-voltage and strong-electromagnetic interference environment; a high-speed digital serial communication SERDES technology is adopted, low-speed parallel signals are converted into high-speedserial signals, and point-to-point double-wire data transmission is achieved, so that the transmission capacity and the system performance can be improved, and the communication cost is greatly reduced.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

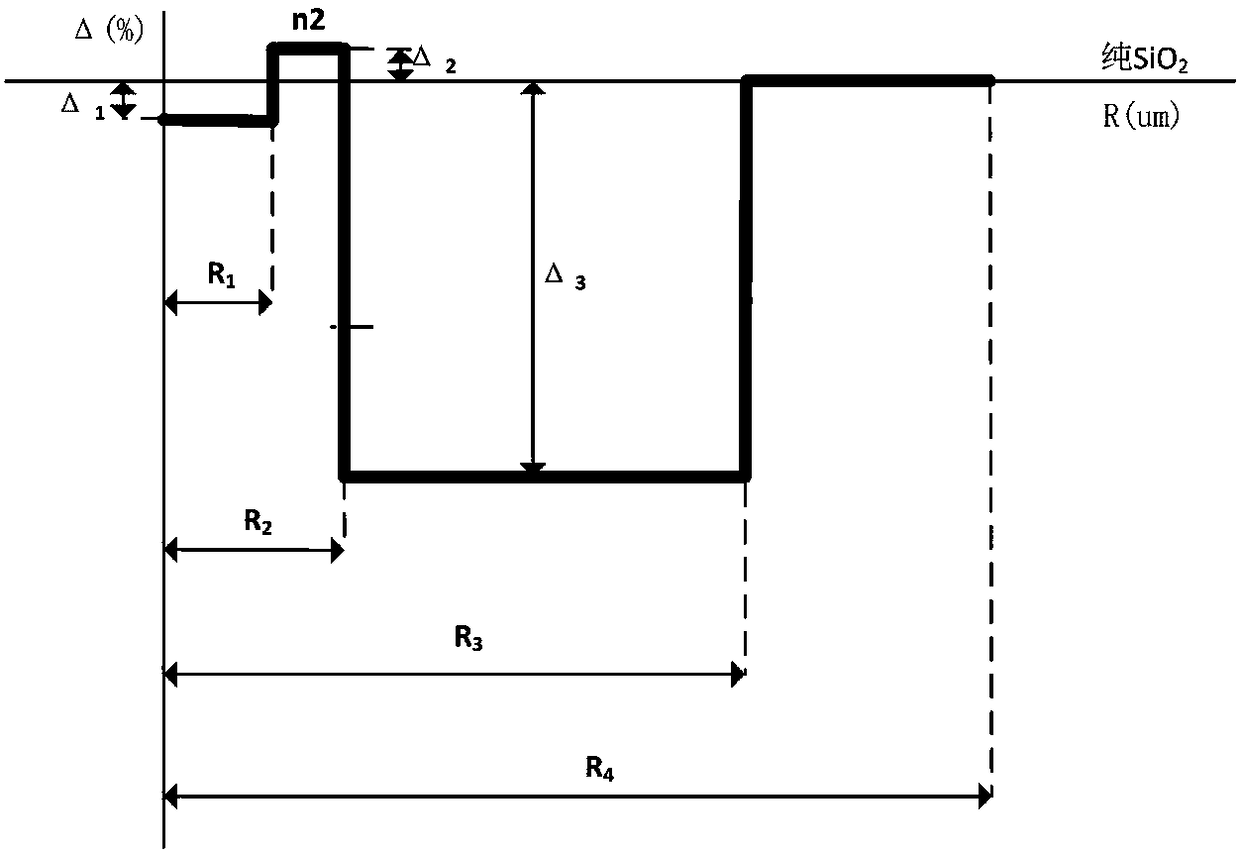

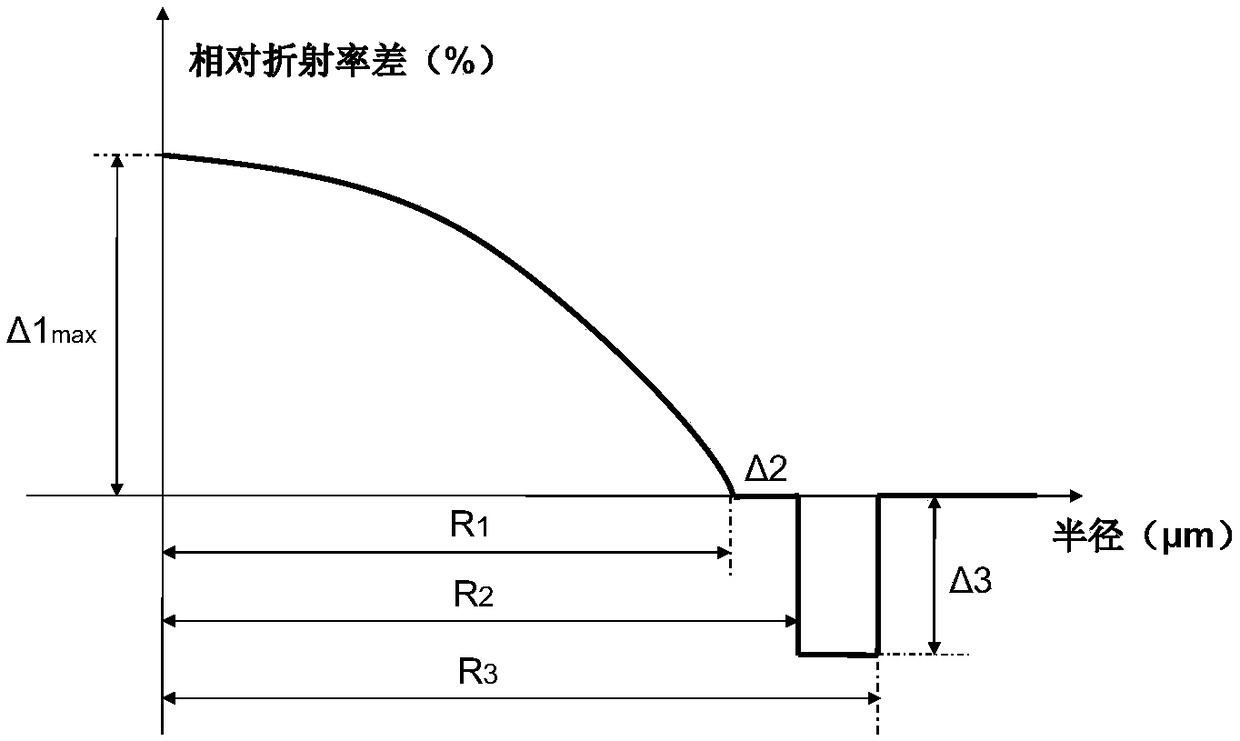

Single mode optical fiber with ultralow loss and large effective area and manufacturing method thereof

ActiveCN108469648AIncrease the effective areaReduce power densityGlass making apparatusOptical fibre with multilayer core/claddingAlkali metal oxideRelative refractive index

The invention discloses a single mode optical fiber with ultralow loss and a large effective area and a manufacturing method thereof. A bare optical fiber of the single mode optical fiber comprises acore layer and a cladding layer from inside to outside in sequence, the core layer comprises an inner core layer and an outer core layer which are arranged from inside to outside in sequence, the radius R1 of the inner core layer is 1.5-3 microns, the relative refractive index difference delta 1 of the inner core layer is greater than or equal to 0.01% and less than or equal to 0, the radius R2 ofthe outer core layer is 5-6 microns, and the relative refractive index difference delta 2 of the outer core layer is greater than or equal to 0 and less than or equal to 0.05%. The core layer is hardly doped with germanium and is a silicon glass layer doped with fluorine and an alkali metal oxide; the cladding layer includes a depressed cladding layer and an outer cladding layer which are arranged from inside to outside in sequence, the radius R3 of the depressed cladding layer is 40-50 microns, the relative refractive index difference delta 3 of the depressed cladding layer is greater than or equal to -0.25% and less than or equal to -0.15%, the ratio R3 / R2 of the radius R3 of the depressed cladding layer to the radius R2 of the outer core layer is greater than or equal to 8, the radiusR4 of the outer cladding layer is 62.5 microns, and the outer cladding layer is a pure silica glass layer. According to the single mode optical fiber with ultralow loss and the large effective area and the manufacturing method thereof, attenuation coefficients can be reduced, and the effective area is increased.

Owner:FENGHUO COMM SCI & TECH CO LTD

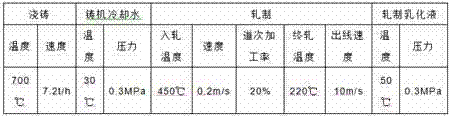

Preparation method of Al-Zr-RE alloy round aluminum rod

The invention relates to a preparation method of an Al-Zr-RE alloy round aluminum rod and belongs to the technical field of aluminum alloy materials. In the production of the round aluminum rod, according to the preparation method, a proper amount of zirconium and rare earth is added to the smelting process of pure aluminum liquid to obtain an Al-Zr-RE alloy; the Al-Zr-RE alloy is formed into the aluminum alloy round rod by virtue of the production process of smelting, standing, casting, rolling and the like; an aluminum alloy conductor formed by use of the aluminum alloy round rod by drawing is extremely low in sag when working at a relatively high temperature for a long time because the tensile strength retention rate of the conductor is kept above 90%, and therefore, the conductor can be used as a long-span overhead conductor; besides, the power transmission capacity of the conductor is greatly improved, the utilization rate of the aluminum is increased and the construction cost is relatively saved.

Owner:YUNNAN ALUMINUM

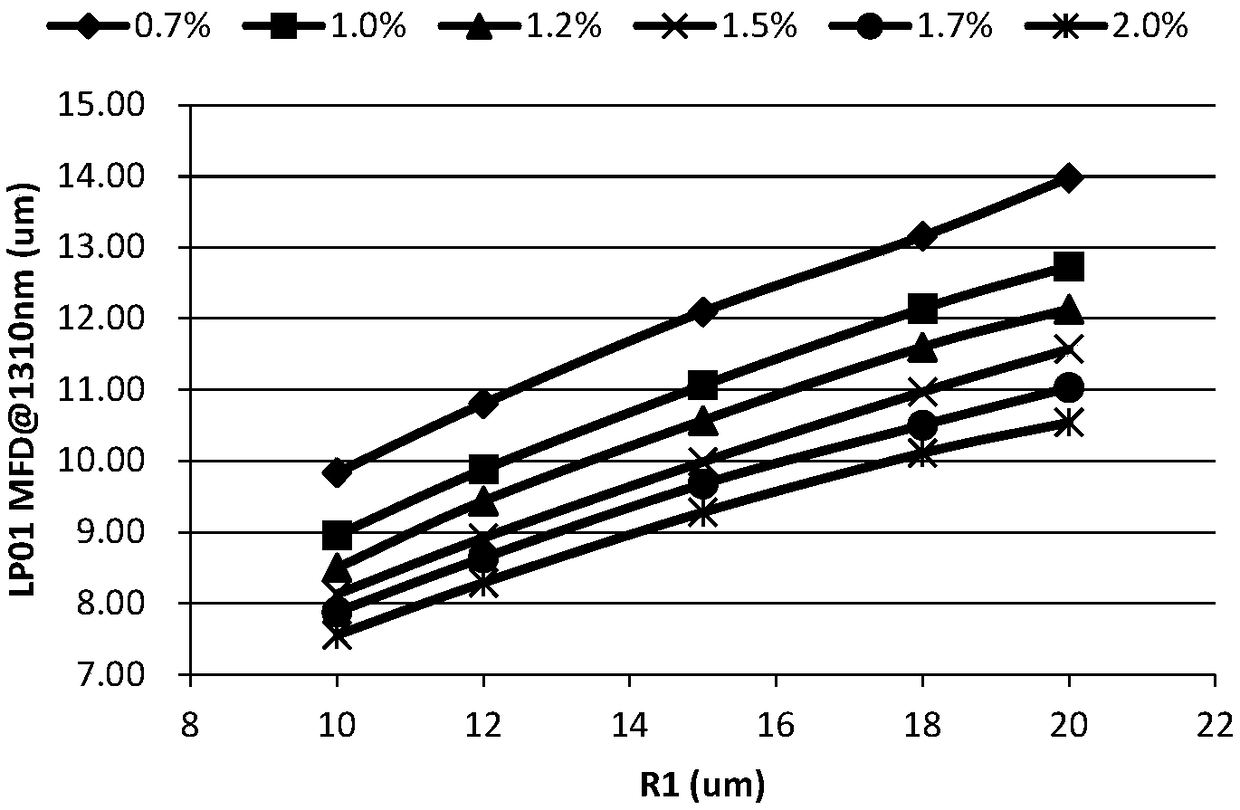

Small-core-diameter graded index fiber

ActiveCN109188603AImprove bend insensitive performanceImprove bending resistanceOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingAccess networkRelative refractive index

The invention relates to a small-core-diameter graded index fiber. The small-core-diameter graded index fiber comprises a core layer and claddings; the claddings are an inner cladding, a sunken cladding and an outer cladding in sequence from inside to outside; the small-core-diameter graded index fiber is characterized in that the refractivity profile of the core layer is parabolic, a distributionindex alpha is 1.9-2.1, the radius R1 of the core layer is 10-21 [mu]m, and the maximum relative refractive index difference delta 1max of the center of the core layer is 0.7-1.7%; the core layer isa Ge, P and F-coped silicon dioxide glass layer, the inner cladding is a pure silicon dioxide layer or an F-doped silicon dioxide glass layer, the one-sided width of the inner cladding is 0.5-5 [mu]m,delta 2 is -0.4-0%, and the one-sided width of the sunken cladding is 2-10 [mu]m, delta 3 is -0.8-0.2%; and the outer cladding is a pure silicon dioxide glass layer. The small-core-diameter graded index fiber can be compatible with an existing OM3 / OM4 multimode fiber, and also can support a wavelength division multiplexing technology in a wavelength range of 850-950nm; the small-core-diameter graded index fiber can be compatible with a single mode fiber, and supports single mode transmission of 1,310nm and 1,550nm; and the small-core-diameter graded index fiber has excellent bending-resistantperformance and can be suitable for access networks and miniaturized optical devices.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

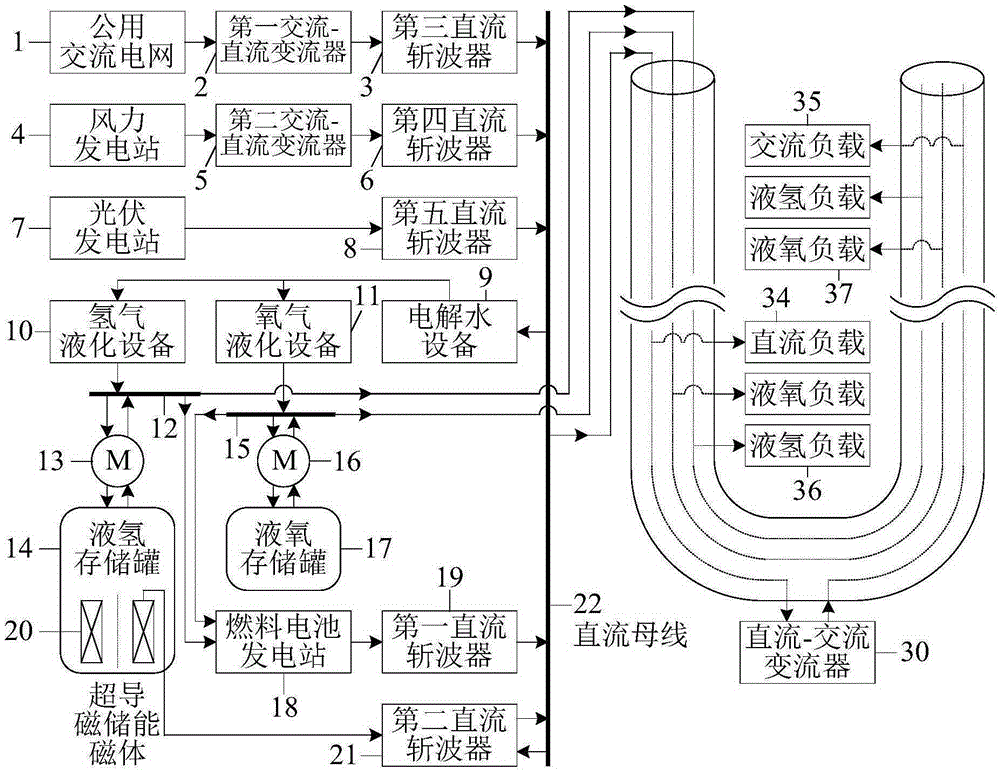

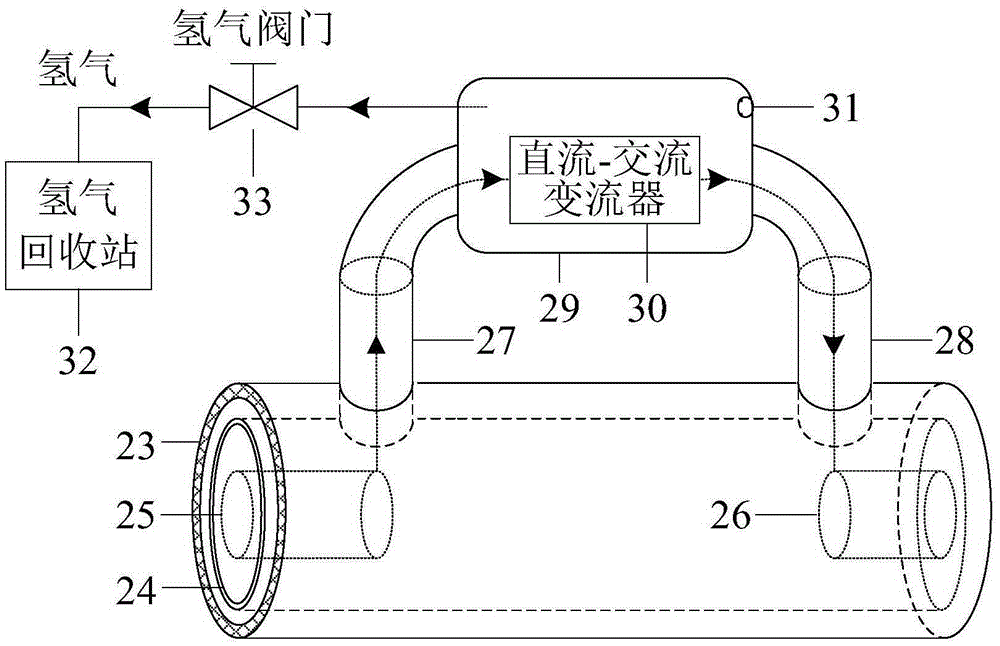

Multi-source compound superconductive micro electrical network system and energy management method thereof

ActiveCN105305506AImprove transmission capacityImprove efficiencyElectrical apparatusInstabilityLiquid hydrogen

The invention discloses a multi-source compound superconductive micro electrical network system and an energy management method thereof. The multi-source compound superconductive micro electrical network system comprises a public electrical network subsystem, a renewable energy generation subsystem, a DC bus, a liquid hydrogen main pipe, a liquid oxygen main pipe, an electrical energy storage and utilization subsystem, a composite energy source transmission and utilization subsystem, an energy state monitor and an energy management controller, wherein the energy state monitor is used for monitoring electrical energy state information of the DC bus and energy storage state information of the electrical energy storage and utilization subsystem, the energy management controller is used for controlling the electrical energy storage and utilization subsystem for storing excessive electrical energy on the DC bus, excessive liquid hydrogen in the liquid hydrogen main pipe and excessive liquid oxygen in the liquid oxygen main pipe or compensating insufficient electrical energy in the DC bus, insufficient liquid hydrogen in the liquid hydrogen main pipe and insufficient liquid oxygen in the liquid oxygen main pipe. Through the multi-source compound superconductive micro electrical network system, problems of renewable energy generation intermittence and instability are effectively solved, and high-quality electrical energy use can be realized for user terminals.

Owner:SICHUAN NORMAL UNIVERSITY

Planetary gear multi-way drive stepless speed variator

InactiveCN101070901AImprove acceleration performance and stability performanceHigh transmission efficiencyToothed gearingsVariatorGear ratio

The present invention discloses a stepless speed change device of epicyclic gear to achieve multi-channel drive, which is desinged by rotation and revolution of the epicyclic gear under different condition and control with different extent, and different distributive principle of torsion and rotate speed. It comprises two sets (or more than two)of rotating mechanism with epicyclic gear, one set is to be connection of input stage and input torsion, and the other as output stage driving back gera train .two rotating device of input stage and output stage connected through different gear ratio .which make up two drive path is low speed high torsion and hige speed low torsion, and epicyclic gear and assistant device are installed again in stepless speed change device or drive path to change gear ratio of the drive path. It is the gear teeth fixed stepless speed change device, have efficiency of the gear ratio and high-capacity driving.

Owner:龙宏元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com