Planetary gear multi-way drive stepless speed variator

A technology of continuously variable transmissions and planetary gears, which is applied in the direction of gear transmissions, transmissions, belts/chains/gears, etc., and can solve problems that cannot be applied to large-displacement, high-power automobiles, discontinuous transmission ratios of hydraulic automatic transmissions, and automobiles. CVT has not been popularized to achieve the effects of low production cost and equipment investment, less auxiliary and servo systems, improved speed-up performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: In conjunction with Fig. 1, the optional planetary carrier [1] in the input stage planetary gear mechanism is used as the main input gear of the input stage planetary gear mechanism, and is connected with the torque power, and the sun gear [10] of the input stage planetary gear mechanism is used ] and the ring gear [8] are used as the two output gears of the input stage; in the output stage planetary gear mechanism, the planetary carrier [4] is selected as the main output gear of the output stage planetary gear mechanism to drive the rear stage transmission mechanism, and the output stage The sun gear [5] and the ring gear [7] of the planetary gear mechanism are used as two input gears of the output stage. Use the output sun gear [10] of the input stage planetary gear mechanism and the input ring gear [7] of the output stage planetary gear mechanism to form the transmission path [2] of the input stage sun gear output stage ring gear for torque transmission,...

Embodiment 2

[0037] Embodiment 2: In conjunction with Fig. 2, the ring gear [1] is selected as the main input gear of the input-stage planetary gear mechanism in the input-stage planetary gear mechanism, and is connected with the torque power, and the sun gear [10] of the input-stage planetary gear mechanism is used. ] and the planetary carrier [3] as the two output gears of the input stage; in the output stage planetary gear mechanism, the ring gear [5] is selected as the main output gear of the output stage planetary gear mechanism to drive the rear stage transmission mechanism, and the output stage The sun gear [7] and the planet carrier [6] of the planetary gear mechanism are used as two input gears of the output stage. Use the output sun gear [10] of the input-stage planetary gear mechanism and the input planetary carrier [6] of the output-stage planetary gear mechanism to form a high-speed and low-torque transmission path [9] for torque transmission; use the output planetary carrier o...

Embodiment 3

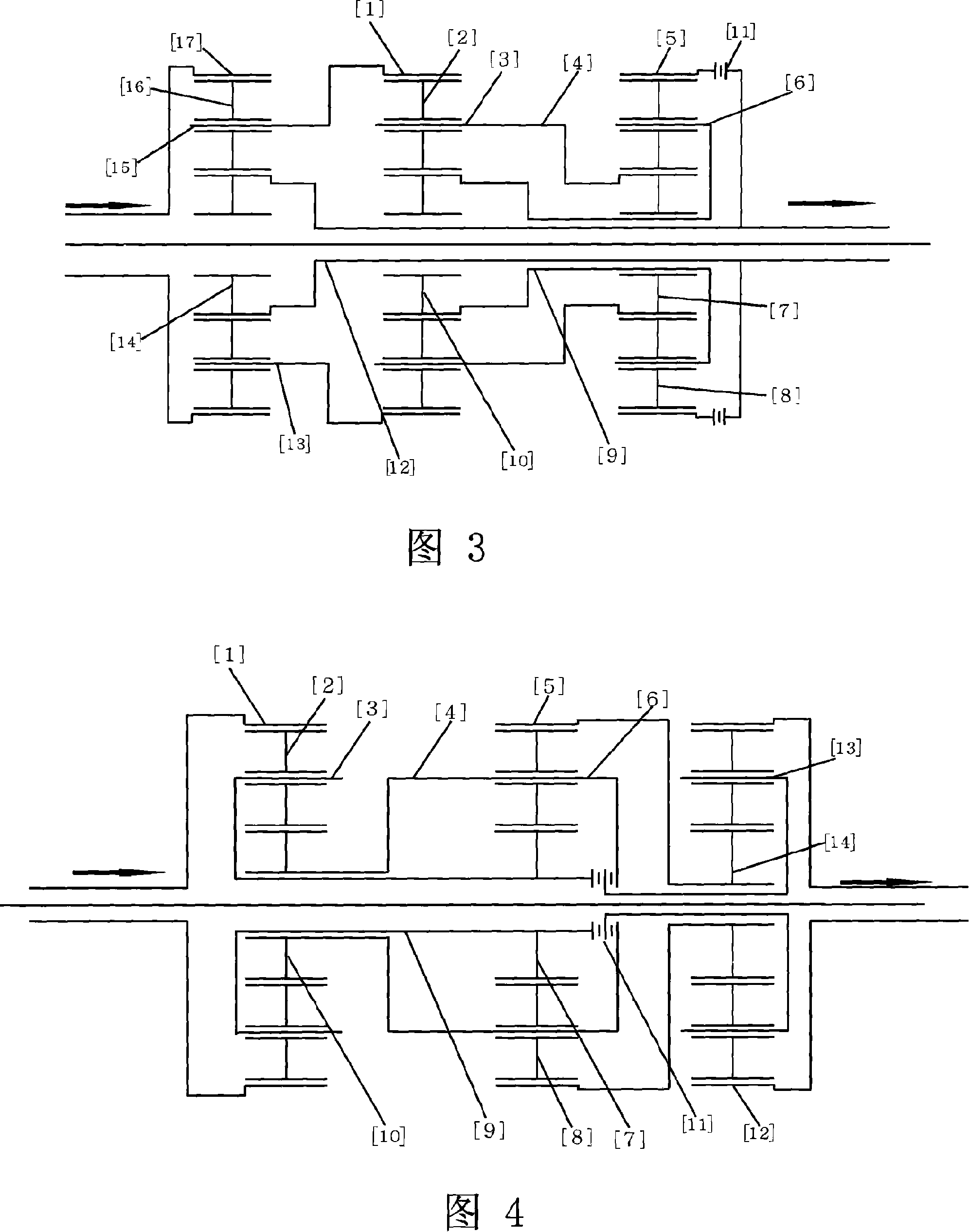

[0038] Embodiment 3: in conjunction with Fig. 3, it is on the basis of embodiment 2 (or embodiment 1), before the input stage of continuously variable transmission, one stage of planetary gear mechanism is added as drive stage. Use the ring gear [17] of the driving stage as the input wheel to connect with the input torque, use the planetary carrier [15] of the driving stage as the auxiliary wheel to drive the main input gear [1] of the CVT, and use the sun gear [14] of the driving stage ] as the drive wheel through the clutch [11] to link to each other with the main output gear [5]. Within a certain range, the rotation speed of the planetary carrier [15] is coordinated and synchronized with the rotation speed of the sun gear [14] after being changed by the continuously variable transmission to complete the synthesis of torque; when the resistance torque is small, the output gear [14] When the rotating speed is very high, the rotating speed of the planet carrier [15] is lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com