Wall climbing robot for cleaning surfaces of ship hulls

A wall-climbing robot and surface cleaning technology, which is applied in the field of wall-climbing robots, can solve problems such as poor design of cleaning operation modules, problems with movement flexibility, and poor cleaning effects, and achieve good obstacle-crossing performance, simple transmission mechanism, and easy cleaning. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

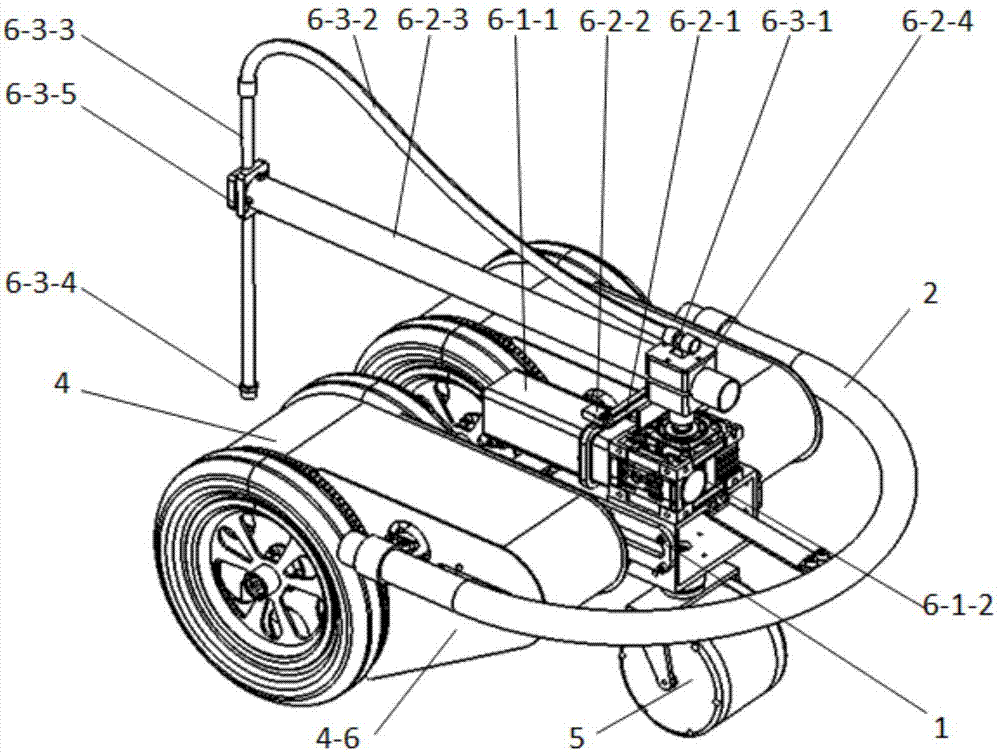

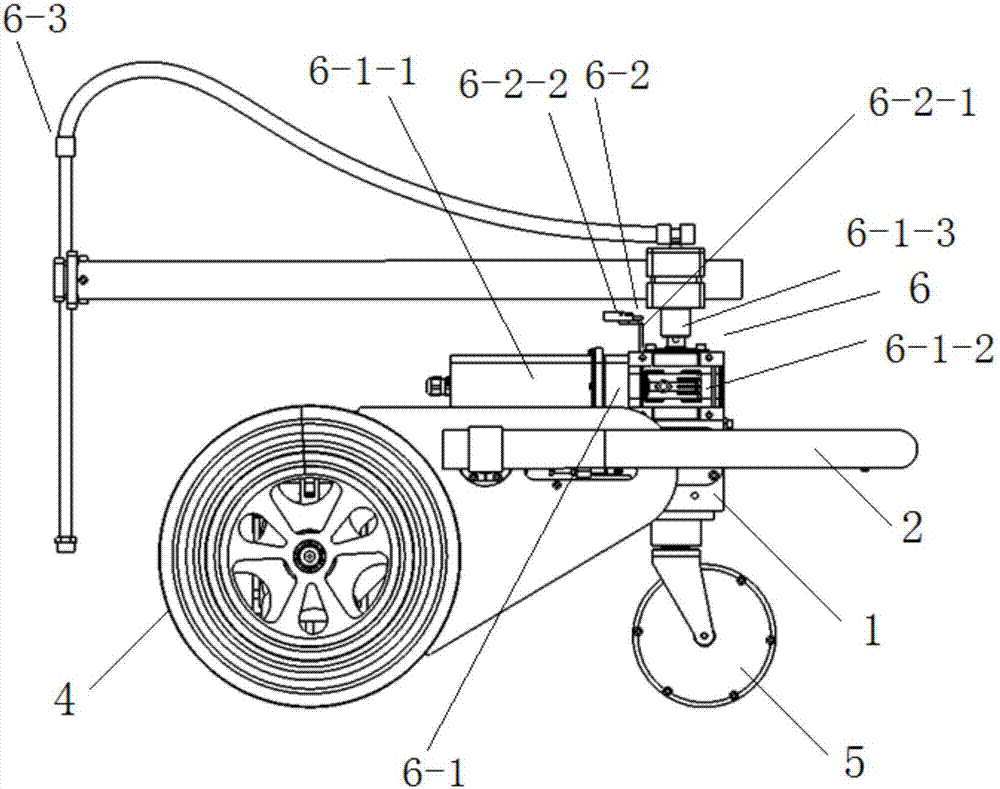

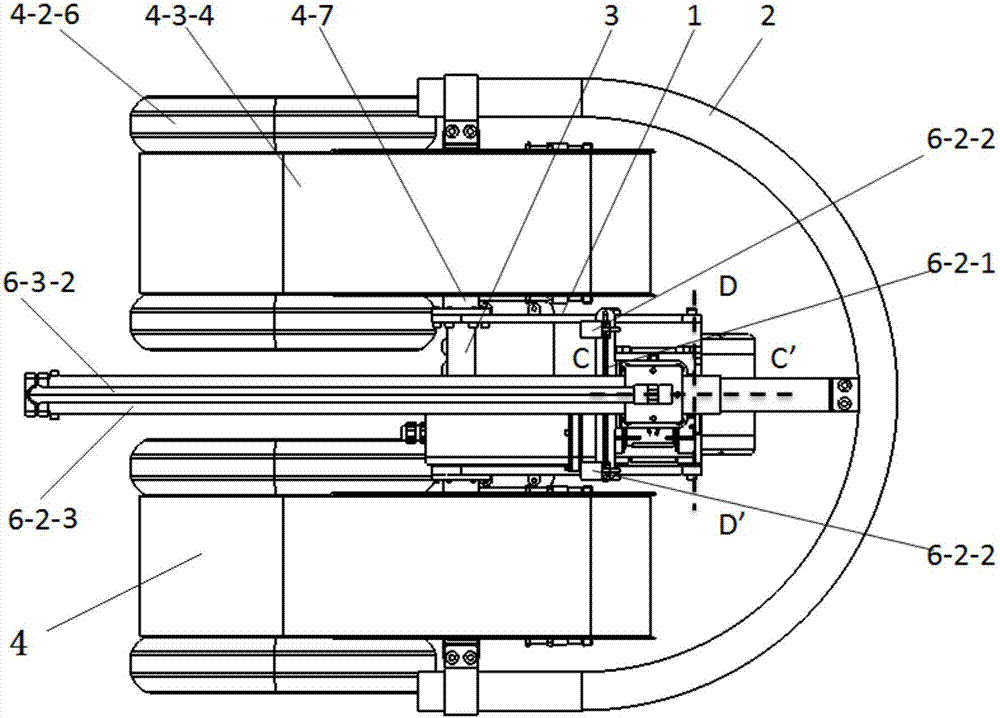

[0047] Such as figure 1 , figure 2 , image 3 As shown, the hull surface cleaning wall-climbing robot of the present invention includes a mounting frame 1 and a protective frame 2; a reinforcing shaft 3 is fixed on the mounting frame 1, and a group of driving wheel modules 4 are respectively installed on both sides of the reinforcing shaft 3; The universal wheel module 5 is installed in the lower part of the middle part; the cleaning operation module 6 is installed in the middle upper part of the rear part of the installation frame 1; the protection frame 2 is used to connect the driving wheel module 4 and the installation frame 1 on both sides, and plays an auxiliary transportation function.

[0048] Such as Figure 10 As shown, the installation frame 1 includes a square frame 1-1 in the middle and a connecting piece 1-2 on both sides; the square frame 1-1 is provided with the output shaft of the No. 2 worm gear reducer that can be inserted into the cleaning operation modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com