Method for preparing high-strength, high-conductivity and heat-resistant aluminum alloys

An aluminum alloy, high-conductivity technology, applied in the field of powder metallurgy, can solve the problems of limited electrical conductivity, rapid strength decline, and increased erection costs, and achieve the effects of little impact on electrical conductivity, preventing grain growth, and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

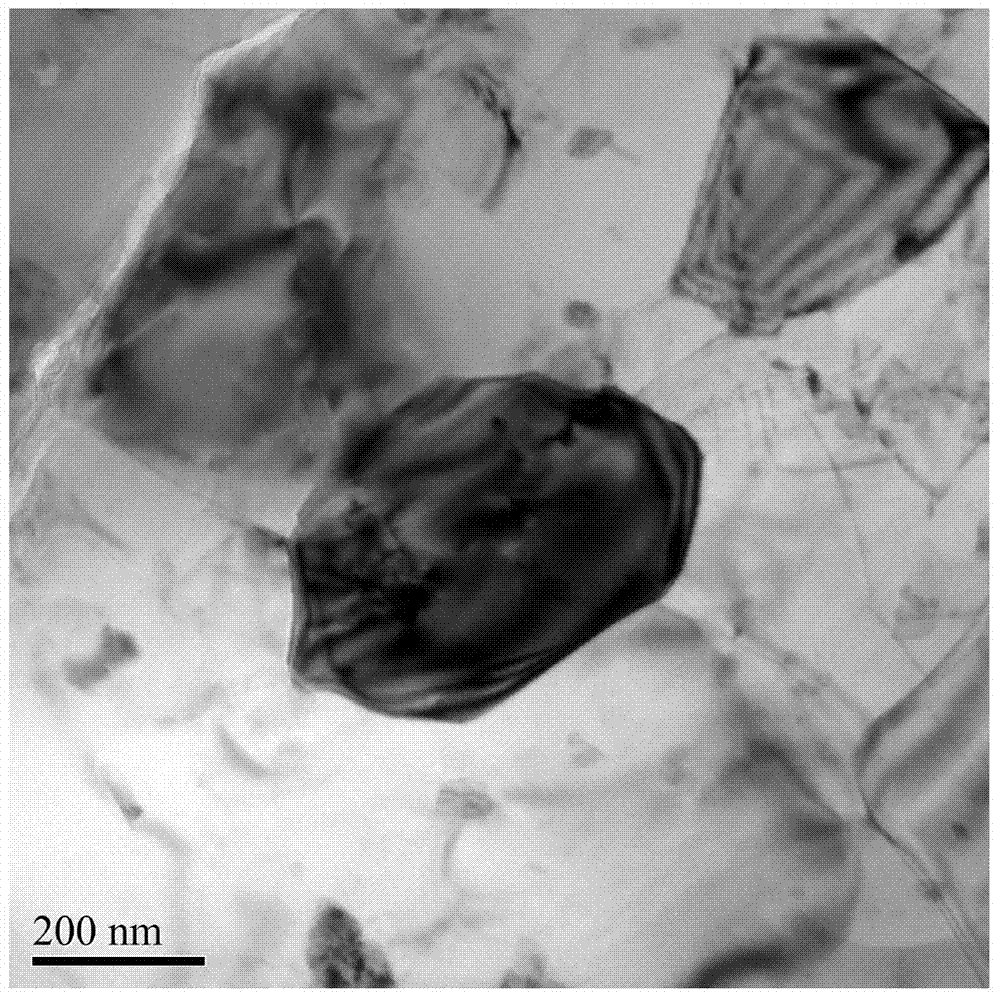

Image

Examples

Embodiment 1

[0018] 1) Put pure aluminum powder and steel balls into a ball milling jar at a volume ratio of 3:1, and add stearic acid, a ball milling aid with 1% of the mass of aluminum powder, into the ball milling jar.

[0019] 2) Carry out ball milling on the loaded materials, the ball milling time is 5 hours, the rotating speed of the ball mill is 30rpm.

[0020] 3) Take out the aluminum powder after ball milling, put it into a bag for cold isostatic pressing, the pressure of cold isostatic pressing is 150MPa, and the holding time is 2min.

[0021] 4) The blank obtained after cold isostatic pressing is put into an atmosphere furnace for sintering, and the sintering temperature is 600°C.

[0022] 5) The aluminum rod obtained after sintering is hot-extruded, and the extrusion ratio is 4.

[0023] 6) Cold drawing the rod obtained after extrusion into a wire of required size.

Embodiment 2

[0025] 1) Put pure aluminum powder and steel balls into a ball milling jar at a volume ratio of 3:1, and add stearic acid, a ball milling aid with 1% of the mass of aluminum powder, into the ball milling jar.

[0026] 2) Carry out ball milling on the loaded materials, the ball milling time is 8 hours, and the ball mill speed is 40rpm.

[0027] 3) Take out the aluminum powder after ball milling, put it into a bag for cold isostatic pressing, the pressure of cold isostatic pressing is 180MPa, and the holding time is 2min.

[0028] 4) The blank obtained after cold isostatic pressing is put into an atmosphere furnace for sintering, and the sintering temperature is 620°C.

[0029] 5) The aluminum rod obtained after sintering is hot-extruded, and the extrusion ratio is 20.

[0030] 6) Cold drawing the rod obtained after extrusion into a wire of required size.

Embodiment 3

[0032] 1) Put pure aluminum powder and steel balls into a ball milling jar at a volume ratio of 3:1, and add stearic acid, a ball milling aid with 1% of the mass of aluminum powder, into the ball milling jar.

[0033] 2) Carry out ball milling on the loaded material, the ball milling time is 10h, and the ball mill speed is 50rpm.

[0034] 3) Take out the aluminum powder after ball milling, put it into a bag for cold isostatic pressing, the pressure of cold isostatic pressing is 200MPa, and the holding time is 2min.

[0035] 4) Put the blank obtained after cold isostatic pressing into an atmosphere furnace for sintering, and the sintering temperature is 600-640°C.

[0036] 5) The aluminum rod obtained after sintering is hot-extruded, and the extrusion ratio is 40.

[0037] 6) Cold drawing the rod obtained after extrusion into a wire of required size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com