High fat biscuit mix and products resulting therefrom

a biscuit mix and high fat technology, applied in the field of dry flour mixes, can solve the problems of product appearance tilt, product height and tilt of baked products, and inconvenient for consumers, and achieve the effects of less moisture, more moist, and flaky crumb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

The following examples further illustrate the invention. They are not meant to constitute implied or express limitations of the scope which is filly set forth in the foregoing text.

working examples 1-10

Compositions Were Then Formulated Using Various Shortening Compositions.

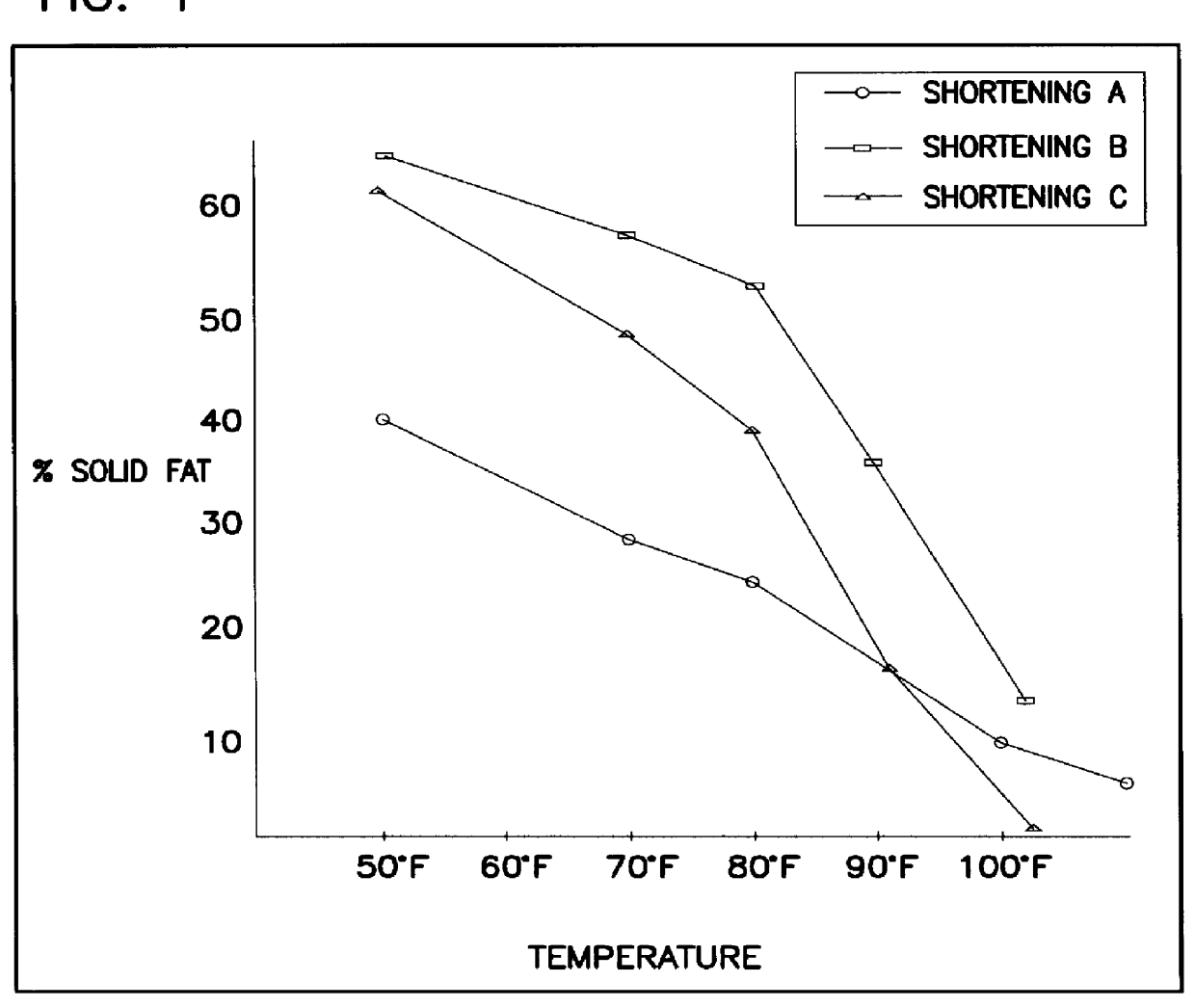

______________________________________ Shortening Constituent Working Examples A* B** C*** D**** ______________________________________ 1 (Control) (30) (70) 5.20% 12.10% 2 (40) (60) 6.92%% 10.38% 3 (70) (30) 12.10% 5.20% 4 (60) (40) 10.38% 6.92% 5 (60) (40) 9.60% 6.40% 6 (50) (50) 8.65% 8.65% 7 (60) (40) 10.38% 6.92% 8 (50) (50) 8.65% 8.65% 9 (40) (60) 6.92% 10.38% 10 (30) (70) 5.20% 12.10% ______________________________________ Total Shortening in Each Example = 17.30% *AndersonClayton (soybean / cotton seed oil) shortening available under Product Code No. 635 (SFI = 50.degree. F., 39.5% .+-. 0.4% solids; 70.degree. F., 28% .+-. 3.5; 80.degree. F., 24.5% .+-. 2.5; 92.degree. F. 15% .+-. 2; 100.degree. F., 9% .+-. 2; 100.degree. F., 5% MAX) **AndersonClayton (100% soybean oil) shortening available under Product Code No. 858 (SFI = 50.degree. F., 65% .+-. 3; 70.degree. F., 57% .+-. 3; 80.degree. F., 53% .+-. 3; 92...

working example 1

______________________________________ Working Example 1 Ingredient Percent (Wt-%) ______________________________________ Hard Flour 11.11 Soft Flour 33.00 Water 29.15 Shortening (Plastic) 12.10 Shortening Chip 5.20 Buttermilk 2.97 Soda 1.09 Sodium Acid 0.88 Pyrophosphate Sodium Aluminum 0.44 Phosphate Mono Calcium 0.19 Phosphate Sugar 1.24 Corn Solids 0.74 Salt 0.99 Albumen 0.30 Caseinate 0.40 Dairy Flavor 0.20 ______________________________________

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com