Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

224results about "Dough cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Snack having a soft edible layer and method of making

The present invention is directed to a method of making a shelf stable edible snack. The method comprises the steps of: (A) providing an edible core having an outside surface; and (B) applying at least one soft edible layer that substantially covers the outside surface of the edible core; wherein the outer layer is applied by a method comprising the steps of: (a) applying a base liquid onto the outside surface of the edible core, thereby forming a liquid coated component; (b) applying a dry powder to the liquid coated component, thereby forming an edible layered component; and (c) optionally, (i) drying the liquid coated core after step (a), (ii) drying the edible layered component after step (b), or (iii) drying the liquid coated core after step (a) and drying the edible layered component after step (b); wherein the soft edible layer has a water activity of about 0.2 to about 0.8 at 25° C.

Owner:MARS INC

Flour and dough compositions and related methods

ActiveUS20050255219A1Increase concentrationReduced active-enzyme contentReady-for-oven doughsMeat/fish preservation by heatingWheat germWheat grain

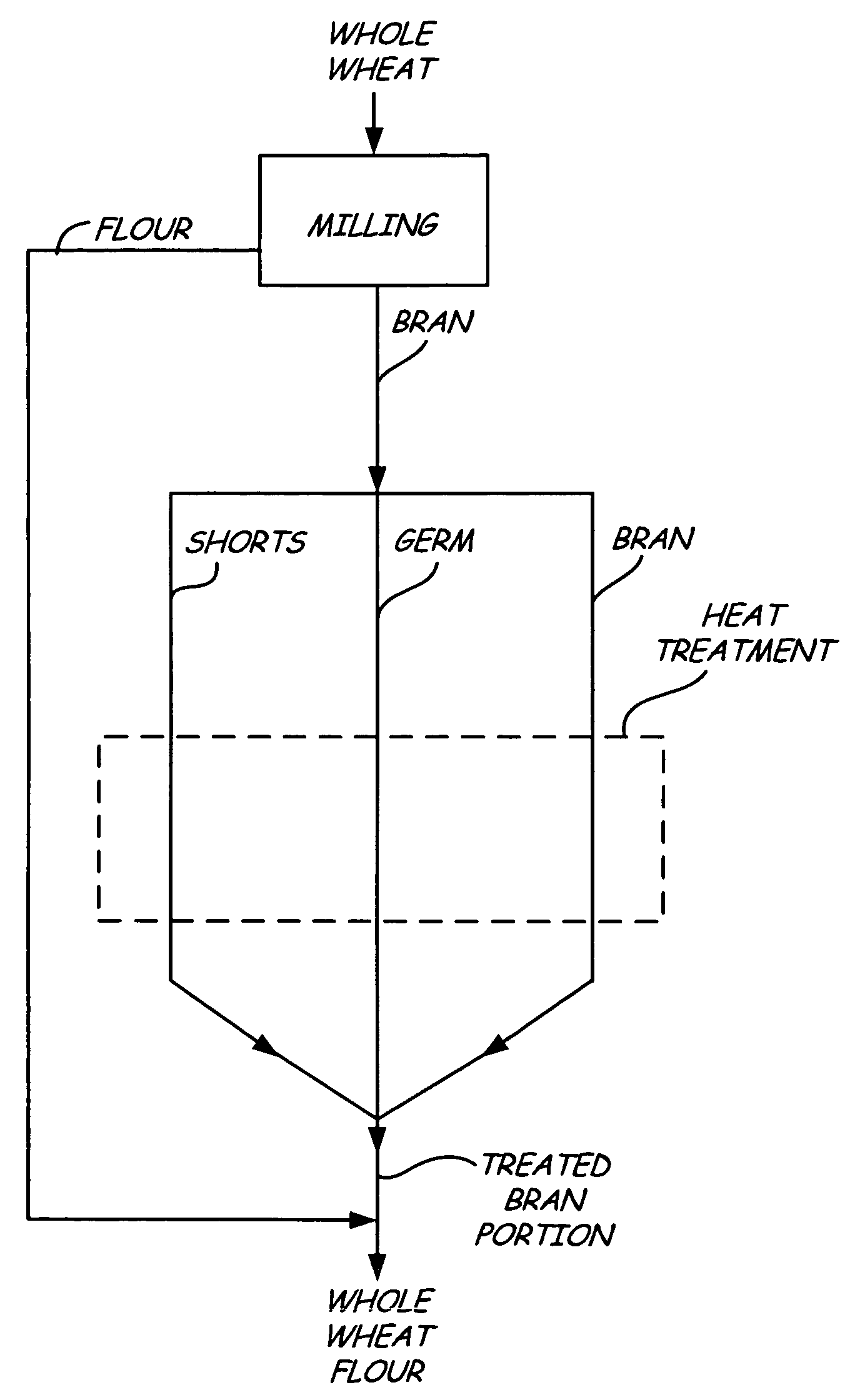

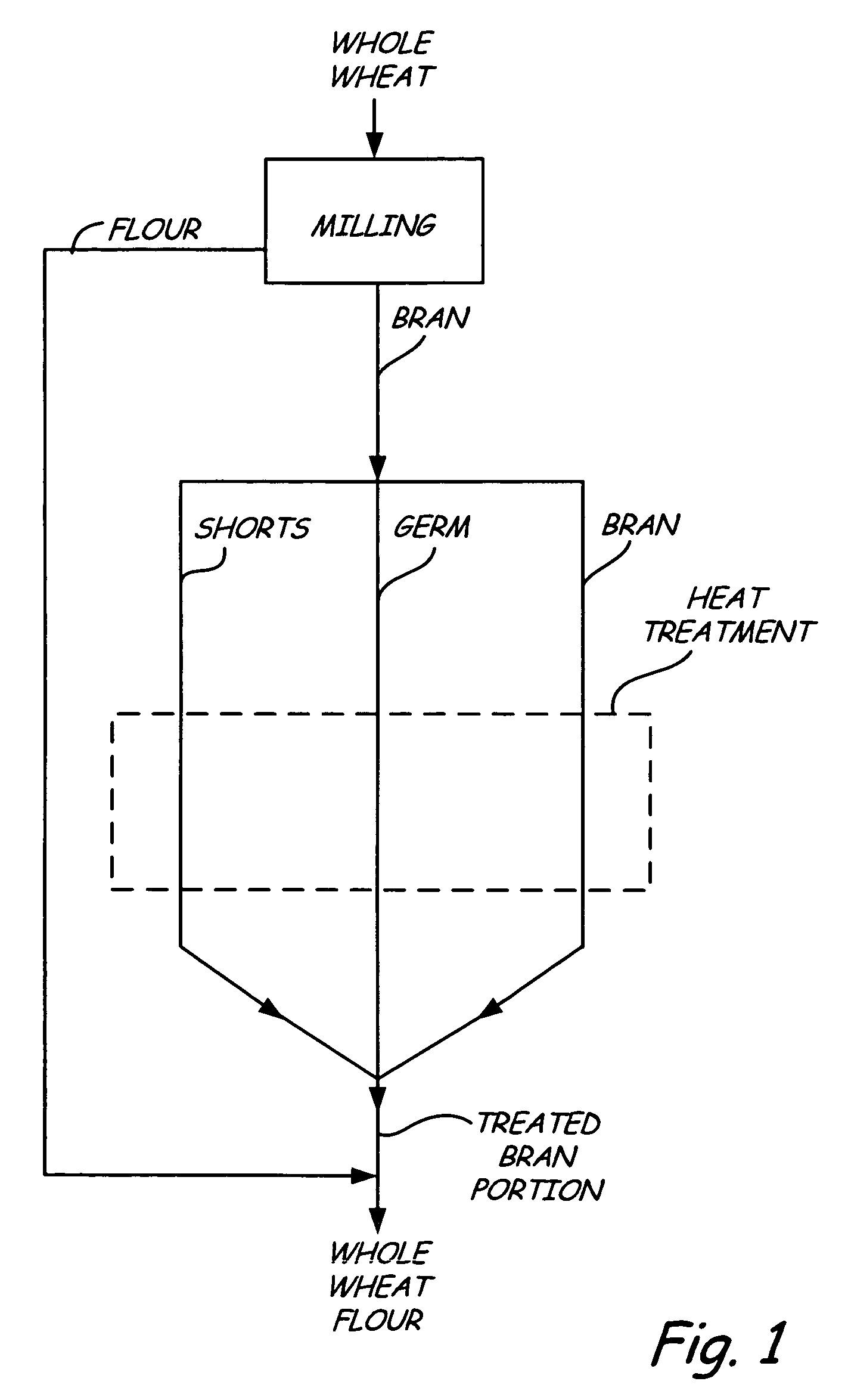

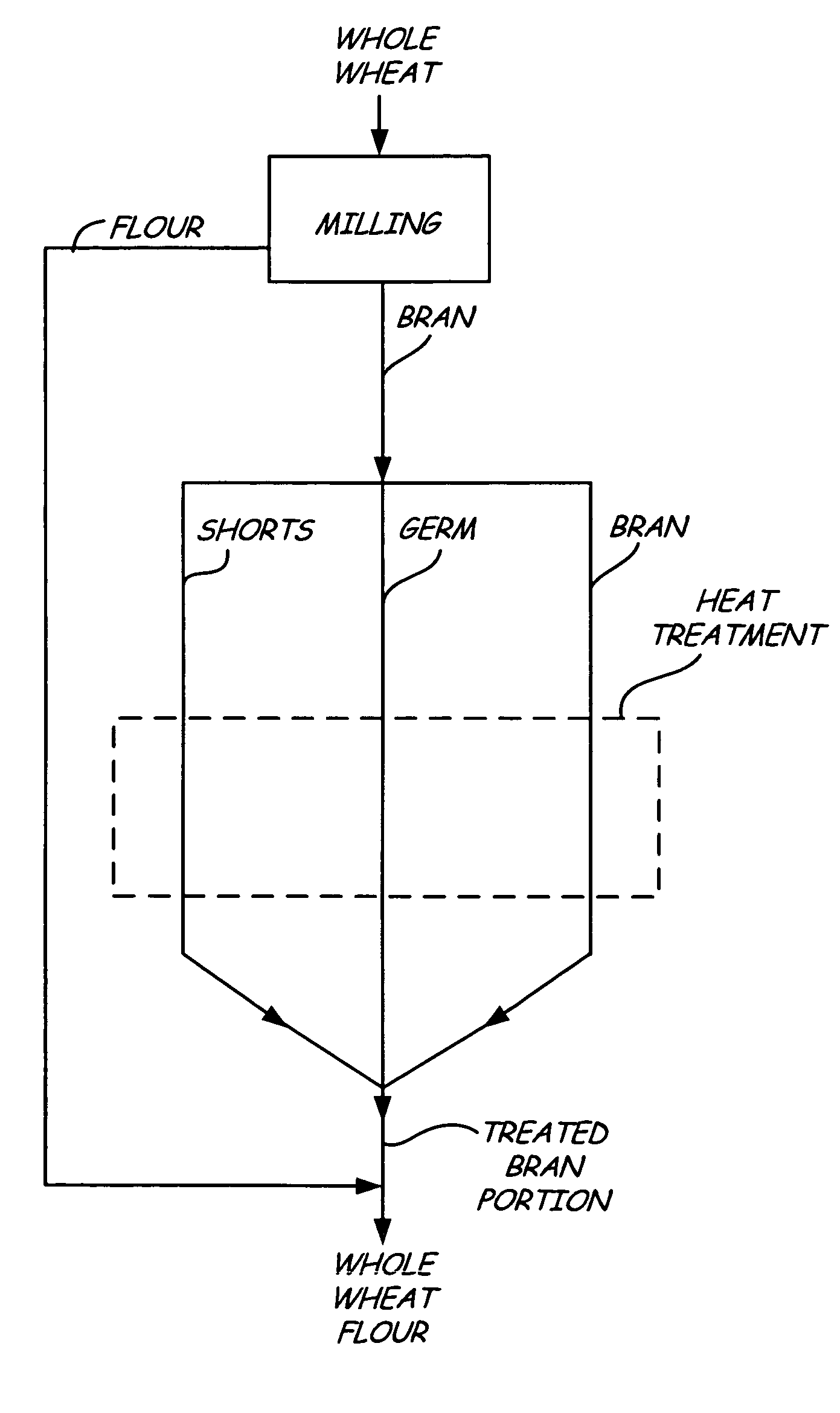

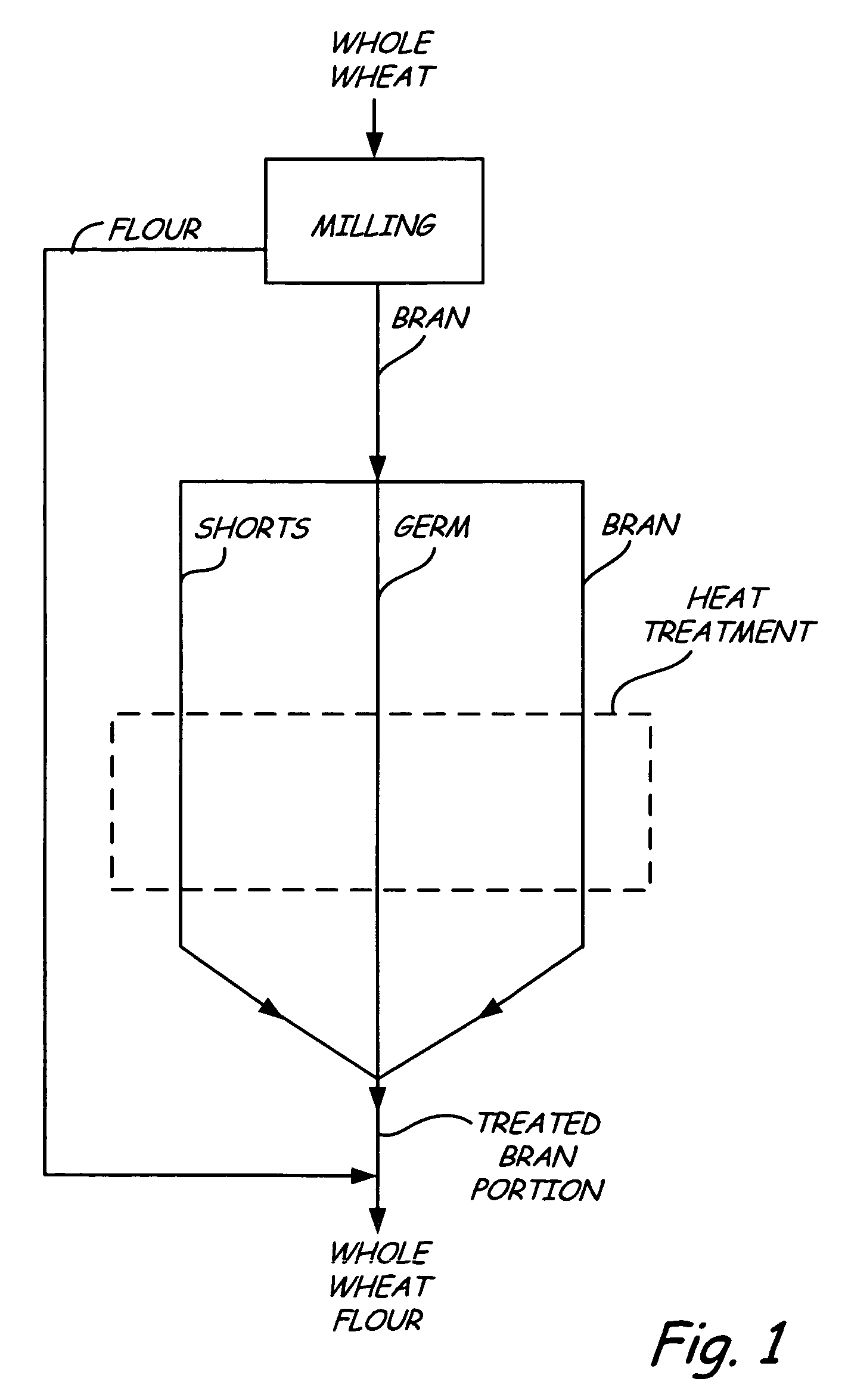

Described are methods of treating wheat grain, including reducing the amount of active enzymes in a milled wheat grain by treating a portion of the wheat grain that includes one or more of wheat bran or wheat germ to deactivate enzymes; as well as flour and dough compositions prepared from the treated portion of wheat grain.

Owner:GENERAL MILLS INC

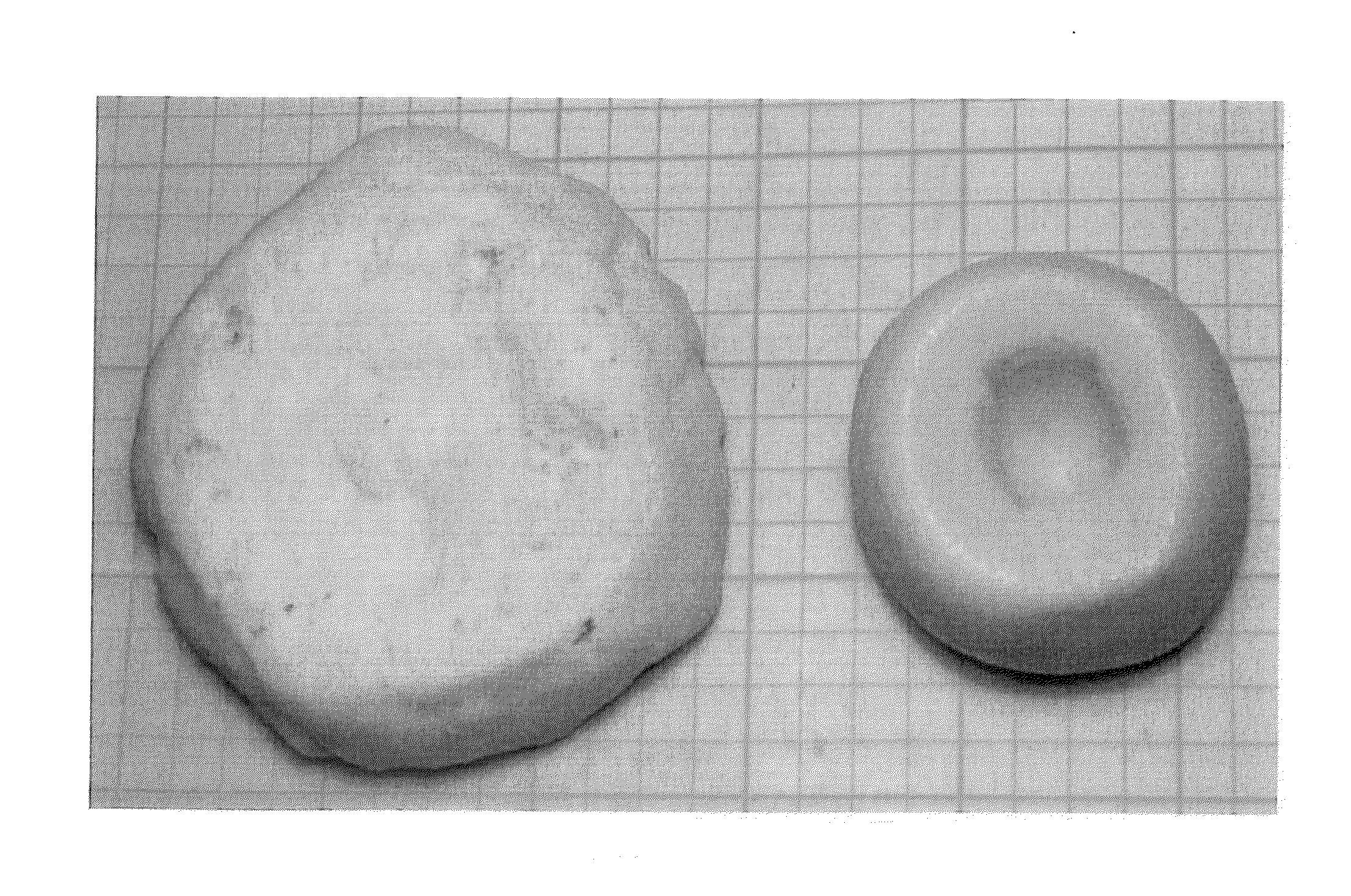

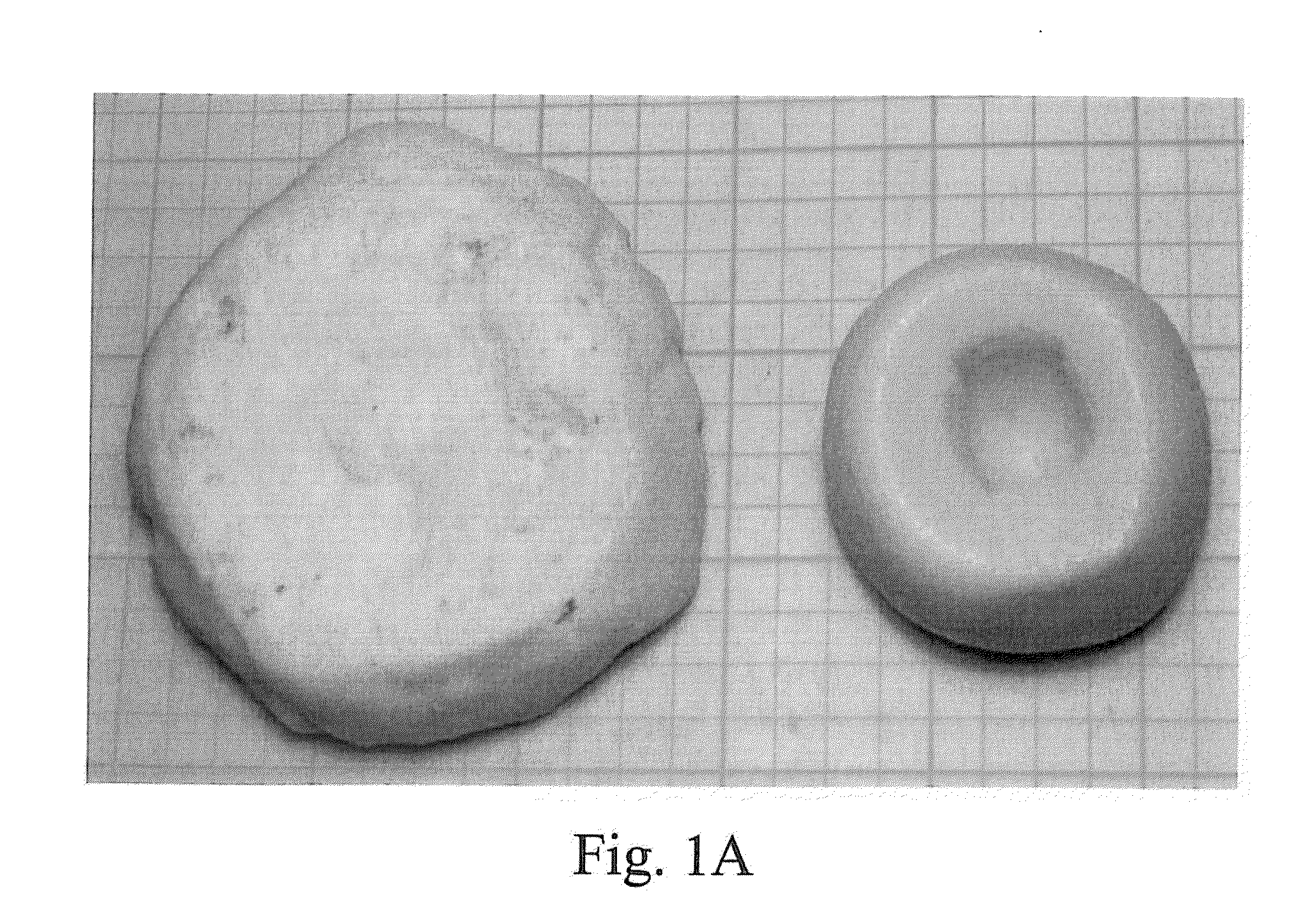

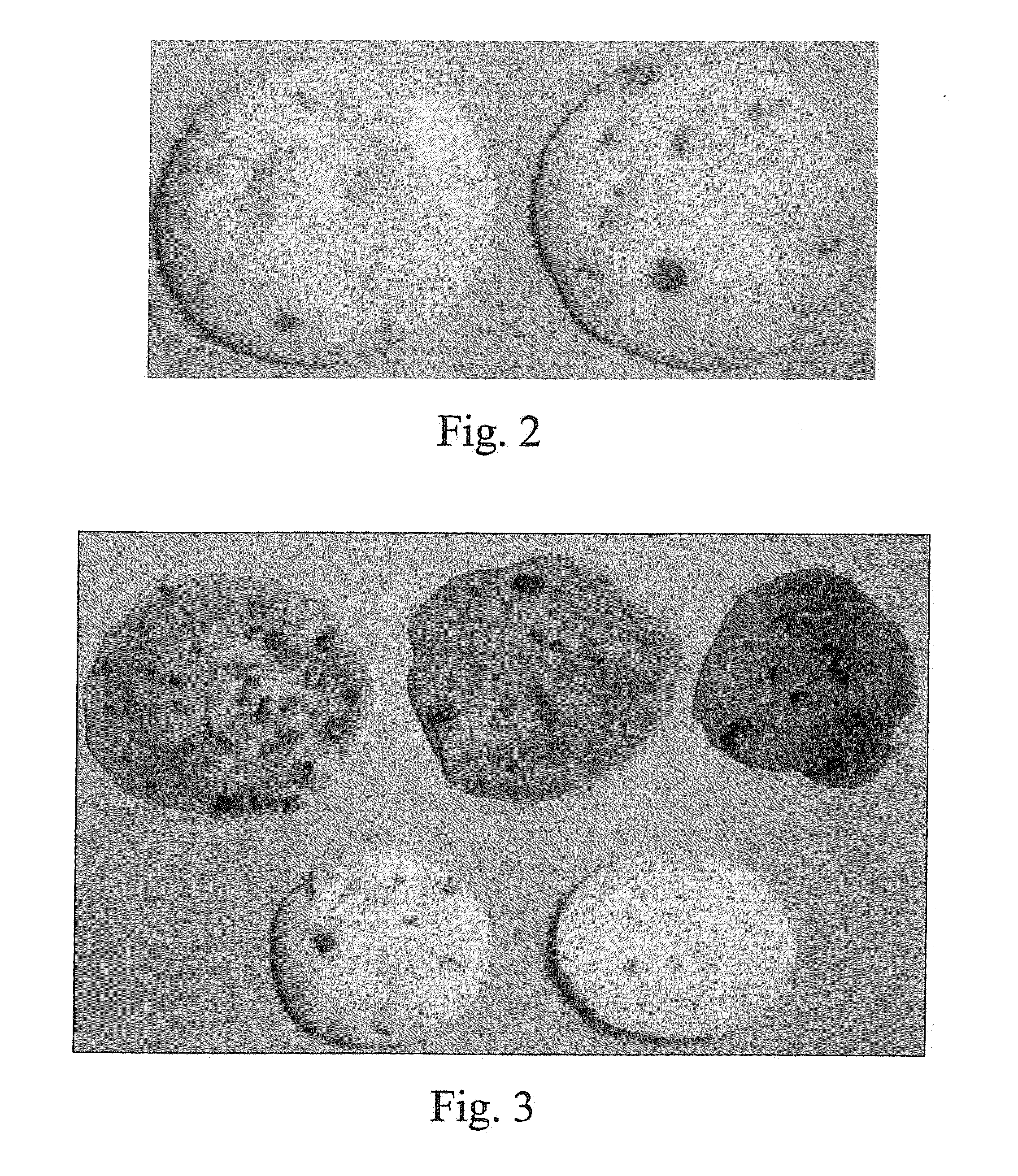

Method for making sweet cookie dough having an imprinted surface

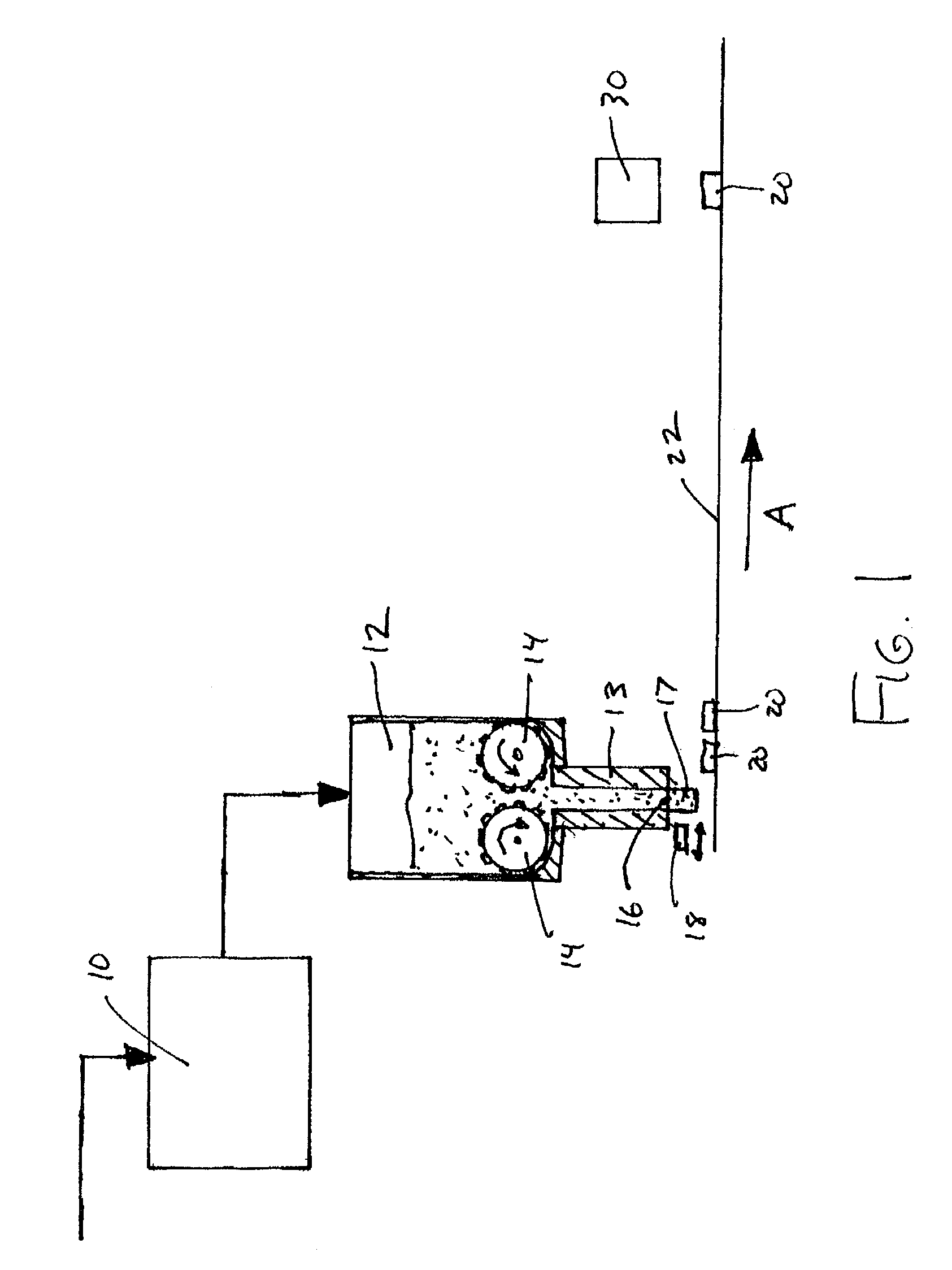

ActiveUS7067167B2Rapid and efficient and systematic processConfectioneryCeramic shaping apparatusWire cuttingEngineering

Rapid, efficient, and systematic processes and apparatuses for making repeatable imprints on multiple, individual sweet dough pieces are provided. An advantage of the process is the ease of making uniform imprints that are aligned with the individual dough pieces as formed and deposited. Such provides the ability to create a three-dimensional pattern on the surface of a sweet dough piece, particularly a soft cookie dough piece. The methods can be accomplished by high-speed wire cutting production methods as well as other dough piece depositing apparatuses, such as roller-type depositors.

Owner:GENERAL MILLS INC

Freezer to retarder to oven dough

A frozen dough comprising flour, a high yeast level comprising one or more yeast with activity covering temperature range of 33-140° F., emulsifiers, dough conditioners, stabilizers, sugar, lipid source and optionally supplemental gluten such that the frozen dough does not require a conventional proofing (proofer) step prior to freezing or prior to baking. When the frozen dough is thawed in a retarder at 33-42° F. for at least 12 hours, or at an elevated temperature of between 43-85° F. for at least 1 hour, and then baked, the baked products have good appearance, taste and texture, and a specific volume of at least 4 cc / gram.

Owner:RICH PRODUCTS

Flour and dough compositions and related methods

ActiveUS7258888B2Increase concentrationReduced active-enzyme contentReady-for-oven doughsMeat/fish preservation by heatingWheat germWheat grain

Described are methods of treating wheat grain, including reducing the amount of active enzymes in a milled wheat grain by treating a portion of the wheat grain that includes one or more of wheat bran or wheat germ to deactivate enzymes; as well as flour and dough compositions prepared from the treated portion of wheat grain.

Owner:GENERAL MILLS INC

High fat biscuit mix and products resulting therefrom

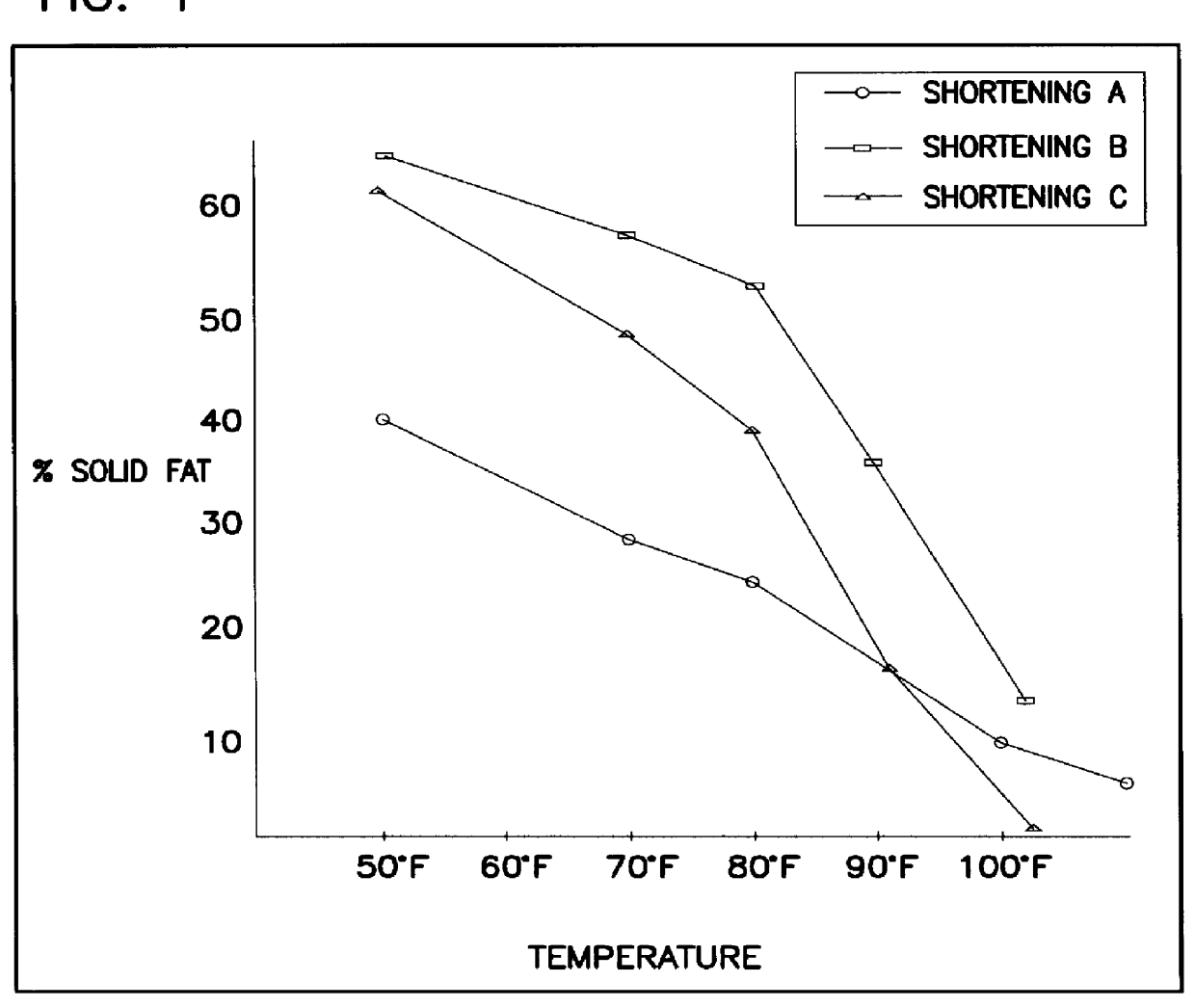

The invention is a high fat biscuit mix as well as dough and biscuit products resulting therefrom. The mix comprises flour, a leavening agent, and emulsifier along with a protein supplement and shortening. The shortening has a high initial solids content at low temperatures (50 DEG F.) and a melting point of 104 DEG F. or less resulting in a biscuit product having an improved moistness, flakiness and uniform height. The protein supplement and emulsifier generally provide a product having an improved outer crust layer, improved height and shape, and an interior which is tender without being doughy. The mix and resulting dough comprise a high concentration of fat and further a high concentration of fat contributed by shortening chips within the dough.

Owner:U S BANK NAT ASSOC +1

Compositions and methods relating to freezer-to-oven doughs

InactiveUS6884443B2Useful propertyStrengthen and stabilizeReady-for-oven doughsPre-baking dough treatmentYeastModified atmosphere

Owner:GENERAL MILLS INC

Reduced sucrose cookie dough

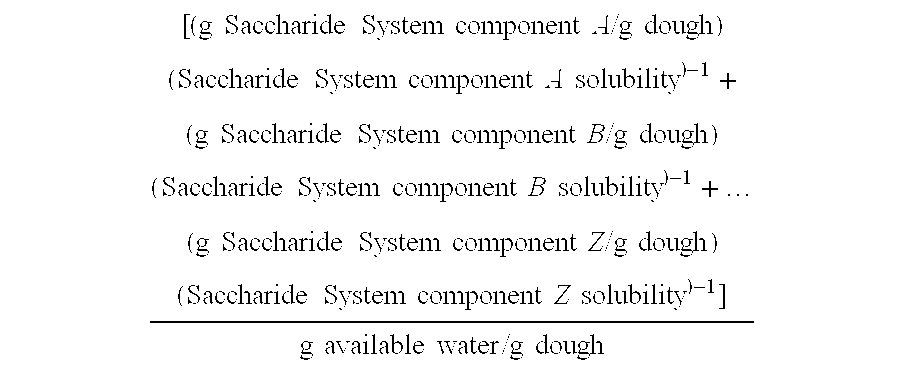

A reduced sucrose cookie dough is provided comprising a Saccharide System. The Saccharide System comprises a crystalline sugar alcohol comprising at least one member selected from the group consisting of crystalline maltitol, -crystalline lactitol, and crystalline isomalt and at least one member selected from the group consisting of a liquid sugar alcohol and a long chain sugar complex. The Saccharide System has a Collective Solubility that is within about 20% of the solubility of sucrose in the dough. The cookie dough has a sucrose content of less than 0.5 grams per serving size. Methods of making the cookie dough are also provided.

Owner:GENERAL MILLS INC

Method of making a shelf stable edible snack having an outer dough layer

The present invention is directed to a method of making a shelf stable edible snack. The method comprises the steps of: (A) providing an edible core having an outside surface; and (B) applying at least one outer dough layer that substantially covers the outside surface of the edible core; wherein the outer layer is applied by a method comprising the steps of: (a) applying a base liquid onto the outside surface of the edible core, thereby forming a liquid coated component; (b) applying a dry powder to the liquid coated component, thereby forming an edible layered component; and (c) optionally, (i) drying the liquid coated core after step (a), (ii) drying the edible layered component after step (b), or (iii) drying the liquid coated core after step (a) and drying the edible layered component after step (b); and (d) cooking to form the shelf stable edible snack, wherein the outer dough layer has a water activity of about 0.2 to about 0.8 at 25° C.

Owner:MARS INC

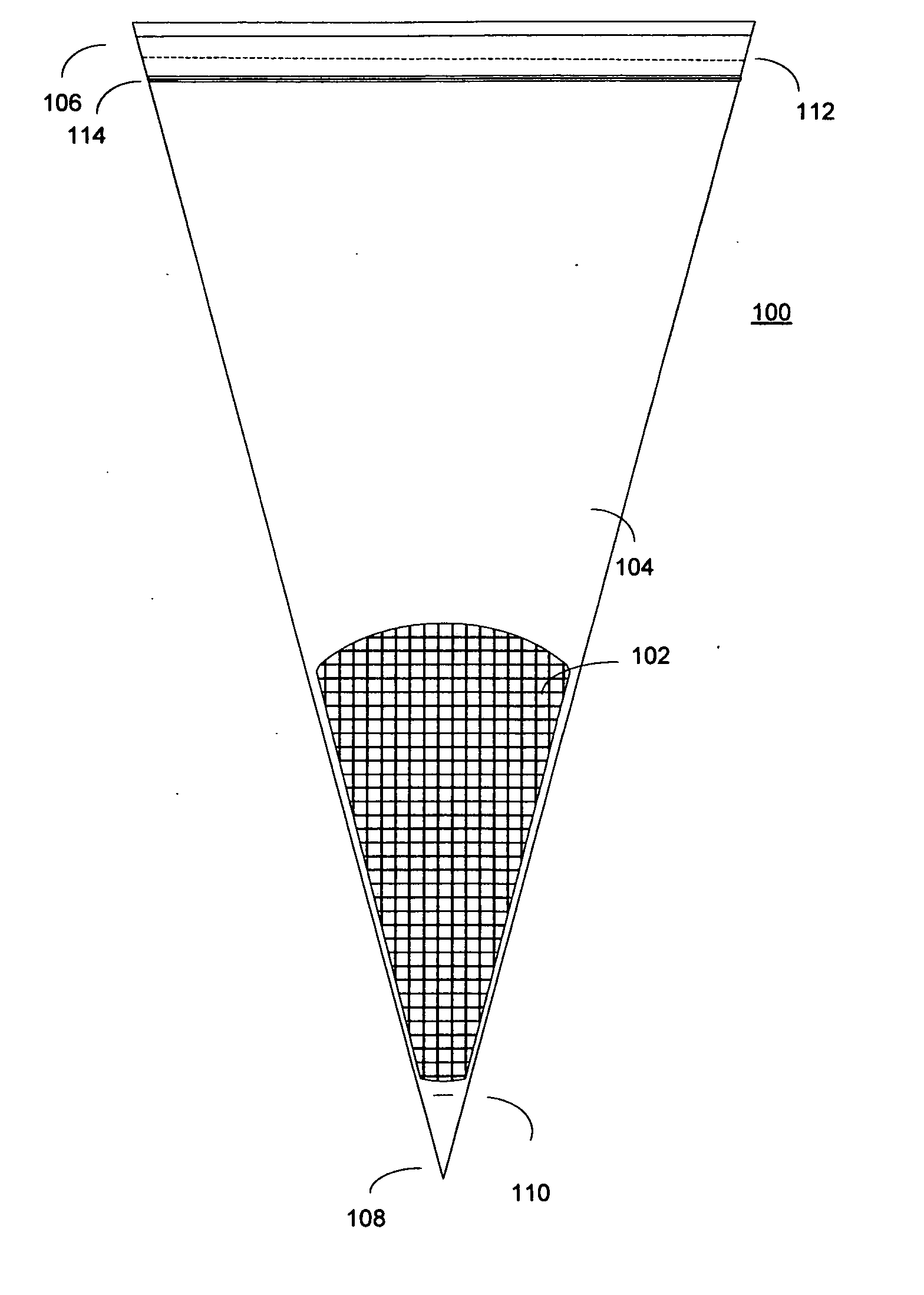

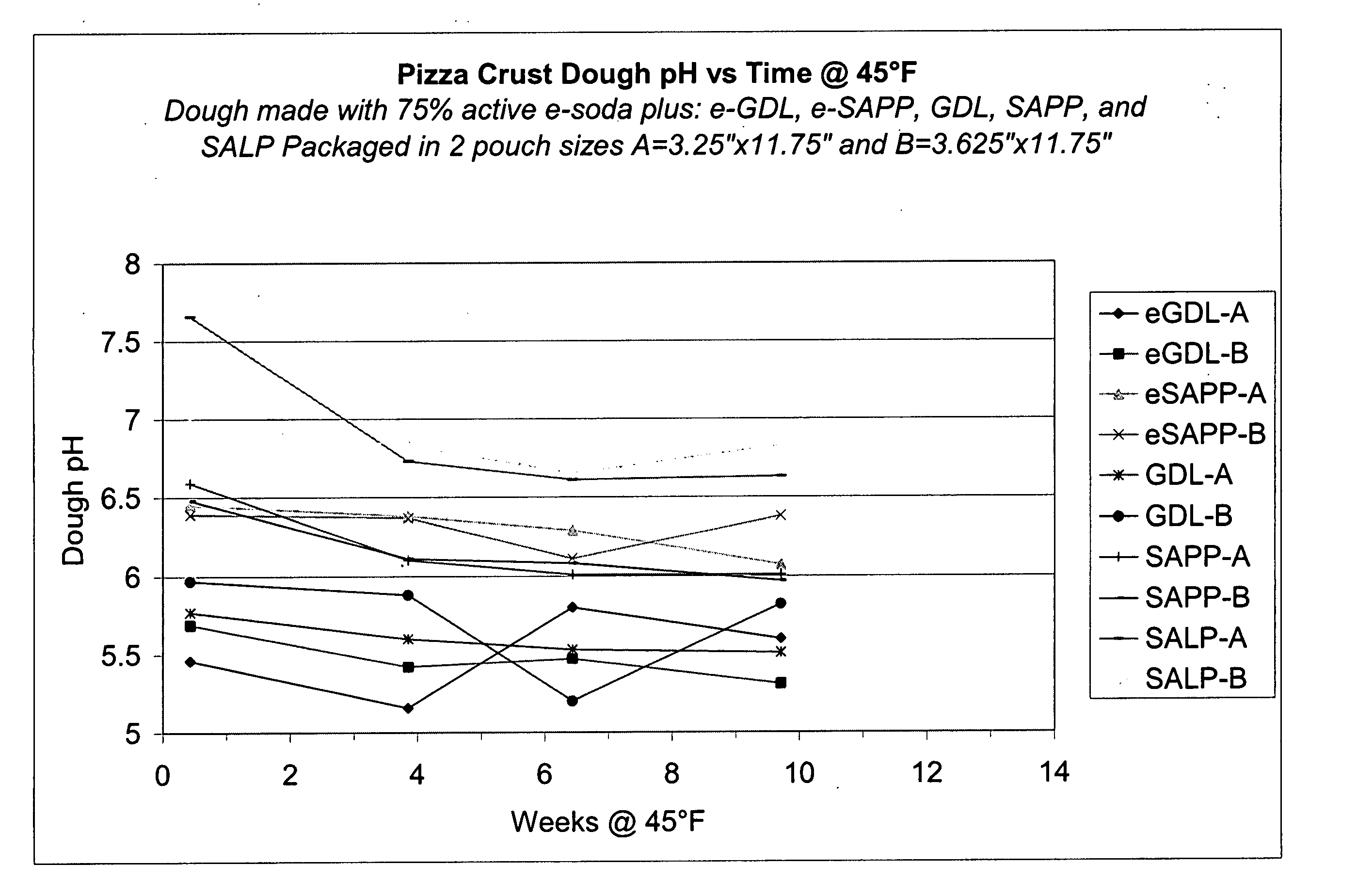

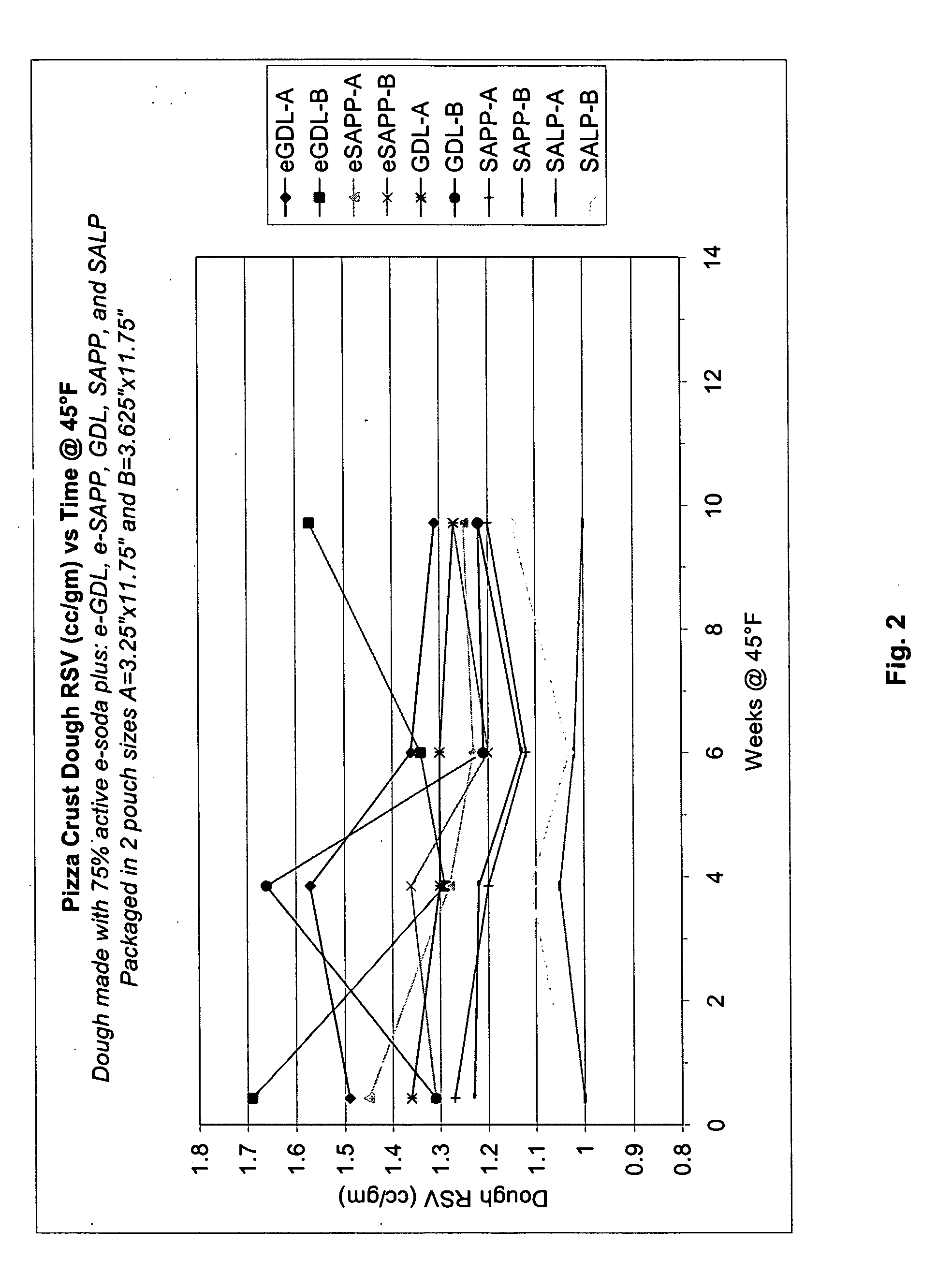

Packaged, non-developed dough product in low pressure package, and related compositions and methods

ActiveUS20050271773A1Trend downImprove stabilityReady-for-oven doughsConfectioneryCompound (substance)Chemistry

Described are methods and compositions relating to non-developed dough compositions leavened by chemical leavening systems that include an encapsulated basic chemical leavening agent, wherein the dough composition can be refrigerated in a low pressure package and can exhibit desired browning upon baking.

Owner:GENERAL MILLS INC

Microwavable frozen cookie dough

A microwavable cookie dough composition is provided, along with methods of microwave-baking cookies. The cookie dough can be microwave-baked from the raw, frozen state without thawing or pre-baking. The cookie dough also does not require the use of a susceptor to achieve even heating. The resulting cookie has acceptable spread, crumb structure, and texture comparable to a conventional oven-baked cookie.

Owner:CARAVAN INGREDIENTS

Formula and process for producing frozen sheeted dough

ActiveUS20070218167A1High stressConsiderable convenienceReady-for-oven doughsPre-baking dough treatmentAdditive ingredientAir cell

A process of producing a frozen sheeted dough, which can be prepared without using stress-free sheeting process and transferred directly from the freezer to oven without a proofing step. The process comprises mixing the dough ingredients comprising yeast and chemical leavening agents; resting the dough to form air cell structure; subjecting the dough to high stress sheeting compressions and freezing the dough. The frozen dough can be directly transferred to an oven without a proofing step. The resulting baked product has desirable texture and taste.

Owner:RICH PRODUCTS

Frozen microwaveable bakery products

InactiveUS20050136167A1Sufficient structureReduce the amount requiredBakery product refreshing by heating/thawingReady-for-oven doughsBiotechnologyWater activity

A frozen microwaveable bakery product having an open grain structure including from about 40 to about 58% by weight of a cereal grain flour having high protein content. The bakery product has a yeast leavened bread dough matrix including from about 4 to about 8 weight percent of a blend of sweeteners including water activity reducing agents effective to bind water within the bakery product to reduce the amount of free moisture in the bread dough matrix and minimize sublimation of moisture in frozen storage. Preferred embodiments can contain an enrobed portion containing a food or foods. Methods of making the frozen microwaveable bakery products are also disclosed including a step of freezing the products for frozen storage following proofing the products to a rise of about 30 to about 35% of the actual projected leavening capacity.

Owner:FIRST PRODS A MINNESOTA CORP

Process for the manufacture of deep-frozen, ready for baking dough pieces

InactiveUS6113952ARapid hydrolysisImprove textureReady-for-oven doughsMilk preparationYeastDeep frozen

Owner:N V CERES

Method for producing a composite dough-based product

InactiveUS7147881B2Satisfactory structureEasy to handleLeguminous plant bakery productsBaking mixturesGlutenWheat flour

A method for making a composite dough by preparing a wheat dough by mixing wheat flour, fat and water in a manner effective to form an homogeneous and cohesive gluten structure followed by sheeting the dough into a sheet; separately preparing a non-wheat dough by mixing a non-wheat flour and water to form a homogeneous mass of dough that is sufficiently cohesive to be subsequently handled; assembling the wheat dough with the non-wheat dough; and laminating the wheat and non-wheat doughs to form a composite dough.

Owner:NESTEC SA

Refrigerable extended shelf-life liquid batter and method for its production

InactiveUS20040043123A1Extended shelf lifeMicrobiologically stableBakery battersBakery productsOrganic acidBrauniellula

A ready-to-use refrigerable liquid batter for preparing pancakes, waffles, brownies, muffins, cakes and the like comprises a starch component and an organic acid or a mixture of organic acids. The batter has been microbiologically stabilised by heating to a temperature below the gelatinisation temperature of the starch component for a time period sufficient to substantially reduce the bacterial count of the batter so as to make the batter storable for at least three weeks at a temperature of 8° C. or lower. Also disclosed is a process for preparing a batter of this kind.

Owner:BETTERBATTER SWEDEN

Scoopable dough and products resulting therefrom

A scoopable dough can be used to prepare cut biscuits, drop biscuits, dumplings, flat bread, crackers, pizza dough, doughnuts, fritters, hushpuppies, muffins, pastry crusts, coffee cake, quick bread, scones, cobbler-type crust, and the like. A scoopable dough has desirable viscoelastic properties and is shelf stable without being stored in a container that is deoxygenated and / or hermetically sealed at freezing and refrigeration temperatures. A scoopable dough includes flour, a protein supplement, a shortening, a humectant, a leavening system having at, least portion of the leavening system encapsulated, and water. The flour and water can be in a flour-to-water ratio of between about 2:1 and about 1:1. A scoopable dough can also include a texture-modifying agent, an emulsifier, a hydrocolloid, a dough-developing agent, a nutritional supplement, a flavoring, a shelf-life stabilizer, an organic acid, and / or a binder of metal ions.

Owner:GENERAL MILLS INC

Compositions and methods relating to freezer-to-oven doughs

InactiveUS20050031733A1Useful propertyLarge expansionReady-for-oven doughsPre-baking dough treatmentYeastCompound (substance)

Described are dough compositions and methods, wherein the dough composition is prepared using a metabolized portion of dough comprising bubbles, metabolically active yeast, and developed dough matrix, combined with non-metabolized yeast, and wherein the dough composition preferably has useful properties such as yeast-leavened freezer-to-oven capabilities, without the need for chemical leavening agents or modified atmosphere packaging.

Owner:GENERAL MILLS INC

Pasteurized uncooked batters and refrigerated ready-to-bake batters, and the methods of manufacturing

Described are uncooked batters that have been effectively pasteurized and have no gelatinized starch. These batters are characterized as having low viscosity, a water activity of greater than 0.90, the absence of an active leavening agent, and a total plate count of less than 1000 per gram. There are two methods of manufacturing these pasteurized uncooked batters. One method uses irradiated flour and sterile aqueous liquid to make a pasteurized flour slurry; the other method uses a process of treating the whole grain at temperature and time conditions such that the exterior of grain is pasteurized followed by wet milling of the whole grain in a sterile aqueous liquid such that the slurry passes through a 20 mesh screen. In both methods, the farinaceous material remains uncooked and the starch has not been gelatinized. The pasteurized aqueous flour slurries, are then added to the pasteurized remaining ingredients of the batter in a sterile environment. Refrigerated Ready-to-Bake batters can be made by the addition of gas upon dispensing the batter from a container having the batter and a compressed gas such as carbon dioxide, nitrous oxide, or nitrogen.

Owner:MITCHELL CHERYL R +1

Method of baking yeast-fermented frozen bread products

InactiveUS6896916B2Shorten defrosting timeNecessary defrost timeBaking mixturesPre-baking dough treatmentYeastAdditive ingredient

A method of making a bread product comprising formulating and mixing a bread dough having flour as a major ingredient, and having the following additional ingredients, where percentages are based on the flour weight:Ingredients%Salt 1.8-2.3Yeast3.0; 2.5-4.5Sweetener 0.3-2.0Gluten 0.5-4.0L-Cysteine 10-100 PPMWater 50-65Oxidant 0.1-0.5Enzymes0.01-0.5Gum0.01-0.5pre-forming the dough into open molds shaped suitably for the bread product;pre-proofing the dough for less than 30 minutes in at least 70% relative humidity at a temperature in the range of 80° F. to 100° F.;freezing the pre-proofed dough to a temperature below 0° C.;partially defrosting the dough for a period of time of 60 minutes or less; andplacing the partially defrosted dough in a pre-heated oven at a temperature of about 170° C. to 180° C. to produce the bread product in less than 3 hours.

Owner:MAPLE LEAF BAKERY

Reduced sugar sweet roll

InactiveUS20060172053A1High expectationLow and no sugar contentBaking mixturesBakery productsBiotechnologyPolydextrose

A low or no sugar sweet roll product or intermediate is provided wherein at least a portion of the sweetness of the sweet roll product is provided by a non-nutritive sweet flavorant provided in combination with at least one sugar alcohol having a molecular weight less than about 350. Additionally, specific formulations of non-nutritive sweet flavorant with defined sugar alcohols and / or polydextrose are provided when the non-nutritive sweet flavorant and sugar alcohol is in the filling component or the icing component of the sweet roll product or intermediate.

Owner:GENERAL MILLS MARKETING INC

Method for Reducing Proofing Time for Baked and Other Products

ActiveUS20100166911A1Without compromising quality and organoleptic propertyShorten proofing timeReady-for-oven doughsPre-baking dough treatmentProcess engineeringBiology

A method for producing dough which has reduced proofing time. The proofing time is at least 33% less that that required in the absence of vacuum exercising. The method comprises mixing the dough ingredients, forming gas nucleation sites by proofing the dough, exercising the dough by subjecting the dough to cycles of differential pressure, allowing the dough to return to ambient pressure and then, optionally, baking the dough.

Owner:RICH PRODUCTS

Freezer to retarder to oven dough

Owner:RICH PRODUCTS

Ready to bake layered dough product and methods

InactiveUS20060078660A1Light appearanceReady-for-oven doughsBakery productsBaking powderRefrigerated temperature

The invention relates to a ready-for-use bakery dough product which can be preserved in the refrigerator and which is prepared from flour, sugar, egg, starch, emulsifiers, baking powder, water and fat, and provided in a bar or block form. This bakery dough is placed in a baking tin and then baked to form individual baked products. In addition, the block can be formed of different dough layers or strips, or each portion can be provided with a different color, decoration or filling. Different doughs can be swirled together to provide a marbled appearance in the block or in the layers or strips. The dough and resulting bakery product can be filled.

Owner:NESTEC SA

Method of producing frozen dough, and related products

InactiveUS20050266119A1Avoid damageAffect propertyReady-for-oven doughsPre-baking dough treatmentFrozen storageOrganoleptic

Described are methods for preparing frozen dough compositions that exhibit desirable frozen storage stability and that can also exhibit desirable baked organoleptic (e.g., taste, smell, and texture) properties, as well as related methods.

Owner:GENERAL MILLS INC

Method for producing frozen dough

ActiveUS20070160709A1Great tasteUniform crumbReady-for-oven doughsWort preparationCooking & bakingForming gas

The present invention provides a method for producing frozen dough which can be directly transferred from freezer to oven without a proofing or thawing step. The process comprises mixing the dough ingredients, forming gas nucleation sites, exercising the dough by subjecting to cycles of pressure differentials and freezing the dough. The frozen product can be transferred directly from the freezer to an oven for baking.

Owner:RICH PRODUCTS

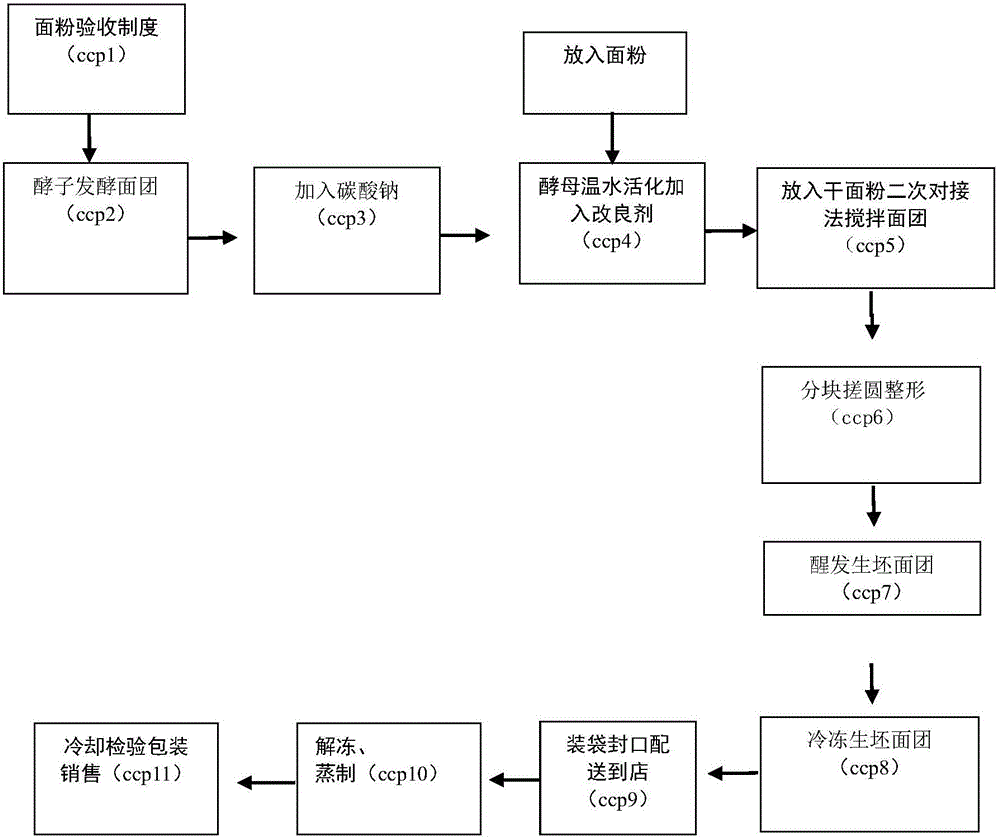

Method for making frozen dough through fermented-rice wine

InactiveCN106173922AGood serviceImprove product qualityFood freezingPre-baking dough treatmentDough fermentationFood science

The invention relates to a method for making a frozen dough through fermented-rice wine. The method comprises the following steps that 1, flour and water are mixed for sour dough fermentation, and a fermented dough is obtained; 2, the fermented dough and dietary alkali are mixed to be uniform, and a first dough is obtained; 3, activated yeast is added into the first dough, a modifying agent is added, the mixture is mixed to be uniform, and a second dough is obtained; 4, flour for secondary butt connection is added into the second dough obtained in the step 3, stirring is carried out, and a third dough is obtained; 5, the third dough is divided into blocks, rolled to be round and reshaped; 6, the rolled and reshaped dough is fermented, and the fermented dough is obtained; 7, the fermented dough is frozen at the temperature of -80--120 DEG C for 10-20 min, the center of the dough is at the temperature of -10--15 DEG C, and the frozen dough is obtained. The frozen dough prepared through the method has the advantages of being convenient to convey and store before being steamed and being free of crack and good in taste after being steamed.

Owner:北京美味阳光食品科技有限责任公司

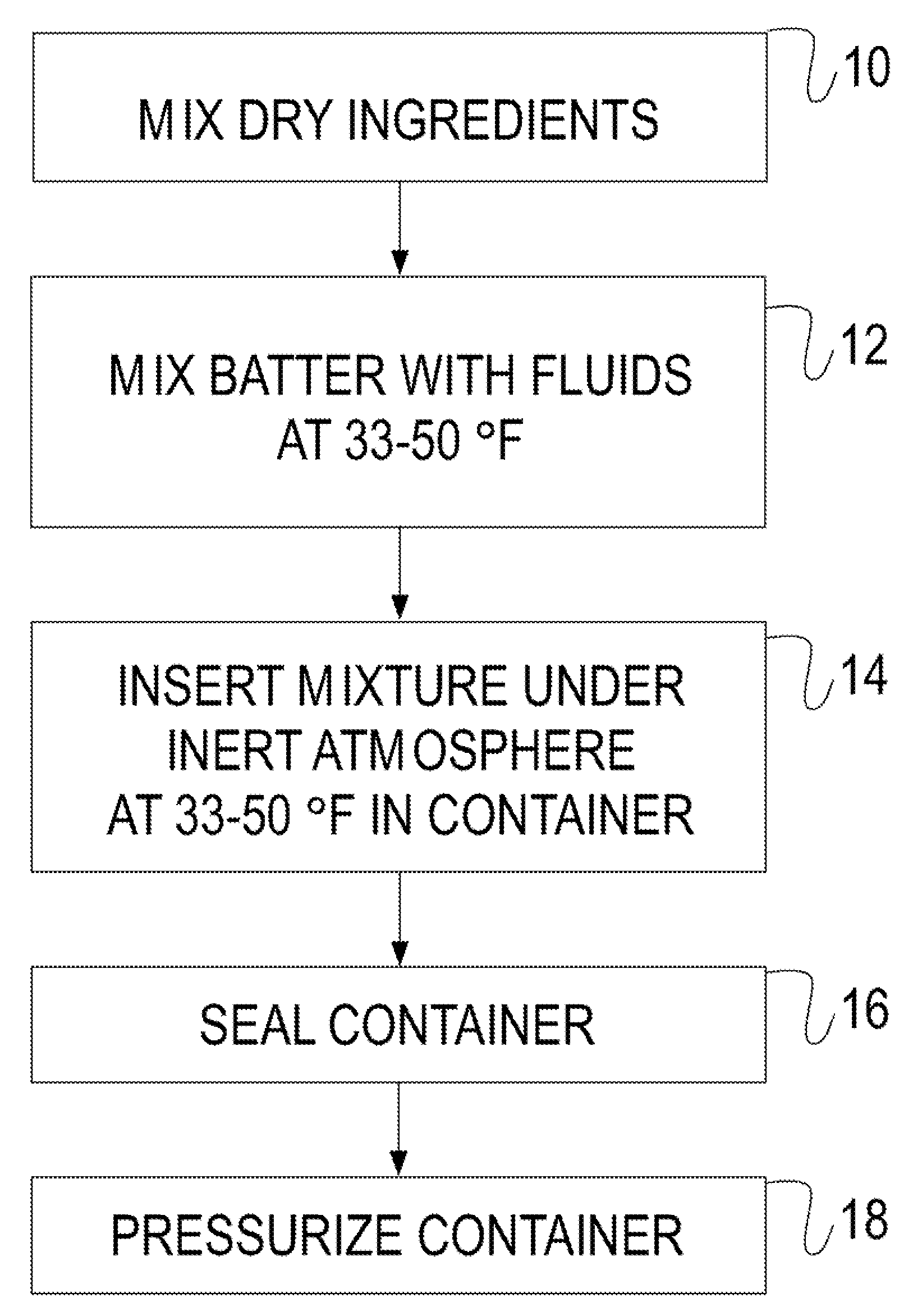

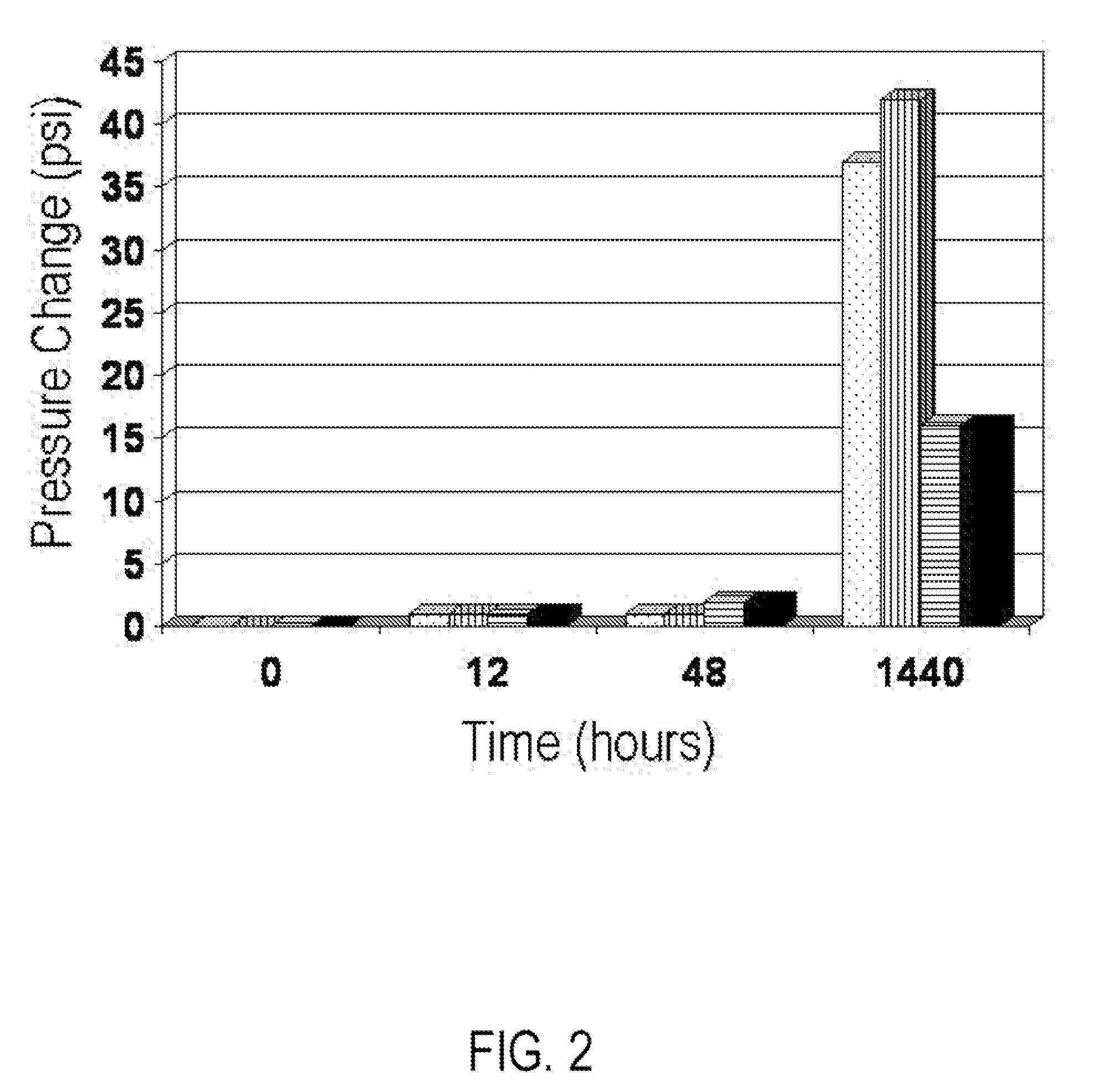

Refrigerator stable pressurized baking batter

In various embodiments of the present invention, a bakable batter mixed using cold process conditions and provided in a pressurized can, can be used to bake a variety of food products. In various embodiments of the present invention, a bakable batter mixed under inert atmosphere conditions and provided in a pressurized can, can be used to bake waffles and pancakes. In an embodiment of the present invention, carbon dioxide is combined with a water-mixed dry batter recipe under pressure at reduced temperature to give a refrigerator stable batter mix. The carbon dioxide reduces the viscosity of the batter to allow the batter to be dispensed for the life time of the product. The carbon dioxide aerates the food product giving light and fluffy baked products. The carbon dioxide acts as a browning agent while the food product is baking to give an a brownish appearance, crunchy texture and attractive taste to the food product.

Owner:BLASTER FOOD TECH LP

System and method of preparing frozen baking items

InactiveUS20120207886A1Maintain quality lifeMaintain shelf lifeReady-for-oven doughsMeat/fish preservation by freezing/coolingCooking & bakingAdditive ingredient

A method of preparing a frozen mixture that may be thawed and baked without adding additional ingredients is provided. A mixture is prepared, placed into an oversized pastry bag, and frozen. Air is evacuated from the bag which is then heat sealed. The frozen mixture can be distributed for purchase by customers at retail outlets. The product can be thawed, kneaded, and piped from the bag directly into a baking mold. If desired, flavoring or other ingredients may be added during or following the thawing stage, and can be kneaded prior to piping.

Owner:SHULEVITZ CAROLYN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com