Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about "Baked wafer shaping/moulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

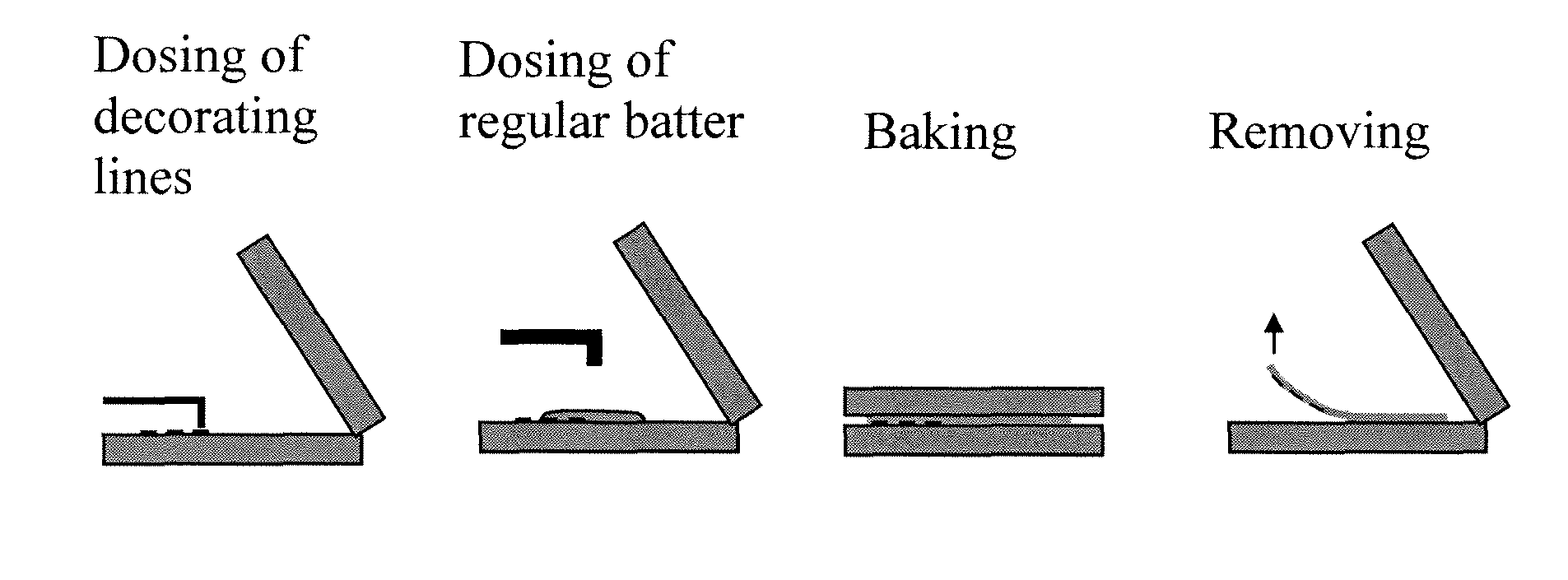

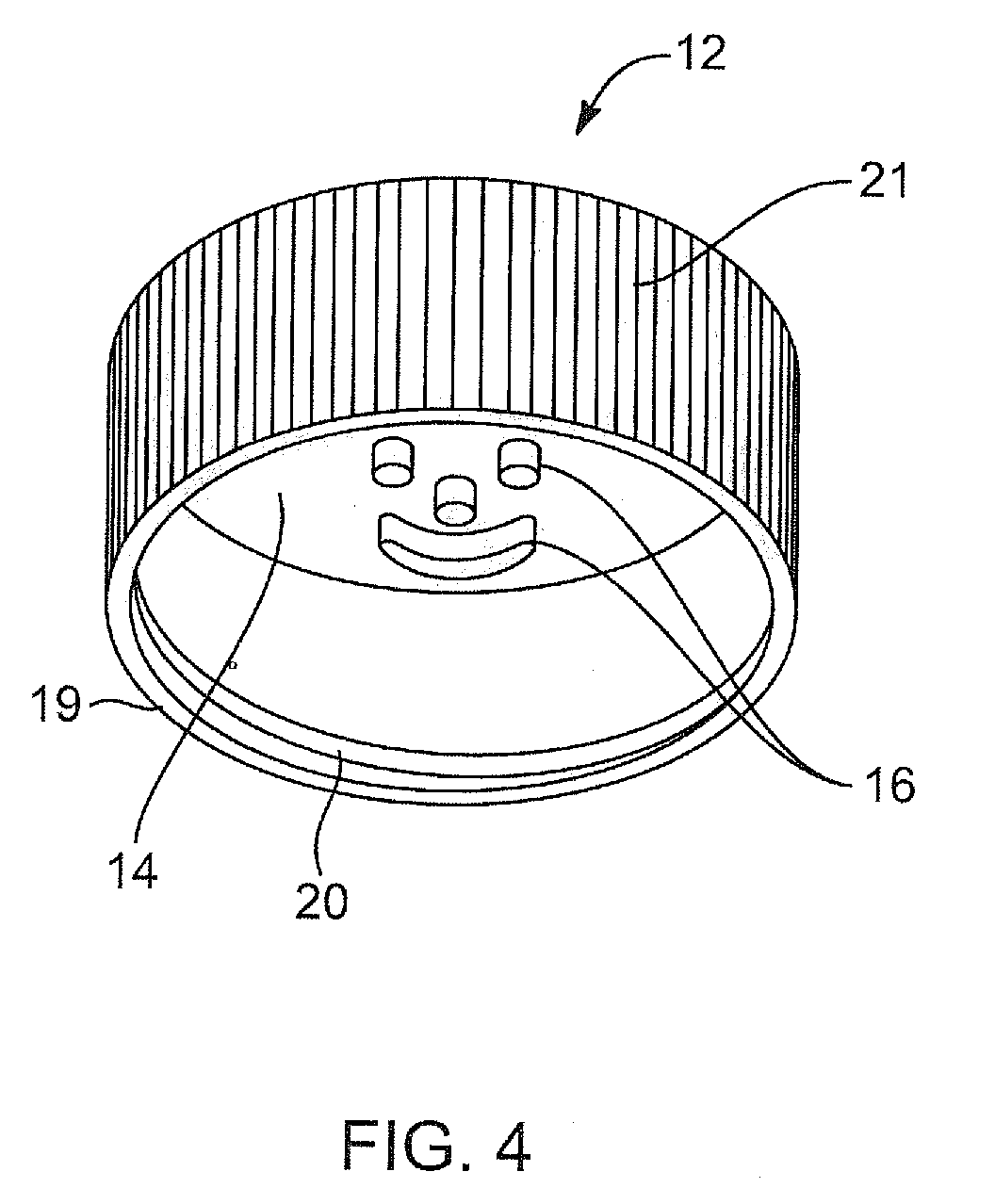

Multi-colored cake cones

The present invention relates to a multi-colored baked cake cone typically for holding ice cream or other confection novelties. This cone is made of a dough bi-layer that includes at least a first layer of a conventional cake dough that contains sugar and a second layer of a modified cake dough that imparts at least one color other than brown to the cone after baking. The cone is typically associated with a sleeve that is at least partially transparent to display the multicolor cone.

Owner:SOC DES PROD NESTLE SA

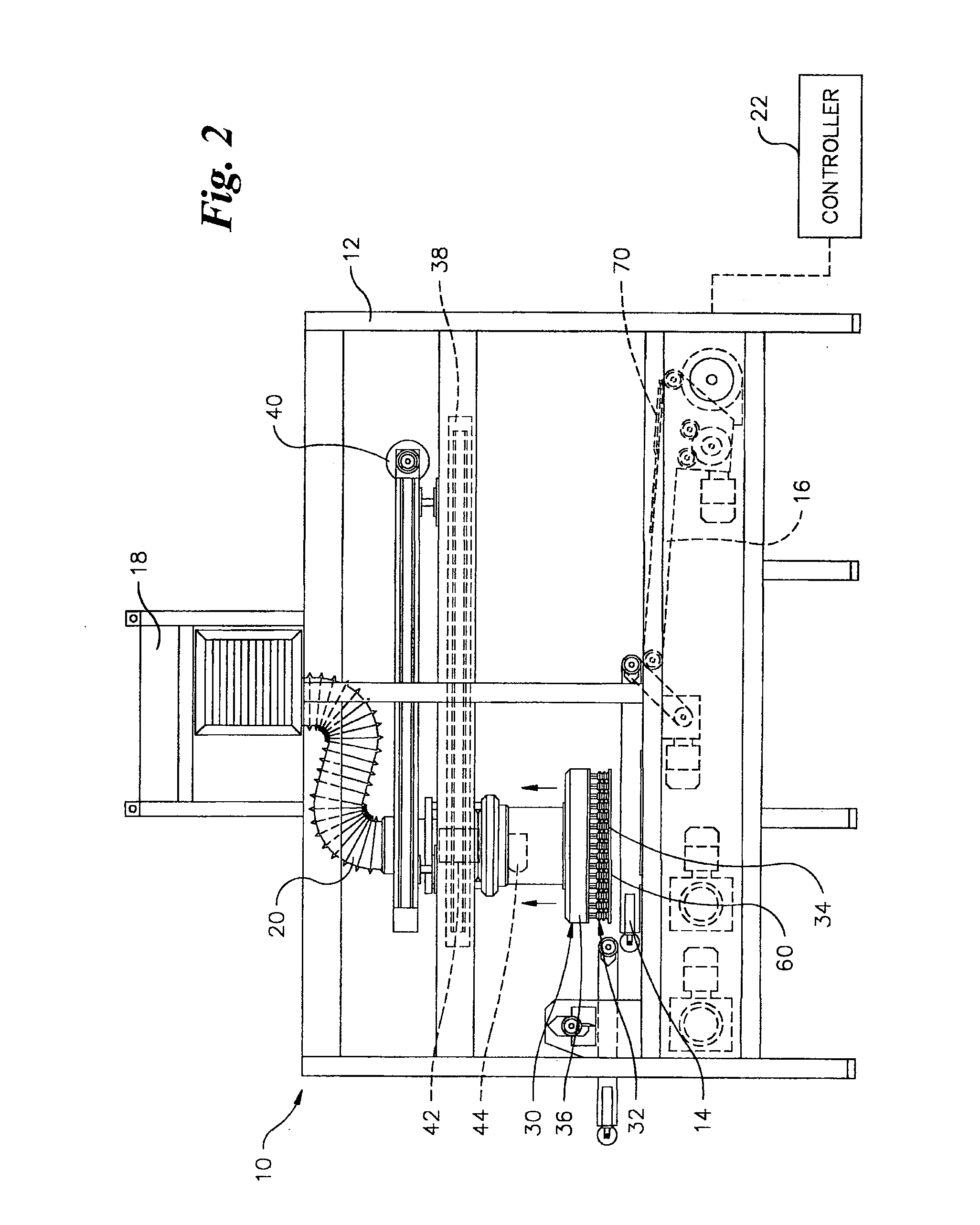

Apparatus, system, and method for a bread cutter and impression devices

InactiveUS20080241326A1Easy to shapeImprove lookConfectionerySweetmeatsAdditive ingredientEngineering

A sandwich sealing crust removing method and apparatus also include bread marking and imaging mechanisms for one or more of indenting, embossing, coloring, cutting, and forming. The apparatus is capable of cutting the crust from a prepared sandwich having filling ingredients between at least two slices of bread in the sandwich. The cut edge area on the sandwich is also sealed to insure that the filling ingredients stay within a pocket formed in the bread. One or more element of the apparatus is also capable of embossing images onto the sandwich and / or a bread slice(s). One of a plurality of devices has removably coupled marking elements that can be used on sandwiches. The marking elements may include one or more removably coupled elements for shaping, marking, embossing, cutting, coloring, indenting, and / or other mechanism(s).

Owner:EKBERG LANE

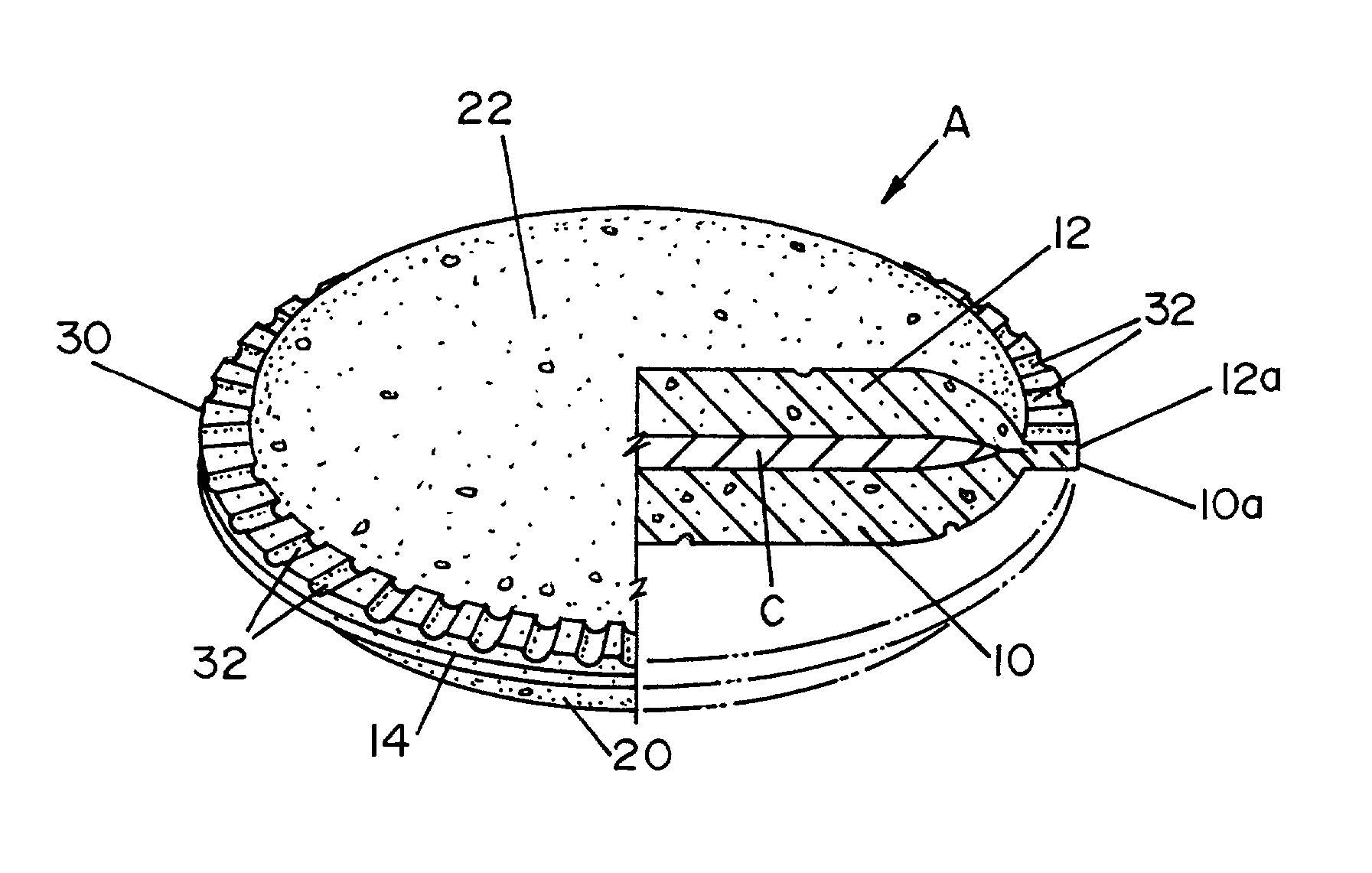

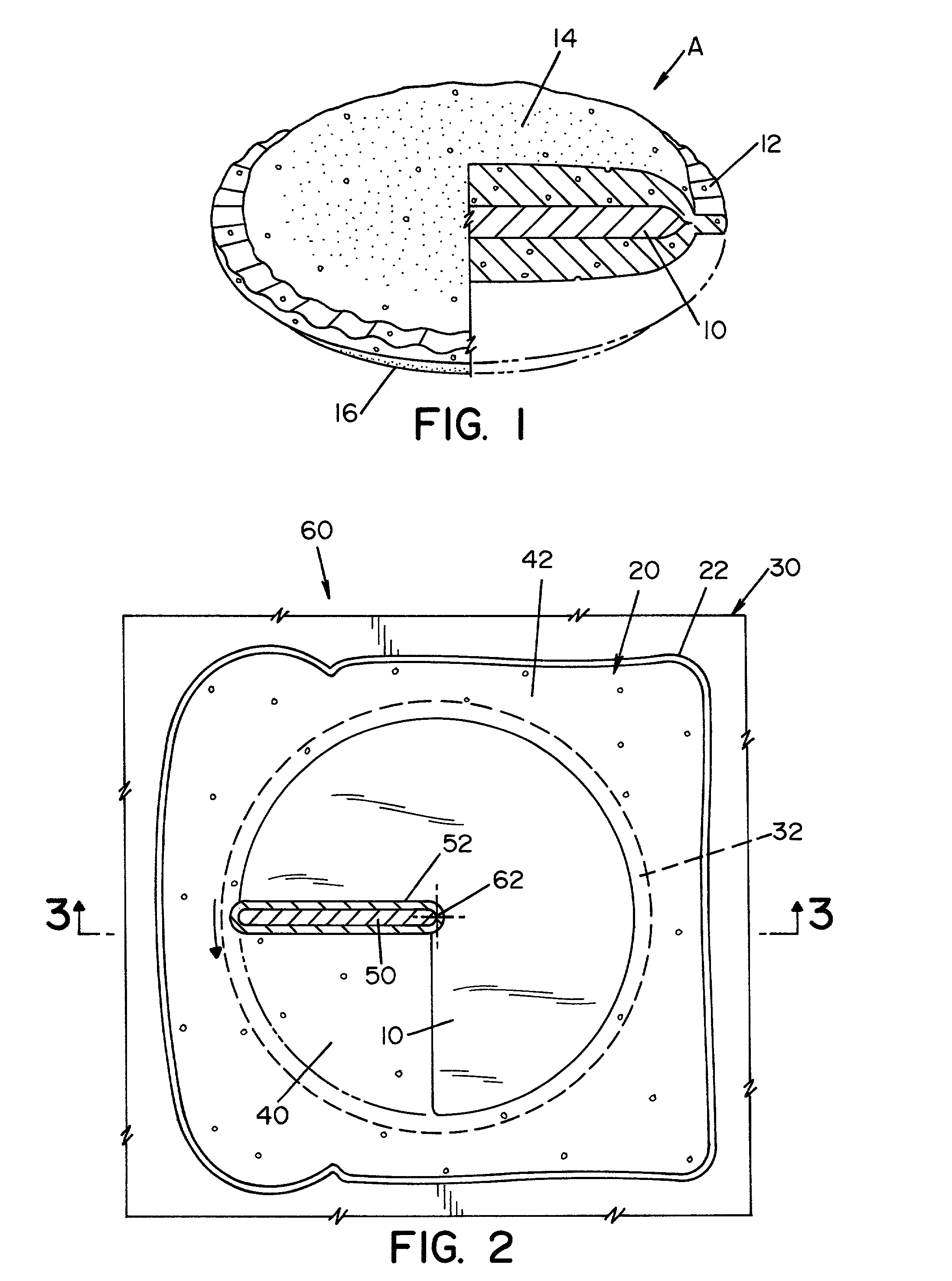

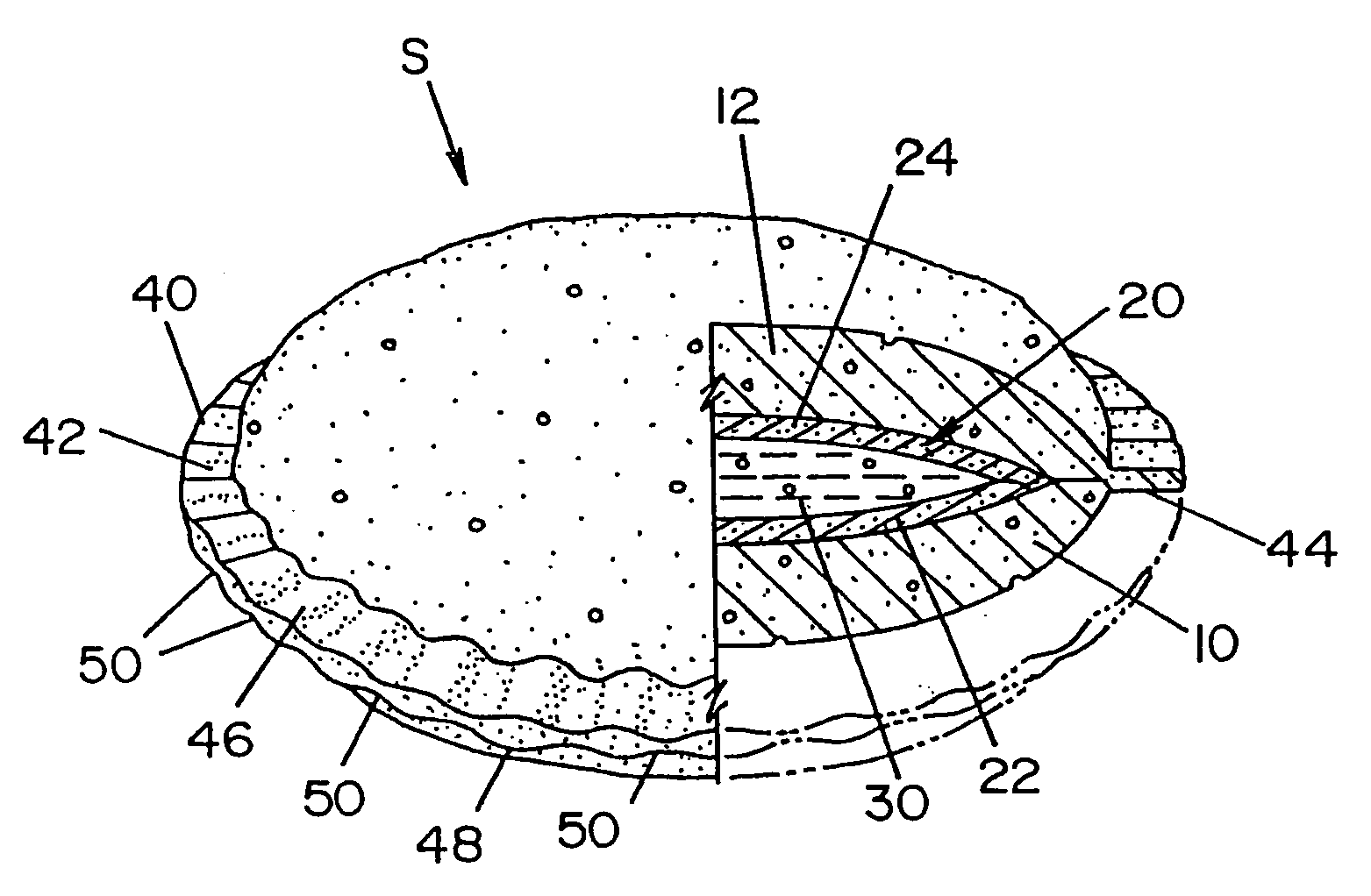

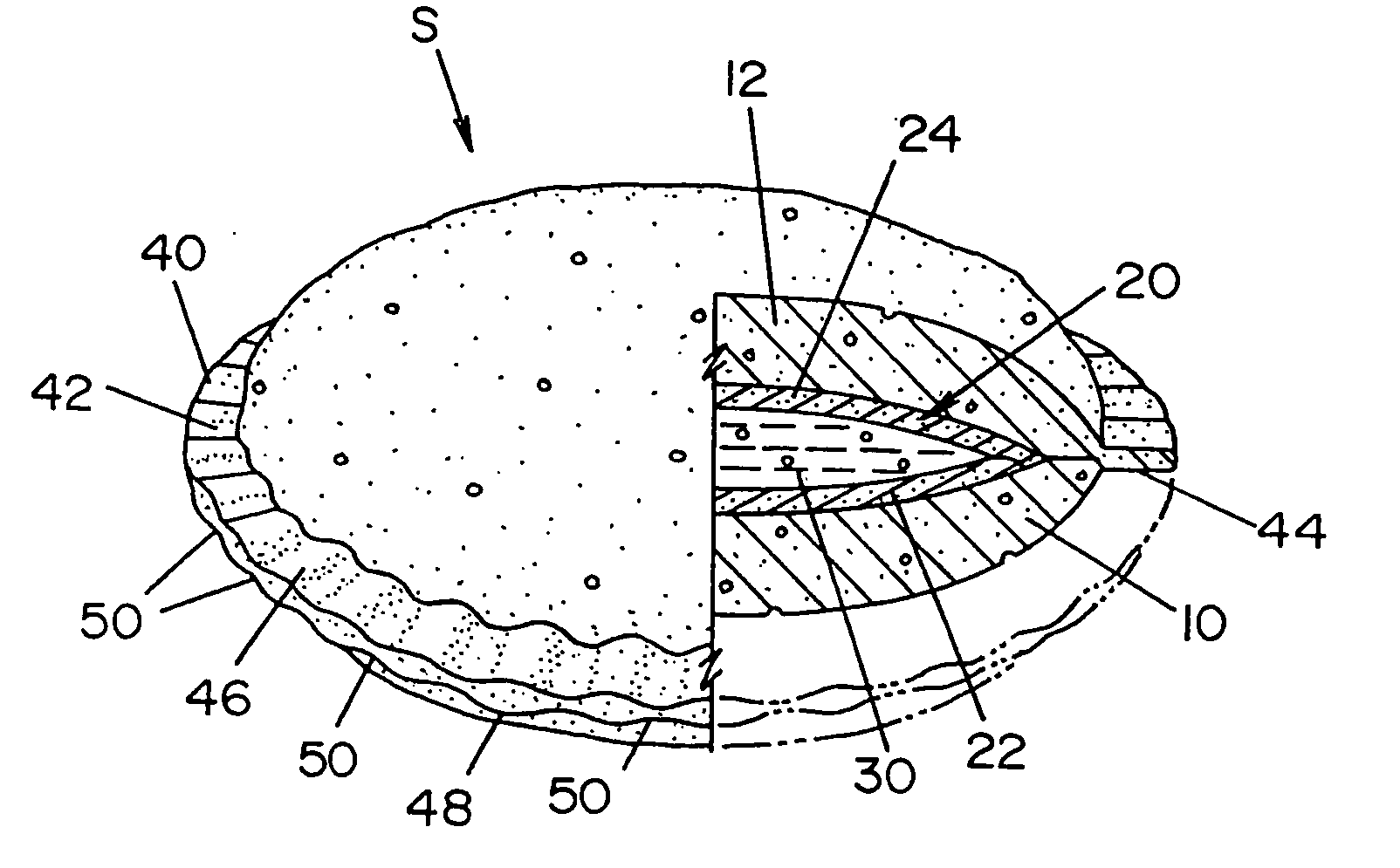

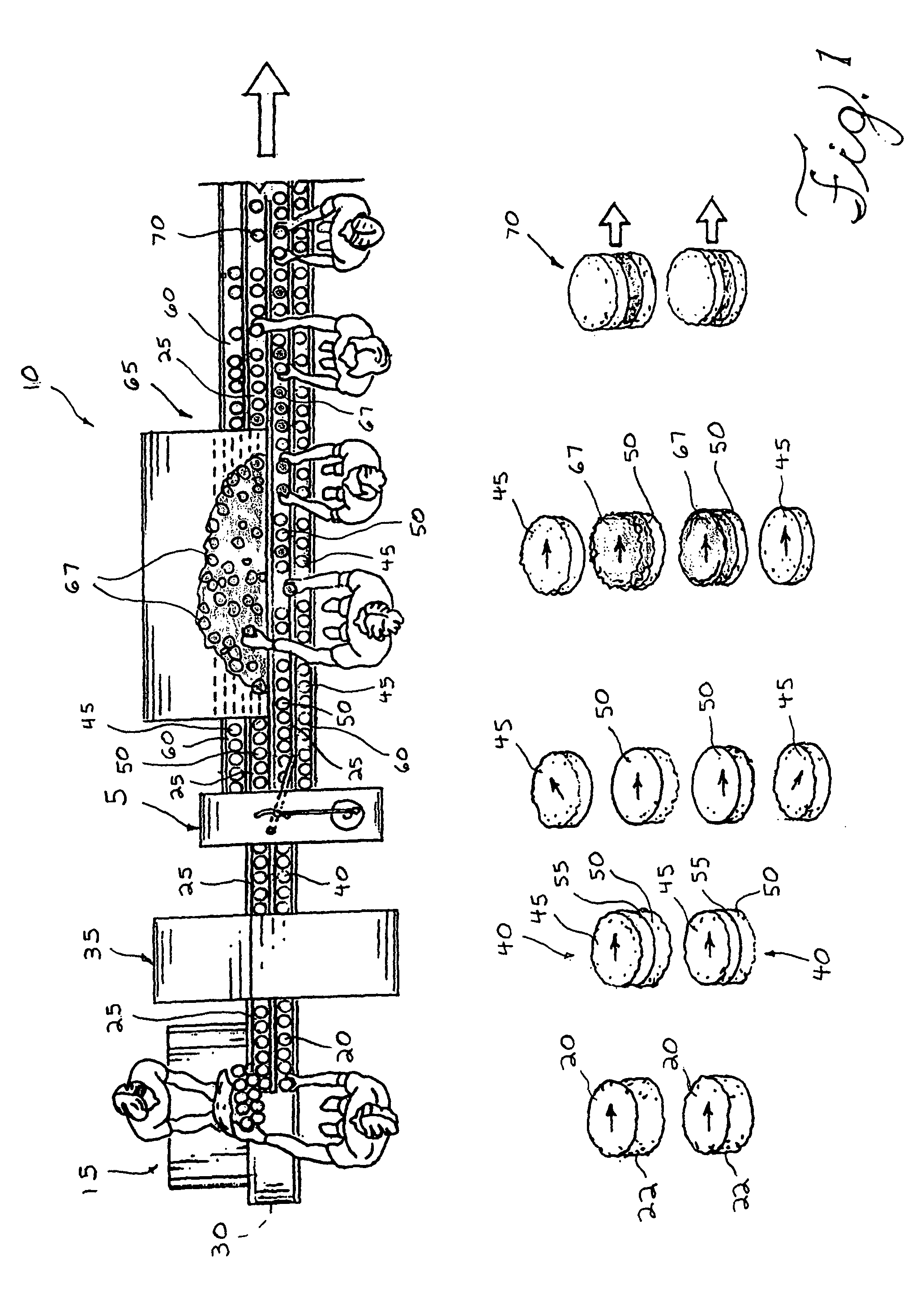

Frozen crustless sliced sandwich and method and apparatus for making same

A frozen sandwich for commercial sales comprising a first portion of bread cut from a first slice of crusted bread and having an outer surface, a given periphery and a center area surrounded by a marginal area. A layer of masticated, plasticized cheese deposited on the center area of the first slice and spaced inwardly from the marginal area. A second portion of bread cut from a second slice of crusted bread and overlying the first portion and the center layer of cheese. The second portion also having an outer surface, a periphery generally matching the periphery of the first portion and a marginal area generally matching and coextensive with the marginal area of the first portion where the marginal areas are compressed together to form a seal generally matching the peripheries of the bread portions and the outer surfaces of the bread portions are heat scorched to transform a thin skin of the cut bread portions into a toasted bread condition.

Owner:THE J M SMUCKER CO

Apparatus and method for producing sandwich cookie having dissimilarly-sized base cakes

A cookie cup sandwich cookie having dissimilarly-sized base cakes is continuously produced by applying a layer of filler cream to a lower base cake and applying an upper base cake to the lower base cake so that the outer periphery of the upper base cake surrounds the layer of filler cream. The apparatus for the production of the sandwich cookies includes at least one rotary molder for producing lower base cakes and upper base cakes having different sizes, a filler cream depositor that deposits a layer of filler cream on each of the lower base cakes, and a conveyer system for transporting and at least substantially concentrically aligning the dissimilarly sized lower and upper base cakes.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

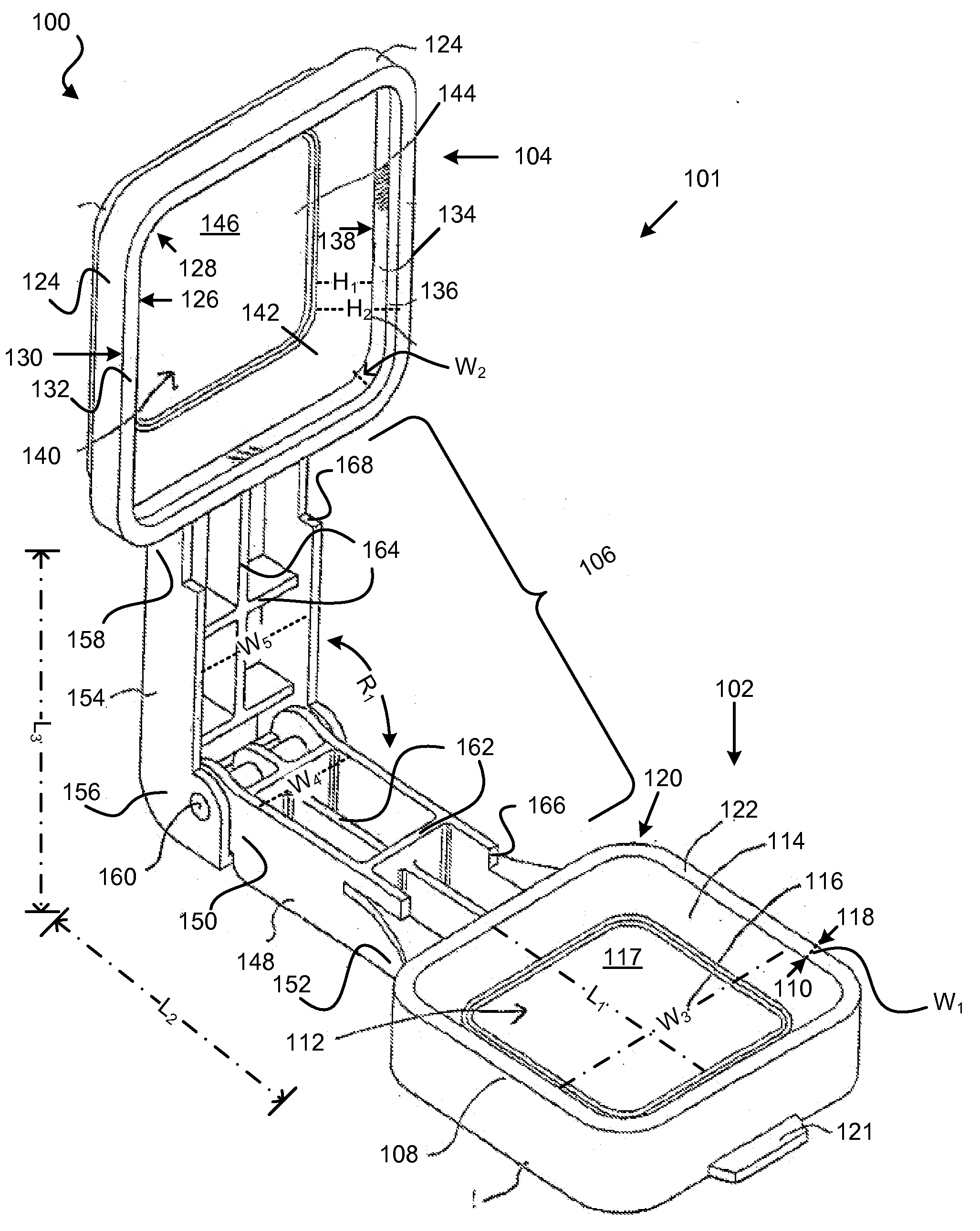

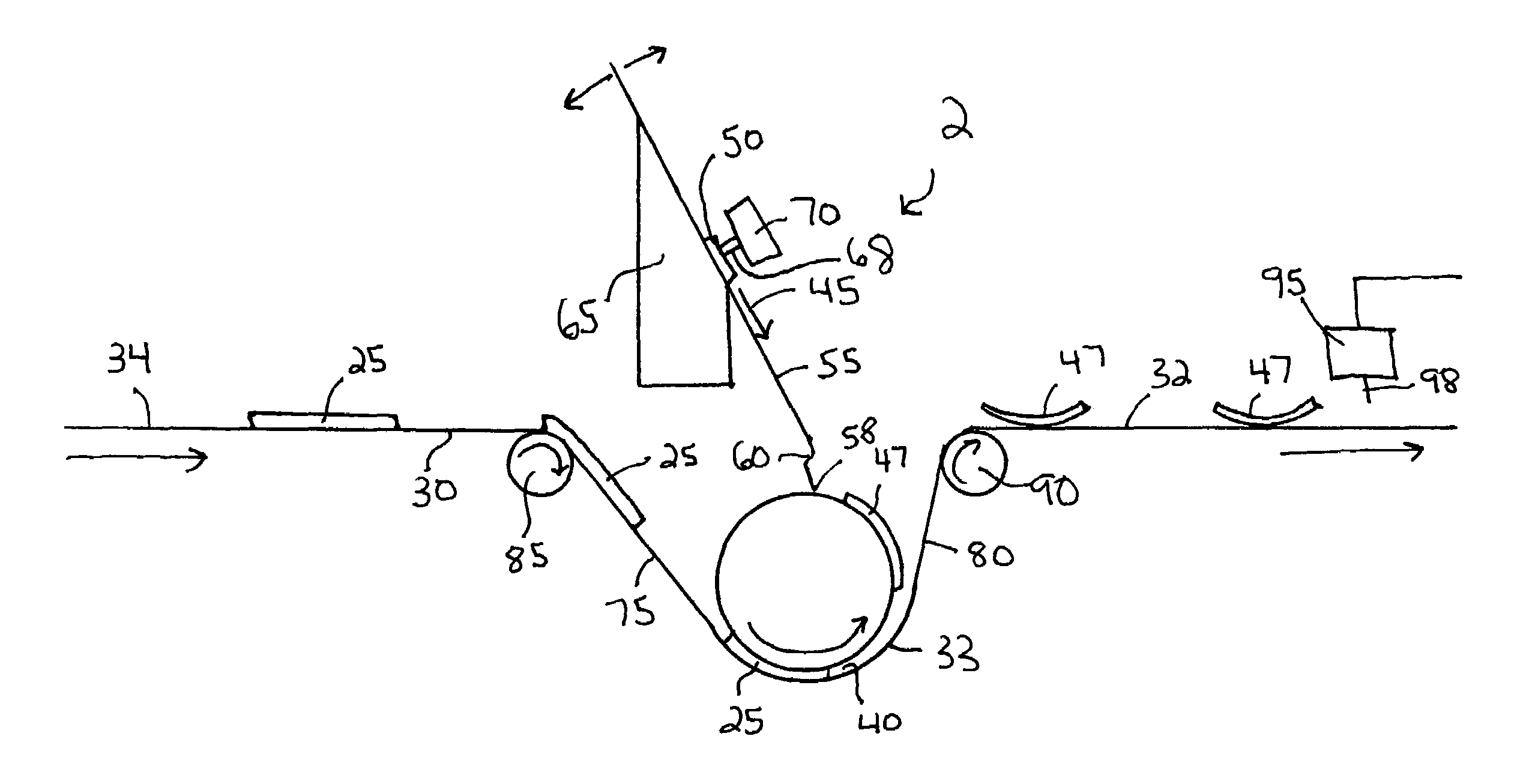

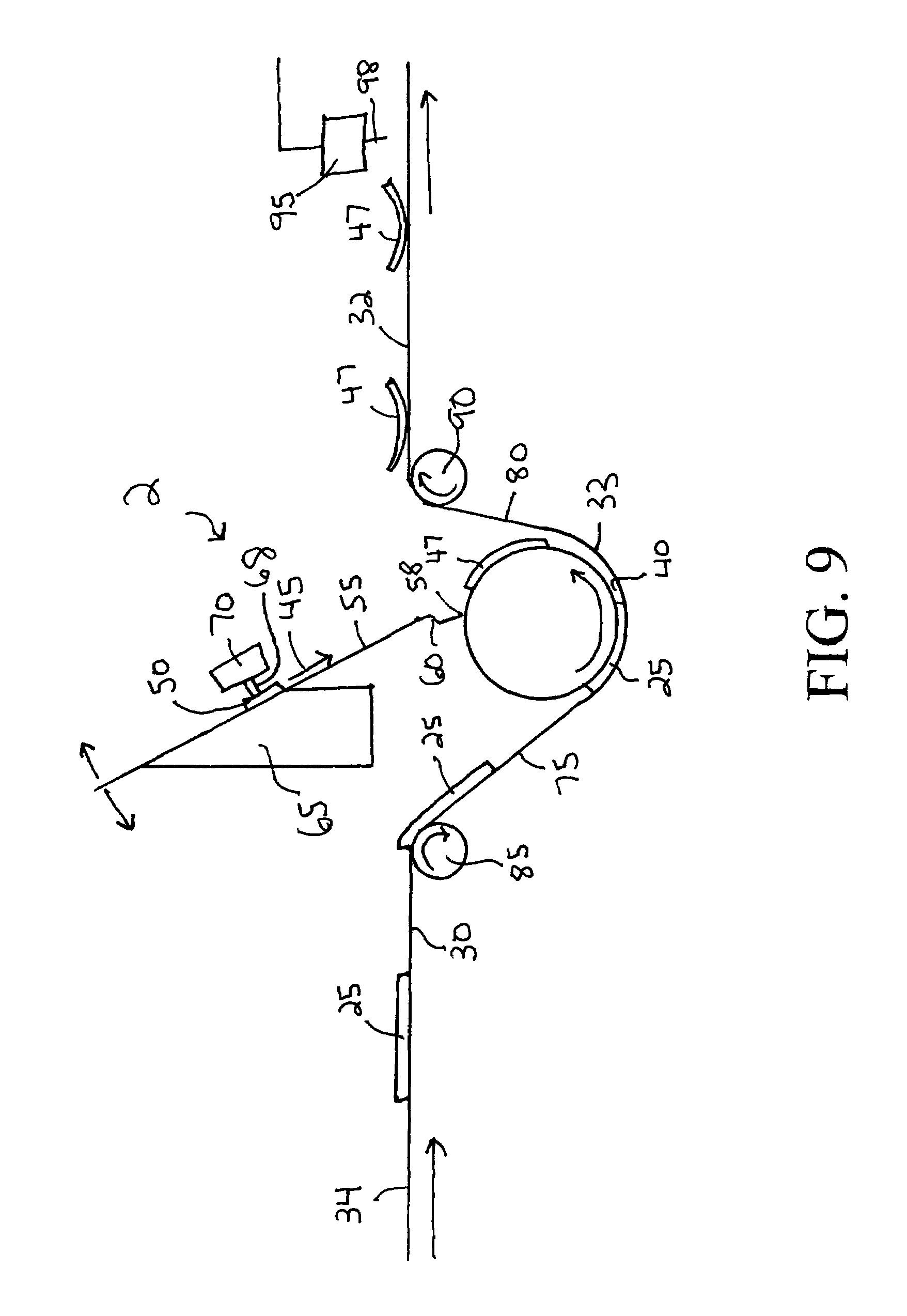

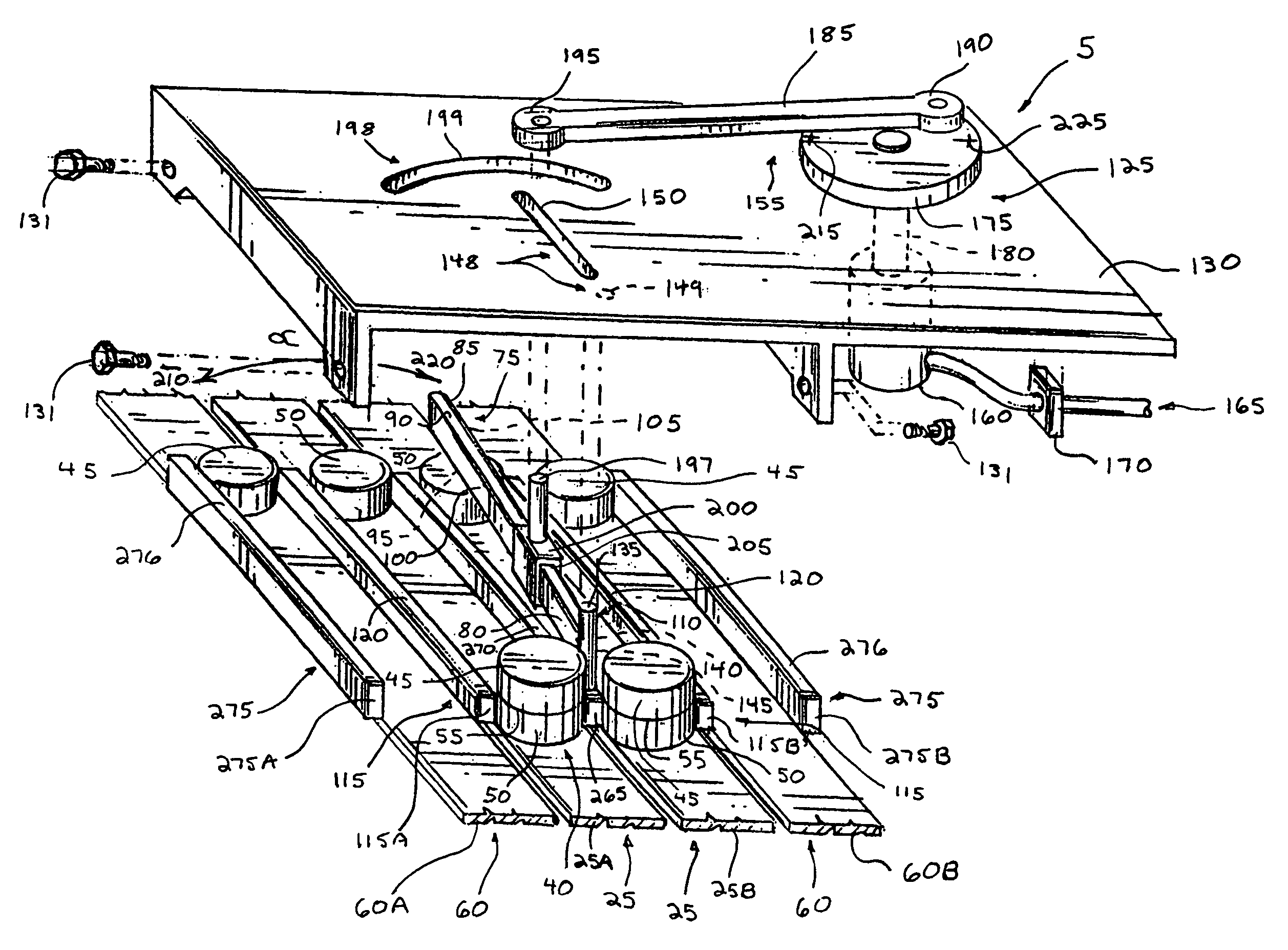

Apparatus, system, and method for making sandwiches

InactiveUS20070144359A1Easy transitionEasy to openFood shapingBaked wafer shaping/mouldingFilling materialsAdditive ingredient

An apparatus, system, and method are disclosed for making sandwiches. A bladeless sandwich making apparatus is provided with lower and upper tools having sandwich receiving cavities configured to accommodate sandwich ingredients and a mechanism for mounting configured to operate as a hinge and as a handle. Bread layers and filling may be placed within the apparatus in an open position. A filling material cup may be used for filling preparation. Beneficially, the apparatus may include an impression bar or plate to imprint design on an outer sandwich surface or for sandwich separation. The upper tool is configured to engage the lower tool to remove sandwich crusts and seal sandwich edges. The crustless sandwich with sealed edges may be consumed, stored, or heated. A method is disclosed for making sandwiches without crusts and sealed edges with or without designs on the sandwich surface.

Owner:EKBERG LANE +2

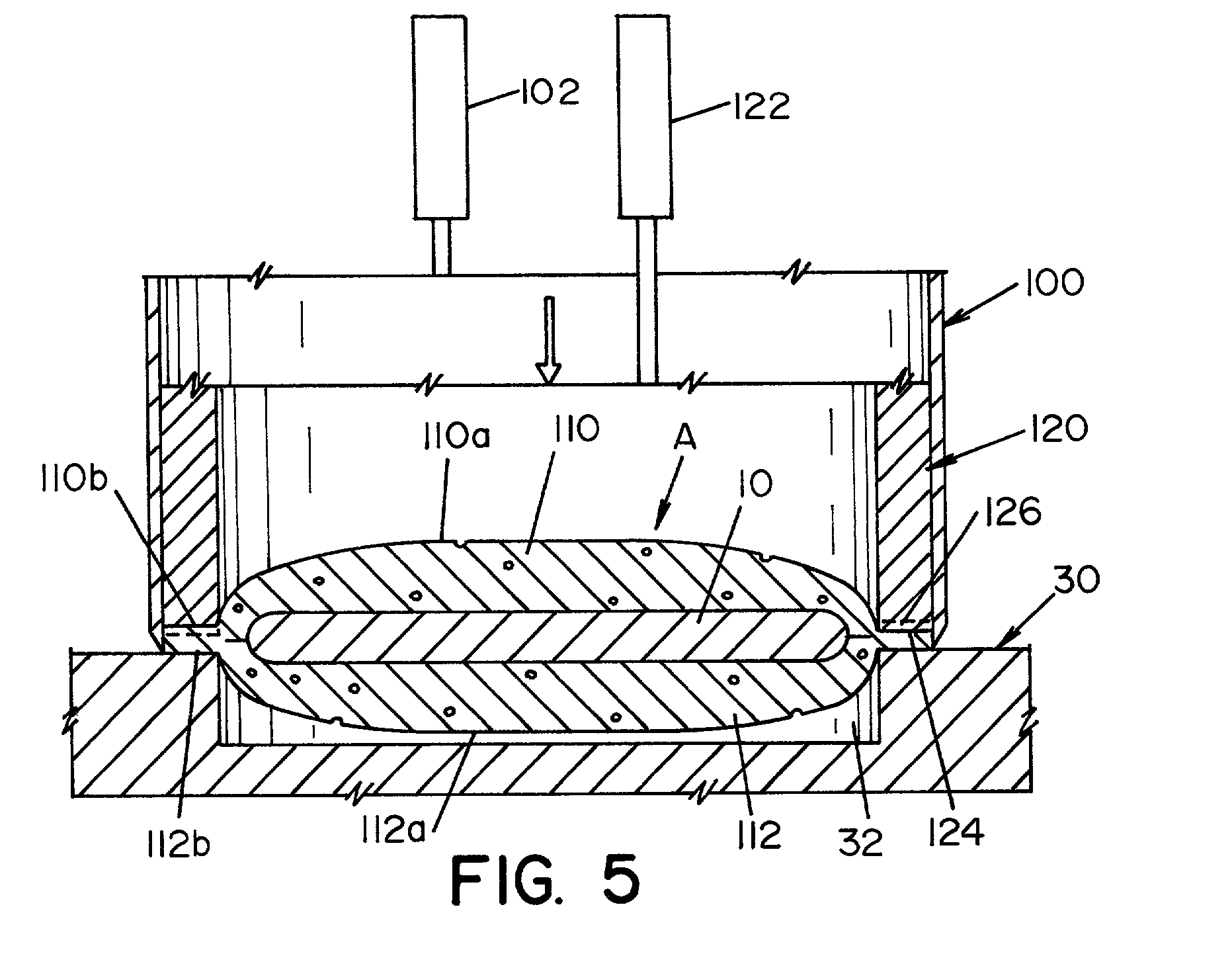

Frozen sandwich and method of making same

InactiveUS20030008037A1Affect resultPositively lockingConfectioneryPreservation by coolingBiomedical engineeringEdge region

A frozen sandwich for commercial sales comprising a first portion of bread cut from a first slice of crusted bread. This first portion has an outer surface, a given periphery and a center area surrounded by a marginal area. A layer of unmelted solid cheese is deposited on the center area and is spaced inwardly from the marginal area. A second portion of bread cut from a second slice of crusted bread and overlying the first portion and the layer of cheese has an outer surface, a periphery generally matching the periphery of the first portion and a marginal area generally matching and coextensive with the marginal area of the first portion. The marginal areas are smashed together sufficiently to form a seal generally matching the peripheries of the bread portions. The surfaces of the bread portions are heat scorched to transform a thin skin of the portions into toasted bread.

Owner:THE J M SMUCKER CO

Composite frozen confections

InactiveCN101170908AAct as an adhesiveGreat tasteBakery product recyclingFrozen sweetsParticulatesButter cocoa

A reformed biscuit product suitable for forming composite frozen compositions comprises a solid mixture of a particulate cooked biscuit material and a cocoa butter equivalent type of confectionery fat is described; the process for manufacturing it comprises coating the particles with the fat, compacting the mixture of particulate biscuit and fat in an agglomerate of the shape of a receptacle or coating and maintaining the shape of the compacted mixture by solidification of the fat; also described is a process for manufacturing a composite frozen confection comprising a reformed biscuit product formed into a cone containing ice cream.

Owner:NESTEC SA

Process and apparatus for forming a wave chip product

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Apparatus and method for producing sandwich cookie having dissimilarly-sized base cakes

A cookie cup sandwich cookie having dissimilarly-sized base cakes is continuously produced by applying a layer of filler cream to a lower base cake and applying an upper base cake to the lower base cake so that the outer periphery of the upper base cake surrounds the layer of filler cream. The apparatus for the production of the sandwich cookies includes at least one rotary molder for producing lower base cakes and upper base cakes having different sizes, a filler cream depositor that deposits a layer of filler cream on each of the lower base cakes, and a conveyer system for transporting and at least substantially concentrically aligning the dissimilarly sized lower and upper base cakes.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

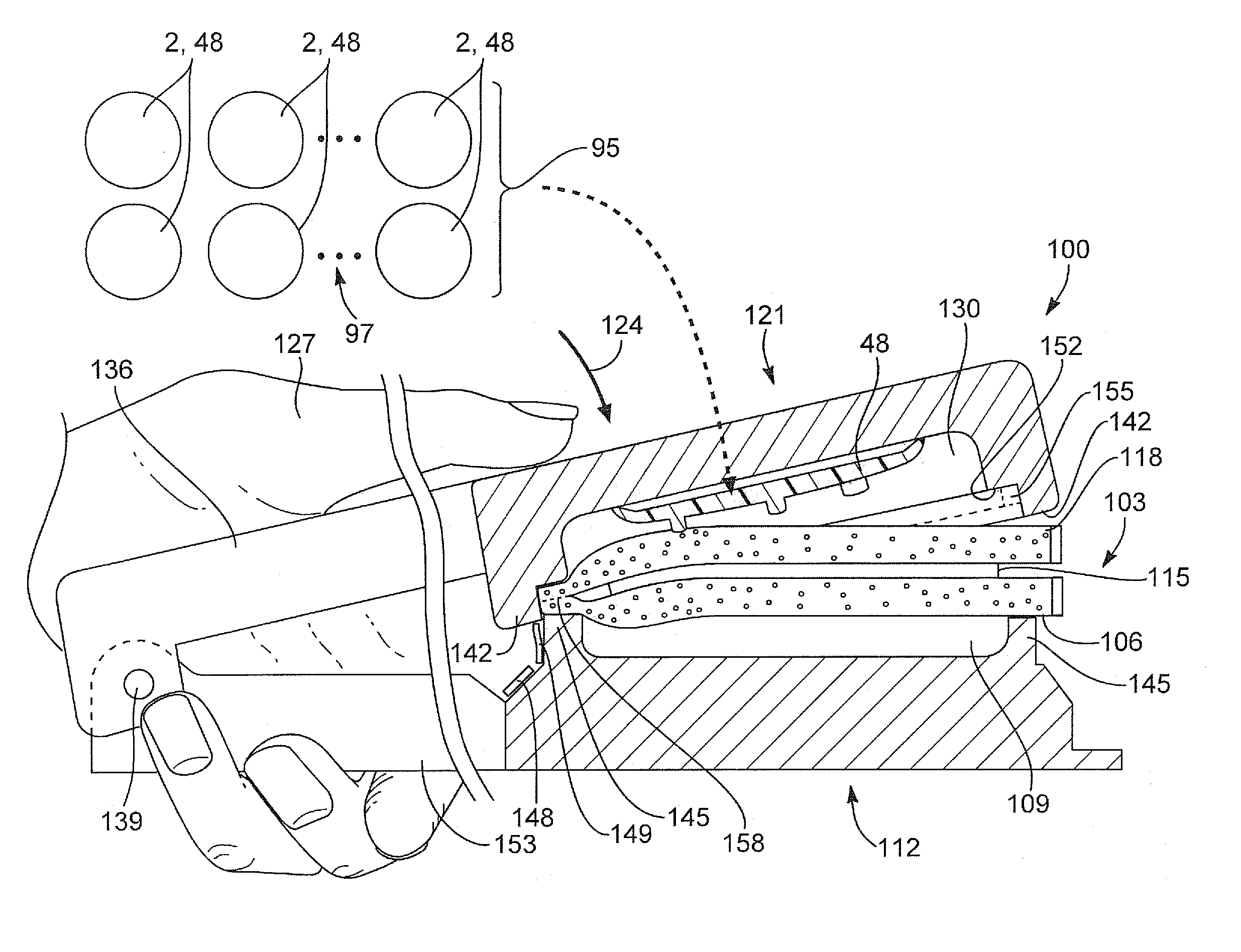

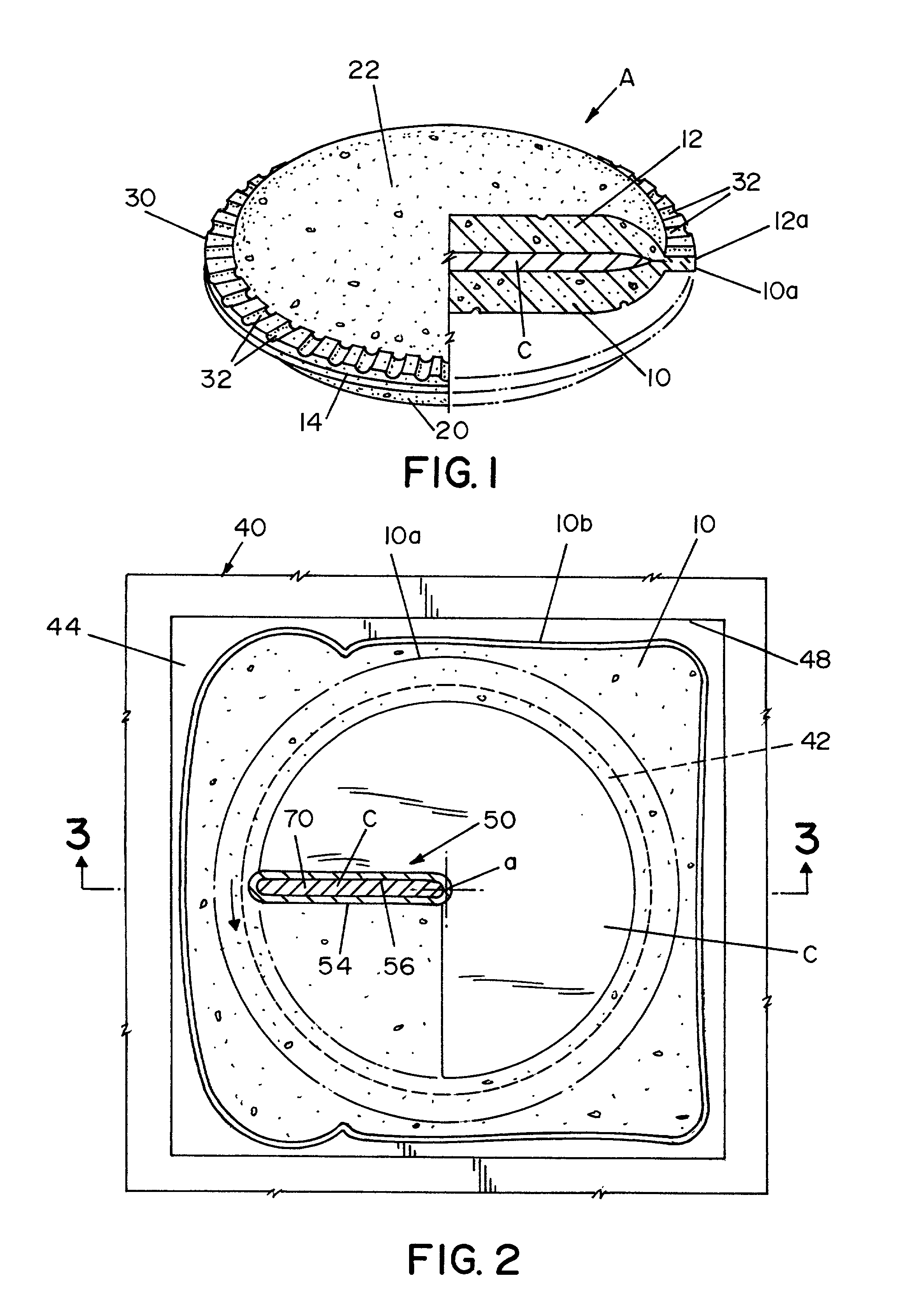

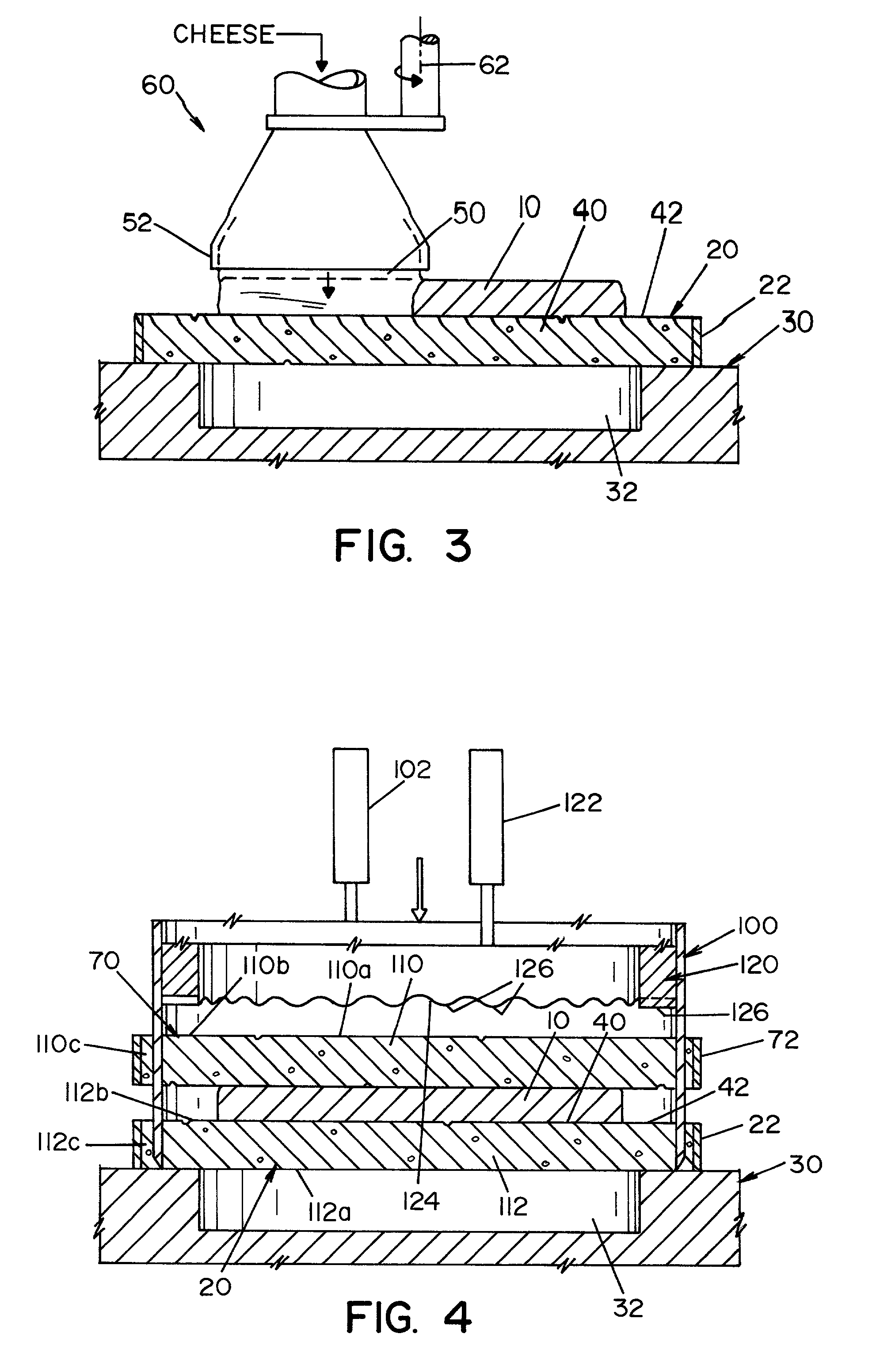

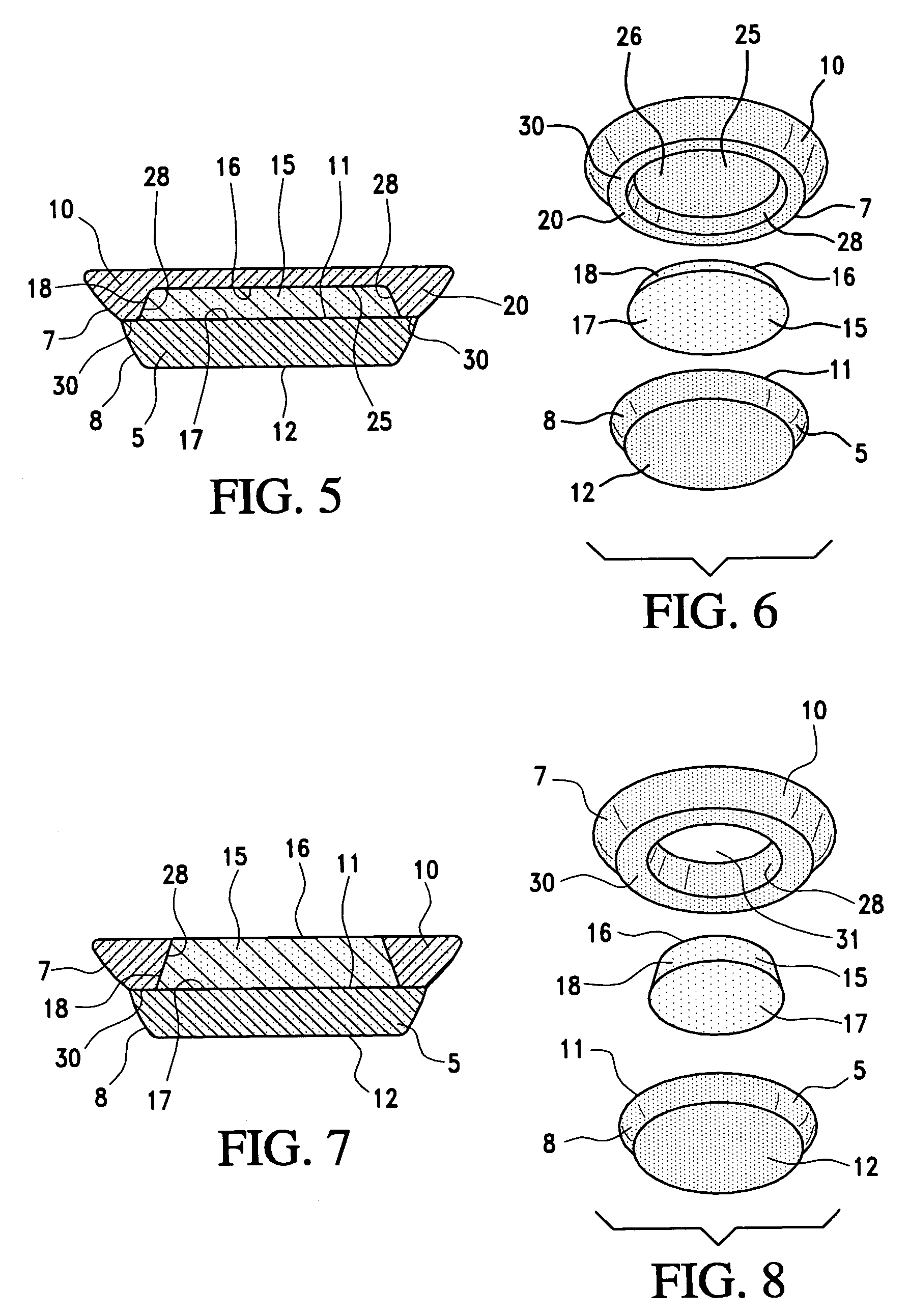

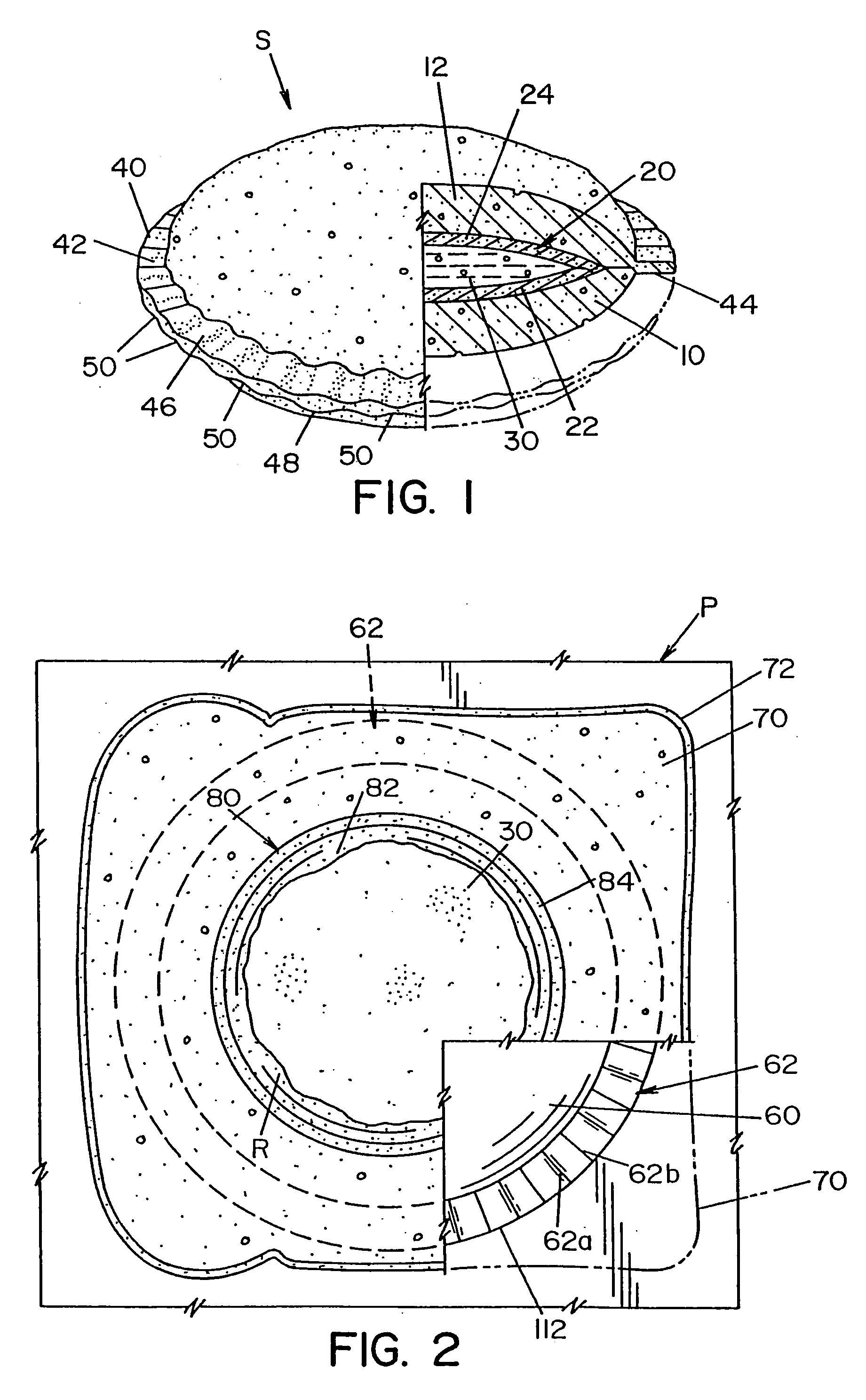

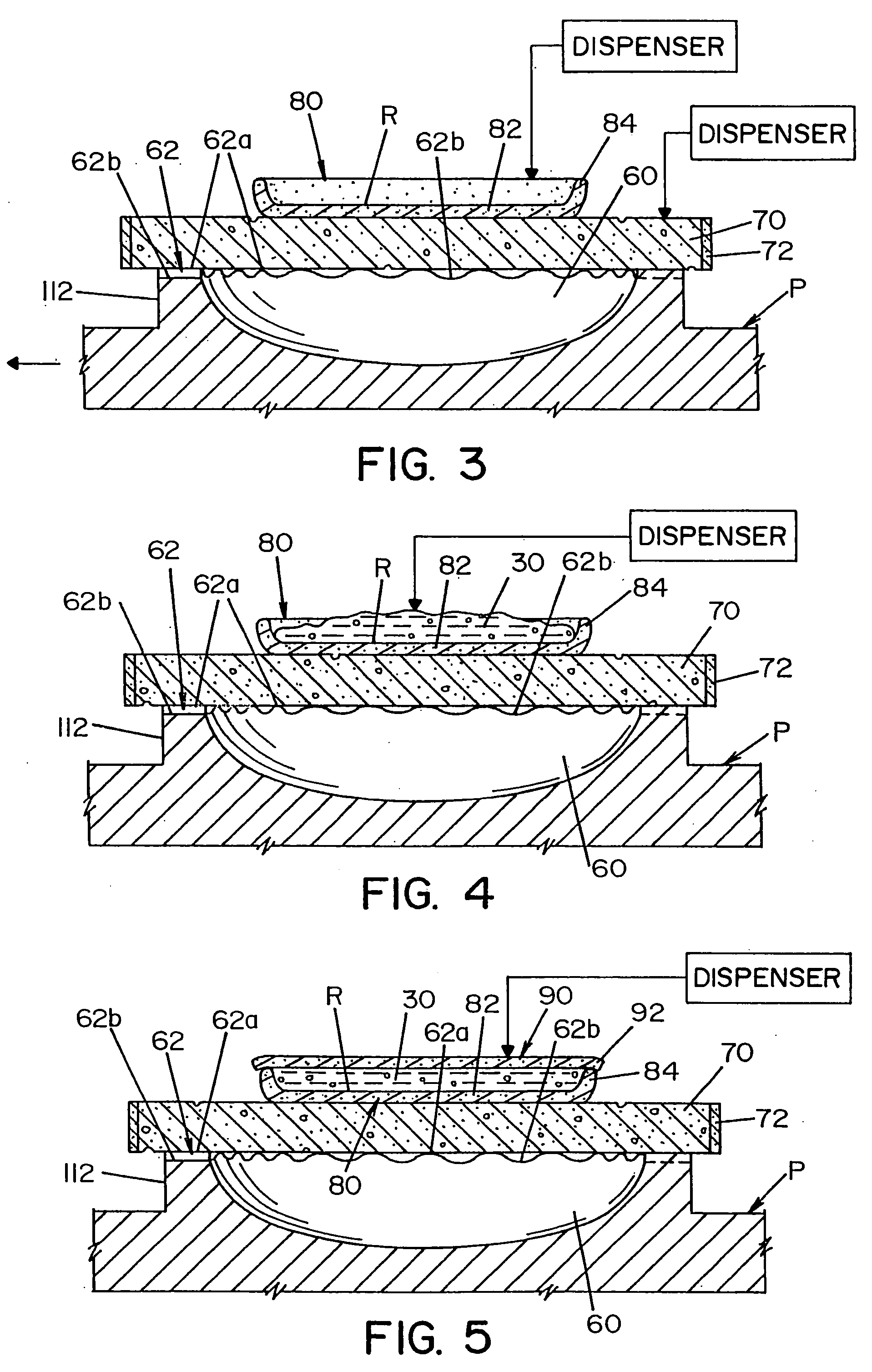

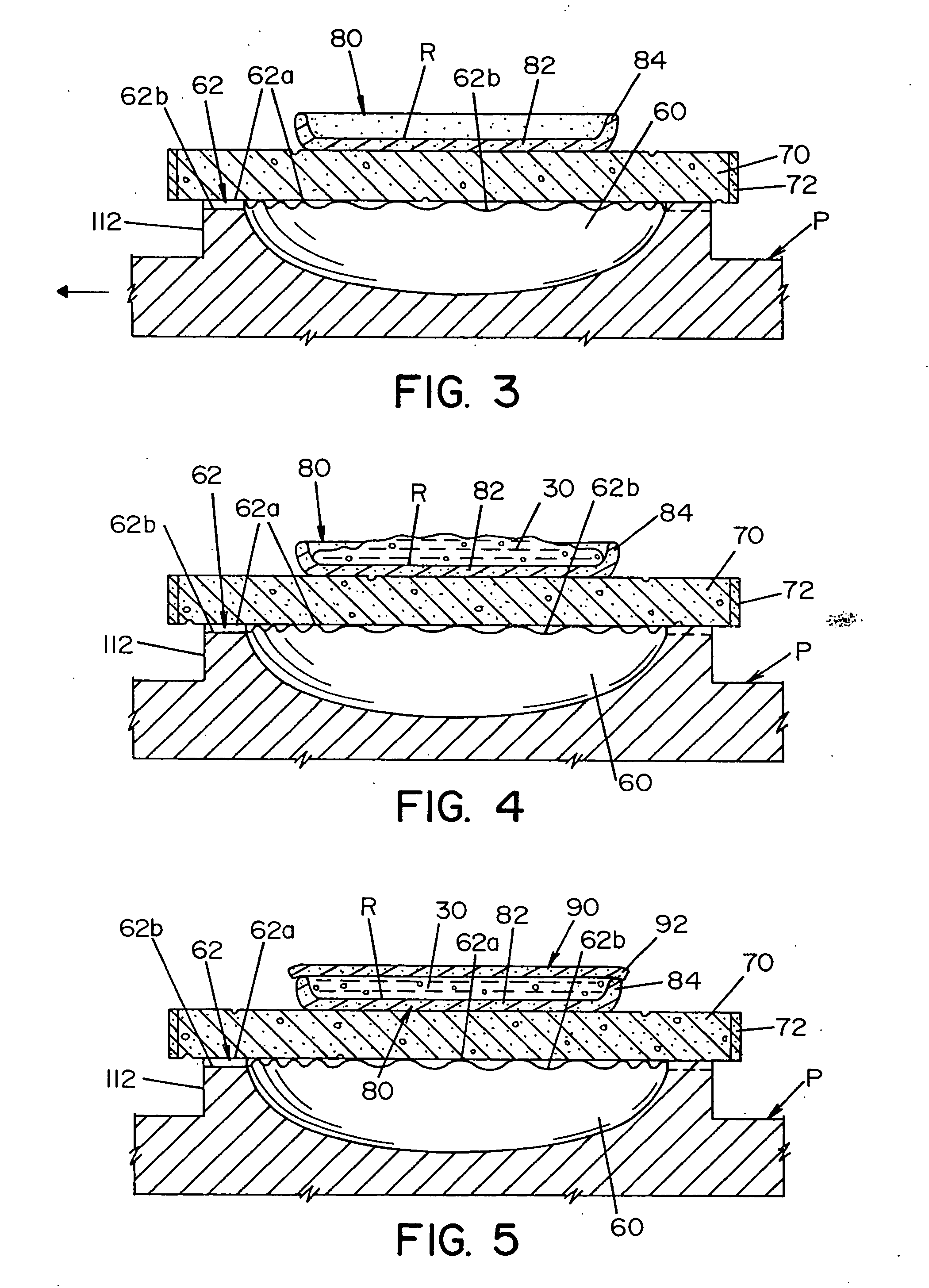

Method and apparatus for making commercial crustless sandwiches and the crustless sandwich made thereby

InactiveUS20060073246A1Small sizeBakery productsBaked wafer shaping/mouldingEngineeringMechanical engineering

A method of making a crustless sandwich from two slices of bread with outer crusts, the method comprising: placing a first slice of bread on a platen; forming a mass of a first food spread onto the central portion of the first slice of bread in a position spaced inwardly from a marginal area where the mass is formed with an inner lower layer with an outer rim extending upwardly from the lower layer to define a closed pocket or receptacle recess in the mass; placing a second food spread in the receptacle recess; closing the receptacle recess with a layer of the first food spread generally coextensive with the mass and supported on the outer rim of the mass to encapsulate the second food spread into a center composite food layer; placing a second slice of bread over the first slice to cover the center composite food layer; cutting the bread slices in unison in a cut pattern to remove the crusts of the slices; and, pressing the two bread slices together by force through the slices against a pressure surface on the platen to crimp the slices into a crustless sandwich.

Owner:THE J M SMUCKER CO

Method and apparatus for making commercial crustless sandwiches and the crustless sandwich made thereby

InactiveUS20040180115A1Quality improvementPrevent undesired seepageConfectionerySweetmeatsMechanical engineeringManufacturing engineering

A method of making a crustless sandwich from two slices of bread with outer crusts, the method comprising: placing a first slice of bread on a platen; forming a mass of a first food spread onto the central portion of the first slice of bread in a position spaced inwardly from a marginal area where the mass is formed with an inner lower layer with an outer rim extending upwardly from the lower layer to define a closed pocket or receptacle recess in the mass; placing a second food spread in the receptacle recess; closing the receptacle recess with a layer of the first food spread generally coextensive with the mass and supported on the outer rim of the mass to encapsulate the second food spread into a center composite food layer; placing a second slice of bread over the first slice to cover the center composite food layer; cutting the bread slices in unison in a cut pattern to remove the crusts of the slices; and, pressing the two bread slices together by force through the slices against a pressure surface on the platen to crimp the slices into a crustless sandwich.

Owner:THE J M SMUCKER CO

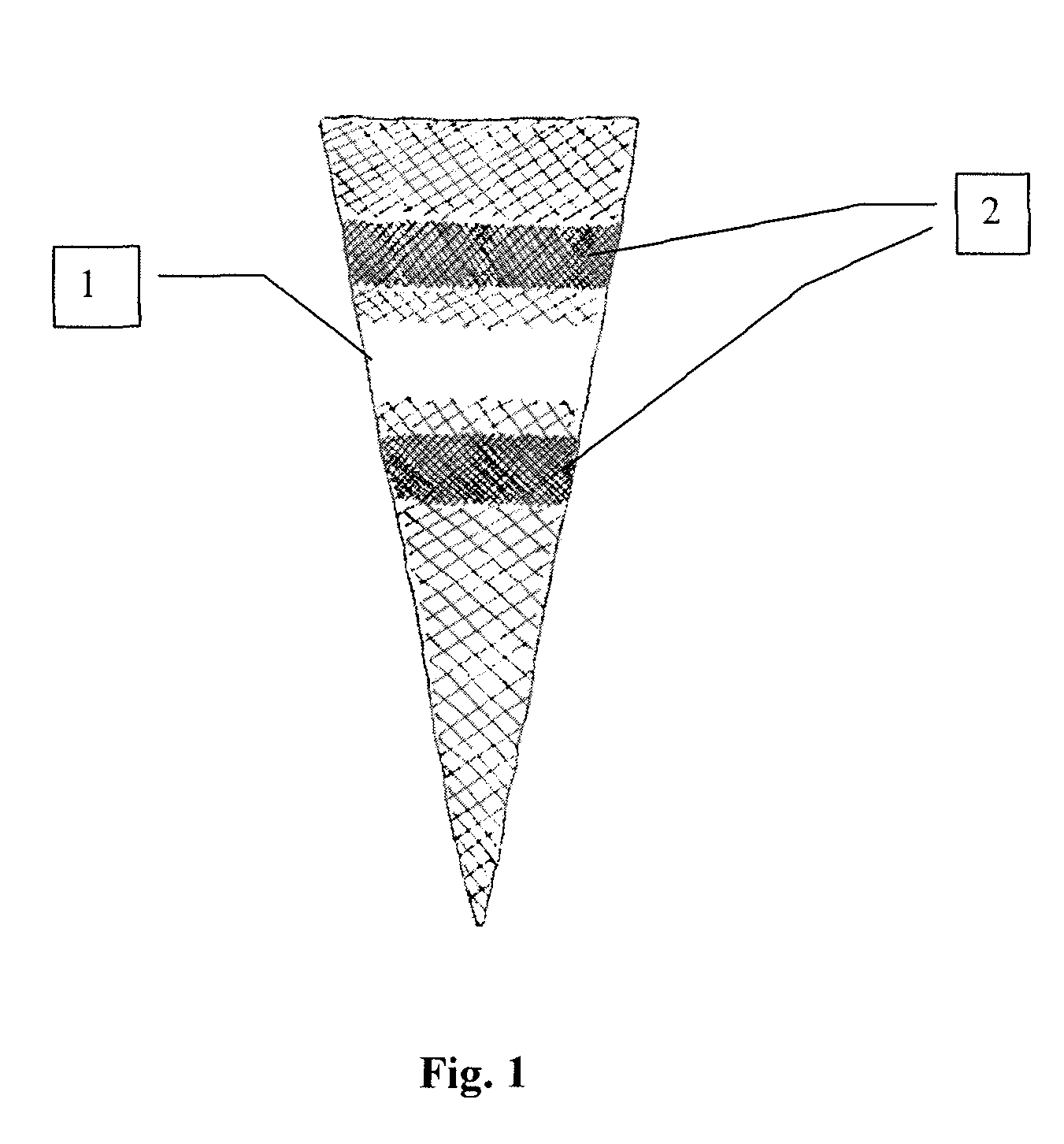

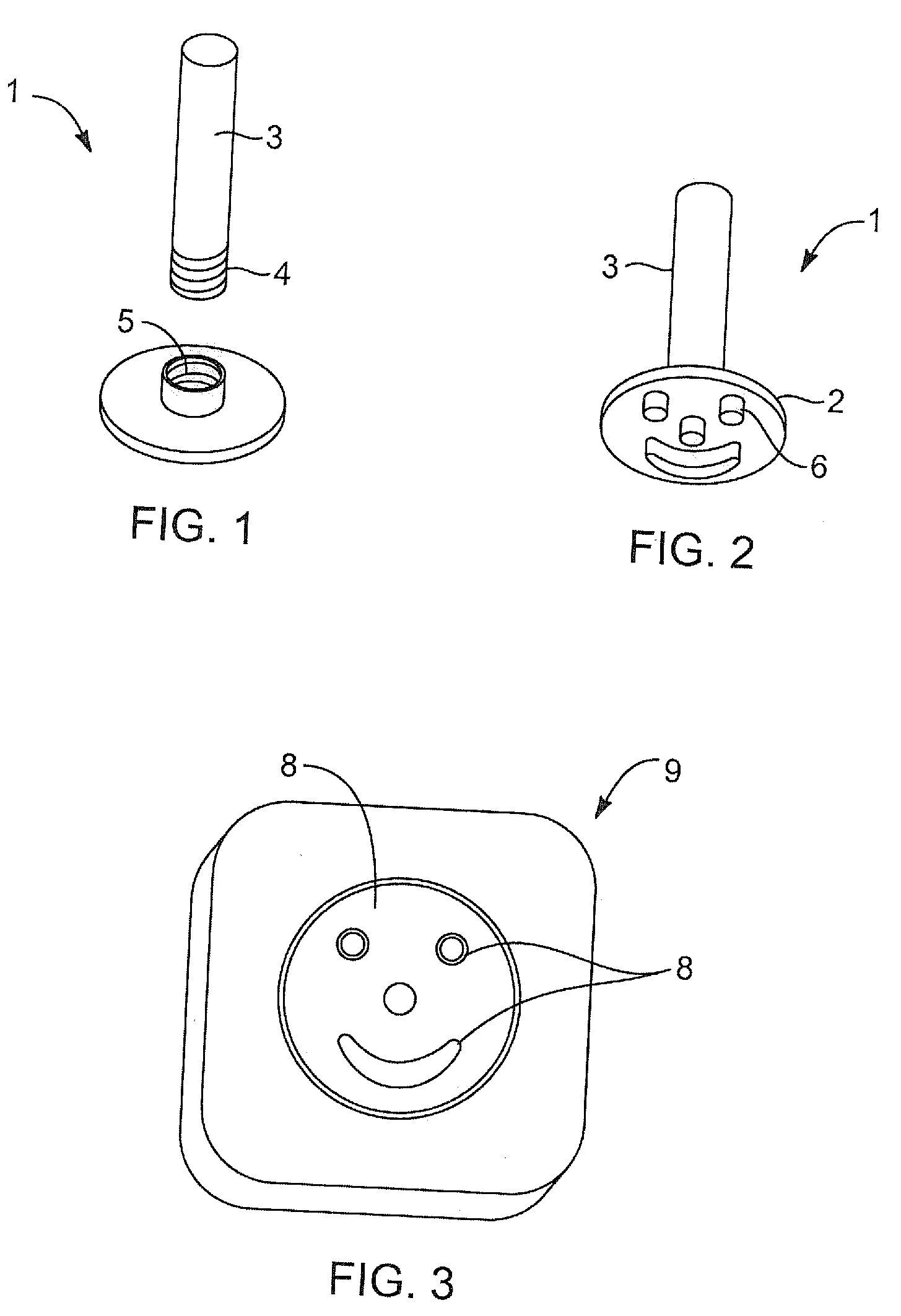

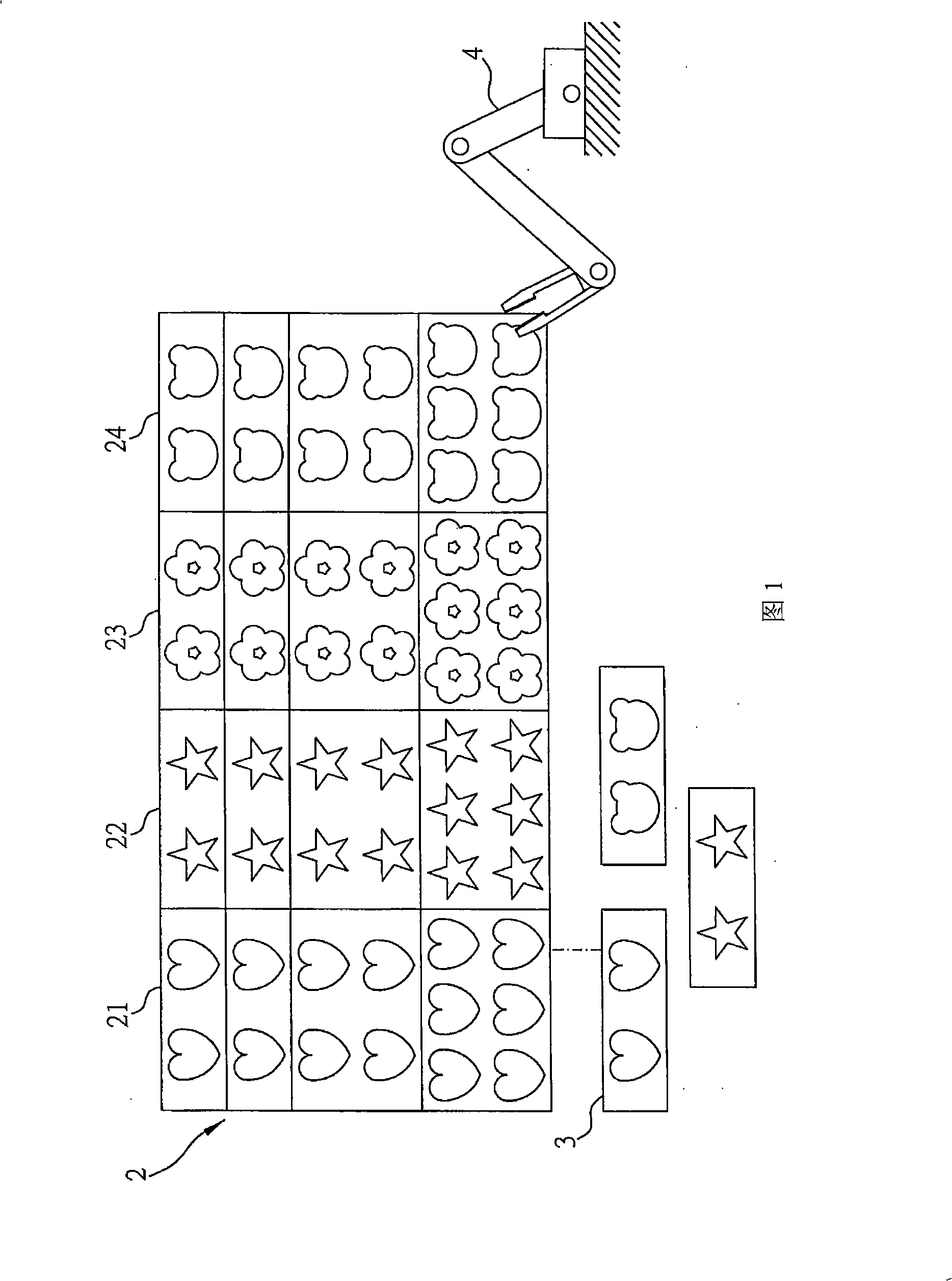

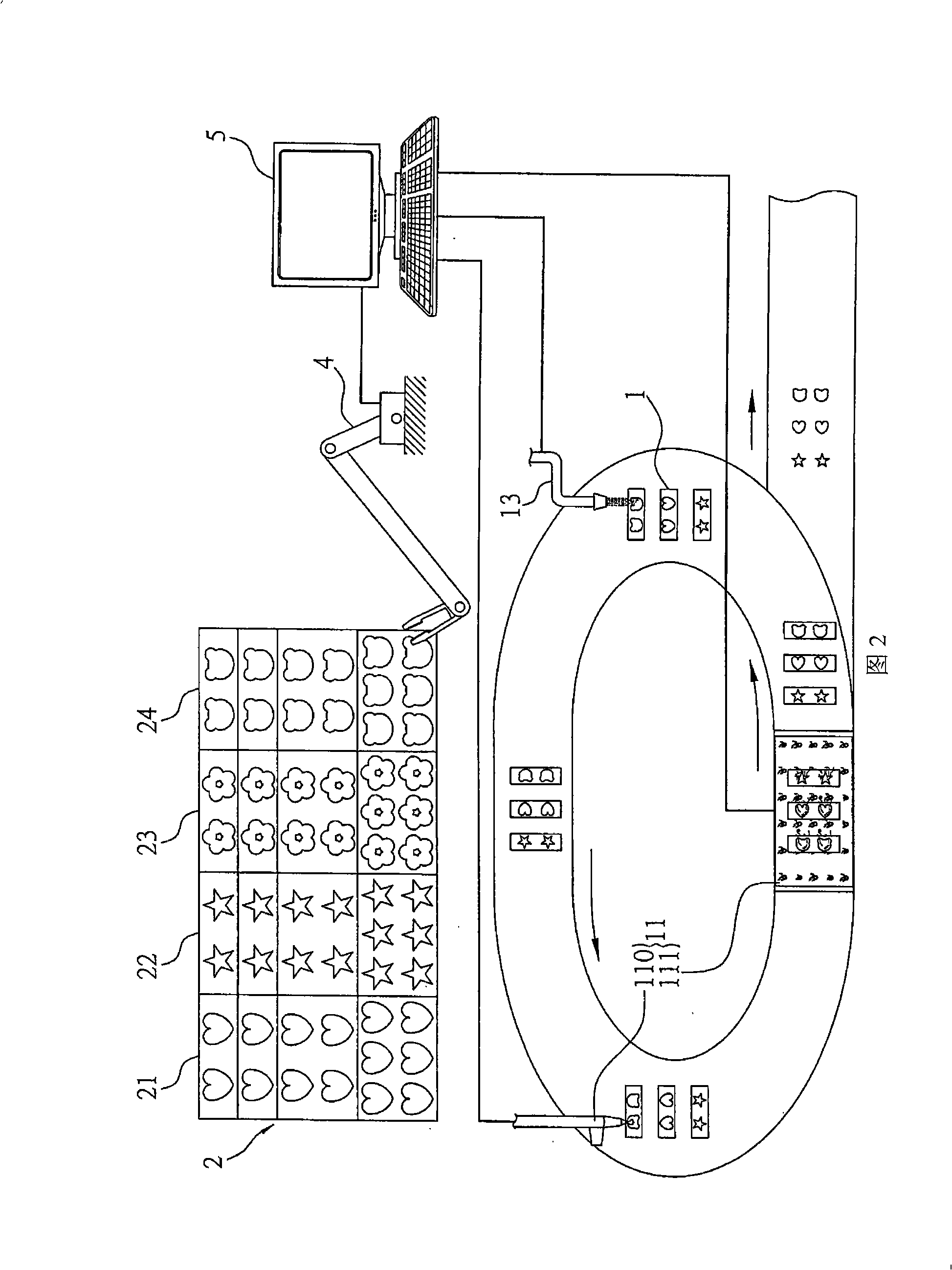

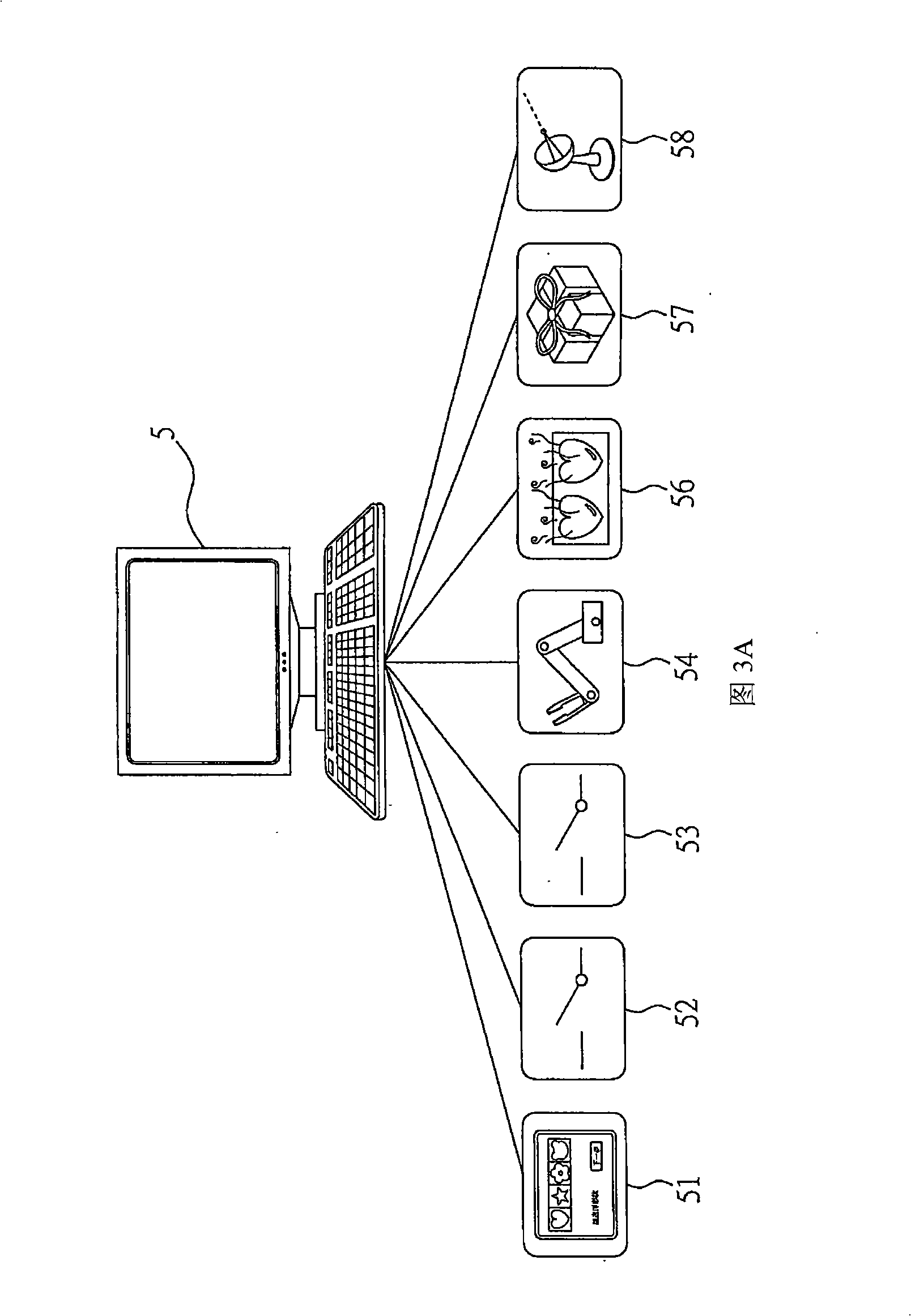

Food forming device and foods producing system having the device

InactiveCN101268788AFully enjoy the fun of customizationIncrease desire to buyBaked wafer shaping/mouldingFood materialEngineering

The invention discloses a food production system used for shaping the appearance of food. The system comprises a food molding device which comprises a mould unit provided with a plurality of moulds, and a mould replacing unit used for moving out of and in the moulds from the mould unit, a molding unit used for filling food raw materials in the mould and solidifying and molding, and a control unit producing food by the procedure. The food production system of the invention has automation equipment and can rapidly produce food, and can keep the quality of the food.

Owner:IND TECH RES INST

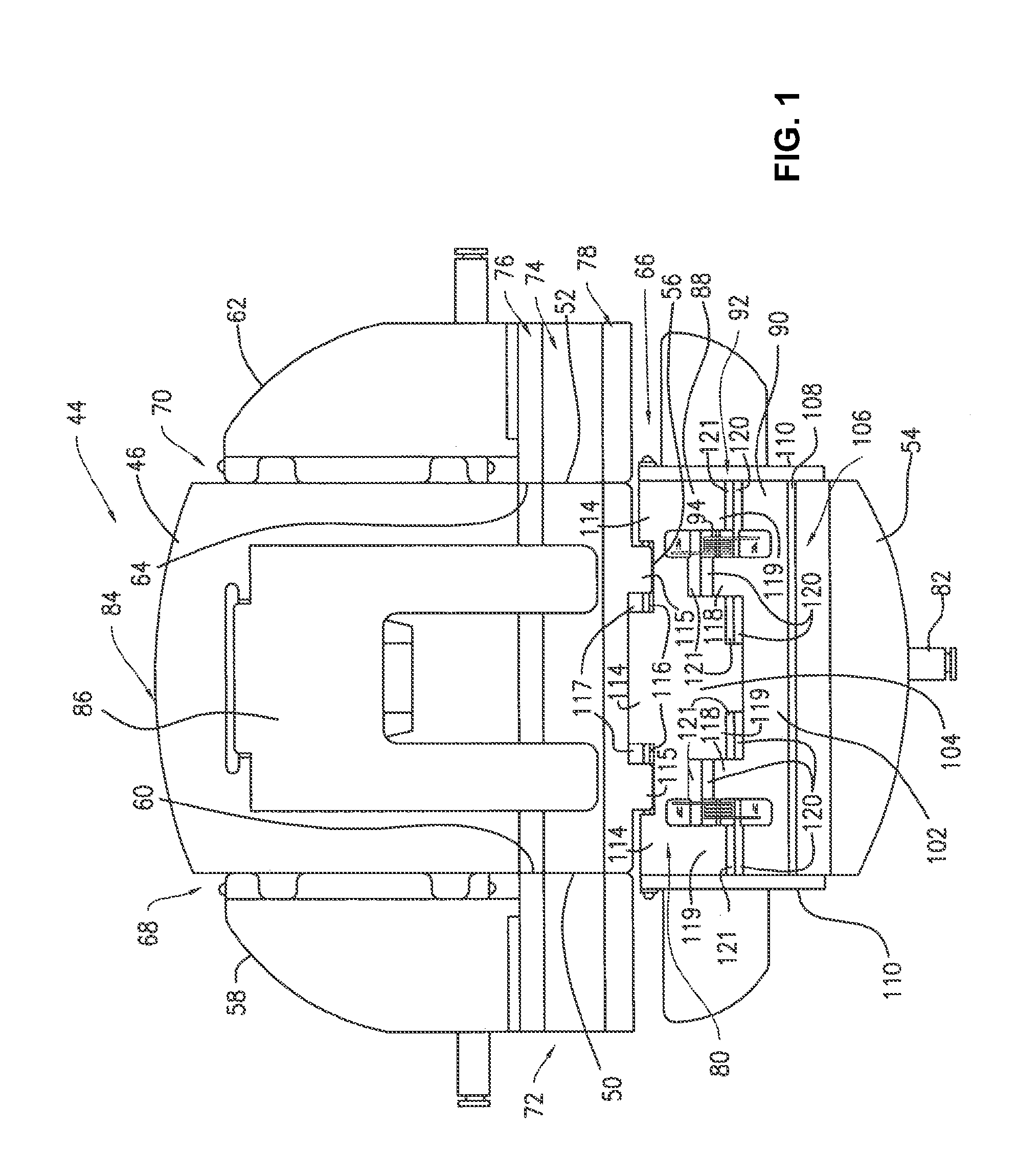

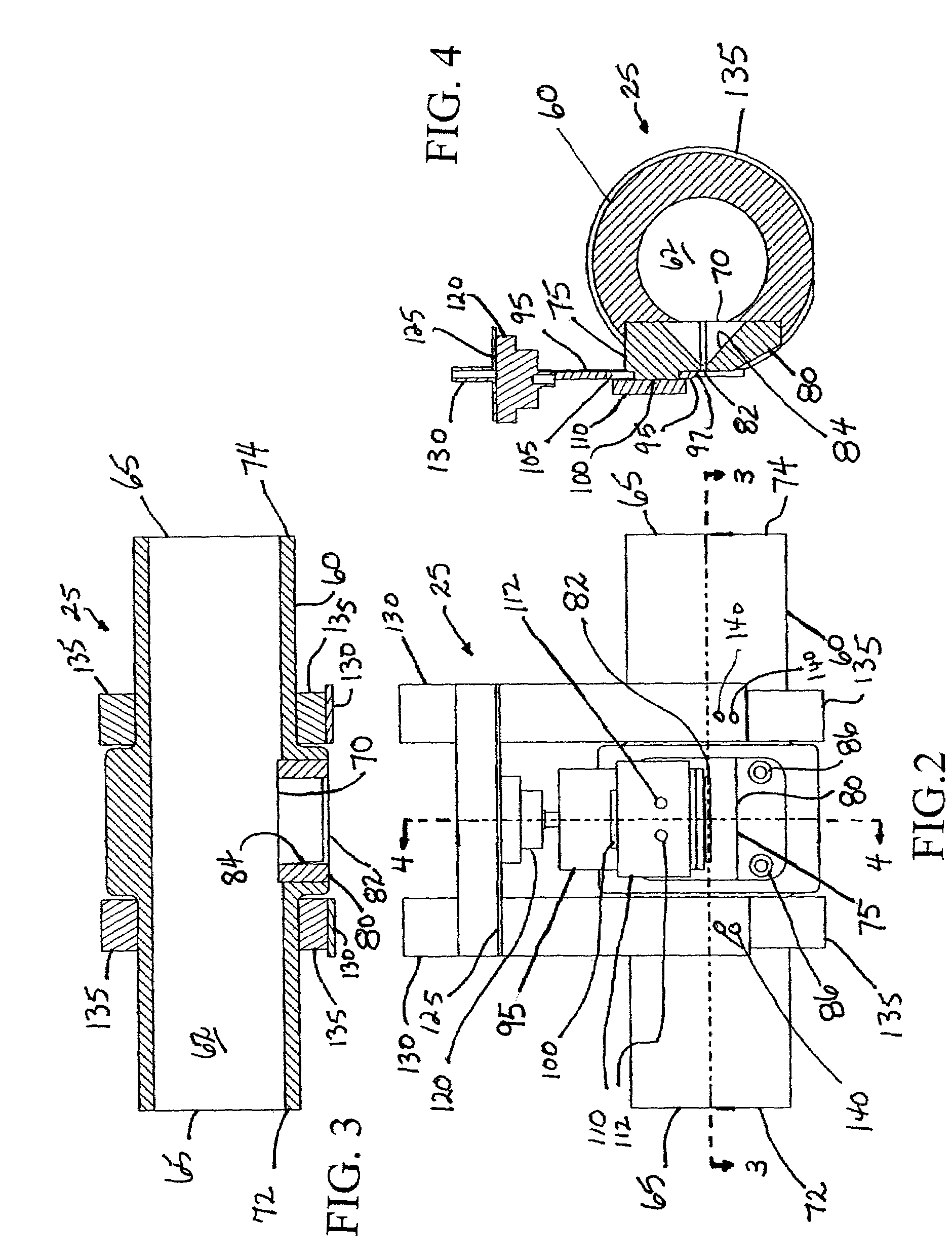

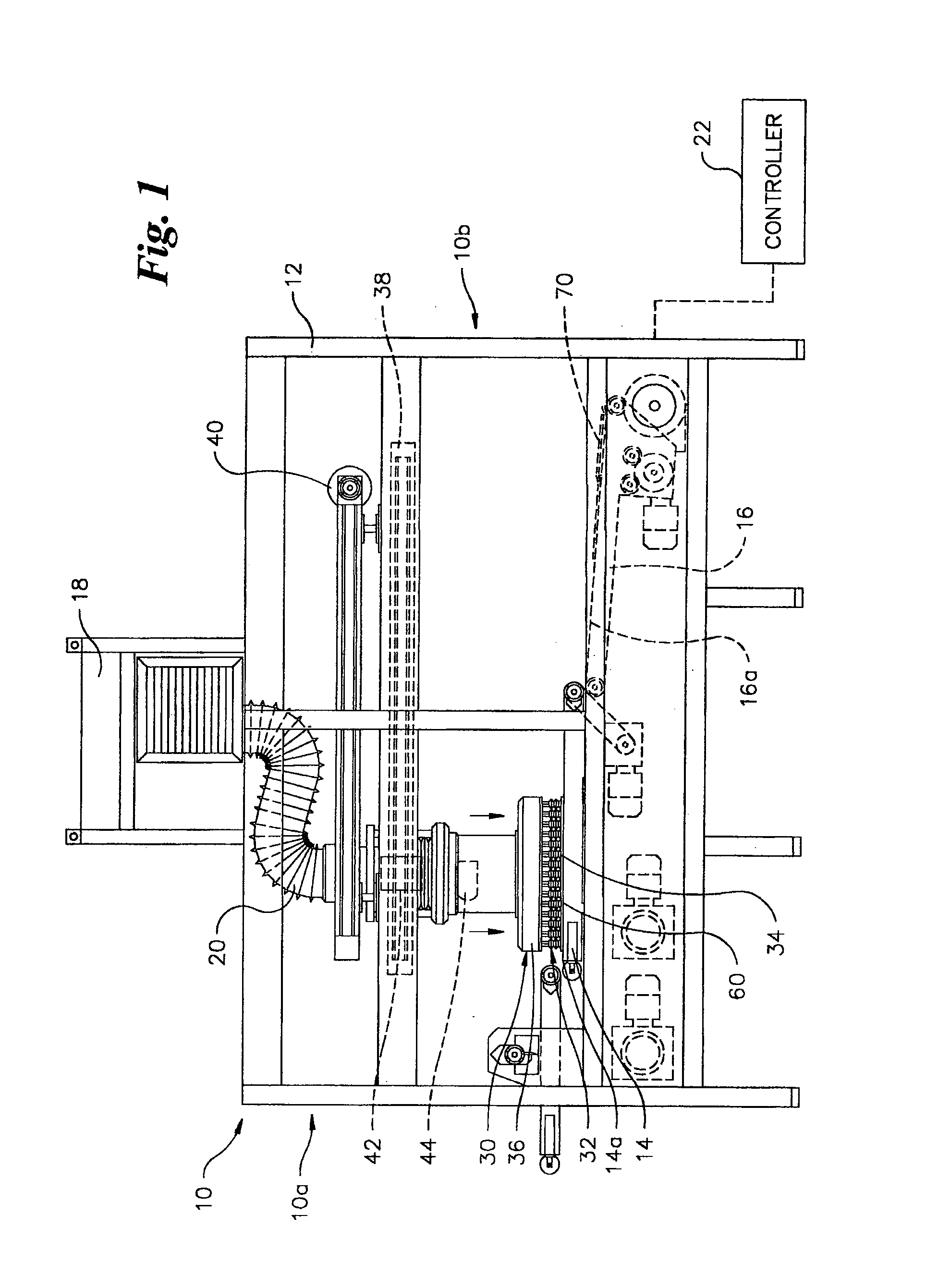

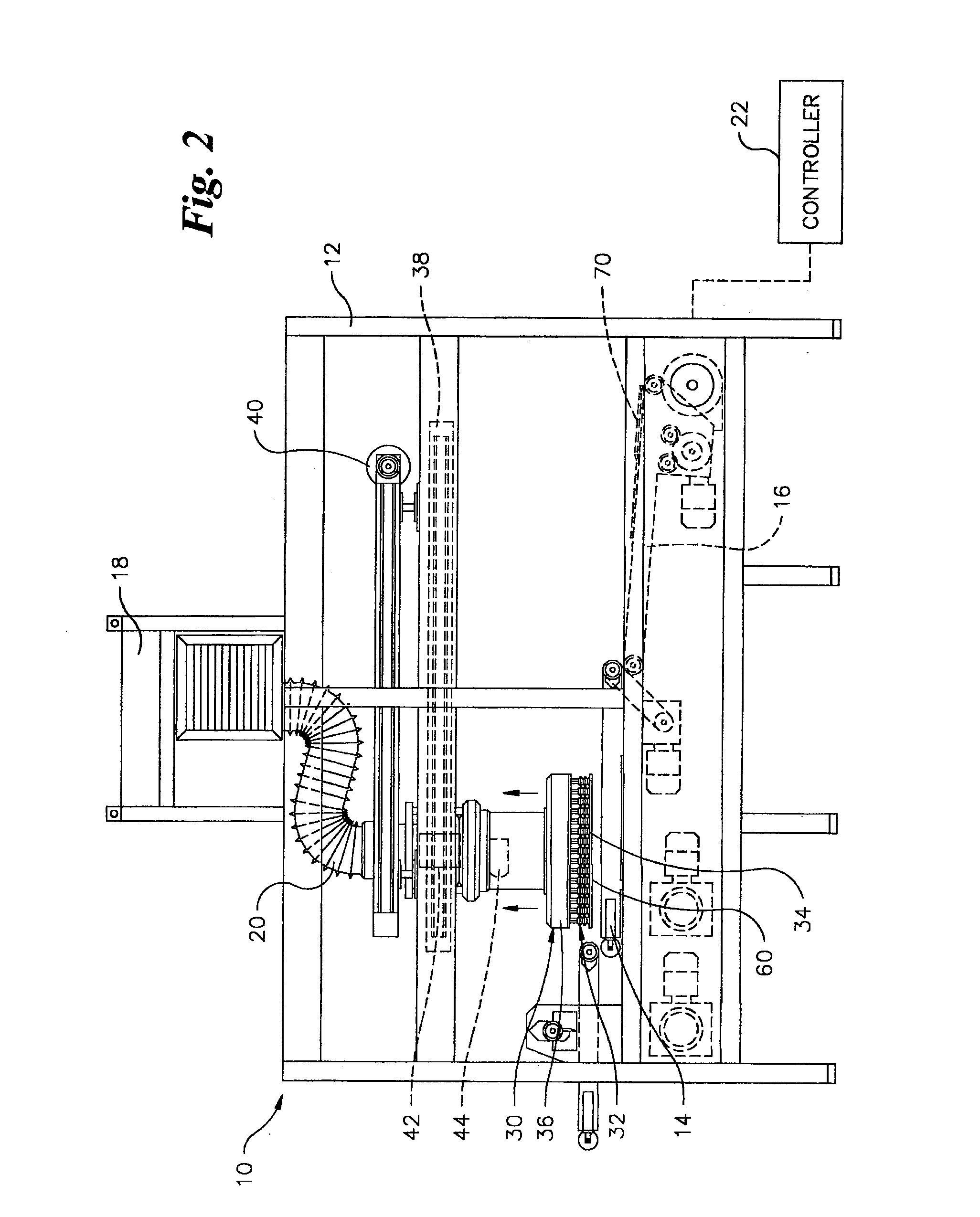

Product de-topper

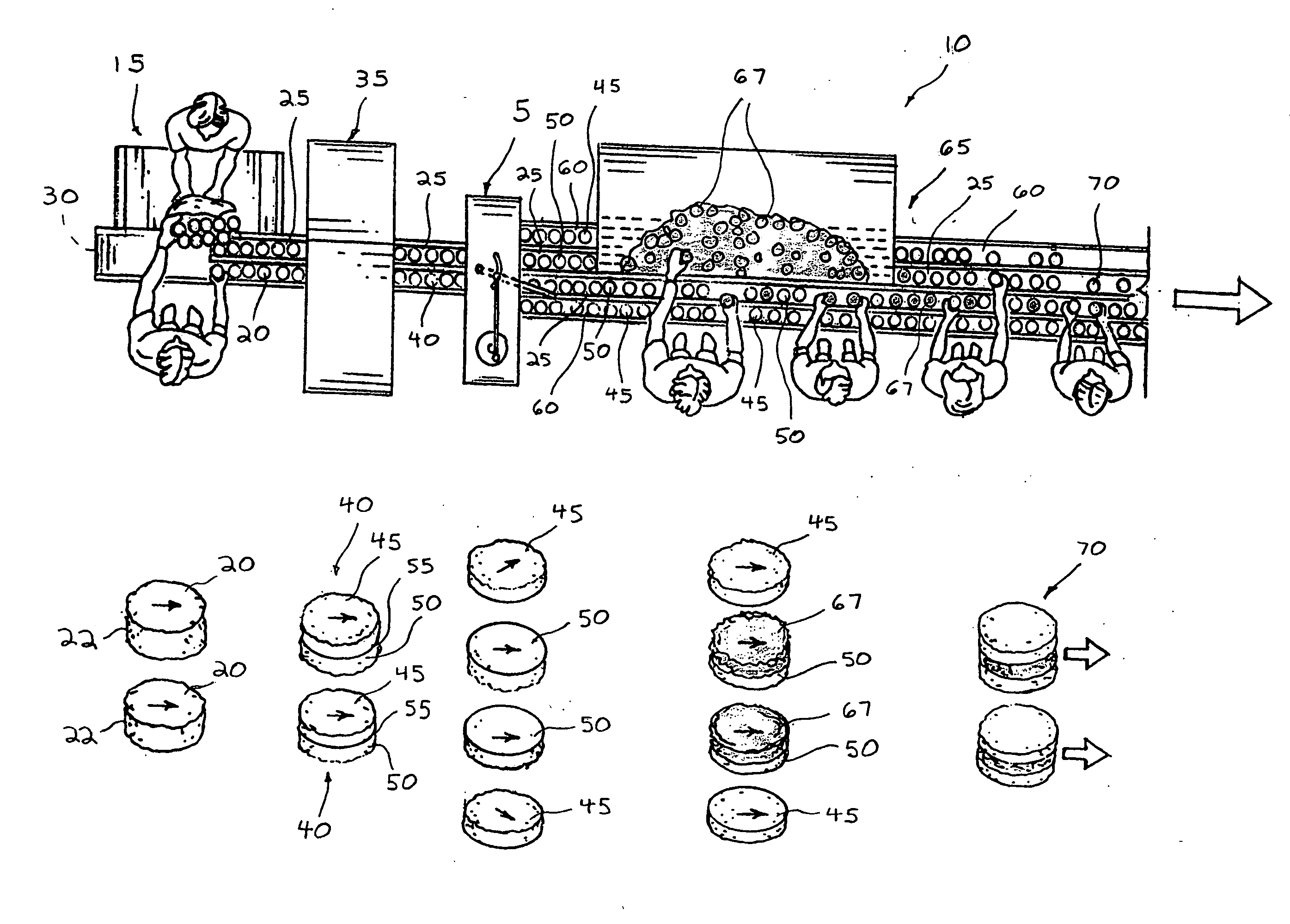

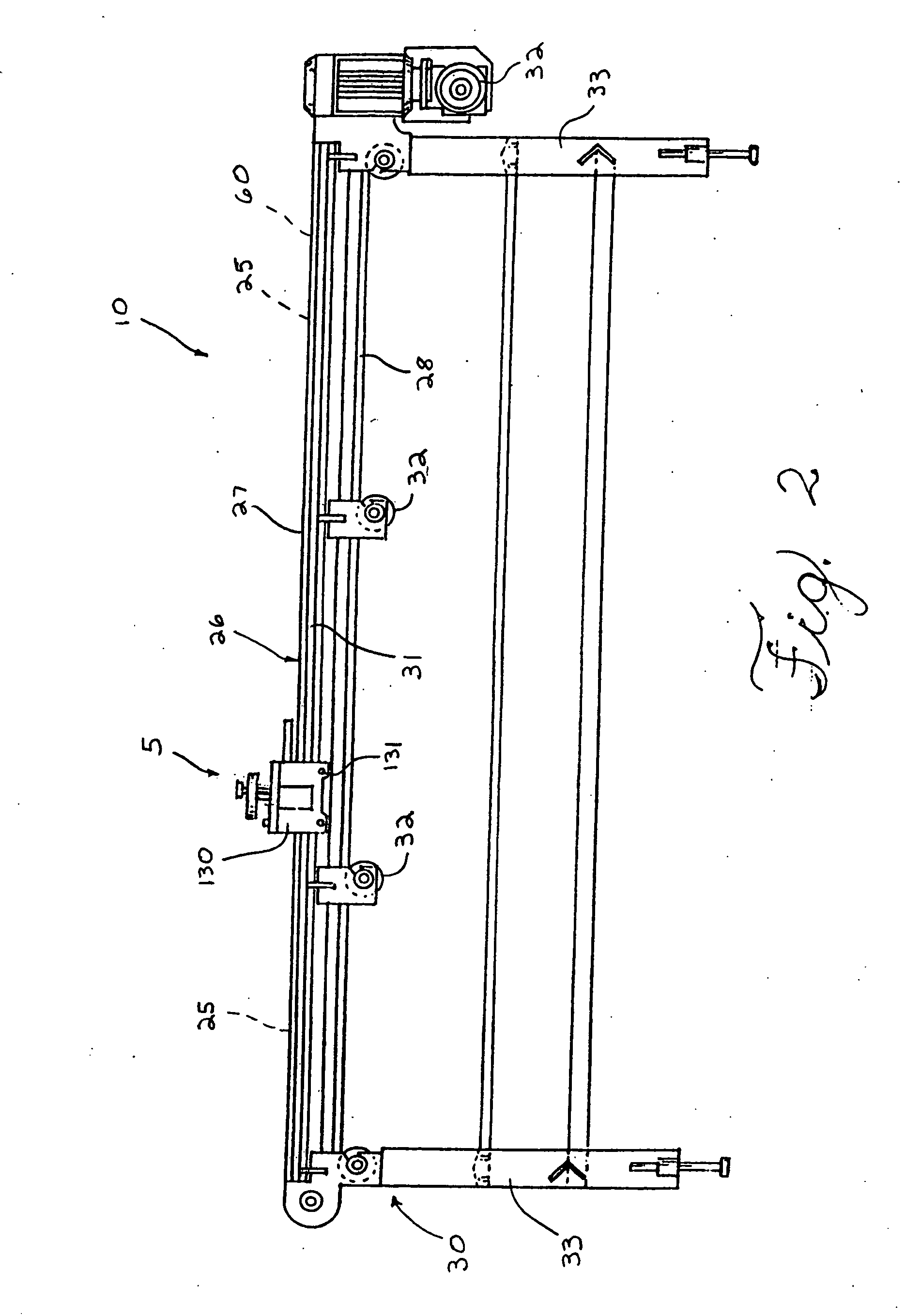

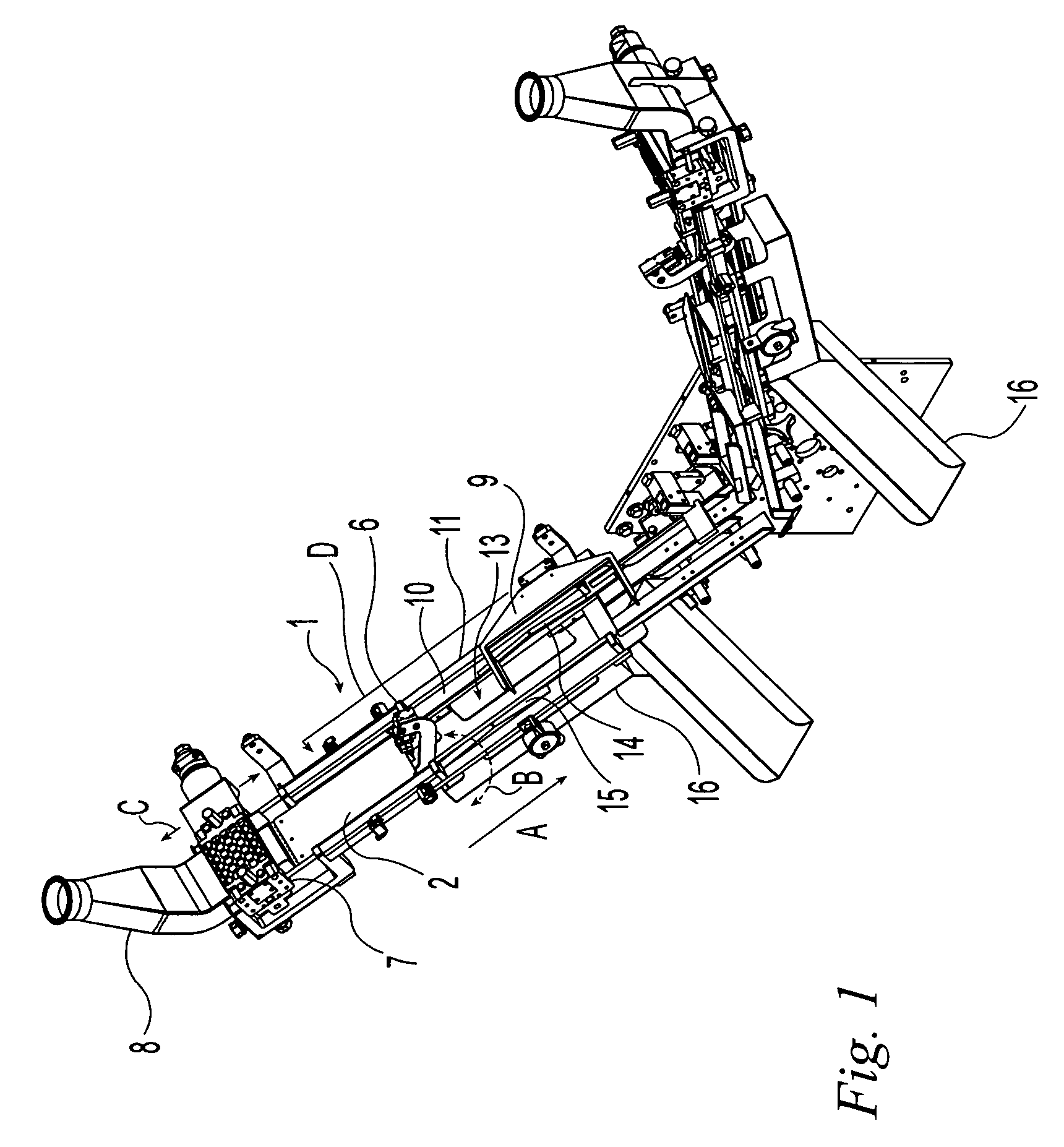

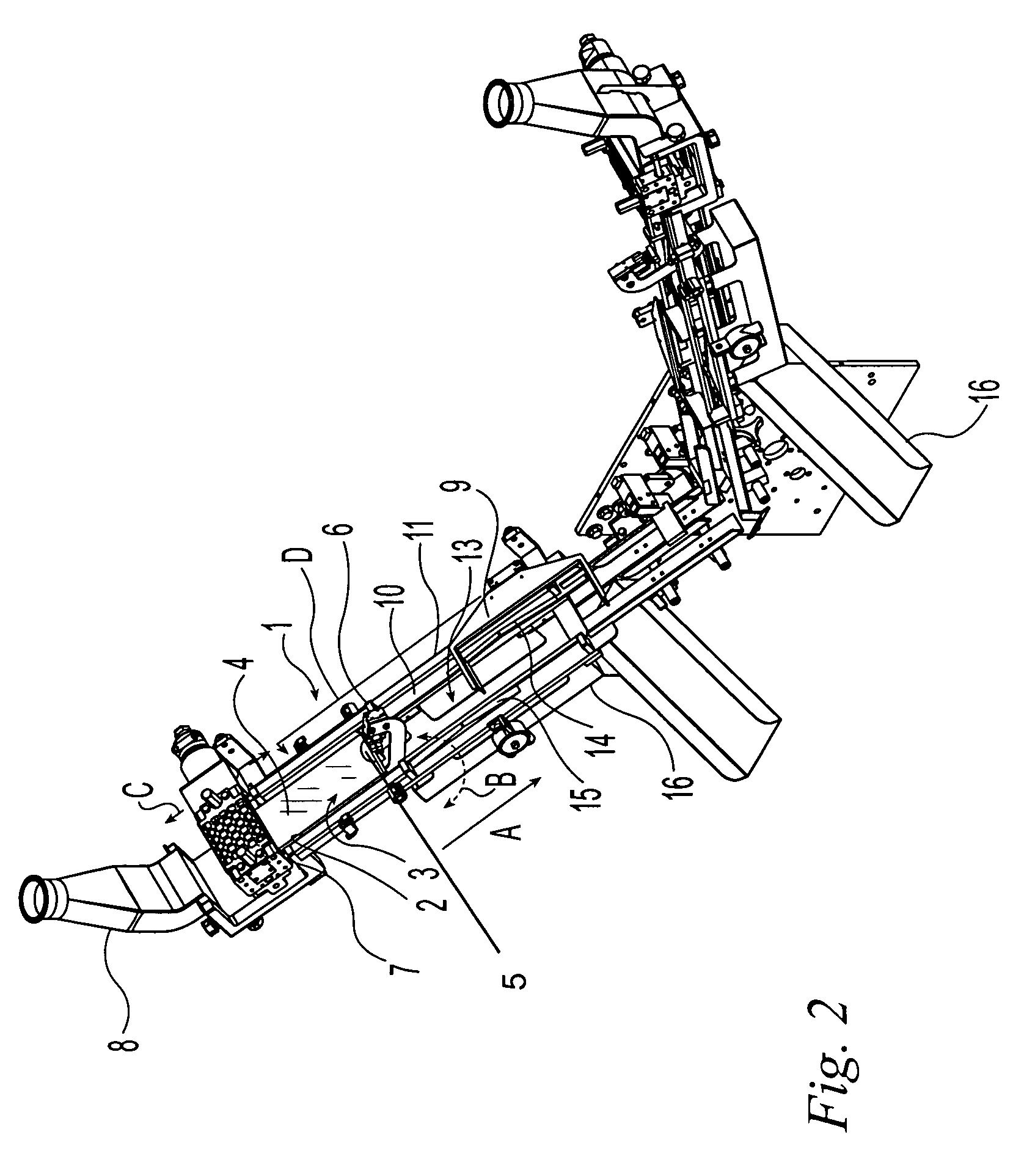

InactiveUS20070084698A1Facilitates desired partingEasy to separateFruit stoningFood shapingReciprocating motionLower upper

The present invention relates to equipment for assembling food products, and more specifically to an apparatus and method for separating or parting stacked food products during a food production process. The invention, a de-topper, facilitates the desired parting or separation of stacked products having at least upper and lower sections defining a separation line. In parting stacked products along the separation line, the de-topper comprises a longitudinal arm and at least one primary conveying path for conveying the at least upper and lower sections of the stacked products towards the arm. A drive reciprocates the arm so that the reciprocating arm sweeps the upper sections of the stacked products from the at least one primary conveying path and onto a secondary conveying path, located outwardly thereof. The lower and upper sections are thereafter conveyed on the respective primary and secondary conveying paths away from the reciprocating longitudinal arm.

Owner:AUBRY LARRY +2

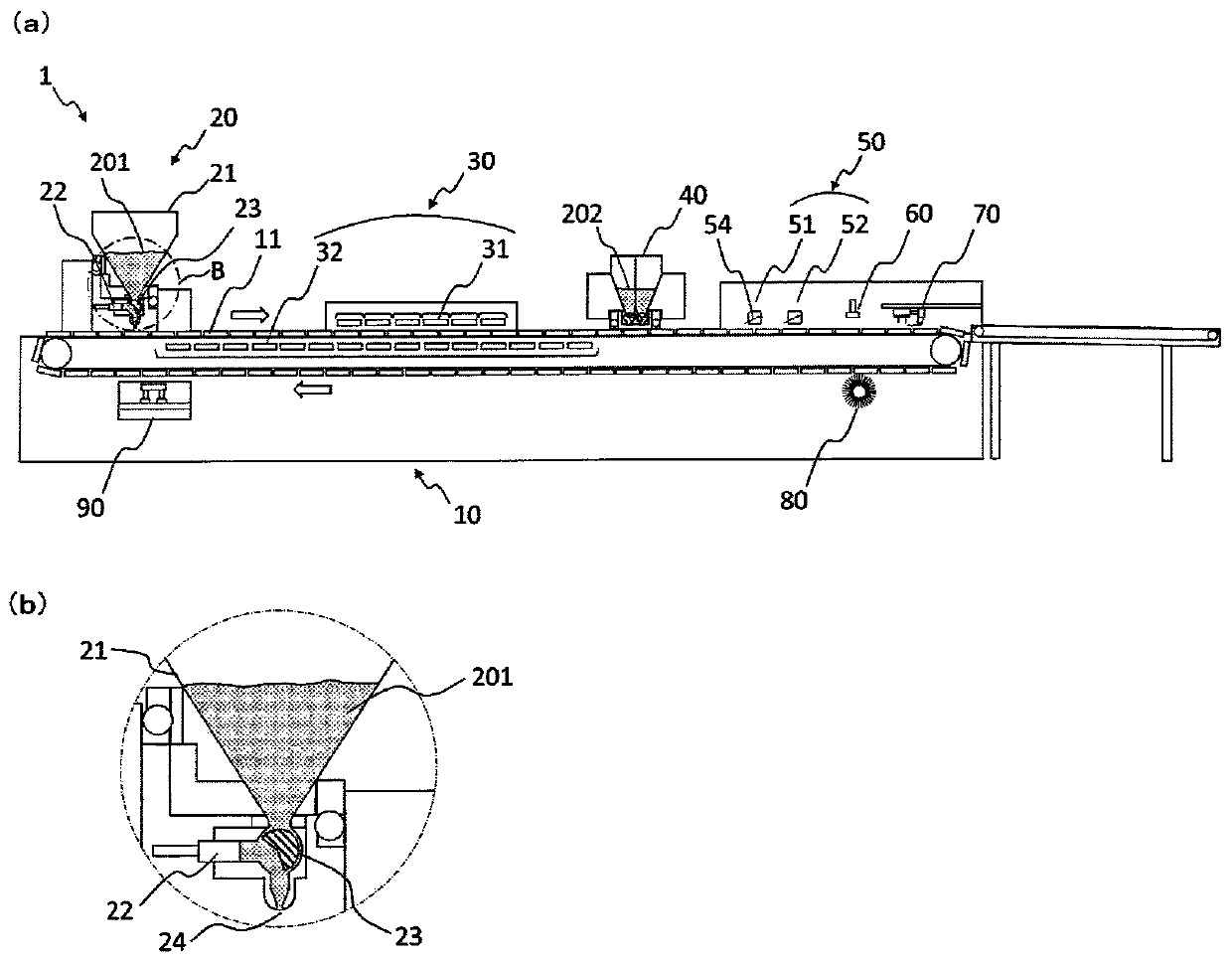

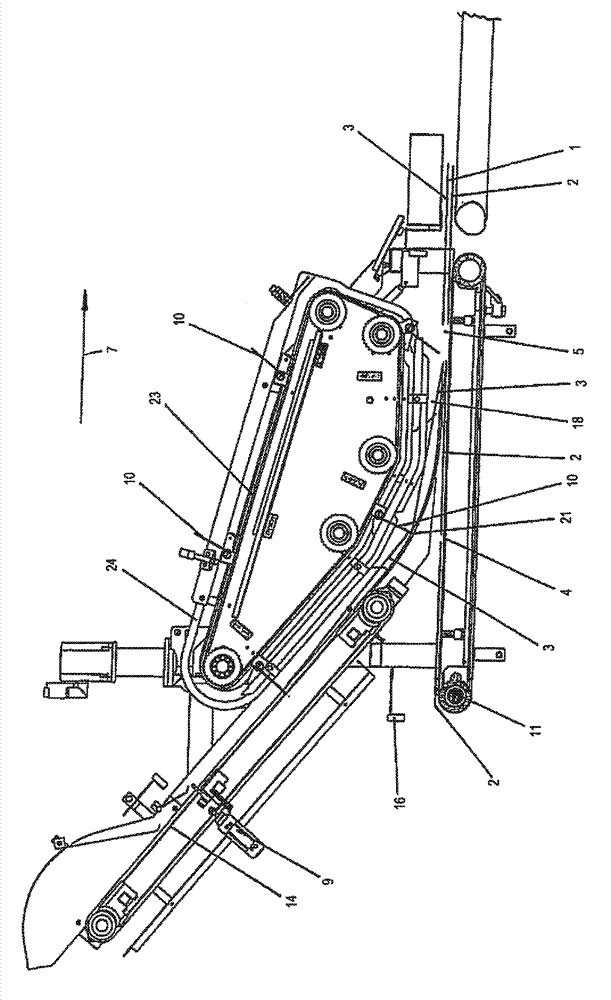

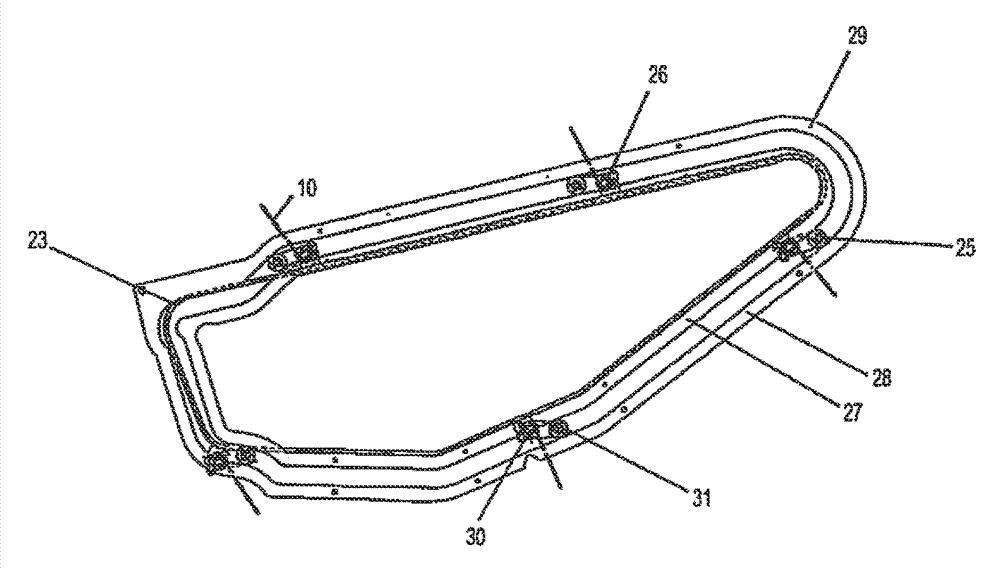

Bean paste wrapping machine, and bean paste wrap manufacturing method

InactiveCN110831440ASimple structureLow initial costConfectioneryBaking ovenBiologyMechanical engineering

Provided a bean paste wrapping machine and a bean paste wrap manufacturing method that continuously perform two-stage molding in which one end of dough on a baking sheet being circulated by continuousfeeding is molded so as to fold towards a filling, after which the dough is molded so as to cover the filling. The bean paste wrapping machine according to the present invention is characterized by including a conveyance device that comprises a baking sheet circulated by continuous feeding, and a molding device that is mounted to the conveyance device, the molding device comprising a first molding part that molds one end of baked dough so as to fold towards a bean paste filling, and a second molding part that further molds the dough molded by the first molding part so as to cover the bean paste.

Owner:MASDAC

Food Folding Platform And Components Therefor

A folding platform includes a base, first folding flap, lift arm, and lift arm linkage. The first folding flap is rotatably connected with the base and facilitates the folding of a food item placed on the folding platform. The lift arm linkage is rotatably connected with the base and the lift arm to operatively lift the lift arm and allow the lift arm to rotate in a first rotational direction, and includes a spring that engages the lift arm linkage and the lift arm, and biases the lift arm in a second rotational direction opposite the first rotational direction. The lift arm is capable of rotating a first rotational distance, and rotating a second rotational distance greater than the first rotational distance without bending or breaking when the lift arm contacts an obstruction. The lift arm automatically returns to its normal position due to the bias force of the spring.

Owner:SOLBERN CORP

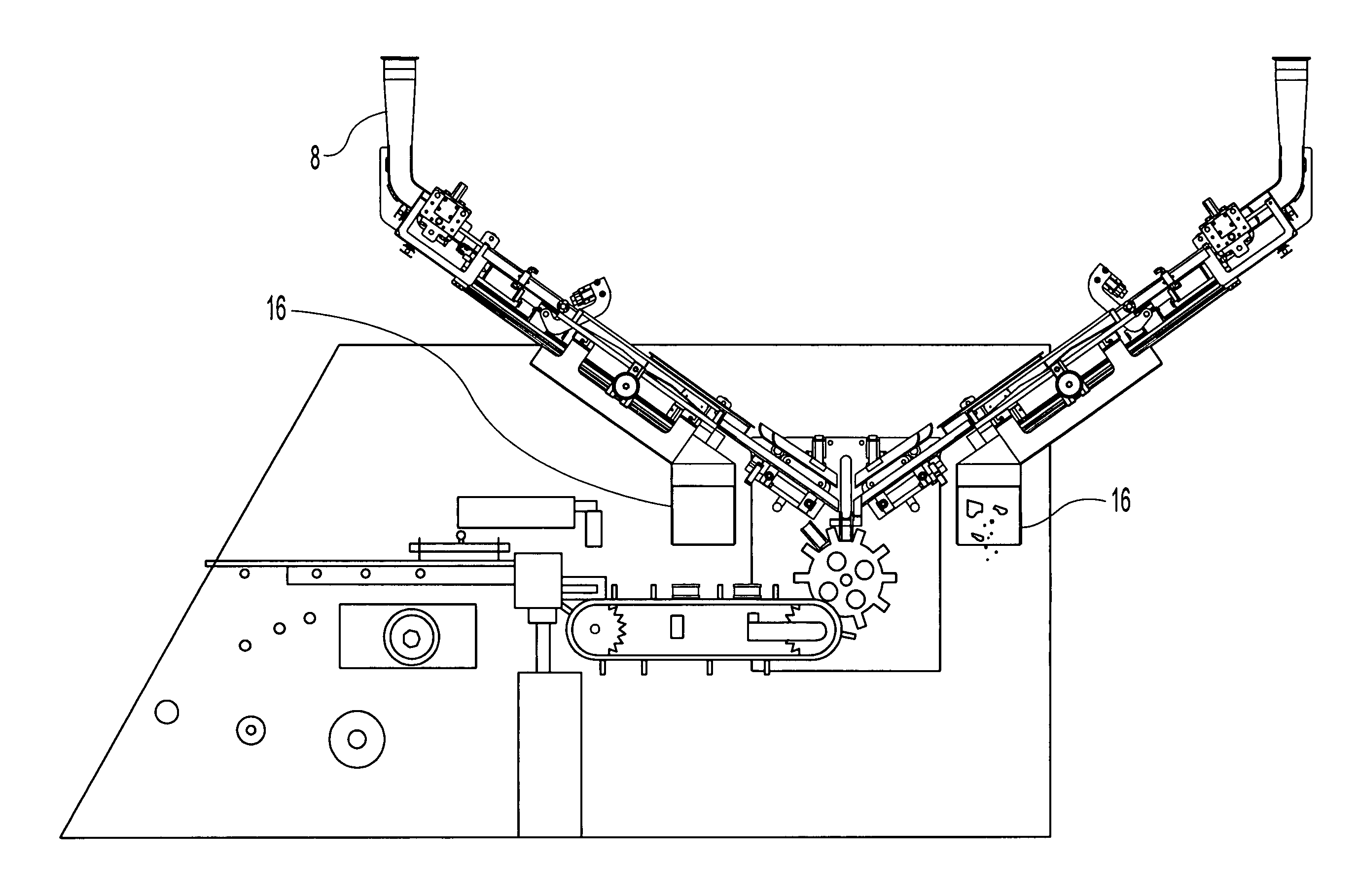

Product de-topper

InactiveUS7757602B2Facilitates desired parting and separationFruit stoningFood shapingReciprocating motionEngineering

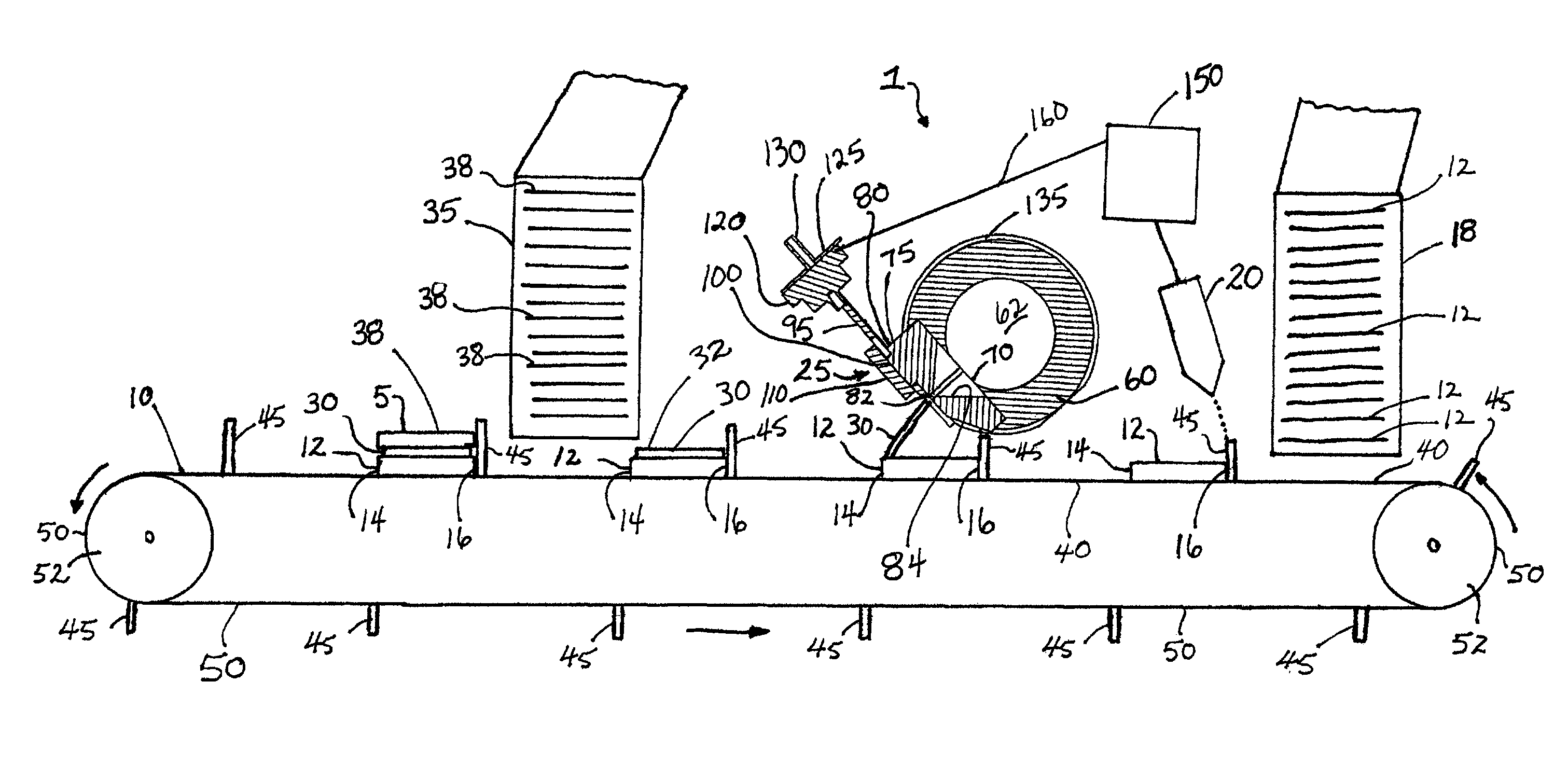

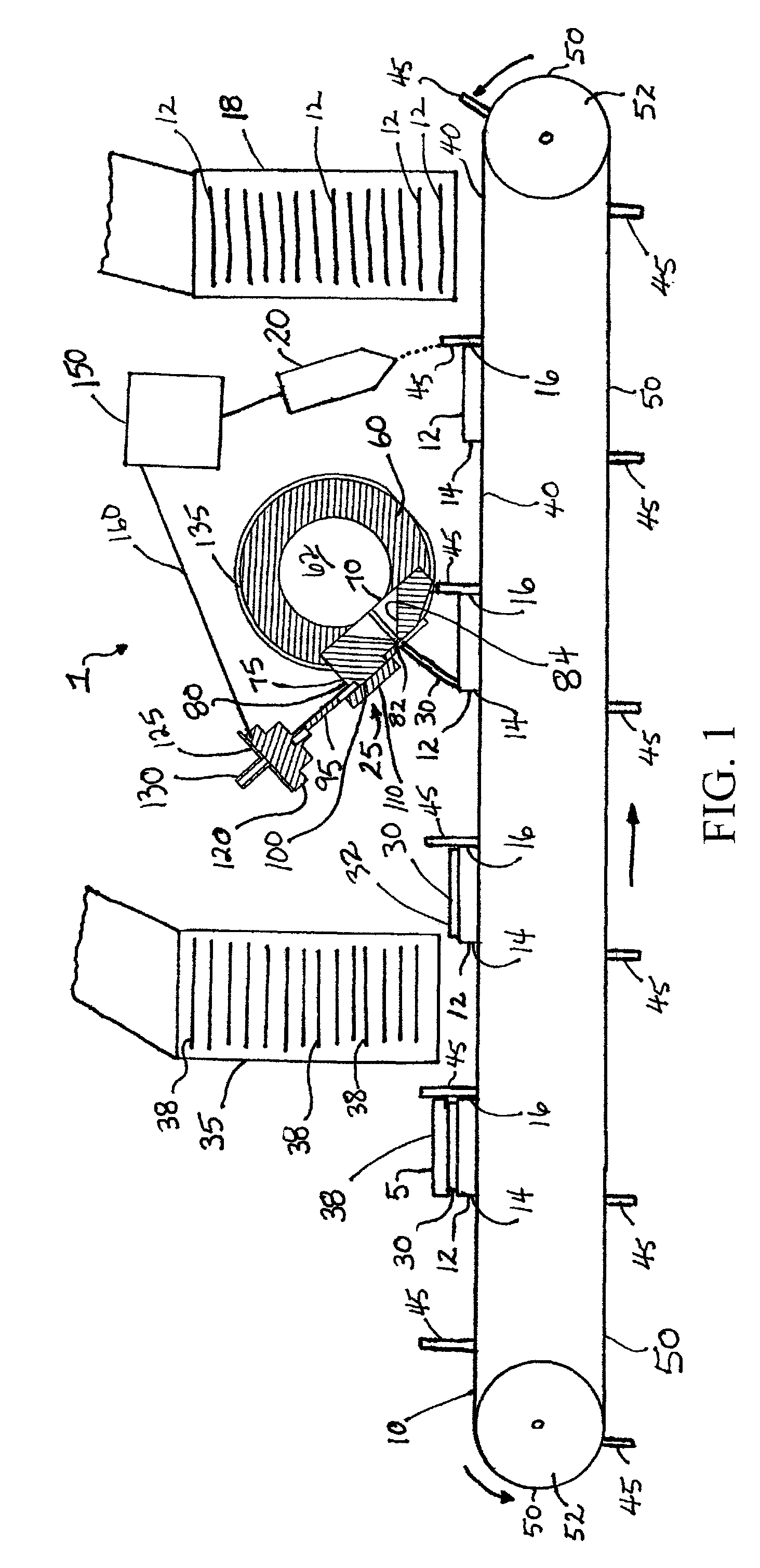

The present invention relates to equipment for assembling food products, and more specifically to an apparatus and method for separating or parting stacked food products during a food production process. The invention, a de-topper, facilitates the desired parting or separation of stacked products having at least upper and lower sections defining a separation line. In parting stacked products along the separation line, the de-topper comprises a longitudinal arm and at least one primary conveying path for conveying the at least upper and lower sections of the stacked products towards the arm. A drive reciprocates the arm so that the reciprocating arm sweeps the upper sections of the stacked products from the at least one primary conveying path and onto a secondary conveying path, located outwardly thereof. The lower and upper sections are thereafter conveyed on the respective primary and secondary conveying paths away from the reciprocating longitudinal arm.

Owner:AUBRY LARRY +2

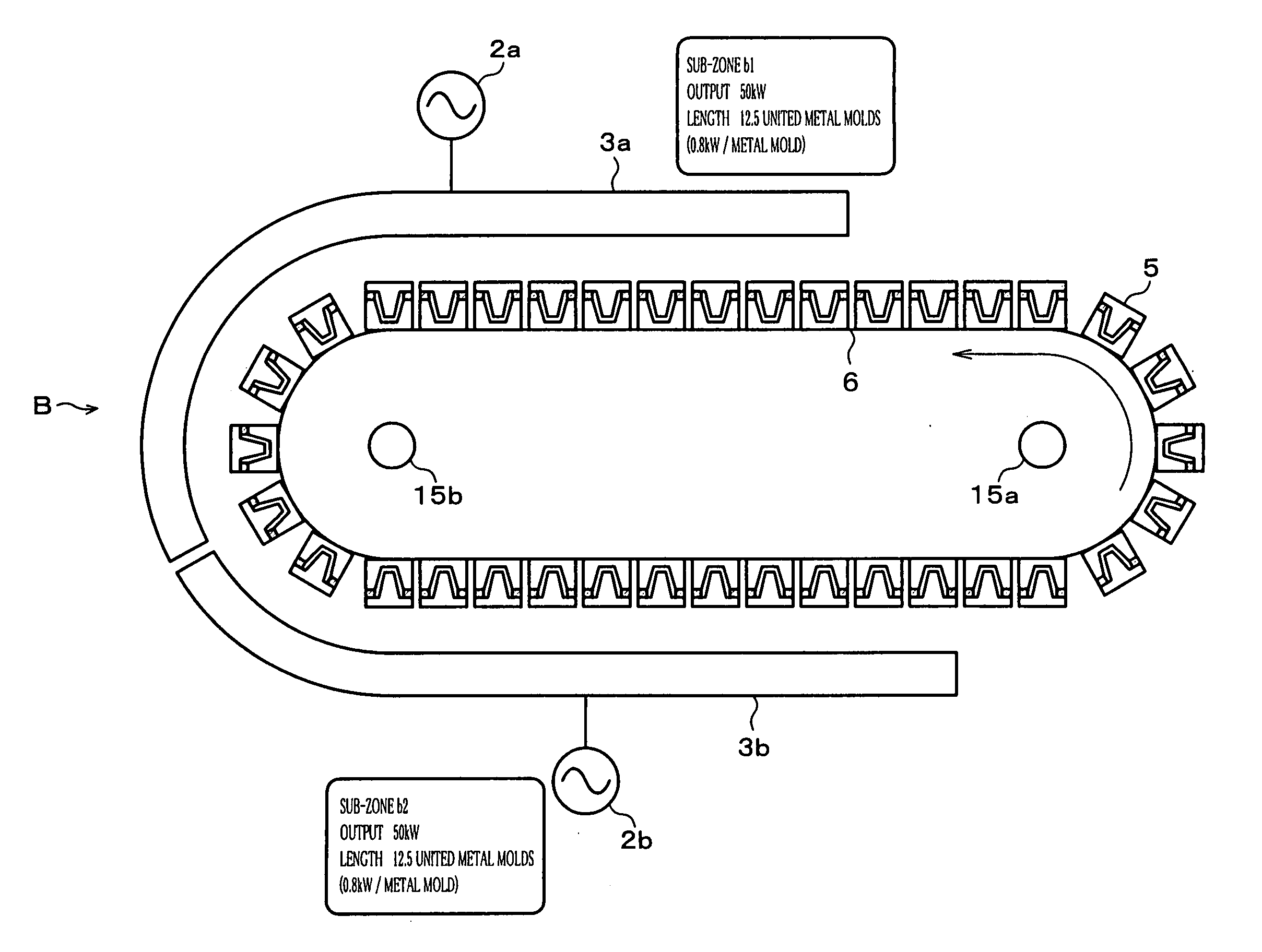

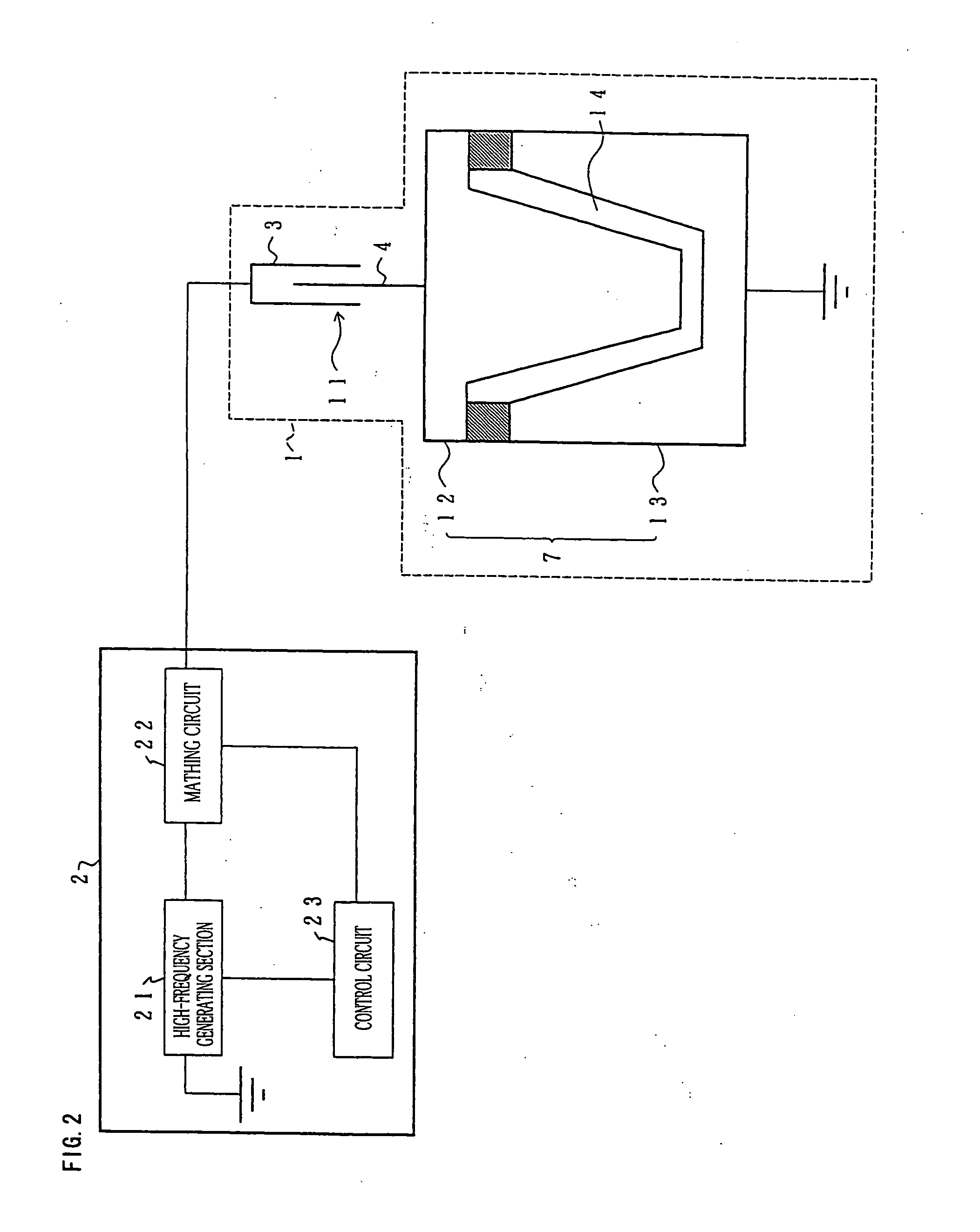

Method of manufacturing hot formed object, and device and method for continous high-frequency heating

InactiveUS20050098926A1Avoid high frequencyDielectric heating circuitsConfectioneryTransmission beltElectrical and Electronics engineering

Raw materials are portioned in a plurality of molds, which are continuously moved and transferred to a heating area by a conveyer. The heating area is divided into a plurality of sub-areas, each of which has power source means and power feeding means. The raw materials are heated and molded by applying high frequency to the molds from the power feeding means. Even if the heating apparatus is large, it is possible to restrain or prevent concentration of high-frequency energy since the heating area is divided into sub-areas.

Owner:NISSEI KK +1

Apparatus for unwrapping and transporting frangible wafers for ice cream sandwiches and the like

InactiveUS7322166B1Reduce needPotential for contaminationWrapper folding/bending apparatusArticle unpackingCombined useEngineering

The present invention is an apparatus and method for unwrapping a package of frangible articles bearing a wrapping material, the wrapping material having a rear portion and a forward tab, the forward tab adapted to open the wrapping material when pulled, the apparatus comprising: (a) a support member for supporting the package; (b) a grasping mechanism adapted to grasp the forward tab and to pull the forward tab so as to open the wrapping material; (c) an engaging mechanism adapted to grasp the rear portion and pull the wrapping material so as to remove the wrapping material from the frangible articles. The invention may be used in conjunction with standard confection filling, transport and packaging machinery and mechanisms.

Owner:INTERBAKE FOODS

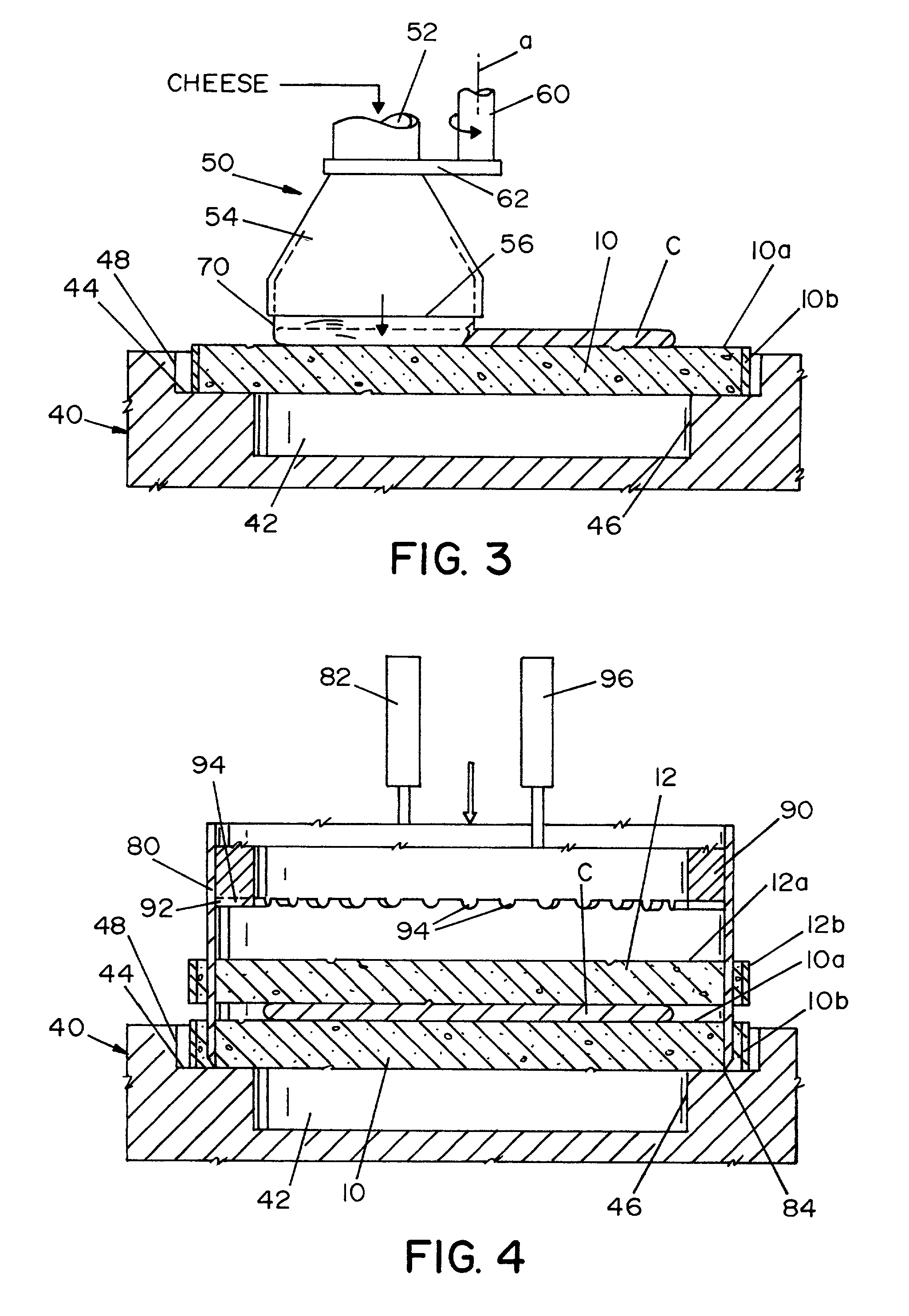

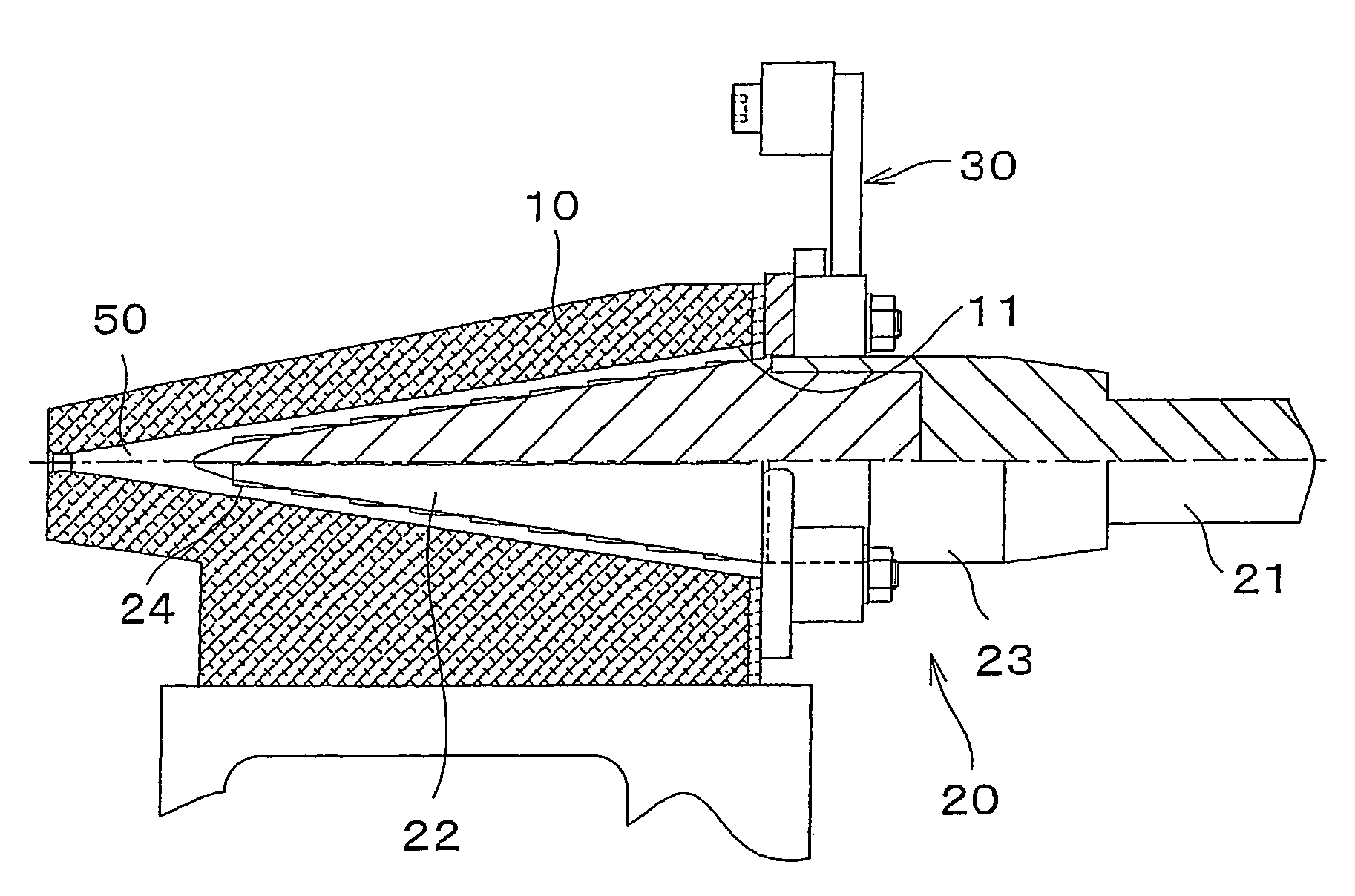

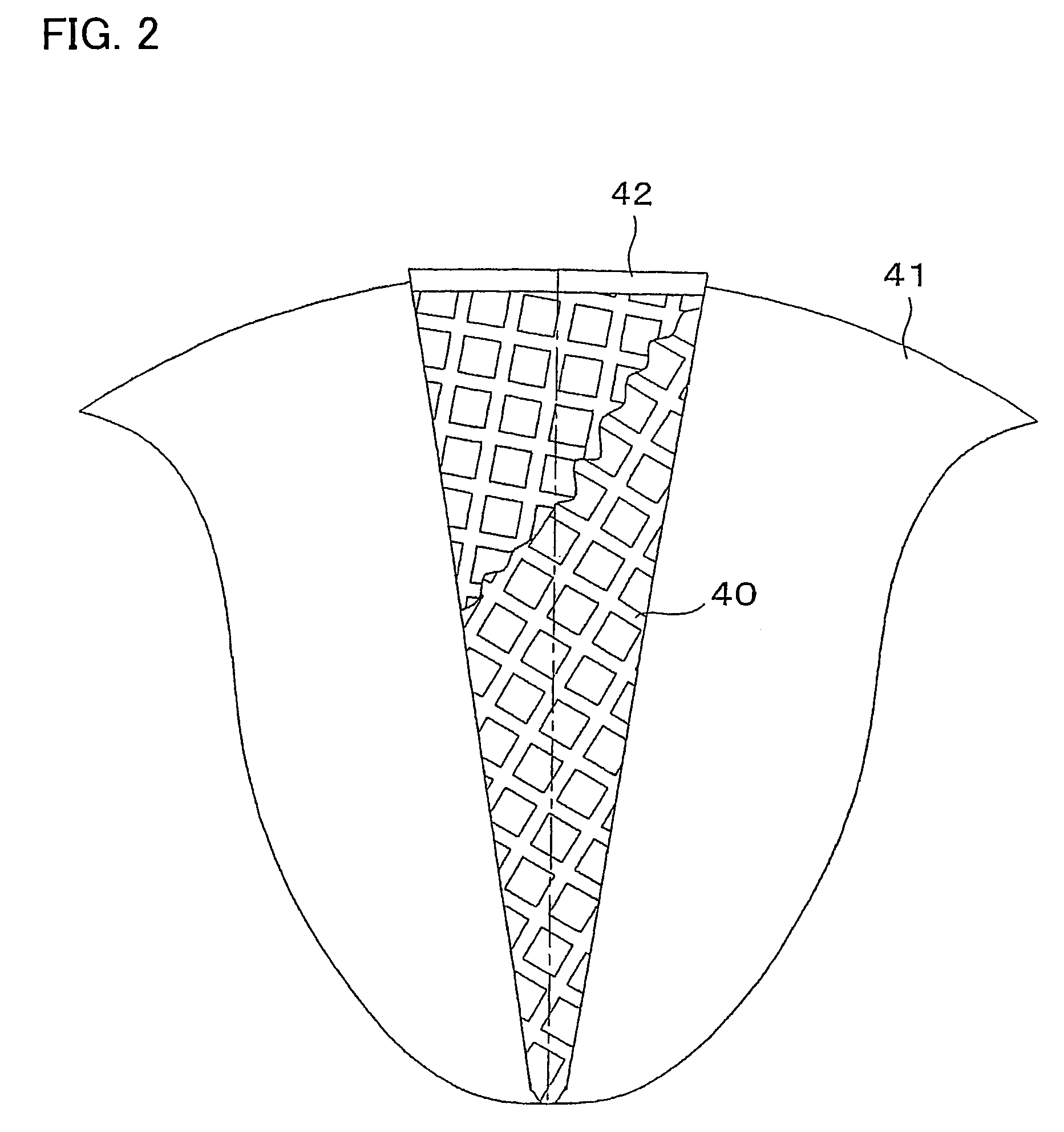

Rolled coned manufacturing apparatus

InactiveUS7344371B2Avoid misalignmentStable conditionsDough treatmentConfectioneryConical formsEngineering

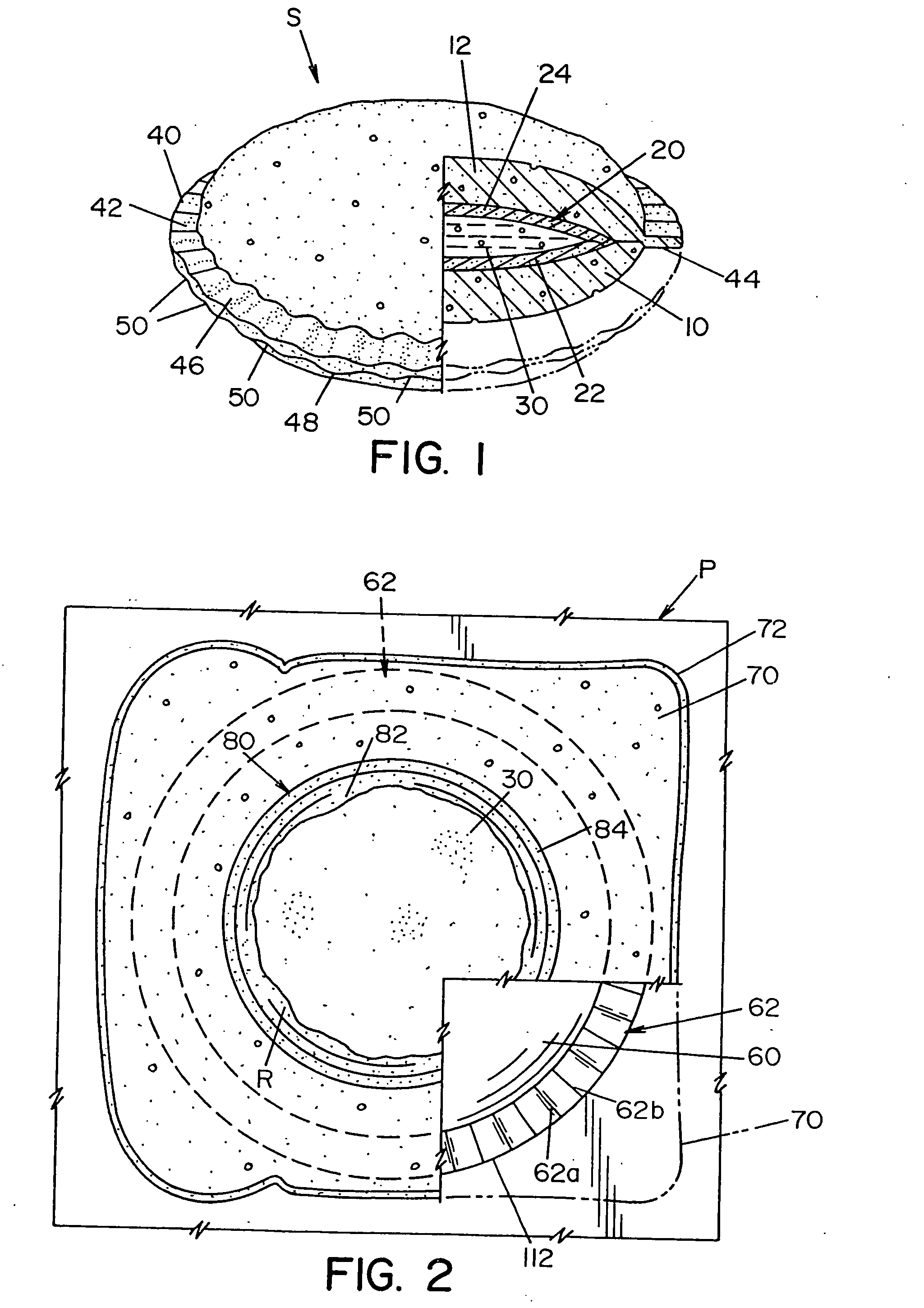

A concave half (10) having a conical inside and a convex half (20) having a conical outside and being fitted therein are fitted in each other. An openable and closable, loop-shaped supporting means as a toggle-jointed link (30) rotatably supports and pushes a cylindrical part (23) of the convex half (20) onto the axis on at least three points on the outer periphery of the cylindrical part (23), with an axis of the concave half (10) and an axis of the convex half (20) being aligned with each other when the supporting means is closed. The toggle-jointed link (30) is openable and closable, wherein a plurality of rolling objects such as rollers (31) are provided inside the loop, thereby improving function as a bearing of the supporting means and efficiently manufacturing quality rolled cones (40).

Owner:NISSEI KK

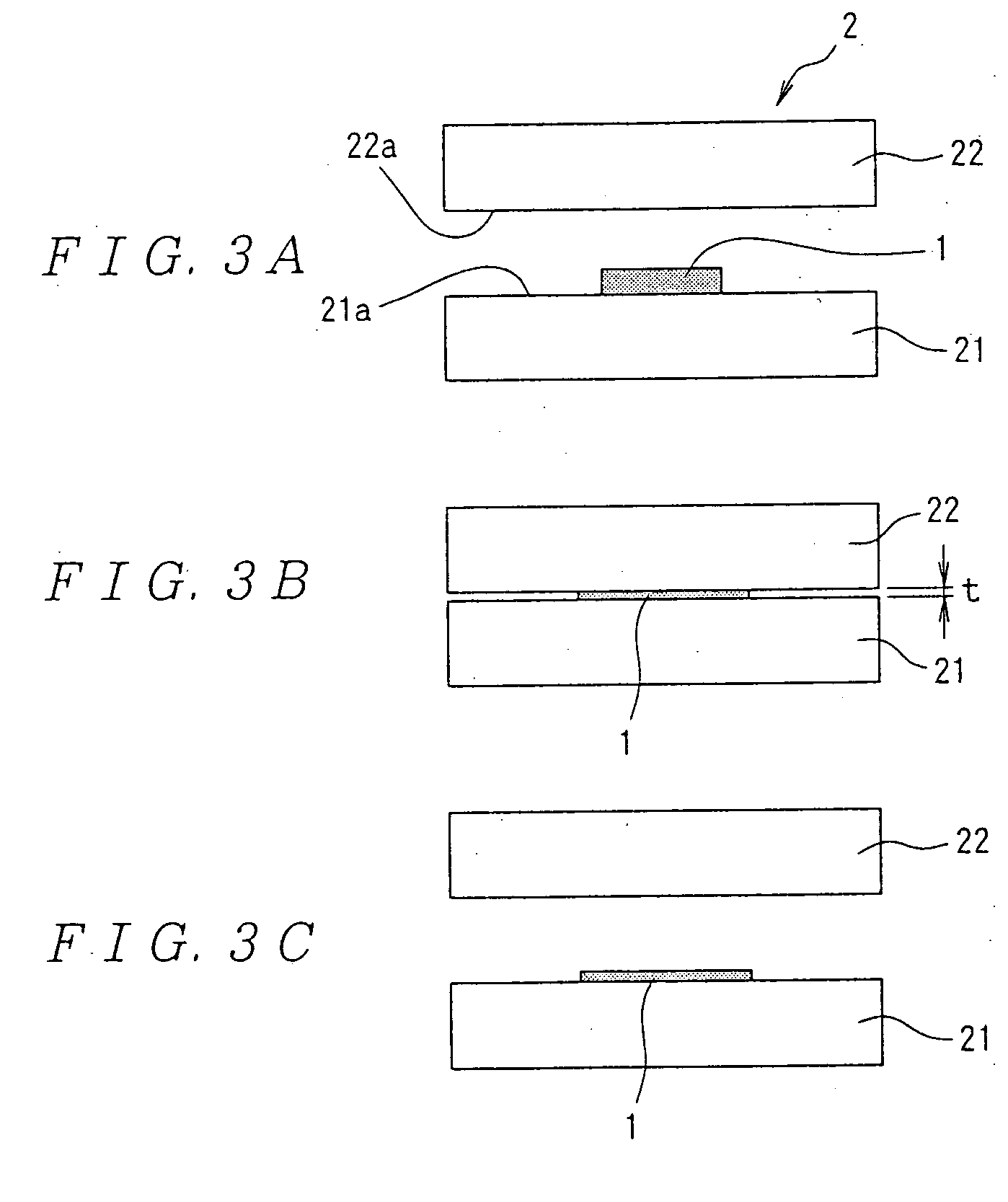

Method and device for producing waffle sandwich blocks

ActiveCN103687493AAccurate up and down positioningIncrease productionBaked wafer shaping/mouldingEngineeringMechanical engineering

Owner:HAAS FOOD EQUIP

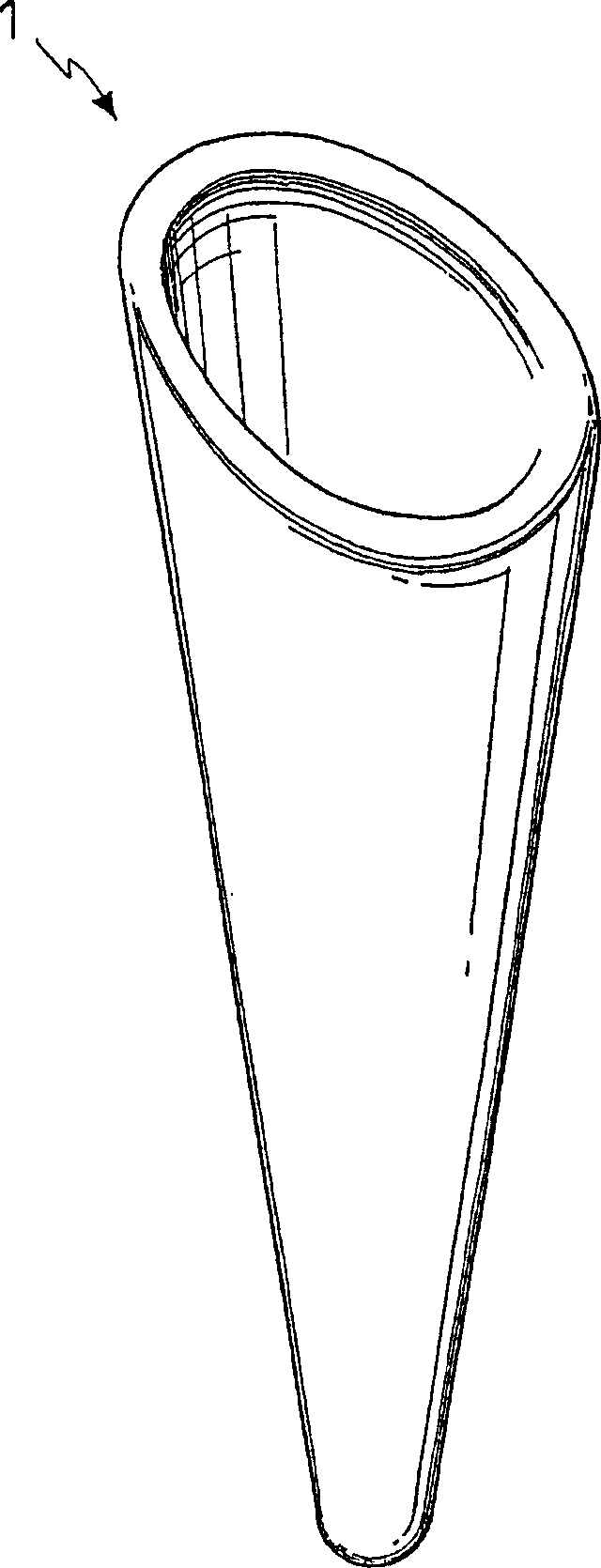

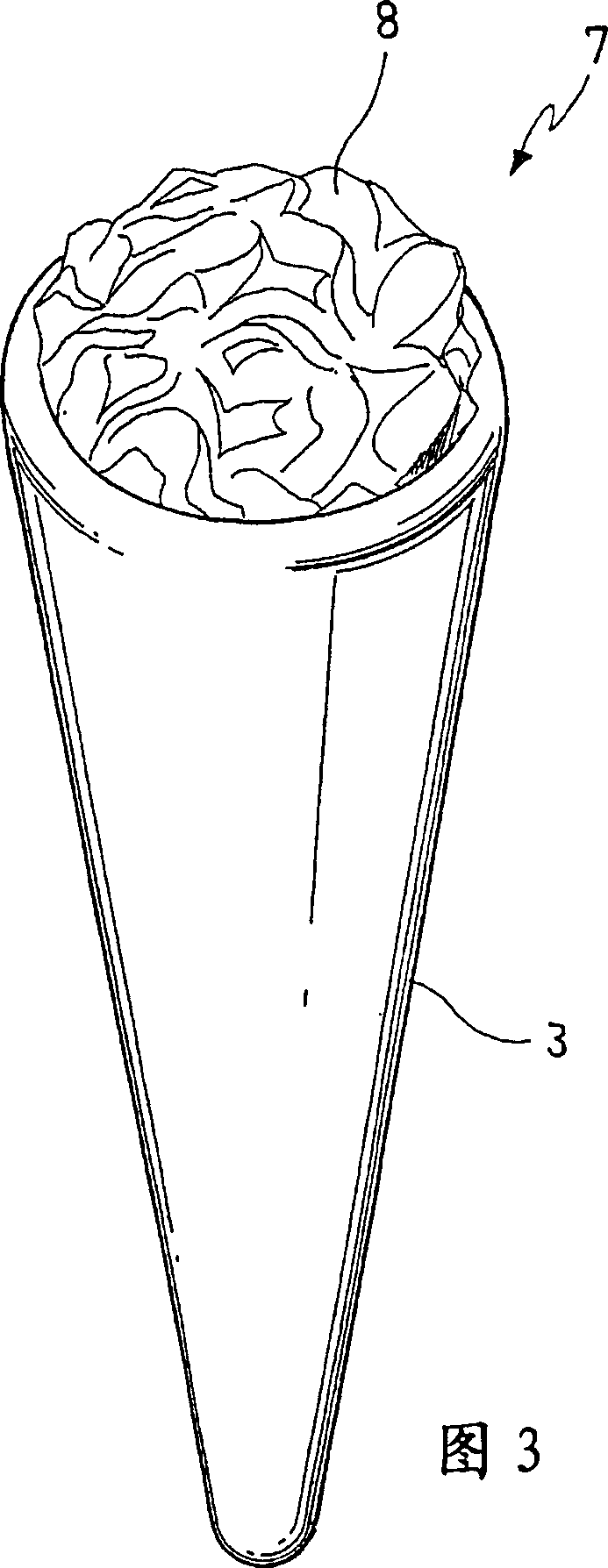

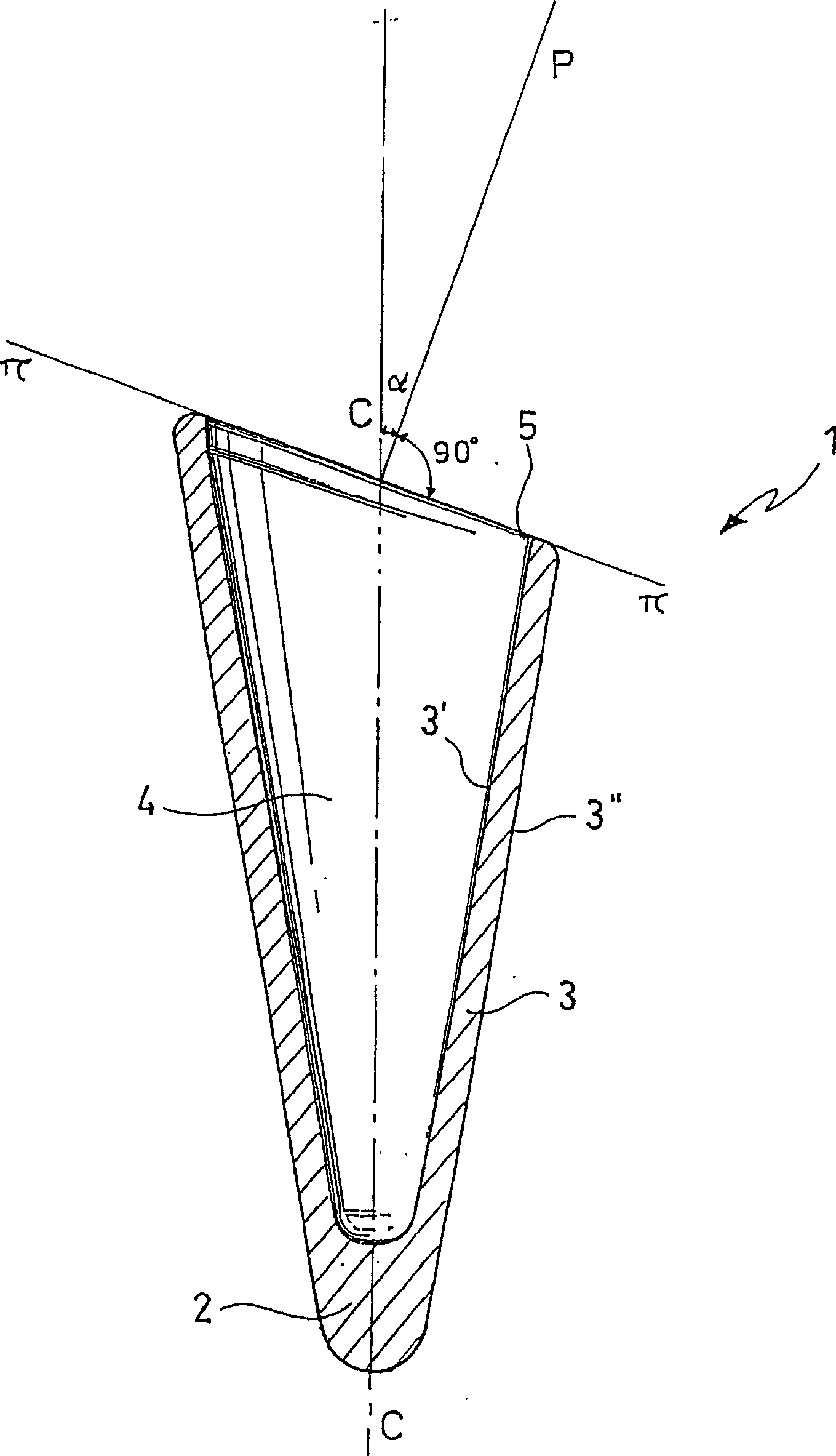

Filling food, related semi-processed food and its production method and apparatus

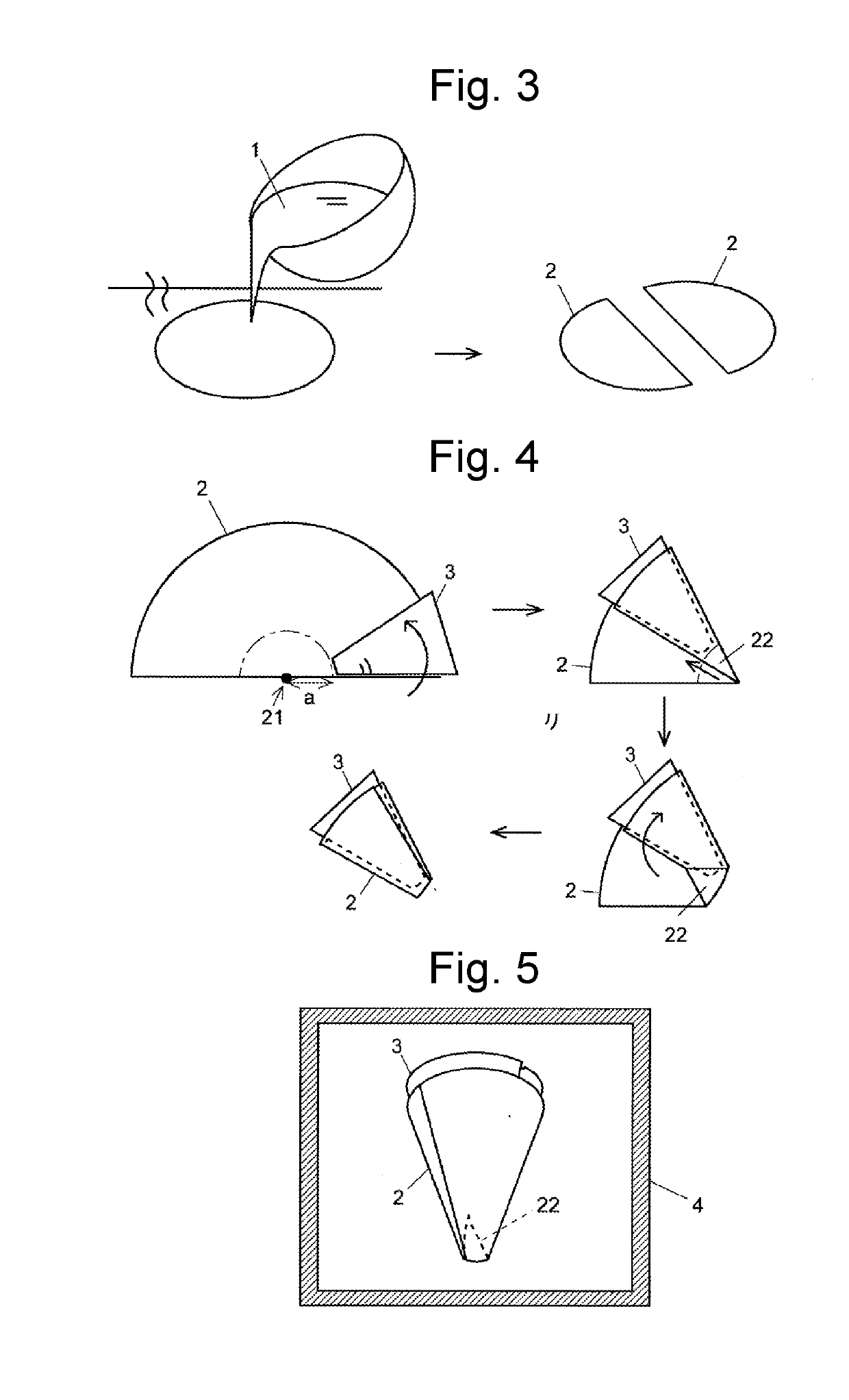

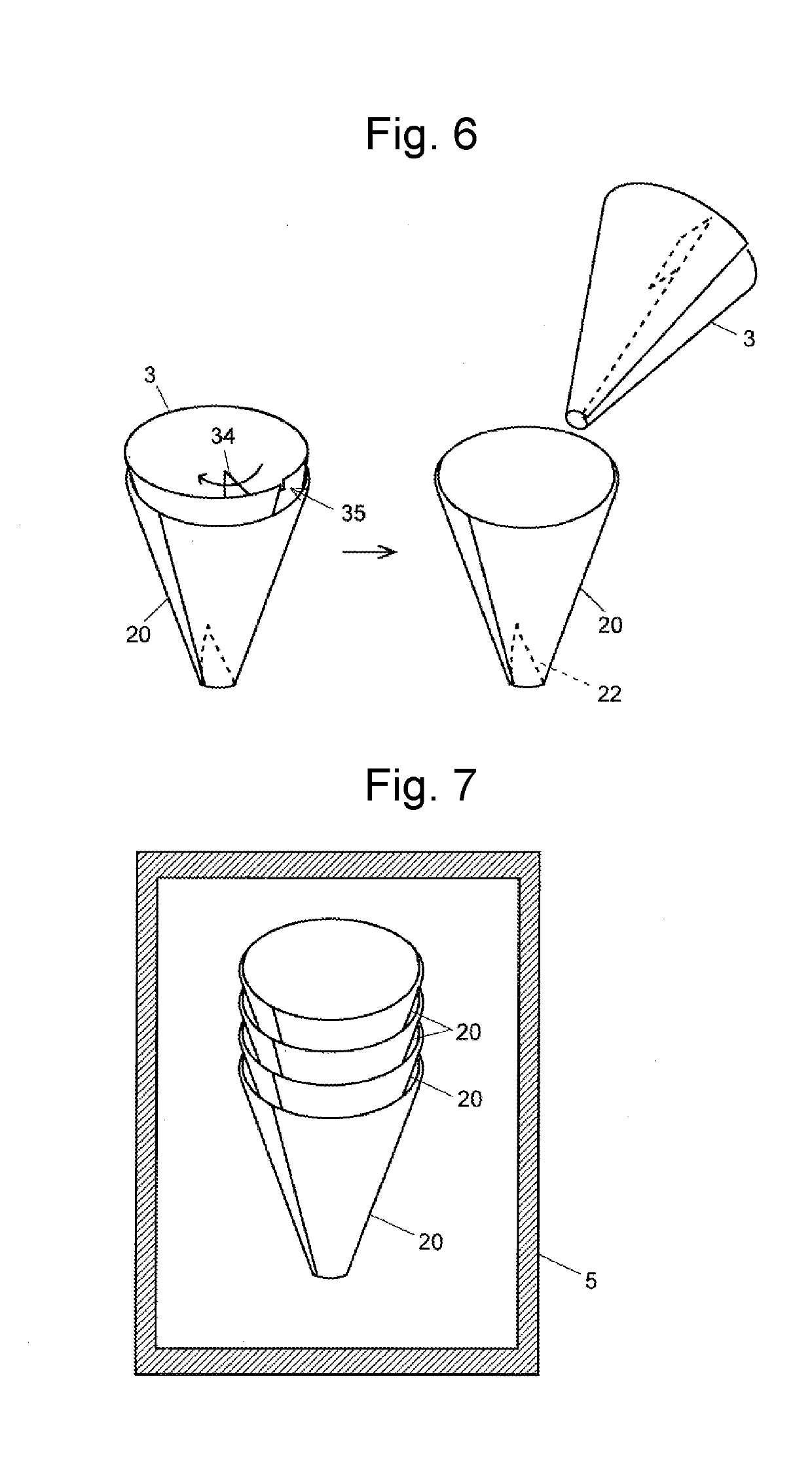

The present invention relates to a filled food product (7), the semi-processed product (1) from which the food product is obtained and the methods and plant (30) for producing the same. The semi-processed product (1) consists of a single whole piece of dough. Such dough consists of a partially cooked mixture of water and flour. The semi-processed product (1) is formed into a goblet-like shape, has an axis (c-c) and an opening which defines a plane (PI). The axis (c-c) is inclined and oblique with respect to the plane (PI) of the opening. The finished food product (7) is obtained by the filling and the cooking of the semi-processed product (1).

Owner:PYCONO

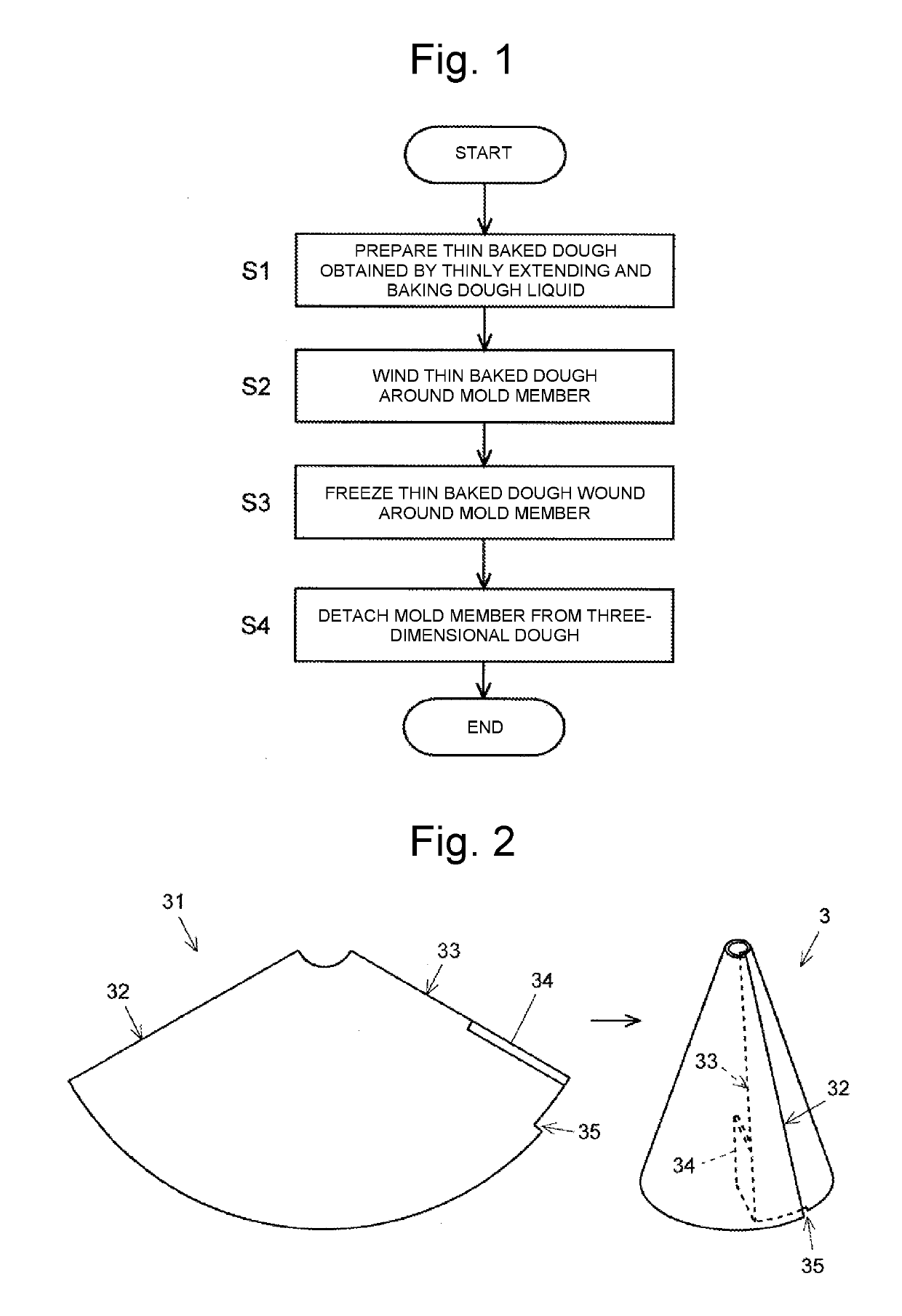

Dough for food, producing method therefor, and mold member for producing dough

Owner:SNATS FOODS CO LTD

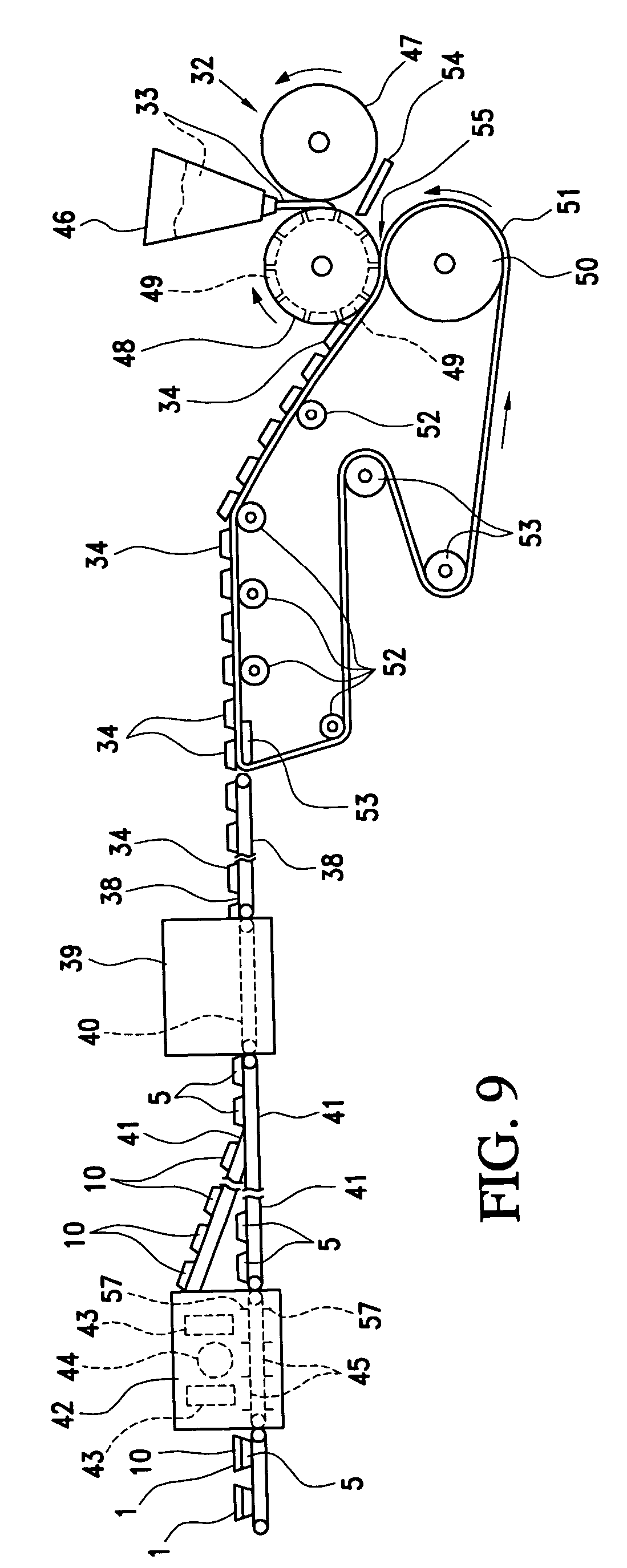

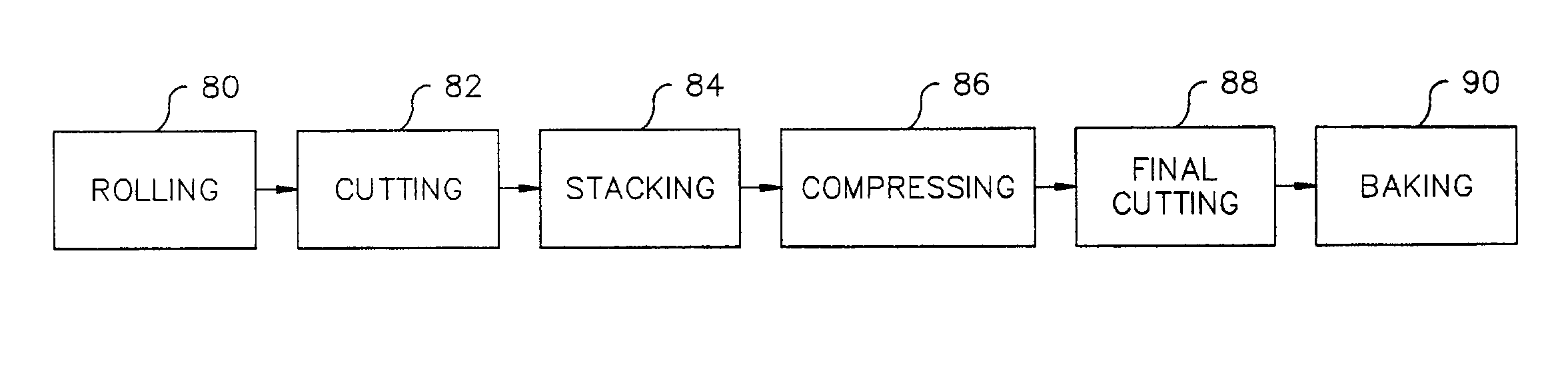

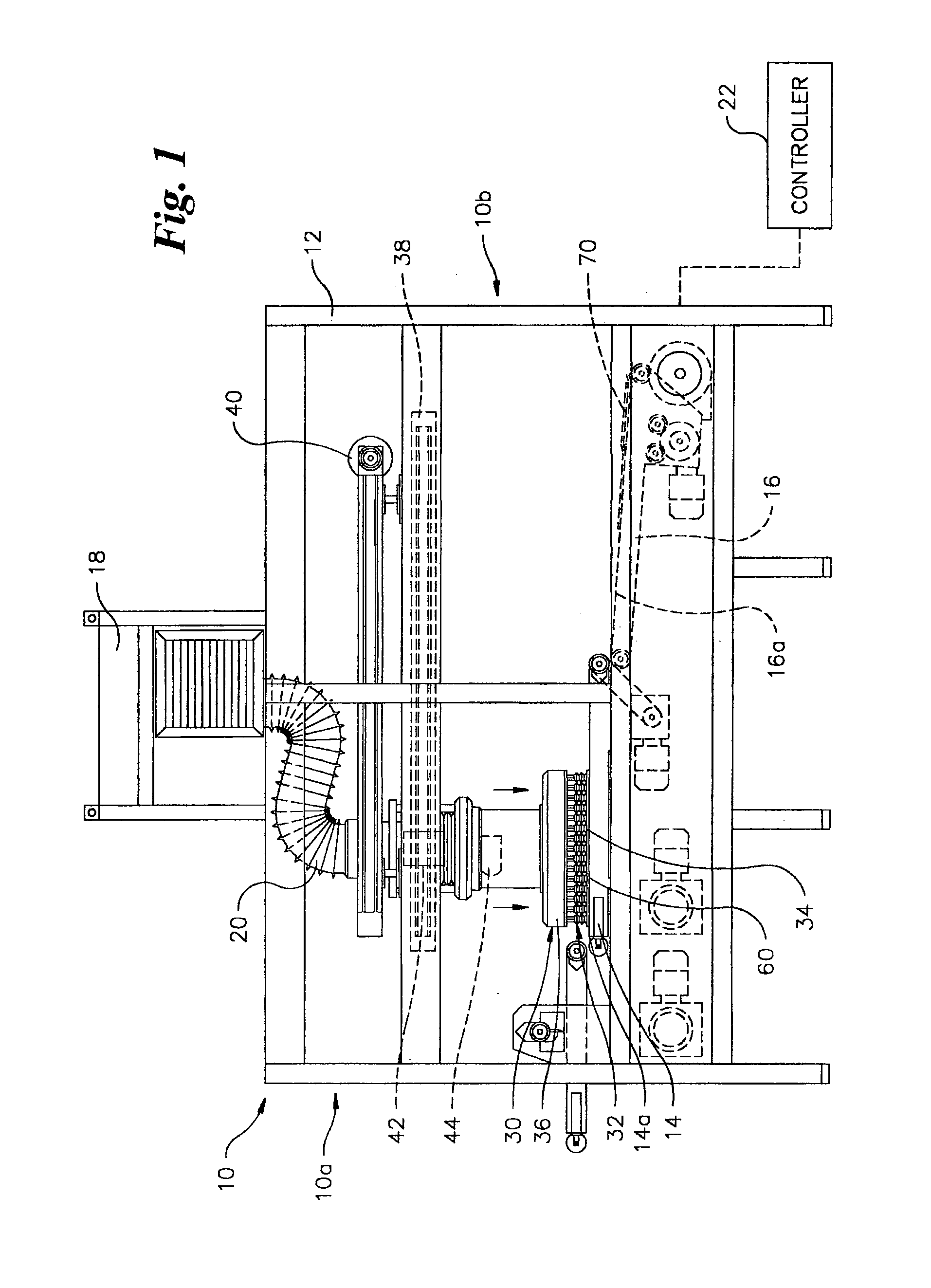

Ribbon cutter apparatus and method for making sandwich baked goods

A method for the continuous production of sandwich baked goods having a high volume of filler includes conveying a bottom base cake, detecting the position of the base cake, and extruding a filler through a die aperture to form a ribbon in response to the detection of the position of the bottom base cake. In response to detection of the base cake, a signal or timing mechanism may activate a guillotine knife or blade to open the die aperture to allow filler to be deposited on the bottom base cake and to close the die aperture to sever or cut the ribbon to a predetermined dimension. The severing prevents further flow of the filler through the die aperture until the next bottom base cake is detected and the die aperture is again opened to allow filler to be deposited on the next bottom base cake.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

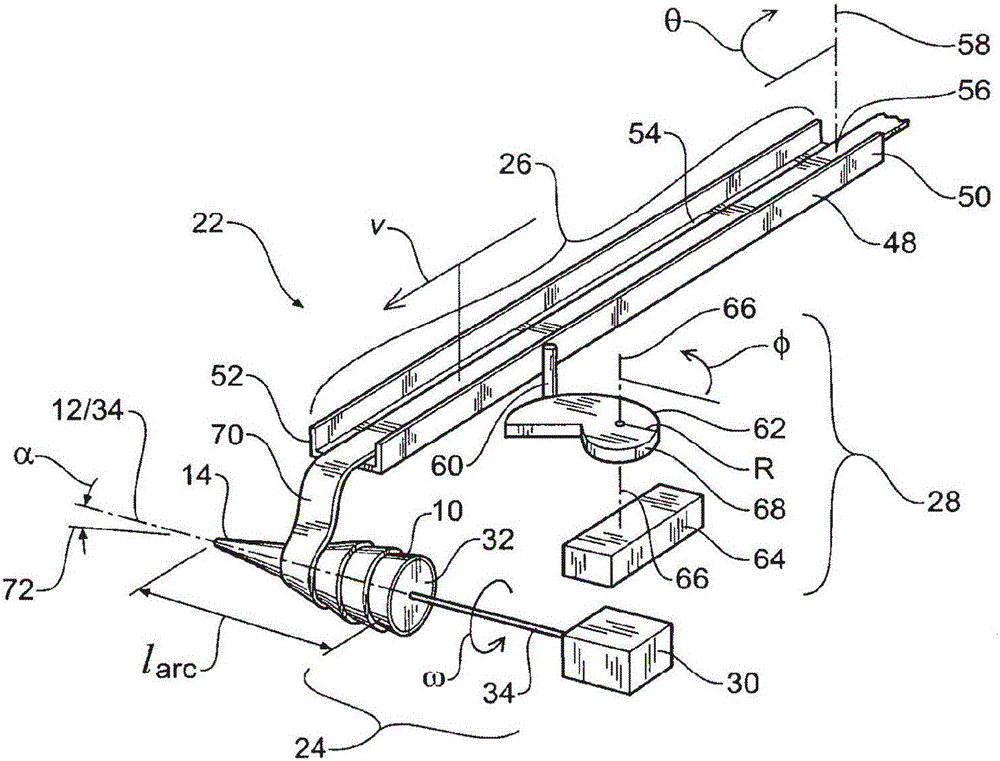

Apparatus and Method for Movement and Rotation of Dough Sheets to Produce a Bakery Products

InactiveUS20080178748A1Improve uniformityPromote consistent expansionDough shapingFood coatingEngineeringMechanical engineering

Owner:READING BAKERY SYST

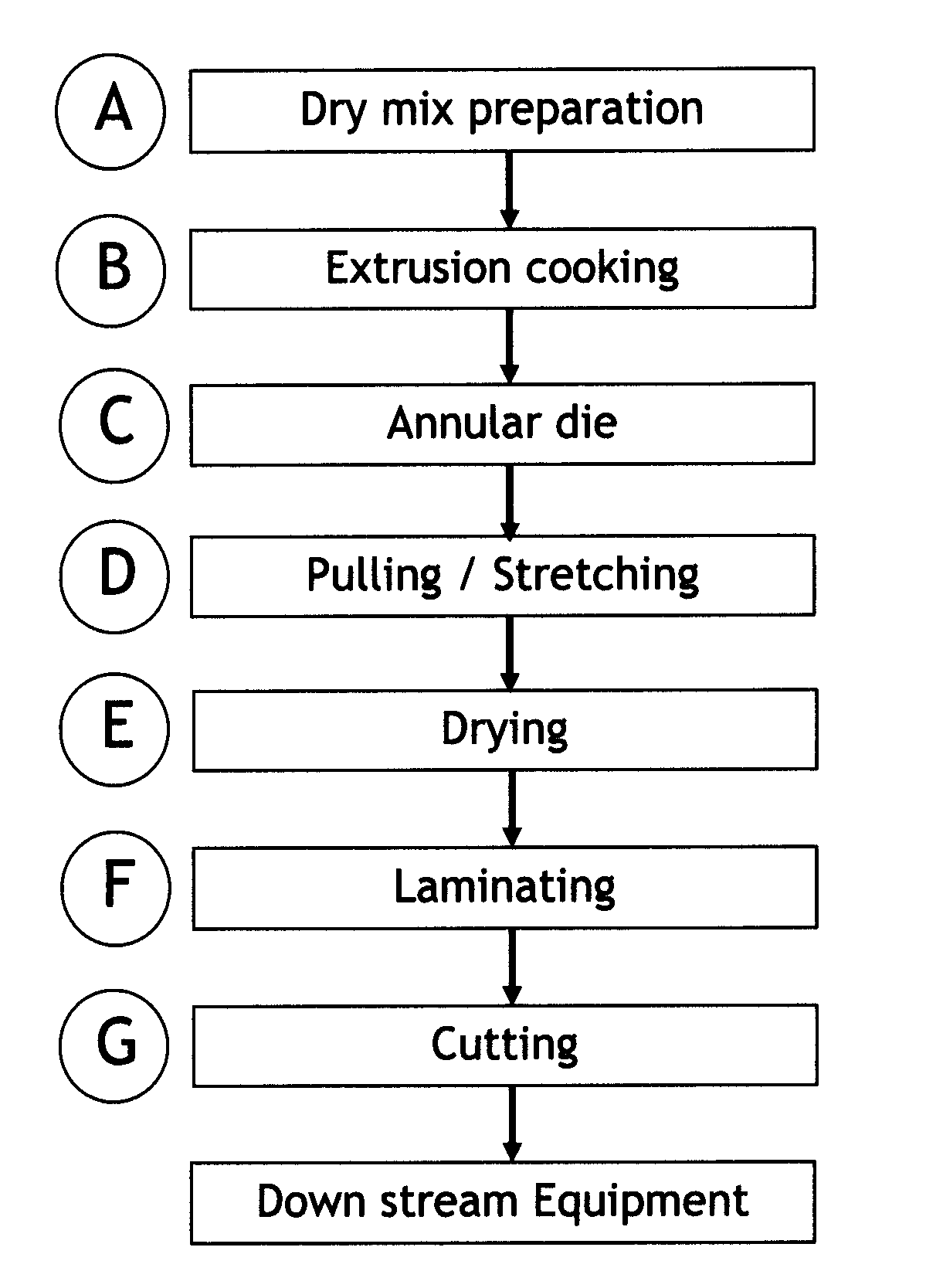

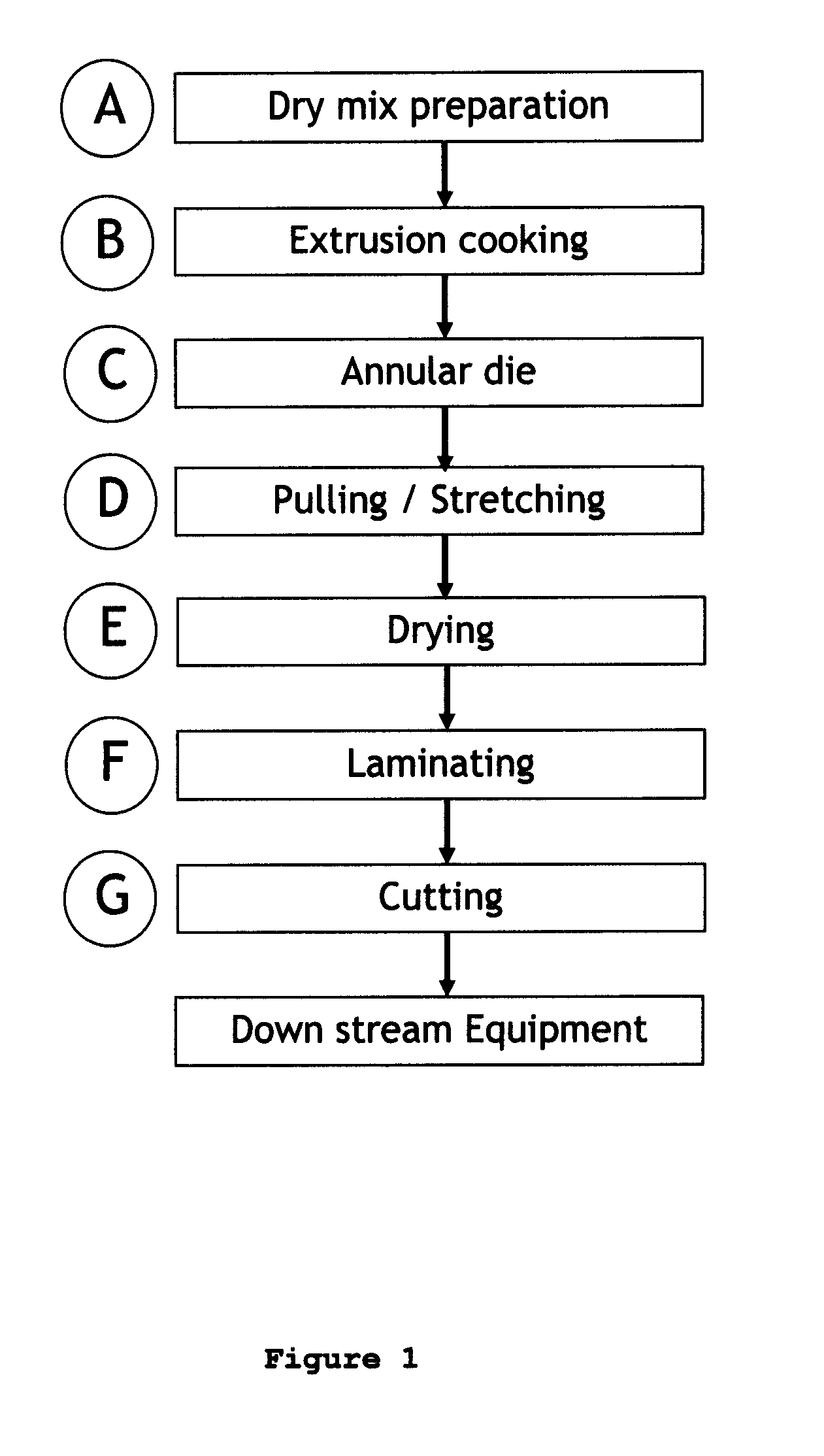

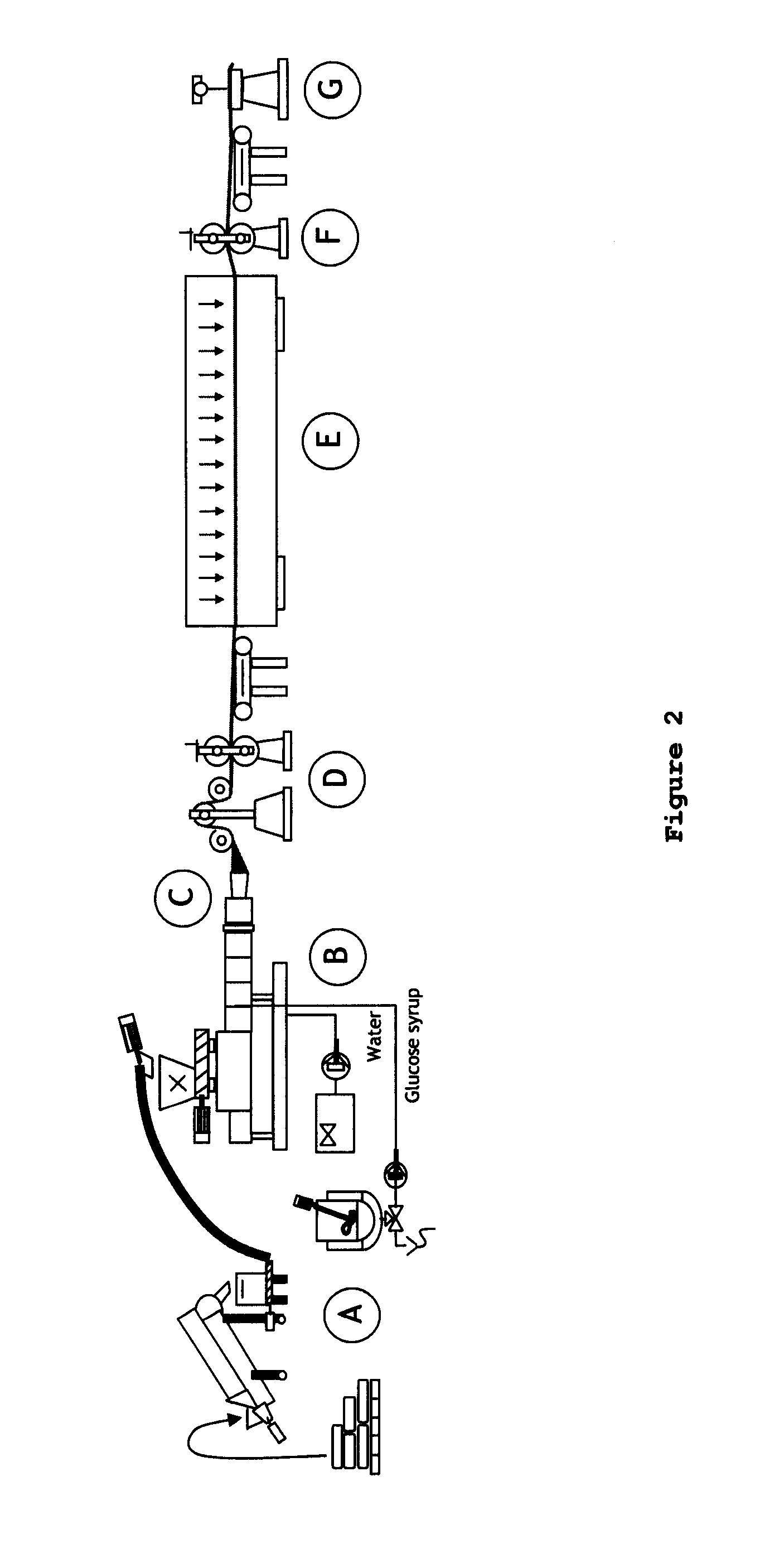

Production of edible wafers by extrusion

InactiveUS20090317524A1Unprecedented widthImprove textureDough treatmentFrozen sweetsProduction lineEngineering

A method for producing wafers by extrusion comprising the steps of a. Preparing an ingredient mix b. Feeding the mix in an extruder and cooking the mix c. Extruding the cooked mix such that an extruded and expanded non-planar structure is formed d. Unfolding the structure to give a large extruded sheet e. Subjecting the extruded sheet to stretching / pulling f. Adjusting the sheet in order to obtain a desired thickness g. Drying the sheet h. Separating the sheet into wafers of desired dimensions The invention also relates to the wafers thus produced and to a wafer production line.

Owner:NESTEC SA

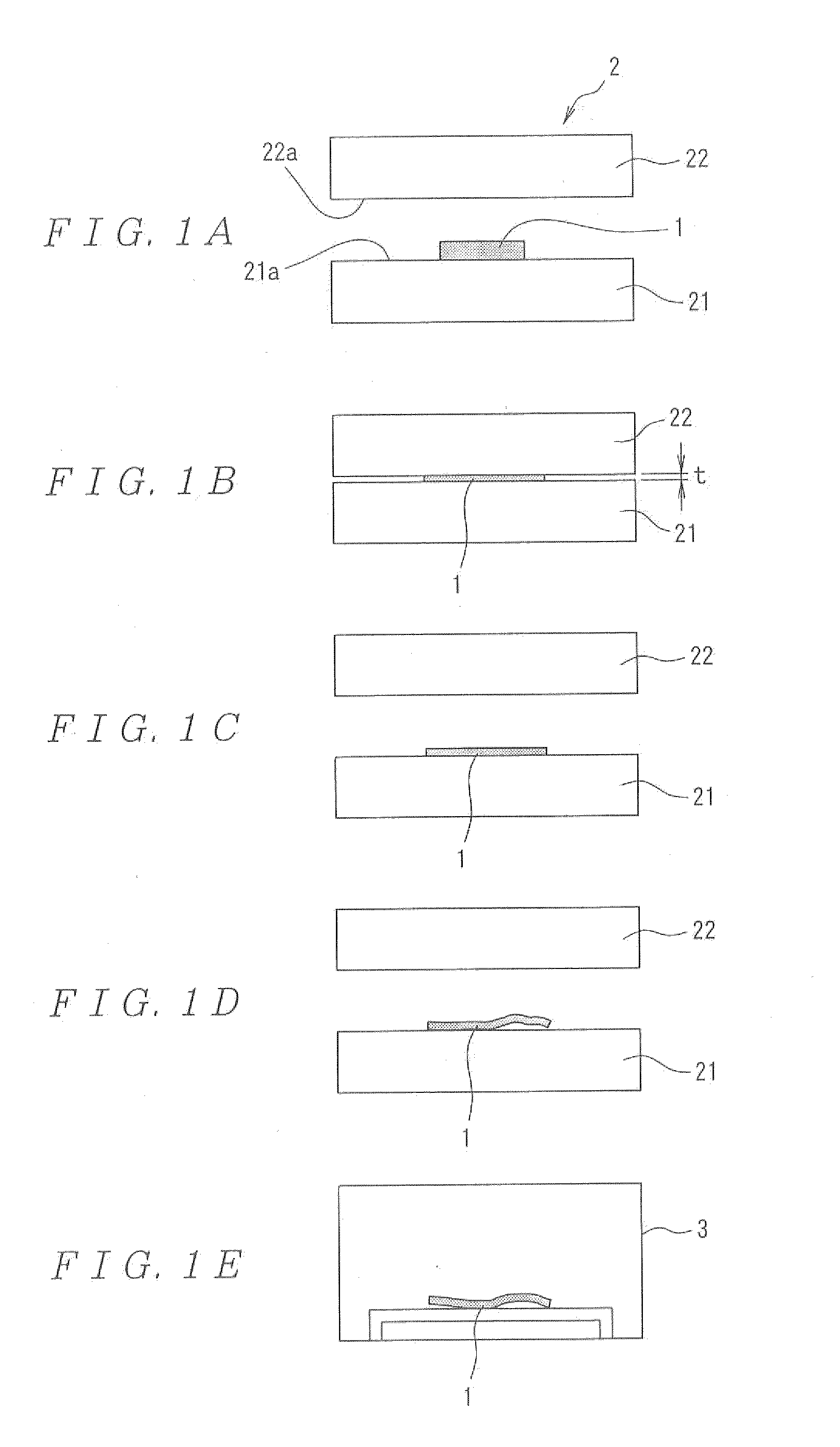

Method for Manufacturing a Snack, a Snack, and Food Like a Snack

Disclosed herein are methods for producing a snack comprising the steps of rolling out a material comprising of bread and heating the material until a moisture content of the material decreases to a predetermined moisture content that is less than an original moisture content of the material. The resulting product has a curled edge. The resulting product can be seasoned. Also disclosed are snacks produced from the methods herein and foods like a snack produced from the methods disclosed herein.

Owner:OYATSU CO CO LTD

Process for producing snack, snack and snack-like food

This invention provides a method for producing a snack, which makes it possible to obtain cakes made from bread with a texture like potato chips. Bread stripped of the brown-baked crust is cut to obtain a slice of bread with a thickness of not less than 1 mm, and the slice is subjected to a process of heating under pressure in a press device. When the moisture content of the bread becomes about 30 mass %, the bread is removed from the press device 2, and dried by hot air. Thus, a processed product with the curled outer edges (a snack before seasoning) is obtained.

Owner:OYATSU CO CO LTD

Apparatus and Method for Movement and Rotation of Dough Sheets to Produce a Bakery Products

Owner:READING BAKERY SYST

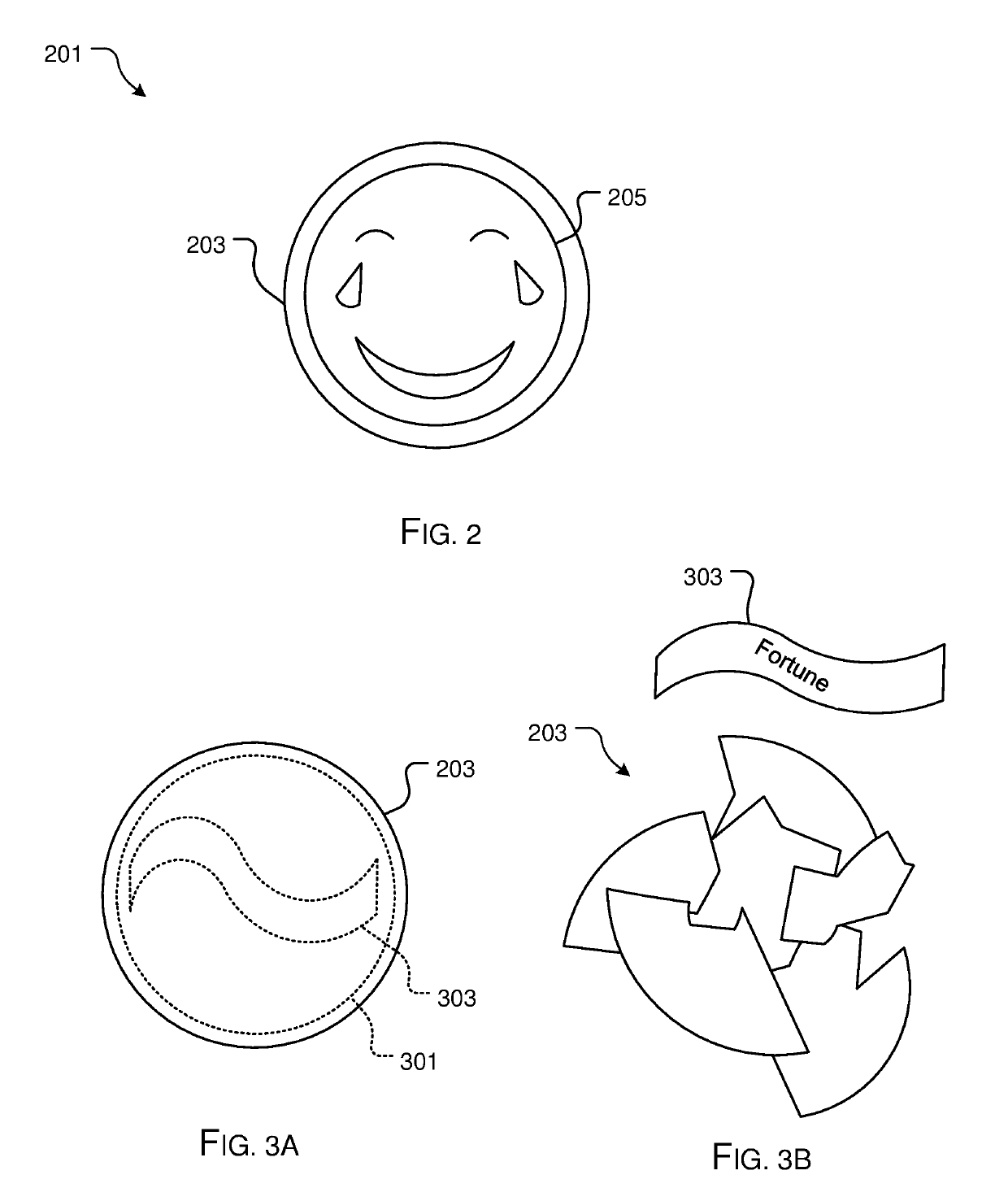

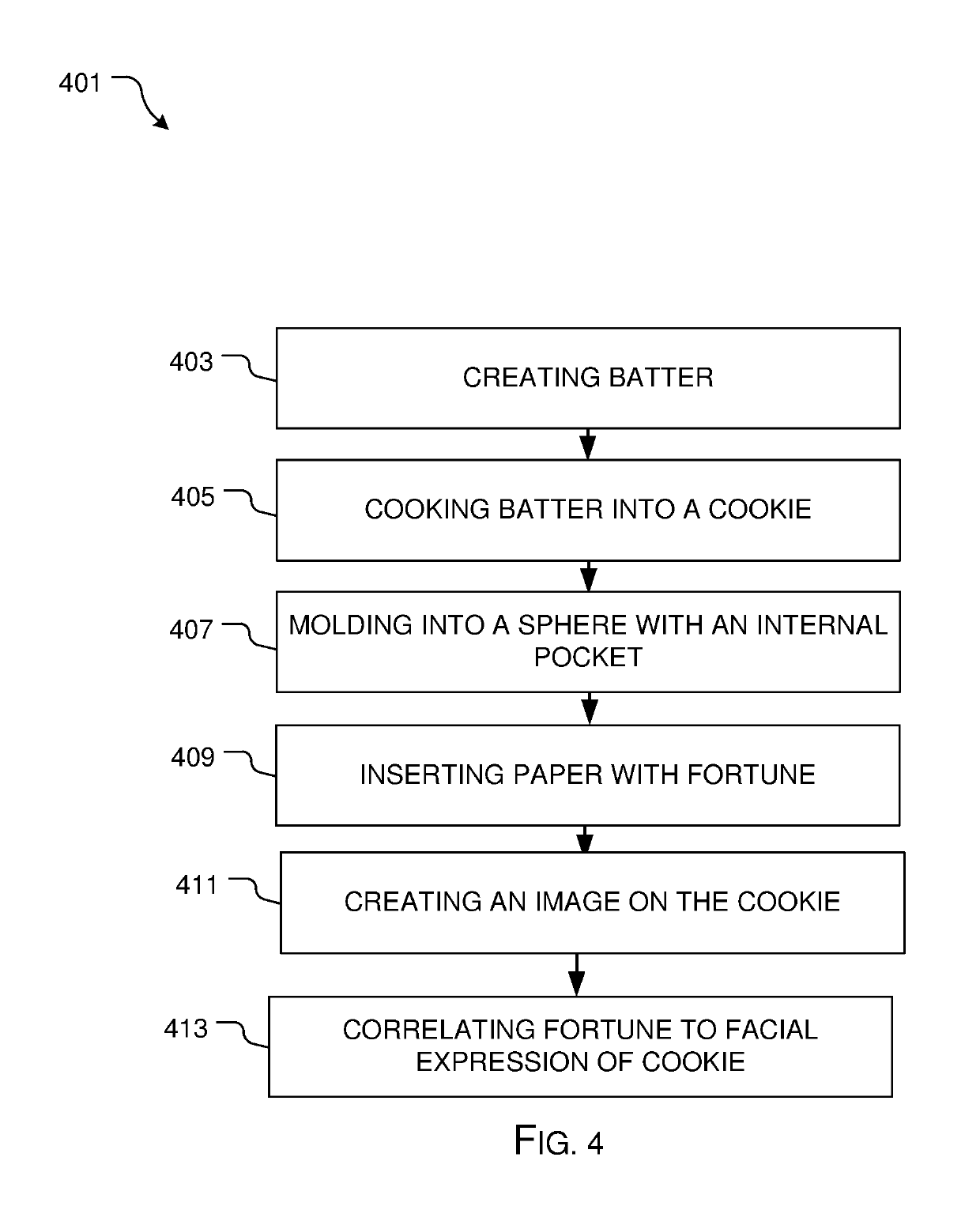

Fortune cookie and method of making the same

A fortune cookie includes a body composed of an edible cookie batter and the body being spherical in shape and having an internal pocket contained therein; an image displayed on an exterior surface of the body; and a piece of paper disposed within the internal pocket, the piece of paper having a fortune written thereon; the piece of paper is removable from the internal cavity via breaking the body.

Owner:SCHMUCK JOSEPH

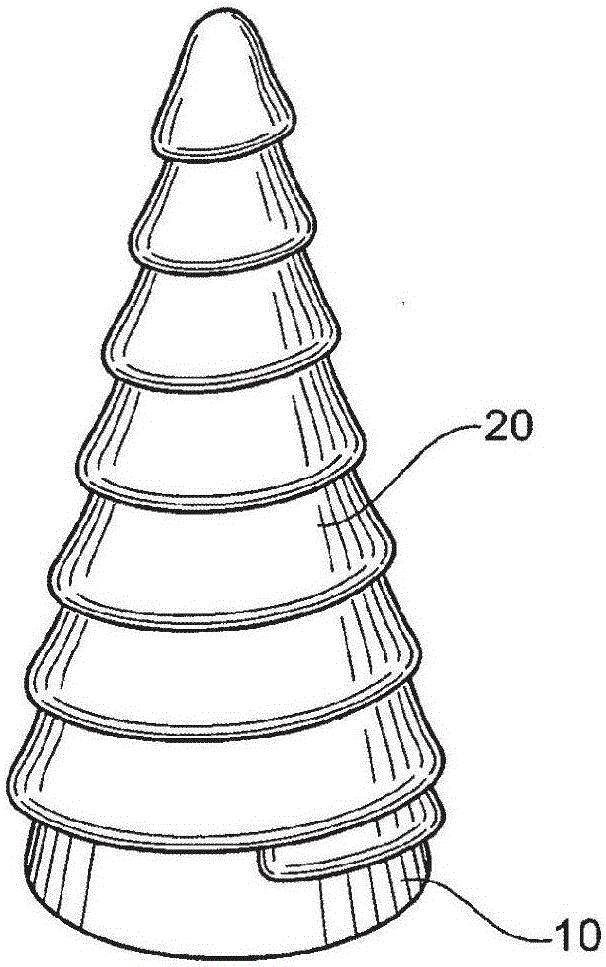

Bake form for manufacturing food product

ActiveCN105934156AStable and reliable productionReliable hardnessDough sheet coiling machinesBakery productsConstant linear velocityConveyor belt

An automated system and method for manufacturing a cone- shaped food product holder (20) requires the coordinated use of a forming unit (24), a conveyor unit (26) and a control unit (28). In their combination, the forming unit (24) rotates a conically-shaped bake form (10) at a constant angular velocity <omega>. Simultaneously, the conveyor unit (26) advances a bread dough strip on a conveyor belt (54) at a constant linear velocity v, for deposit of the bread dough strip onto the bake form (10). In order to account for the conical configuration of the bake form, the actions of the forming unit (24) and the conveyor unit (26) are coordinated by the control unit (28). Specifically, the control unit (28) moves the conveyor unit (26) with a predetermined rotation relative to the forming unit (24) to form the food product holder (20) on the forming unit (24) for subsequent baking.

Owner:CONEWICH ENTERPRISES PARTNERSHIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com