Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

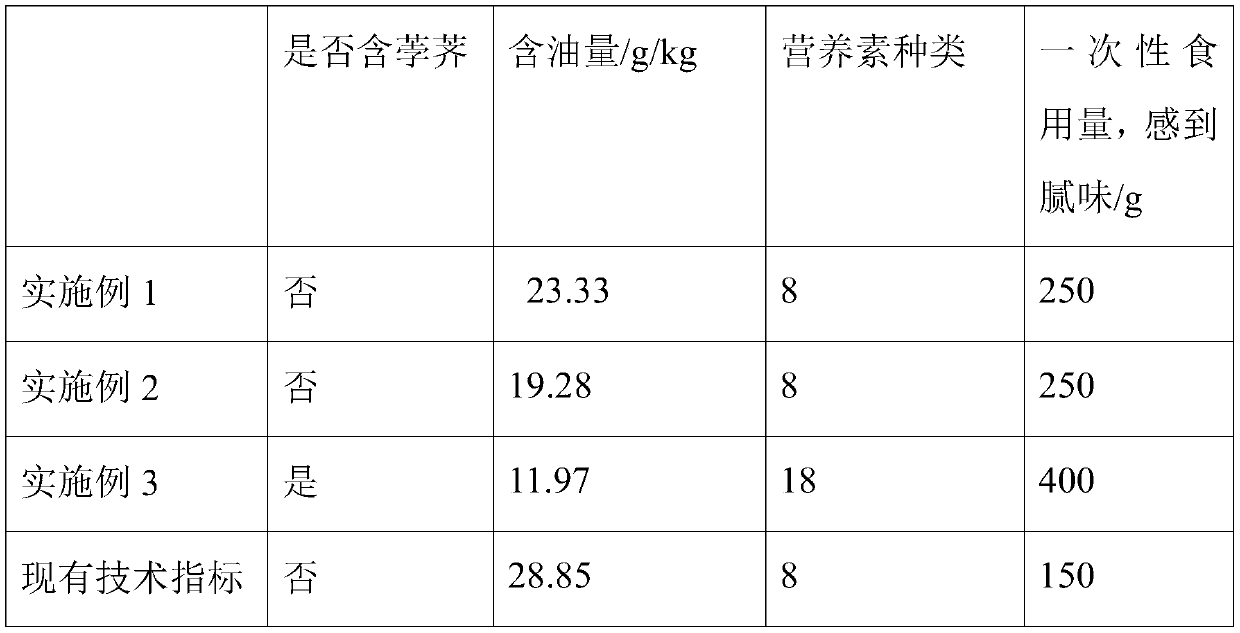

42results about How to "Less oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

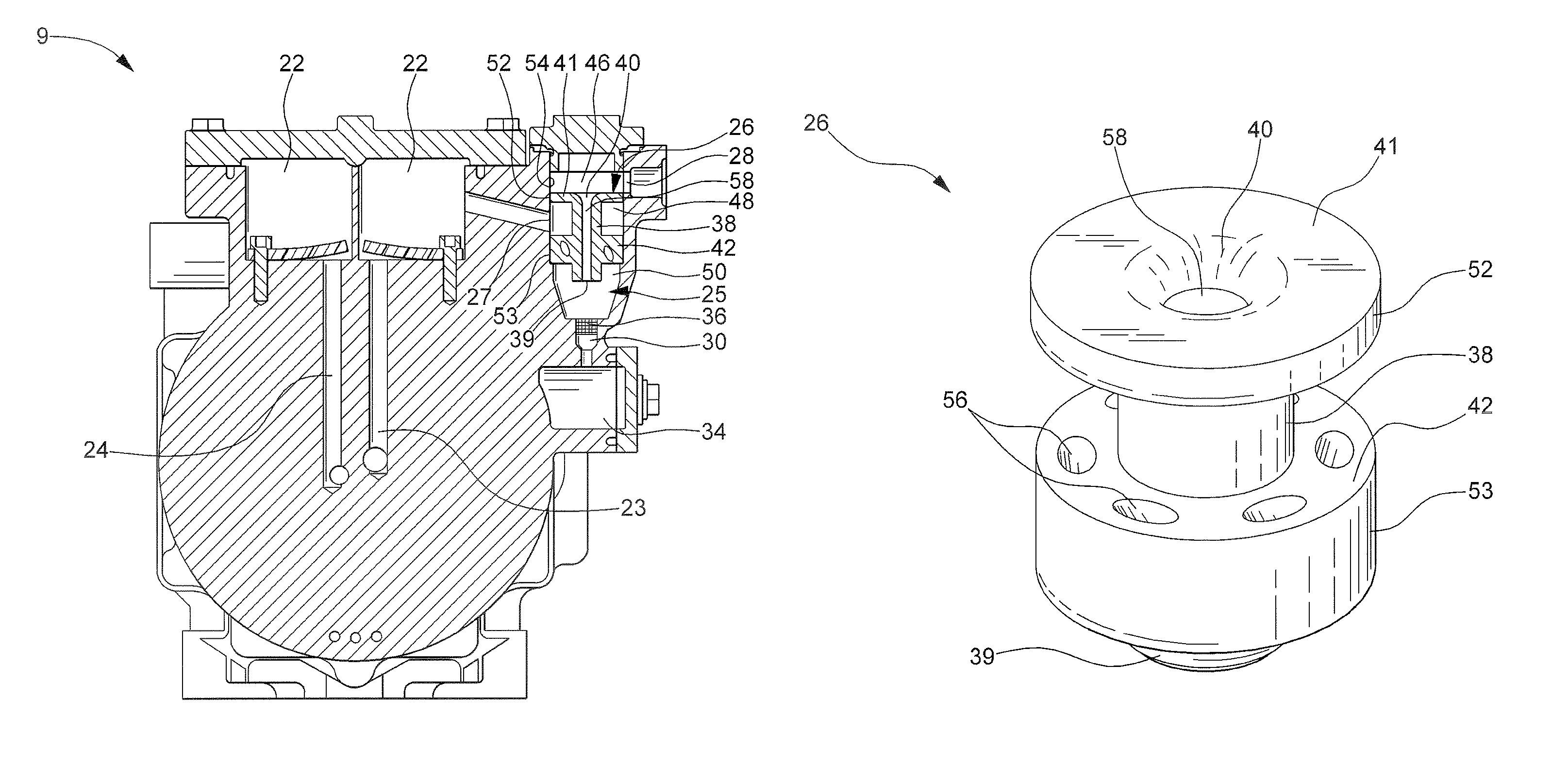

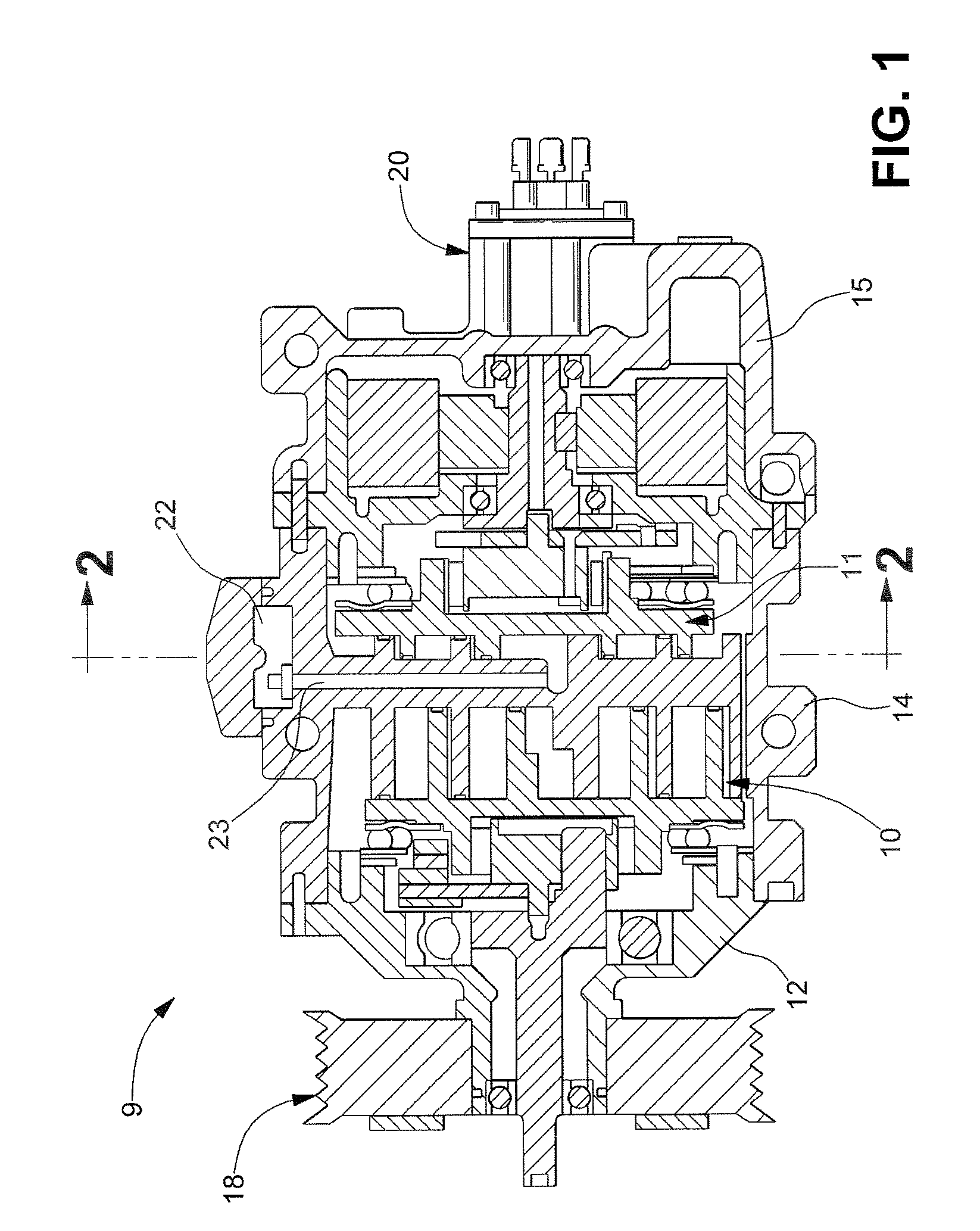

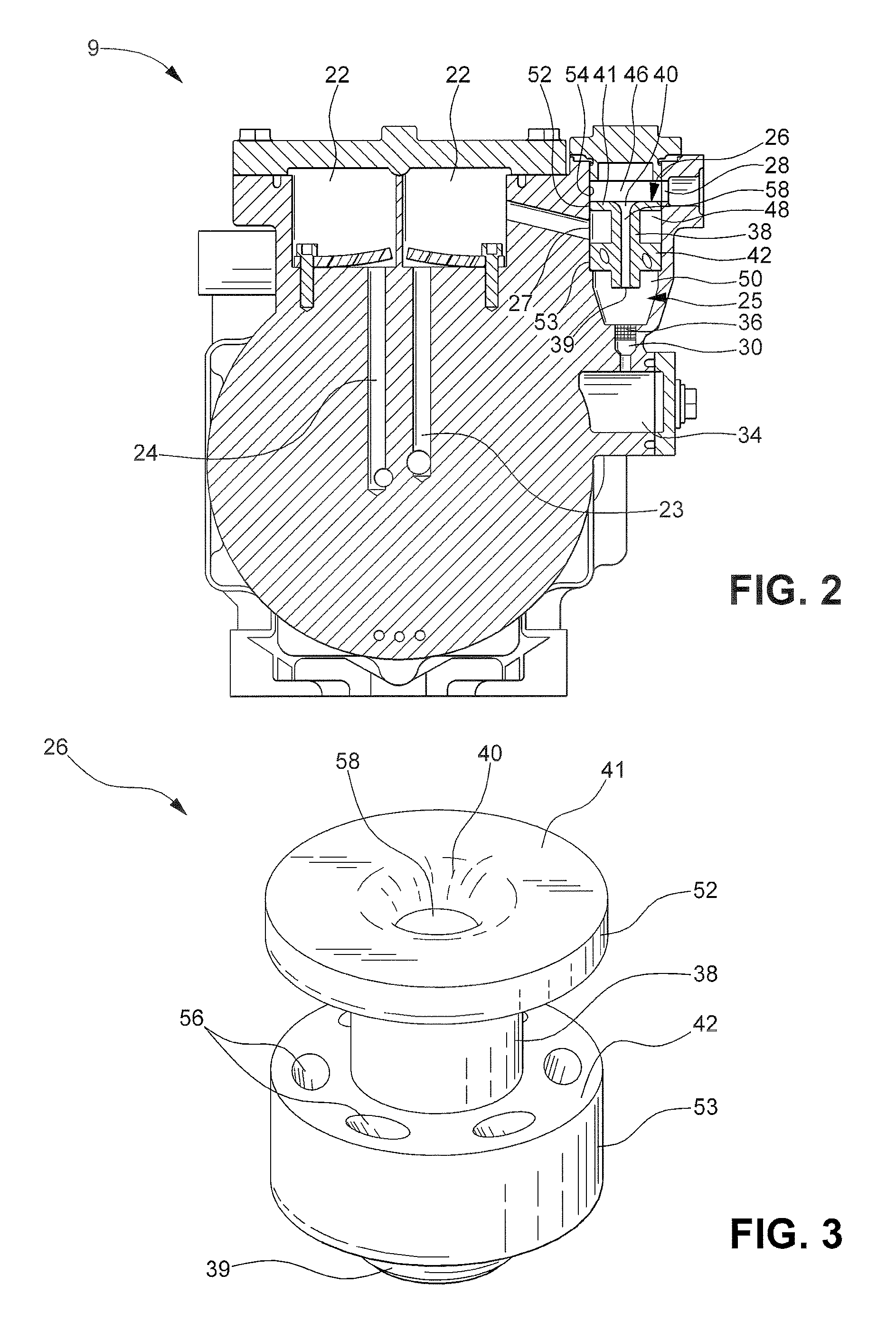

Fluid separator for a compressor

ActiveUS7708537B2Minimize complexityLow costRotary/oscillating piston combinations for elastic fluidsCombination devicesEngineeringShaft collar

A fluid separator for a compressor is disclosed including a hollow main body having an annular flange and an annular collar formed thereon, wherein the annular collar includes an annular array of apertures formed therein for separating a liquid from a fluid and attenuating pressure pulsations of the fluid.

Owner:HANON SYST

Food product and process for reducing oil and fat content in cooked food

InactiveUS7163707B2Minimize absorptionLess fatProtein composition from fishMeat/fish preservationProtein solutionMyofibril

A process for cooking a food in oil and / or fat is provided. A dry protein mixture, a dry alkaline protein mixture, an aqueous alkaline protein mixture or an aqueous acidic protein is added to a food prior to cooking. The dry protein mixture, dry alkaline protein mixture, aqueous alkaline protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:PROTEUS INDUSTRIES INC

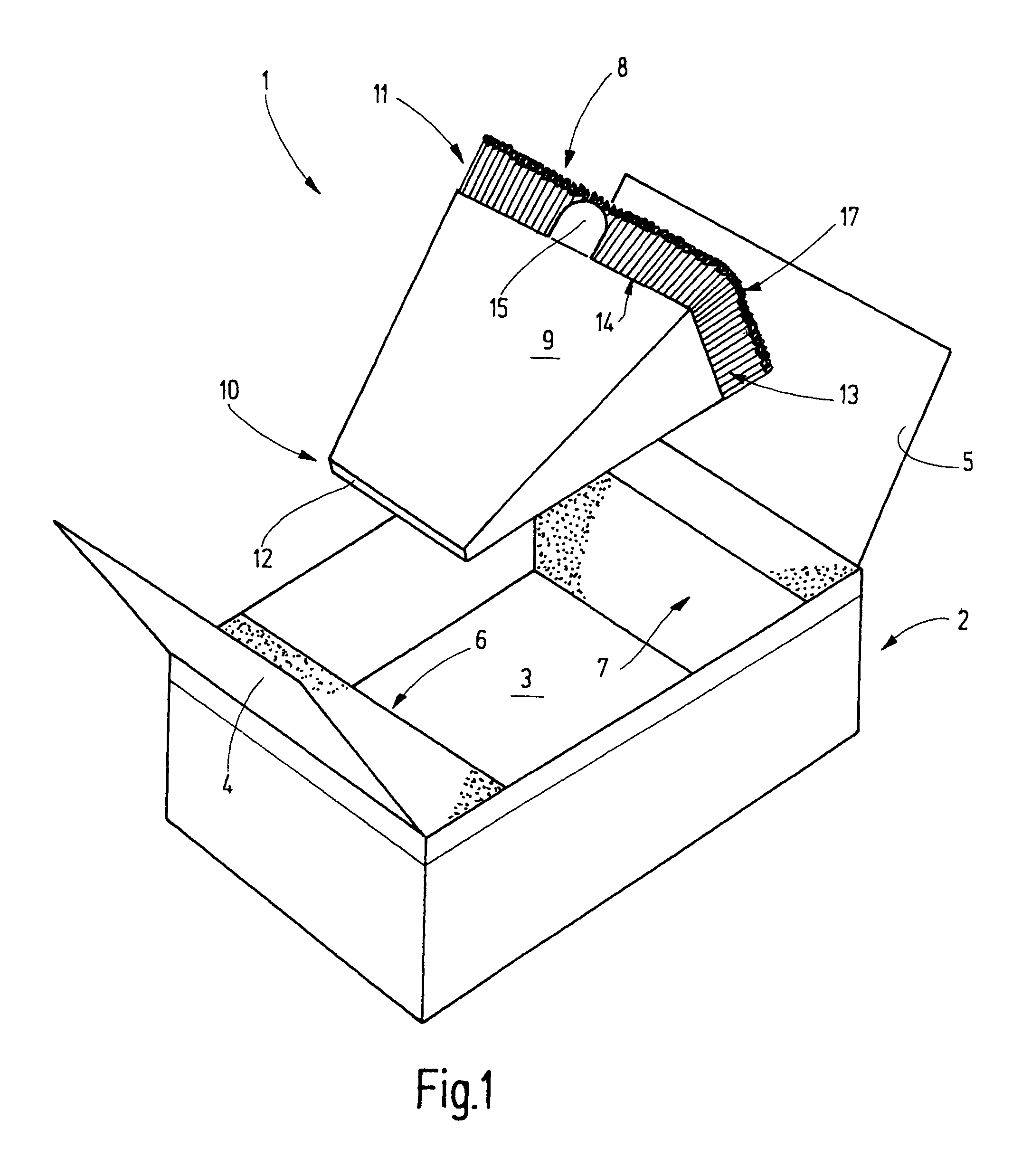

Package for felting needles

ActiveUS7798325B2Easy to handleReduce riskSewing needlesOther accessoriesEngineeringMechanical engineering

A wedge-shaped receptacle (9) is provided for packaging felting needles (8). The wedge shape is configured in such a manner that the felting needles lie in the receptacle in a mutual lateral engagement, that is, they are held approximately parallel to one another and they firmly clamp one another without their tips abutting against the receptacle body. This, on the one hand, results in a particular protection of the felting needles (8) during transportation and, on the other hand, results in a simple handling with the lowest danger of injuries.

Owner:GROZ BECKERT KG

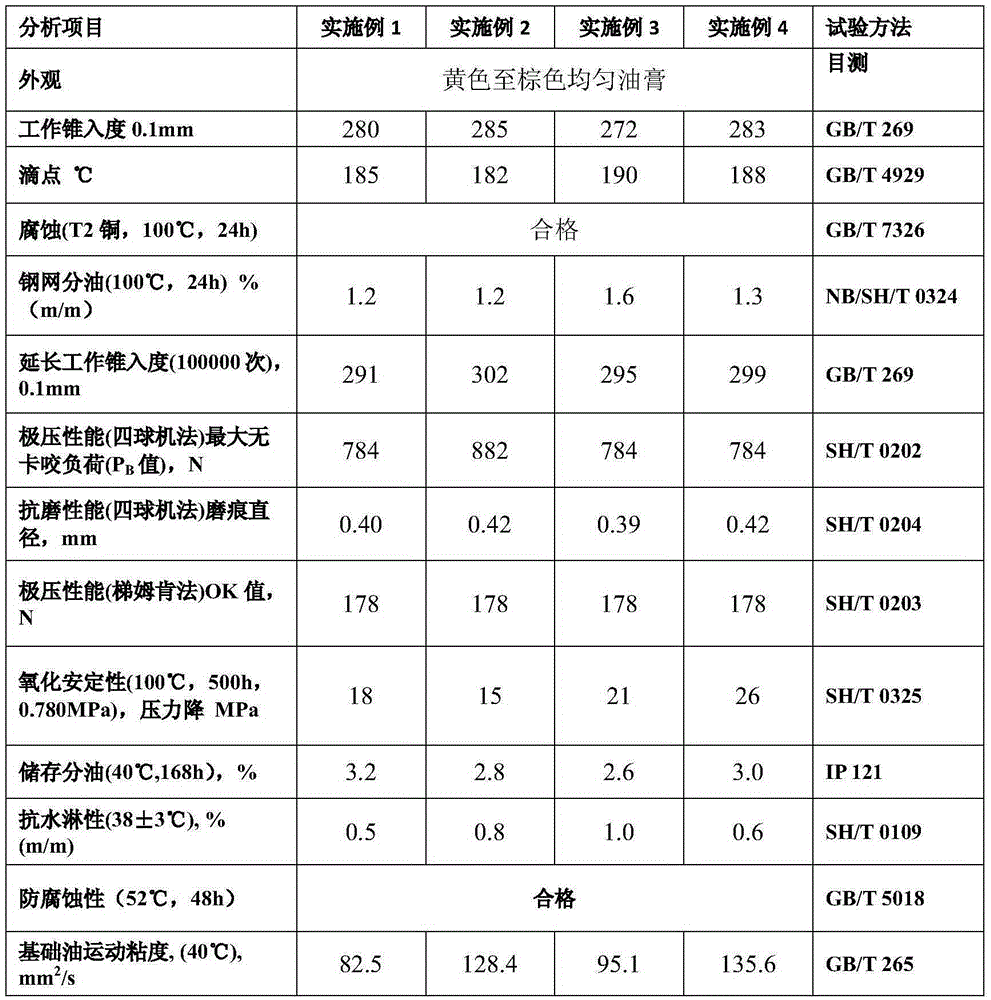

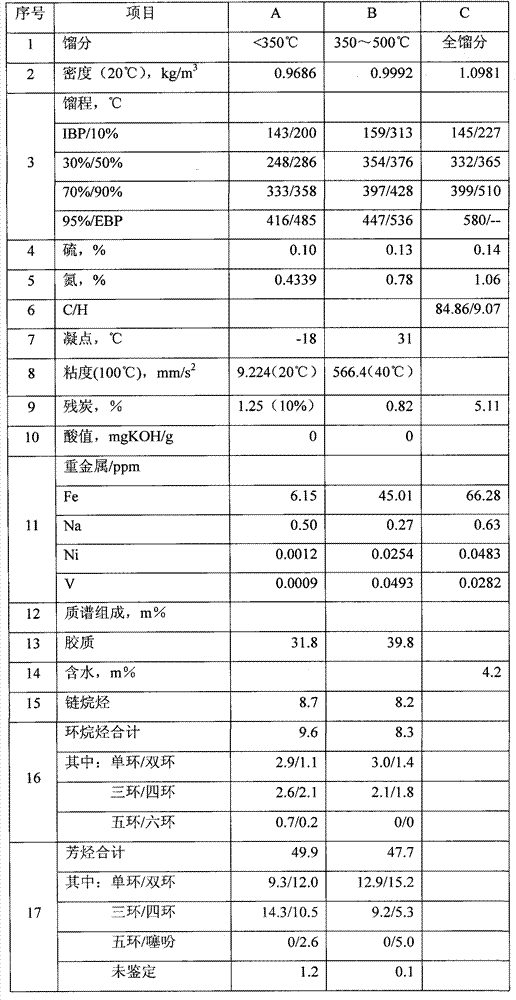

Anti-rust extreme pressure lithium lubricating grease composition and preparation method

InactiveCN105331426AImprove extreme pressure performanceImprove shear stabilityLubricant compositionAntioxidantLithium hydroxide

The invention relates to an anti-rust extreme pressure lithium lubricating grease composition and a preparation method thereof. The composition is prepared from 5.5%-12.5% of thickening agents, 72.8%-91.3% of base oil, 0.5%-3.8% of extreme pressure anti-wear agents, 0.28%-1.25% of antioxidants and 0.02%-1.05% of anti-rust anti-corrosion agents, wherein the base oil is high-viscosity mineral oil. The preparation method of the composition comprises the steps that one third of the base oil and 12-hydroxy stearin or a mixture of 12-hydroxy stearin and stearic acid are heated to the temperature ranging from 60 DEG C to 80 DEG C, a lithium hydroxide solution is added, the temperature is raised to range from 180 DEG C to 220 DEG C after a reaction is completed, one third of quenching oil is added, the extreme pressure anti-wear agents, the anti-rust anti-corrosion agents and the rest of the base oil are added after cooling is conducted, and the composition is prepared after grounding is conducted. The novel lubricating grease containing the extreme pressure components and the anti-rust anti-corrosion components has the excellent extreme pressure property and anti-corrosion property and can be widely applied to severer environment conditions with a medium or heavy load and water.

Owner:CHINA PETROLEUM & CHEM CORP

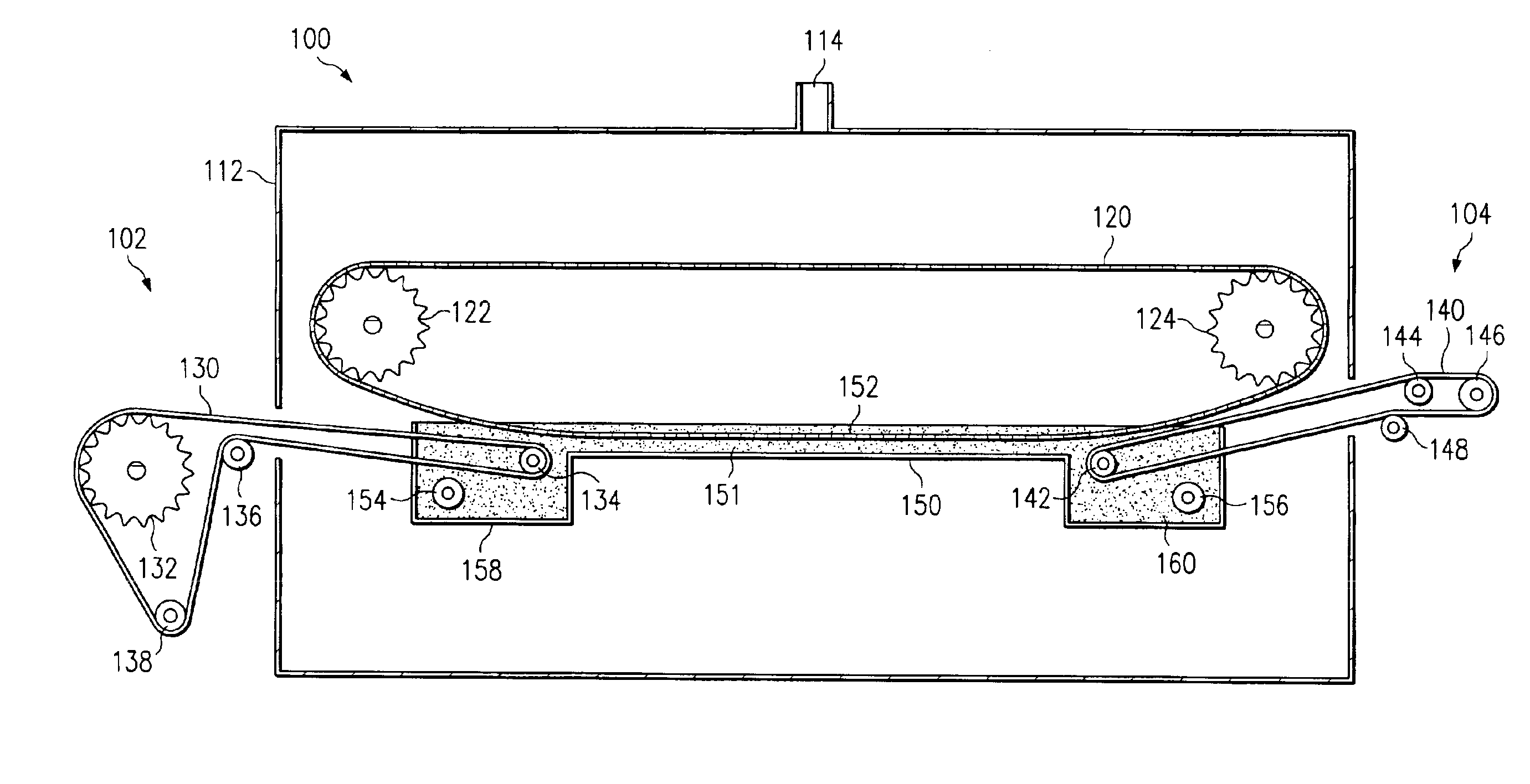

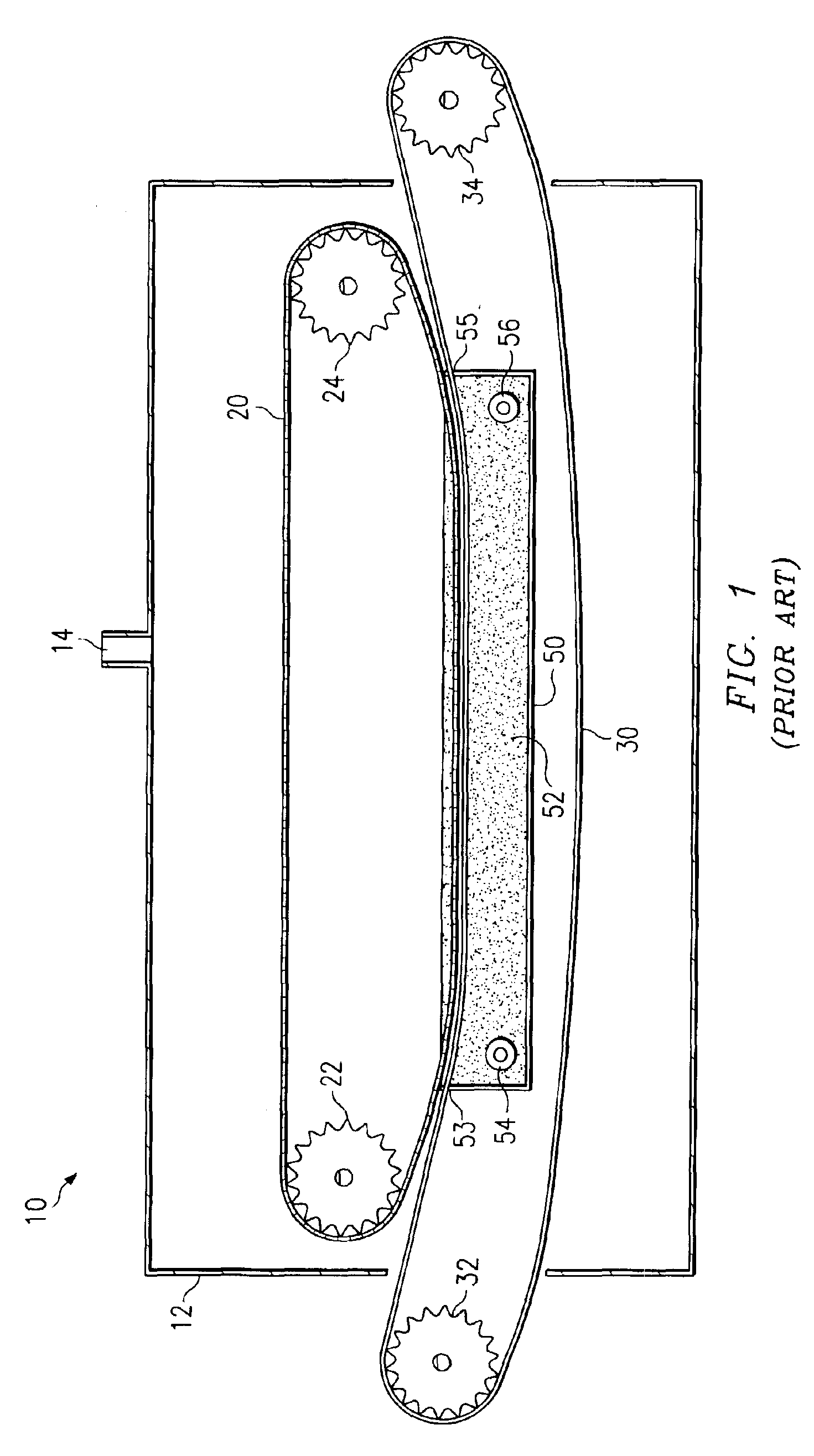

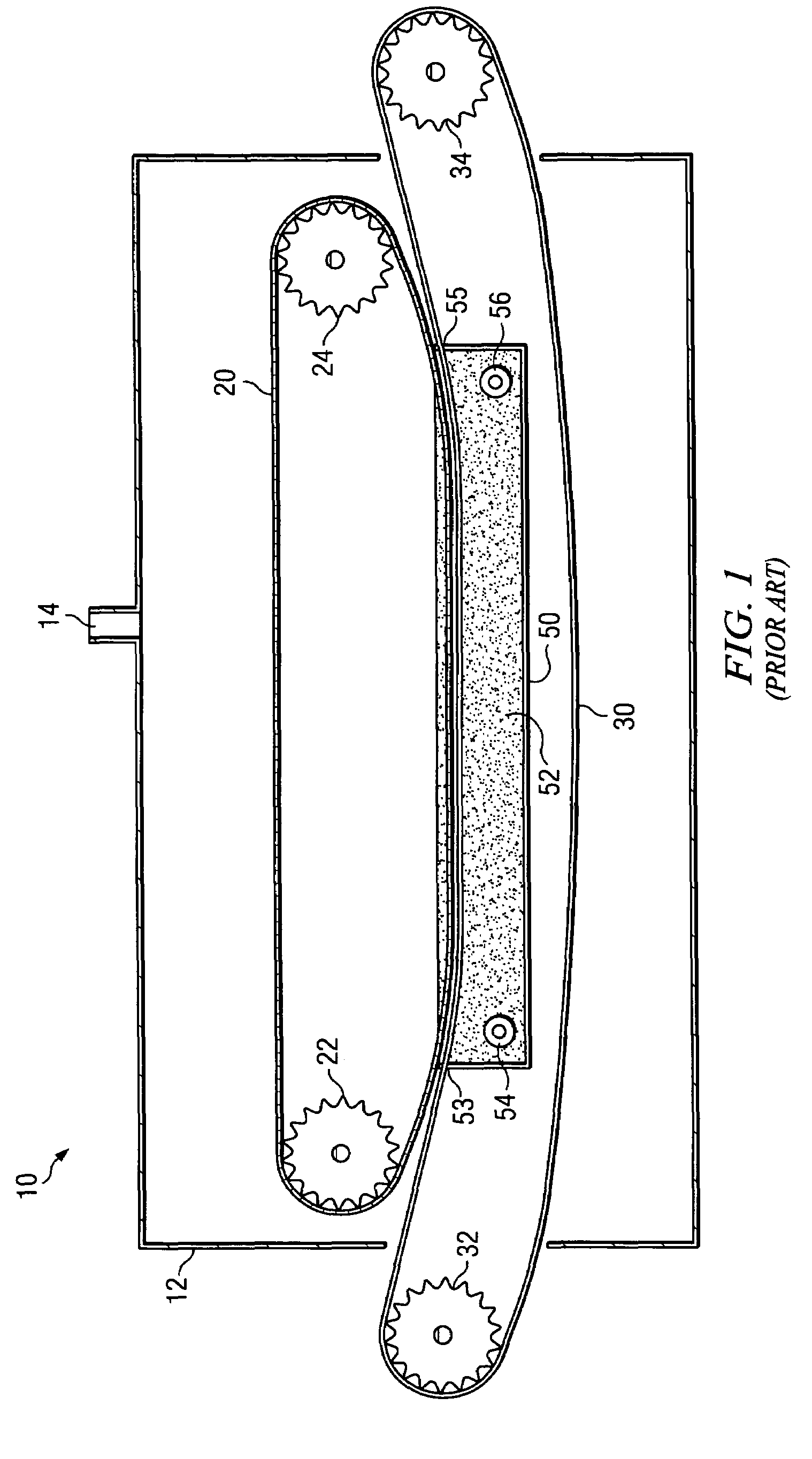

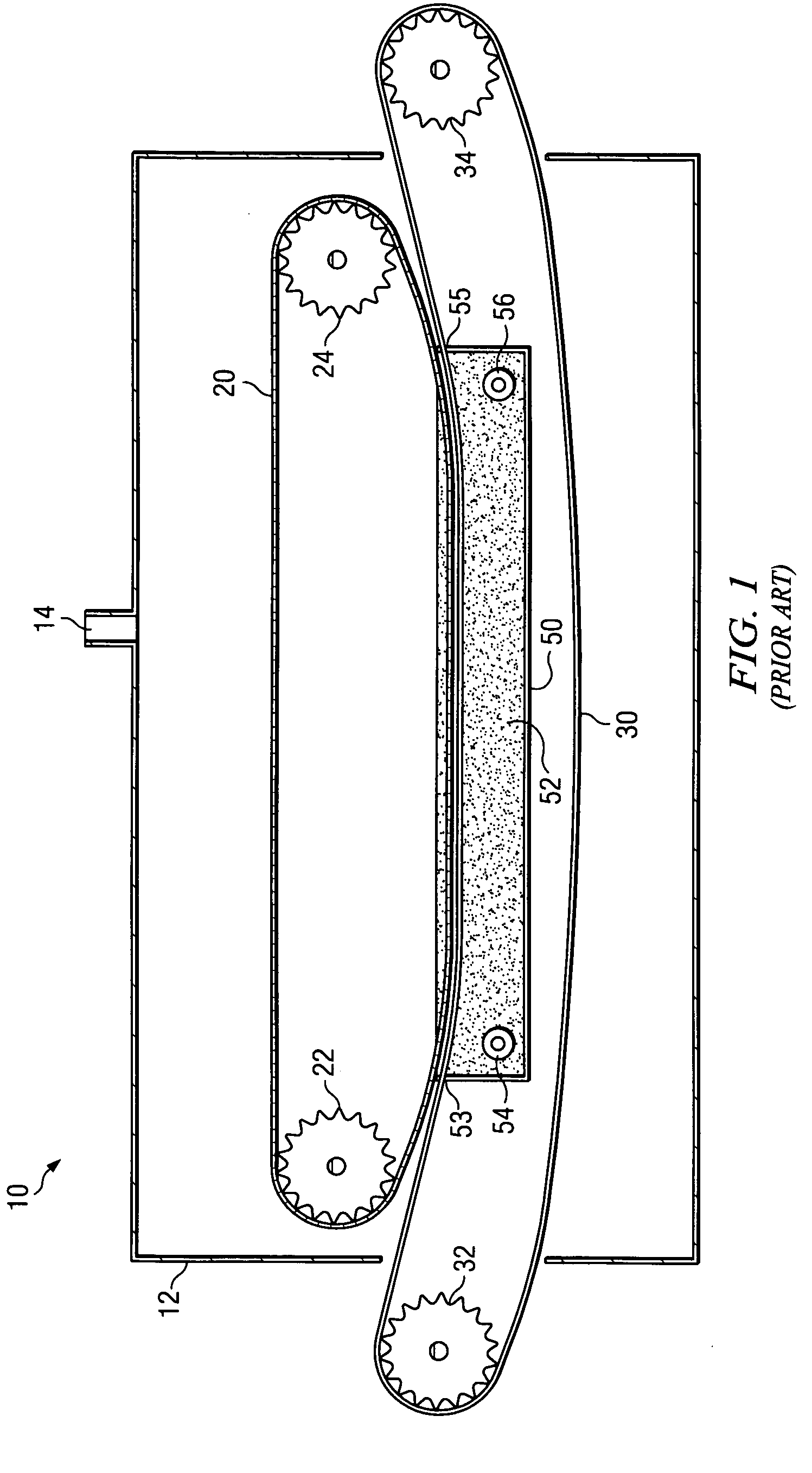

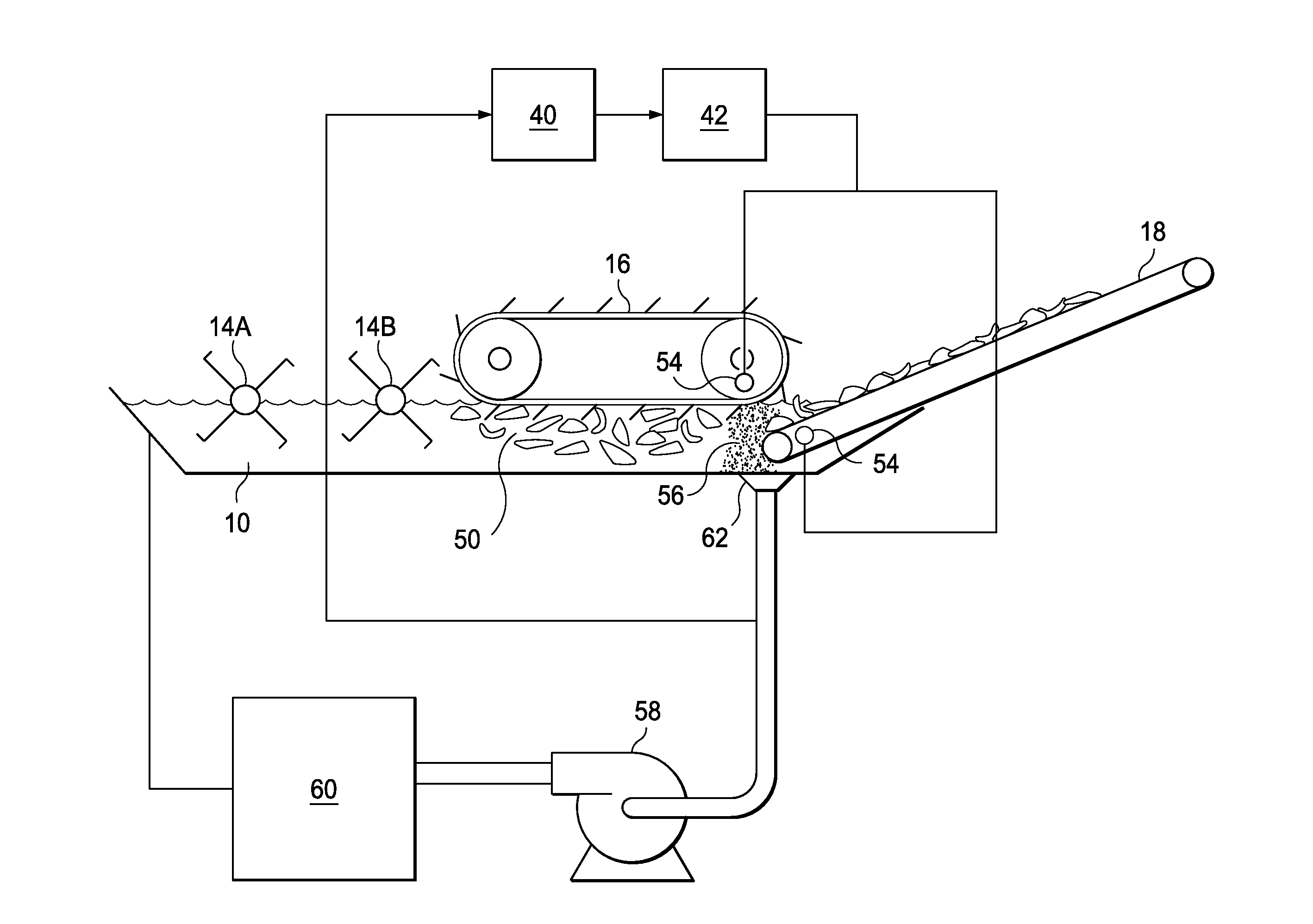

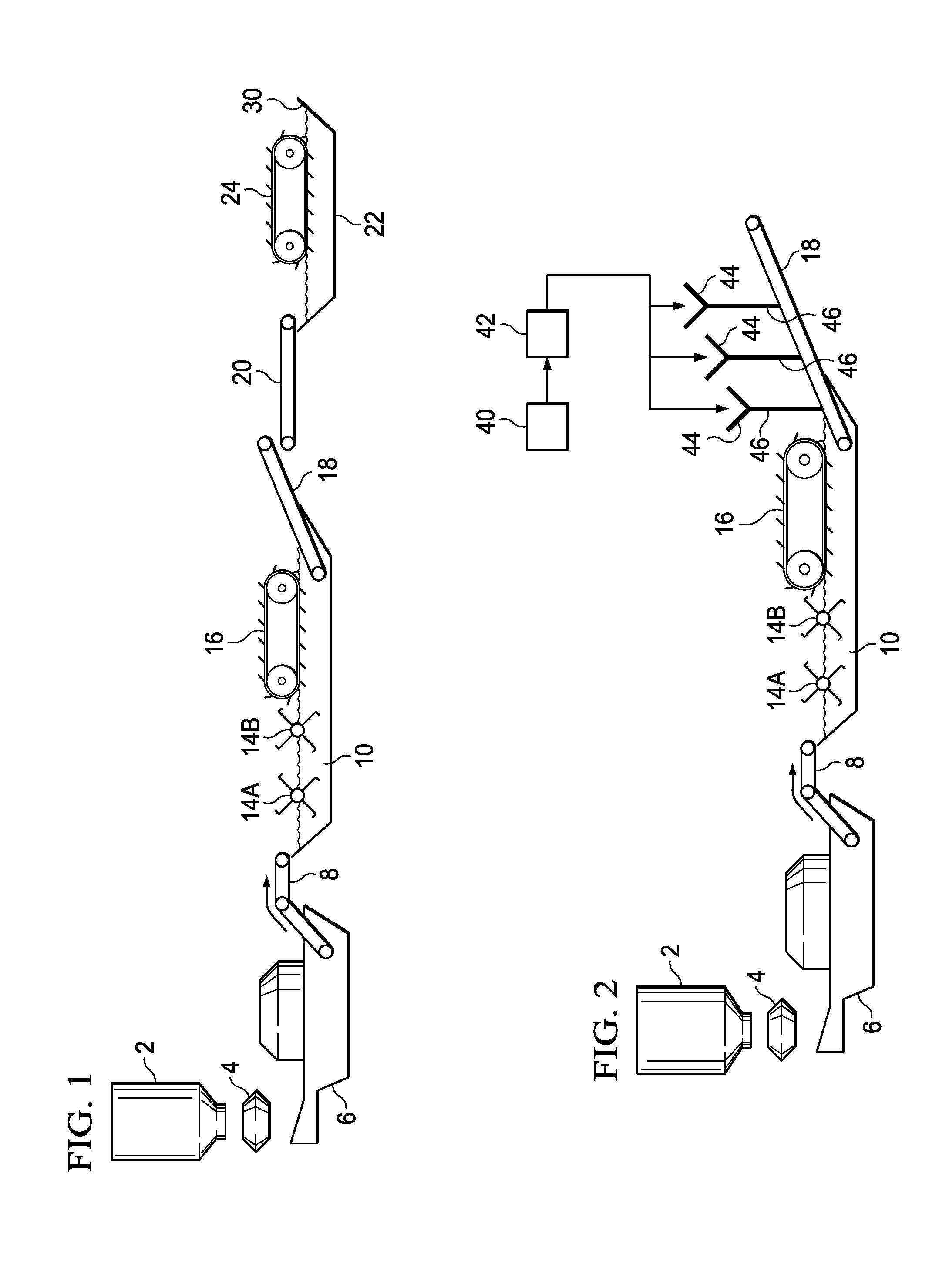

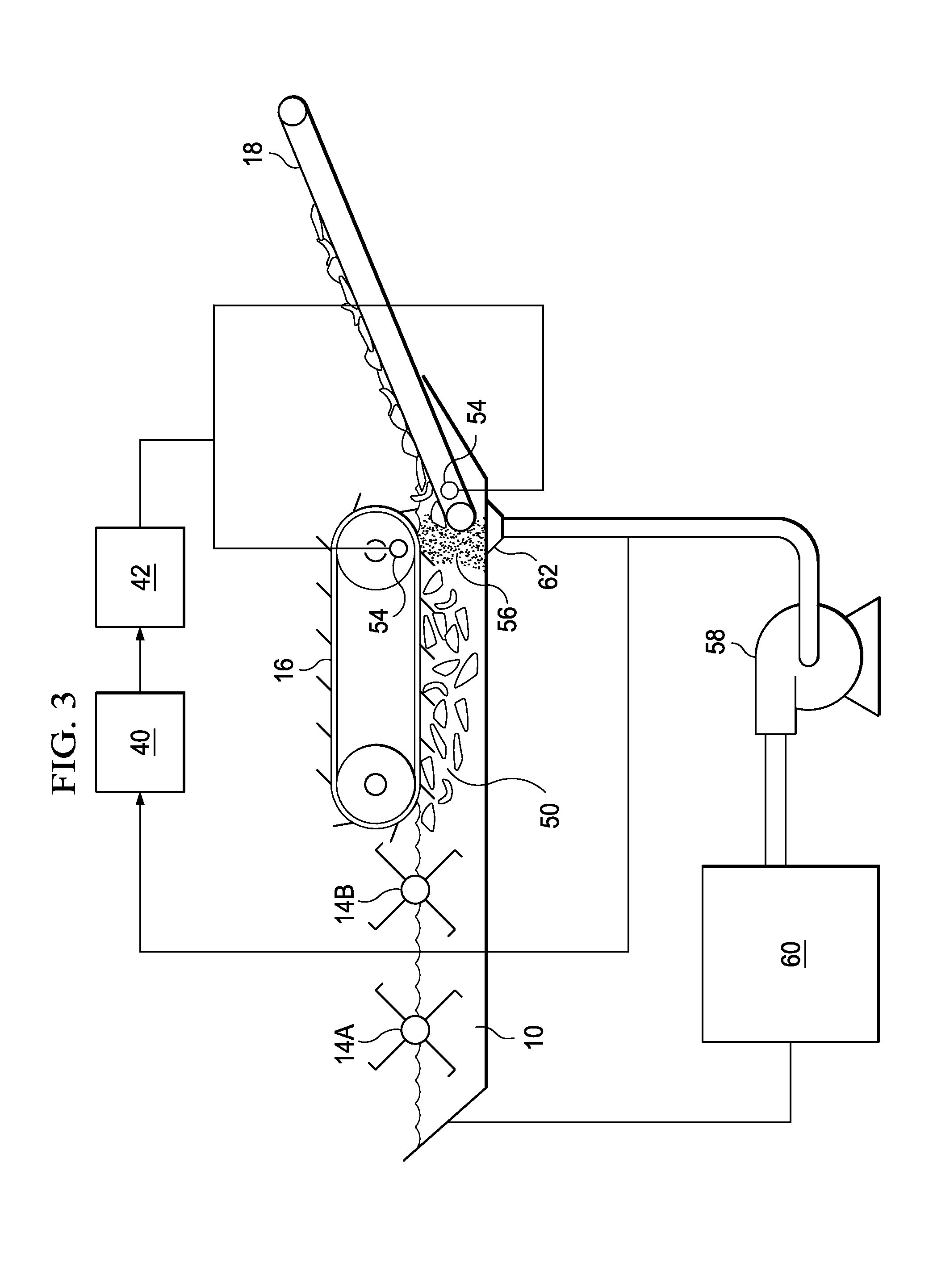

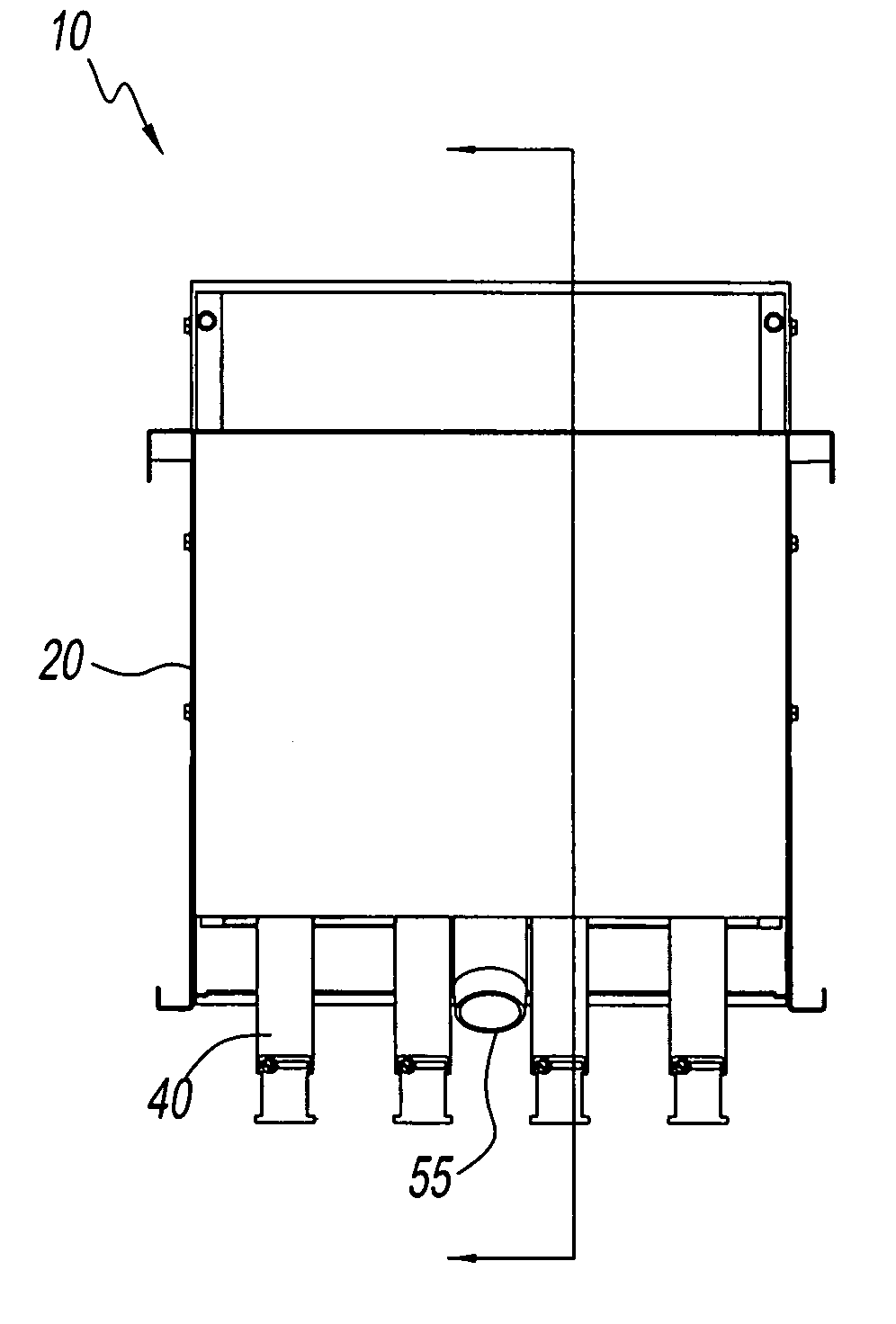

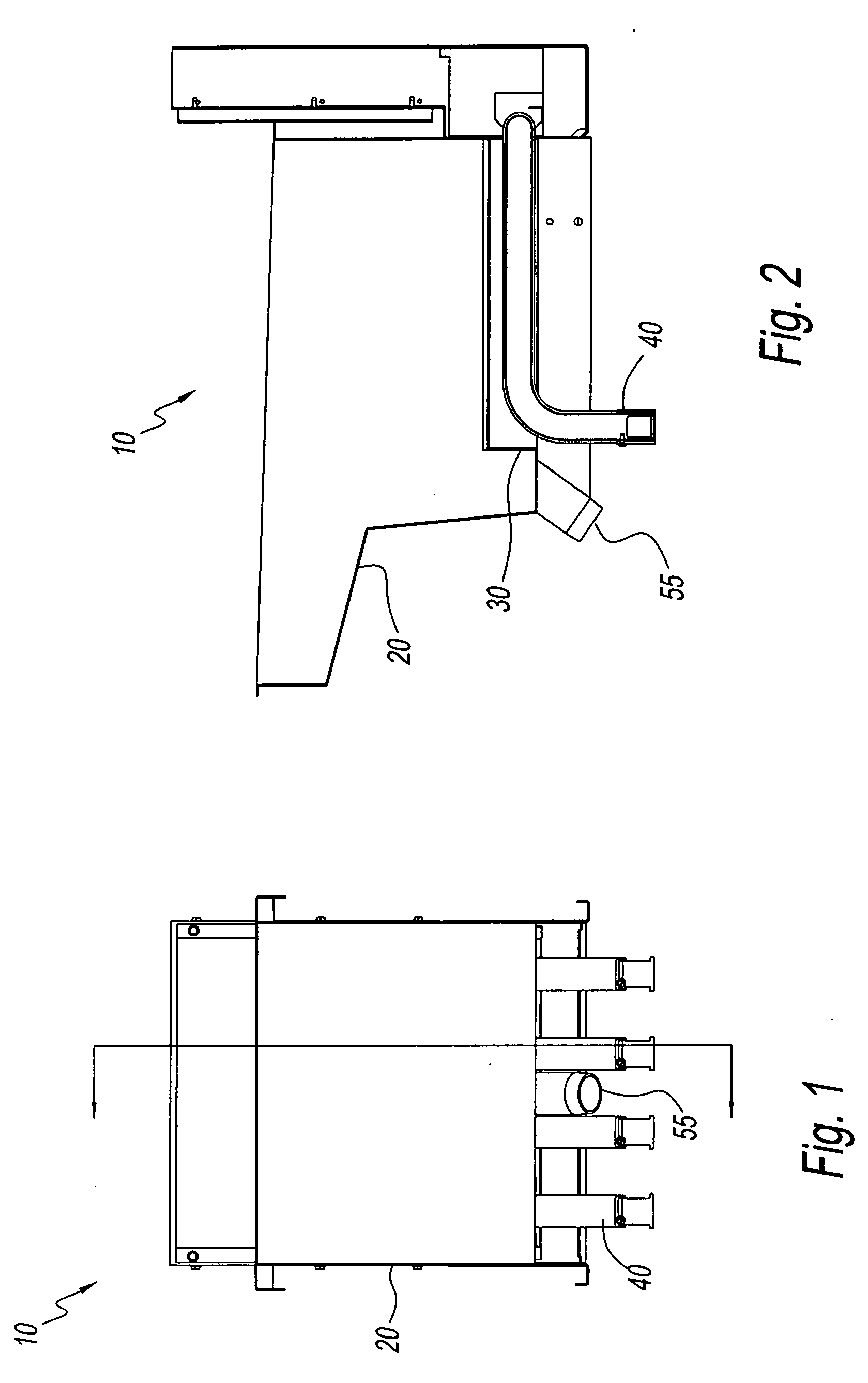

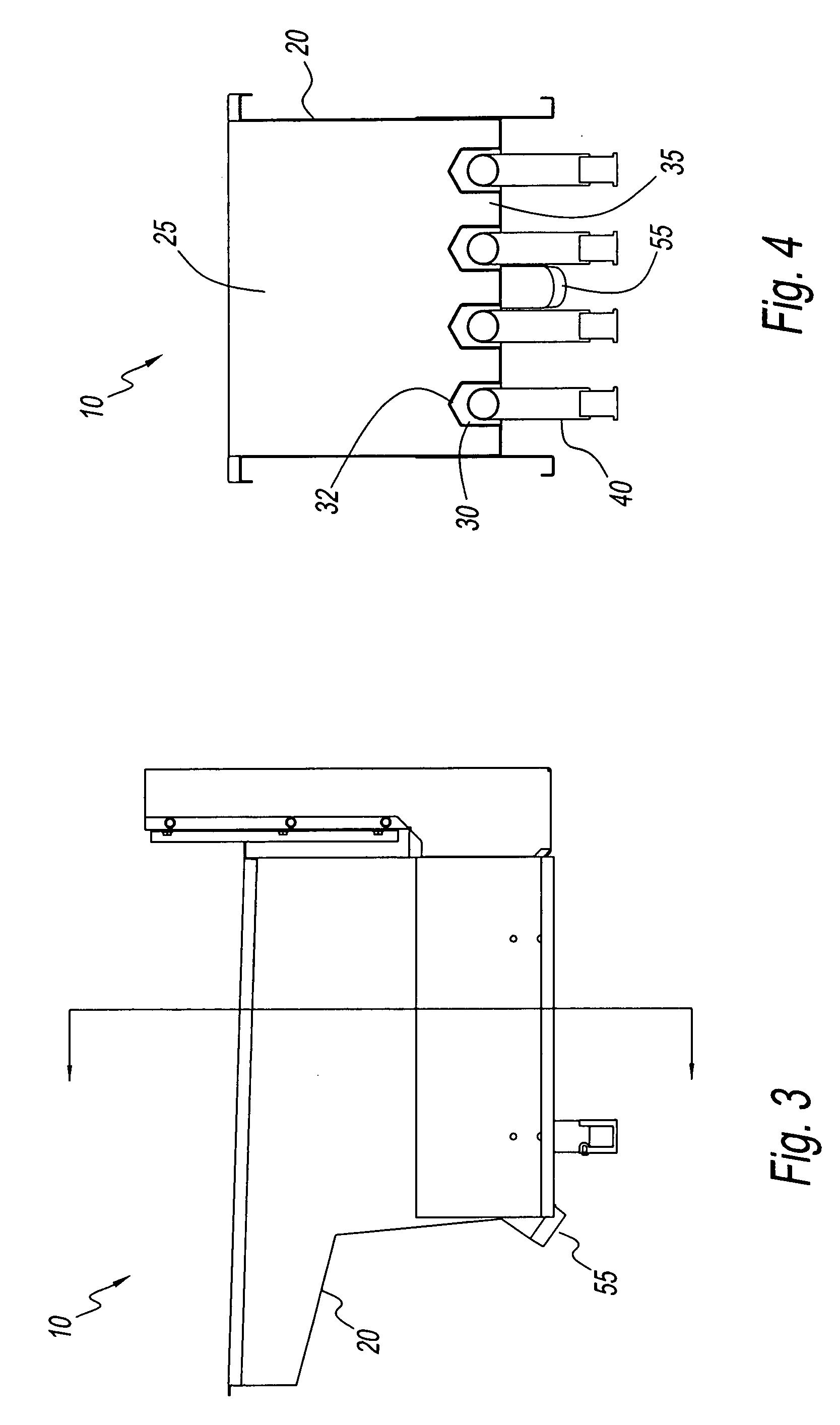

Single mold form fryer with enhanced product control

InactiveUS6875458B2Positively controlledReduce amountMilk preservationCooking vesselsEngineeringMechanical engineering

A mold form fryer utilizing a top conveyor that transports snack pieces through a constant velocity oil stream without the need of a bottom mating mold or conveyor. Herein, the form fryer is provided with a top conveyor disposed above a fryer oil pan positioned longitudinally through the fryer. Uncooked snack pieces are provided to the fryer oil pan by a bottom entrance conveyor. Snack pieces, once in oil within the fryer, meet with molding surfaces on the top conveyor. At the exit portion of the fryer, a bottom exit conveyor receives the cooked snack pieces from the top conveyor. As no continuous bottom conveyor is utilized, the fryer oil pan may be provided with a reduced volume segment situated between the bottom entrance and exit conveyors. Additionally, the molding surfaces may be selected to produce uniformly shaped snack pieces that are either convexly or concavely shaped when viewed upon the bottom exit conveyor.

Owner:FRITO LAY NORTH AMERICA INC

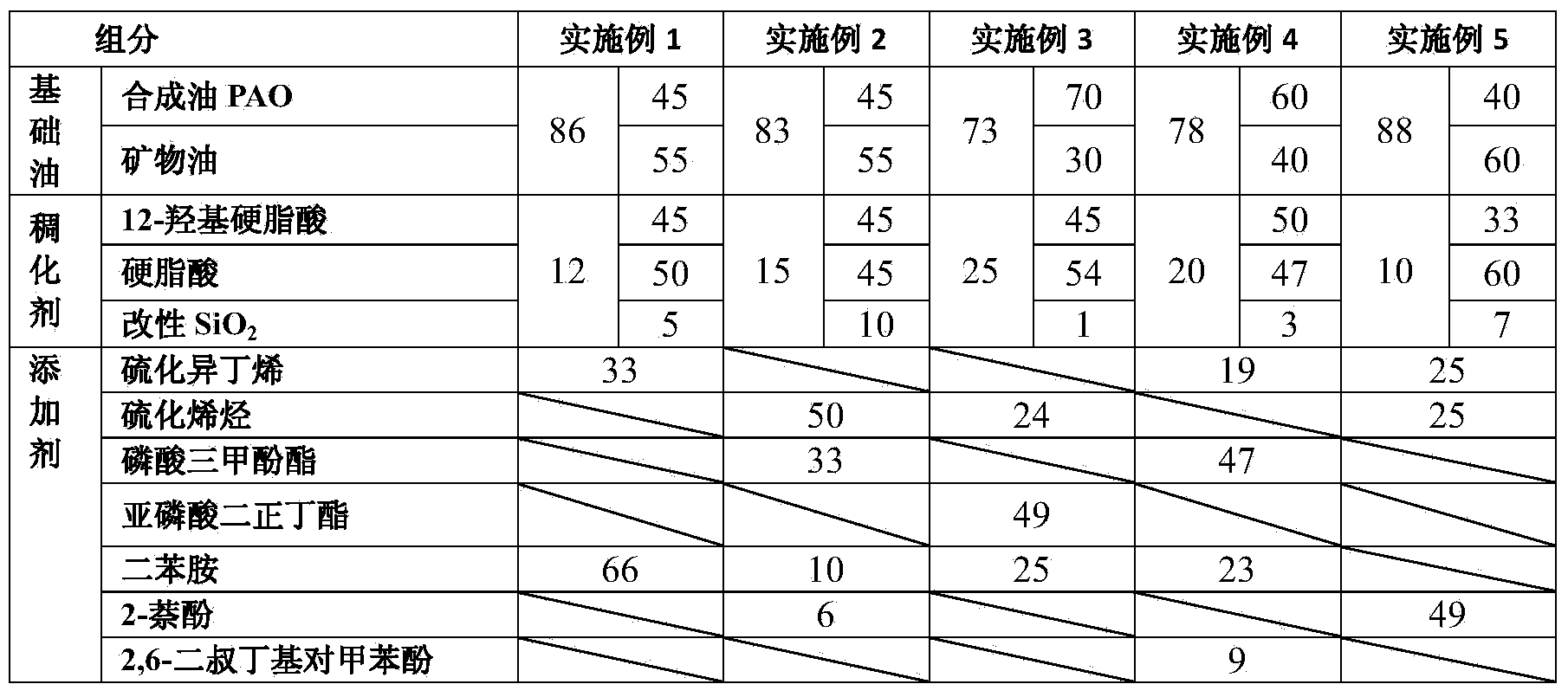

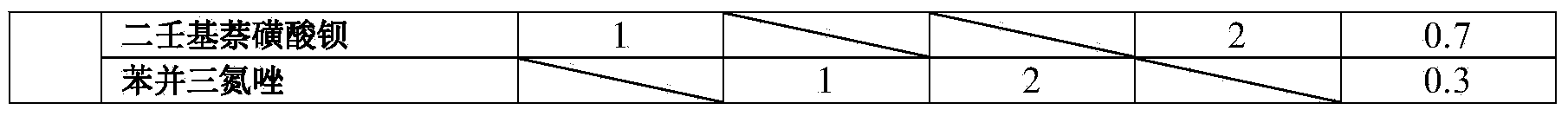

Lubricating grease containing modified silica component and preparation method of lubricating grease

ActiveCN103484204AImprove shear stabilityLittle change in cone penetrationPigment treatment with organosilicon compoundsLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to lubricating grease containing a modified silica component and a preparation method of the lubricating grease. The excellent properties of silicone grease and lithium lubricating grease are well combined through modified SiO2. With total weight of a composition as benchmark, the lubricating grease provided by the invention comprises the following components: a thickening agent accounting for 10-25% of the total weight and including 12-hydroxystearic acid, stearic acid and the modified SiO2; base oil accounting for 73-88% of the total weight and consisting of synthetic oil and mineral oil; and additives mainly including the following three types: (a) 0.6-1.8% of anti-wear reagent at extreme pressure, (b) 0.32-1.32% of antioxidant, and (c) 0.02-0.04% of antirust preservative. The novel lubricating grease containing modified SiO2 has excellent shear stability and storage stability and is a kind of SiO2-containing lithium lubricating grease in which high and low temperature, colloid stability and water resistance are greatly improved. The lubricating grease is especially suitable for application under harsh environmental conditions of high temperature and heavy load.

Owner:CHINA PETROLEUM & CHEM CORP

High-temperature no-dropping-point lubricating grease and production technique thereof

InactiveCN102051256ALong fatliquoring cycleWide adaptabilityLubricant compositionSulfonateSodium Bentonite

The invention relates to a high-temperature no-dropping-point lubricating grease and a production technique thereof. The high-temperature no-dropping-point lubricating grease is prepared from the following components in parts by weight: 13.7-84.4 parts of base oil, 5-15 parts of bentonite thickener, 5-50 parts of composite calcium sulfonate lubricating grease, 5-20 parts of tackifier, 0.5-1 part of antioxidant and 0.1-0.3 part of metal deactivator. The preparation method of the composite calcium sulfonate lubricating grease comprises the following steps: converting superhigh-base-number calcium sulfonate with a conversion agent at 60-100 DEG C for 20-60 minutes until the superhigh-base-number calcium sulfonate becomes obviously thickened, and heating to 140-180 DEG C to remove water. The high-temperature no-dropping-point lubricating grease has the advantages of long grease addition period and wide adaptability, and can be used in high-temperature positions; and at high temperature, the high-temperature no-dropping-point lubricating grease also has the advantages of no coking, light discolorment, less oil bleeding, low loss and longer service life.

Owner:辽宁海华科技股份有限公司

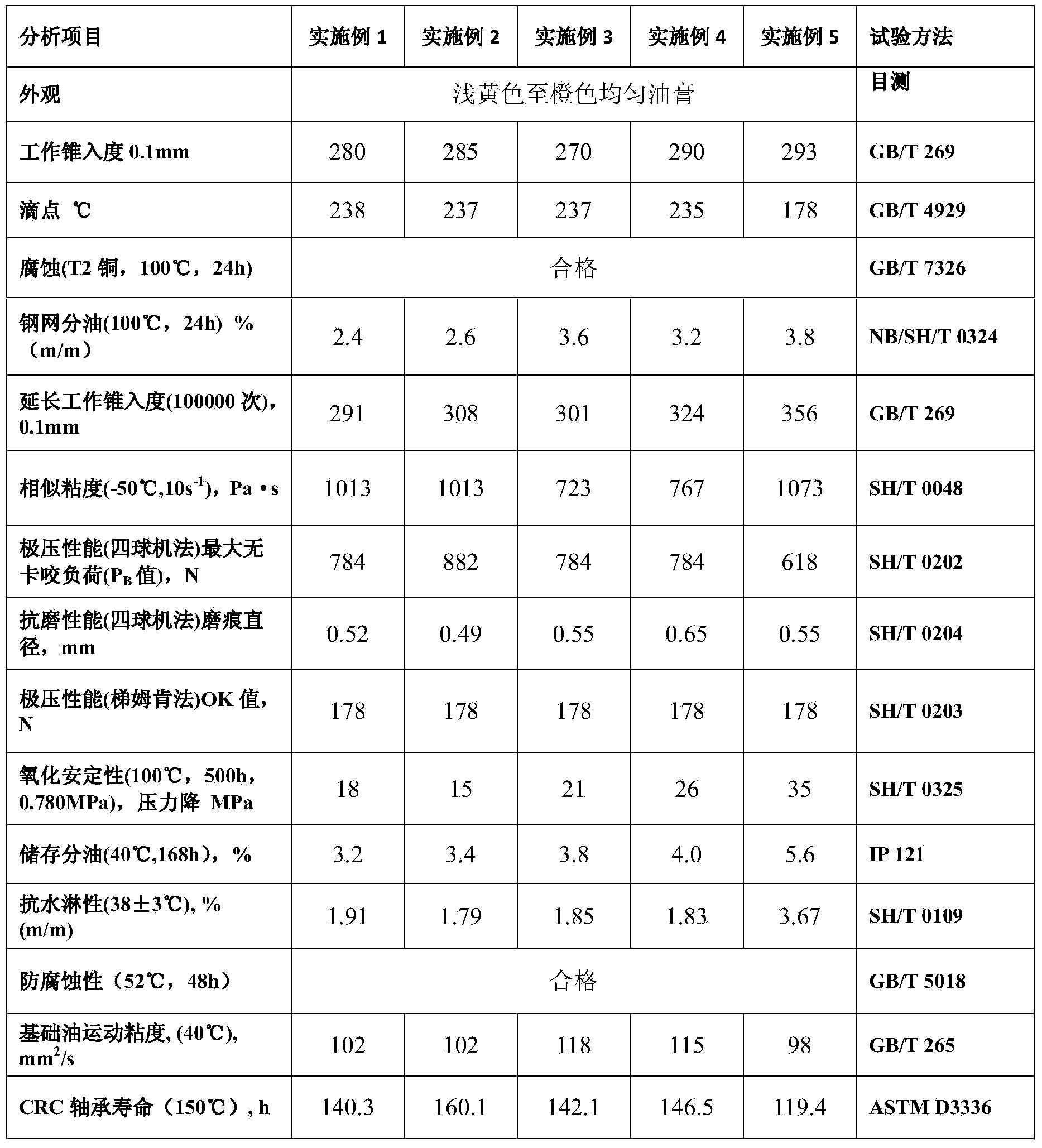

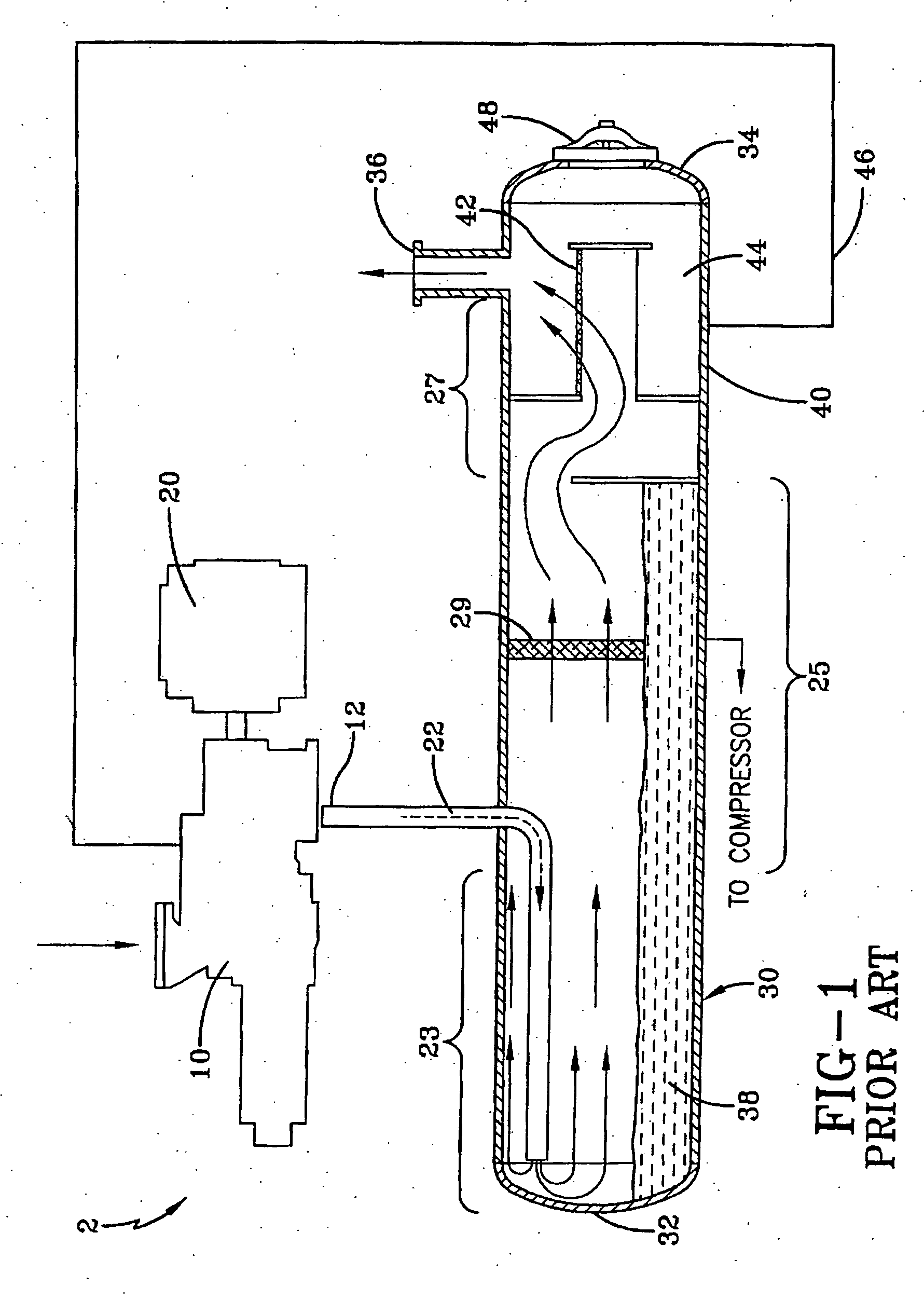

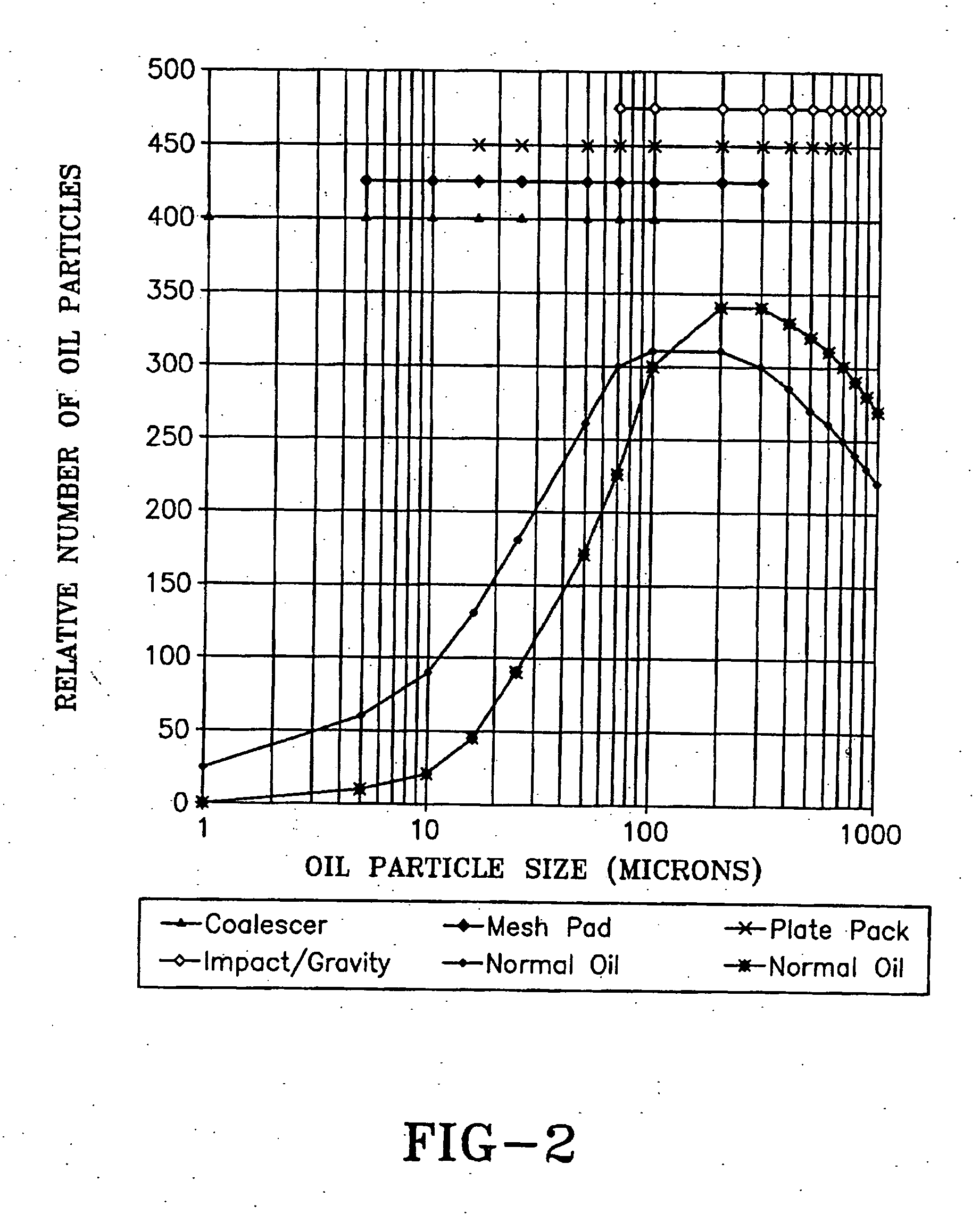

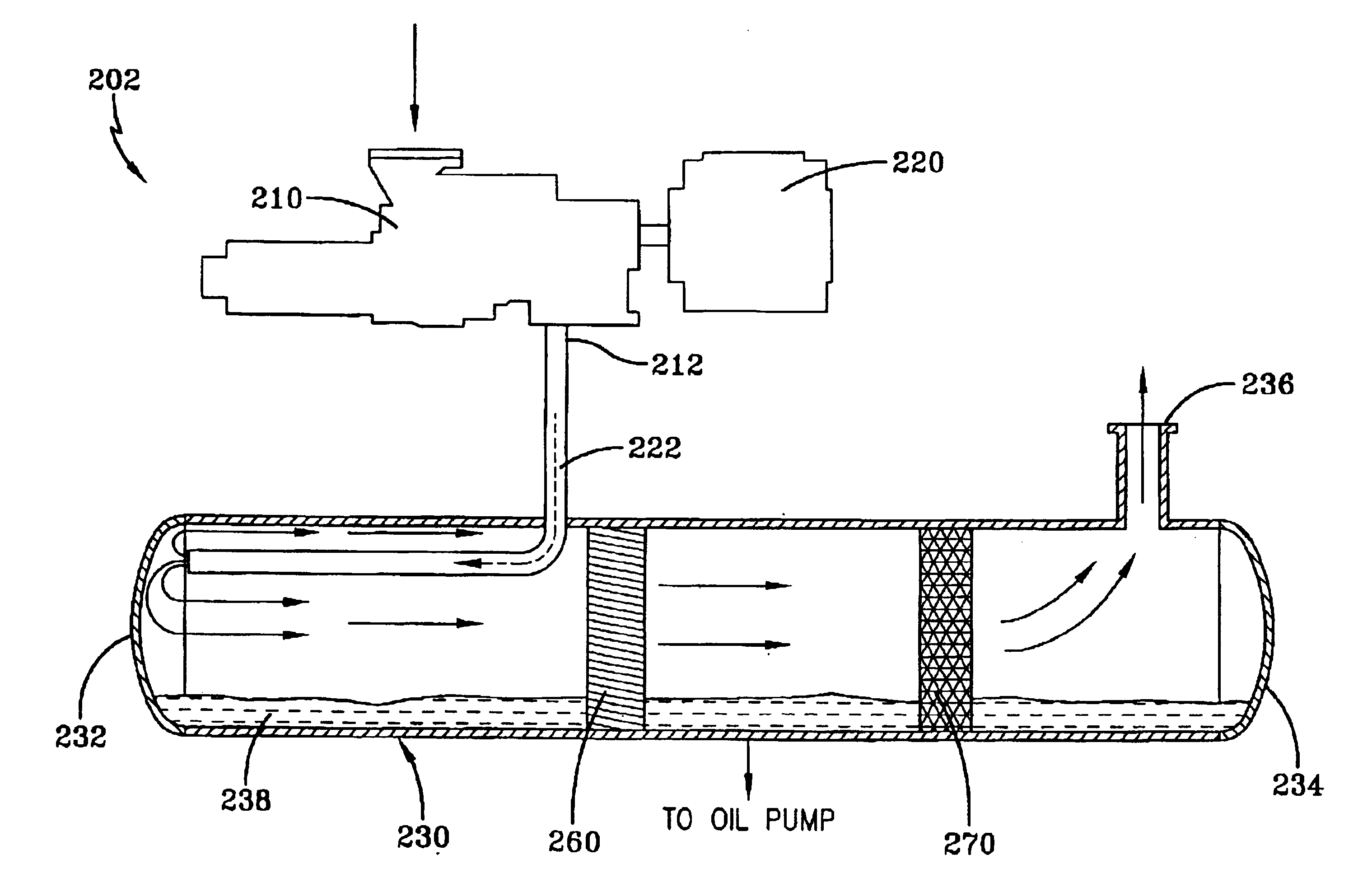

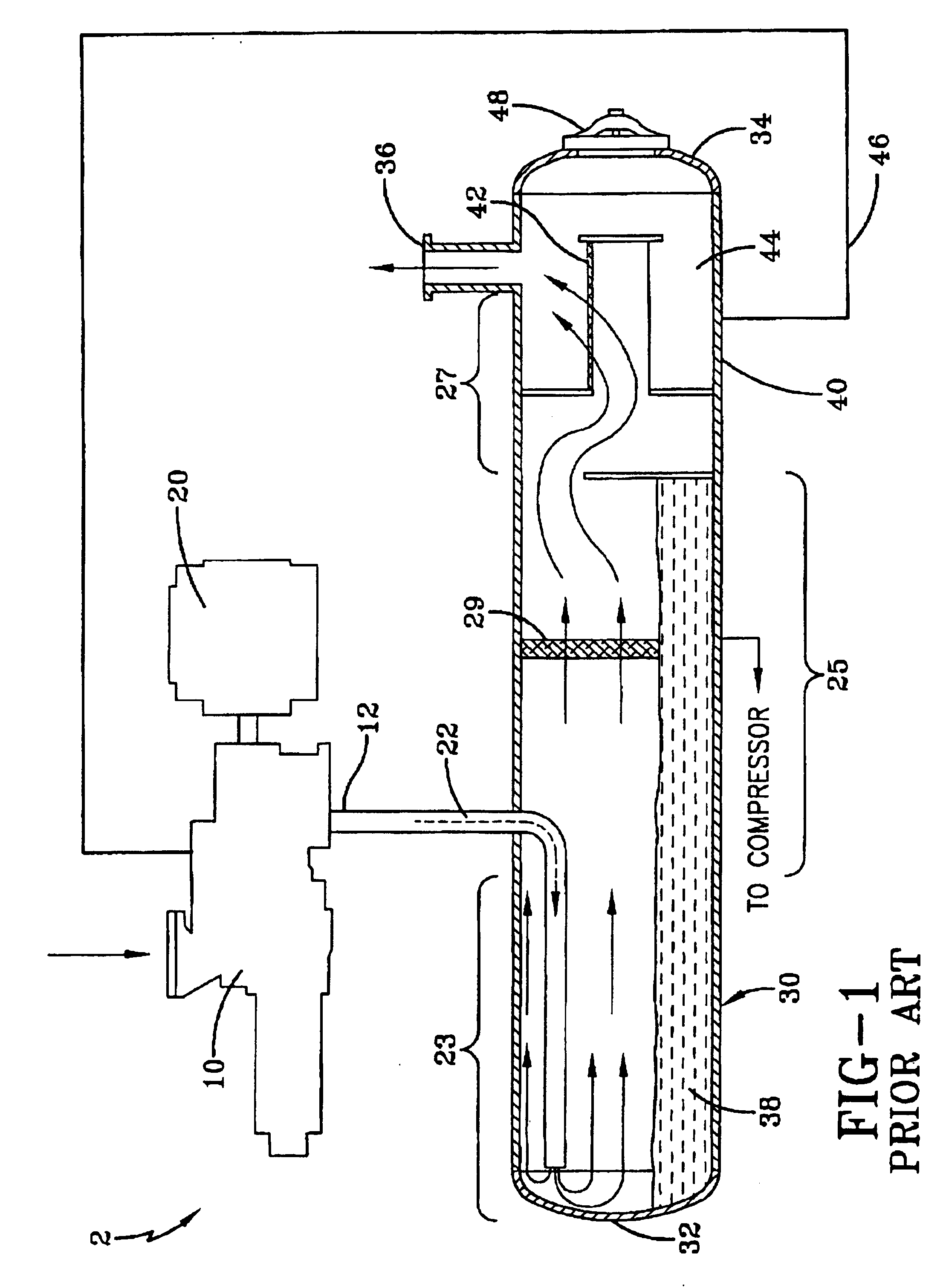

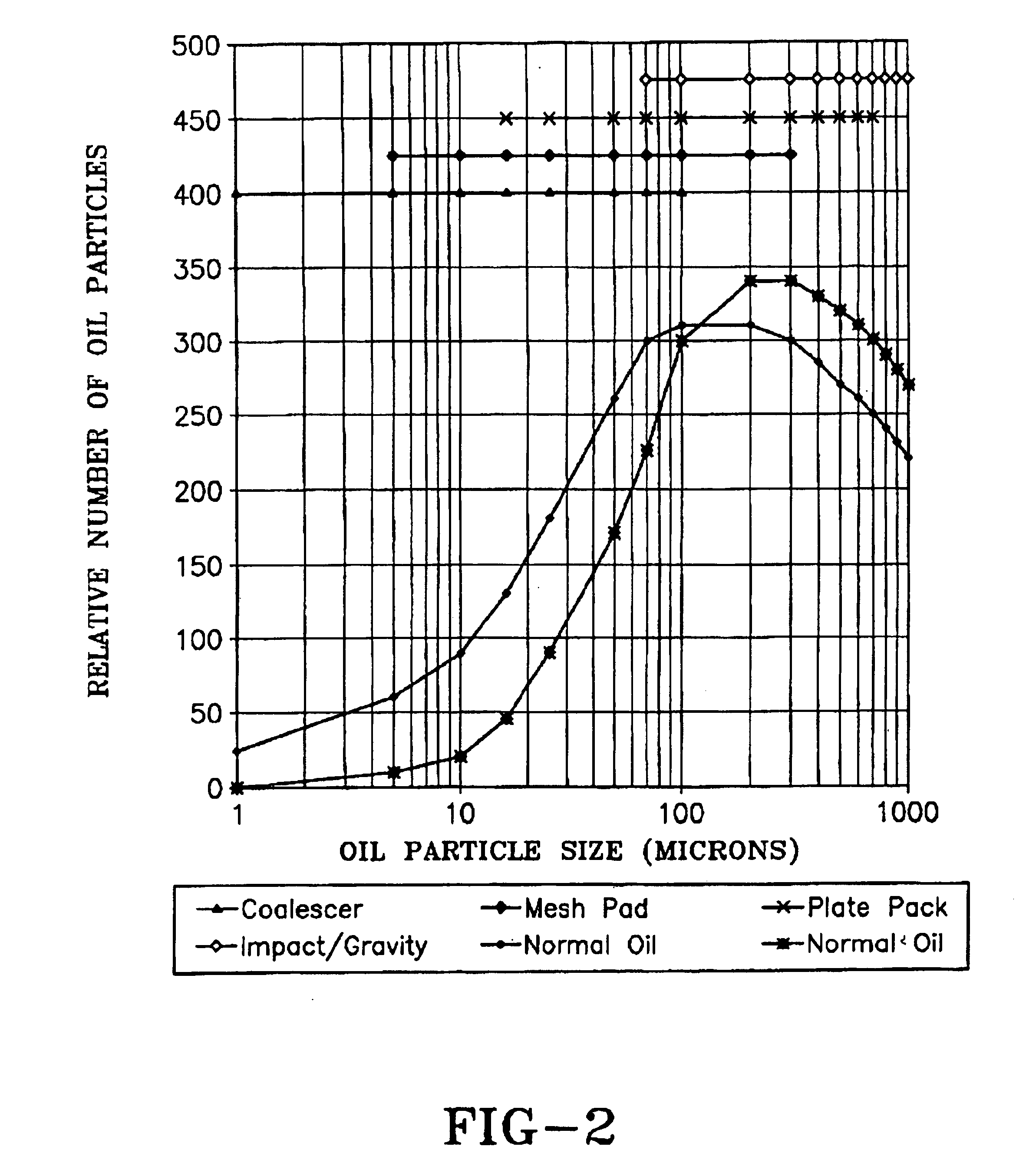

Compressor systems for use with smokeless lubricant

InactiveUS20050022551A1Eliminate and minimize formationLow efficiencyCombination devicesRotary piston pumpsEngineeringLubrication

A compression system including a compressor driven by a motor, an optional accumulator, a liquid / gas separator, heat exchangers in the form of a condenser and an evaporator, expansion valves and conduit in the form of piping to connect these components together. The liquid / gas separating means is a lubricant separator, typically a cylindrical horizontal or vertical vessel used in conjunction with a gas compressor. The lubricant separator accepts discharge flow from the compressor which includes a mixture of a “smokeless” lubricant and refrigerant gas in a range of particle sizes forming a fluid stream, separates the refrigerant gas from the lubricant and collects the lubricant for reuse in the compressor. Because the lubricant used in the lubrication system rapidly agglomerates into larger size droplets and does not produce an aerosol, the separator does not require a coalescer element to coalesce aerosol and does not require a manway for serving the coalescer element. The coalescer element is replaced with a more reliable and durable mesh pad to agglomerate the larger sized droplets. The overall size and space requirements associated with the separator are reduced.

Owner:YORK INT

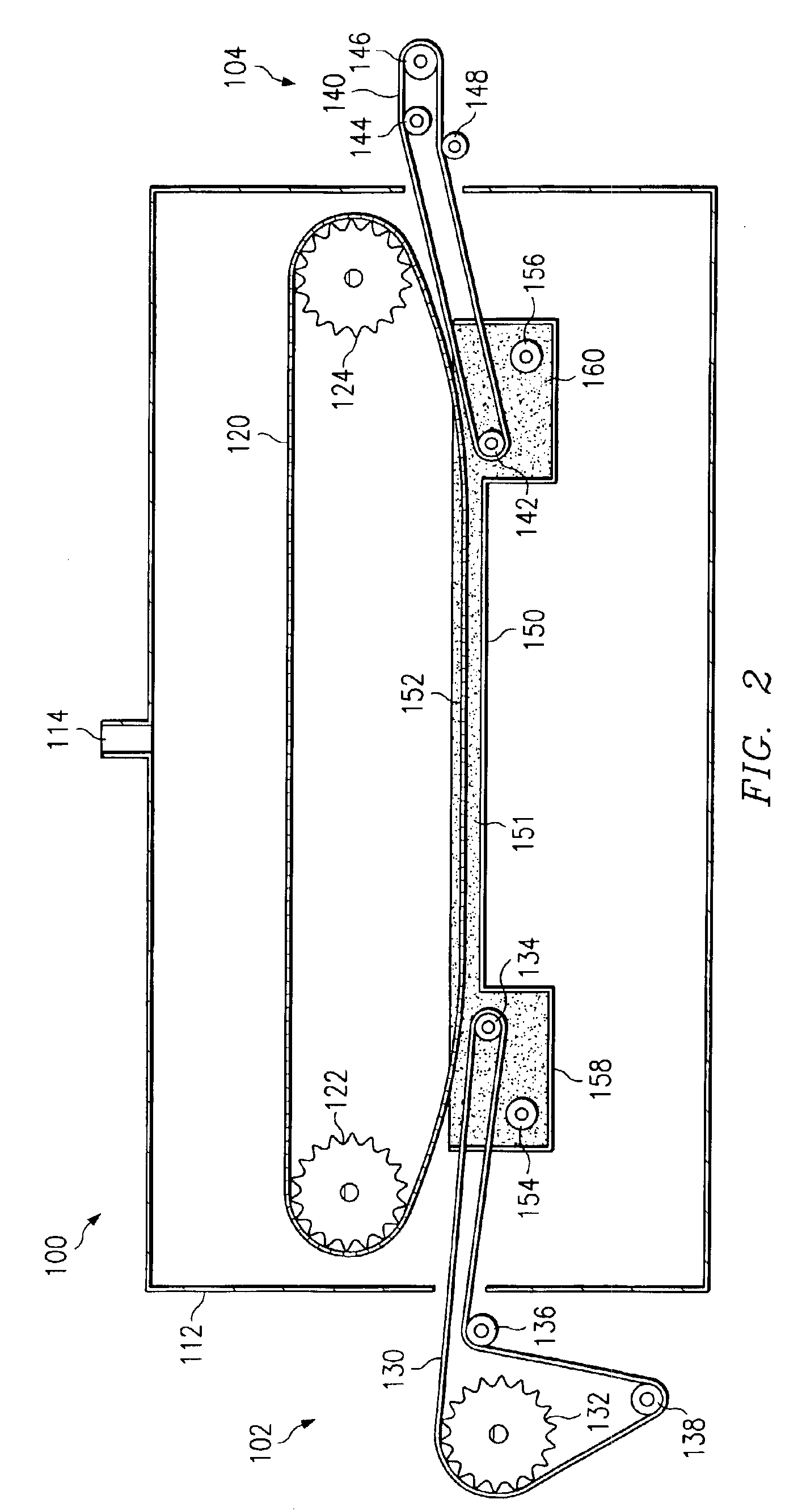

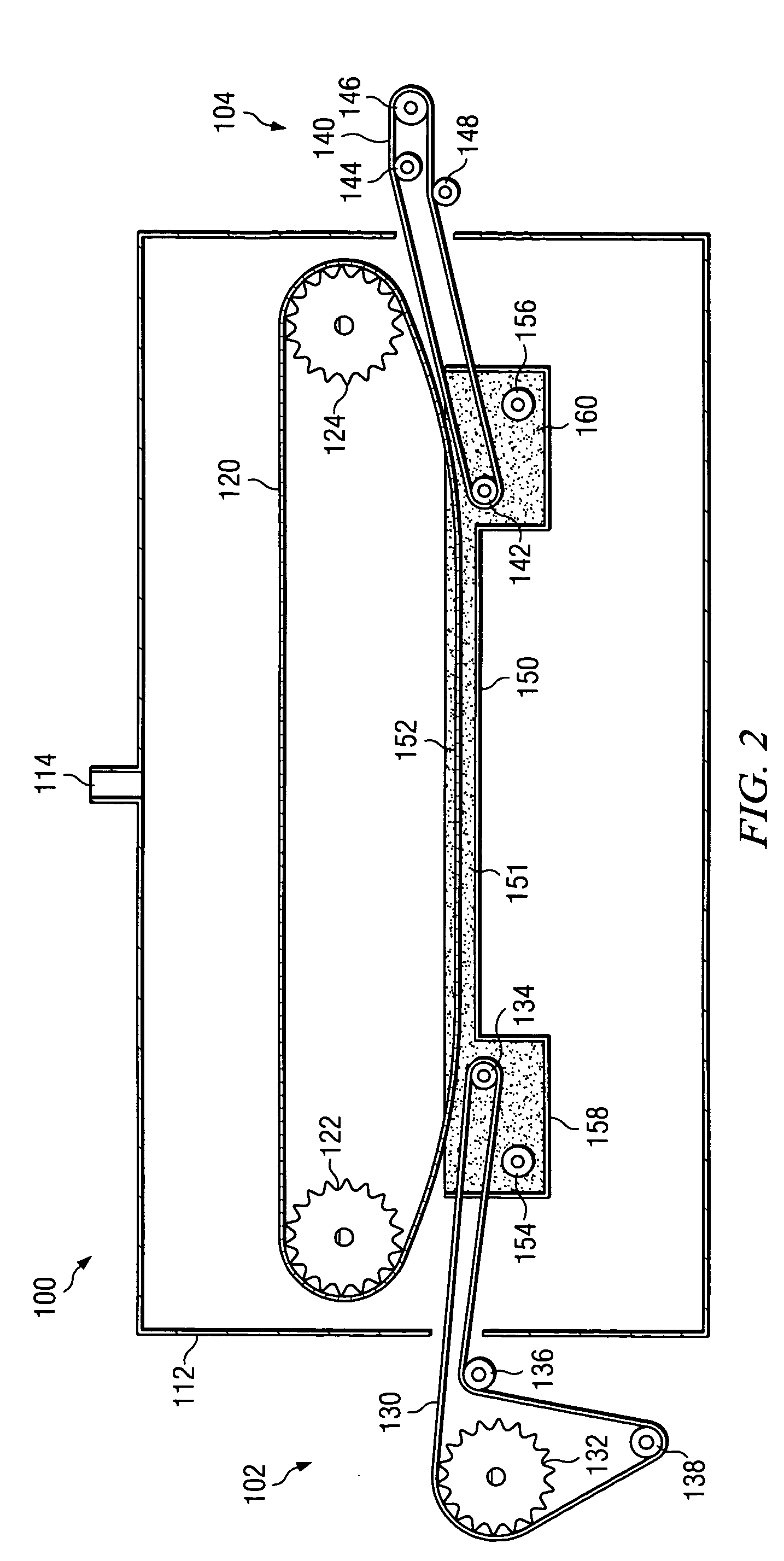

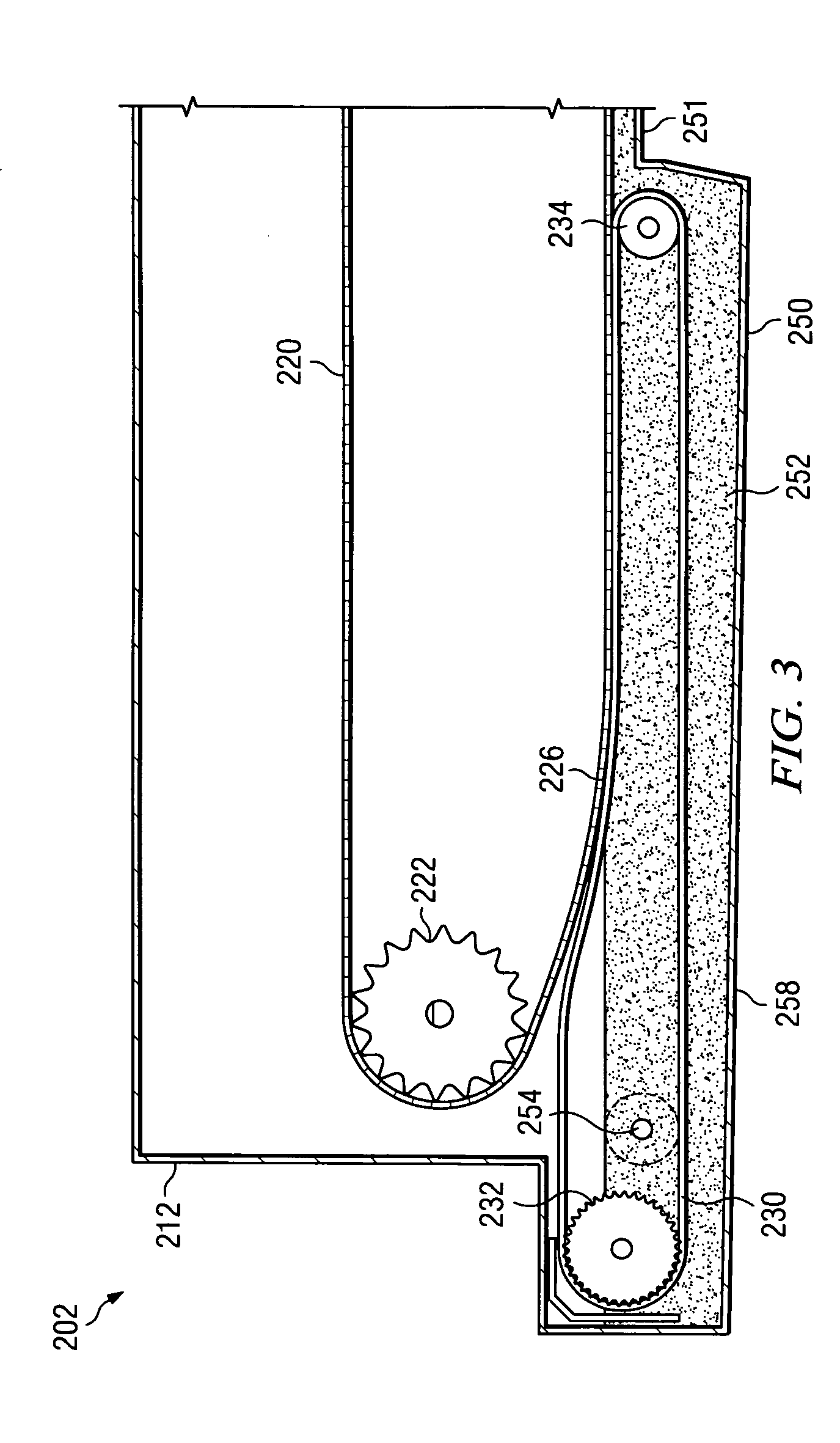

Single mold form fryer with product centering elements

InactiveUS7207263B2Reduce amountReduce oilFood preservationMeat processingEngineeringMechanical engineering

A mold form fryer utilizing a top conveyor that transports snack pieces through a constant velocity oil stream without the need of a bottom mating mold or conveyor. Herein, the form fryer is provided with a top conveyor disposed above a fryer oil pan positioned longitudinally through the fryer. Uncooked snack pieces are provided to the fryer oil pan by a bottom entrance conveyor. Snack pieces, once in oil within the fryer, meet with a top conveyor having convex molding surfaces with product-centering elements. At the exit portion of the fryer, a bottom exit conveyor receives the cooked snack pieces from the top conveyor. As no continuous bottom conveyor is utilized, the fryer oil pan may be provided with a reduced volume segment situated between the bottom entrance and exit conveyors.

Owner:FRITO LAY NORTH AMERICA INC

Compressor systems for use with smokeless lubricant

InactiveUS6880360B2Eliminate and minimize formationMinimizes and eliminates likelihoodCombination devicesCorrosion preventionEngineeringLubrication

A compression system including a compressor driven by a motor, an optional accumulator, a liquid / gas separator, heat exchangers in the form of a condenser and an evaporator, expansion valves and conduit in the form of piping to connect these components together. The liquid / gas separating means is a lubricant separator, typically a cylindrical horizontal or vertical vessel used in conjunction with a gas compressor. The lubricant separator accepts discharge flow from the compressor which includes a mixture of a “smokeless” lubricant and refrigerant gas in a range of particle sizes forming a fluid stream, separates the refrigerant gas from the lubricant and collects the lubricant for reuse in the compressor. Because the lubricant used in the lubrication system rapidly agglomerates into larger size droplets and does not produce an aerosol, the separator does not require a coalescer element to coalesce aerosol and does not require a manway for serving the coalescer element. The coalescer element is replaced with a more reliable and durable mesh pad to agglomerate the larger sized droplets. The overall size and space requirements associated with the separator are reduced.

Owner:YORK INT CORP

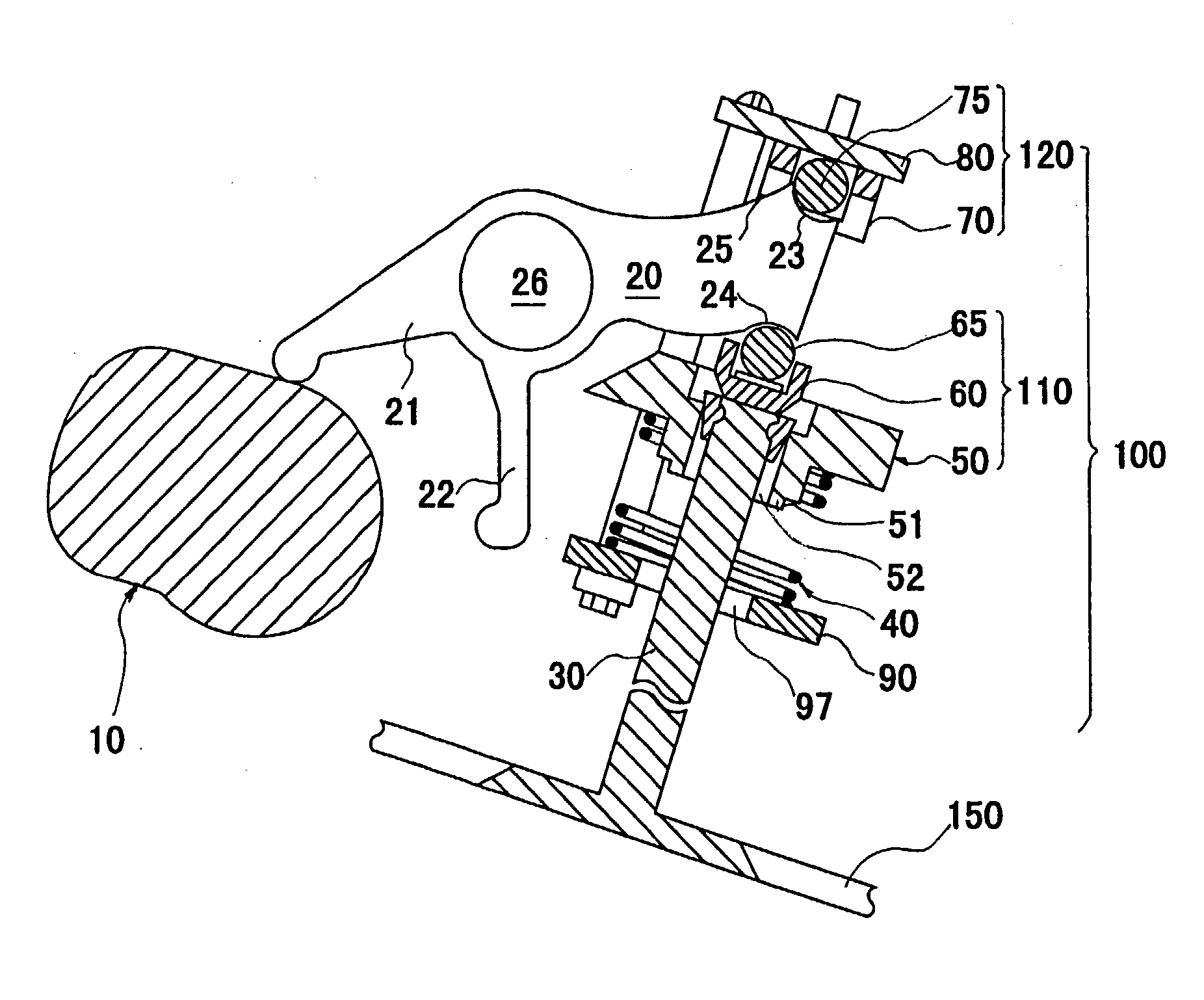

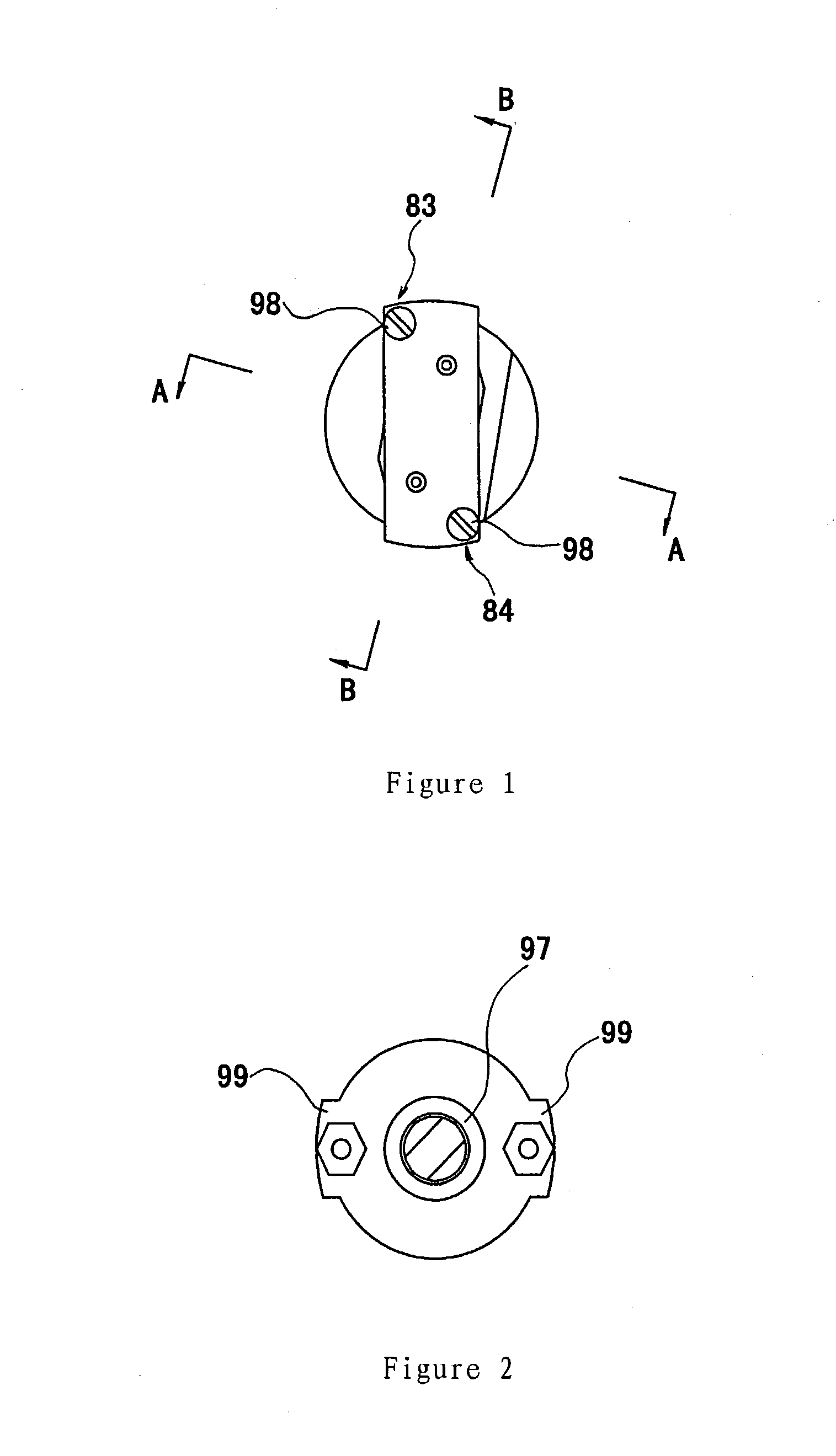

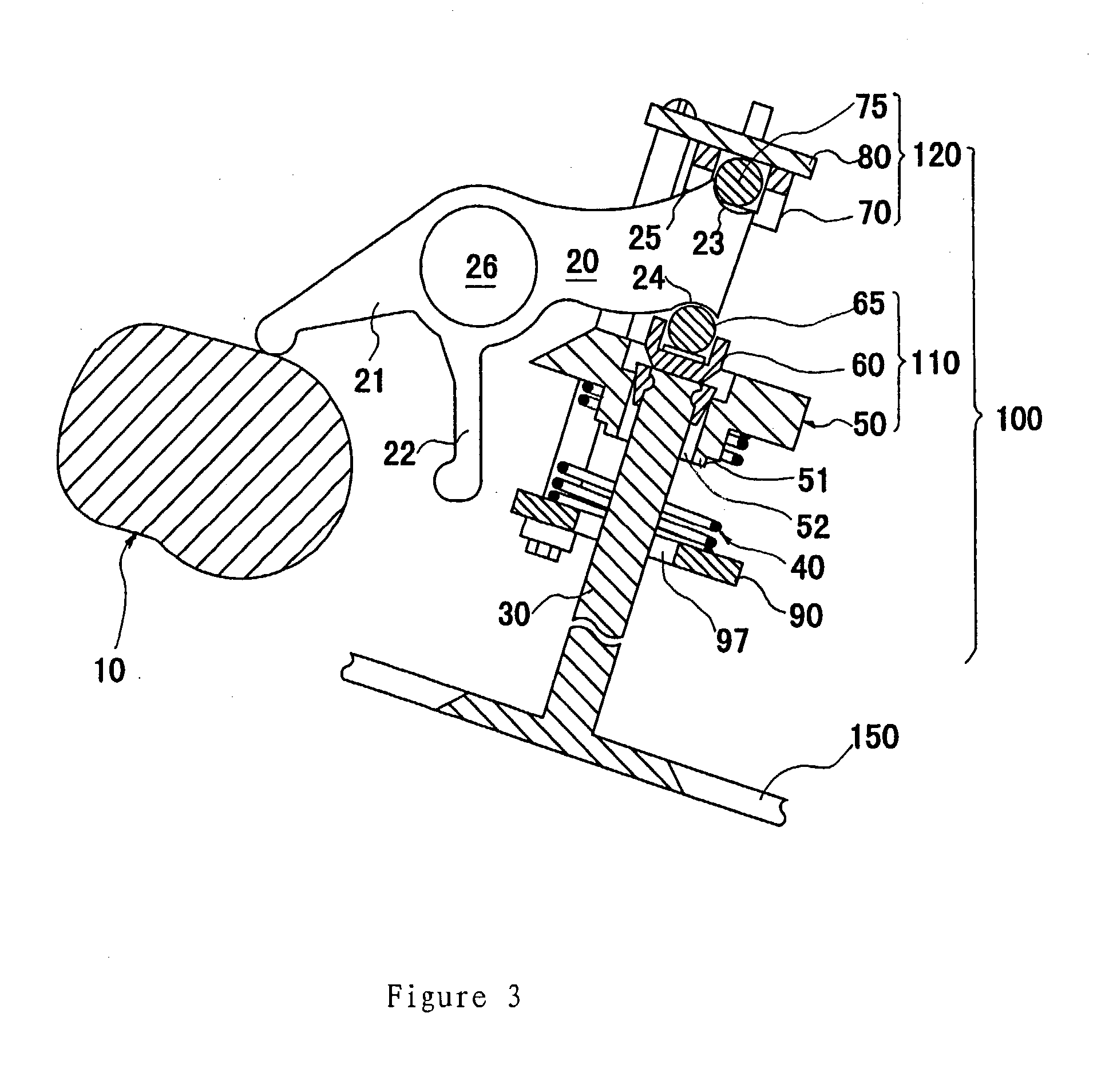

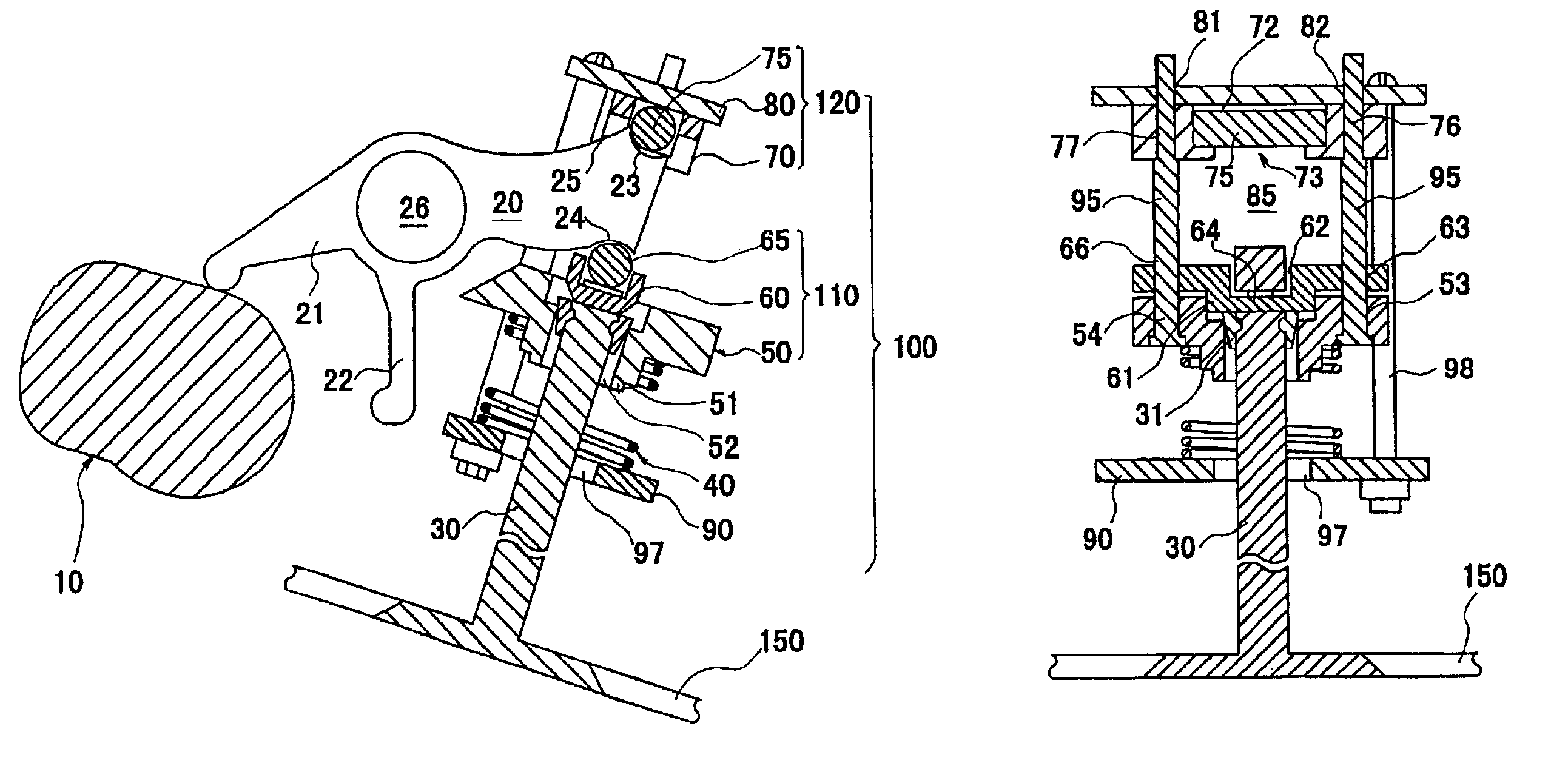

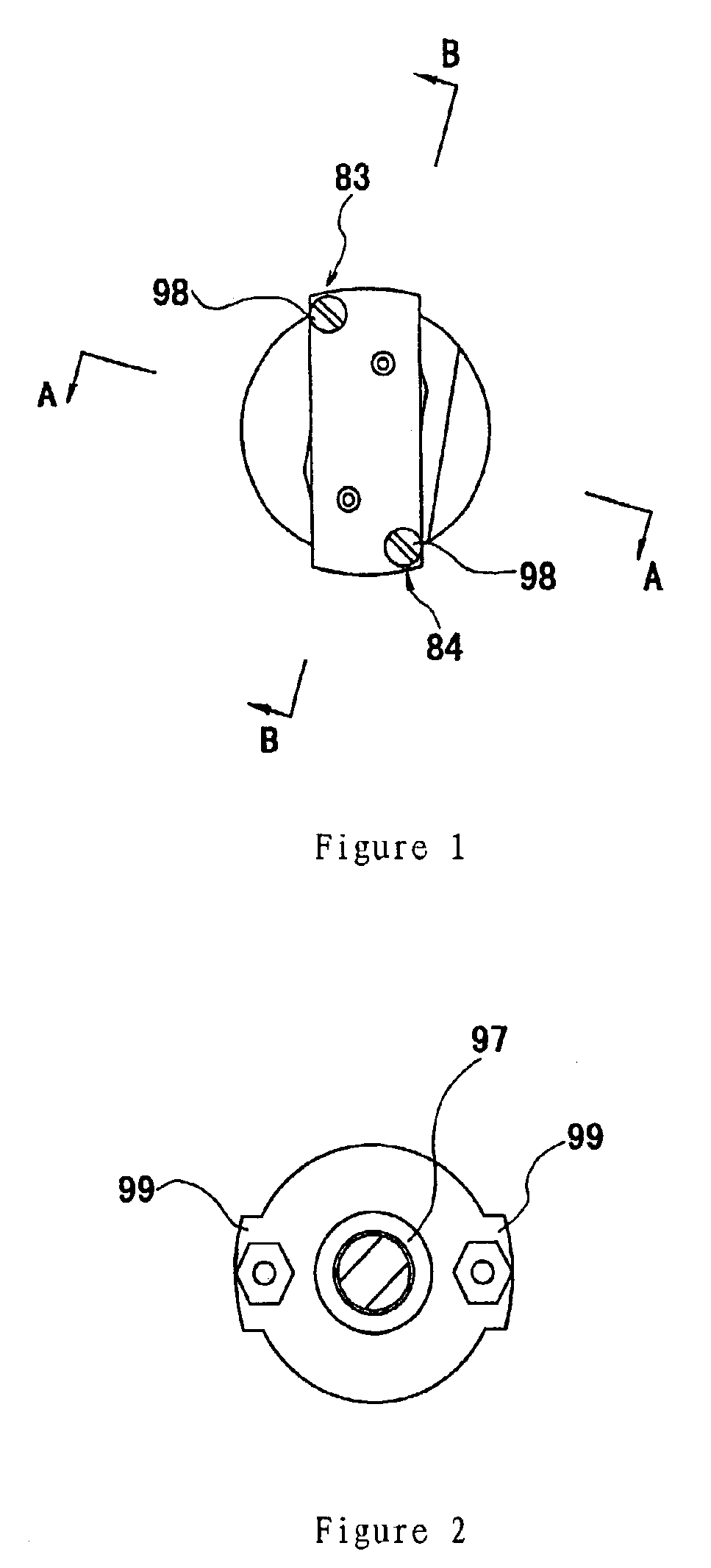

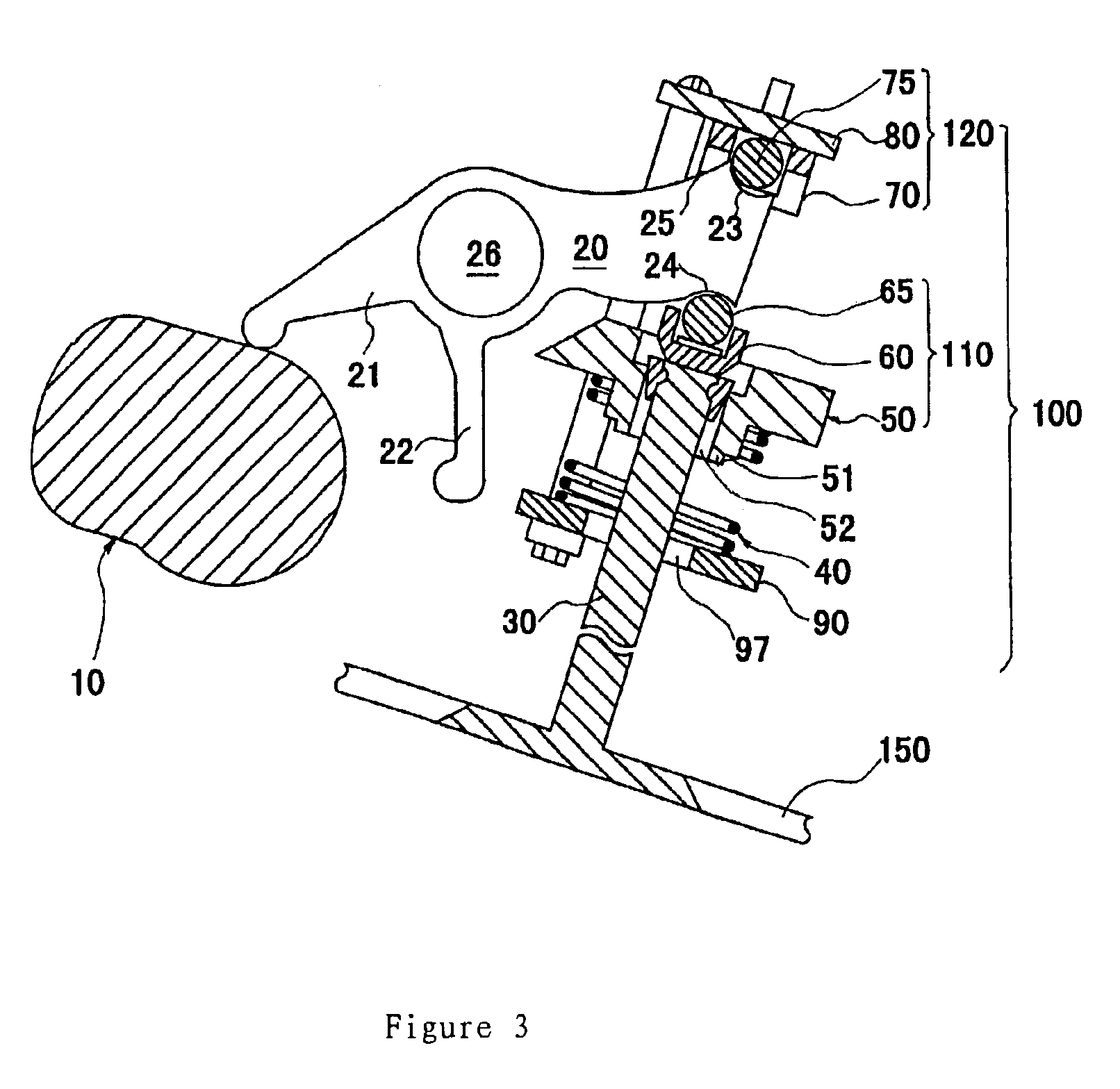

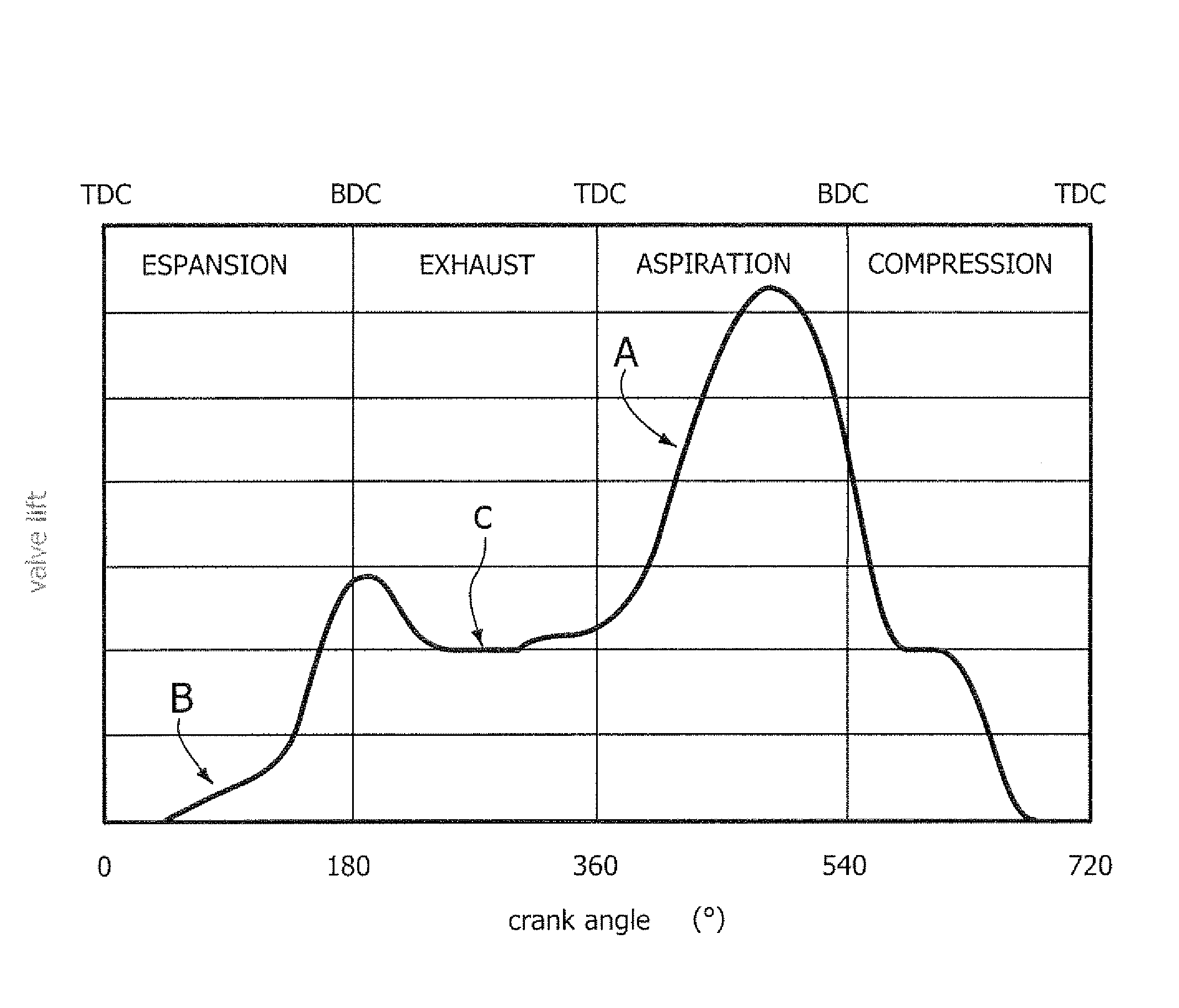

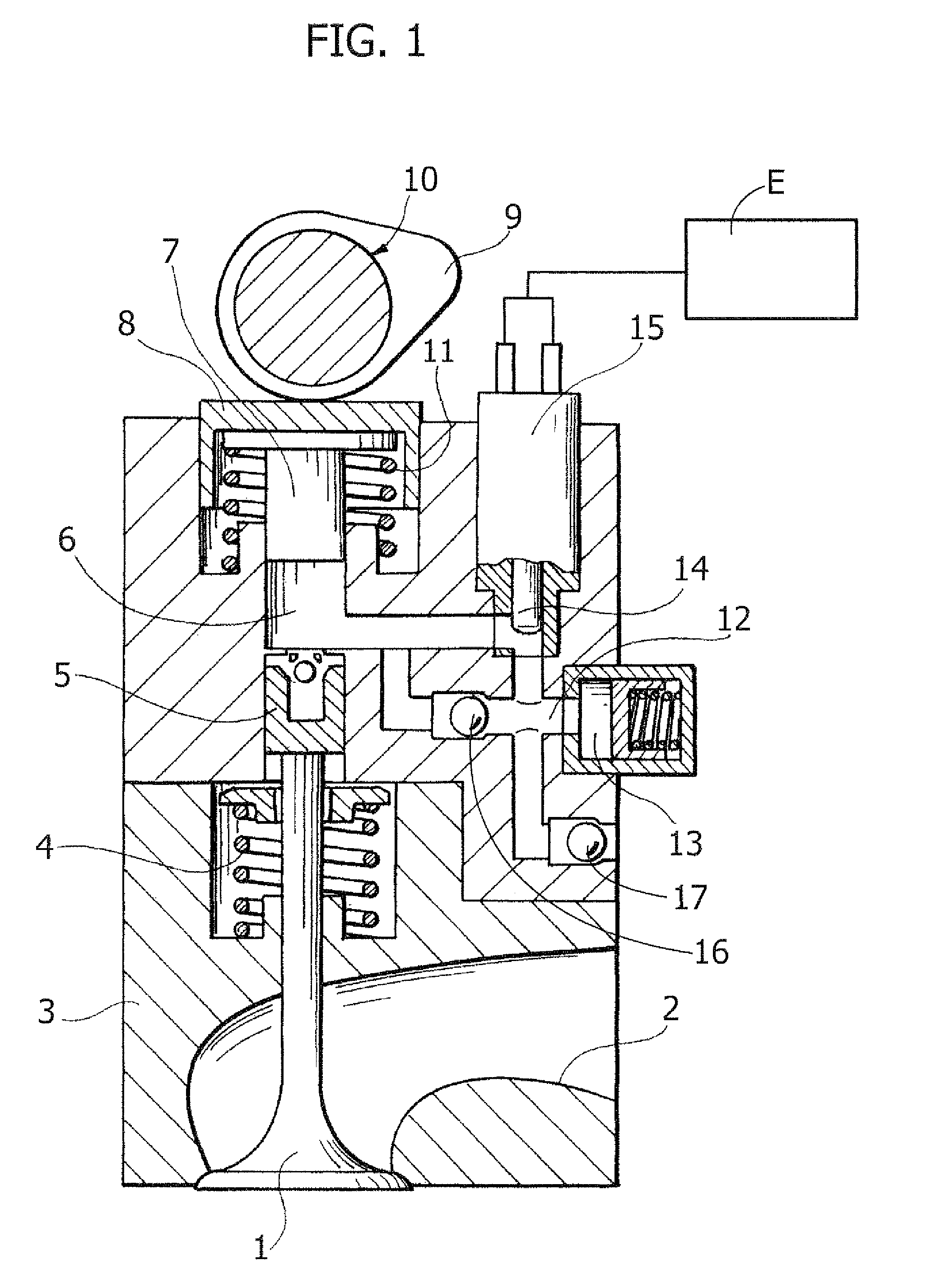

Control device for an air valve of an engine

The present invention provides a mechanism for controlling the intake valve of an internal combustion engine, which mechanism is capable of consuming less energy, i.e. less oil. Through uniquely designed cam and rocker as well as joining mechanism joining the rocker and the stopper, this mechanism does not incur the spring resistance as opening the intake valve, thus the engine per se does not additionally consume energy, so that the object of reducing oil cost and promoting power output may be achieved.

Owner:LAU

Control device for an air valve of an engine

The present invention provides a mechanism for controlling the intake valve of an internal combustion engine, which mechanism is capable of consuming less energy, i.e. less oil. Through uniquely designed cam and rocker as well as joining mechanism joining the rocker and the stopper, this mechanism does not incur the spring resistance as opening the intake valve, thus the engine per se does not additionally consume energy, so that the object of reducing oil cost and promoting power output may be achieved.

Owner:LAU

Food product and process for reducing oil and fat content in cooked food

InactiveUS20050069626A1Minimize absorptionLess fatProtein composition from fishMeat/fish preservationProtein solutionProtein FADD

A process for cooking a food in oil and / or fat is provided. A dry protein mixture, a dry alkaline protein mixture, an aqueous alkaline protein mixture or an aqueous acidic protein is added to a food prior to cooking. The dry protein mixture, dry alkaline protein mixture, aqueous alkaline protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:PROTEUS INDUSTRIES INC

Diesel engine having cams for controlling the intake valves, which have a main lobe and an additional lobe radiused to each other

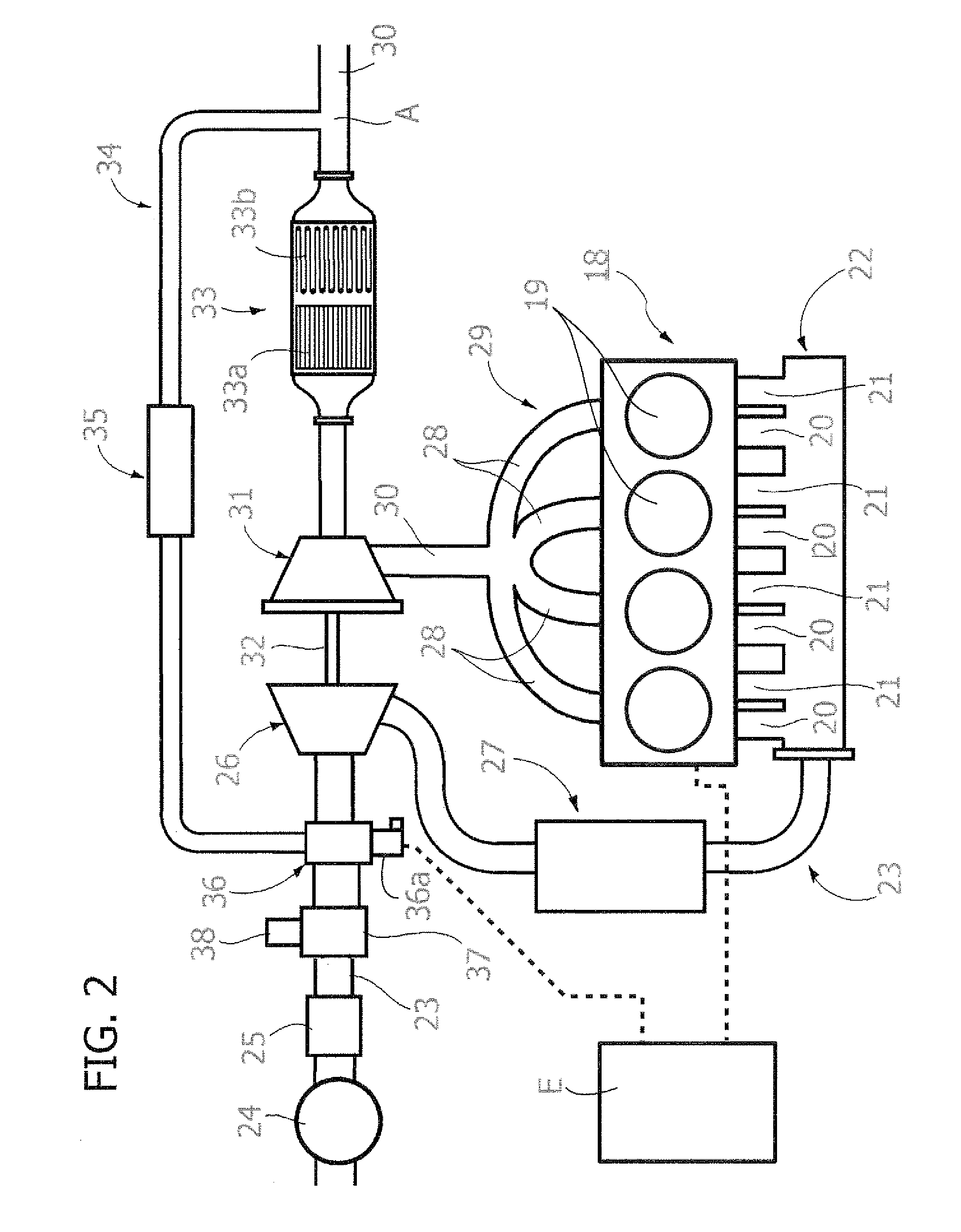

ActiveUS8447499B2Maximum flexibilitySimple and efficientNon-fuel substance addition to fuelDigital data processing detailsInlet valveCam

A supercharged diesel engine is equipped with an electronically controlled hydraulic system for variable actuation of the intake valves of the engine. The cam that controls each intake valve has an additional lobe for causing an additional opening of the intake valve, during the expansion and exhaust strokes, so as to provide an exhaust-gas recirculation directly inside the engine. The aforesaid additional lobe has its descending stretch radiused to the main lobe with a stretch corresponding to a non-zero lift of the valve in such a way that the profile of the lift of the valve has a portion corresponding to a substantially non-zero value of the lift that radiuses the descending stretch of the profile of the additional lift to the ascending stretch of the profile of the main lift.

Owner:CENT RICERCHE FIAT SCPA

Churros and method for making same

InactiveUS20050112261A1Less oilPre-baking dough treatmentPreservation by coolingMarkedly elevated IgEAdditive ingredient

Owner:1010684 ONTARIO

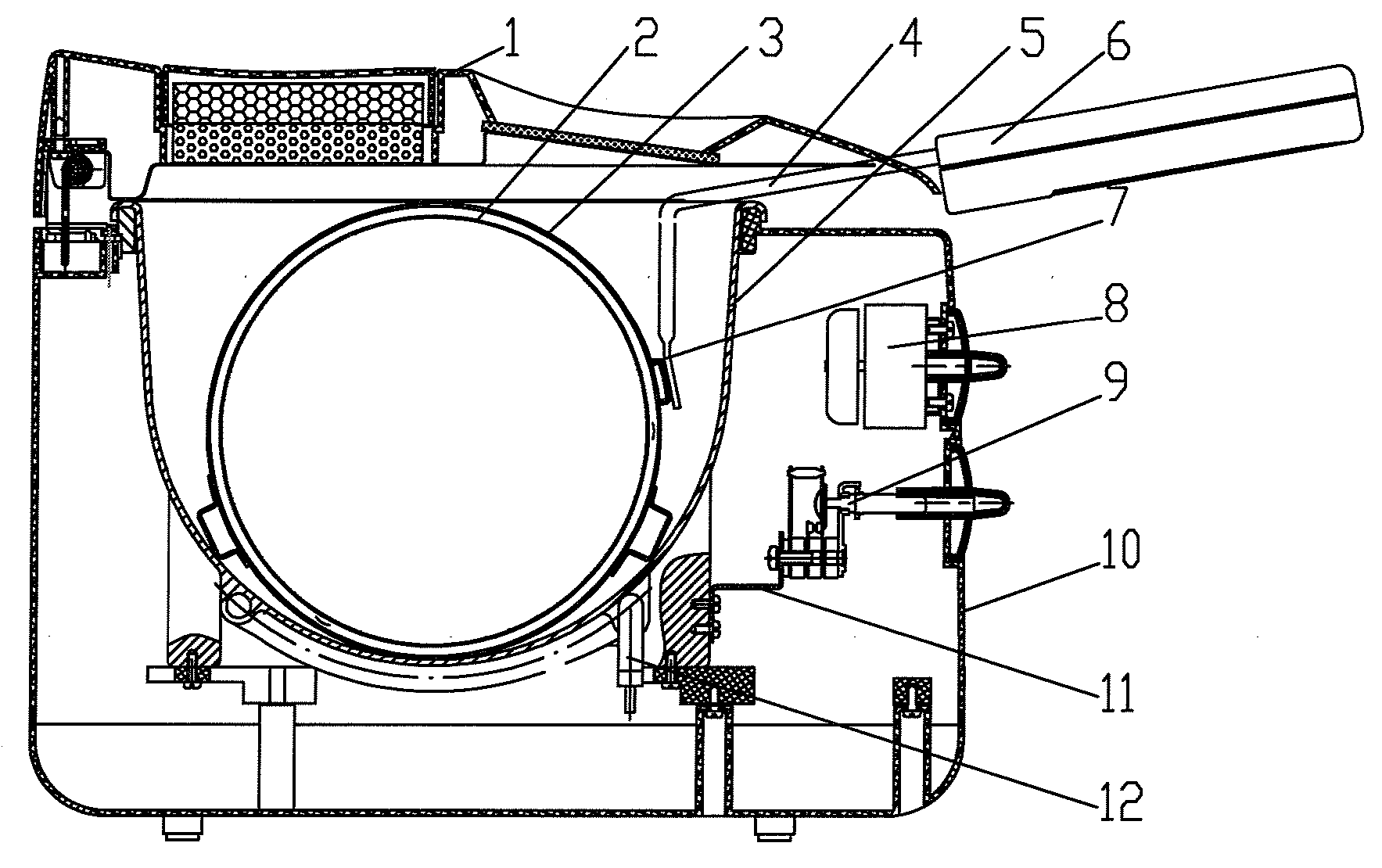

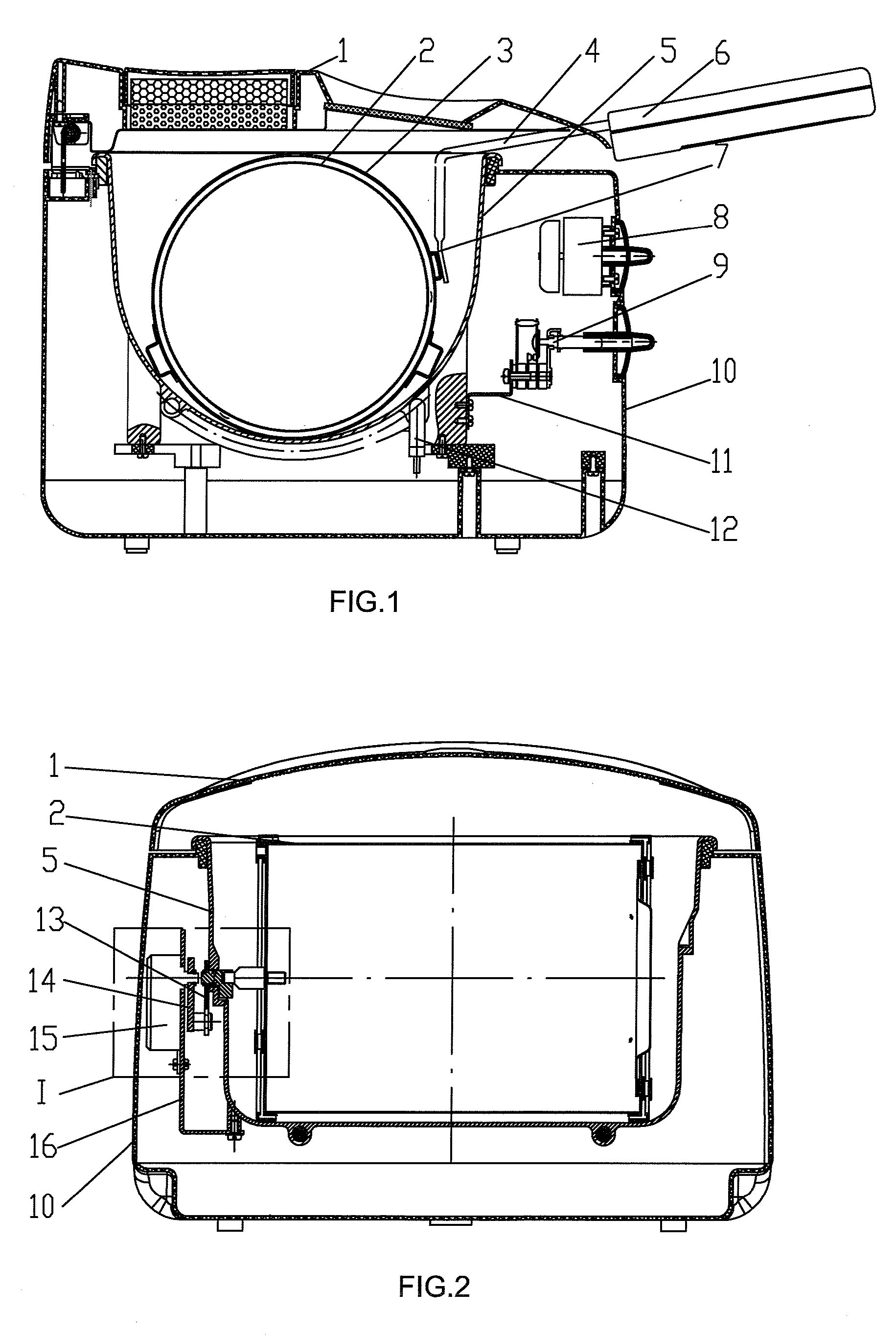

Electric Heating Apparatus With An Automatic Rotating Food Basket

InactiveUS20080110350A1Fry food more effectively and evenlySave oilDeep fat fryersElectric heatingEngineering

The present invention provides an electric heating apparatus with an automatic rotating food basket. With the present invention, the food basket assembly is suspended inside the fryer body, and the food basket assembly is driven by the rotating mechanism to rotate 360° in the fryer body. Therefore, during the process of frying food, the food and the basket rotate together and the food is immersed fully in the hot oil, which results in even flying with less oil, and more quantity of food can be cooked.

Owner:WANG DONG LEI

Single mold form fryer with product centering elements

InactiveUS20050019463A1Positively controlledReduce amountMeat processingFood shapingEngineeringMechanical engineering

A mold form fryer utilizing a top conveyor that transports snack pieces through a constant velocity oil stream without the need of a bottom mating mold or conveyor. Herein, the form fryer is provided with a top conveyor disposed above a fryer oil pan positioned longitudinally through the fryer. Uncooked snack pieces are provided to the fryer oil pan by a bottom entrance conveyor. Snack pieces, once in oil within the fryer, meet with a top conveyor having convex molding surfaces with product-centering elements. At the exit portion of the fryer, a bottom exit conveyor receives the cooked snack pieces from the top conveyor. As no continuous bottom conveyor is utilized, the fryer oil pan may be provided with a reduced volume segment situated between the bottom entrance and exit conveyors.

Owner:FRITO LAY NORTH AMERICA INC

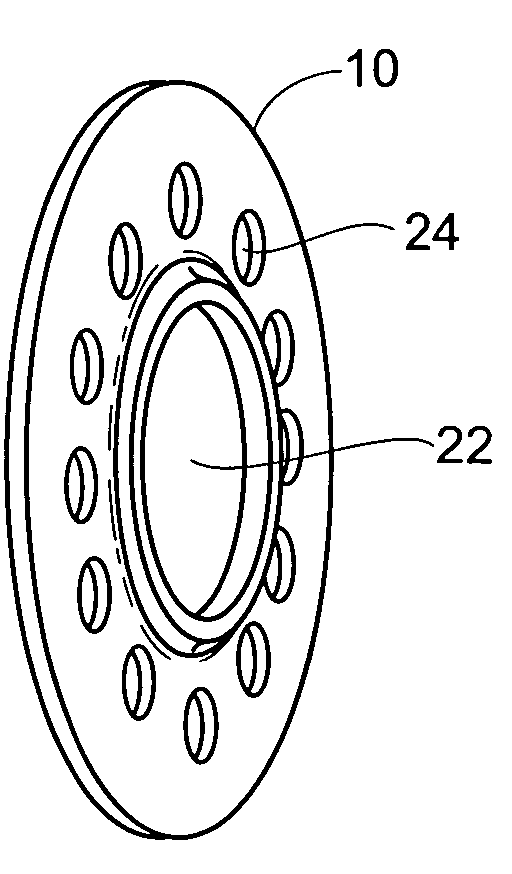

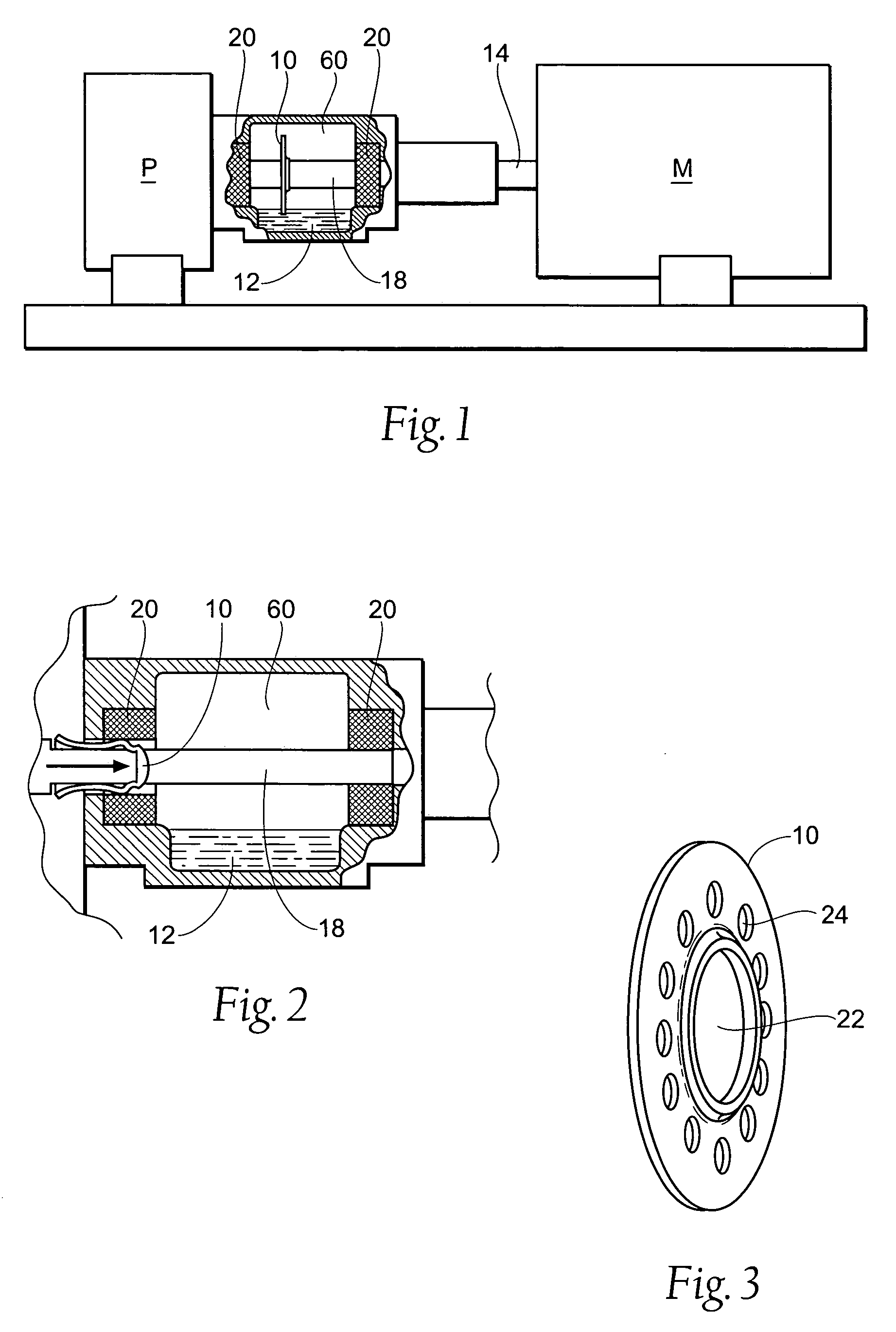

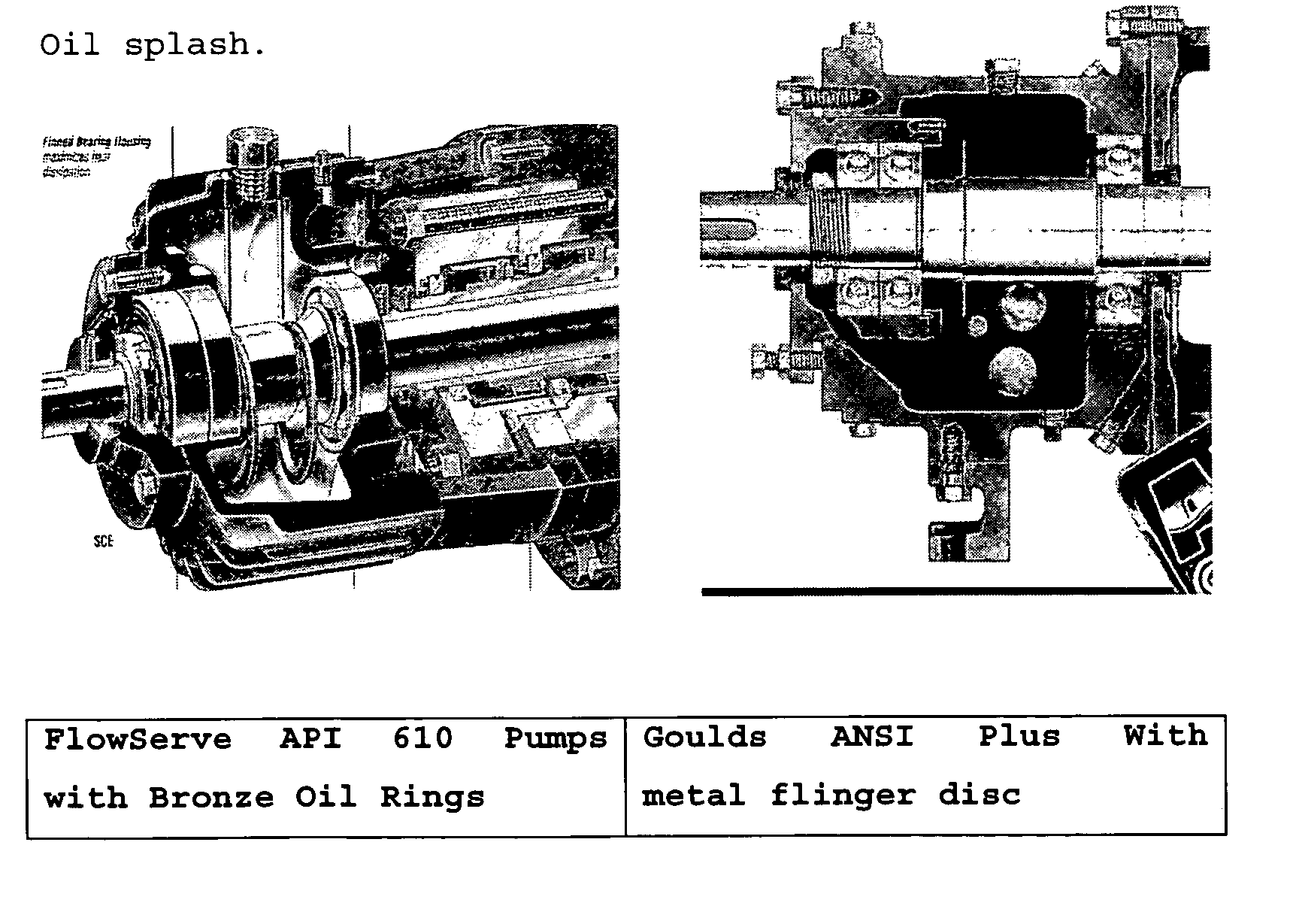

Flinger disc

ActiveUS7862875B2Easy to assemble and disassembleReduce the temperatureDrip or splash lubricationLayered productsEngineeringLubrication

To achieve proper lubrication, a bearing housing or reservoir is filled with a predetermined amount of lubricant. When the machine, of which a bearing is a component, is operated, a flexible flinger disc provides proper lubrication by disturbance of the lubricant.

Owner:TRICO CORP

Potato chip

ActiveUS20130266720A1Less oilFruit and vegetables preservationFood preparationChipped potatoesEngineering

A potato chip that has more oil near its outer surfaces than in its interior and a unique RVA profile is disclosed. The organoleptic properties of the inventive potato chips compare favorably to known and commercially available potato chips.

Owner:FRITO LAY NORTH AMERICA INC

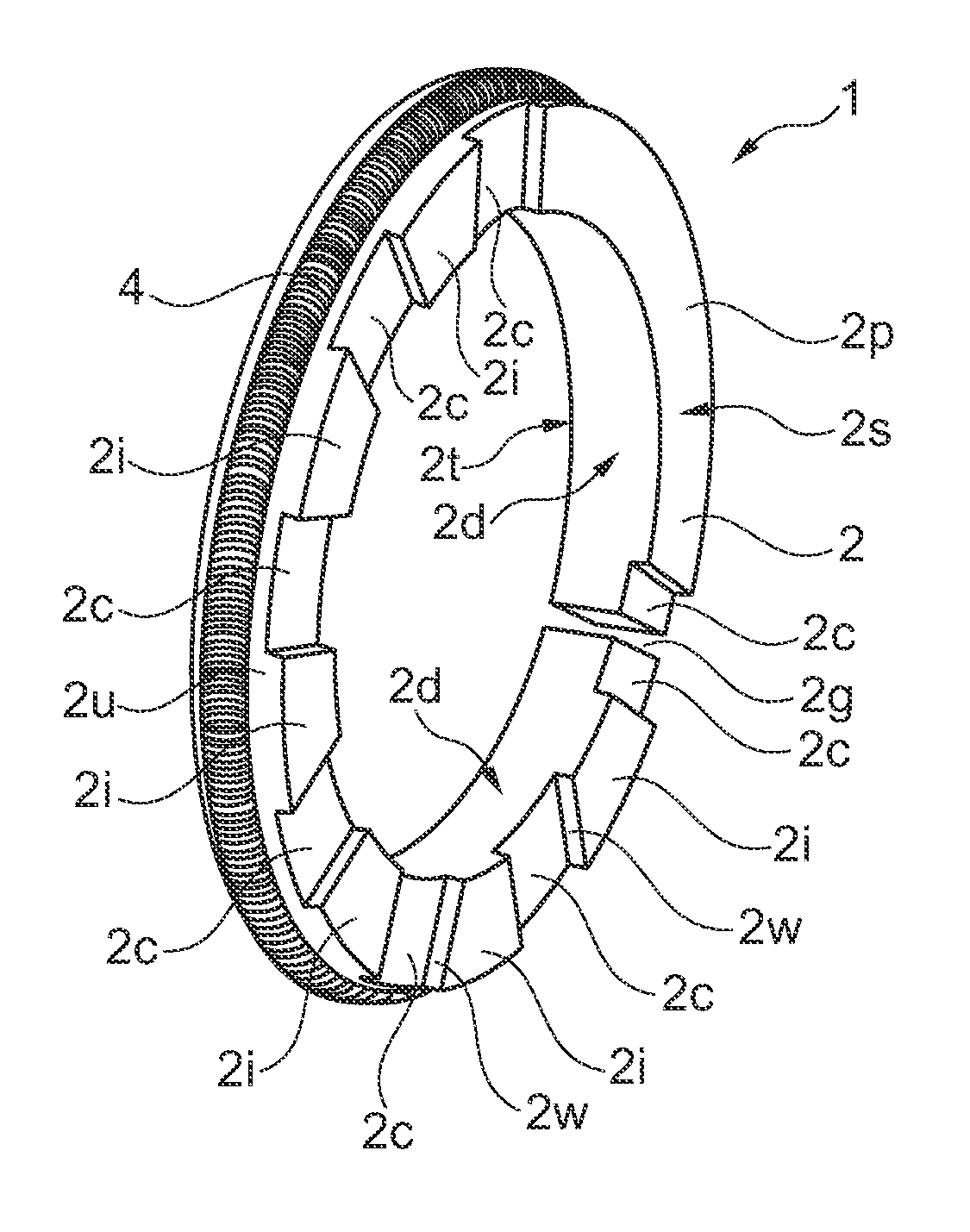

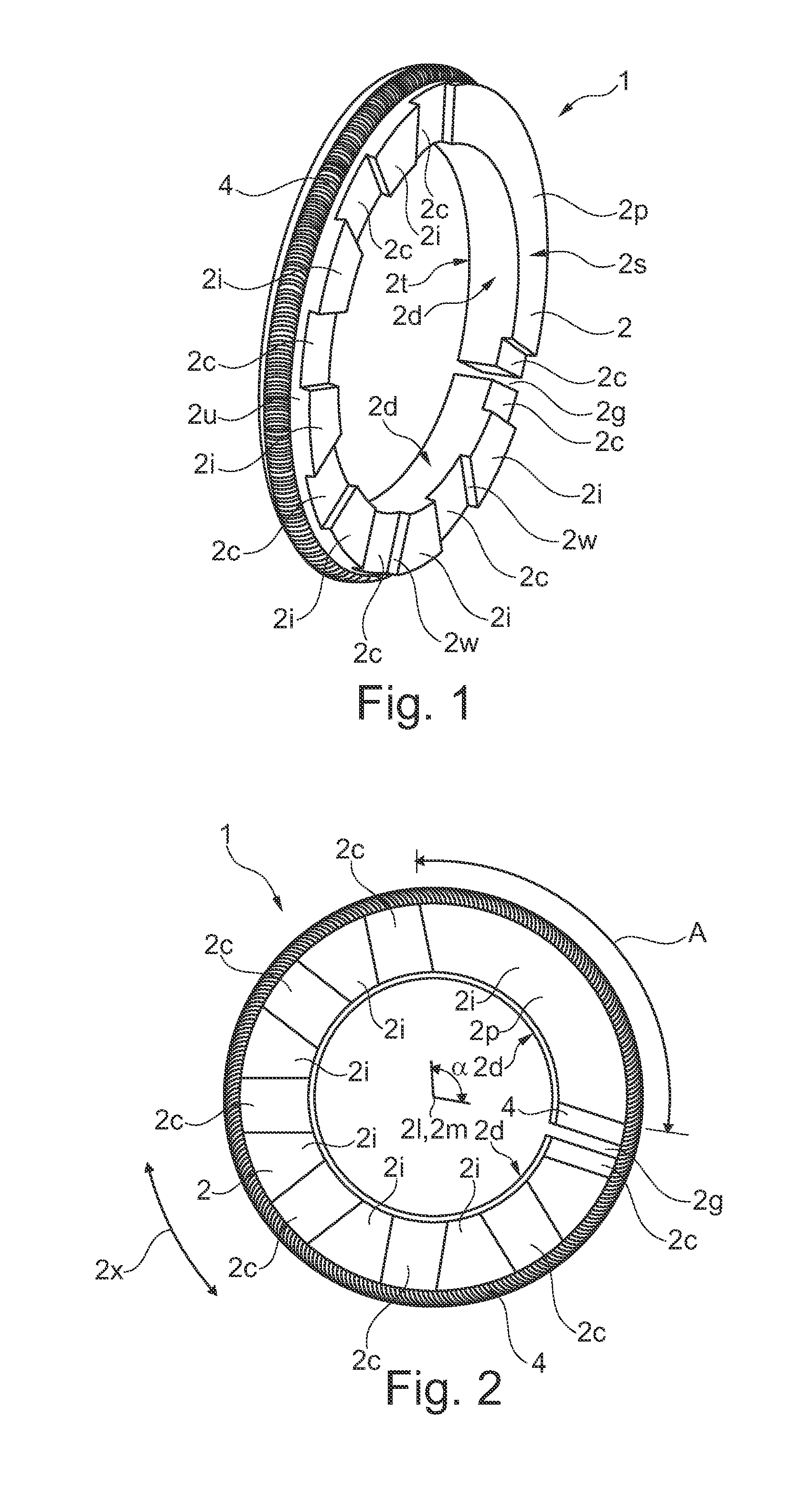

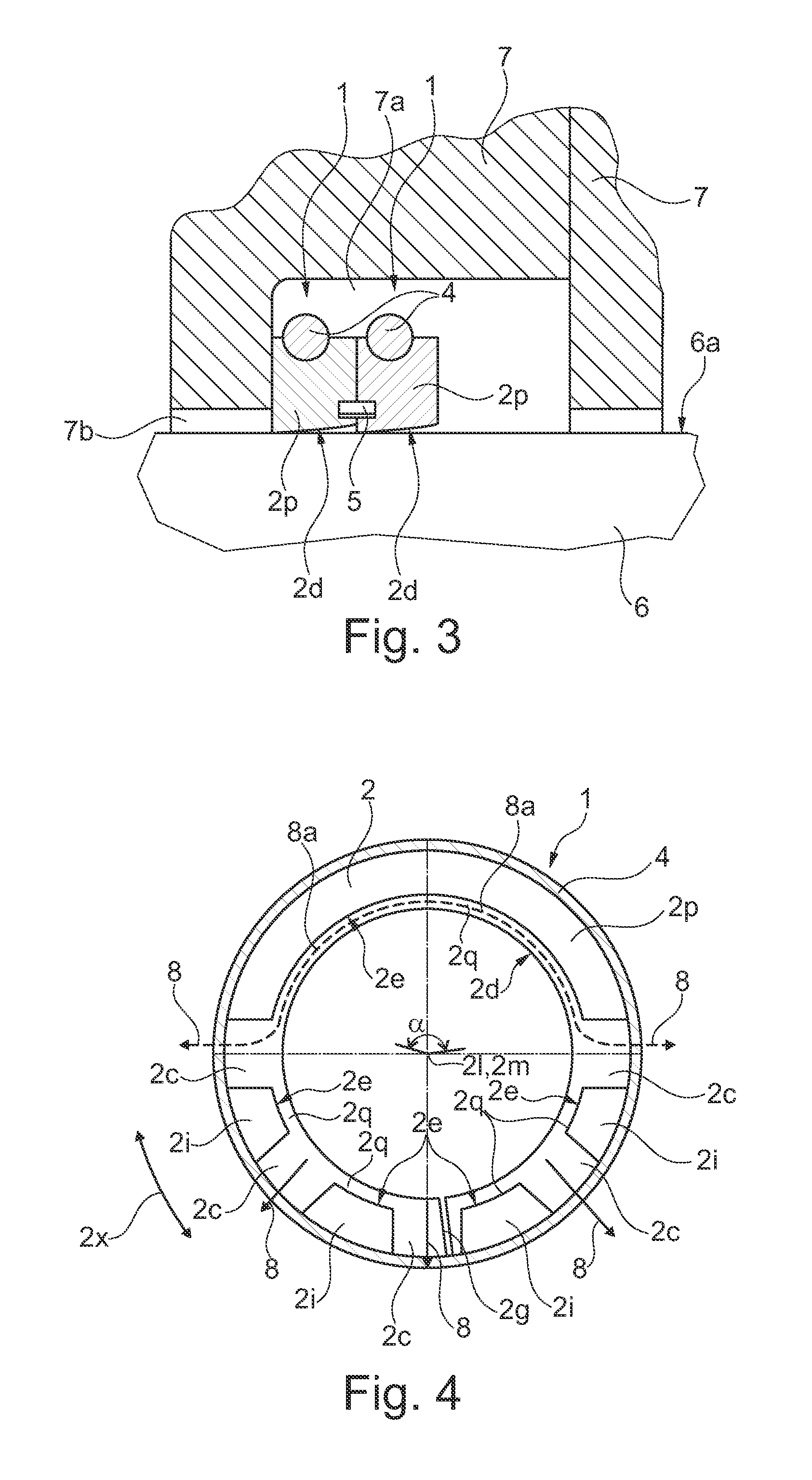

Oil scraper ring

ActiveUS20130307220A1Good for scrapingLess oilEngine sealsPiston ringsMechanical engineeringAngular range

The oil control ring (2) extends in a circumferential direction (2x) about a center (2l) and has a longitudinal axis (2m) that passes through the center (2l), wherein the oil control ring (2) has an end face (2d) that faces the center (2l), and wherein the oil control ring (2) has a first lateral surface (2s), a second lateral surface (2t), and an outer surface (2u) facing away from the center (2l), wherein the oil control ring (2) has a plurality of channels (2c) extending toward the center (2l) on the first lateral surface (2s), said channels being arranged at mutual distances in the circumferential direction (2x) and extending over the entire width of the first lateral surface (2s) in the radial direction and thereby forming a fluid-conducting connection between the end face (2d) and the outer surface (2u), and wherein crown parts (2i) extending in the circumferential direction (2x) are arranged between pairs of channels (2c), wherein each crown part (2i) protrudes beyond the respective channel (2c) in the direction of extent of the longitudinal axis (2m) and forms a lateral channel surface (2w) for the channel (2c), wherein at least one of the crown parts (5i) is designed as a long crown part (2p) and extends over an angular range (a) between 60 degrees and 350 degrees in the circumferential direction (2x). 212×2121.

Owner:BURCKHARDT COMPRESSION AG

Open pot gas fryer with corrugated bottom

InactiveUS20080022994A1Easy to cleanLower the volumeSteam-heated kettlesDeep fat fryersProcess engineering

Owner:THE FRYMASTER CORP LLC

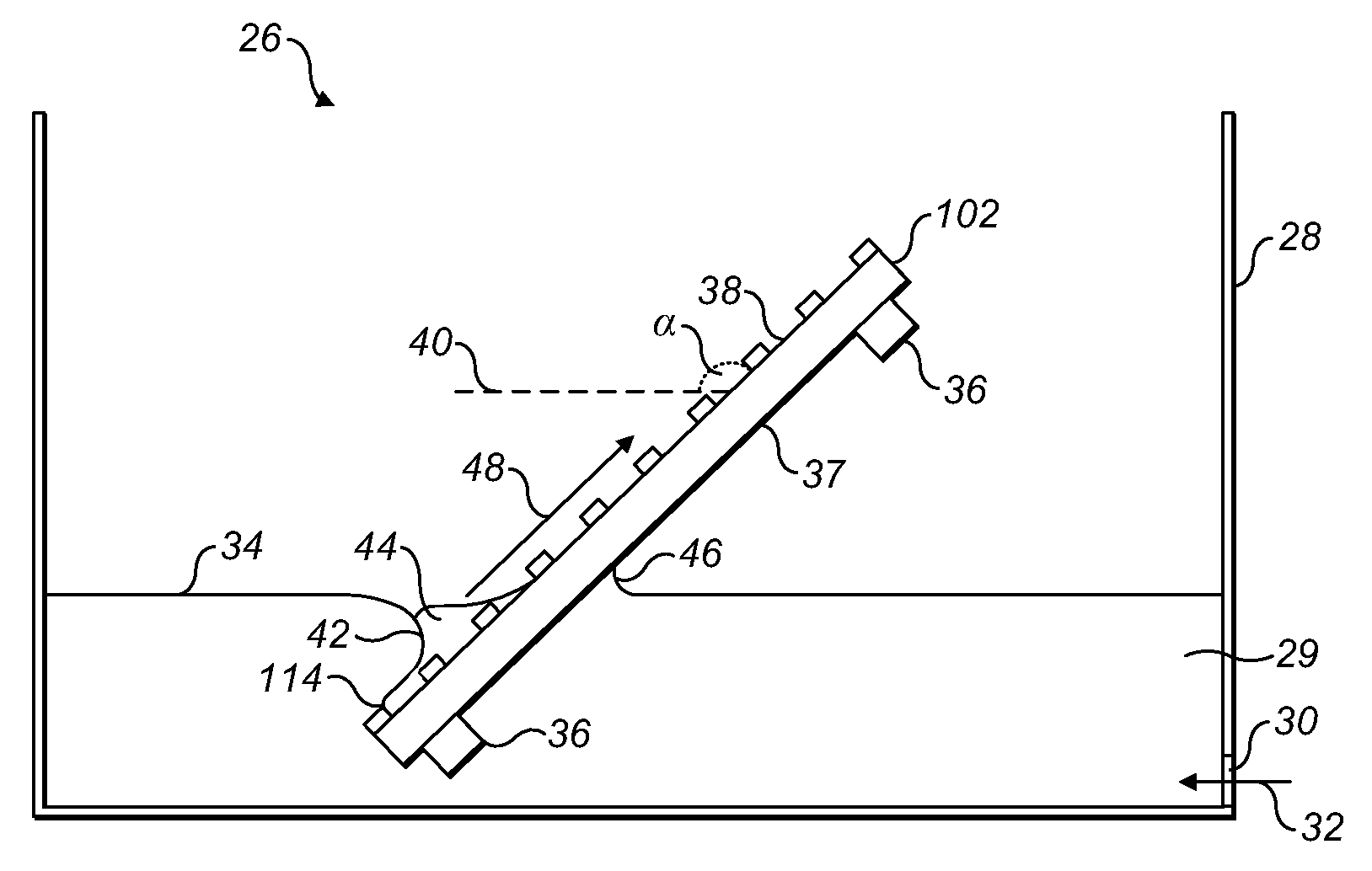

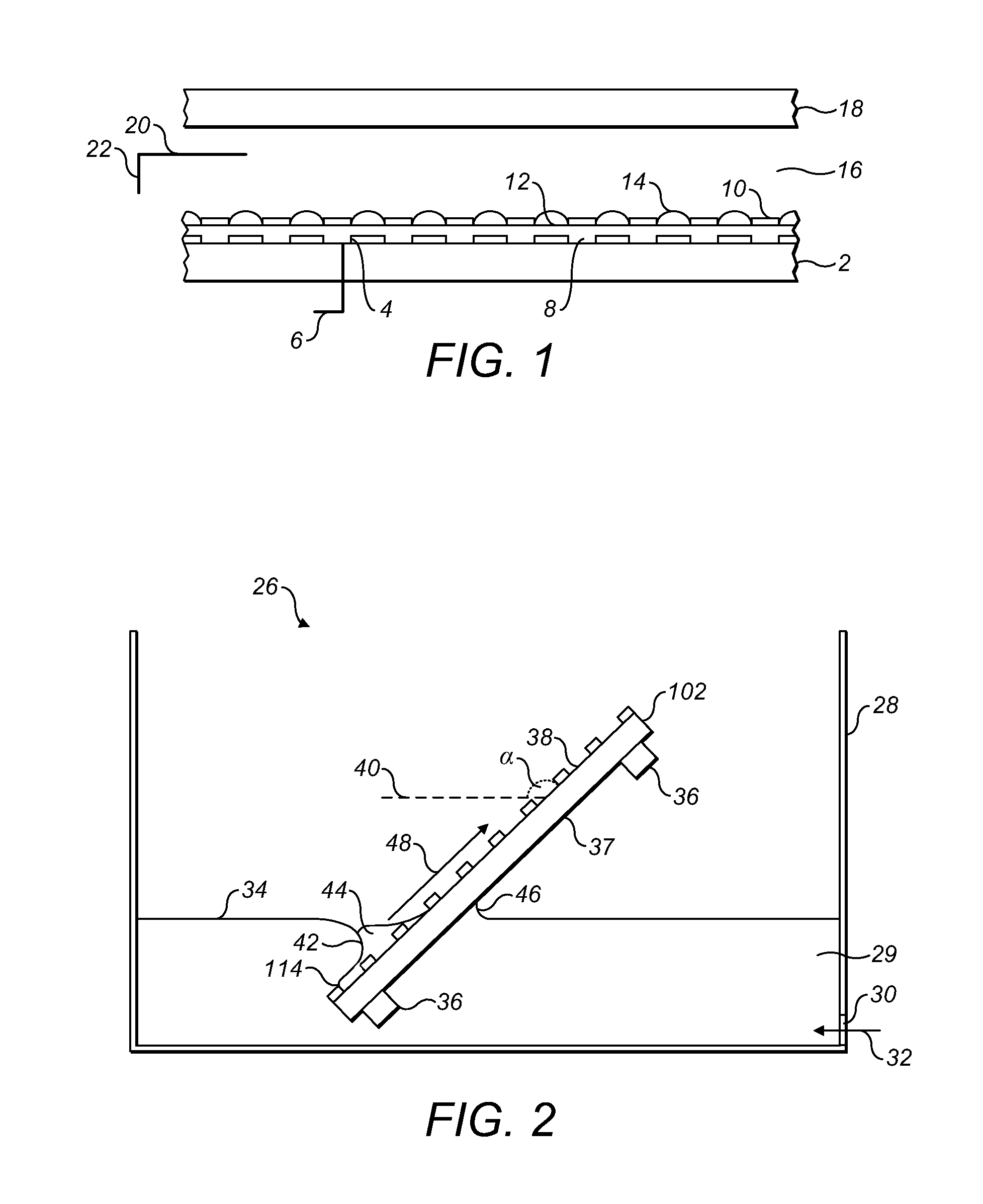

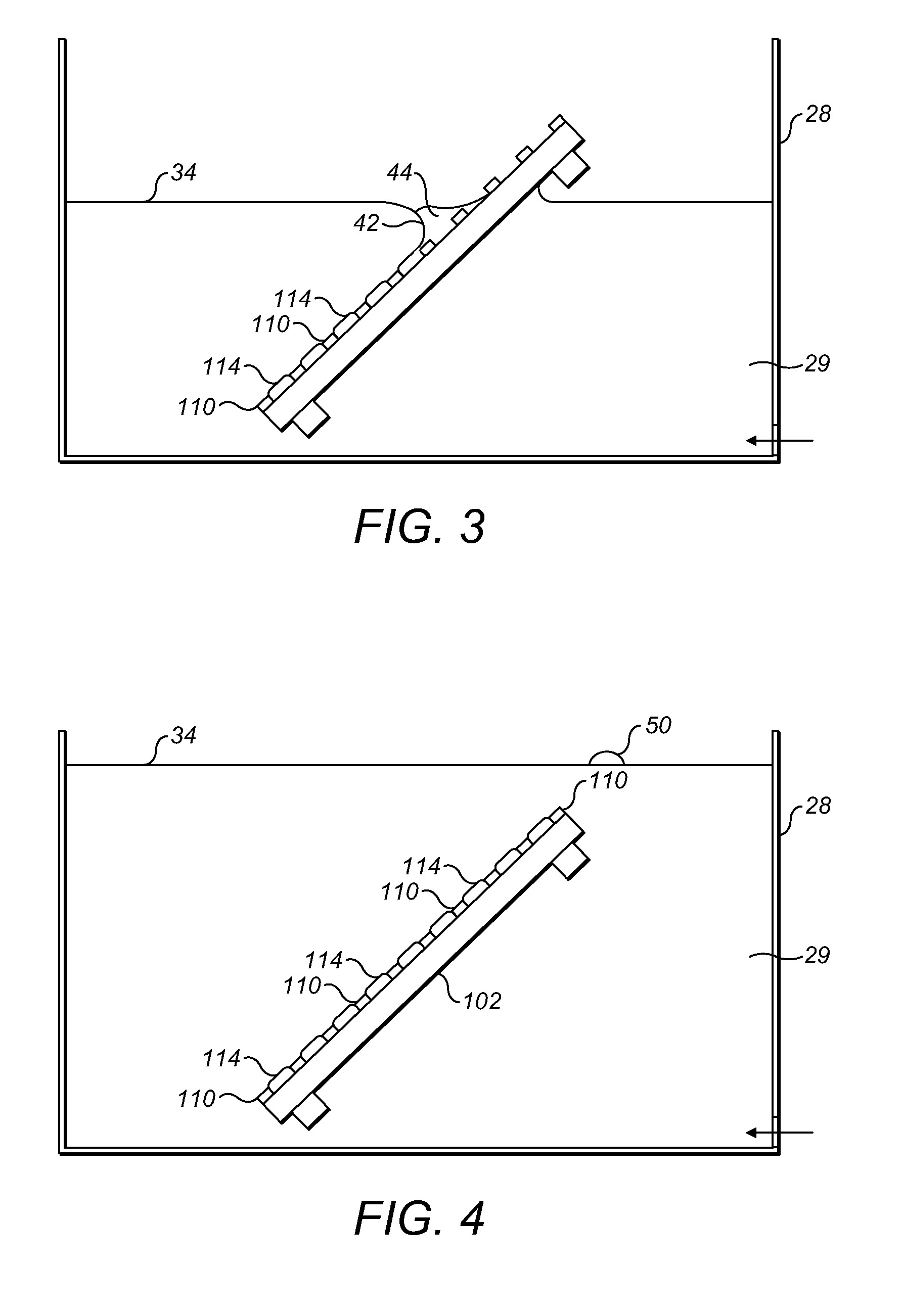

Method of manufacturing an optical display

InactiveUS9134528B2Low costLess oilPipeline systemsThin material handlingDisplay deviceBiomedical engineering

A method for manufacturing an electrowetting device provides a first fluid on a surface of a substrate. The method includes the steps of immersing part of the substrate in a second fluid, the second fluid being immiscible with the first fluid, and a surface of the second fluid forming a gutter along the surface of the substrate; providing a quantity of the first fluid in the gutter; and moving the gutter along the surface of the substrate, the surface of the substrate and a horizontal plane forming an angle between 100 degrees and 170 degrees. Also disclosed is an apparatus for performing the method.

Owner:LIQUAVISTA BV

Process for reducing oil and fat content in cooked potato

A process for cooking a potato in oil and / or fat is provided. An acidic dry protein mixture, an alkaline dry protein mixture, an aqueous alkaline protein mixture or an aqueous acidic protein or peptide derived therefrom is added to a food prior to cooking. The acidic dry protein mixture, alkaline dry protein mixture, aqueous alkaline protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres. The uncooked potato and protein and / or peptide is frozen and then cooked in a fat or oil. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:PROTEUS INDUSTRIES INC

Process fo Reducing Oil and Fat Content in Cooked Food with Pea Protein

InactiveUS20150264971A1Minimize absorptionLess fatDough treatmentFruit and vegetables preservationPea proteinCooked food

A process for cooking a food in oil and / or fat is provided. A dry pea protein mixture or an aqueous pea protein is added to a food prior to cooking. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:KEMIN PROTEINS LLC

Method for preparing light oil from low-hydrogen-content oil with self-contained asphalten

InactiveCN104498077AMinimizeHigh softening pointHydrocarbon distillationTreatment with hydrotreatment processesCoal Tar PitchesChemistry

The invention provides a method for preparing light oil from low-hydrogen-content oil with self-contained asphalten. The method is suitable for processing of medium-low temperature coal tar. According to the invention, a deep evaporation method is adopted to isolate the medium-low temperature coal tar into distillate oil vapor V1 and liquid L1 under the condition of no occurrence of obvious coking, wherein the liquid L1 is mainly composed of macromolecular colloidal bituminous components; after cooling and molding, the liquid L1 used as soft coal or green coal can be used as fire coal to achieve green storage and usage of the liquid L1; and the distillate oil vapor V1 is condensed to obtain an oil product which can be used for preparing a clean oil product via a hydrogenation process. The method for preparing light oil from low-hydrogen-content oil with self-contained asphalten provided by the invention enables the product direction of the macromolecular colloidal bituminous components in medium-low temperature coal tar to jump out of the traditional range of coke, coal tar pitch, fuel oil, suspended-bed or bubbling-bed hydrogenation raw material to produce coal-like products; and the traditional concept of ultimate obtainment of light oil and residual oil through vapor-liqiud separation is converted into the concept of ultimate obtainment of light oil and solid through vapor-liqiud separation.

Owner:何巨堂

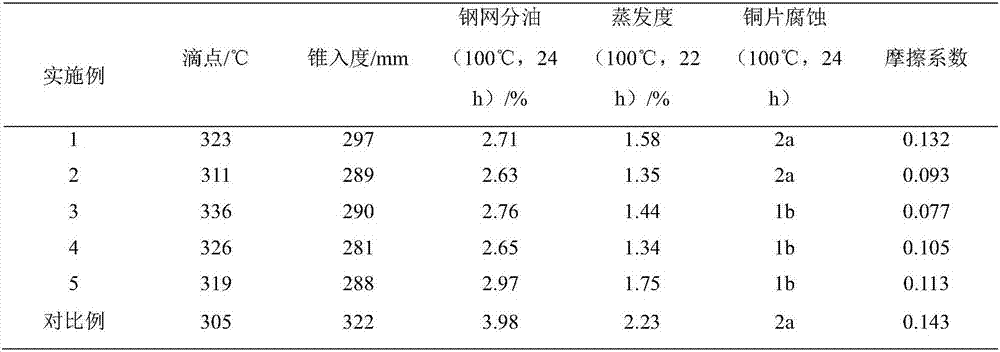

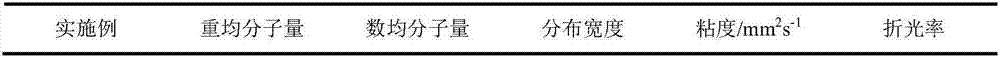

Method for preparing compound Ti-based lubricating grease based on polymethylphenyl silicone

The invention relates to lubricating grease, in particular to a method for preparing compound Ti-based lubricating grease based on polymethylphenyl silicone. Mineral oil, polymethylphenyl silicone, 12-hydroxystearic acid and benzoic acid are mixed and heated to 95 DEG C, and heat insulation with stirring is performed to obtain a mixture 1. The mixture 1 is heated to 120 DEG C, titanate is added, heat insulation with stirring is performed, during the period by-products are blown out and condensed and collected, and the mineral oil and polymethylphenyl silicone are added into the system after 5 h to obtain a mixture 2. The mixture 2 is slowly heated to 220 DEG C to perform high-temperature refining; after the mixture 2 is heated to a required temperature, maintaining the temperature for 1-5 min, and then pouring the mixture 2 into a stainless container, performing natural cooling to room temperature and then adding water and repeatedly performing stirring and shearing, performing grinding and homogenization, and obtaining the compound Ti-based lubricating grease. The dropping point of the compound Ti-based lubricating grease prepared according to the method can reach 336 DEG C, steel mesh oil separation is less, the evaporation loss is small, a copper sheet is corroded up to standard, and the compound Ti-based lubricating grease has low friction coefficient.

Owner:JIANGSU UNIV

Standard formula and technological process of black gold crispy meat

InactiveCN110623213ACrispy tasteCrispy, healthy and nutritiousFood scienceMonosodium glutamateCuttlefish

The invention discloses a standard formula and technological process of black gold crispy meat. The standard formula of the black gold crispy meat comprises high-quality streaky pork, egg liquid, oldbruised ginger, sweet potato powder, low-gluten flour, garlic powder, edible salt, monosodium glutamate, clear water and cuttlefish juice. The black gold crispy meat fried by the formula is crispy intaste, healthy and nutritional, the matching making technological process of the black gold crispy meat is simple, and the black gold crispy meat is less in oil content, fresh and cool in taste and suitable for old and young people.

Owner:成都大有拈头品牌策划有限公司

Flinger disc

InactiveUS20060073303A1Easy to assemble and disassembleReduce the temperatureLayered productsBearing componentsCircular discFuel tank

To achieve proper lubrication, a bearing housing or reservoir is filled with a predetermined amount of lubricant. When the machine, of which a bearing is a component, is operated, a flexible flinger disc provides proper lubrication by disturbance of the lubricant.

Owner:TRICO CORP

Process for reducing oil and fat in cooked food with pea protein

ActiveUS9028905B2Minimize absorptionLess fatMeat/fish preservationDough treatmentPea proteinCooked food

A process for cooking a food in oil and / or fat is provided. A dry pea protein mixture or an aqueous pea protein is added to a food prior to cooking. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:KEMIN PROTEINS LLC

Drunk pepper for hotpot condiment and fermented brewing method of drunken pepper

PendingCN114766649AImprove practicalityGood nourishing effectLipidic food ingredientsNatural extract food ingredientsBiotechnologyBrewing

The invention discloses drunken peppers for hotpot condiments and a drunken pepper fermentation brewing method, and relates to the technical field of drunken peppers. The drunken pepper for the hotpot condiment comprises the following formula raw materials: red capsicum frutescens, red capsicum frutescens, ginger, garlic, kaoliang spirit, seasonings and spices, and the fermentation brewing method of the drunken pepper for the hotpot condiment comprises the four steps of crushing, fermenting, mixing and filling. According to the drunken pepper for the hotpot condiment, the condition of heavy fire does not occur when the drunken pepper for the hotpot condiment is eaten, so that the discomfort caused to part of people due to the fact that the fire is too heavy when the drunken pepper is used as the hotpot condiment is effectively relieved, the practicability of the drunken pepper is effectively enhanced, and the drunken pepper has a good nourishing effect due to the addition of the fructus lycii; and a small amount of oil is added, so that the drunken pepper is rich in taste and spicy but not oily when being eaten, the phenomenon of eating discomfort caused by large oiliness is prevented, the application range of the drunken pepper is widened, and the market competitiveness of the drunken pepper is enhanced.

Owner:四川红福醉椒年代火锅有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com