Standard formula and technological process of black gold crispy meat

A technical process and technology of crispy meat, which is applied in the field of standard formula and technical process of Heijin crispy meat, can solve the problems of crispy meat that cannot be solved, achieve the effect of less oil, simple production process, and balanced nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

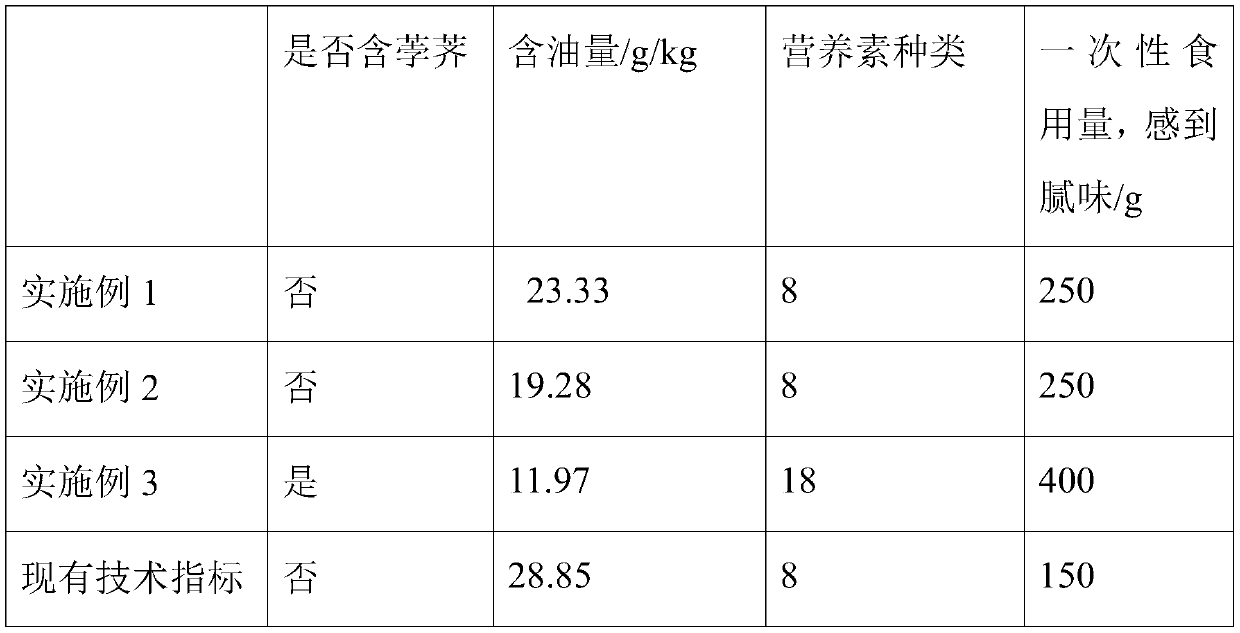

Examples

Embodiment 1

[0020] A standard formula for black golden crispy pork, which includes: fine pork belly 600g, egg liquid 150g, ground ginger 10g, sweet potato flour 250g, low-gluten flour 150g, garlic powder 20g, edible salt 7g, monosodium glutamate 3g, water 180g, cuttlefish juice 4g.

[0021] A technological process of black golden crispy pork, the process steps are:

[0022] (1) Fine-quality pork belly, peeled and cut into 12cm long and 0.8cm wide strips, prepared with 2g edible salt, 10g grated ginger, and 40g water.

[0023] (2) Sweet potato flour, low-gluten flour, garlic powder, egg liquid, edible salt, monosodium glutamate, and cuttlefish juice are mixed with water to make a paste for later use;

[0024] (3) Pour the delicious meat strips into the batter and stir evenly, set aside;

[0025] (4) Boil wide oil in the pot to 180°C oil temperature, pour in the battered meat strips, fry it until the skin is shaped, and pick up the oil for use;

[0026] (5) When the oil in the pot is heated to 200°C,...

Embodiment 2

[0028] A standard formula for black golden crispy pork, which includes: fine pork belly 600g, egg liquid 150g, ground ginger 10g, sweet potato flour 250g, low-gluten flour 150g, garlic powder 20g, edible salt 7g, monosodium glutamate 3g, water 180g, cuttlefish juice 4g.

[0029] A black gold crispy pork technological process, the technological process steps are:

[0030] (1) Fine-quality pork belly, peeled and cut into 12cm long and 0.8cm wide strips, prepared with 2g edible salt, 10g grated ginger, and 40g water.

[0031] (2) Sweet potato flour, low-gluten flour, garlic powder, egg liquid, edible salt, monosodium glutamate, and cuttlefish juice are made into a paste with water for later use;

[0032] (3) Pour the delicious meat strips into the batter and stir evenly, set aside;

[0033] (4) Boil the oil in the pan to a temperature of 180℃, add the battered meat strips, fry until the skin is shaped, and remove the oil for use. The oil control method is to remove the oil and wrap the me...

Embodiment 3

[0036] A standard formula of black golden crispy pork, the formula includes: fine pork belly 600g, egg liquid 150g, ground ginger 10g, sweet potato powder 250g, low-gluten flour 150g, garlic powder 20g, edible salt 7g, monosodium glutamate 3g, water 180g, cuttlefish juice 4g, 50g of chopped water chestnuts.

[0037] A black gold crispy pork technological process, the technological process steps are:

[0038] (1) Fine-quality pork belly, peeled and cut into 12cm long and 0.8cm wide strips, prepared with 2g edible salt, 10g grated ginger, and 40g water.

[0039] (2) Red potato flour, low-gluten flour, garlic powder, egg liquid, edible salt, monosodium glutamate, cuttlefish juice, water chestnut minced and mixed with water to make a paste for later use;

[0040] (3) Pour the delicious meat strips into the batter and stir evenly, set aside;

[0041] (4) Boil the oil in the pan to a temperature of 180℃, add the battered meat strips, fry until the skin is shaped, and remove the oil for use. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com