Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Good for scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

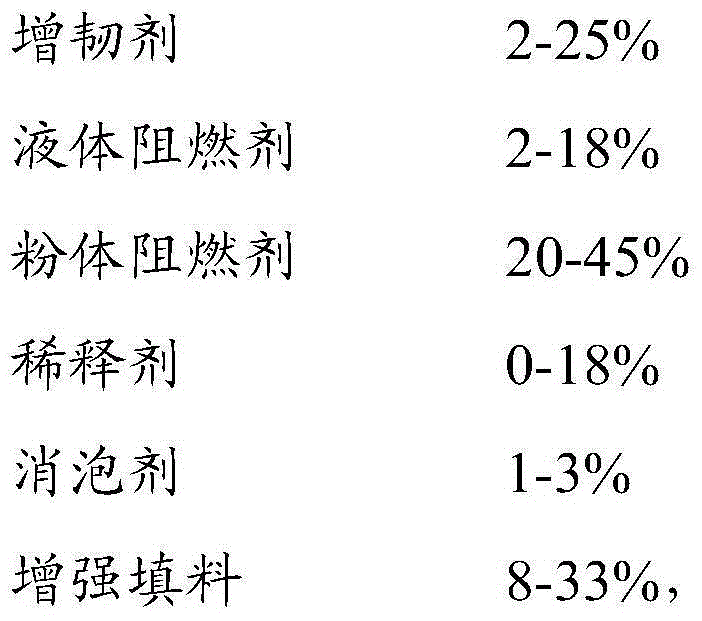

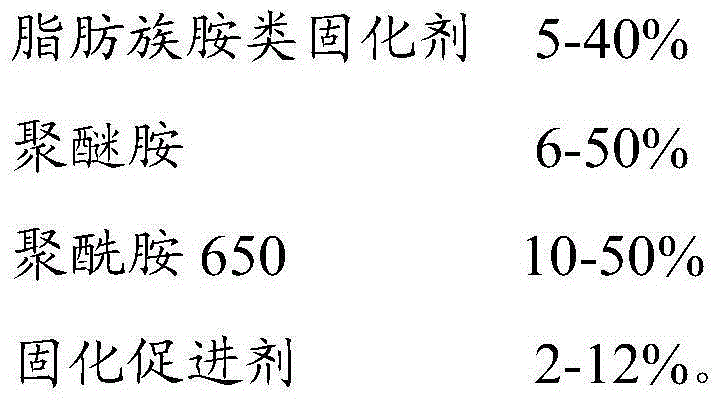

Two-component epoxy glue and preparation method thereof

ActiveCN105062395AReduced cured crosslink densityRelatively consistent viscosityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAliphatic amine

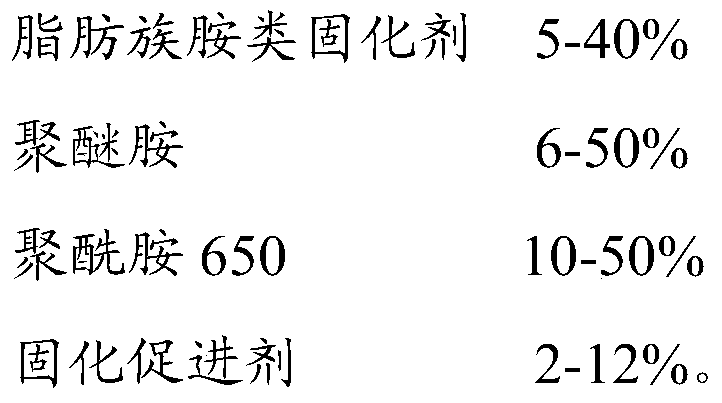

The invention relates to two-component epoxy glue and a preparation method thereof. The two-component epoxy glue comprises a component A and a component B, and the component A comprises epoxy resin, a toughening agent, a liquid flame retardant, a powder flame retardant, a diluent, an antifoaming agent and reinforcing fillers; the component B comprises an aliphatic amine curing agent, polyether amine, polyamide 650 and a curing accelerator. According to the two-component epoxy glue and the preparation method thereof, screening is conducted on the components of the epoxy glue, performance complementation of the components is achieved, a two-component epoxy glue with excellent comprehensive performance is formed through synergetic cooperation, the toughness, the anti-stripping strength and the anti-impact performance of the epoxy glue are significantly improved, the flame-retardant performance can reach the grade UL94-V0, the operable time is more appropriate, the curing time is short, and the continuous production can be achieved.

Owner:GUANGZHOU BAIYUN CHEM IND

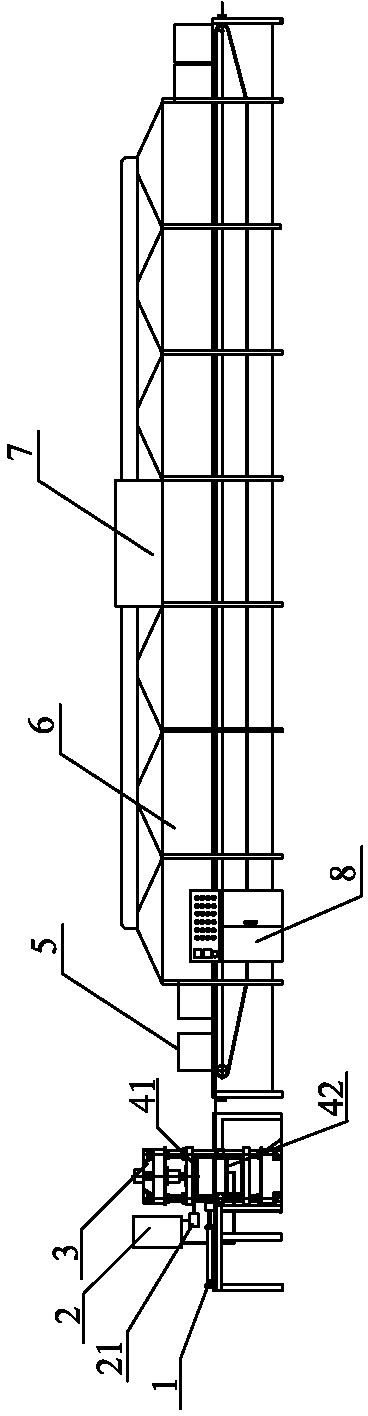

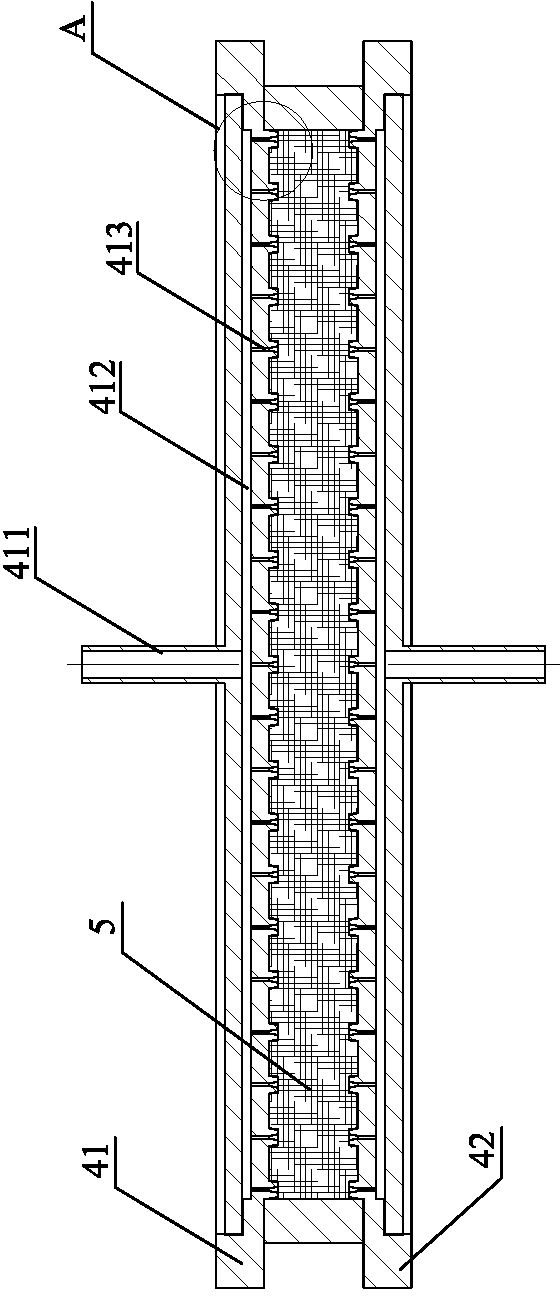

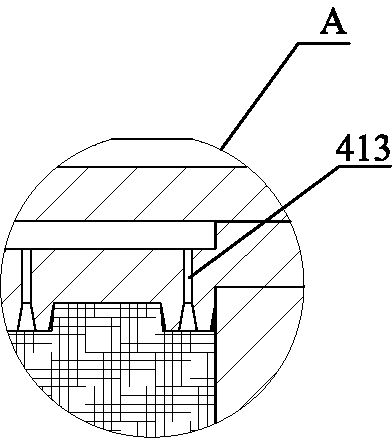

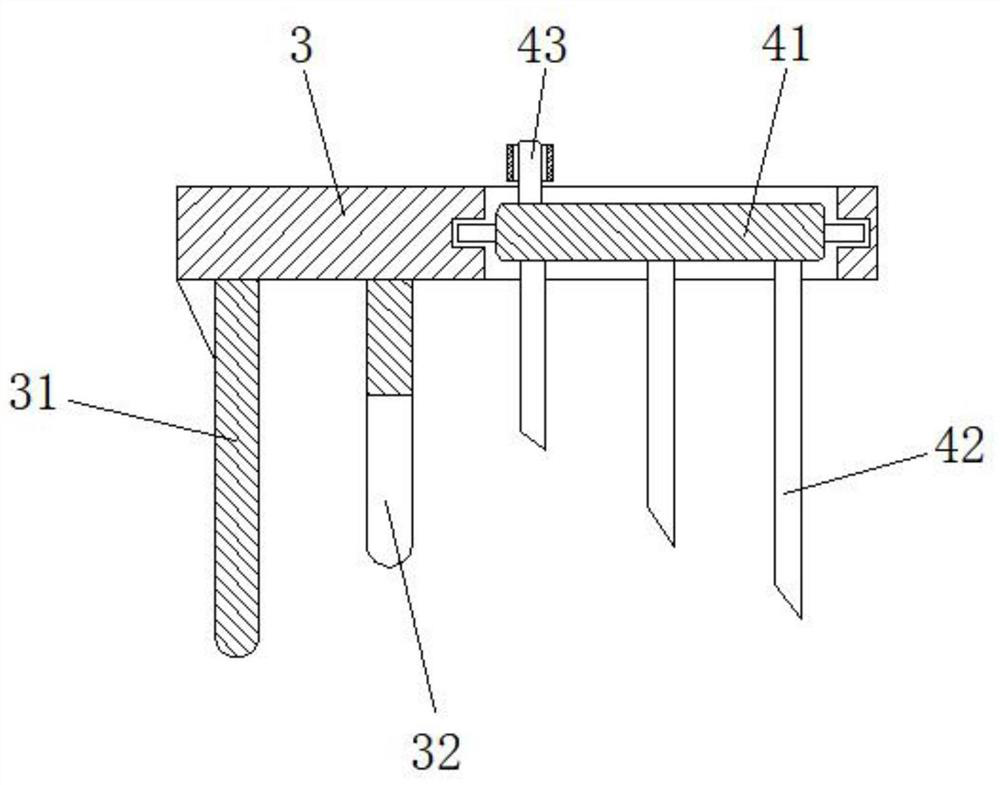

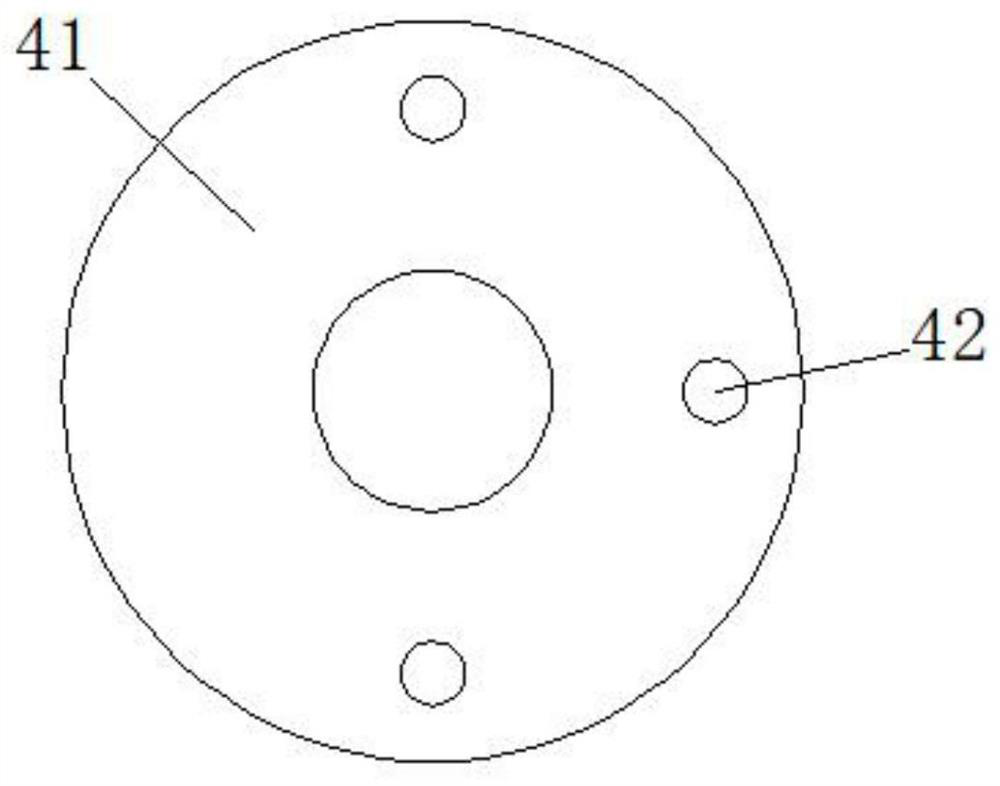

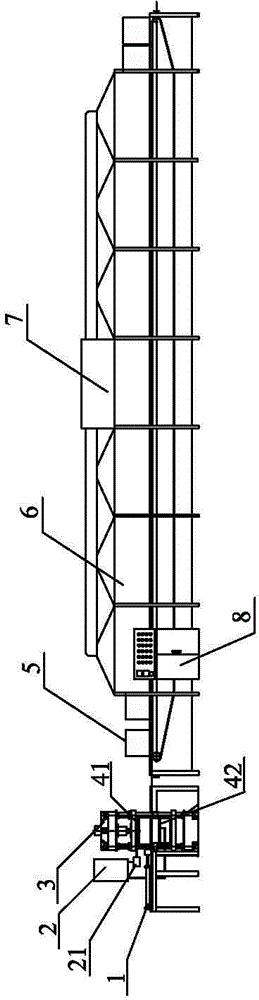

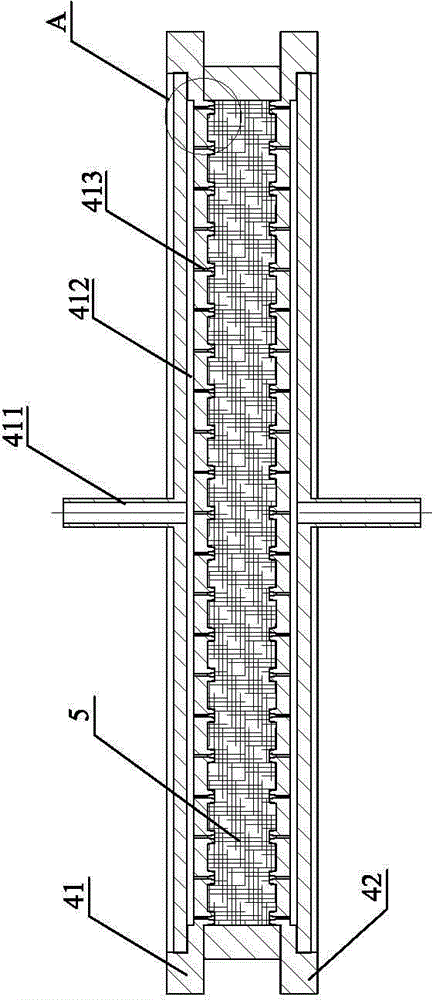

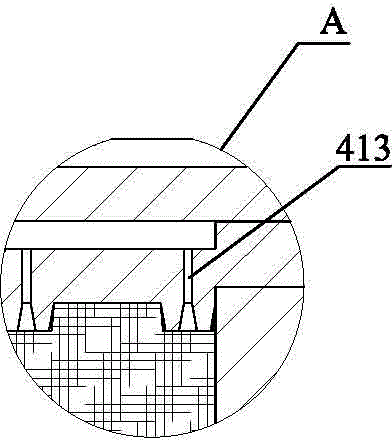

A-grade fireproofing thermal insulation material as well as production equipment and method thereof

InactiveCN103265722AImprove performanceNot easy to come outHeat proofingFire proofingThermal insulationFireproofing

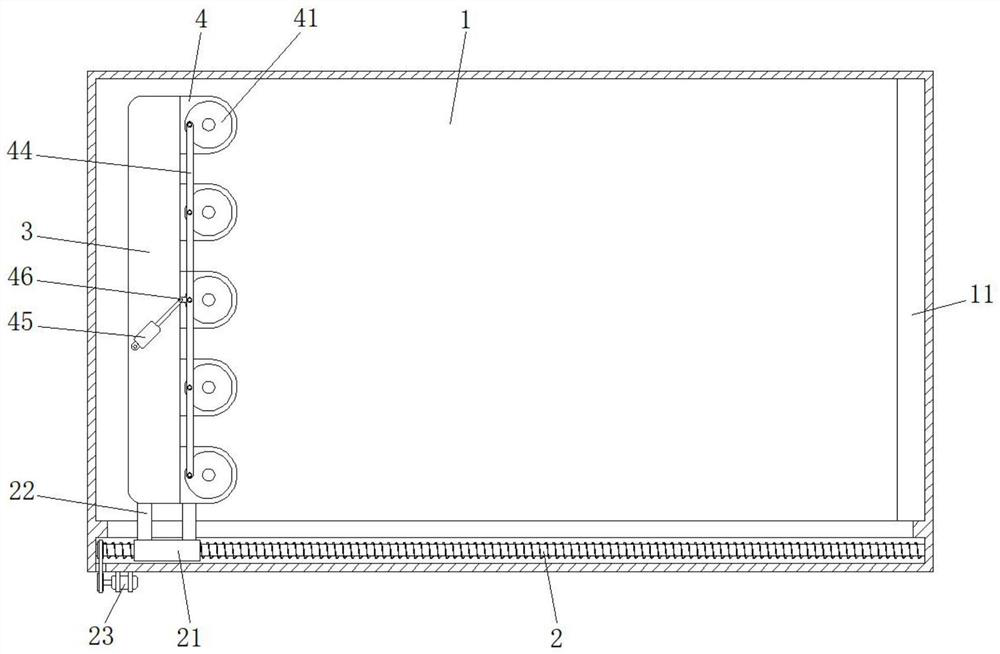

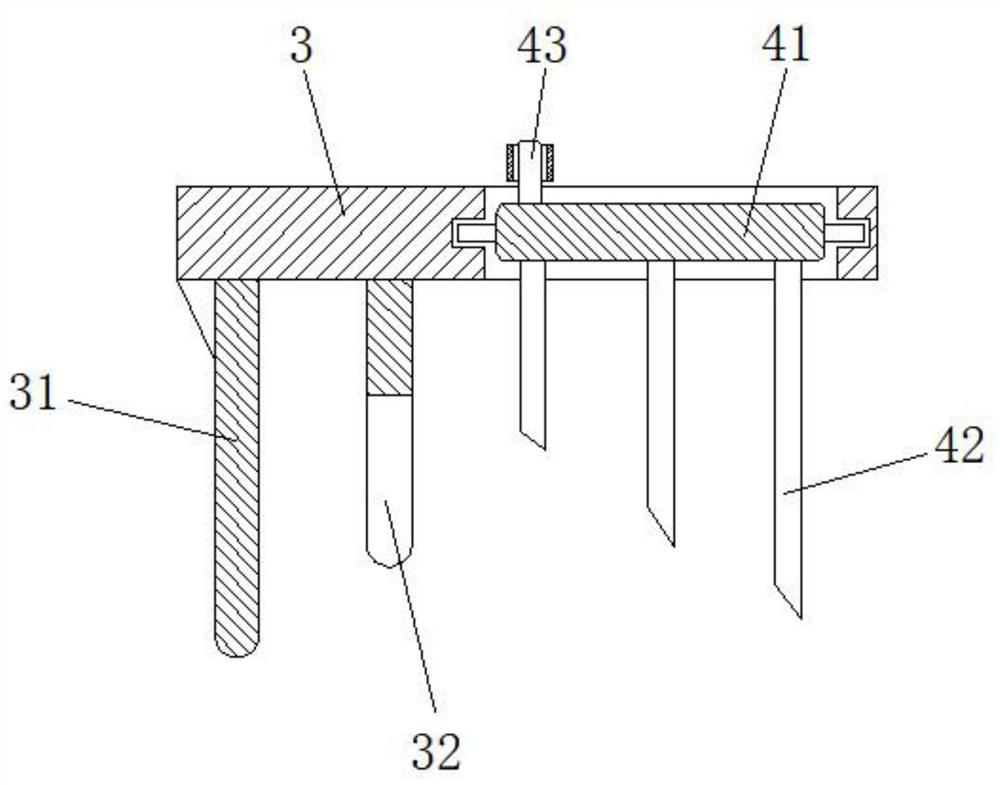

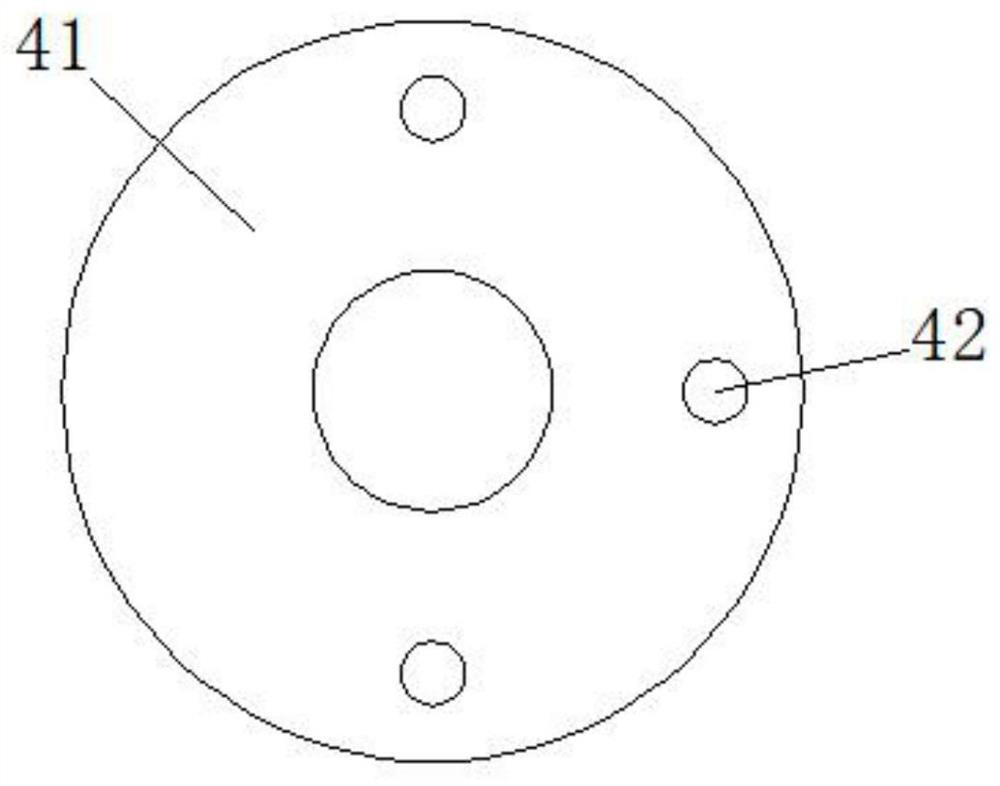

The invention discloses an A-grade fireproofing thermal insulation material as well as production equipment and method thereof and belongs to the technical field of fireproofing thermal insulation materials of exterior walls of buildings. According to the method, inorganic fireproofing glue is injected into an organic foam material body, and spaces of an organic foam material are filled by utilizing the inorganic fireproofing glue, so that an inorganic fireproofing material and the organic material body can be firmly combined, fireproofing and heat retaining properties of the organic foam material are improved, and strength of the fireproofing thermal insulation material is enhanced; and besides, a concave-convex surface is formed on a die in the method, so that the surface of the pressed fireproofing thermal insulation material is uneven, mud scraping in construction can be facilitated, and strength of bonding between mud and the thermal insulation material is enhanced.

Owner:山东德润机电设备制造有限公司

Preparation method and using method of anti-stripping exterior wall putty powder

The invention discloses a preparation method and a using method of anti-stripping exterior wall putty powder. The preparation method comprises the following steps of: step one, adding 6-8 parts of talcum powder, 2-4 parts of white bentonite and 12-14 parts of white portland cement to a pulverizer so as to be pulverized to obtain powder less than 150 meshes; step two, mixing the obtained powder, 40-44 parts of diatomite, 7-9 parts of high-strength gypsum powder and 6-8 parts of titanium dioxide, placing the mixture in a pulverizer so as to be pulverized for 10-15 minutes, then adding 2-3 parts of hydroxypropyl methyl cellulose, and pulverizing for 5-10 minutes again; step three, sieving the powder obtained in the step two by using a screen mesh with 320 meshes, wherein sieve residue is the anti-stripping exterior wall putty powder. The using method comprises the following steps of: placing the anti-stripping exterior wall putty powder in a container, adding water to the putty powder in the proportion of the exterior wall putty powder to the water being 10: (2-3), adding a right amount of pigment according to the color of an exterior wall, soaking for 40-60 minutes, and then stirring the mixture for 5-10 minutes by adopting a stirrer for blade coating.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

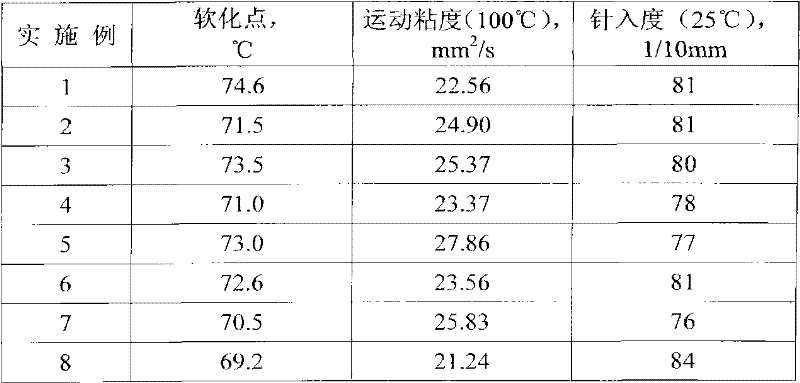

Aeroengine turbine guide vane polishing protection wax and polishing method

ActiveCN102453442AImprove plasticityImprove adhesionGrinding machinesPolishing compositionsWaxEngineering

The invention discloses aeroengine turbine guide vane polishing protection wax and a polishing method. The aeroengine turbine guide vane polishing protection wax is prepared from petroleum wax, abietic resin, hydrocarbon cream, a butylene polymer and the like by mixing processing according to a specific ratio. The aeroengine turbine guide vane polishing protection wax has good plasticity, good adhesiveness, appropriate physical and chemical performances and excellent use performances, is convenient for knife coating, can be removed easily, does not produce corrosion, toxins and pollution, and is environmentally friendly. The polishing method adopting the aeroengine turbine guide vane polishing protection wax comprises the following steps of protecting an air-guiding hole of a turbine guide vane by the aeroengine turbine guide vane polishing protection wax, carrying out polishing processing, and then removing the aeroengine turbine guide vane polishing protection wax. The polishing method can effectively prevent that metal chips block the air-guiding hole in turbine guide vane polishing.

Owner:CHINA PETROLEUM & CHEM CORP +1

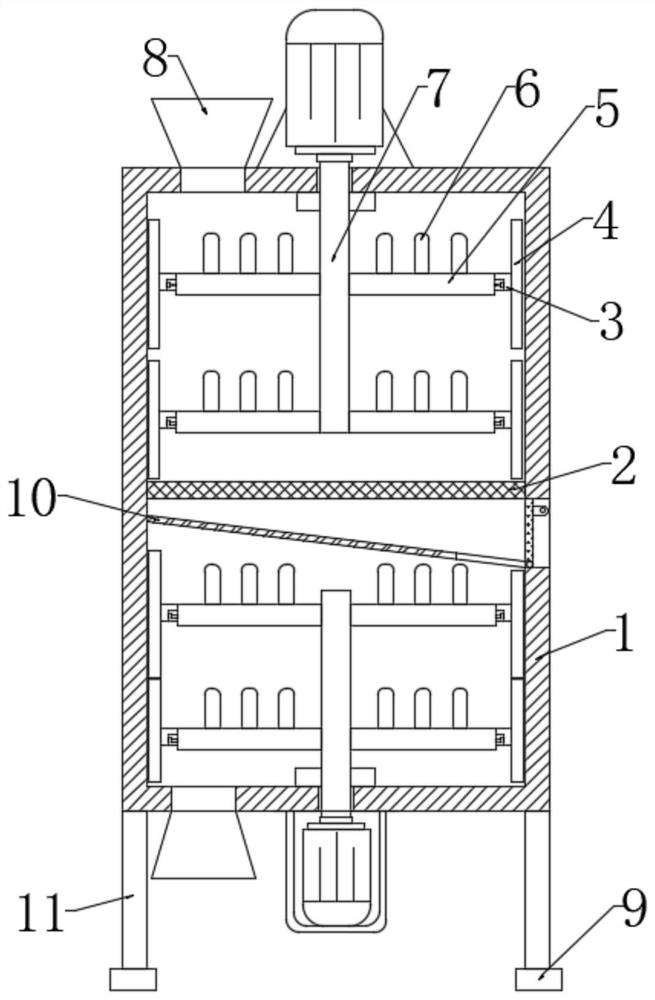

Feed mixing production machine for animals

InactiveCN107519811AImprove uniformityHigh degree of automationFeeding-stuffRotary stirring mixersAutomationFodder

The invention discloses a feed mixing production machine for animals. The feed mixing production machine comprises a mixing box body, wherein a feed mixing cavity is formed in the mixing box body; a feed inlet is formed in the top part of the mixing box body; a feed storage box is arranged above the mixing box body; the bottom part of the feed storage box is connected with a feed outlet pipe; the feed outlet pipe stretches into the mixing box body and does rotational motion around the axis of the feed outlet pipe; the bottom end of the feed outlet pipe is sequentially connected with multiple uniform feed dividing and stirring pipes which are obliquely arranged along a circumferential direction of the feed outlet pipe; a steel wire net is arranged between two adjacent uniform feed dividing and stirring pipes; a separating plate is arranged in the feed mixing cavity; a feed passing opening is formed in the separating plate; a lower cavity is internally provided with a grinding roller; multiple vertical scrapping plates are arranged at the bottom part of the separating plate; the bottom ends of the scrapping plates are tangent to the grinding roller. According to the feed mixing production machine disclosed by the invention, material mixing uniformity is increased through uniform feeding, and meanwhile, caked feed can ground, so that feed oil blocks can be crushed, the material mixing uniformity is further improved, the automation degree is high, and the production efficiency is improved.

Owner:成都和谐生物科技有限公司

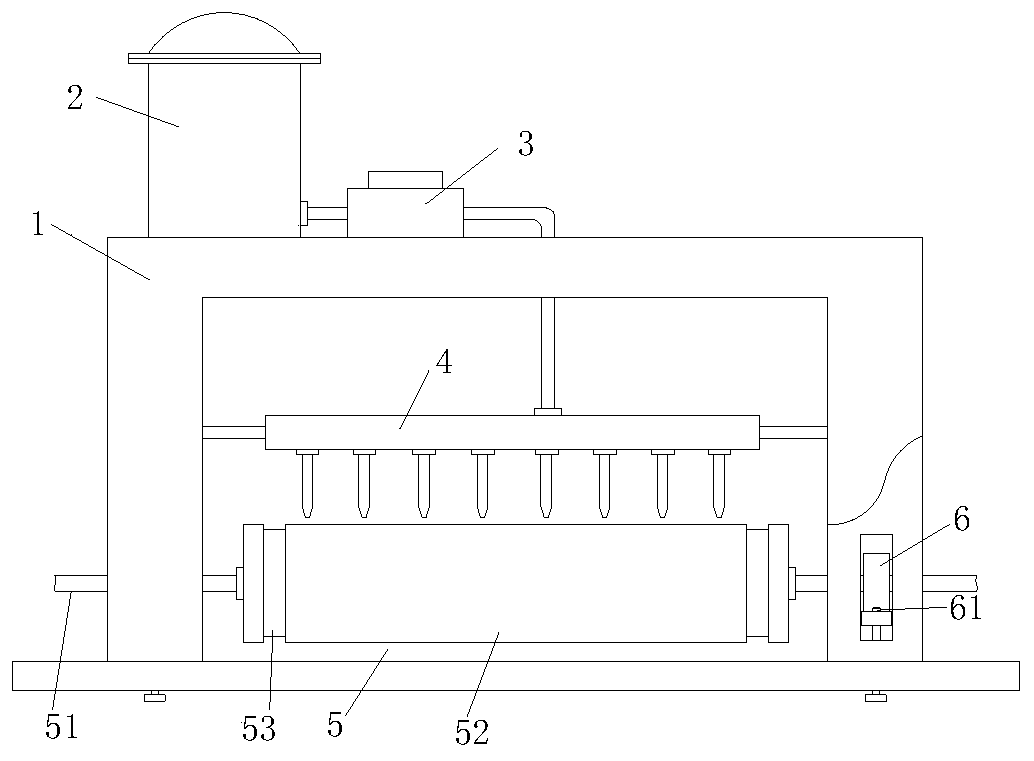

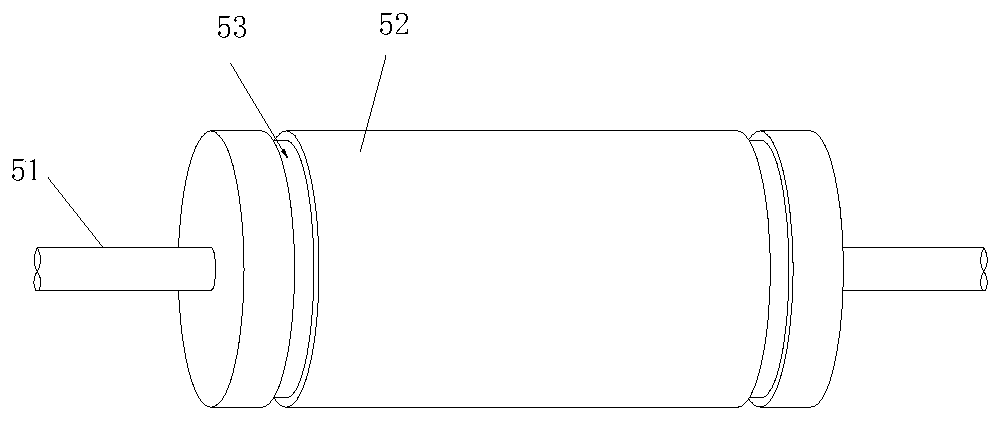

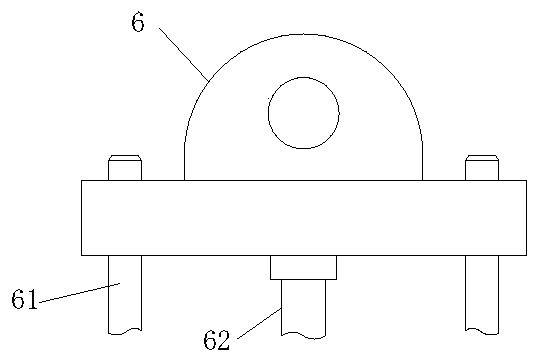

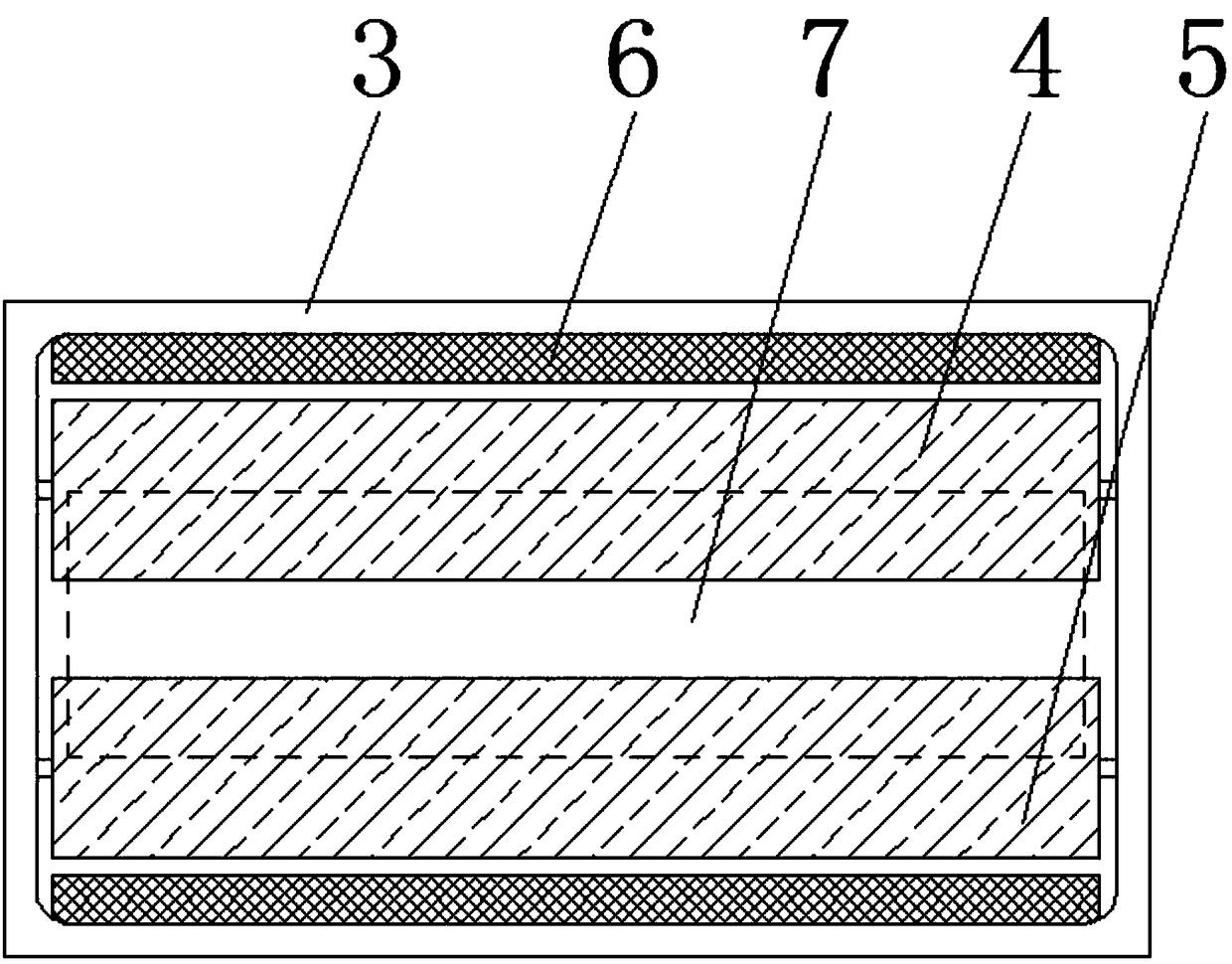

Polyurethane composite fabric gluing mechanism

InactiveCN110639753AGood for scrapingAdjust the clearanceLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention discloses a polyurethane composite fabric gluing mechanism. The polyurethane composite fabric gluing mechanism comprises a bracket, a glue tank which is installed on the top part of thebracket and a pump body which is connected with the glue tank, the discharge end of the pump body is connected with a glue shunt through a pipeline, the pipeline penetrates through the bracket from the top part of the bracket downward and is connected with a feeding port of the glue shunt, and the two ends of the glue shunt are fixedly installed on the bracket through a mounting beam, and a plurality of discharging ports and a glue outlet are arranged under the glue shunt; an upper glue roller is arranged under the glue outlet, the upper glue roller is rotationally arranged on the bracket, anda excessive glue collection box which can make the glue uniform is fixed on the bracket. According to the polyurethane composite fabric gluing mechanism, glue feeding is carried out from the upper part of the fabric, gluing is uniform, and a scraping plate is arranged, so that the overall coverage the glue on the glue roller is uniform and glue is saved to a certain extent.

Owner:HAINING JIESHENG NEW MATERIAL

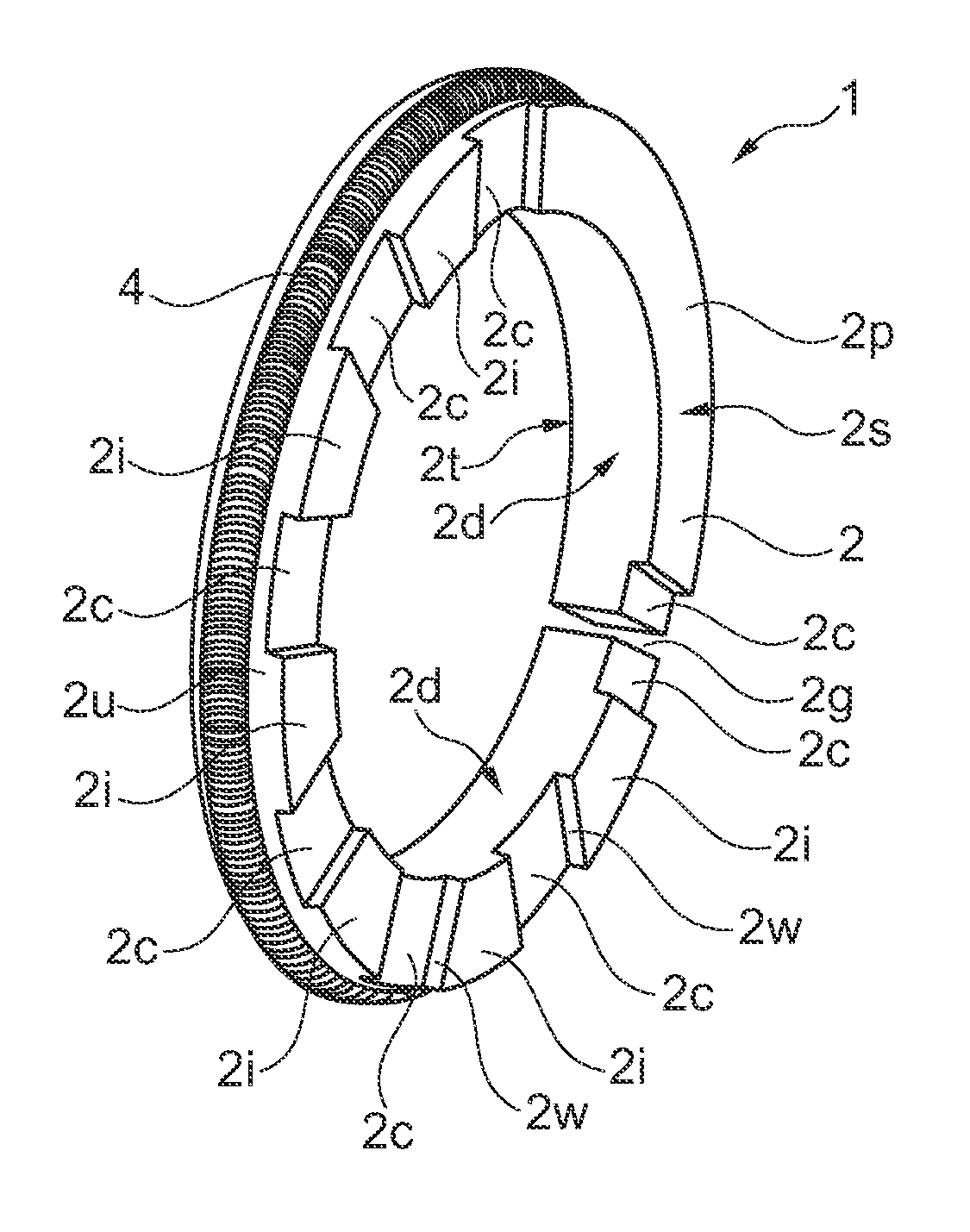

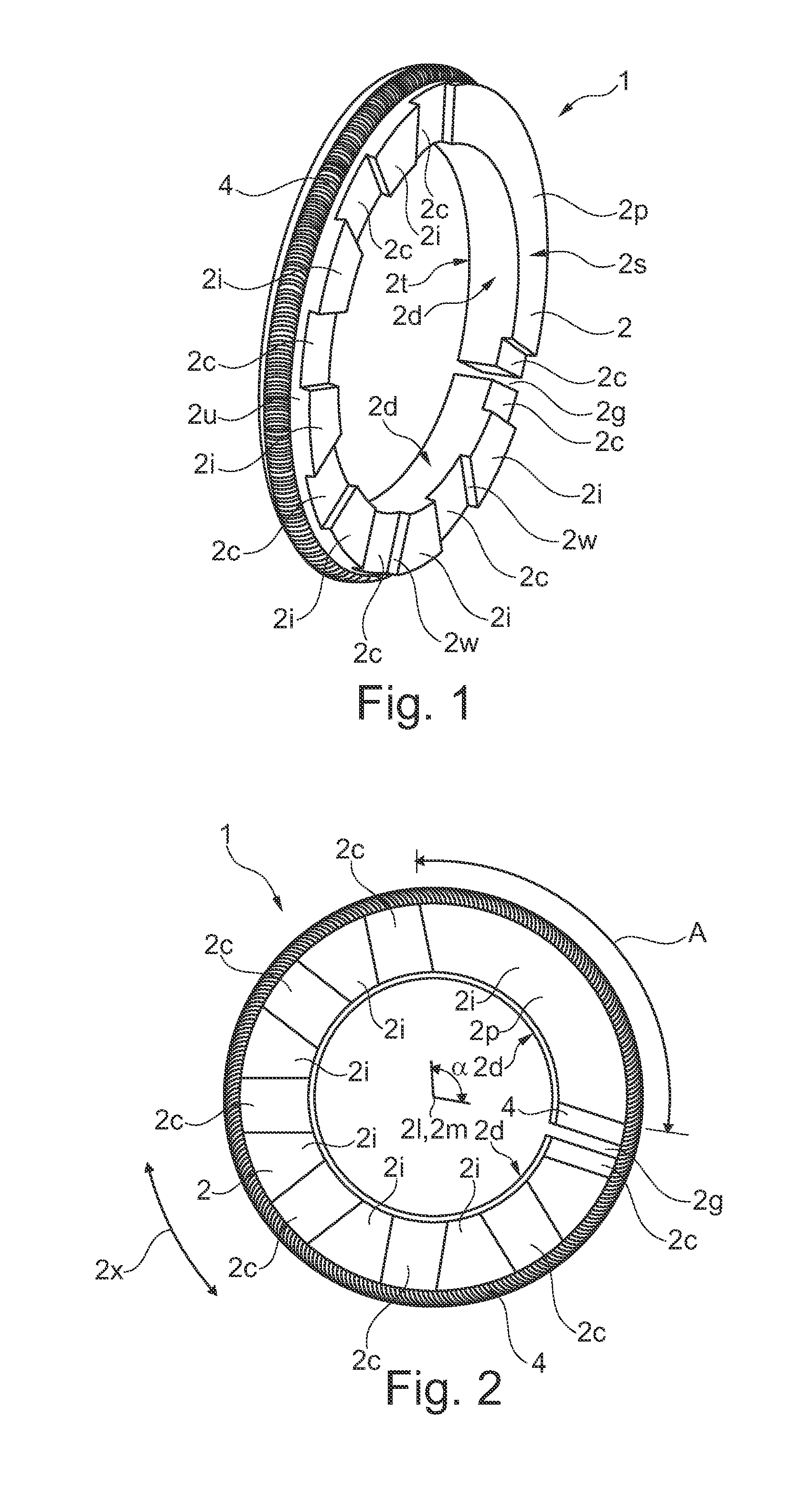

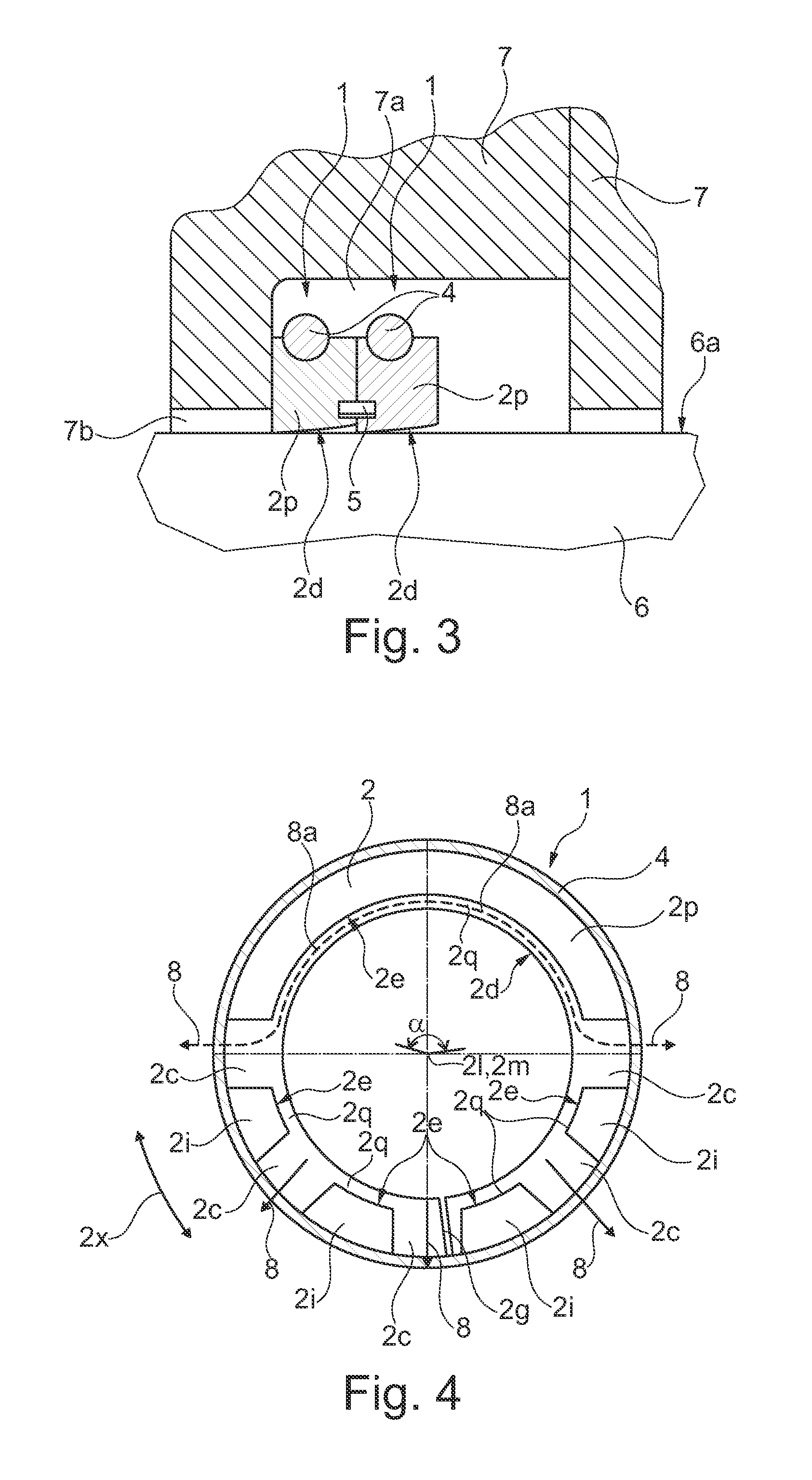

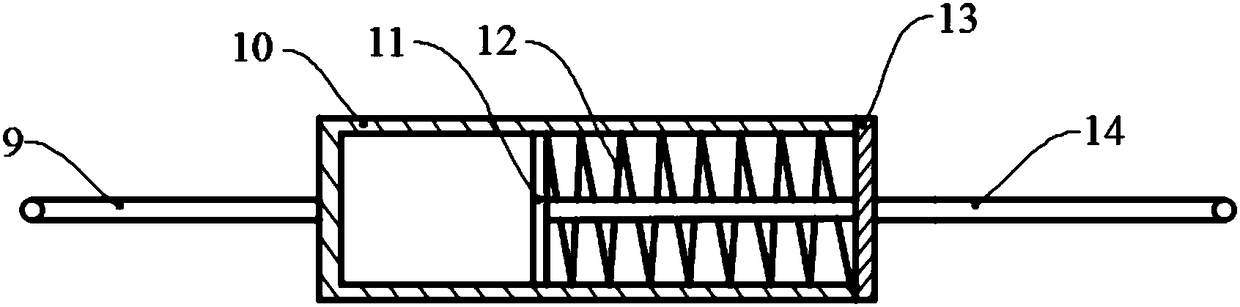

Oil scraper ring

ActiveUS20130307220A1Good for scrapingLess oilEngine sealsPiston ringsMechanical engineeringAngular range

The oil control ring (2) extends in a circumferential direction (2x) about a center (2l) and has a longitudinal axis (2m) that passes through the center (2l), wherein the oil control ring (2) has an end face (2d) that faces the center (2l), and wherein the oil control ring (2) has a first lateral surface (2s), a second lateral surface (2t), and an outer surface (2u) facing away from the center (2l), wherein the oil control ring (2) has a plurality of channels (2c) extending toward the center (2l) on the first lateral surface (2s), said channels being arranged at mutual distances in the circumferential direction (2x) and extending over the entire width of the first lateral surface (2s) in the radial direction and thereby forming a fluid-conducting connection between the end face (2d) and the outer surface (2u), and wherein crown parts (2i) extending in the circumferential direction (2x) are arranged between pairs of channels (2c), wherein each crown part (2i) protrudes beyond the respective channel (2c) in the direction of extent of the longitudinal axis (2m) and forms a lateral channel surface (2w) for the channel (2c), wherein at least one of the crown parts (5i) is designed as a long crown part (2p) and extends over an angular range (a) between 60 degrees and 350 degrees in the circumferential direction (2x). 212×2121.

Owner:BURCKHARDT COMPRESSION AG

Waterproof and anti-crack outer wall putty powder and preparation method thereof

InactiveCN107090203AStable structureSmooth and delicate appearanceFilling pastesCrack resistanceAnhydrous Calcium Sulfate

The invention discloses a waterproof and anti-crack outer wall putty powder and a preparation method thereof. The outer wall putty powder is prepared from, by weight, 60-80 parts of talcum powder, 10-20 parts of attapulgite clay, 10-18 parts of ground calcium carbonate, 2-8 parts of sodium bentonite, 5-10 parts of calcium oxide, 5-10 parts of anhydrous calcium sulfate, 1-5 parts of polyacrylamide, 0.6-3 parts of carboxymethylcellulose sodium, 2-5 parts of pulverized fuel ash, 0.2-0.5 part of pure iron powder and 0.4-0.8 part of a water repellent. The preparation method comprises the steps of attapulgite clay acidification, vibrating screen grinding, co-heat superfine crushing and the like. The putty powder is firm in structure and smooth and delicate in appearance and has good adhesive force with wall, watertightness, corrosion resistance and cracking resistance are achieved, the preparation method is simple and easy to implement, construction is easy and convenient, and blade coating and leveling performances are excellent.

Owner:合肥市一片叶装饰工程有限公司

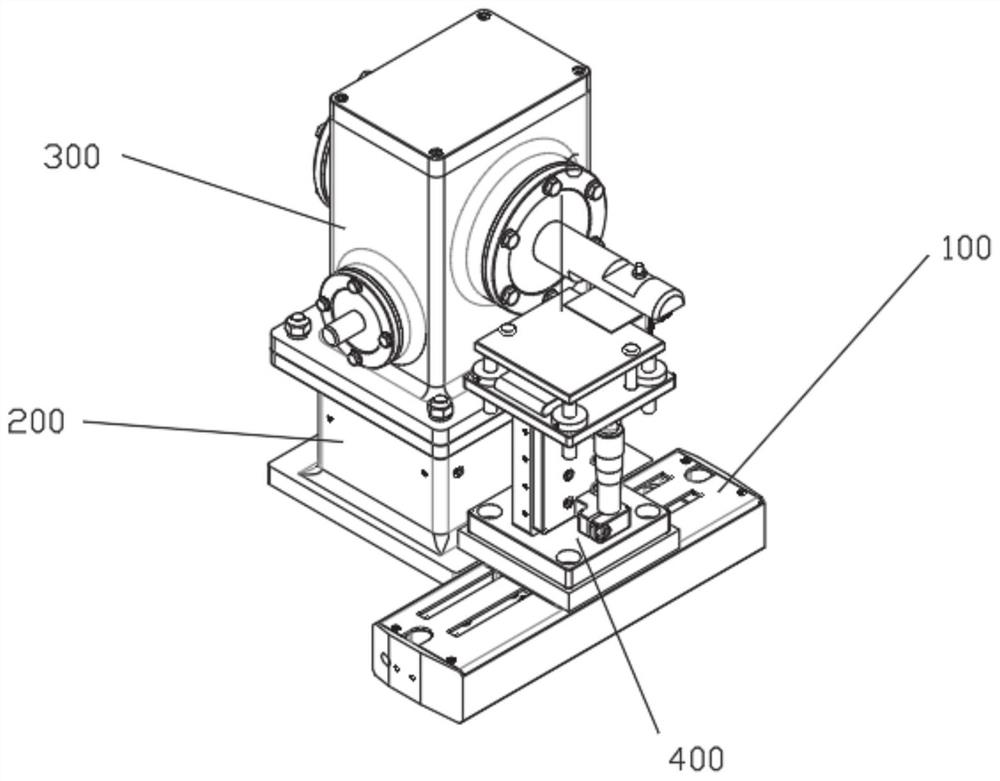

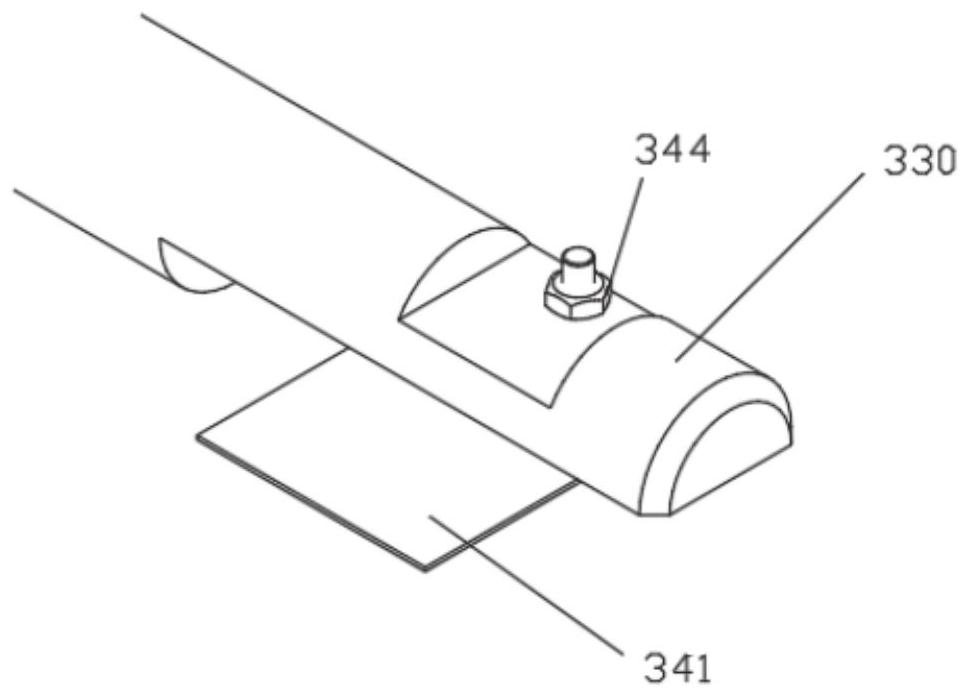

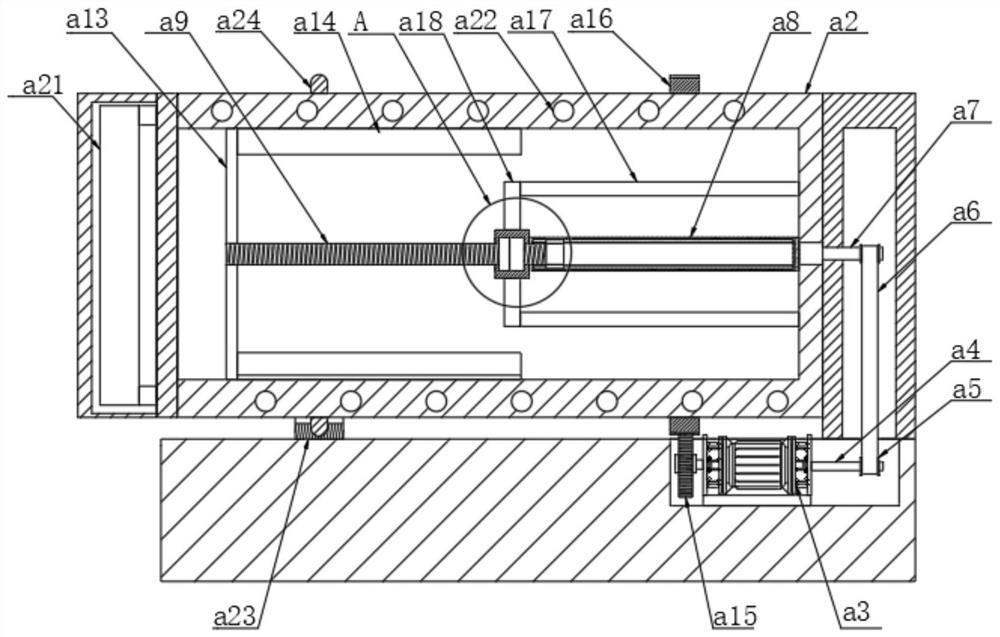

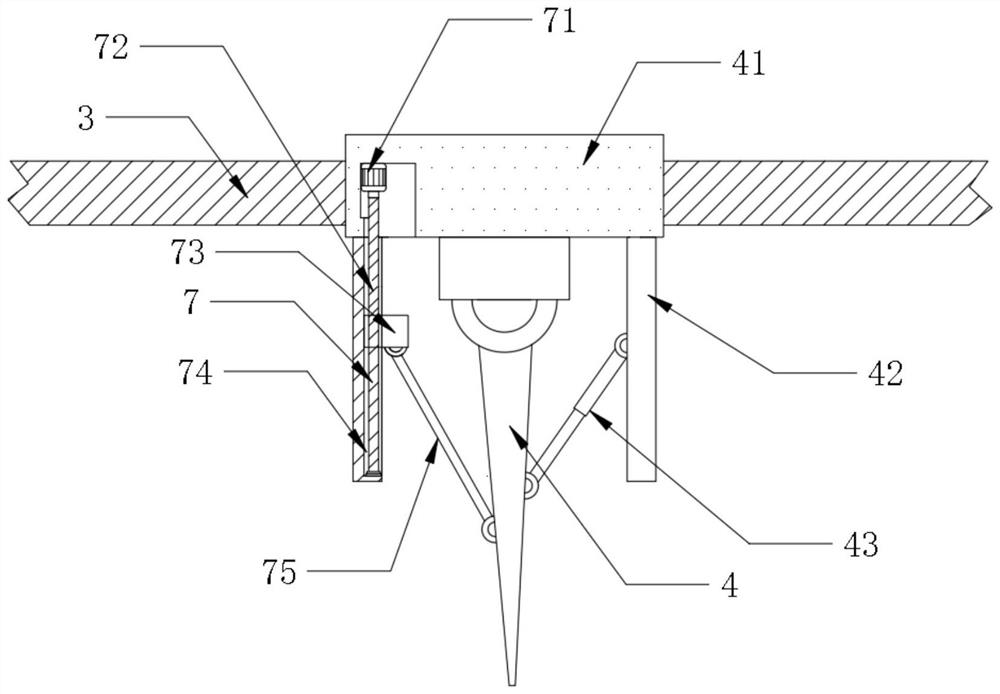

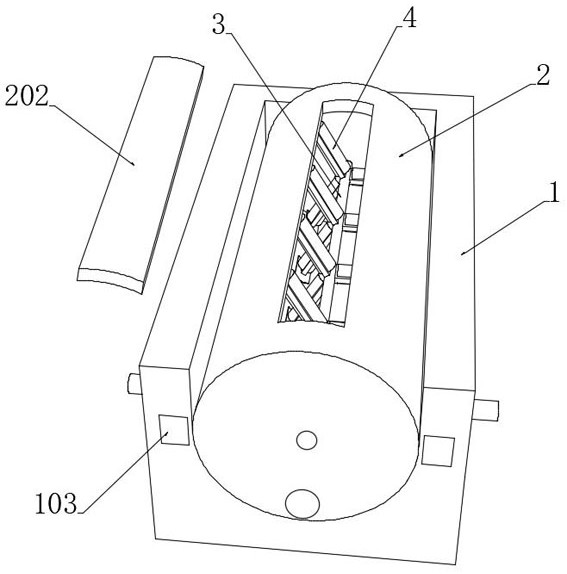

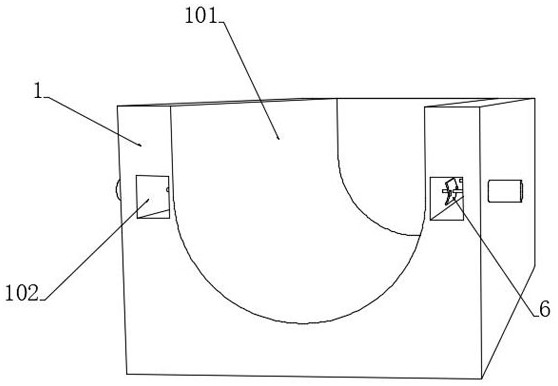

High-precision blade coating equipment and method with adjustable blade coating angle

InactiveCN111992449AGood for scrapingImprove uniformityLiquid surface applicatorsCoatingsStructural engineeringMechanical engineering

The invention discloses high-precision blade coating equipment and method with adjustable blade coating angle. The equipment comprises a scraper angle adjusting mechanism connected with a scraper andcapable of adjusting the scraper angle, and a scraper height adjusting mechanism connected with the scraper angle adjusting mechanism and comprising an inclined block capable of moving horizontally, the top surface of the inclined block is an inclined surface, the bottom of the scraper angle adjusting mechanism is connected with a top plate, the bottom of the top plate is connected with a roller through a supporting rod, the roller is in contact with the top surface of the inclined block, and the inclined block moves to drive the scraper angle adjusting mechanism to lift so as to adjust the height of the scraper.

Owner:SHANDONG UNIV +3

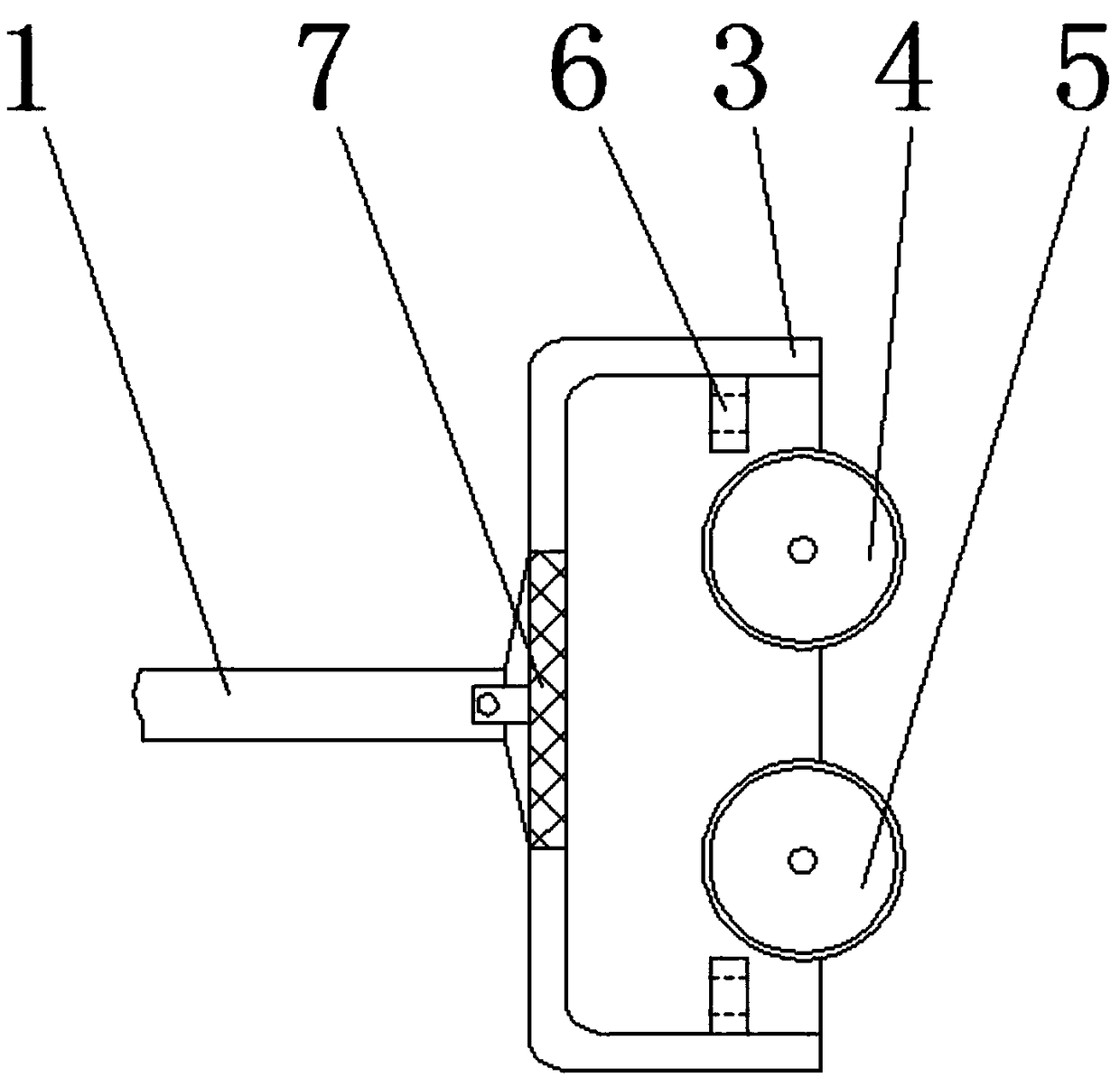

Paint spraying device for wooden products

InactiveCN108435496AEasy to paintAvoid pollutionLiquid surface applicatorsCoatingsControl switchElectromagnetic pump

The invention discloses a paint spraying device for wooden products. A spraying cover is arranged at the upper end of a push rod, an upper coating roller and a lower coating roller are arranged at theposition, close to an opening, of the interior of the spraying cover, a scraping plate used for removing redundant paint on the roller surface is arranged in the spraying cover, a spraying opening isformed in the middle of the back plate of the spraying cover, an electromagnetic pump is arranged on the upper surface of a barrel plug, a liquid absorption pipeline of the electromagnetic pump penetrates through the lower end surface of the barrel plug and is connected with a liquid absorption hose, the tail end of a liquid outlet pipeline of the electromagnetic pump penetrates through the interior of the push rod and is connected with the outer end of a material spraying opening, and an electromagnetic pump control switch is arranged on the rod body of the push rod. According to the paint spraying device, the coating is drawn out of a barrel through the electromagnetic pump, the liquid outlet pipeline and the push rod are conveyed to the material spraying opening, so that the upper coating roller and the lower coating roller are prevented from being stained with the coating, and the wall surface is conveniently painted; and the scraping plate is favorable for scraping redundant coatings, so that the redundant coatings can be prevented from dropping to the ground; and the whole device is reasonable in structure, and greatly reduces the labor cost.

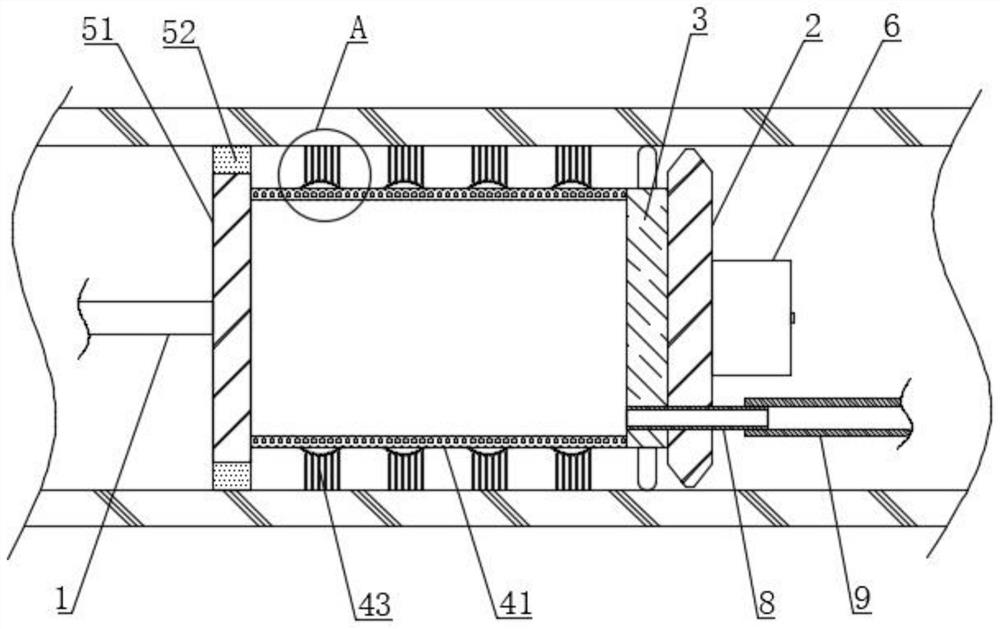

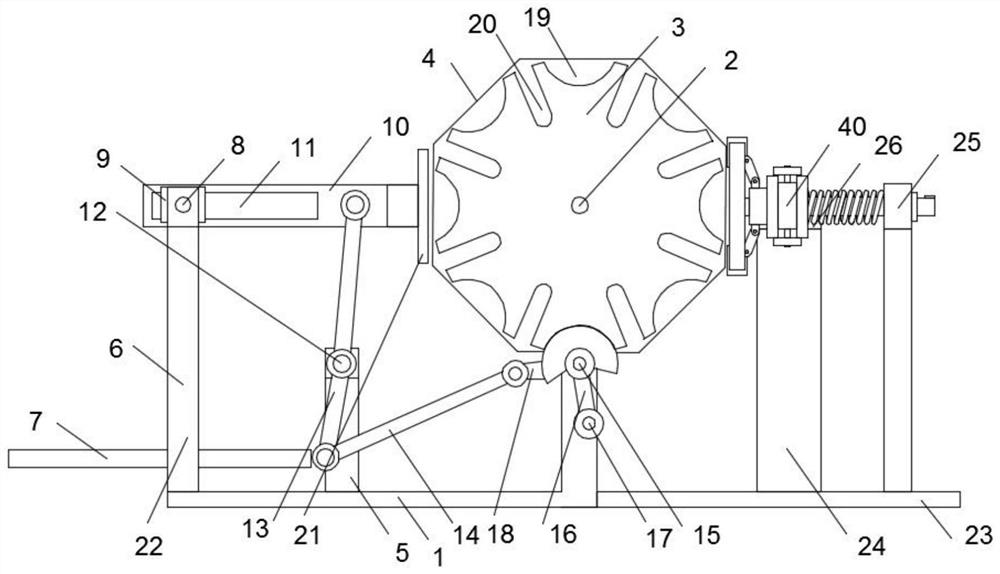

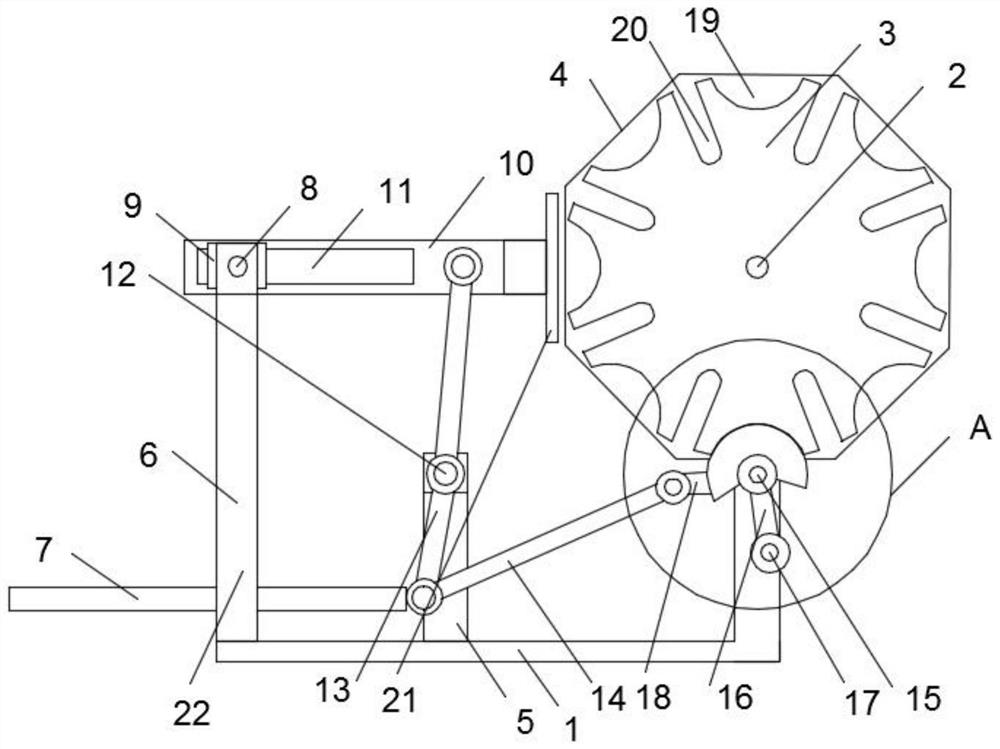

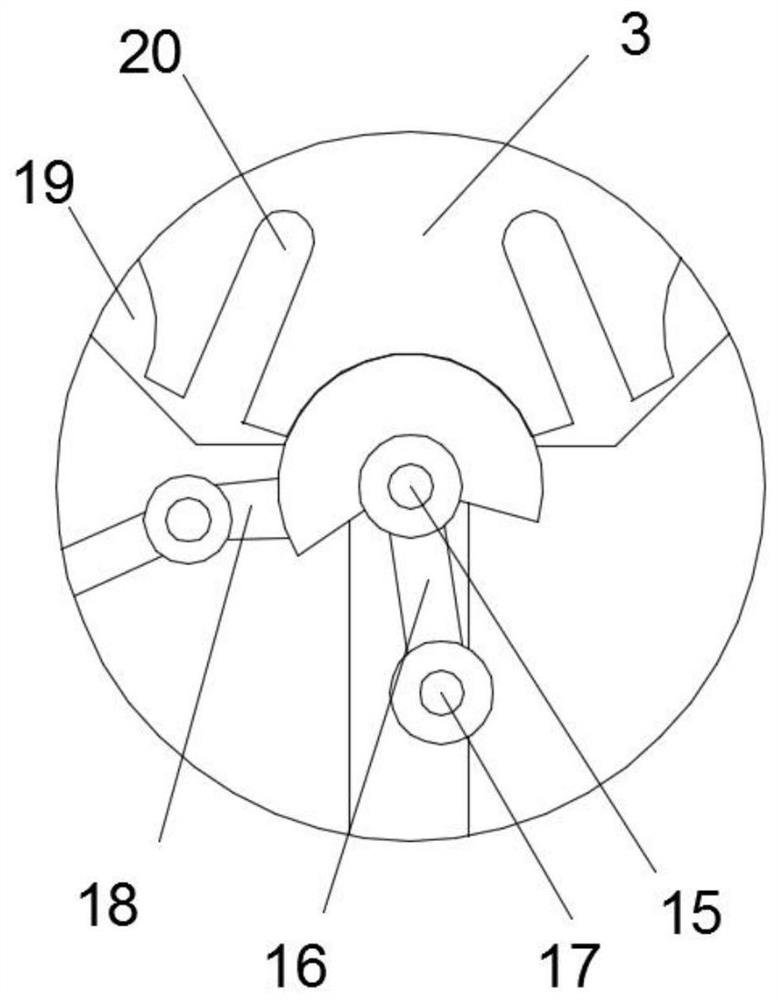

Asphalt pavement regenerant production system

PendingCN113244821AImprove efficiencyEasy to controlRotating receptacle mixersHollow article cleaningEngineeringStructural engineering

The invention provides an asphalt pavement regenerant production system, and relates to the technical field of asphalt regenerant stirring equipment. The asphalt pavement regenerant production system comprises a base and a stirring barrel, a stirring assembly is arranged in the stirring barrel and comprises a sleeve and a reciprocating lead screw, a double-shaft motor is fixedly connected into the base, the output end of the double-shaft motor is fixedly connected with a transmission shaft, one end of the stirring barrel is fixedly connected with a rotating rod, and the rotating rod is fixedly connected with a rotating shaft. the end, extending to the outer side of the stirring barrel, of the rotating rod and one end of the transmission shaft are fixedly connected with belt wheels, and the outer sides of the two belt wheels are sleeved with belts. According to the asphalt pavement regenerant production system, the stirring rod rotates to drive the scraping plate to rotate, so that materials in the stirring barrel can be stirred, meanwhile, materials adhered to the inner wall of the stirring barrel can be scraped, and the stirring effect is improved.

Owner:杨俊杰

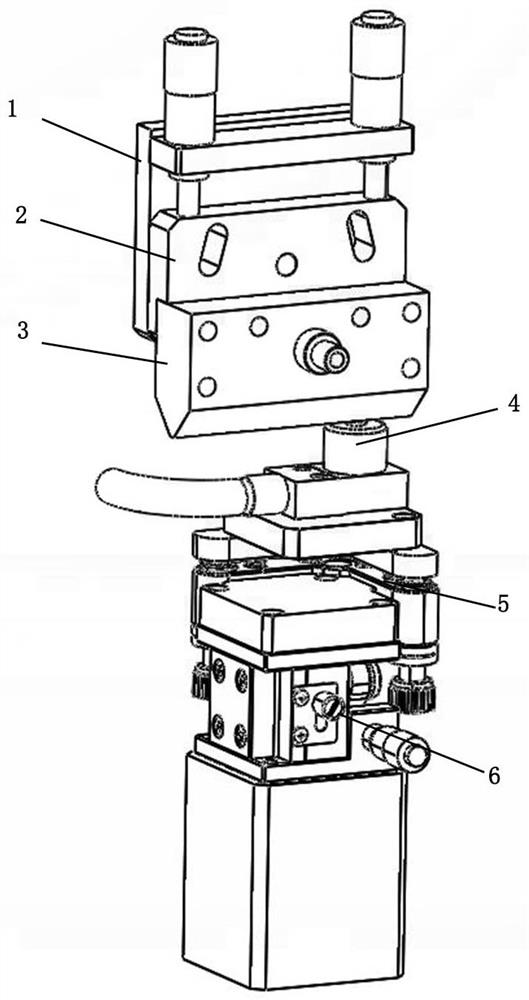

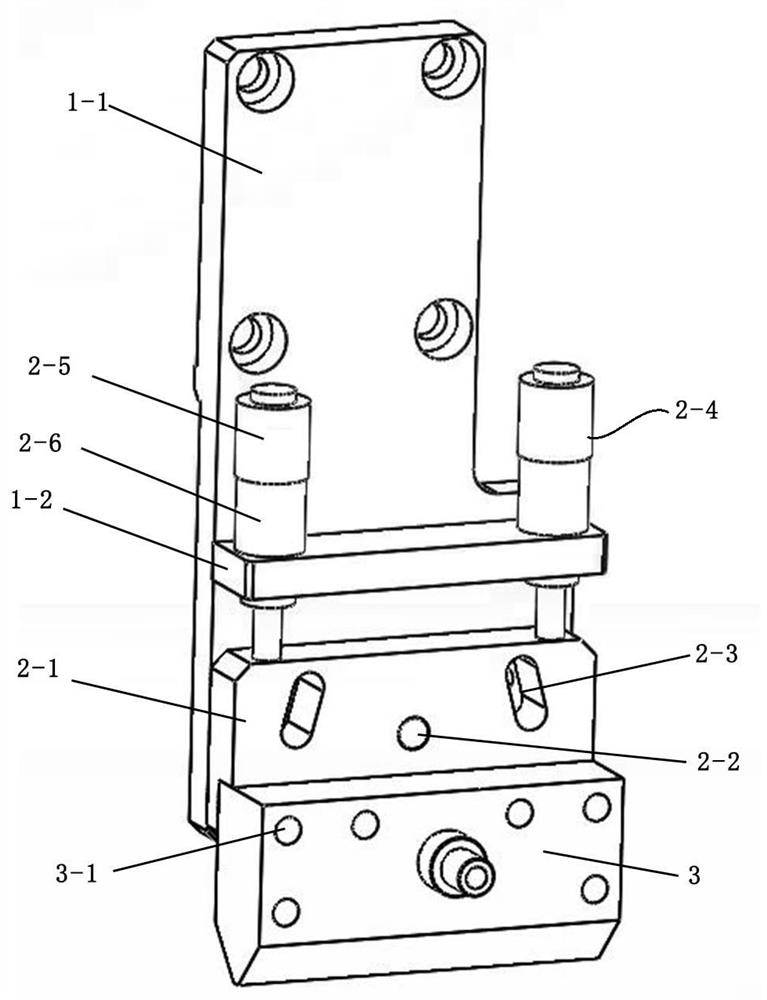

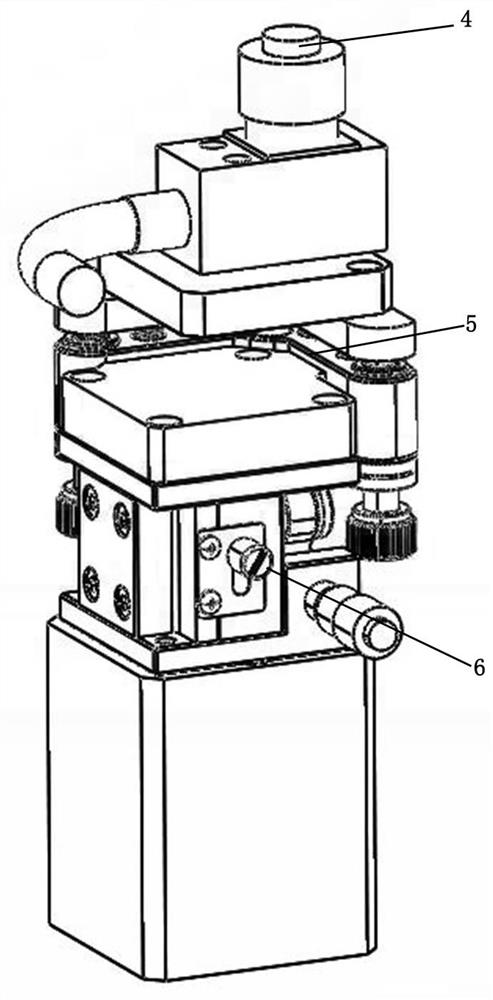

Blade coating alignment calibration device and method

PendingCN114501863ARealize regulationImprove stabilityMultilayer circuit manufactureEngineeringStructural engineering

A blade coating alignment calibration device comprises a supporting seat and an adjusting assembly arranged on the supporting seat, and a scraper is connected to the bottom of the adjusting assembly. The adjusting assembly comprises a coarse adjusting mechanism and a fine adjusting mechanism, and the scraper is fixedly connected to the bottom of the coarse adjusting mechanism; the supporting seat comprises a vertically-arranged lifting plate and a horizontally-arranged supporting plate, the coarse adjusting mechanism is rotationally connected to the lifting plate, and the fine adjusting mechanisms are connected to the supporting plate in a lifting mode and connected to the two ends of the coarse adjusting mechanism; compared with the prior art, the position of the scraper is adjusted through the coarse adjusting mechanism and the fine adjusting mechanism, so that large-range adjustment and small-range adjustment of the scraper can be achieved, the scraper can be fixed through the long-strip-shaped hole after adjustment, the whole scraper has better stability after adjustment is completed, the angle of the two ends of the scraper is measured, and the accuracy of measurement is improved. And the angle of the scraper is consistent with the angle of the processing surface, so that the subsequent blade coating effect is better.

Owner:ENOVATE3D (HANGZHOU) TECH DEV CO LTD

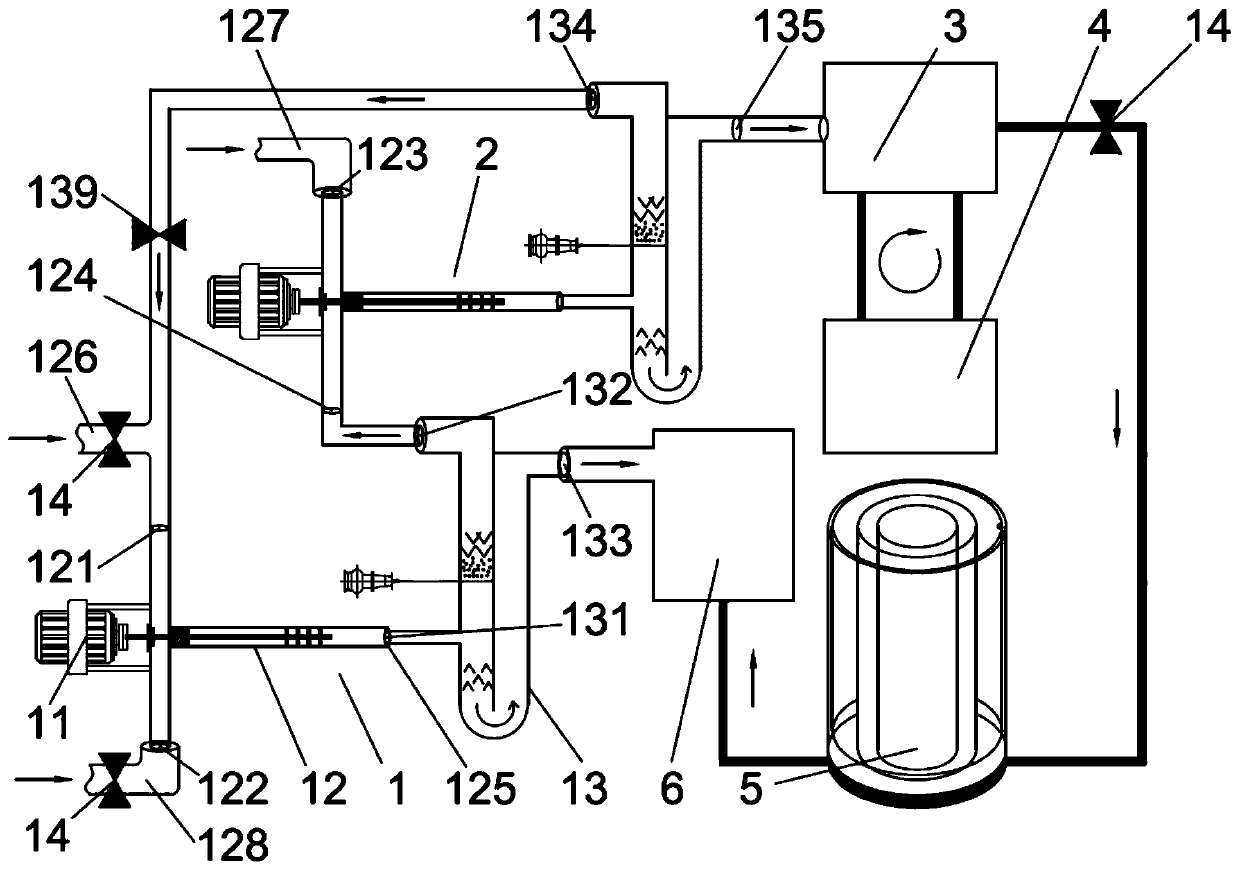

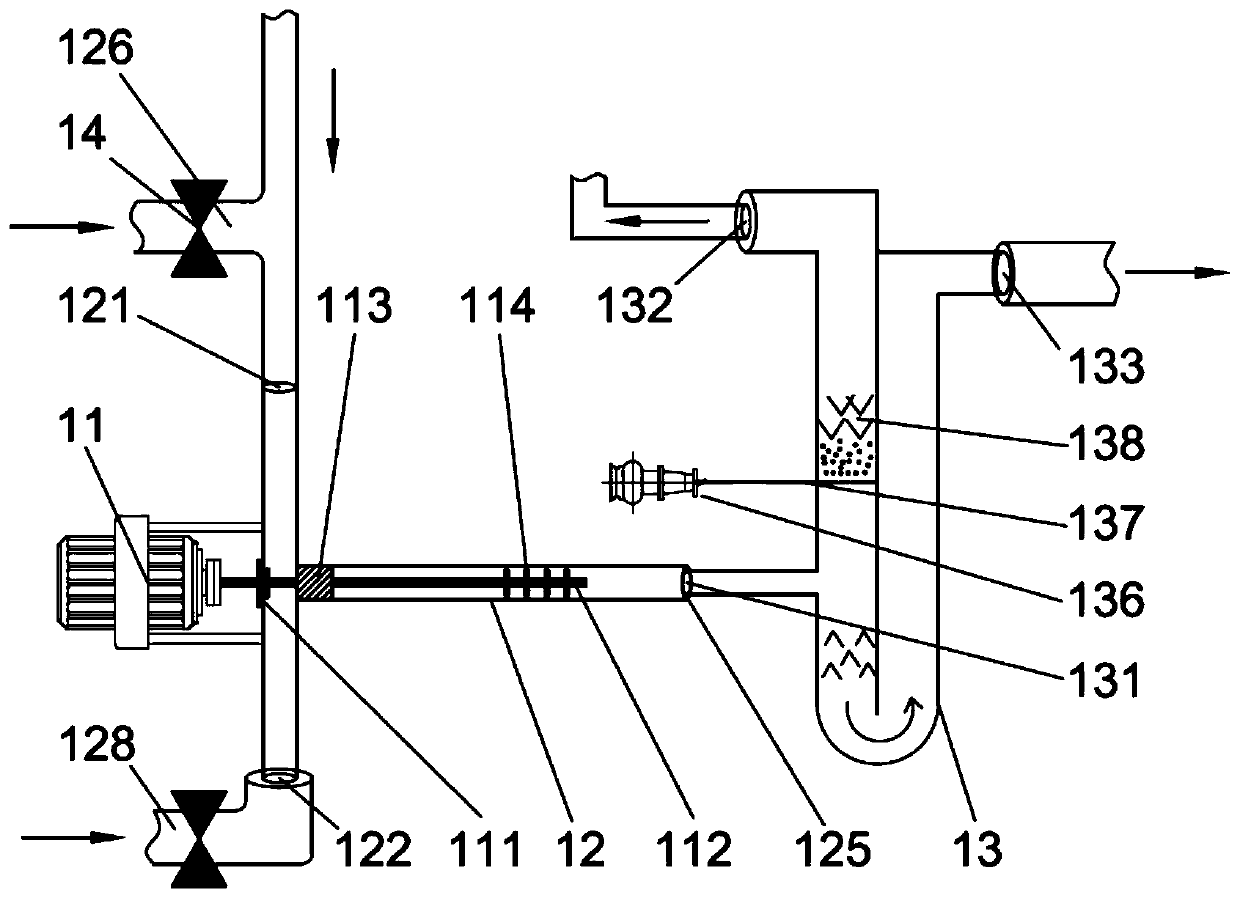

Recovery system for heavy metal in surface treatment wastewater

InactiveCN111573956AIncrease flow rateGuaranteed fluencyFatty/oily/floating substances removal devicesWater contaminantsIndustrial waste waterElectrolysis

The invention provides a recovery system for heavy metal in surface treatment wastewater. The recovery system comprises an extraction system (1), a back extraction system (2), membrane separation equipment (3), an electrodialyzer (4) and an electrolysis recovery device (5), wherein each of the extraction system (1) and the back extraction system (2) comprises a motor (11), a three-way mixer (12) and a communicated oil-water separator (13); and the electrolysis recovery device (5) comprises a bottom plate (51), an anode plate (521), a permeable membrane assembly (522), a cathode plate (523) anda recovery device shell (524). According to the recovery system, high-concentration heavy metal can be repeatedly recycled, so the heavy metal can be completely recycled, and recycling efficiency ishigh; meanwhile, the system can recycle an extraction agent, does not cause resource waste, effectively solves the problem of environmental pollution caused by too high heavy metal content in industrial wastewater, is simple and convenient to operate and wide in application range, and can be used for treating most industrial wastewater.

Owner:CHONGQING UNIV OF ARTS & SCI +1

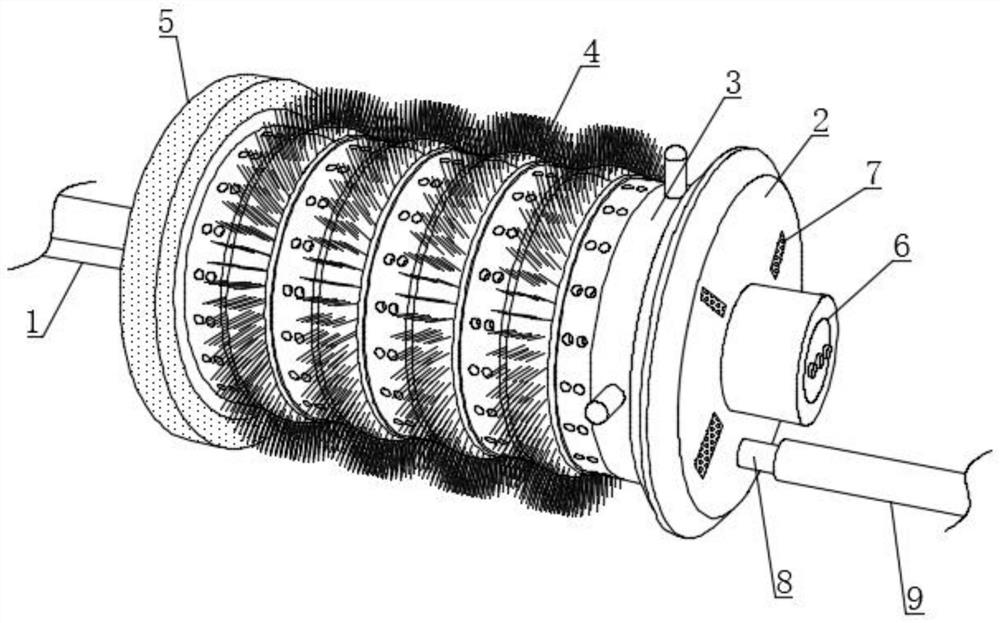

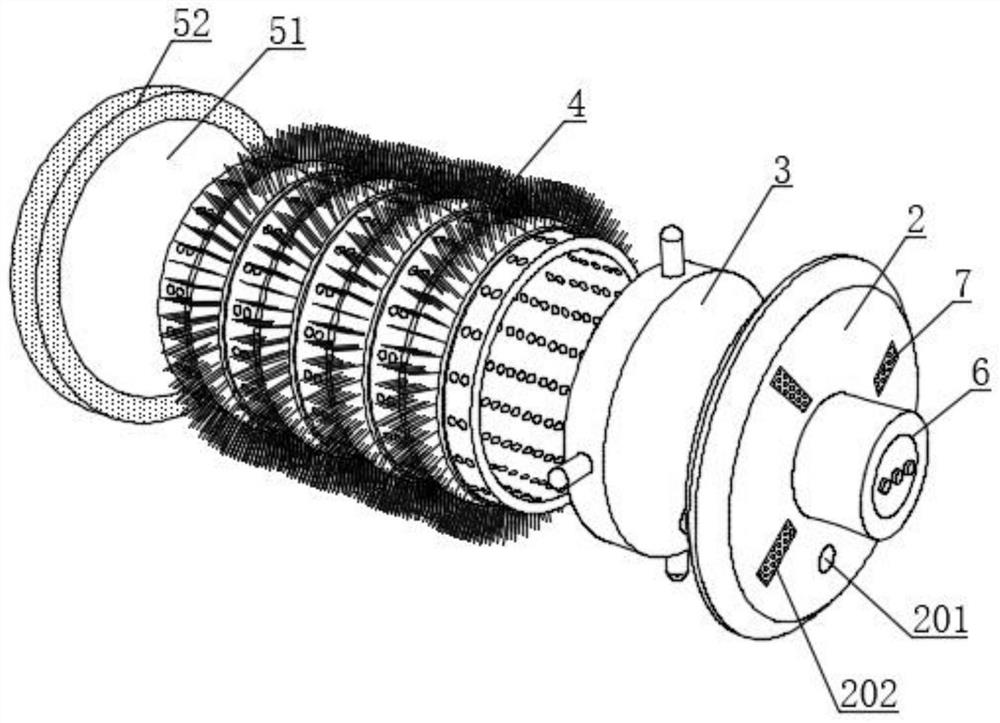

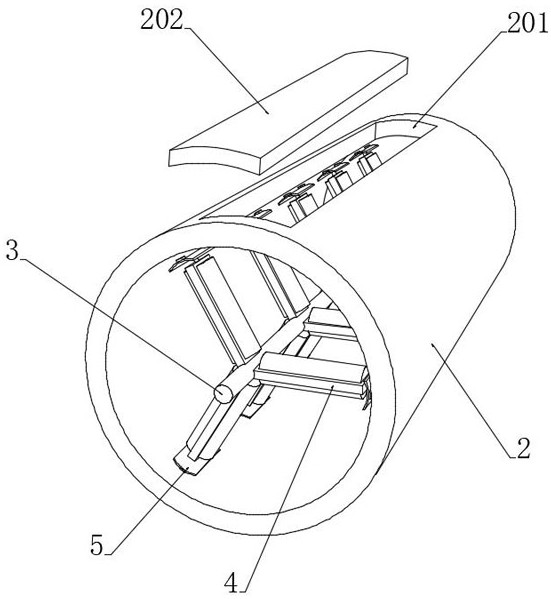

Universal inner wall corrosion prevention and film forming device for bent and straight pipes

PendingCN111804523AEliminate air gapsQuality improvementPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a universal inner wall corrosion prevention and film forming device for bent and straight pipes, and belongs to the field of pipe inner wall corrosion prevention. The universalinner wall corrosion prevention and film forming device for the bent and straight pipes comprises a scraping plate and a sealing plate, wherein the end, close to the sealing plate, of the scraping plate is fixedly connected with a positioning plate, and an inner adaptive applying pipe is fixedly connected between the sealing plate and the positioning plate. According to the universal inner wall corrosion prevention and film forming device for the bent and straight pipes, the space between the sealing plate and the positioning plate is fully filled with a corrosion inhibitor, the corrosion inhibitor makes full contact with the inner wall of a pipe in the area, meanwhile, a plurality of soft brushes are used for brushing the inner wall of the pipe, so that the air gap between the corrosioninhibitor and the inner wall part of the pipe is effectively eliminated, and a uniform and complete anti-corrosion film is formed on the inner wall of the pipe; and the device has the characteristicsof high quality and high benefit in film formation, can be simultaneously suitable for the straight pipes and the irregular bent pipes through the internal adaptive applying pipe consisting of a rubber hose, elastic belts and the soft brushes, can carry out coating film formation process with the same effect on the straight and bent pipes, and has the characteristic of ultrahigh practicability.

Owner:南通宝得利机械制造有限公司

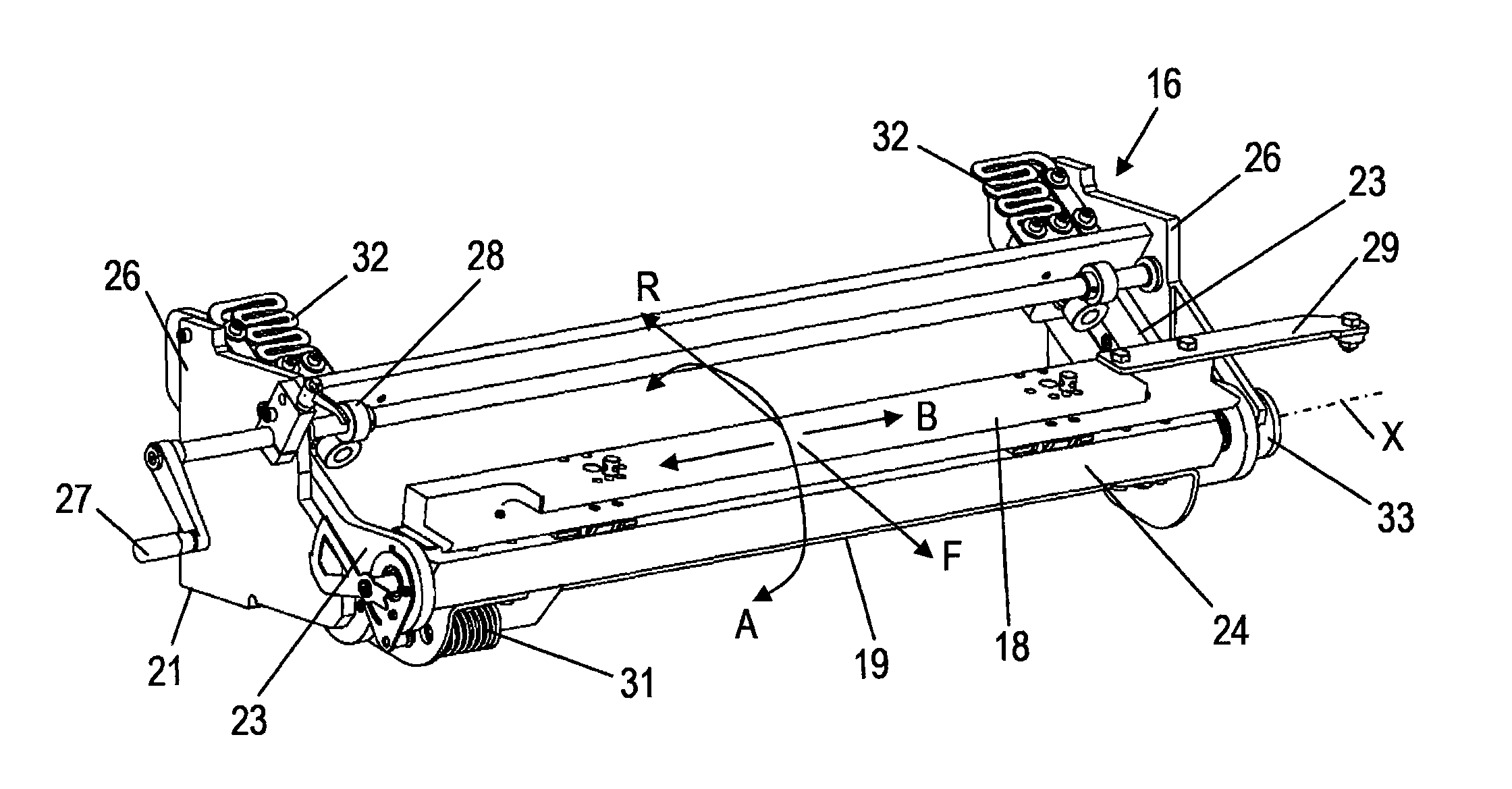

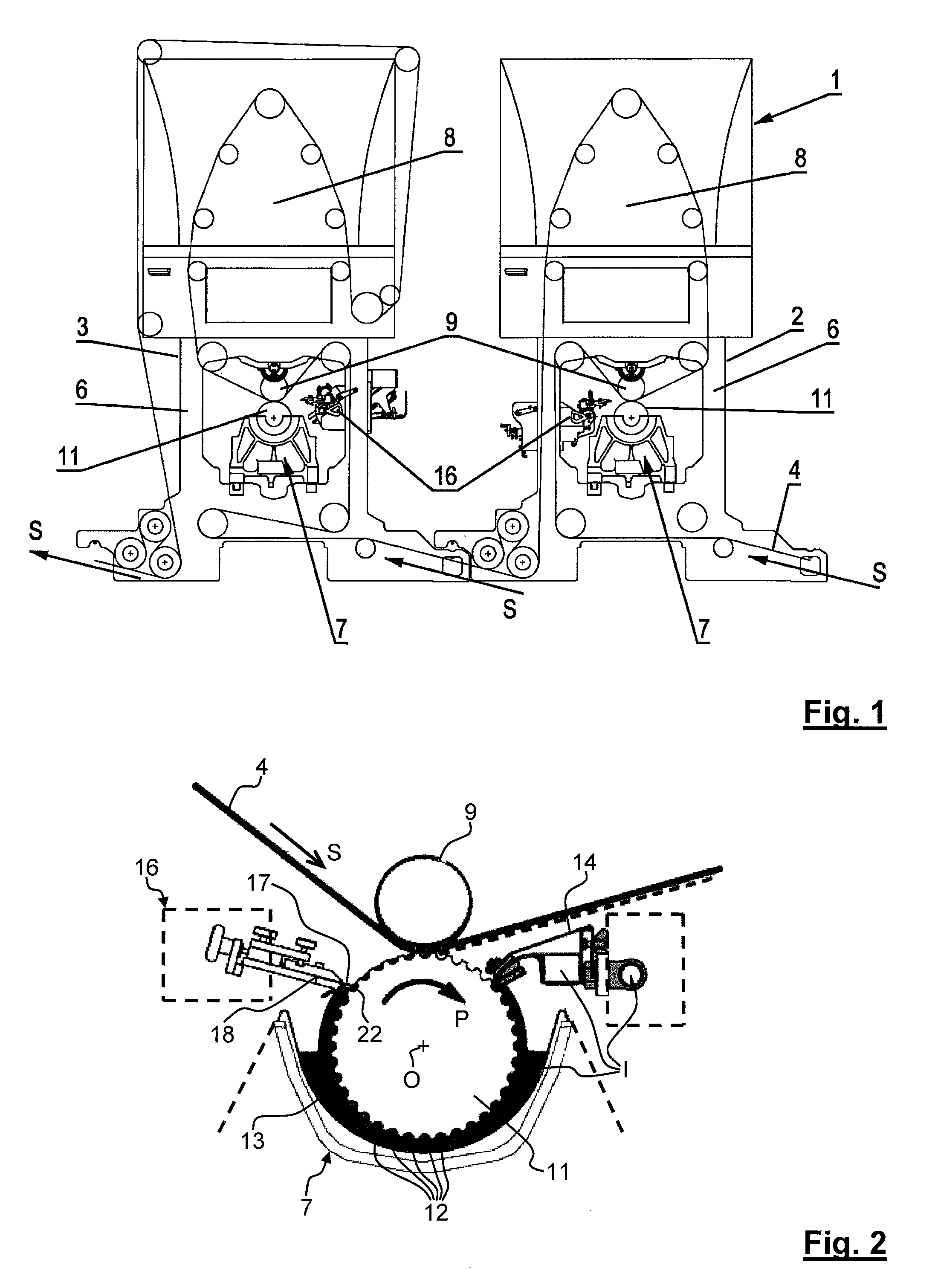

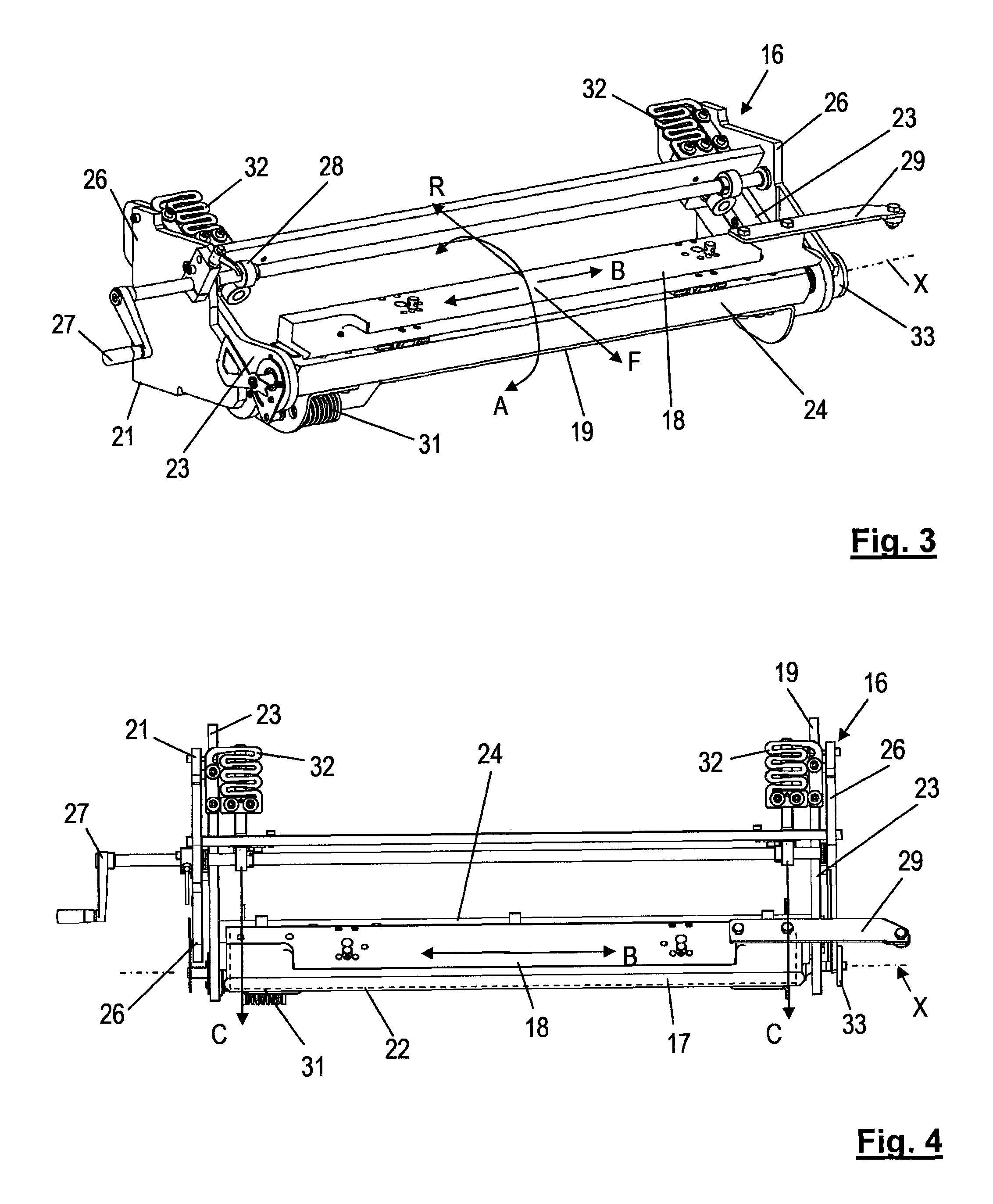

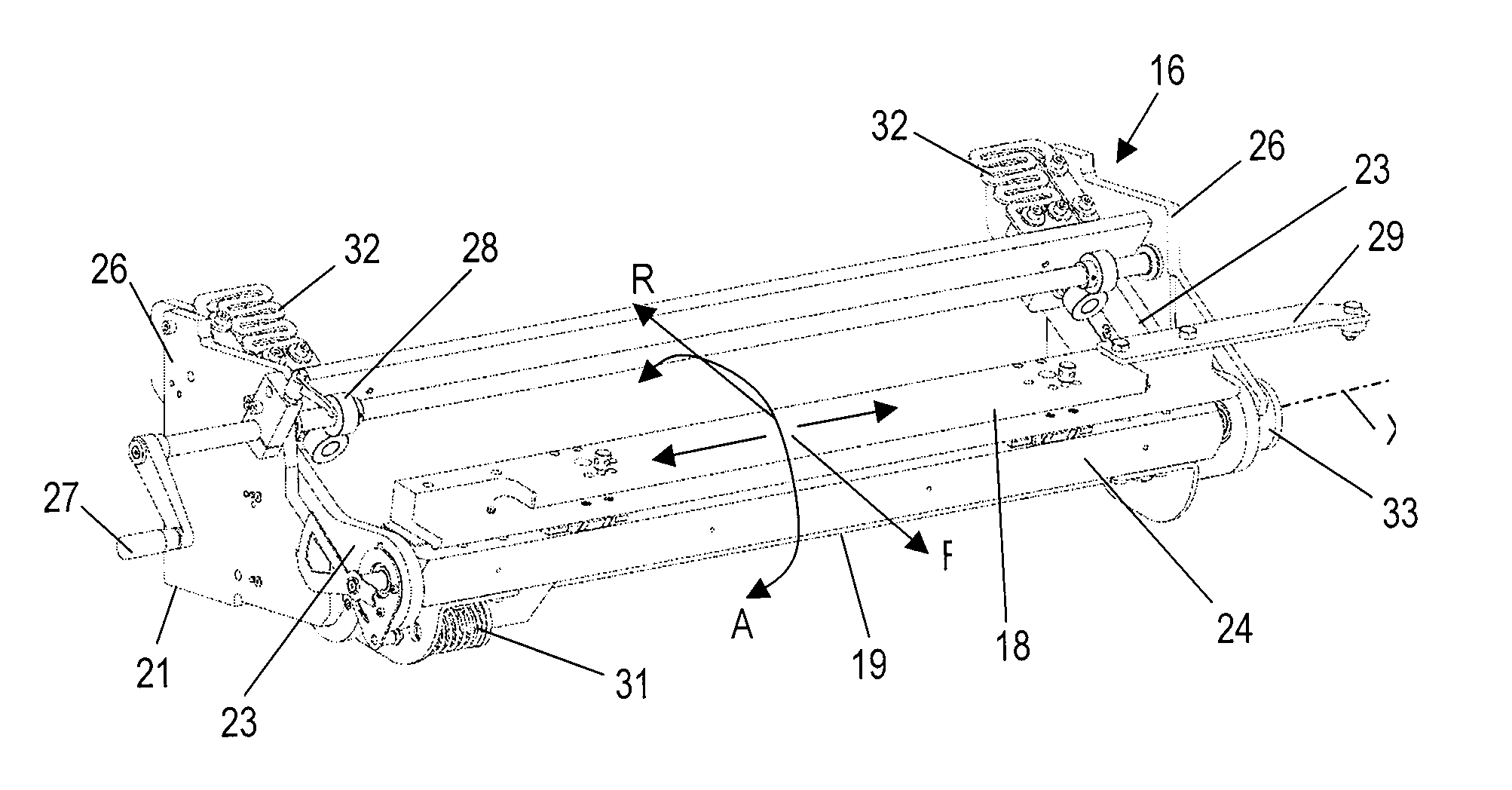

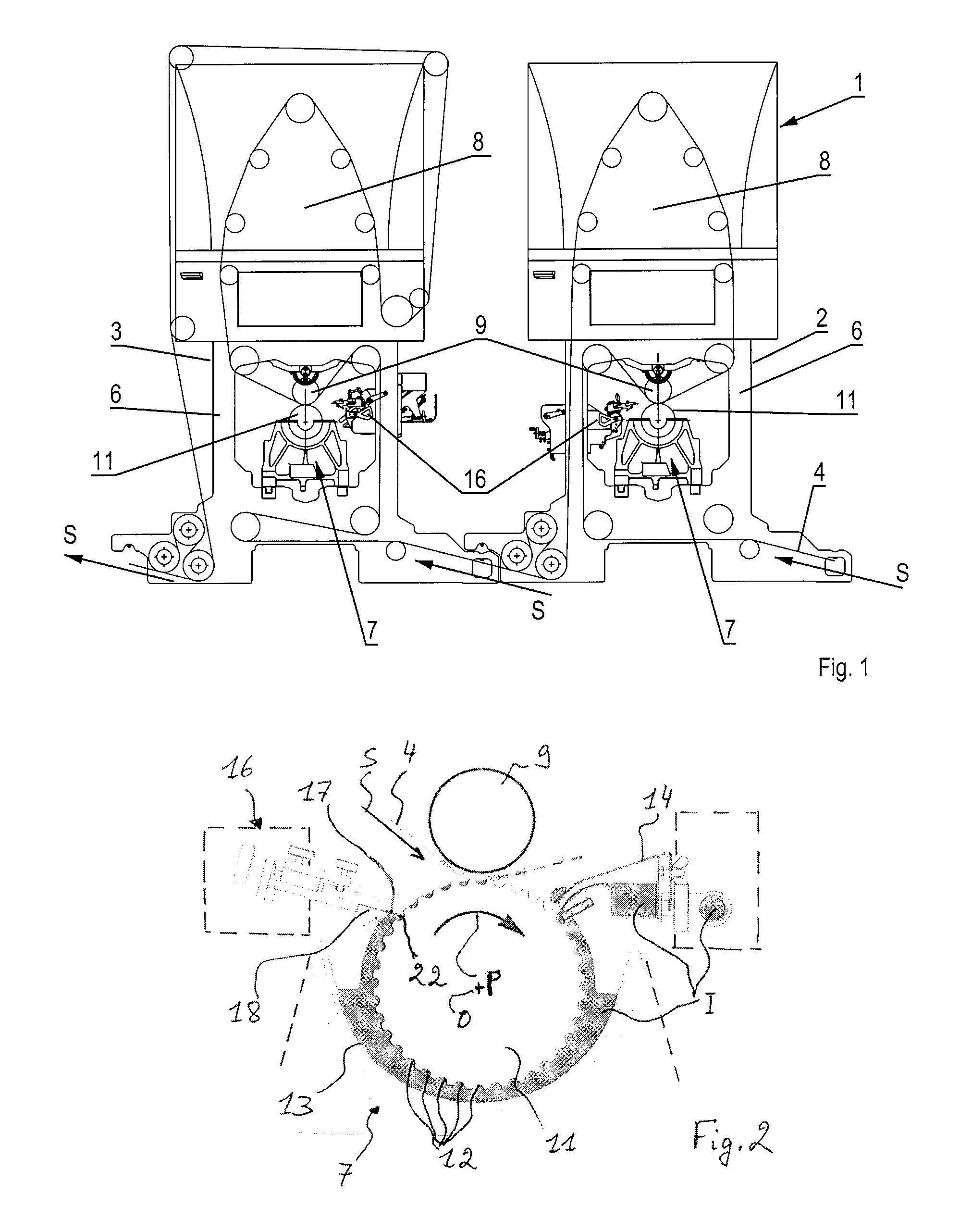

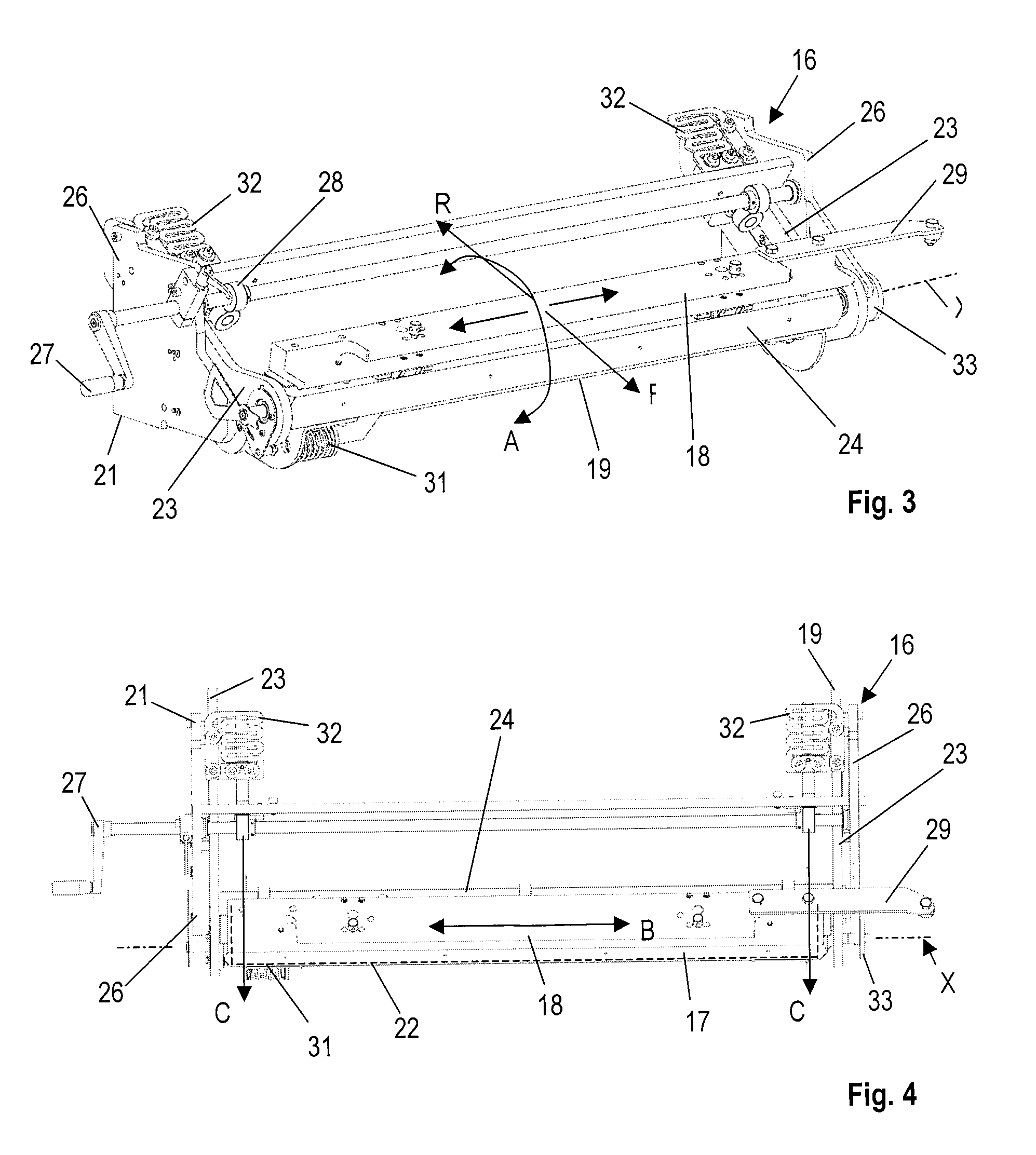

Doctor blade system for print unit intended for a photogravure printing machine

ActiveUS8915184B2Simple and inexpensive to produceImprove effectivenessRotary intaglio printing pressOffice printingReciprocating motionPhotogravure

A doctor blade system intended for a print unit includes a doctor blade support provided with a blade, an edge of the blade is able to come into contact with a peripheral surface of an engraved printing cylinder, a supporting hub, on which the doctor blade support is mounted, a structure fixing the supporting hub to a frame of the print unit. Apparatus provides a reciprocating motion of the blade along the peripheral surface of the engraved cylinder roughly parallel to the axis of revolution of the engraved cylinder. Thrust elements drive movement of the blade along the direction of the peripheral surface of the engraved cylinder. The reciprocating apparatus directly drives the doctor blade support. The thrust element or elements move the supporting hub and the doctor blade support and the blade to maintain a constant contact over the entire length of the edge of the blade with the peripheral surface of the engraved cylinder.

Owner:BOBST MEX SA

Multi-stage crushing barrel for processing veterinary medicines

InactiveCN111729726AAvoid wastingReduce manufacturing costHollow article cleaningGrain treatmentsMechanical engineeringVeterinary Drugs

The invention discloses a multi-stage crushing barrel for processing veterinary medicines. According to the multi-stage crushing barrel, an arc-shaped scraper is arranged, so that the veterinary medicines are easily accumulated on the inner wall of a crushing barrel main body when the crushing barrel main body crushes the veterinary medicines, the scraping of veterinary medicines blocks is facilitated, unnecessary waste of the veterinary medicines is avoided, and the production cost of the veterinary medicines is reduced; a cleaning brush is arranged, the situation that the inner wall of the crushing barrel main body is corroded by veterinary medicine residues on the inner wall of the crushing barrel main body is effectively avoided, and a certain protection effect is achieved on the crushing barrel main body, so that the service life of the crushing barrel is prolonged; and a T-shaped sliding block is arranged, the installation and disassembly processes of an installation plate and astirring shaft are effectively avoided, the labor cost is reduced, and thus the installation and disassembly efficiency of the crushing barrel is greatly improved.

Owner:刘秋英

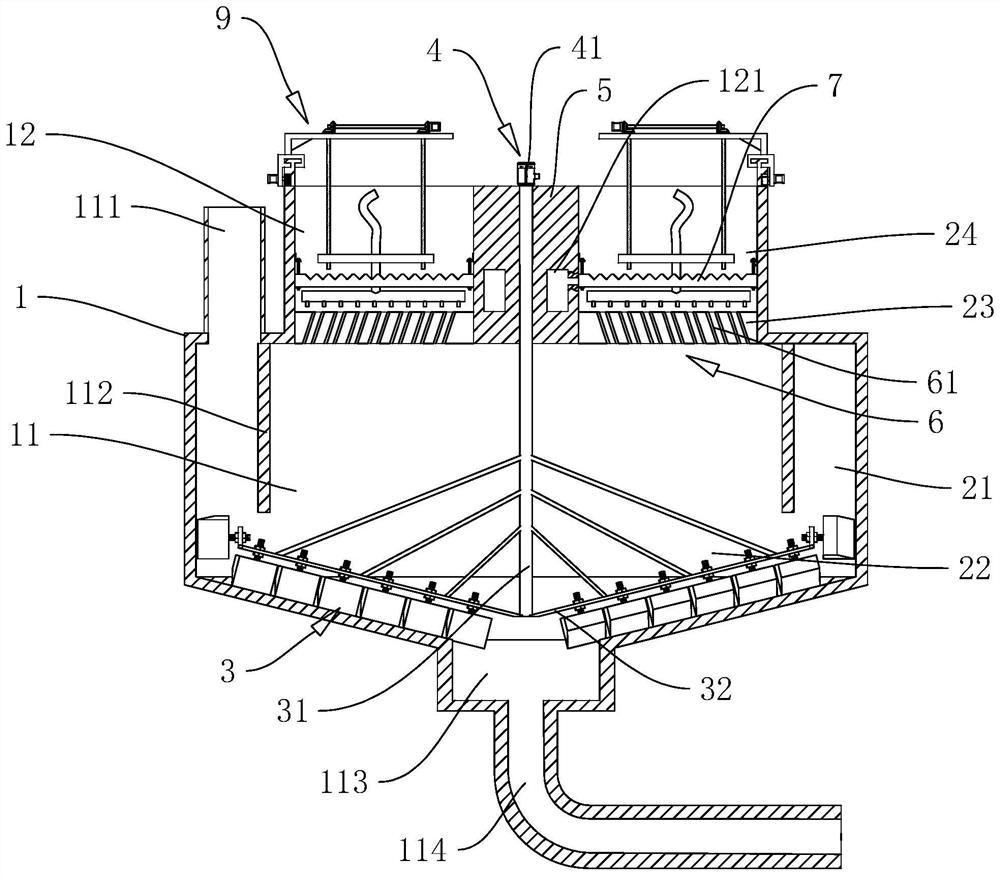

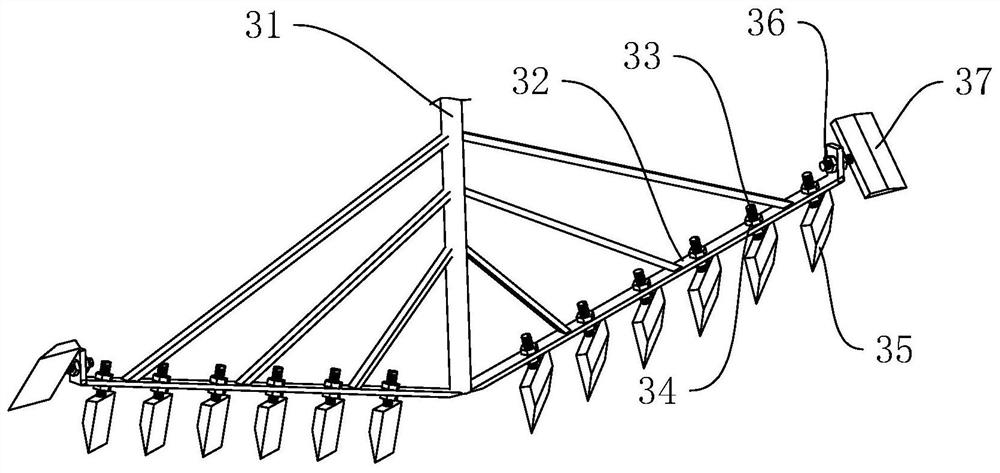

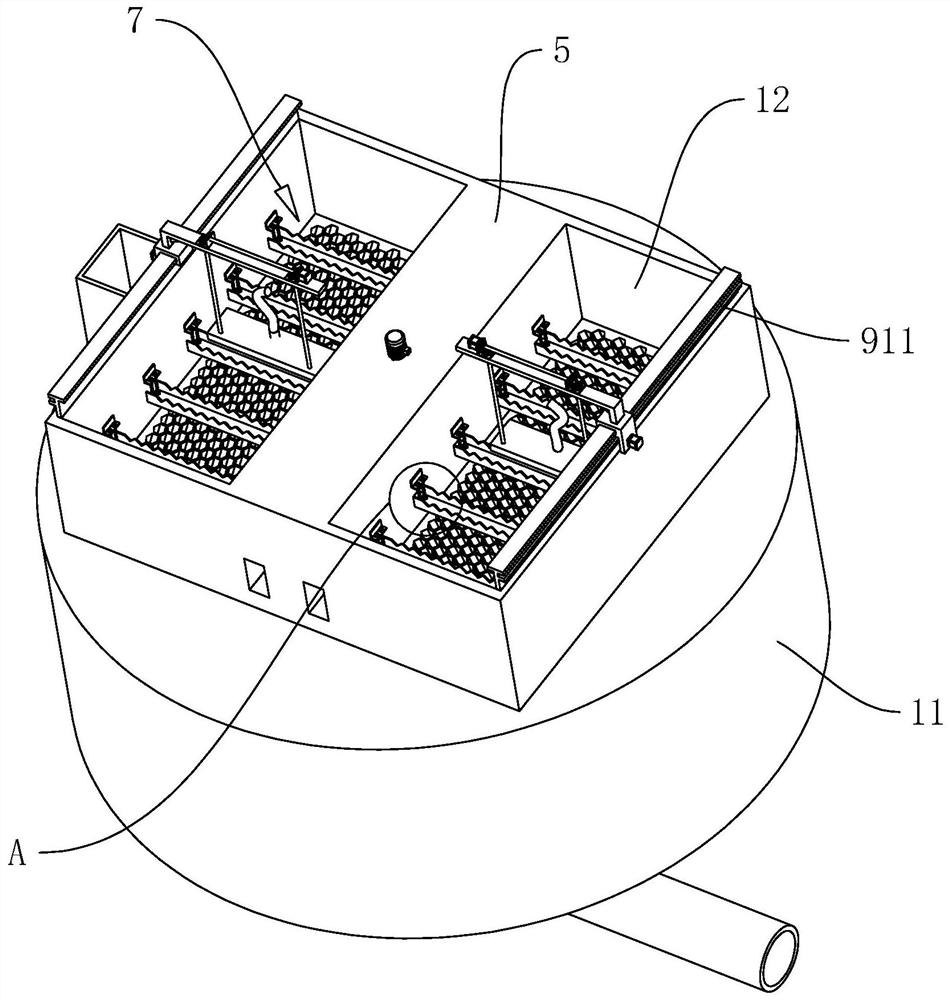

A high-efficiency sedimentation tank that is easy to clean

ActiveCN112245979BImprove sedimentation efficiencyImprove precipitation effectHollow article cleaningSedimentation settling tanksSludgeWater flow

The application relates to a high-efficiency sedimentation tank that is easy to clean. It includes a tank body. The tank body includes a circular pool at the bottom of the pool and two rectangular pools above the circular pool. area, sludge area, sedimentation area and water outlet area, the side wall of the pool body is provided with a water inlet located in the water inlet area, the bottom of the circular pool is equipped with a mud cleaning component located in the sludge area, and the rectangular pool is provided with a The settling component of the tank body is equipped with a fixed platform at the center of the top of the tank body. The driving component for driving the mud cleaning component is arranged on the fixed platform. The side wall of the fixed platform is provided with a water outlet located in the water outlet area. Between the side walls of the rectangular pool A deflector is installed, and the water outlet of the deflector faces the water outlet, and a cleaning device for cleaning the sedimentation component is also arranged on the side of the top surface of the rectangular pool. The application helps to improve the problems of low efficiency of manual cleaning of inclined pipes or inclined plates and poor effect of cleaning sludge at the bottom of the pool.

Owner:深圳市南方水务有限公司

Aeroengine turbine guide vane polishing protection wax and polishing method

ActiveCN102453442BImprove plasticityImprove adhesionGrinding machinesPolishing compositionsEngineeringTurbine

The invention discloses aeroengine turbine guide vane polishing protection wax and a polishing method. The aeroengine turbine guide vane polishing protection wax is prepared from petroleum wax, abietic resin, hydrocarbon cream, a butylene polymer and the like by mixing processing according to a specific ratio. The aeroengine turbine guide vane polishing protection wax has good plasticity, good adhesiveness, appropriate physical and chemical performances and excellent use performances, is convenient for knife coating, can be removed easily, does not produce corrosion, toxins and pollution, and is environmentally friendly. The polishing method adopting the aeroengine turbine guide vane polishing protection wax comprises the following steps of protecting an air-guiding hole of a turbine guide vane by the aeroengine turbine guide vane polishing protection wax, carrying out polishing processing, and then removing the aeroengine turbine guide vane polishing protection wax. The polishing method can effectively prevent that metal chips block the air-guiding hole in turbine guide vane polishing.

Owner:CHINA PETROLEUM & CHEM CORP +1

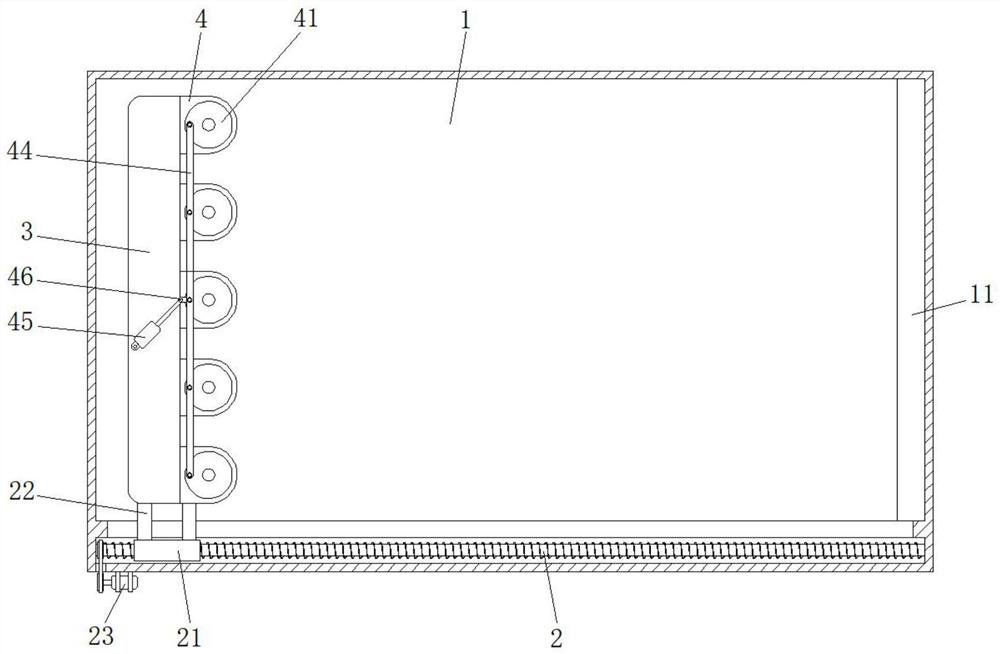

Putty powder scraping and coating device

PendingCN112502399AImprove work efficiencyGood for scrapingBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a putty powder scraping and coating device. Mounting plates are symmetrically and rotatably connected to both sides of two transverse plates through rotating shafts, suction disc holes are formed in the surfaces of the mounting plates at equal intervals, a movable plate is arranged between the two transverse plates, a scraper is arranged on the surface of the movable plate,and X-axis translation mechanisms which can drive the movable plate to move along an X axis are arranged in the transverse plates. According to the putty powder scraping and coating device, under thematching action of the X-axis translation mechanisms and a Y-axis translation mechanism, the scraper moves to scrape and coat in the X-axis direction and the Y-axis direction when scraping putty, andunder the action of a steering mechanism, the scraper can change the direction actively and form an optimal scraping and coating angle. Compared with an existing roof putty scraping mode, the putty powder scraping and coating device has the advantages that workers can scrape and coat putty on a roof more conveniently, manual climbing for scraping and coating is not needed, the scraping and coating direction is linear, the track changing phenomenon cannot occur, and the working efficiency is improved.

Owner:叶洋

PLC intelligent full-automatic control steel drum screen printing machine

ActiveCN112644155AGood for scrapingImprove printing qualityScreen printersScreen printingMechanical engineering

The invention discloses a PLC intelligent full-automatic control steel drum screen printing machine, and particularly relates to the technical field of steel drum screen printing machines. The PLC intelligent full-automatic control steel drum screen printing machine comprises a bottom frame. Through the arrangement of an ink assembly, a driving gear and a sector gear can be in engaged transmission, so that different inner and outer contact positions of a scraper and a reference roller are controlled, the scraper conveniently scrapes ink to the outer surface of a packaging product from outside to inside, an ink coating is formed on the outer surface of the packaging product, the situations of fuzzy printing, adhesion and the like of printed matter are prevented, so that the printing quality is greatly improved; and through the arrangement of a gold stamping assembly, a pressing plate rotates downwards to pick up gold stamping paper on the upper surface of a placing plate, then the pressing plate rotates upwards to conduct hot pressing on the gold stamping paper to the outer wall of the left end of the reference roller, the gold stamping paper generates strong affinity on the outer surface of the packaging product with the formed ink coating, a metal layer is formed, and screen printing of large and medium-sized metal packaging products and glass packaging products is completed, so that a steel drum screen printing machine is low in energy consumption, high in practicability and high in processing and printing efficiency.

Owner:GUANGDONG POLYTECHNIC COLLEGE

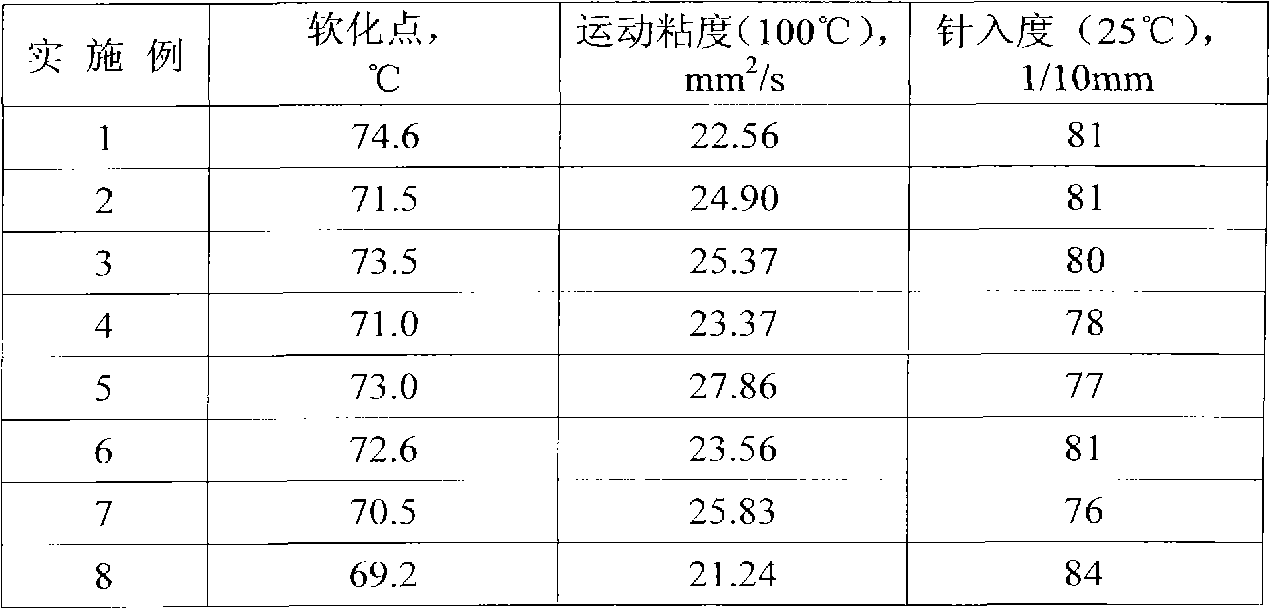

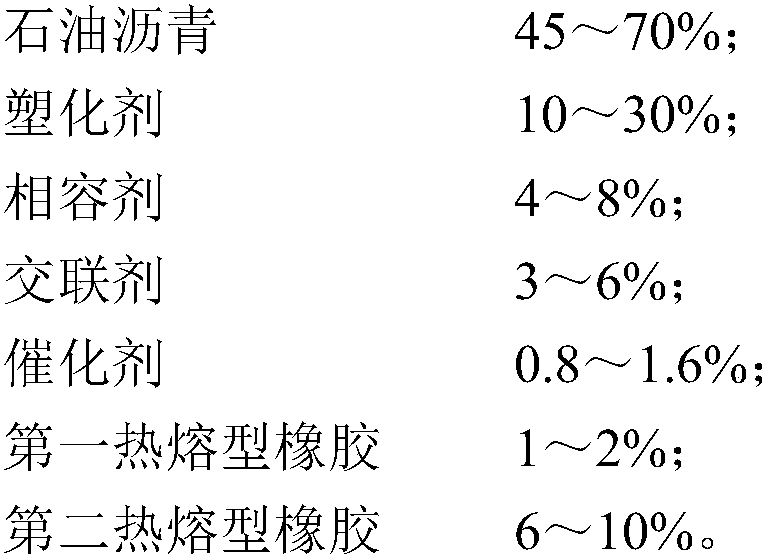

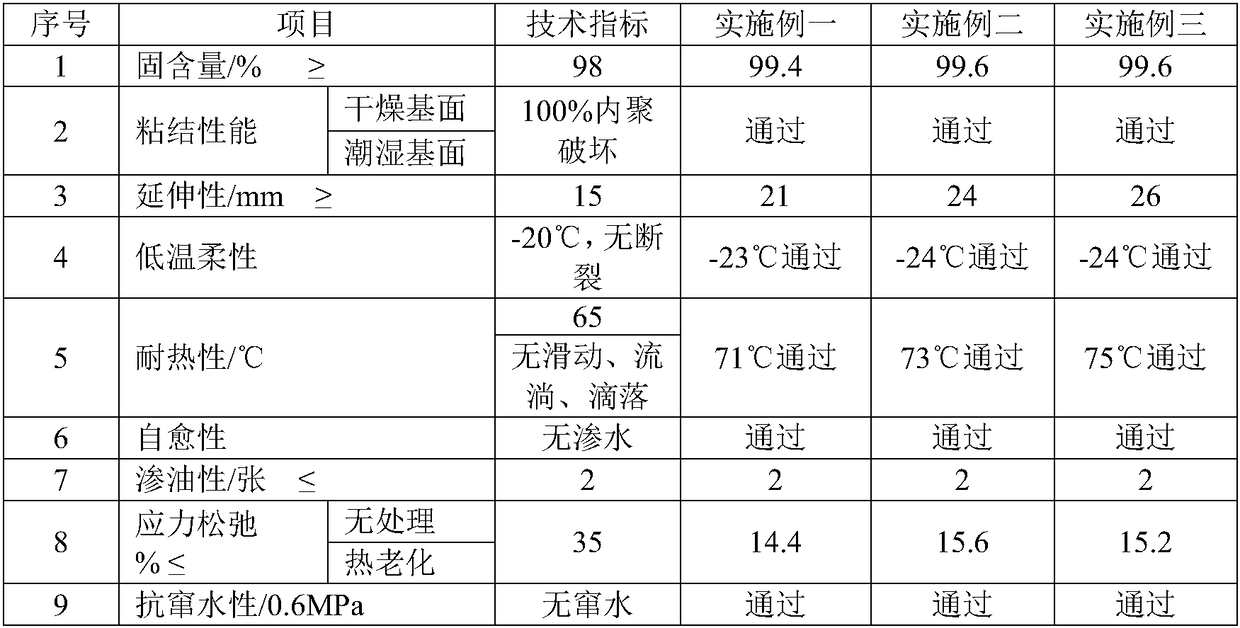

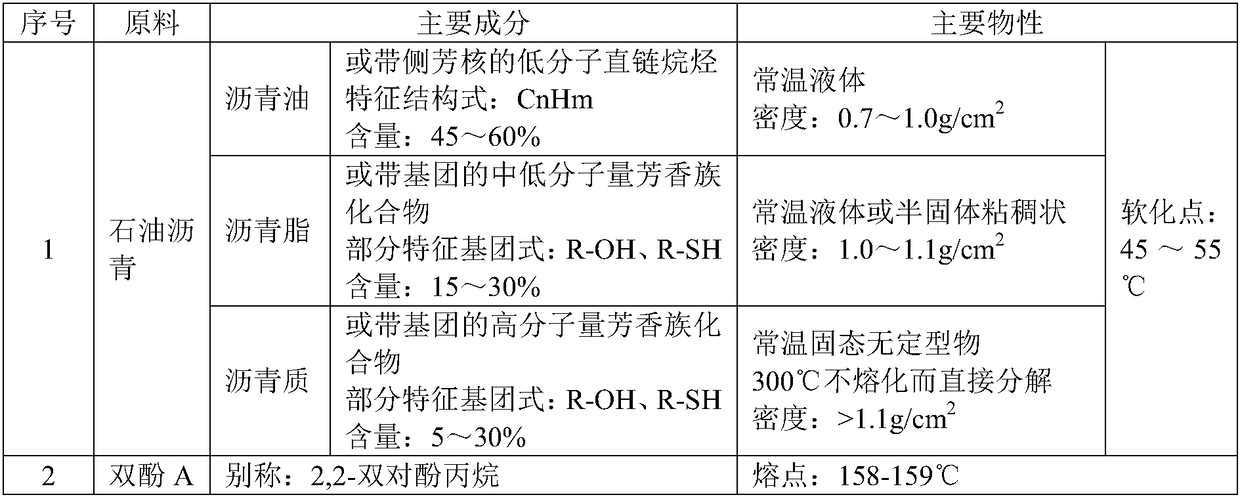

A kind of non-curing rubber asphalt waterproof coating and preparation method thereof

ActiveCN106366923BReduce cohesionLow shear strengthWax coatingsConjugated diene hydrocarbon coatingsPolymer scienceBituminous waterproofing

The invention discloses a non-cured rubber asphalt waterproof coating which is prepared from the following components in percentage by weight: 45 to 70 percent of petroleum asphalt, 10 to 30 percent of a plasticizer, 4 to 8 percent of a compatilizer, 3 to 6 percent of a crosslinking agent, 0.8 to 1.6 percent of a catalyst, 1 to 2 percent of first hot melt type rubber and 6 to 10 percent of second hot melt type rubber. The invention further discloses a preparation method of the non-cured rubber asphalt waterproof coating. By crosslinking modification of the petroleum asphalt by the crosslinking agent and the catalyst, the melting point of the petroleum asphalt is increased, so that adding of SBS (Styrene / Butadiene / Styrene) is reduced, and the effect of improving the high temperature performance of the coating without adding the SBS is achieved; therefore, after being cooled, the coating is sticky and non-cured paste, and is high in creep property and high in self-repairability.

Owner:苏州市姑苏新型建材有限公司

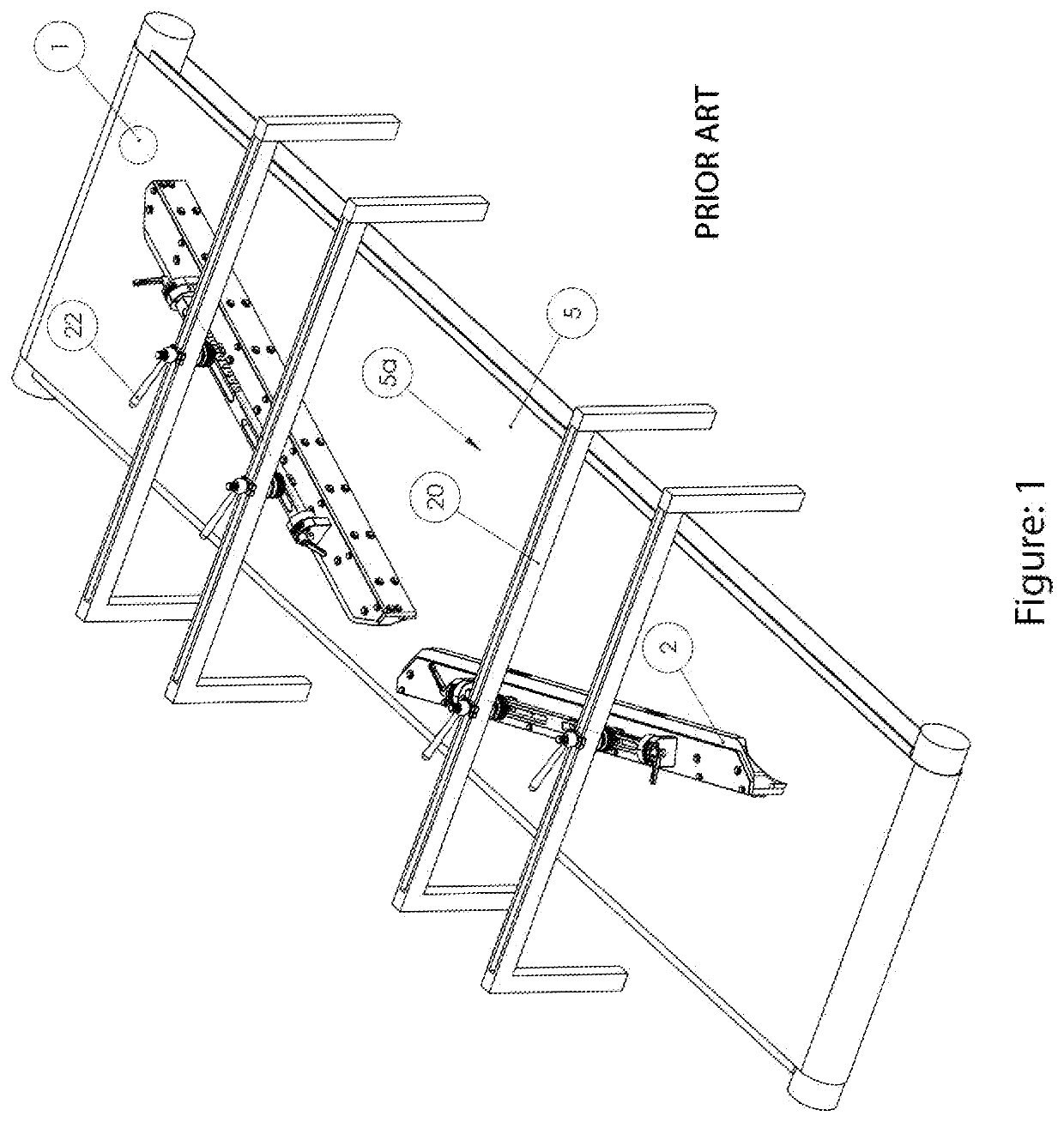

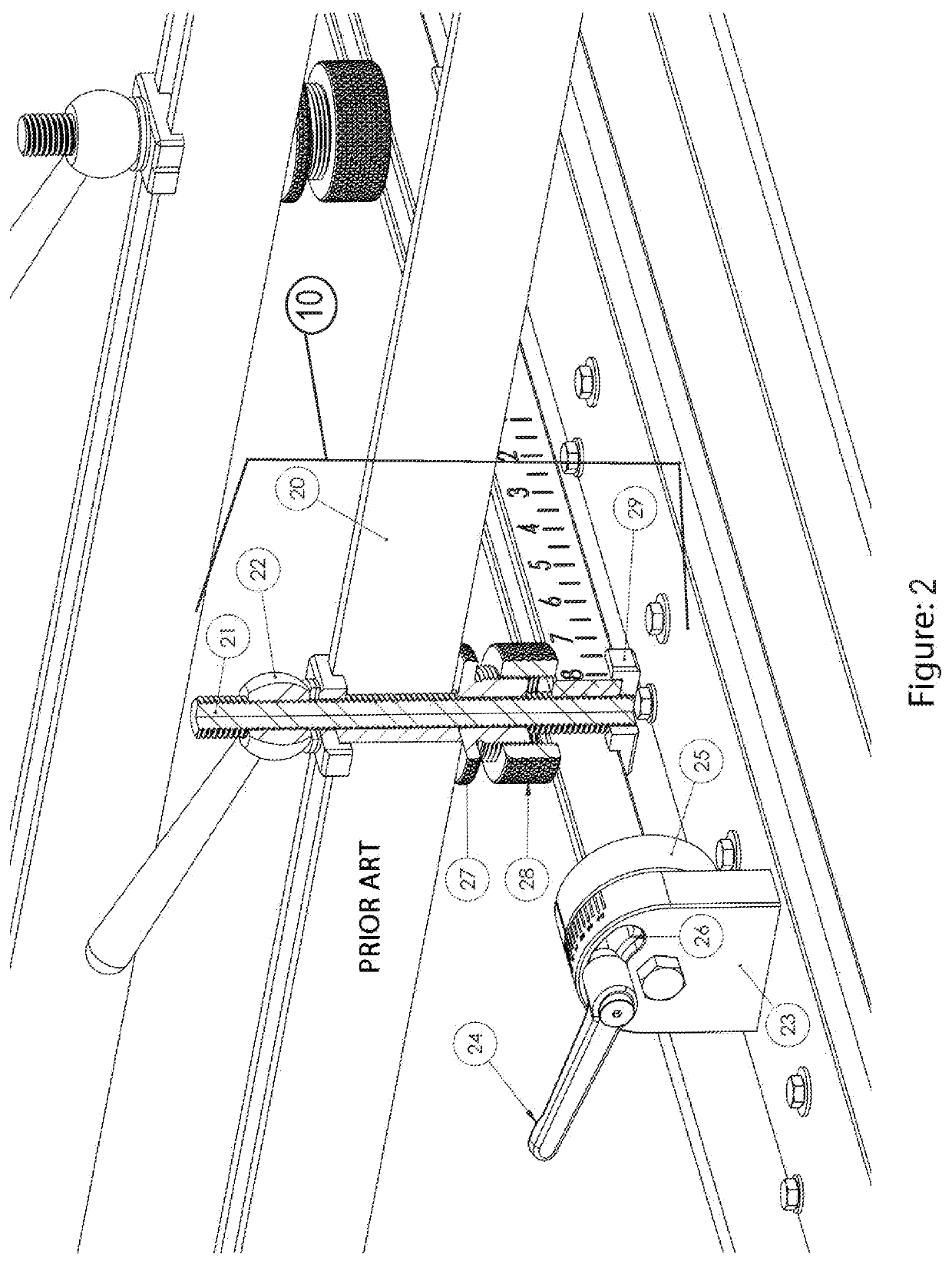

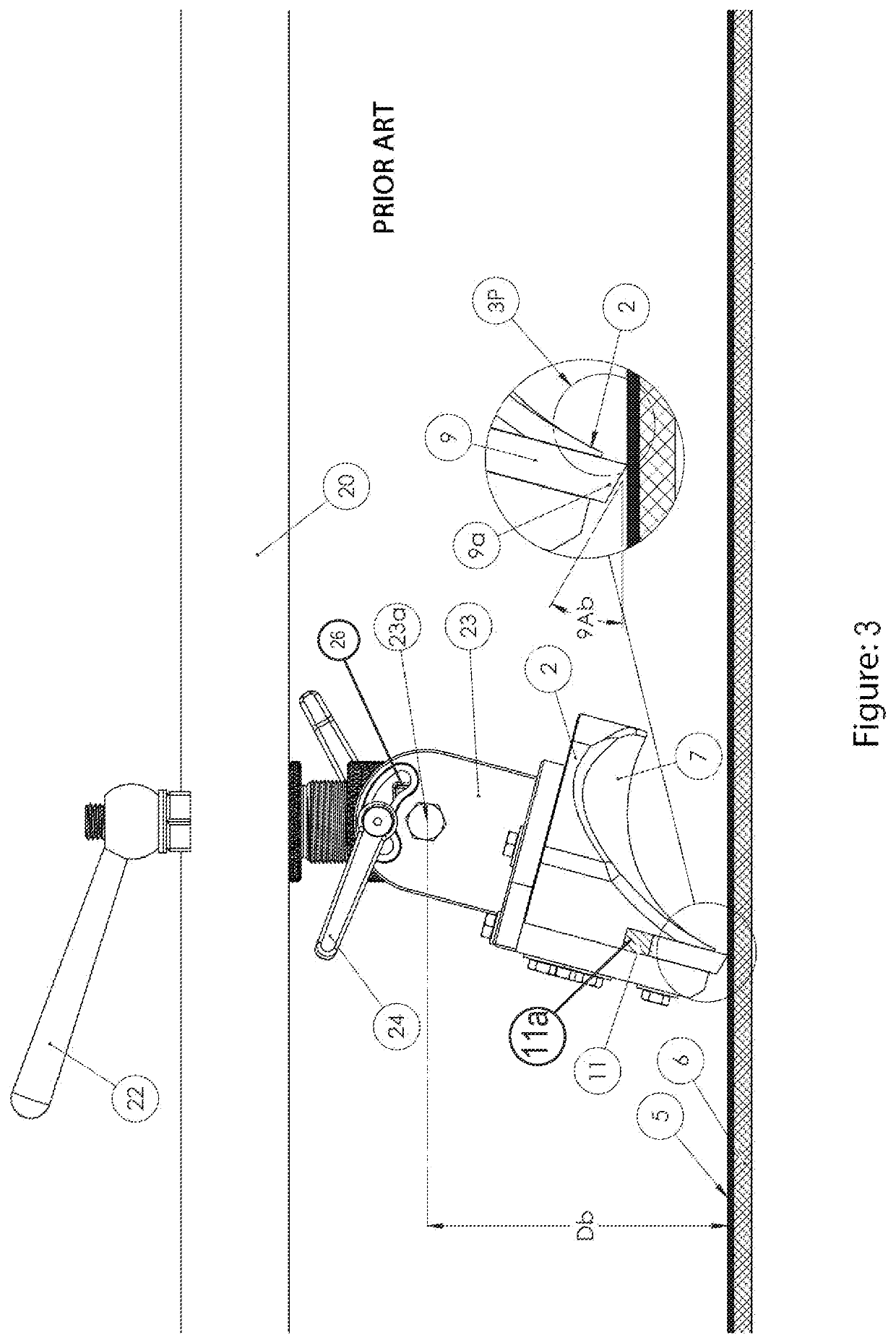

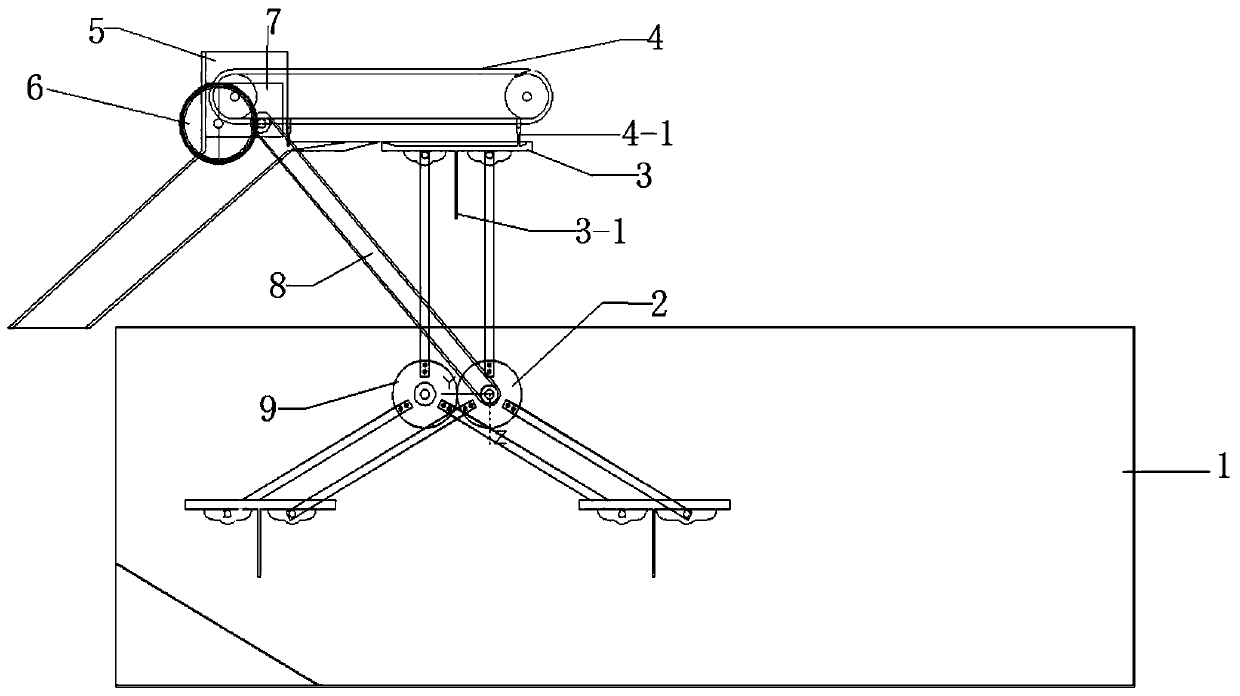

Self-adjusting, rotatable stabilized semi-viscous material rounder bar seal with automatic height adjustment

PendingUS20220007657A1Promote resultsConstant pressureDough homogenization with moulding channelsCamber angleBraced frame

The invention is directed to a rounder or rounding machine having one or more conveyor(s) having a horizontal conveyor surface with a support frame. A rounder bar height adjustment system is provided. Included in the height adjustment system is a bar camber adjustment system. One or more rounder bars are coupled to the support frame by one or more rounder bar height adjustment systems above the conveyor at a set height and at a camber angle set by the at least one camber adjustment system. A rounder bar seal on the rounder bar is provided having a rounder bar seal channel and a rounder bar seal channel contour. The rounder bar seal having a first body member having one or more first semi-spherical contours and a second body extending down at an angle from the first body member, and third body member extending from the first body member and extending in an opposed direction from the second body member. The rounder bar seal channel contour then mates with, at least in part, the first body member through the first semi-spherical contour, with the first body portion being coupled and retained within the channel and rotating freely therein. The second and third body members extending from the first body member and contacting the horizontal conveyor surface of the conveyor belt and self aligning the seal bar with the horizontal conveyor surface such that the rounder bar seal effectively forms a seal.

Owner:SCHMIDT NORMAN

Paint slag fishing device

PendingCN110314432AEasy to catchImprove processing efficiencyGravity filtersStationary filtering element filtersSlagLacquer

The invention discloses a paint slag fishing device. The device comprises a collecting device, a fishing device and a power transmission device used for providing power for the collecting device and the fishing device; the collecting device comprises a transmission belt, a scraping plate and a paint slag bucket, and is arranged on the upper portion of a waste liquid tank, the power transmission device is connected with the fishing device and arranged below the transmission belt and the paint slag bucket, and the fishing device includes liquid leakage hoppers; one end of the transmission belt is arranged in the paint slag bucket, the scraping plate is arranged on the outer surface of the transmission belt, the power transmission device is connected with the liquid leakage hoppers to drive the liquid leakage hoppers to rotate, the scraping plate scrapes paint slag in the liquid leakage hoppers into a feeding inlet of the paint slag hopper, grooves are formed in the liquid leakage hoppers, filtrate holes are formed in the groove surfaces and are variable diameter holes, and the diameters of the filtrate holes are gradually reduced in the direction from the groove surfaces of the bottom surfaces of the liquid leakage hoppers.

Owner:TIANJIN OUPAI INTEGRATION HOUSEHOLD CO LTD

Doctor blade system for print unit intended for a photogravure printing machine

ActiveUS20100116158A1Simple and inexpensive to produceImprove effectivenessRotary intaglio printing pressReciprocating motionPhotogravure

A doctor blade system intended for a print unit includes a doctor blade support provided with a blade, an edge of the blade is able to come into contact with a peripheral surface of an engraved printing cylinder, a supporting hub, on which the doctor blade support is mounted, a structure fixing the supporting hub to a frame of the print unit. Apparatus provides a reciprocating motion of the blade along the peripheral surface of the engraved cylinder roughly parallel to the axis of revolution of the engraved cylinder. Thrust elements drive movement of the blade along the direction of the peripheral surface of the engraved cylinder. The reciprocating apparatus directly drives the doctor blade support. The thrust element or elements move the supporting hub and the doctor blade support and the blade to maintain a constant contact over the entire length of the edge of the blade with the peripheral surface of the engraved cylinder.

Owner:BOBST MEX SA

A kind of asphalt regeneration equipment with good regeneration effect

The invention discloses asphalt regeneration equipment with good regeneration effect, which belongs to the technical field of asphalt regeneration. A plurality of sets of stirring paddles distributed on the driving shaft are arranged inside the mixing drum, and the outer ends of the stirring paddles are connected with magnetic stirring paddles, and are mounted on a support The left and right inner walls of the seat are equipped with magnetic drive paddles that are mutually repulsive with multiple magnetic agitation paddles. The rotating magnetic drive paddles form a magnetic field in a certain area. When multiple agitation paddles drive the magnetic agitation paddles to rotate to the magnetic drive paddle side , using the principle of repulsion of the same polarity of magnetic substances, the rotating magnetic drive paddle can make the magnetic agitation paddle rotate temporarily within this range, so that the stirring shaft and the hollow scraper plate rotate relatively, and the end surface of the paddle is realized during the rotation process At the same time, the periodic short-term rotation cooperates with its revolution along the drive shaft to continuously drive the stir-fry from the bottom upwards, and further agitate the stir-fry during the driving process, which is more conducive to improving the propulsion of the stirring paddle. Stir-fry mixing effect.

Owner:杭州成邦沥青混凝土有限公司

Machine tool chip removal and cleaning device for numerical control machine tool

ActiveCN113601251AScrape off thoroughlyImprove cleaning efficiencyMaintainance and safety accessoriesNumerical controlEngineering

The invention provides a machine tool chip removal and cleaning device for a numerical control machine tool. The machine tool chip removal and cleaning device comprises a chip collecting tank, a chip discharging opening is formed in one side in the chip collecting tank, a lead screw is rotationally connected to the side end of the chip collecting tank, a sleeve is in threaded connection with the outer side of the lead screw, a transverse moving plate is fixedly connected to the outer side of the sleeve through two connecting rods, a scraping plate set is fixed to the bottom side of the transverse moving plate, a plurality of auxiliary plates are further fixed to the side end of the transverse moving plate, circular plates are rotationally connected into the auxiliary plates, scraping rod sets are fixed to the bottom sides of the circular plates, and machine tool chips in the chip collecting tank are conveyed to the chip discharging opening to be discharged under the action of the scraping plate set and the scraping rod sets. According to the machine tool chip removal and cleaning device, the transverse moving plate is glidingly connected in the chip collecting tank, the scraping plate set is fixed to the bottom side of the transverse moving plate, the scraping plate set comprises a first scraping plate and a second scraping plate, the first scraping plate and the second scraping plate form an upper gradient and a lower gradient, then the chips can be scraped thoroughly when the chips are cleaned, and the cleaning efficiency is improved.

Owner:无锡旺特福机床辅机有限公司

A class A fireproof insulation material and its production equipment and method

InactiveCN103265722BImprove performanceNot easy to come outHeat proofingFire proofingThermal insulationFireproofing

The invention discloses an A-grade fireproofing thermal insulation material as well as production equipment and method thereof and belongs to the technical field of fireproofing thermal insulation materials of exterior walls of buildings. According to the method, inorganic fireproofing glue is injected into an organic foam material body, and spaces of an organic foam material are filled by utilizing the inorganic fireproofing glue, so that an inorganic fireproofing material and the organic material body can be firmly combined, fireproofing and heat retaining properties of the organic foam material are improved, and strength of the fireproofing thermal insulation material is enhanced; and besides, a concave-convex surface is formed on a die in the method, so that the surface of the pressed fireproofing thermal insulation material is uneven, mud scraping in construction can be facilitated, and strength of bonding between mud and the thermal insulation material is enhanced.

Owner:山东德润机电设备制造有限公司

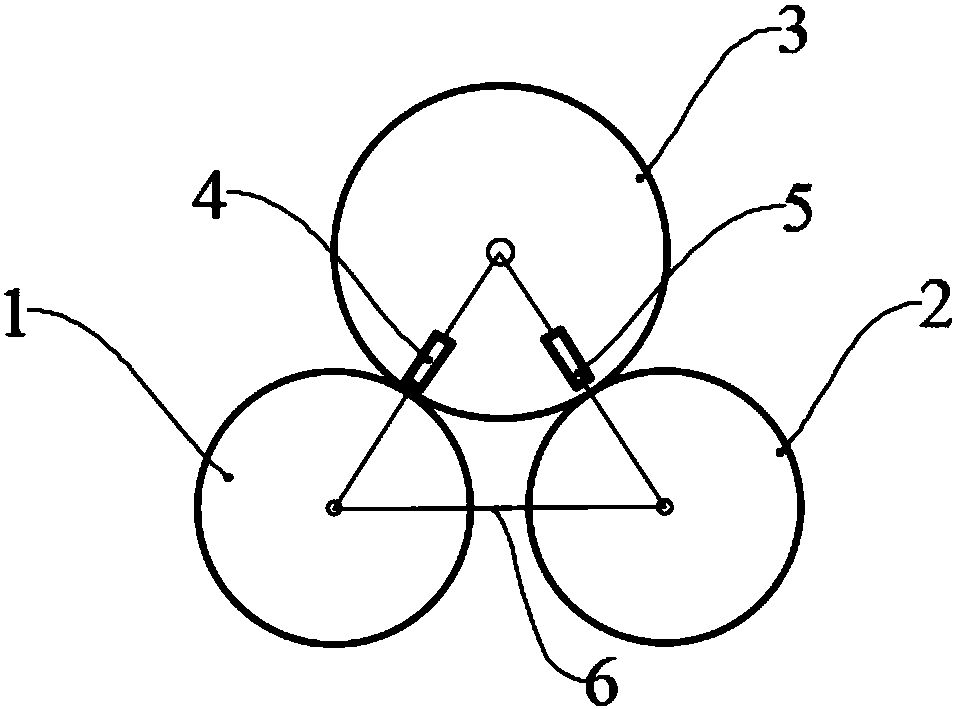

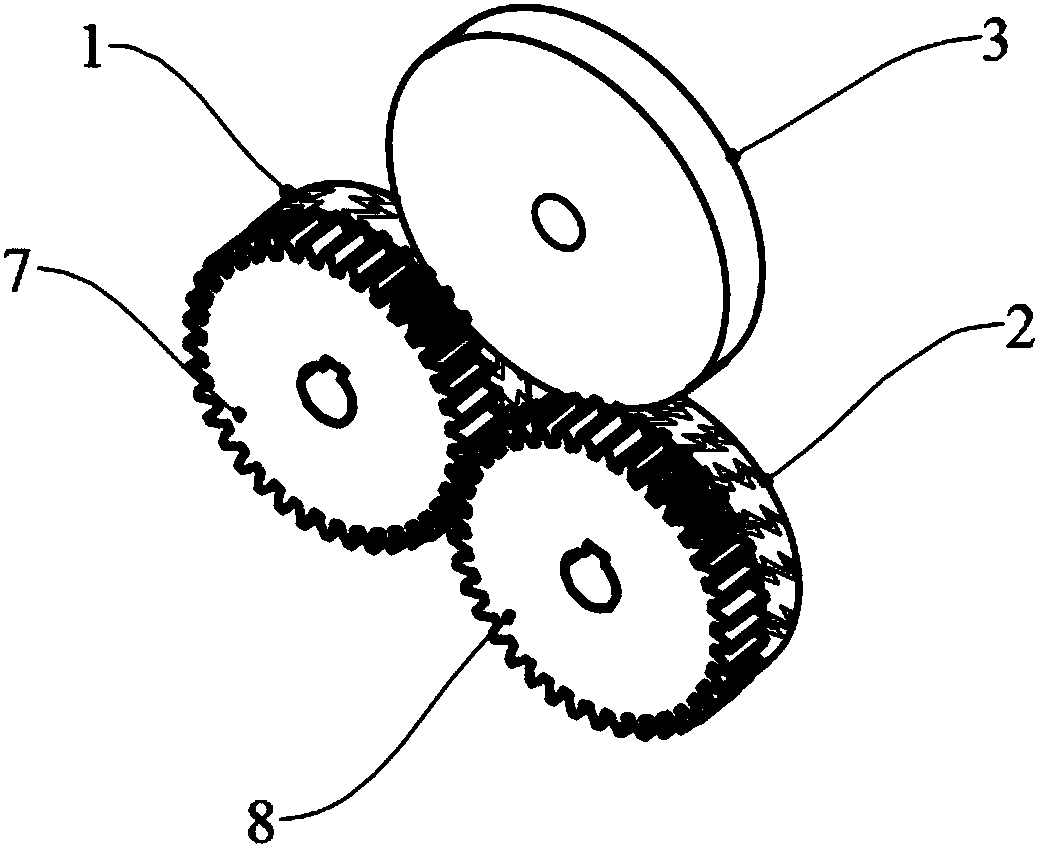

Externally-added self-lubricating gear device

The invention discloses an externally-added self-lubricating gear device. The device is composed of a pair of meshed gears, a pair of rolling wheels and a lubricating wheel made of self-lubricating materials. According to the externally-added self-lubricating gear device, the pair of rolling wheels with knurling structures formed on the surfaces are utilized, and the lubricating wheel with a leftpressing mechanism and a right pressing mechanism is combined, so that the pair of rolling wheels and the lubricating wheel are arranged in a triangular layout; the lubricating property of the self-lubricating materials is efficiently utilized, so that the lubricating requirement of the pair of meshed gears is achieved, and the self-lubricating function of gear transmission is achieved; and the defect that self-lubricating materials used for achieving conventional self-lubricating gear transmission cannot be continuously supplemented is overcome, the real-time, continuous and durable lubricating requirements of a transmission system under the severe working condition can be met, and the objectives of small weight, reliability and persistence of the gear transmission lubricating system areachieved.

Owner:HEFEI UNIV OF TECH

Two-component epoxy adhesive and preparation method thereof

ActiveCN105062395BImprove toughnessHigh peel strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAliphatic aminePolyamide

The invention relates to a two-component epoxy glue and a preparation method thereof. The two-component epoxy adhesive includes A component and B component, and the A component includes: epoxy resin, toughener, liquid flame retardant, powder flame retardant, diluent, defoamer, Reinforcing filler; the B component includes aliphatic amine curing agent, polyether amine, polyamide 650, and curing accelerator. The present invention screens the components of the epoxy adhesive so that the components can complement each other in performance and form a two-component epoxy adhesive system with superior comprehensive performance through synergistic cooperation, which significantly improves the toughness, anti-peel strength, The impact resistance and flame retardancy have also reached the UL94-V0 level, and the operating time is relatively suitable, and the curing time is short, which can realize continuous production.

Owner:GUANGZHOU BAIYUN CHEM IND

A machine tool chip removal and cleaning device for CNC machine tools

ActiveCN113601251BScrape off thoroughlyImprove cleaning efficiencyMaintainance and safety accessoriesNumerical controlEngineering

The invention provides a machine tool chip removal cleaning device for CNC machine tools, comprising a chip collection groove, a chip discharge port is opened on one side of the chip collection groove, and a screw is rotatably connected to the side end of the chip collection groove. A sleeve is threadedly connected, the outer side of the sleeve is fixedly connected with a traverse plate through two connecting rods, a scraper group is fixed on the bottom side of the traverse plate, and a plurality of auxiliary plates are fixed on the side end of the traverse plate. A circular plate is connected in rotation inside, and a scraper group is fixed on the bottom side of the circular plate. Under the action of the scraper group and the scraper group, the machine chips in the scrap collection groove are sent to the chip discharge port for discharge. A traverse plate is slidably connected in the scrap collection tank, and a scraper group is fixed on the bottom side of the traverse plate. The scraper group consists of a first scraper and a second scraper, and the first scraper and the second scraper form an upper and lower part There are two gradients, so that the debris can be scraped off when the debris is cleaned, which improves the cleaning efficiency.

Owner:无锡旺特福机床辅机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com