A class A fireproof insulation material and its production equipment and method

A technology for fire protection and heat preservation and production equipment, which is applied in the direction of heat preservation, fire prevention, and building components, etc. It can solve the problems of uneven overall performance of insulation boards, affecting the durability of insulation materials, and increasing the cost of manpower and material resources, so as to improve fire resistance and heat preservation. , the overall performance is improved, and the effect of not easy to come out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Production equipment for Class A fireproof and thermal insulation materials:

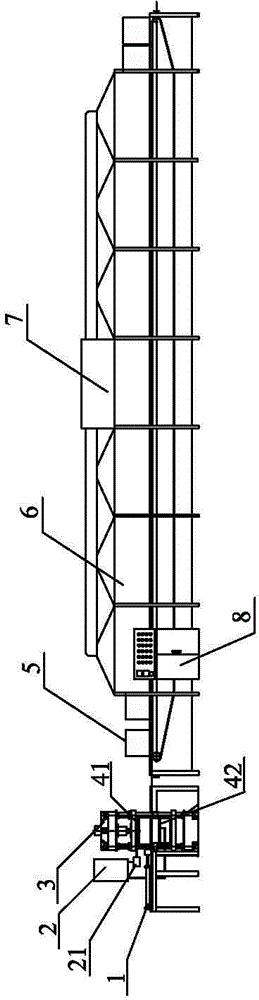

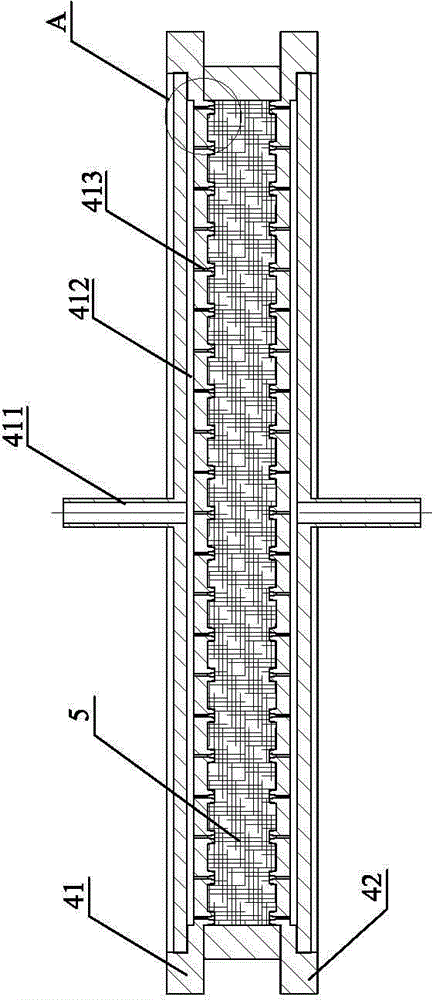

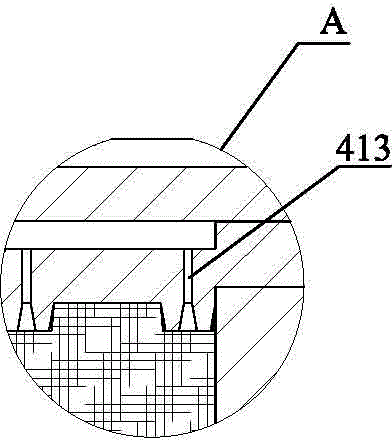

[0036] Such as Figure 1~3 As shown, the production equipment includes a pushing mechanism 1, a fireproof glue storage box 2, a water pump 21, a press 3, an upper mold 41, a lower mold 42, an injection pipe 411, a channel 412, an injection hole 413, an outflow hole 414, and an outflow pipe 415 , drying furnace 6, hot air box 7 and electrical control cabinet 8.

[0037] Pushing mechanism 1 is connected with press machine 3, and mold is installed on press machine 3, and mold comprises upper mold 41 and lower mold 42, and upper mold 41 is provided with injection pipe 411, channel 412 and injection hole 413, and injection pipe 411 and The passage 412 on the upper mold 41 is connected, and the passage 412 is connected with each injection hole 413; the lower mold 42 is provided with an outflow pipe 415, a passage 412 and an outflow hole 414, and the outflow pipe 415 communicates with the passag...

Embodiment 2

[0049] The difference from Example 1 is that this example uses rigid polyurethane foam as the body of the organic foam material; the light inorganic fireproof particles used are glass hollow microspheres; 1% potassium oxide is added during the preparation of the water glass solution. The dosages of inorganic binder, light inorganic fireproof particles, alkaline conditioner and ammonium polyphosphate are 6Kg, 1.6Kg, 1.6Kg and 0.8Kg respectively.

[0050] The weight ratio of the inorganic fireproof adhesive to the organic foam material body in the prepared Class A fireproof and thermal insulation material is 1:1.

[0051] In the combustion test carried out in the laboratory, there is no dripping after burning for 30 minutes at 750°C, and the mass loss is ≤35%, meeting the A2 fire protection requirements; thermal conductivity ≤0.036W / (m·K); strength ≥200kPa.

Embodiment 3

[0053] The difference from Example 2 is that the dosages of inorganic binder, light inorganic fireproof particles, alkaline conditioner and ammonium polyphosphate are 9Kg, 0.5Kg, 0.2Kg and 0.3Kg respectively.

[0054] In the combustion test carried out in the laboratory, there is no dripping after burning for 30 minutes at 750°C, and the mass loss is ≤35%, meeting the A2 fire protection requirements; thermal conductivity ≤0.036W / (m·K); strength ≥200kPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com