Two-component epoxy glue and preparation method thereof

An epoxy adhesive, two-component technology, used in epoxy resin adhesives, adhesives, adhesive types, etc., can solve the problems of industry development influence and constraints, low peel strength, difficult continuous production, etc., to reduce curing. Effects of crosslinking density, improved peel strength, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

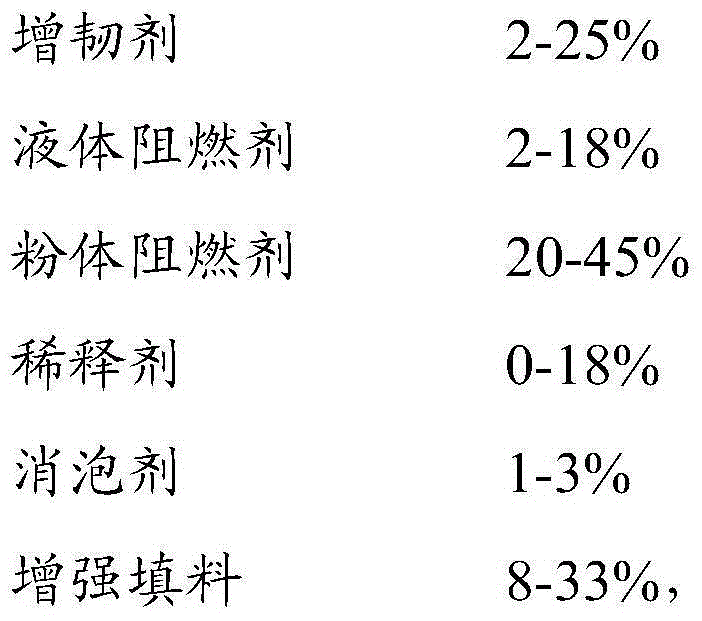

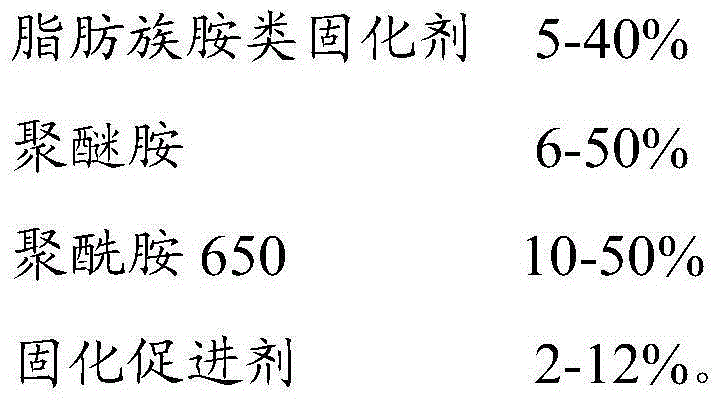

[0047] Present embodiment 6 kinds of two-component epoxy glues, comprise the raw material of percentage by weight as shown in table 1:

[0048] Table 1

[0049]

[0050]

[0051]

[0052] The epoxy resin E-44: epoxy equivalent 210-240g / eq; viscosity (25°C) 20000-40000mPa·s;

[0053] Polyurethane modified epoxy resin SL3451: epoxy value 0.45-0.50eq / 100g, viscosity (25°C) 5000-15000mPa·s;

[0054] Polyurethane modified epoxy resin SL3453: epoxy value 0.37-0.40eq / 100g, viscosity (25°C) 45000-55000mPa·s;

[0055] Epoxy resin DER331: epoxy equivalent 182-192g / eq, viscosity (25°C) 11000-14000mPa·s;

[0056] Epoxy resin DER791: epoxy equivalent 255-275g / eq, viscosity (25°C) 28000-3400mPa·s.

[0057] The preparation method of above-mentioned two-component epoxy glue, comprises the following steps:

[0058] (a) adding the epoxy resin, diluent, toughening agent, liquid flame retardant, fumed silica and defoamer into a planetary mixer, stirring and mixing evenly;

[0059] (b)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com