Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Consistent viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

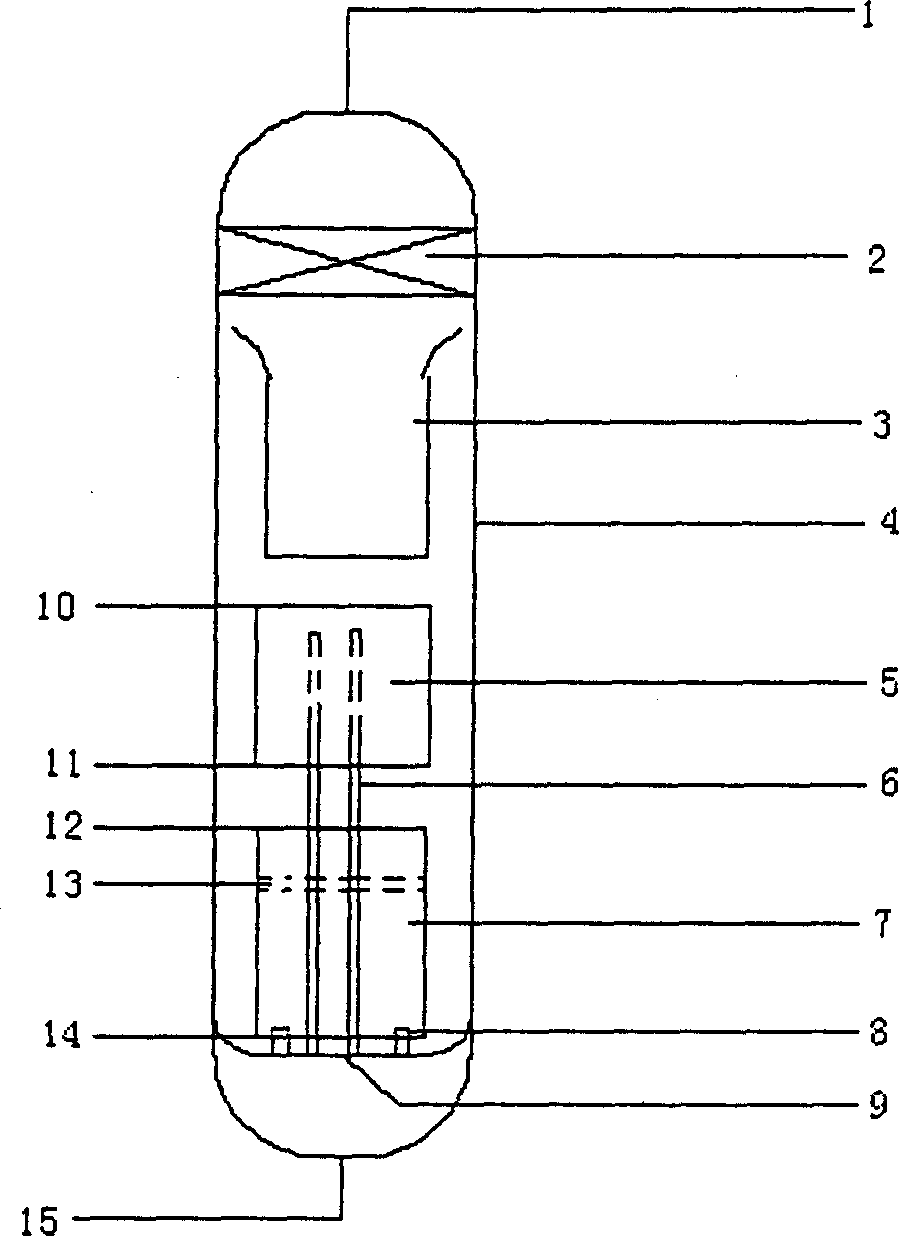

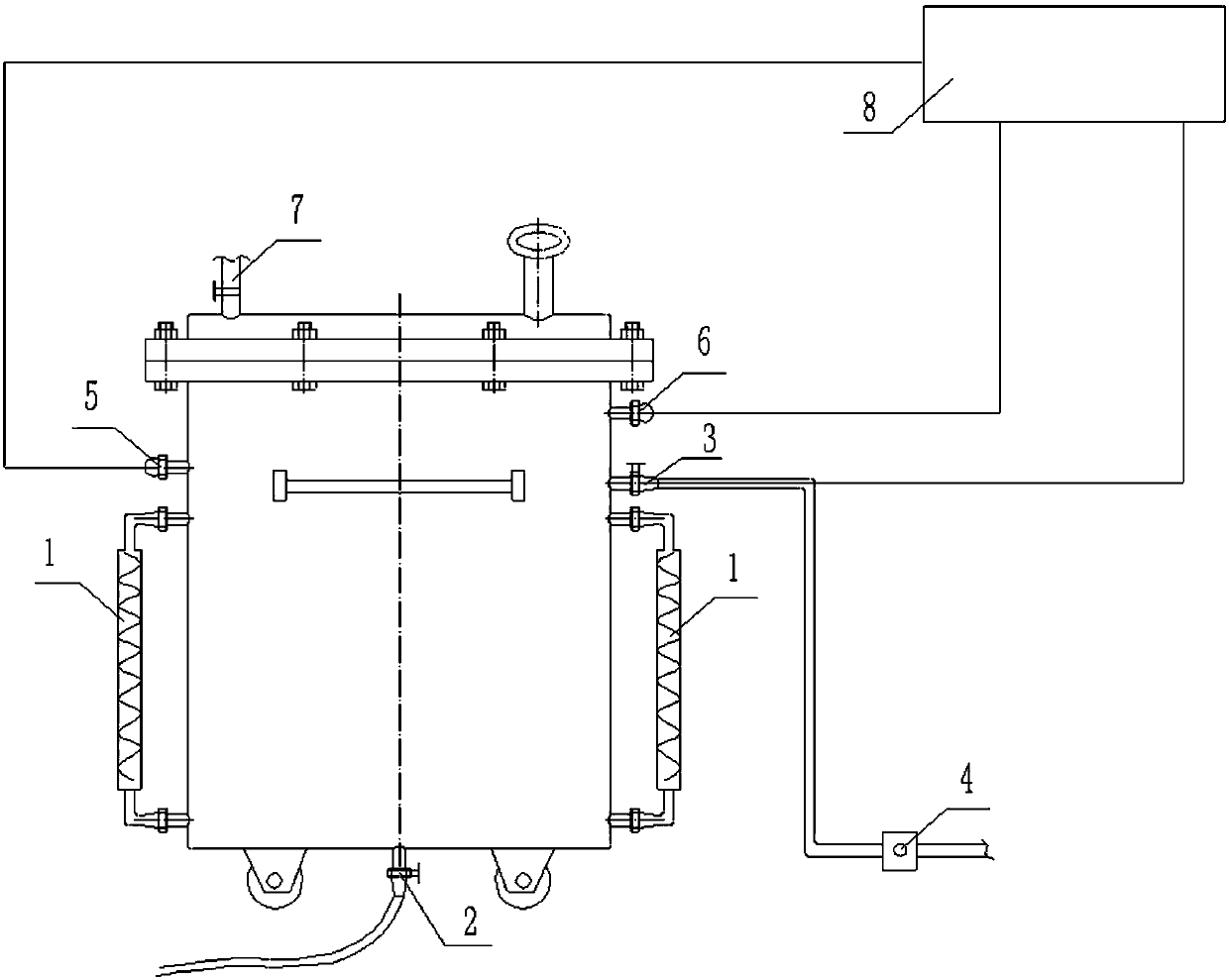

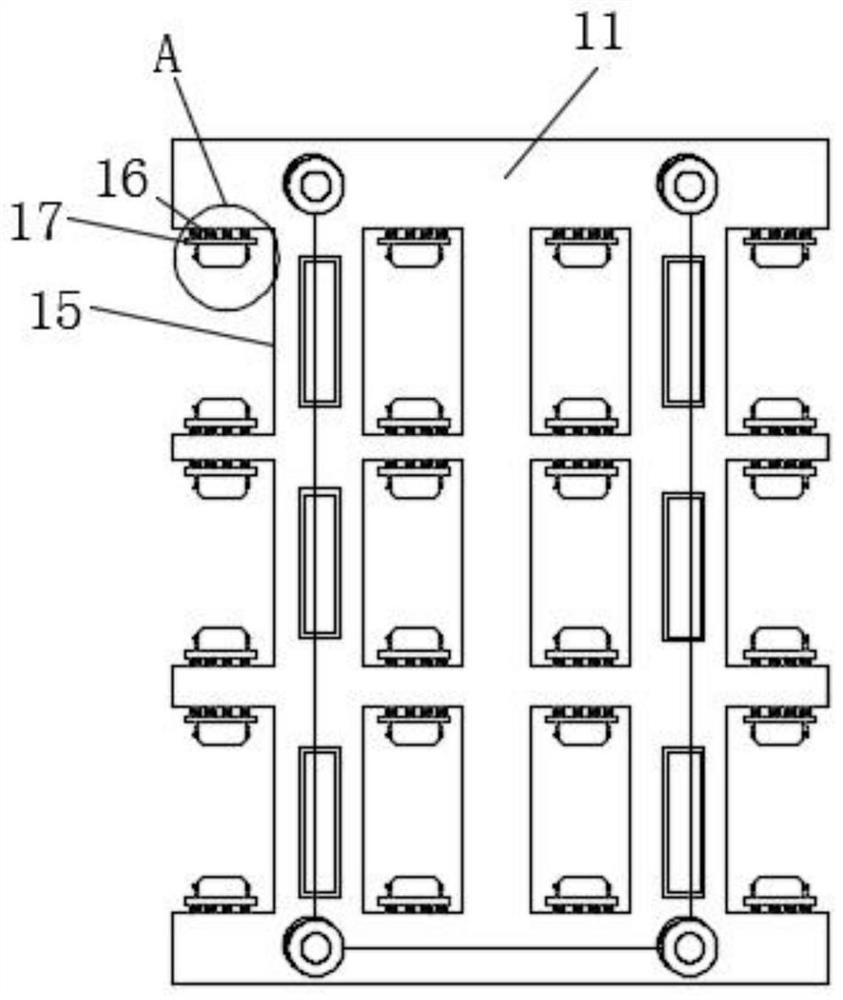

Highly effective slurry phase bed reactor

InactiveCN1593740AEasy to operateAvoid easy cloggingChemical/physical processesNuclear engineeringSpray nozzle

The invention relates to a kind of efficient reactor with paddle bed, which belongs to the chemical machinery field. It is composed mainly with the solid and liquid separator, the inner tube that the track is changeable, the reactor cover, the heat exchanger with an internal component, the riser with the spray nozzle, the inner-tube tank that has the heating and gas distribution function, the spray nozzle for protecting from choking, the mounting plate of the spray nozzle, the heat exchanger, the outlet of the heating coil, the quadratic distribution plate, the heating coil and so on. The beneficial effictiveness of the invention can be described as follows: the reactor and the distributor can't block up easily; the gas and the liquid can be mixed evenly; the reactive efficiency is high; the carrying amount of the catalyst and the solvent is so bit that it can not occur the bias current, channeling and dead bed; the size running quickly, and the viscosity of the size in the reactor is identical generally; the reactor can be shifted out in time, and especially in the stage of the catalytic, reducing and intensifying, it can realize to operate the reactor steadily; otherwise, the distribution of the virgin gas in the reactor along the axle is in agreement on the concentration of the catalyst, so that can make the catalyst have the most activity, and then it can be make the full use of the reactor space.

Owner:TAIYUAN UNIV OF TECH

Hot melt pressure sensitive adhesive and preparation process thereof

The invention discloses a hot melt pressure sensitive adhesive. The main raw materials (by weight parts) of the hot melt pressure sensitive adhesive comprises the following component by weight: 3 to 5 portions of SBS168, 4 to 6 portions of SBS796, 2 to 5 portions of SIS822, 15 to 25 portions of SIS1105, 4 to 12 portions of terpene T-1095, 4 to 12 portions of terpene-modified resin T-100, 20 to 30 portions of rosin-modified resin 138<#>, 16 to 28 portions of rubber-softening oil KN4010, 2 to 6 portions of polyisobutylene PB2400, and 0.2 to 0.6 portions of antioxidant BHT. With the modified formulation of raw materials, the cost of the hot-melt pressure-sensitive adhesive is greatly reduced and the adhesion property of the hot-melt pressure-sensitive adhesive is better than the similar products.

Owner:HENGYANG KETAI CHEM

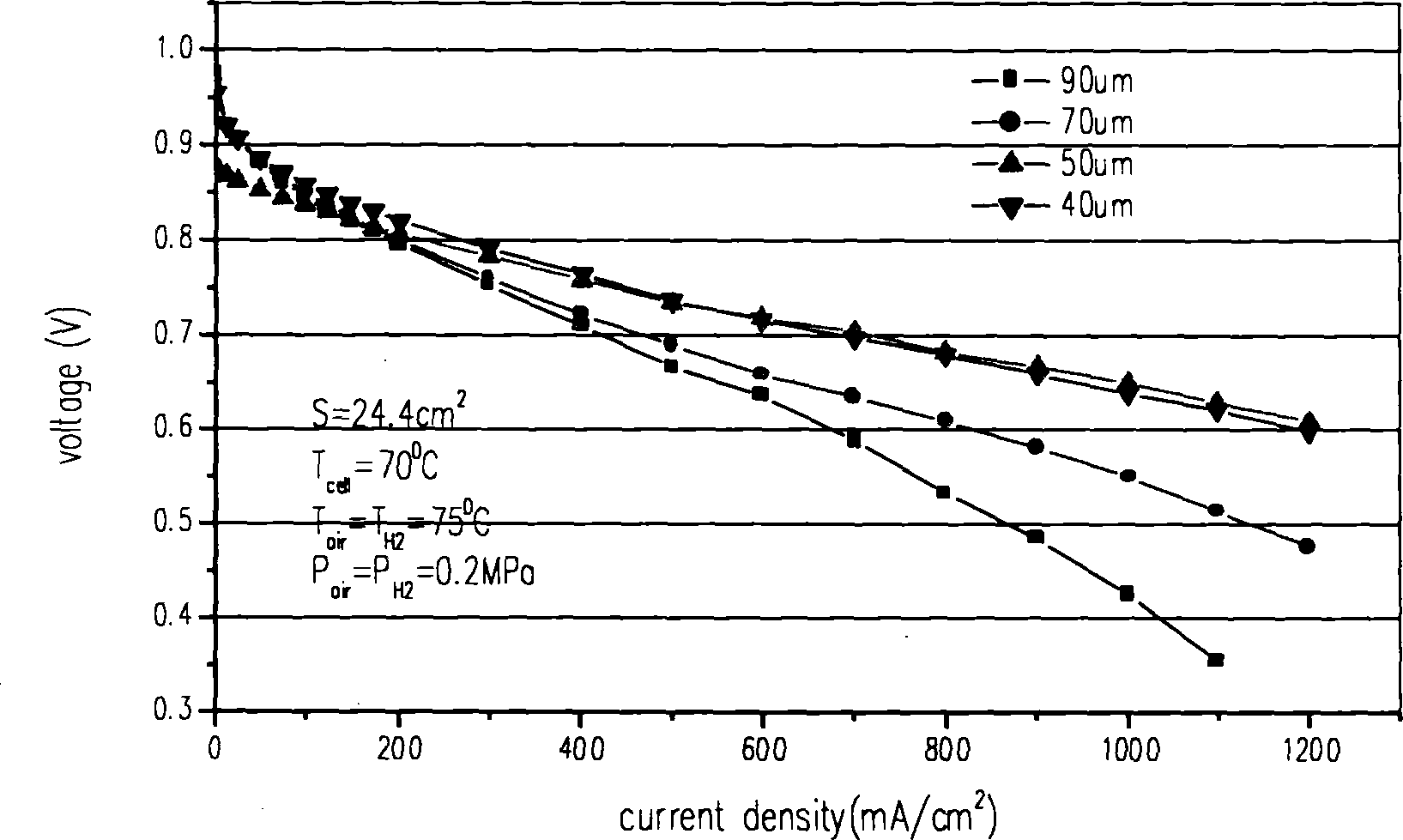

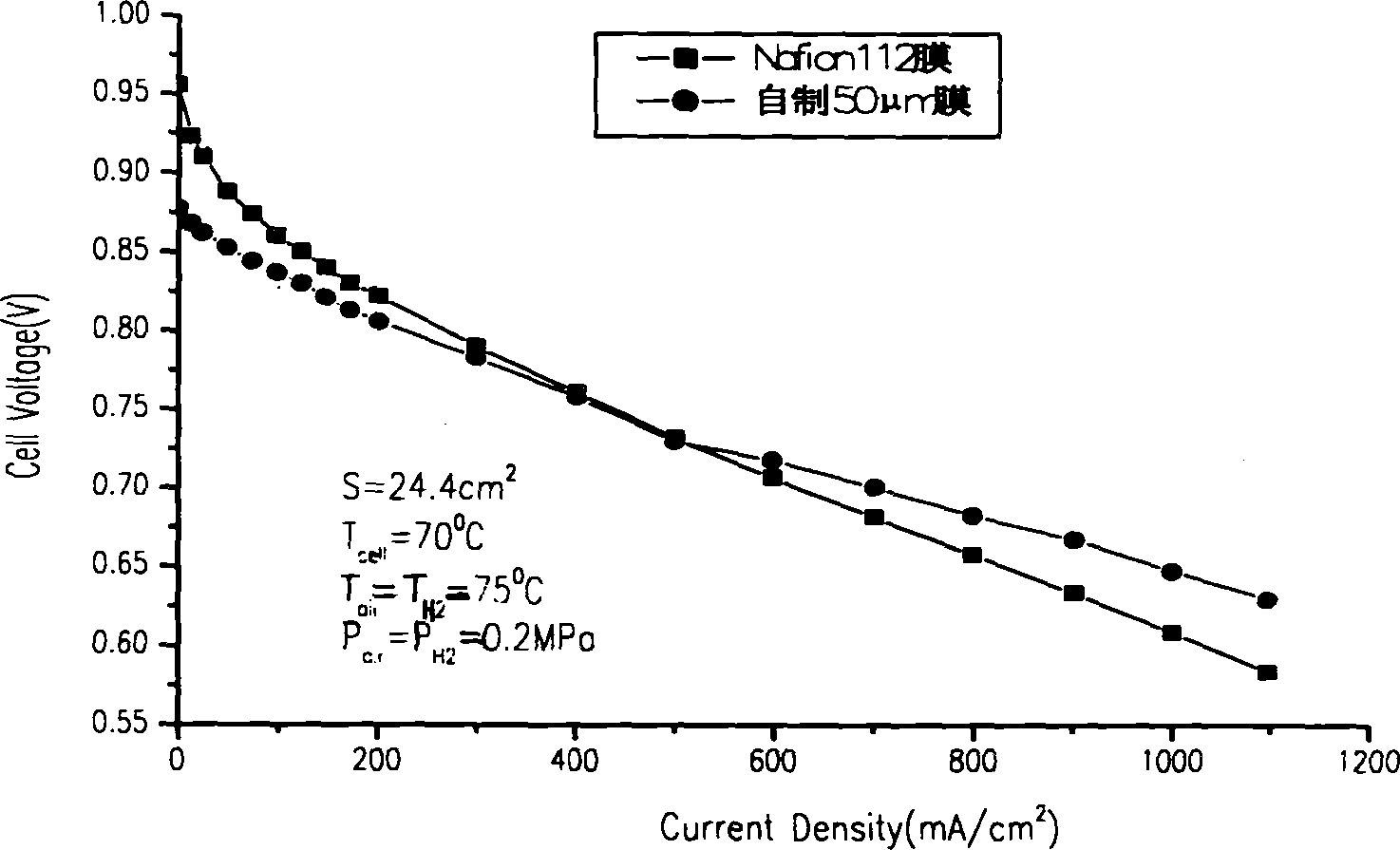

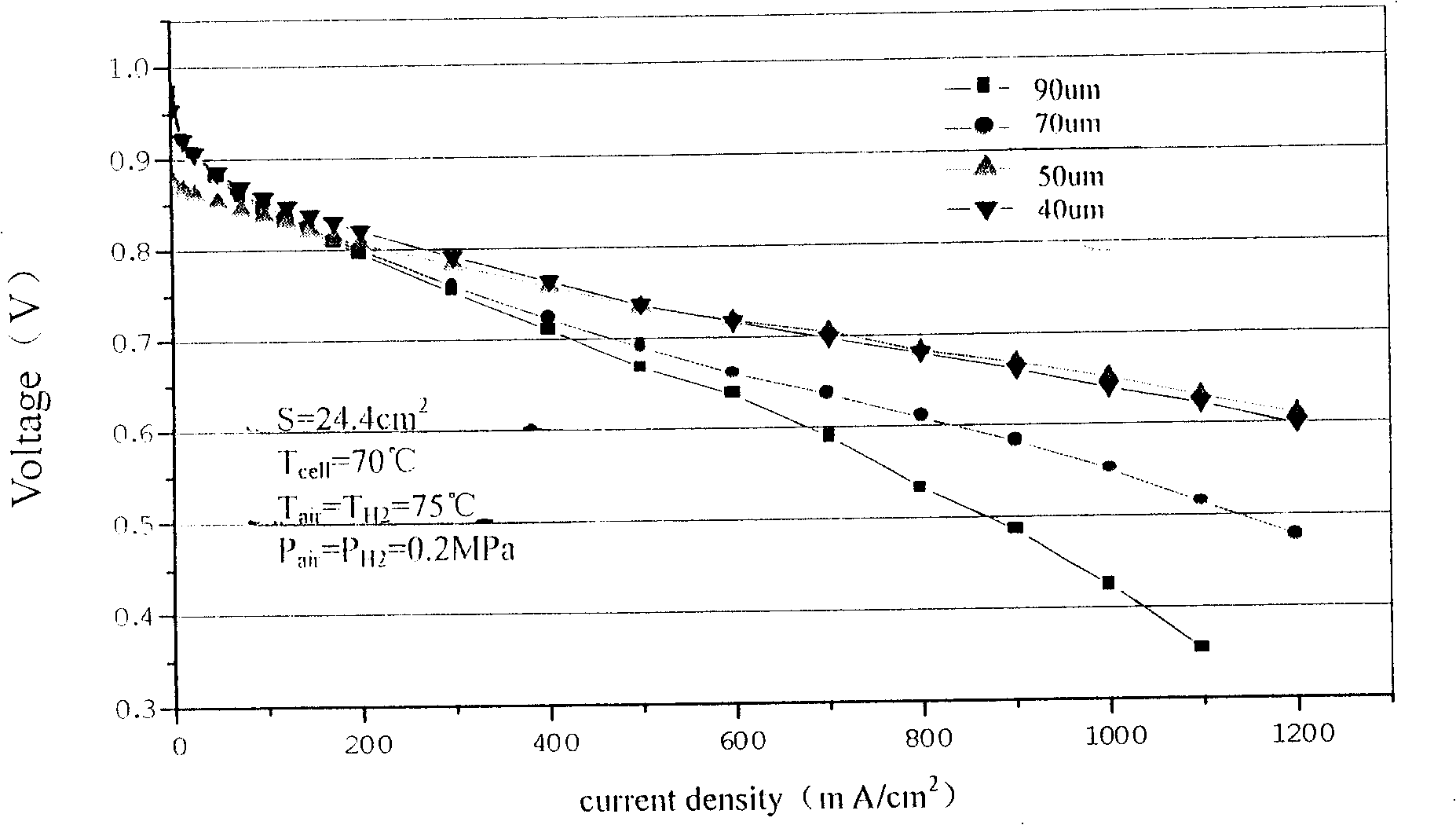

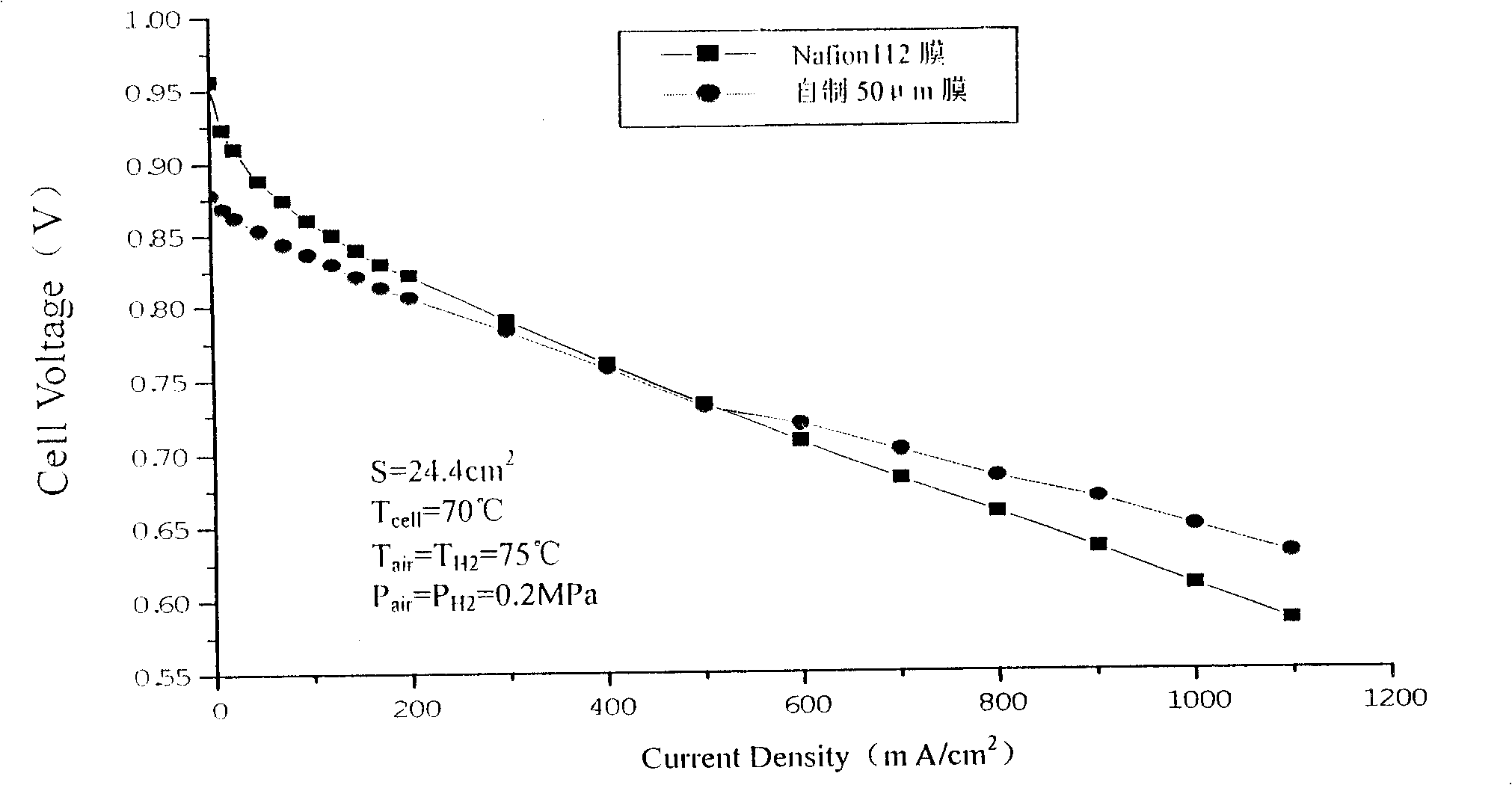

Process for preparing perfluorinated sulfonic resin solution by using waste ion exchange membrane in chlor-alkali industry

The invention discloses a method for preparing perfluoro sulfonic resin with abandoned ion exchange membrane in alkali-chloride industry, comprising following steps: swelling said abandoned ion with lower alcohol, emulsifying it with emulsion machine to resin particle, adding alcohol / water solvent and resin particle into autoclave, dissolving resin particle under high temperature and pressure and protection of nitrogen; getting solid mixture of perfluoro sulfonic resin and solution, separating with solid-liquid separation method and getting perfluoro sulfonic resin solution and solid perfluoro sulfonic resin. The resin solution is characterized by transparent, low content of foreign matter, high purity, similar property to that of Nafion EW 1100 solution, usage in field of mending ionic membrane pinhole and other mechanical damage, preparation of fuel battery proton exchange membrane and stereoscopic electrode and chemical catalysis.

Owner:SUNRISE POWER CO LTD

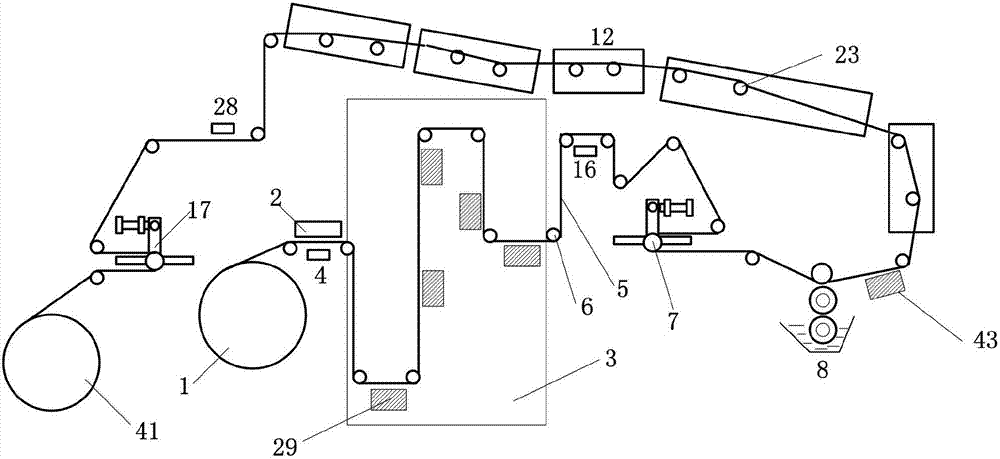

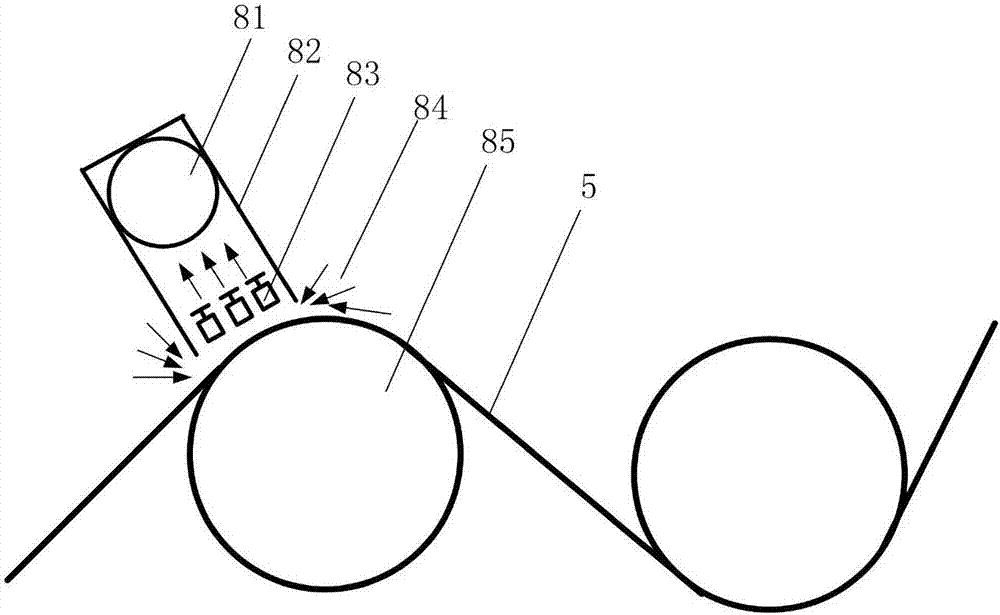

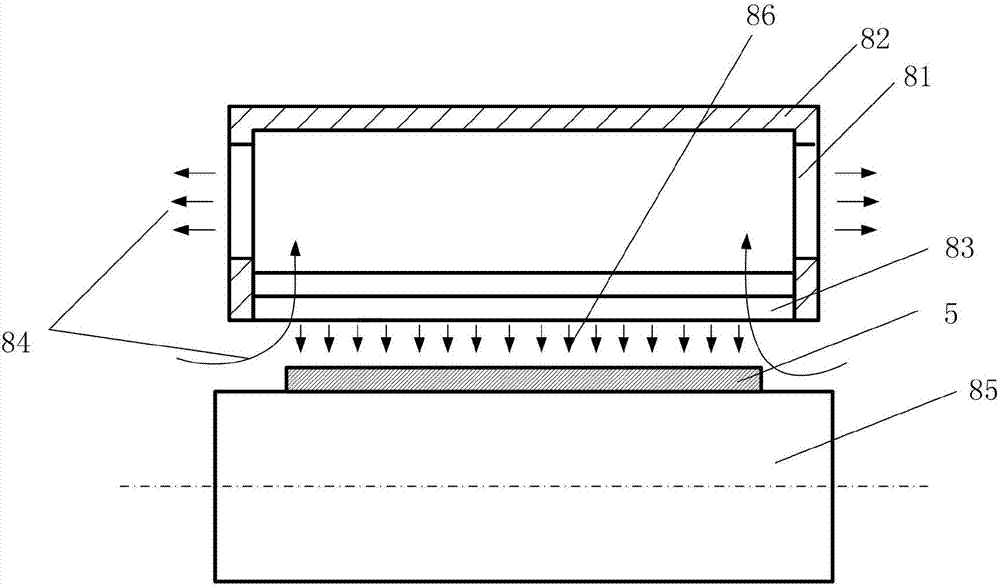

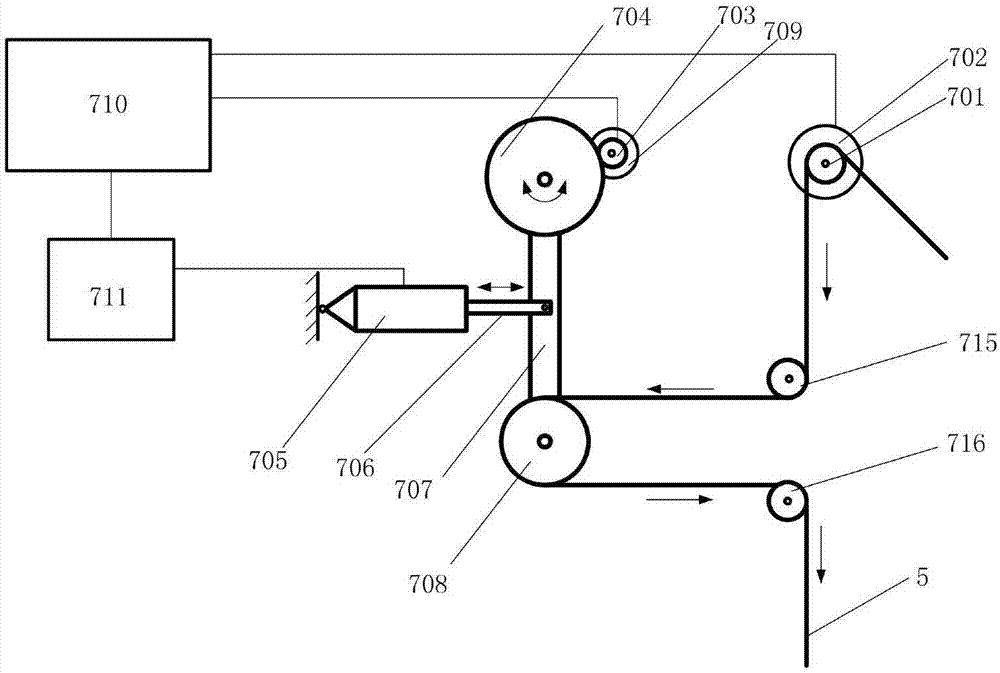

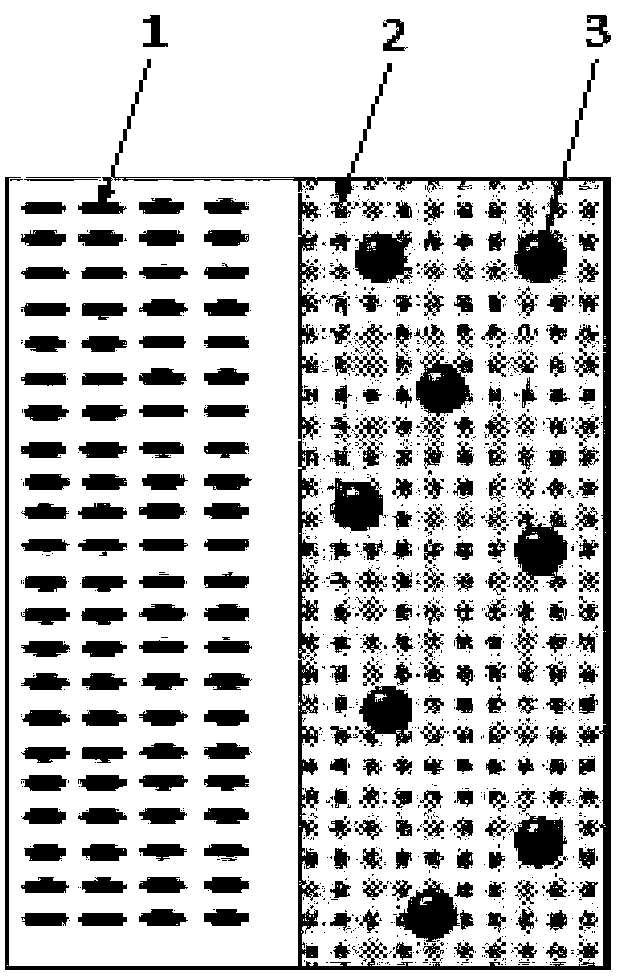

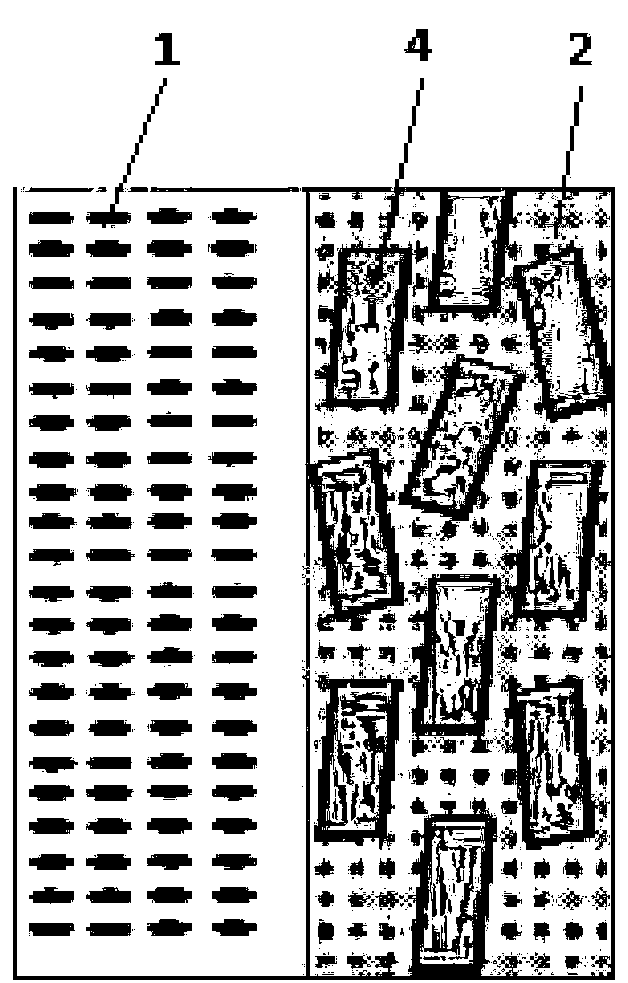

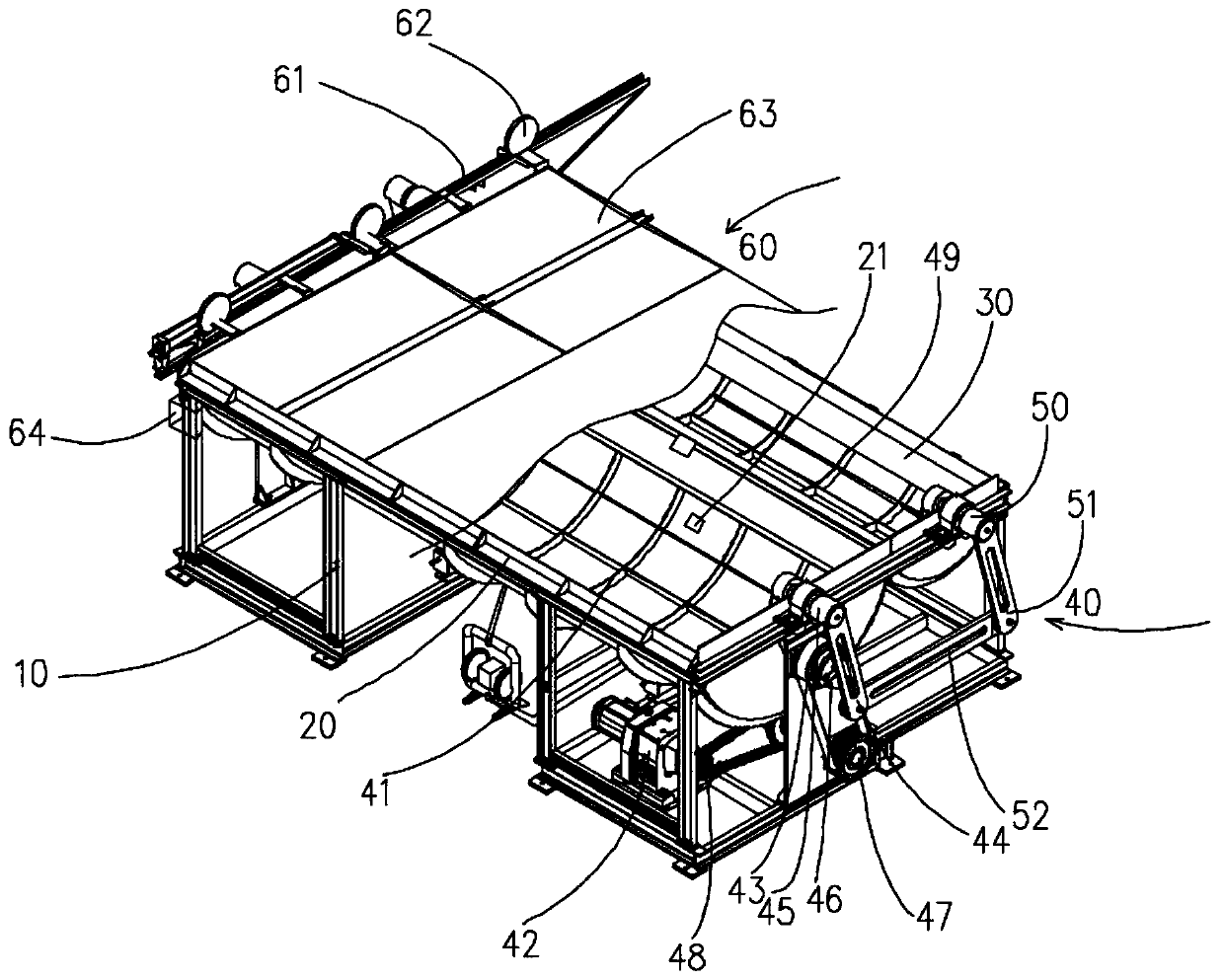

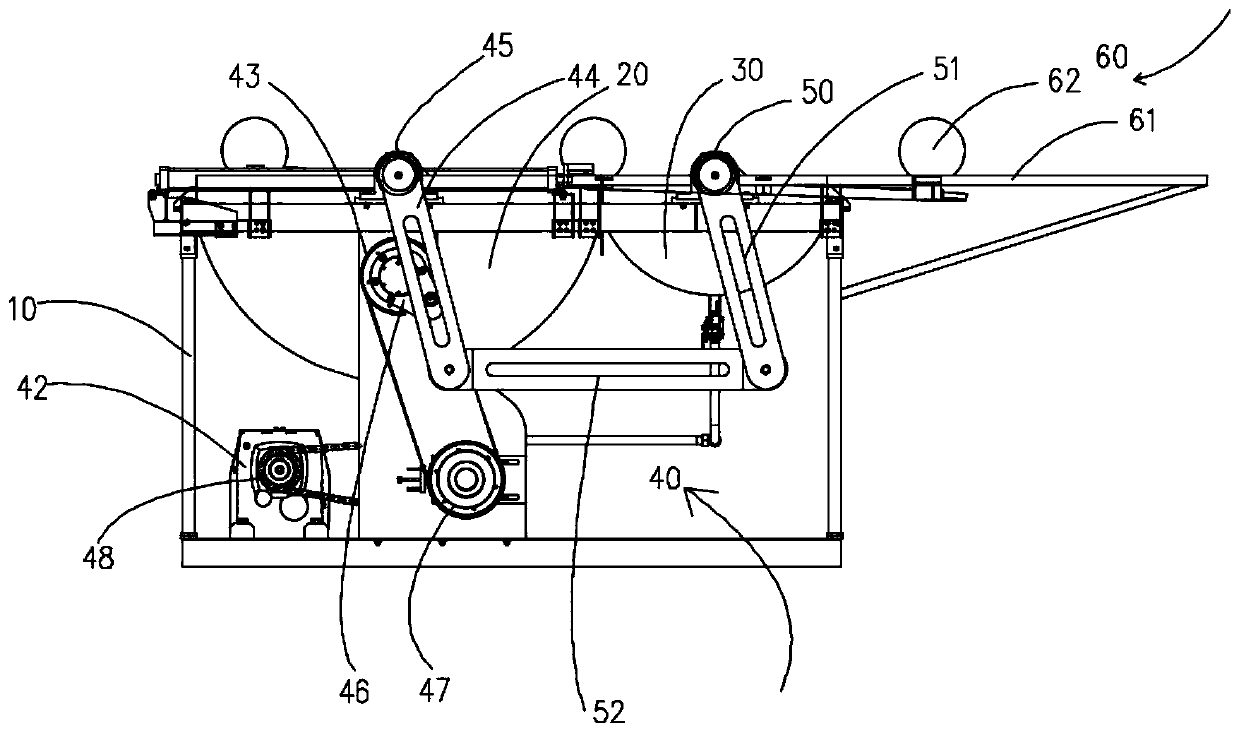

Device for coating graphene on surfaces of metal foils

ActiveCN107457141AThe glue layer is thin and uniformStrong adhesionPretreated surfacesCoatingsMetal foilCopper foil

The invention discloses a device for coating graphene on surfaces of metal foils. The device comprises a control unit, and an unwinding unit, a coating printing device, a baking unit and a winding unit arranged in sequence in a moving direction of the metal foils; the metal foils are aluminum foils or copper foils; the coating printing device comprises a pressing roller, a driving silica gel roller and a driving steel roller laminated from top to bottom; the driving silica gel roller and the driving steel roller are rotated in opposite directions by keeping a micron gap; the driving steel roller is dipped in a colloid pool with viscous materials; and a substrate is arranged between the pressing roller and the driving silica gel roller. The device realizes uniform spraying of materials with submicron thicknesses and thinner layers on the surface of the substrate to meet the thickness requirements of the graphene coated on the metal foils, and achieves excellent adhesion to effectively reduce the contact resistance between carbon particles and the metal foils.

Owner:陕西浩合机械有限责任公司

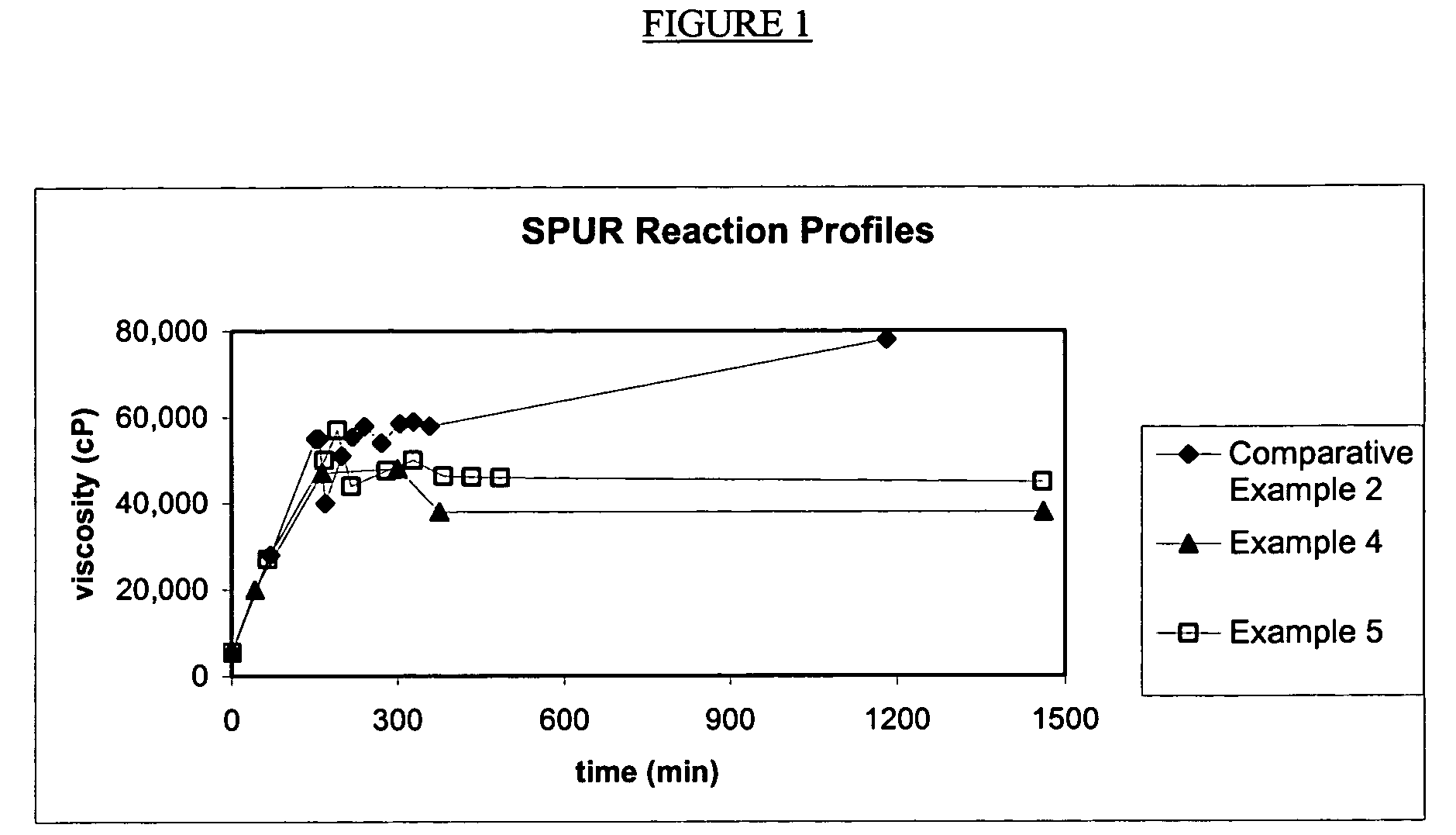

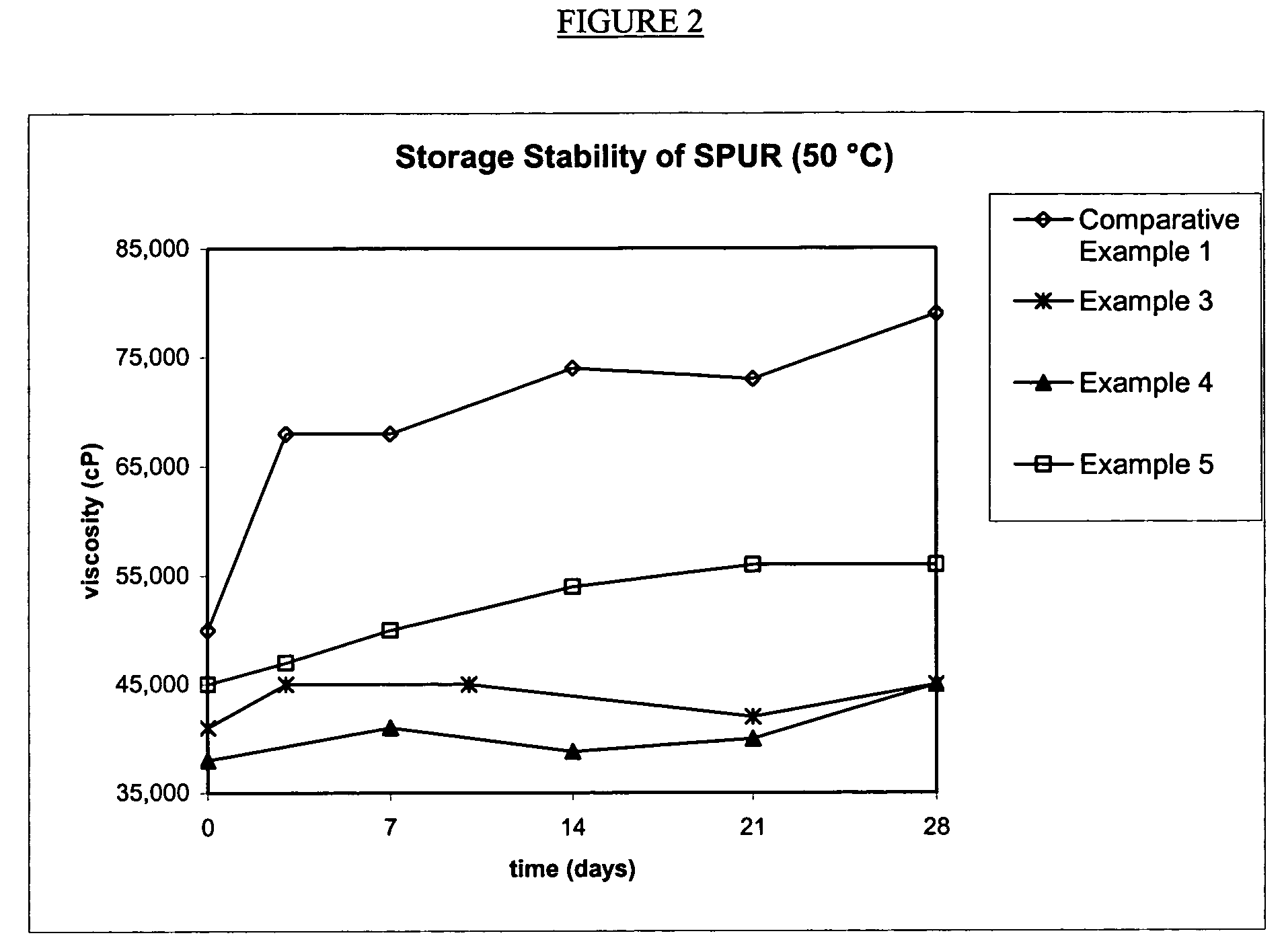

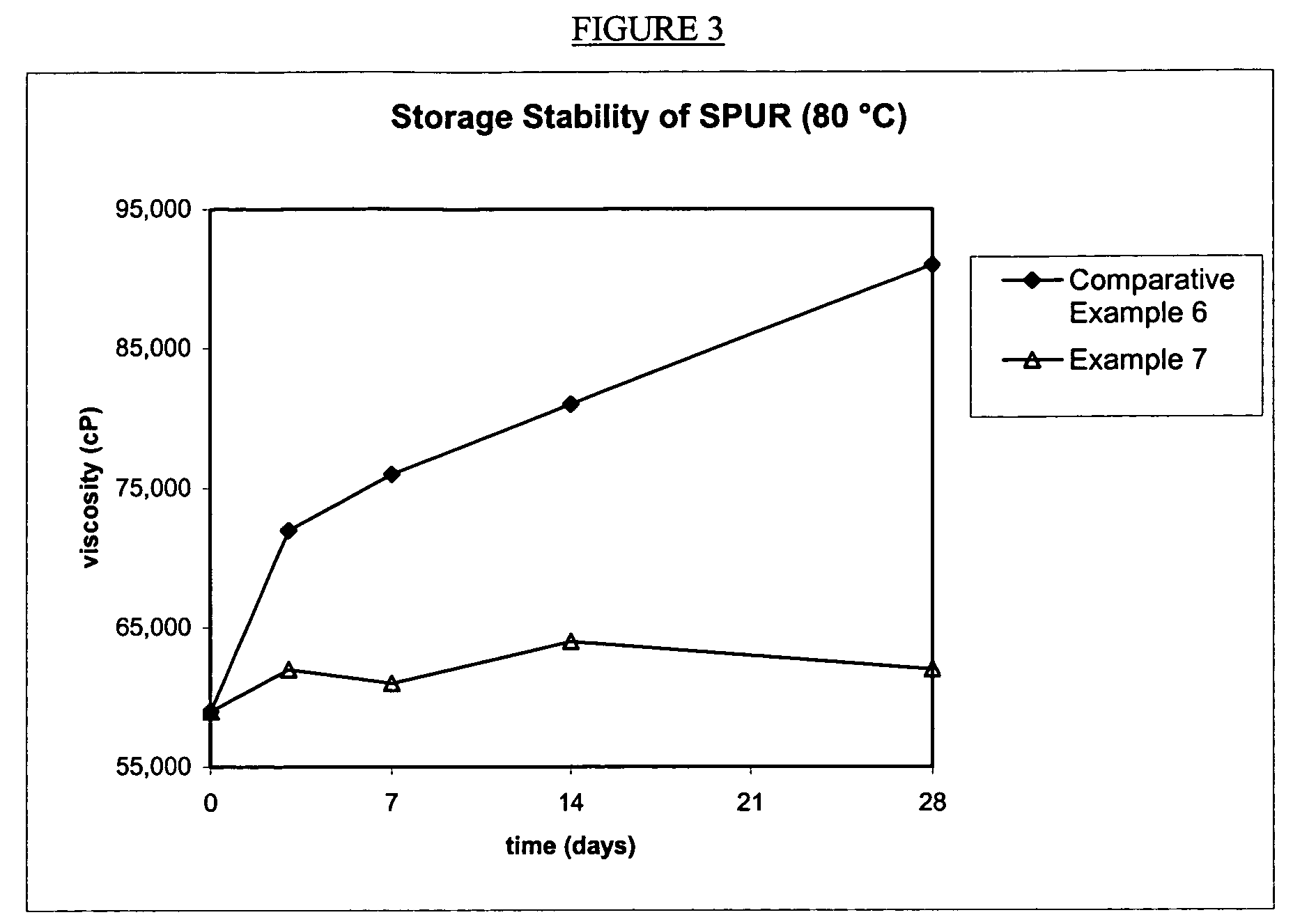

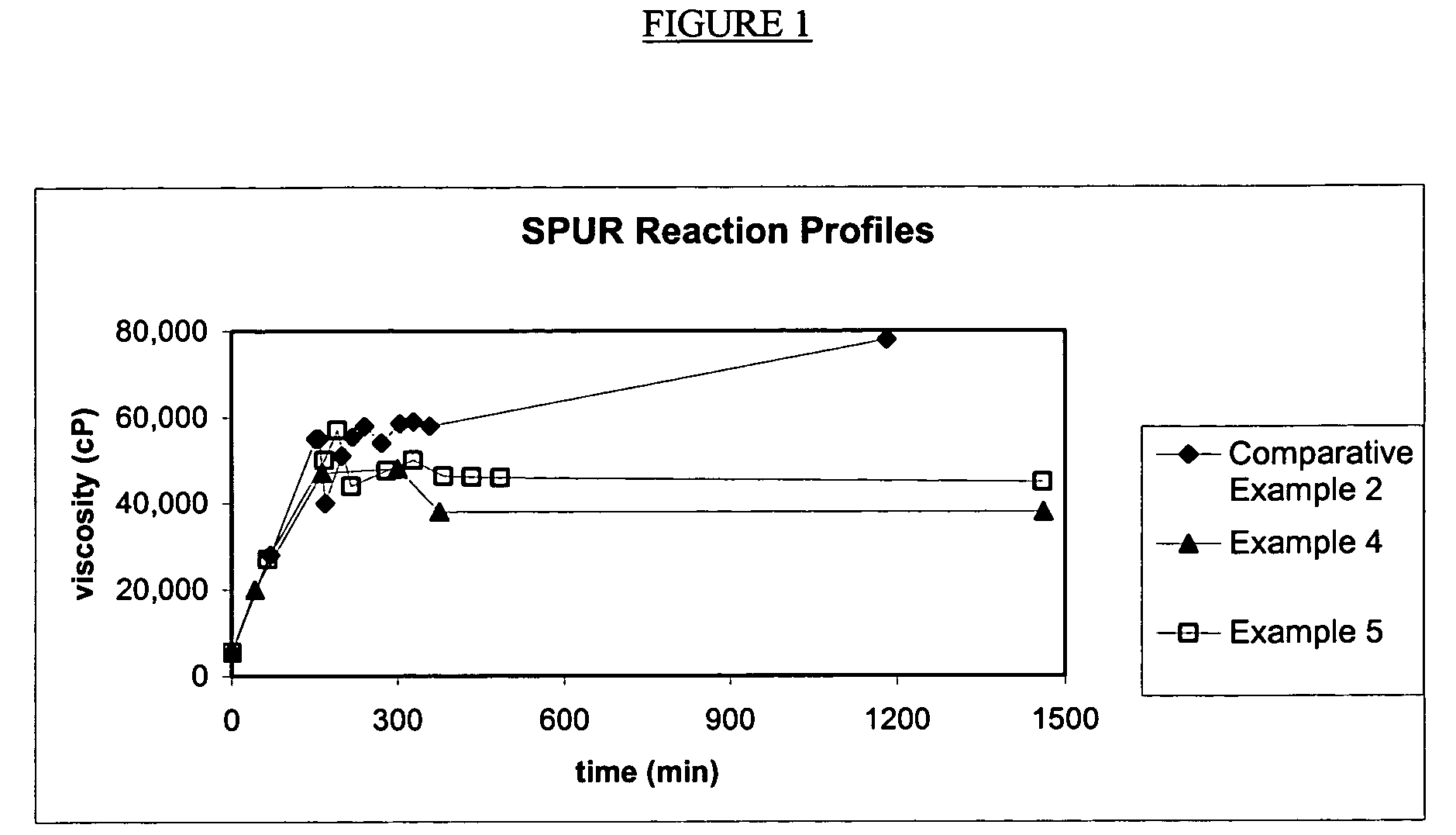

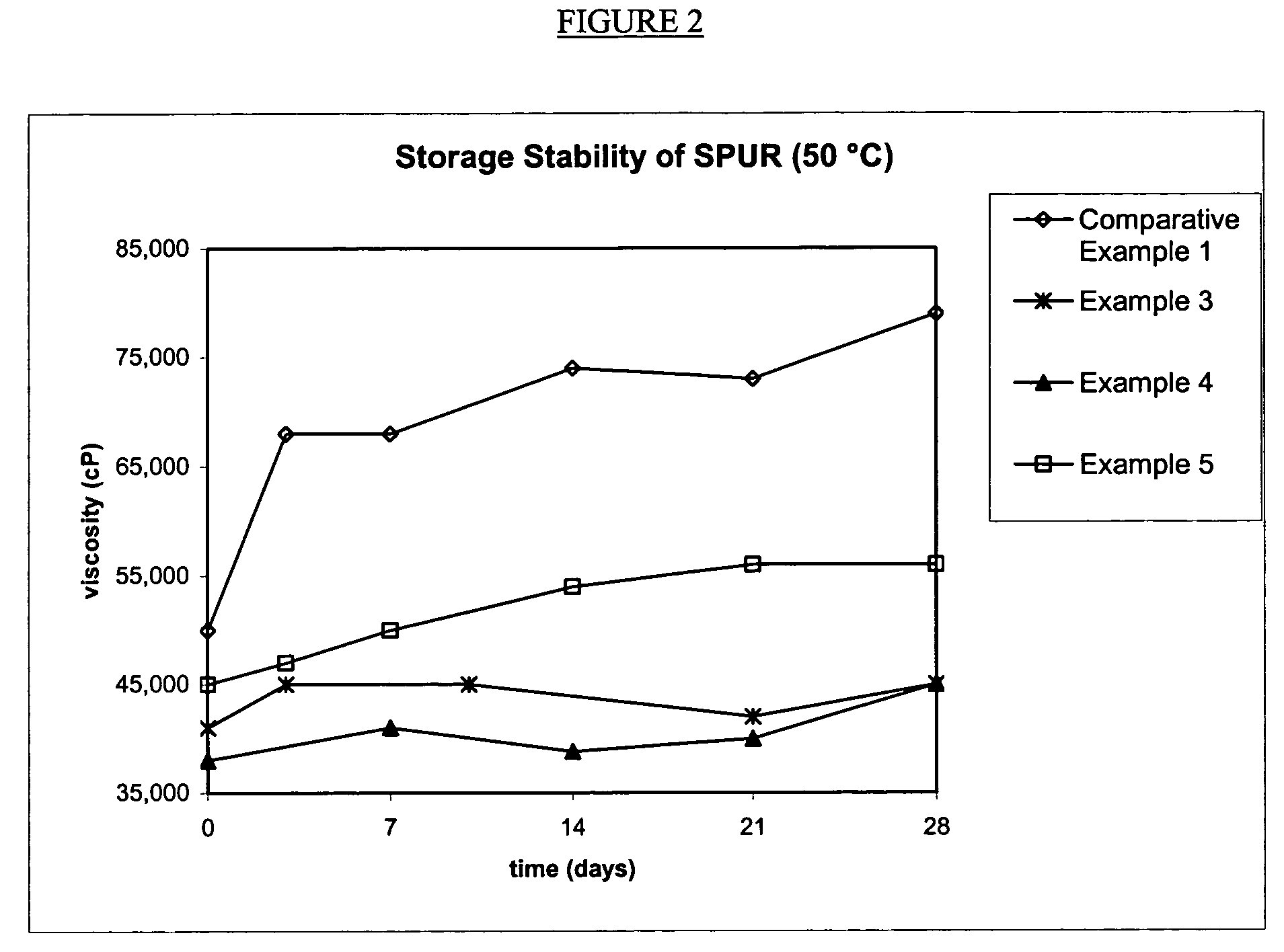

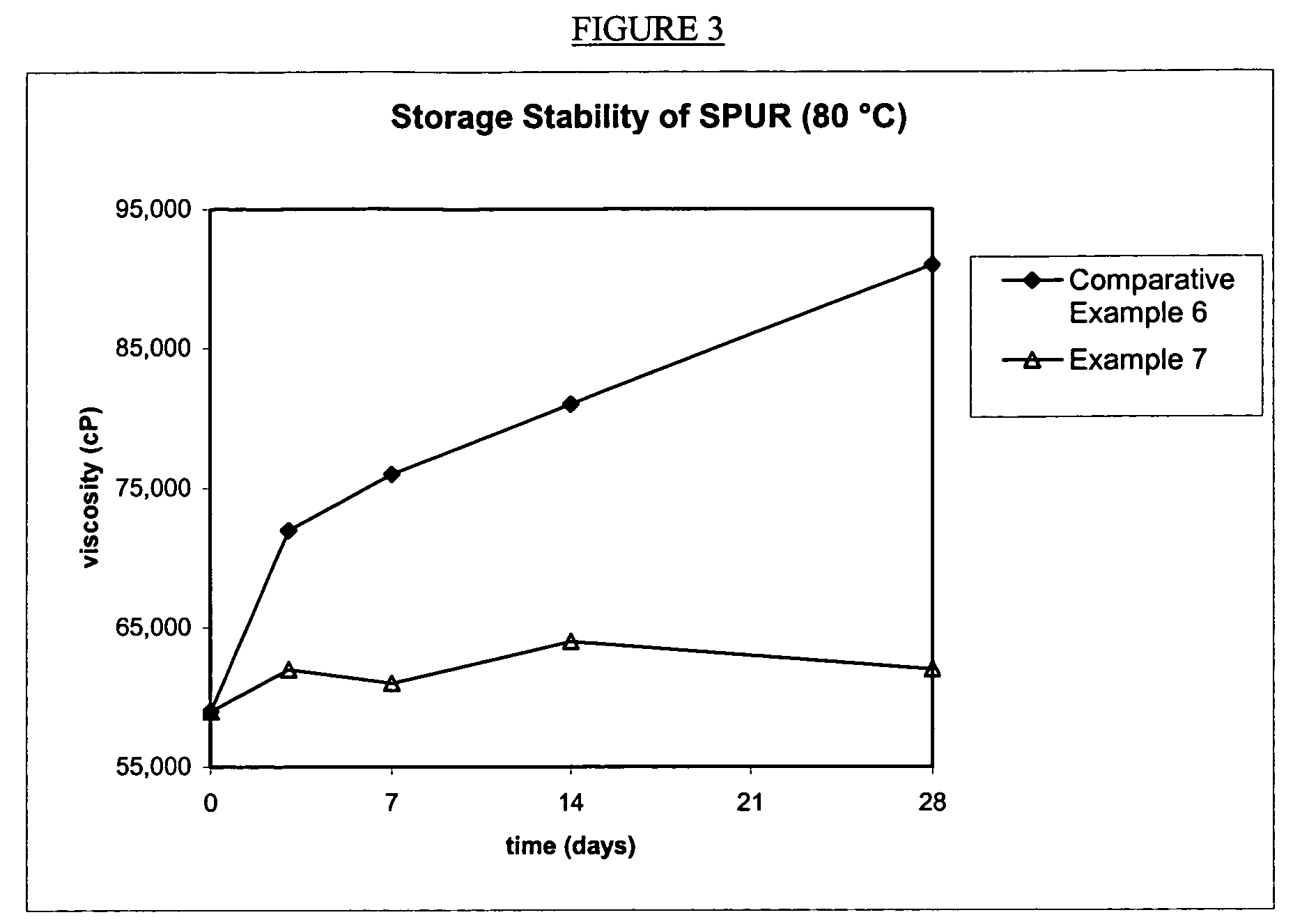

Process for preparing a curable silylated polyurethane resin

The present invention relates to a process for the production of silylated polyurethane resins free of unreacted residual isocyanate possessing consistent viscosity and stability and products therefrom.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Process for preparing a curable silylated polyurethane resin

The present invention relates to a process for the production of silylated polyurethane resins free of unreacted residual isocyanate possessing consistent viscosity and stability and products therefrom.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

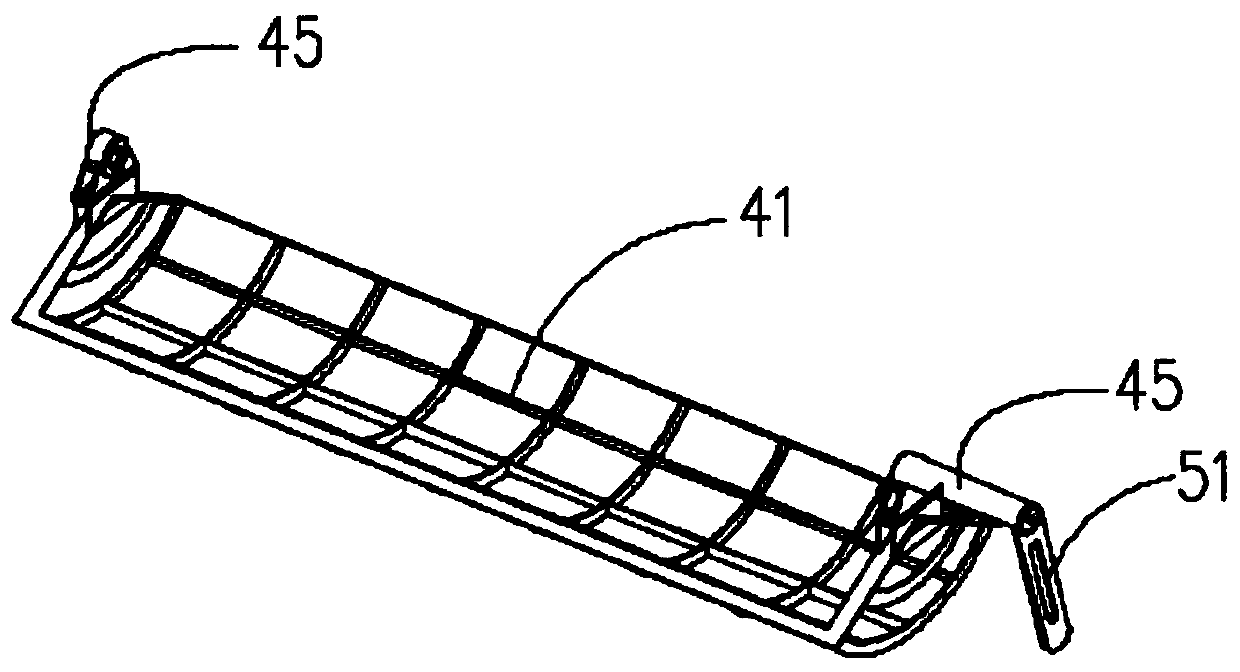

Three-roller coating printing unit for continuously coating surface of base material with viscous material

ActiveCN107350121AThin and uniform glue layerReduce usageLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses a three-roller coating printing unit for continuously coating the surface of a base material with a viscous material. The unit comprises a pressing roller, a driving silica gel roller and a driving steel roller which are stacked from top to bottom. The driving silica gel roller and the driving steel roller rotate in opposite directions, and a micron order gap is kept; the driving steel roller is soaked with a colloid pond containing the viscous material, the base material is arranged between the pressing roller and the driving silica gel roller, and the base material is supported on the supporting roller and moves in the centrifugal force direction of the top vertex of the driving silica gel roller under power traction. Under the effect that the viscous material is extruded, stretched and extended through rotating rollers with the two different rotating speeds and the opposite directions, a rubber layer of the certain thickness is formed on the surface of the rubber covered roller, the material is transferred to the surface of the continuously running base material by means of the pressing roller, the thin and uniform coating is formed, and materials of the micro order and submicron order thickness and thinner materials can be uniformly sprayed to the surface of the base material.

Owner:陕西浩合机械有限责任公司

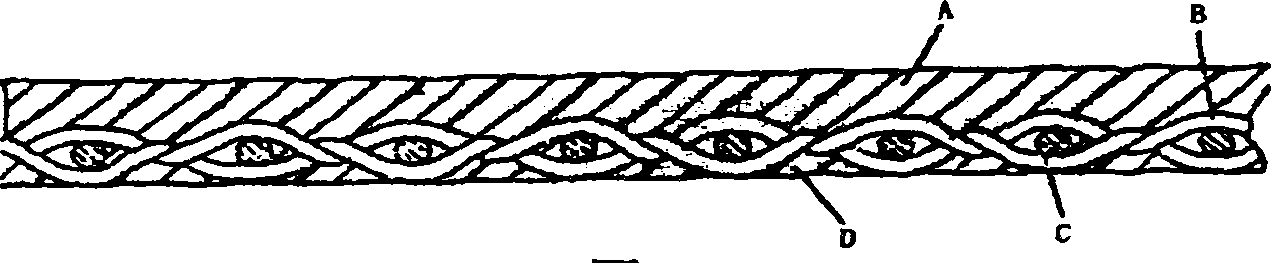

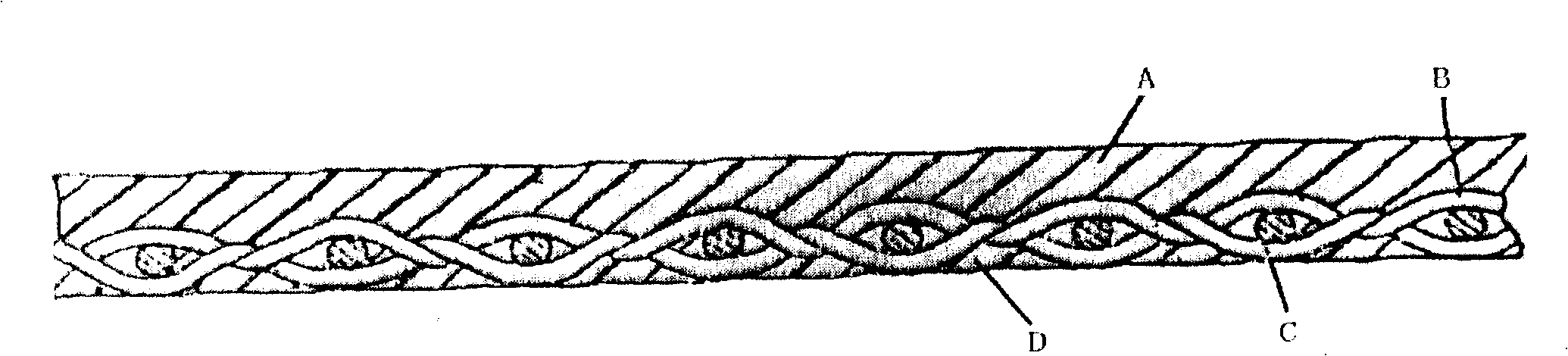

Aramid-spandex sheath-core composite fiber and preparation method thereof

ActiveCN106757508AIncrease elasticityImprove high temperature resistanceConjugated synthetic polymer artificial filamentsDry spinning methodsPolymer scienceSolid structure

The invention relates to an aramid-spandex sheath-core composite fiber and a preparation method thereof. The method is characterized in that a sheath layer spinning solution and a core layer spinning solution are simultaneously extruded in a sheath-core structure and subjected to dry spinning through a spinneret plate assembly of which a spinneret orifice is in a concentric circle form. A sheath layer of the aramid-spandex sheath core composite fiber is made of an aramid 1313 and a core layer is made of spandex; the section of the fiber is of a concentric circle solid structure; the sheath layer accounts for 5-20% of total weight of the fiber; the prepared aramid-spandex sheath core composite fiber has high resilience and also has high temperature resistance, chemical resistance and wear resistance; and meanwhile, the problems that the sheath layer aramid 1313 fiber is not easy to dye, the sheath-core composite fiber is difficult to spin and mold and the contact interface of the sheath layer and the core is easy to peel off are solved.

Owner:ZHEJIANG HUAFENG SPANDEX

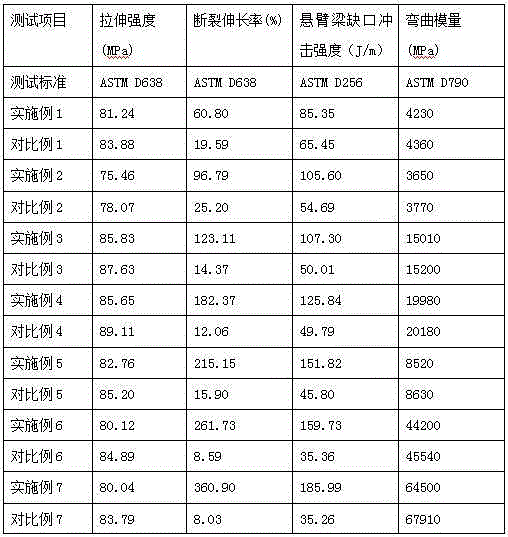

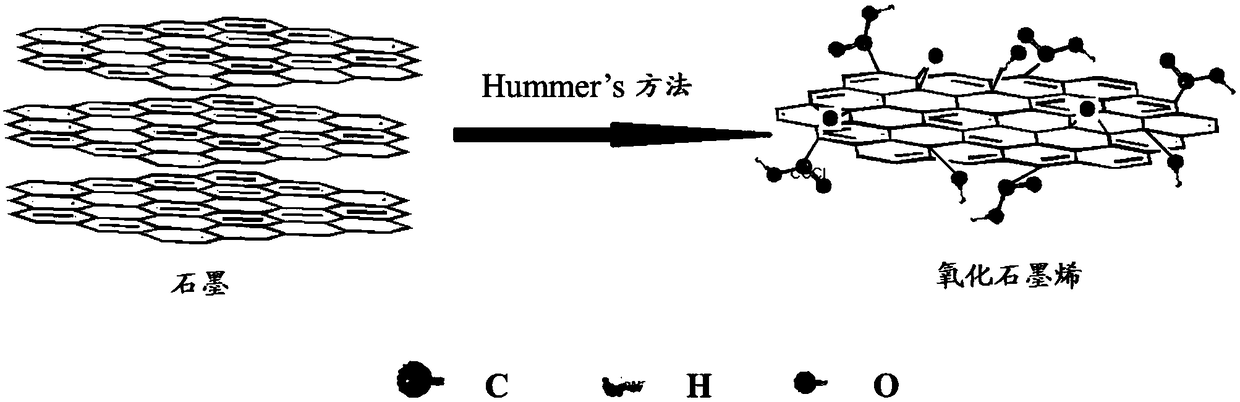

Nano composite material of graphene/nylon/elastomer and preparation method thereof

InactiveCN106478939AImprove performanceSolve the problem of fragmentationElastomerHigh volume manufacturing

The invention discloses a preparation method of a graphene / nylon / elastomer nano composite material. The preparation method comprises the following steps: at first, pre-dispersing graphene in molten polyamide monomers; then adding a catalyst and an activator into the mixed melt of pre-dispersed graphene / polyamide monomers, mixing to obtain a blended solution; adding the blended solution into an extruder, carrying out reactions, extruding the reaction products, carrying out granulation to obtain the master batch of a graphene / nylon nano composite material; adding the abovementioned master batch and elastomer master batch into the extruder, melting, blending, and extruding the mixture to obtain the graphene / nylon / elastomer nano composite material. Graphene is evenly dispersed in the graphene / nylon / elastomer nano composite material. The industrial massive production of the nano composite material is realized. The phenomenon that the toughness of a composite material degrades due to added graphene is greatly relieved. Compared with pure nylon, the mechanical properties such as strength, toughness, modulus, and the like, and thermal properties such as thermal degradation temperature and the like, of the provided nano composite material are prominently improved, and thus the application range is enlarged.

Owner:HEFEI GENIUS NEW MATERIALS

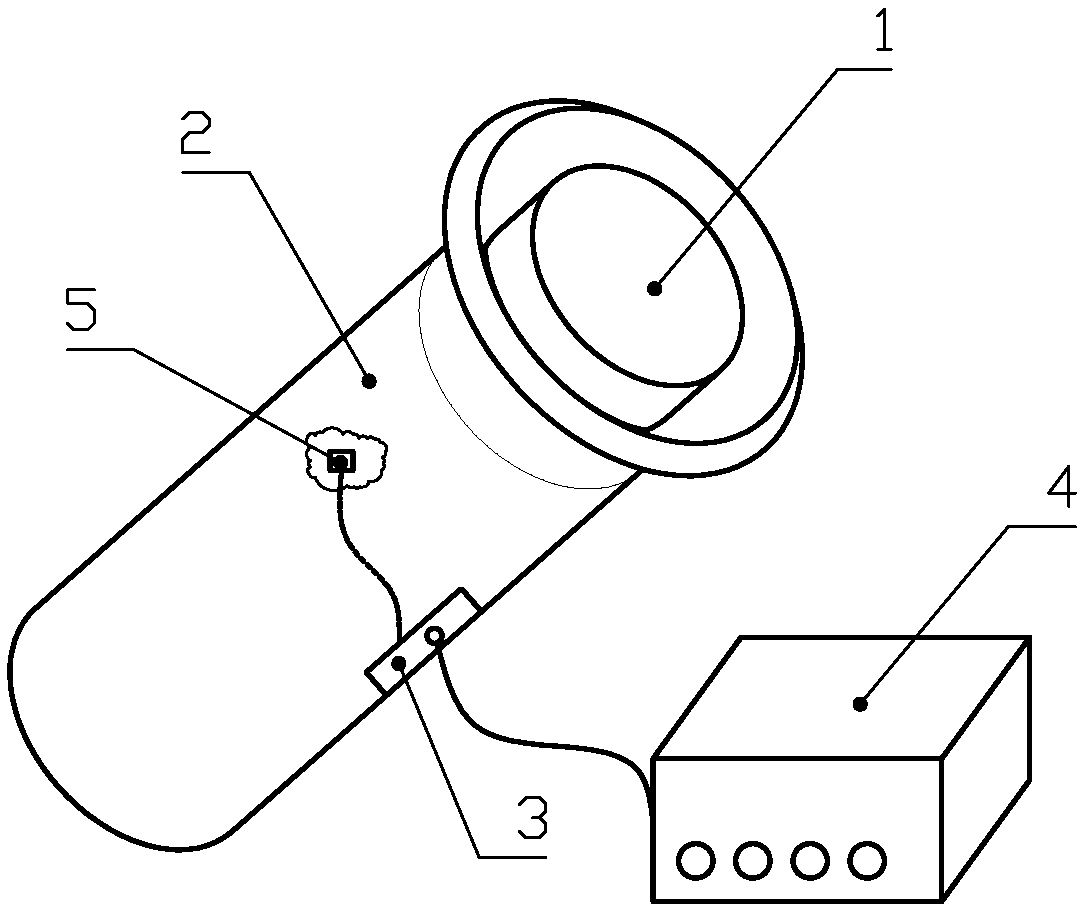

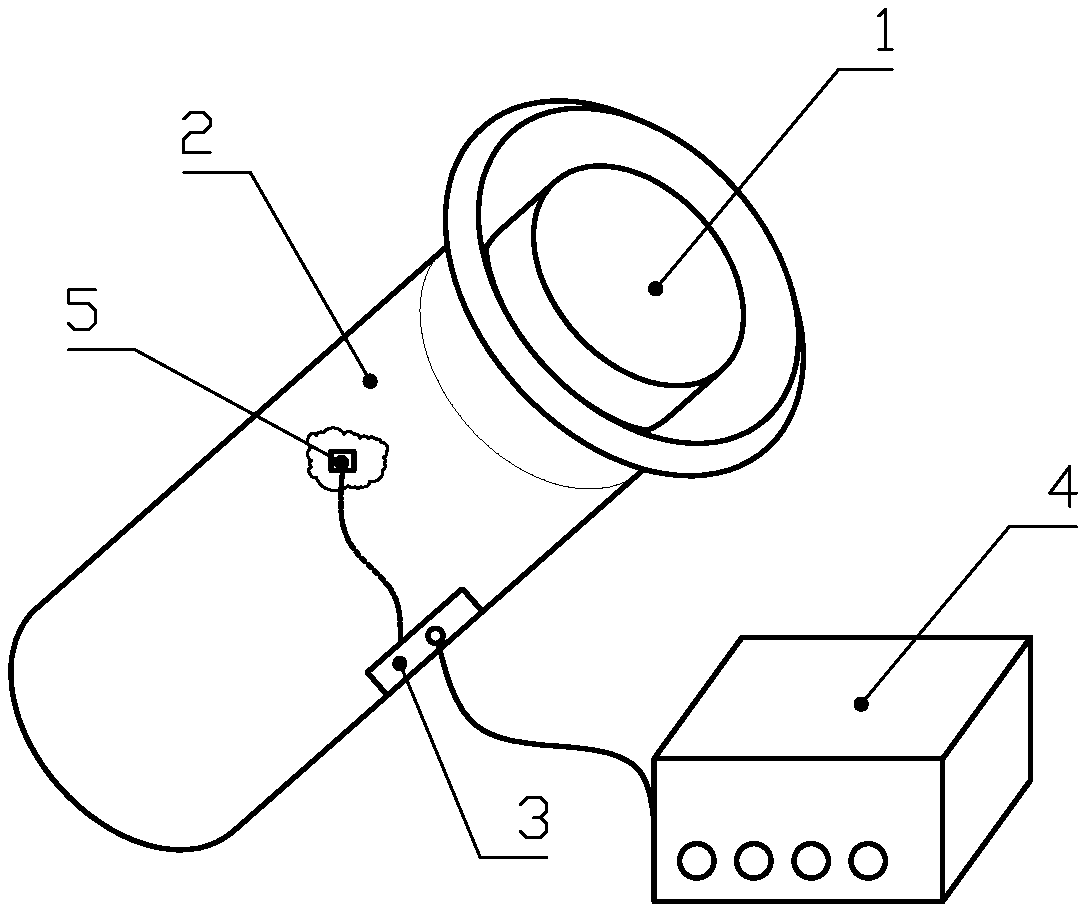

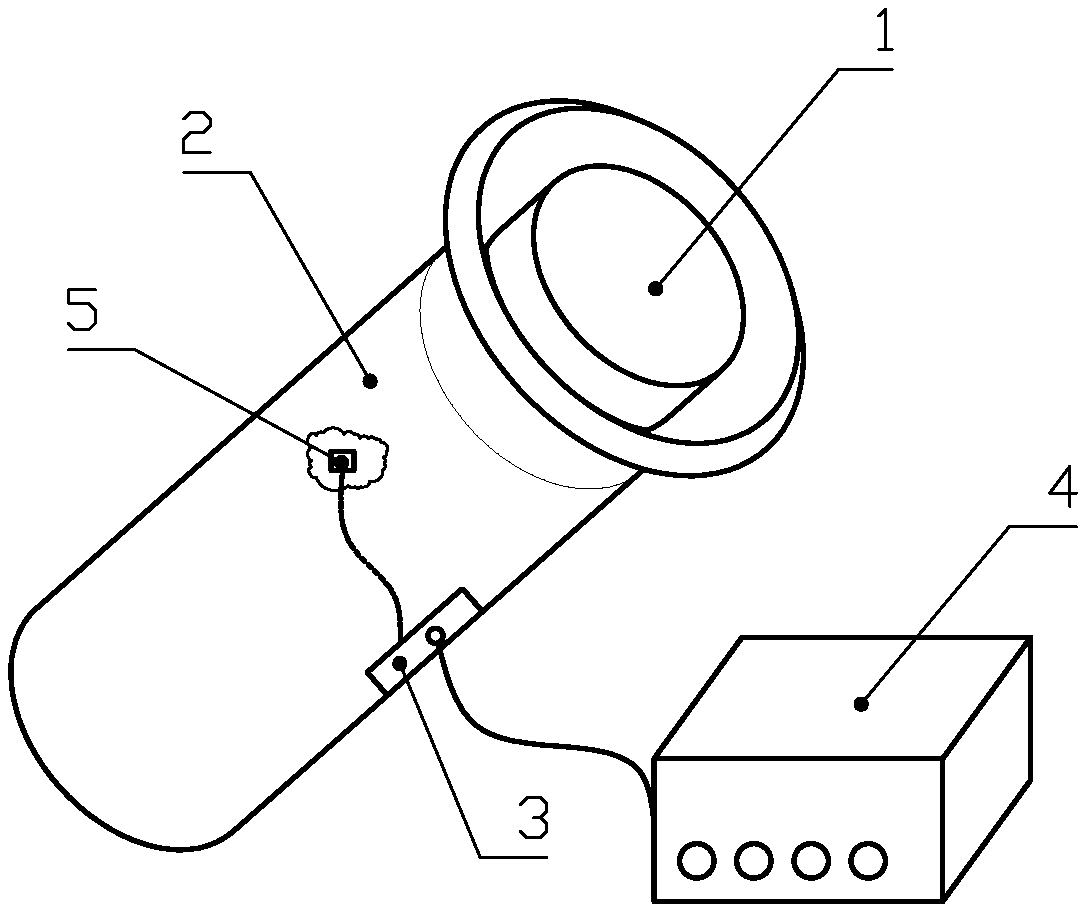

Glue dispensing process

InactiveCN107694867AConsistent viscosityConsistent dispensing volumeLiquid surface applicatorsCoatingsSilver pasteBobbin

The invention discloses a glue dispensing process, mainly a glue dispensing process in chip loading. A constant-temperature heater is used for performing constant-temperature heating control on a cylinder tube of electric conducting silver pulp, so that the temperature of the electric conducting silver pulp in the use process is kept at 33-35 DEG C, and is near a final working temperature of 35 DEG C; and the viscosity of the electric conducting silver pulp in working is relatively constant, so that the glue dispensing quantity in the glue dispensing process is constant. Meanwhile, through standardization of operating steps and process conditions, the stability of the glue dispensing operation is guaranteed, the chip loading quality stability and reliability are finally guaranteed, and theyield is increased.

Owner:江阴苏阳电子股份有限公司

Process and compositions for making optical fiber gels

A process of forming a gel for gel packed transmission cable comprising the steps of dissolving a high molecular weight polymer in oil and thereafter through the use of a rotor and stator mixer effectively incorporating a colloidal silica(s) into the polymer in oil composition. Compositions made from this process having optimized viscosity are also claimed.

Owner:THE LUBRIZOL CORP

Highly effective slurry phase bed reactor

InactiveCN1283349CEasy to operateAvoid easy cloggingChemical/physical processesGas solidSlurry reactor

Owner:TAIYUAN UNIV OF TECH

Process for preparing perfluorinated sulfonic resin solution by using waste ion exchange membrane in chlor-alkali industry

The invention discloses a method for preparing perfluoro sulfonic resin with abandoned ion exchange membrane in alkali-chloride industry, comprising following steps: swelling said abandoned ion with lower alcohol, emulsifying it with emulsion machine to resin particle, adding alcohol / water solvent and resin particle into autoclave, dissolving resin particle under high temperature and pressure and protection of nitrogen; getting solid mixture of perfluoro sulfonic resin and solution, separating with solid-liquid separation method and getting perfluoro sulfonic resin solution and solid perfluoro sulfonic resin. The resin solution is characterized by transparent, low content of foreign matter, high purity, similar property to that of Nafion EW 1100 solution, usage in field of mending ionic membrane pinhole and other mechanical damage, preparation of fuel battery proton exchange membrane and stereoscopic electrode and chemical catalysis.

Owner:SUNRISE POWER CO LTD

Ccheap and practical garment fabrics and processing method thereof

InactiveCN109023655AMeet the requirementsMeet purchasing powerWeft knittingBiochemical fibre treatmentPolyesterHuman body

The invention discloses cheap and practical garment fabrics. The original materials comprises following fibers in a blended manner of: 30-50 parts by weight of cotton fibers, 20-40 parts by mass of modal fibers, 10-20 parts by mass of acetate rayon fibers, 10-30 parts by mass of chitin fibers, 5-10 parts by mass of dacron fibers, 5-15 parts by mass of spandex and 10-15 parts by mass of acrylic fibers. The invention relates to the technical field of garment processing. According to the invention, raw materials comprise following fibers in a blended manner of: 30-50 parts by weight of cotton fibers, 20-40 parts by mass of modal fibers, 10-20 parts by mass of acetate rayon fibers, 10-30 parts by mass of chitin fibers, 5-10 parts by mass of dacron fibers, 5-15 parts by mass of spandex and 10-15 parts by mass of acrylic fibers; the fabrics have the advantages of polyester fiber garments, and have antimicrobial and radio-resistance functions and various kinds of 'green and health care' functions, are safe, effective, and are non-toxic, harmless and non-polluted to human body and environment; requirements of green textiles are met; and the fabrics are cheap, so buying ability of more buyers is met, and sales quantity is improved.

Owner:宁波元元之傲针织织造有限公司

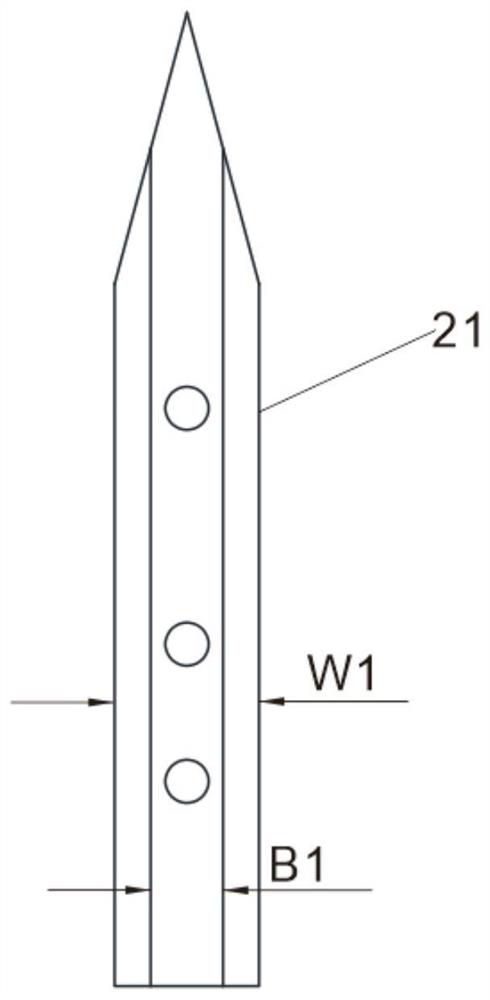

Surface treatment method of dental implant

InactiveCN107157603AImprove stabilityConsistent pH levelsDental prostheticsDrugs solutionSurface cleaning

The invention discloses a surface treatment method of a dental implant; the method is applicable to surface treatment of a dental implant, the treated dental implant gains enlarged contact area and improved binding force with alveolar bone, and the stability of the implant is enhanced. The method comprises: pre-cleaning the surface of the finished dental implant to remove surface metal debris, impurities, oil and the like, soaking the dental implant in a solution of iron chloride, ammonium nitrate, citric acid, glycerol and purified water in a mass ratio of 1:0.5:1:50:50:20, wherein the purity of the drug solution needs to be not less than level III (chemical purity), and treating the surface of the dental implant in an ultrasonic oscillator so that surface treatment uniformity is guaranteed.

Owner:XIAN CONTINENTAL BIOMATERIALS CO LTD

A kind of aramid-spandex sheath-core composite fiber and preparation method thereof

ActiveCN106757508BIncrease elasticityImprove high temperature resistanceConjugated synthetic polymer artificial filamentsDry spinning methodsPolymer scienceSolid structure

The invention relates to an aramid-spandex sheath-core composite fiber and a preparation method thereof. The method is characterized in that a sheath layer spinning solution and a core layer spinning solution are simultaneously extruded in a sheath-core structure and subjected to dry spinning through a spinneret plate assembly of which a spinneret orifice is in a concentric circle form. A sheath layer of the aramid-spandex sheath core composite fiber is made of an aramid 1313 and a core layer is made of spandex; the section of the fiber is of a concentric circle solid structure; the sheath layer accounts for 5-20% of total weight of the fiber; the prepared aramid-spandex sheath core composite fiber has high resilience and also has high temperature resistance, chemical resistance and wear resistance; and meanwhile, the problems that the sheath layer aramid 1313 fiber is not easy to dye, the sheath-core composite fiber is difficult to spin and mold and the contact interface of the sheath layer and the core is easy to peel off are solved.

Owner:ZHEJIANG HUAFENG SPANDEX

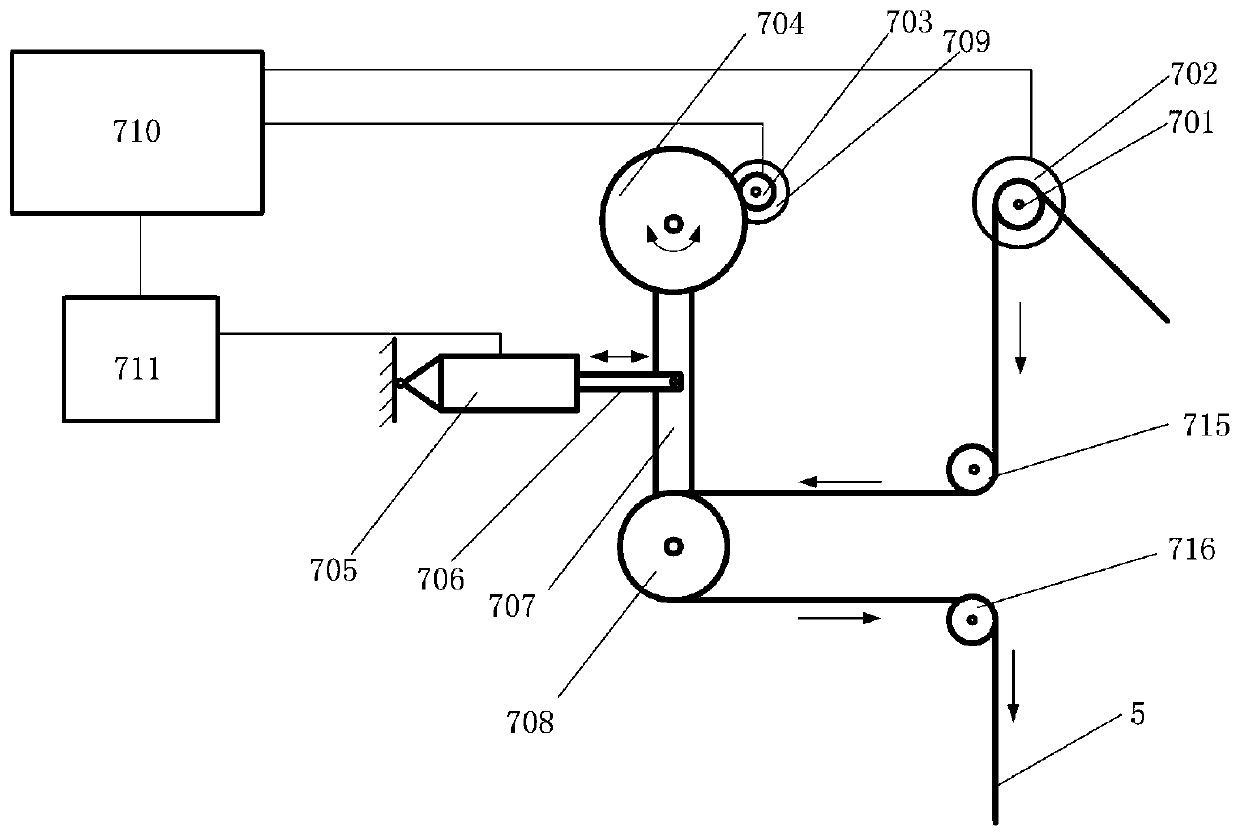

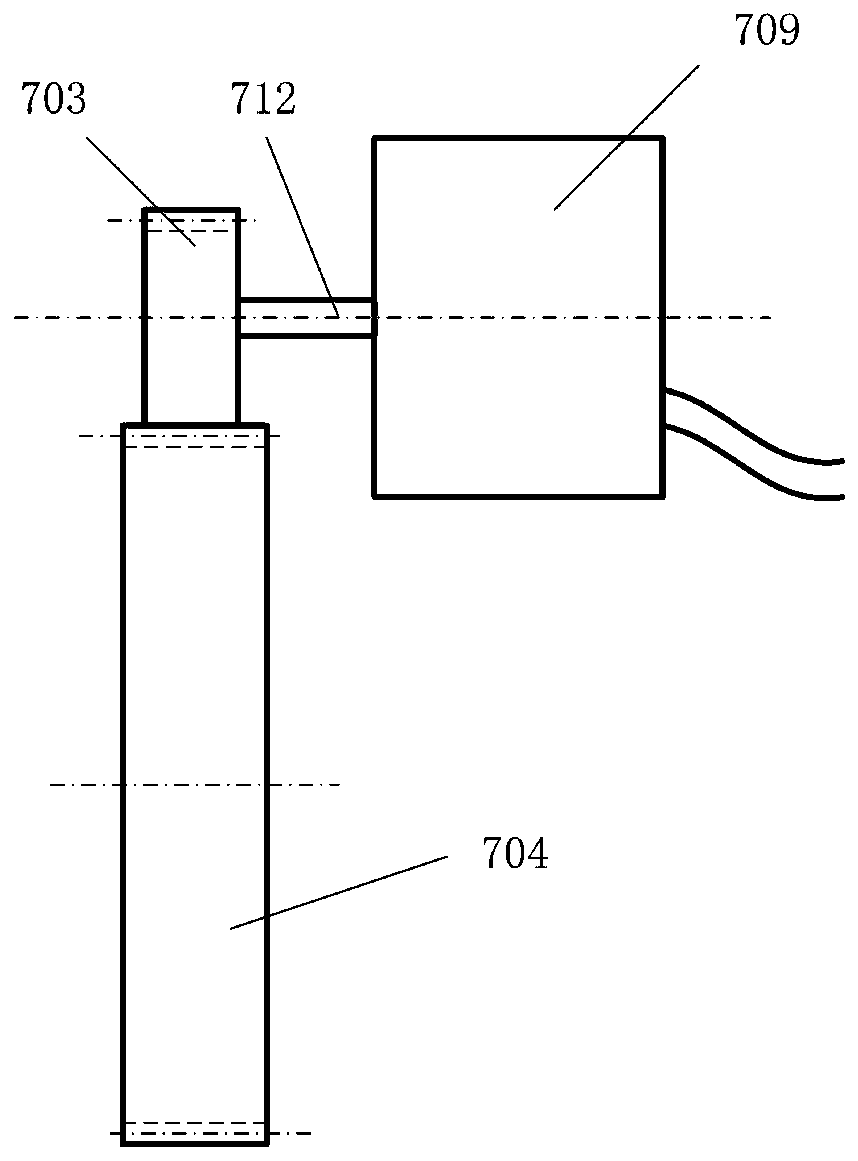

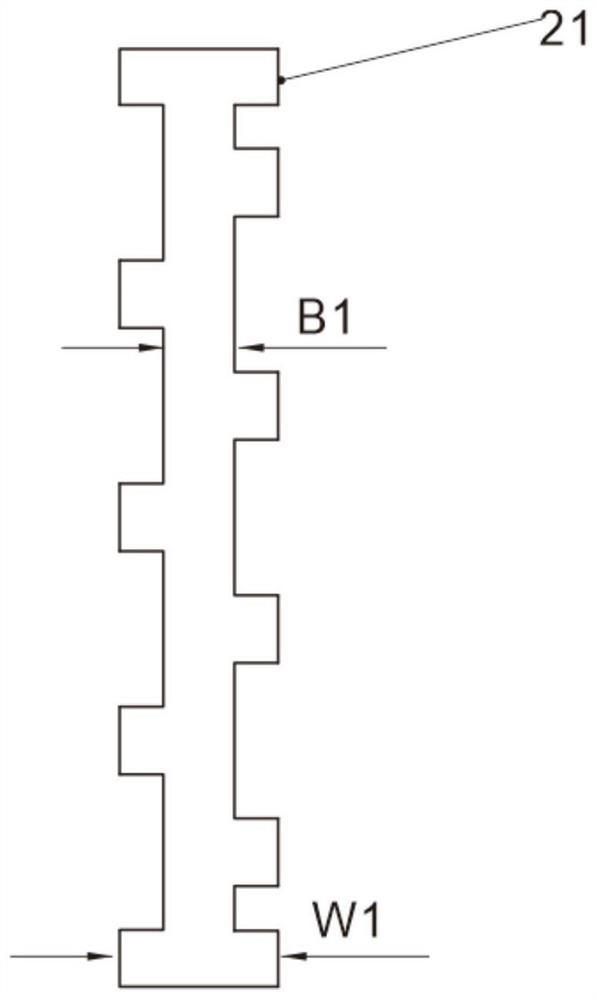

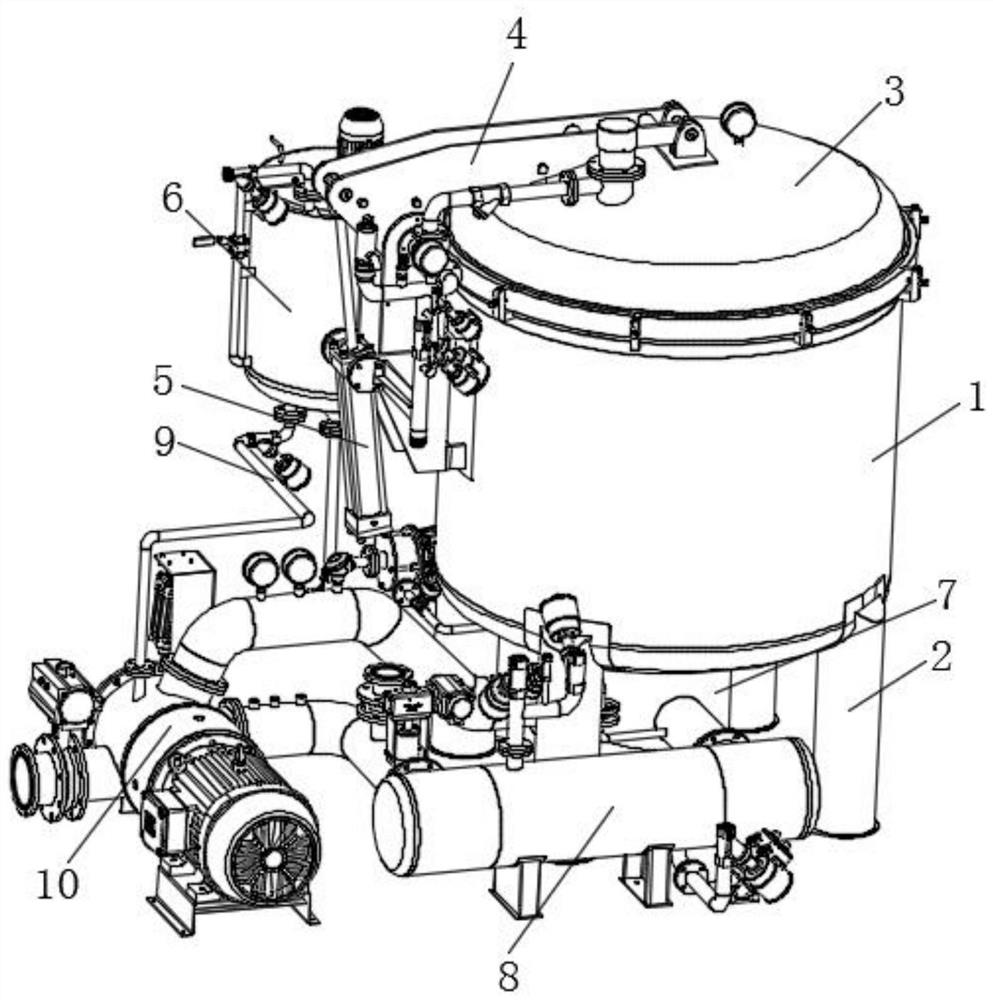

Slurry turnover tank and method avoiding viscosity difference of slurry in turnover tank

InactiveCN108016764AConsistent viscosityGuarantee statusLarge containersRotary piston pumpsSlurryVolumetric Mass Density

The invention discloses a slurry turnover tank and a method avoiding the viscosity difference of slurry in the turnover tank. The slurry turnover tank comprises a tank body. The upper portion of the tank body is connected with a slurry feeding pipe, and the bottom of the tank body is connected with a slurry discharging pipe. A plurality of circulation pipes are evenly distributed on the circumference of the outer portion of the tank body and provided with pumps. The circulation pipes are vertically arranged, and the upper ends and the lower ends of the circulation pipes communicate with the interior of the tank body. The slurry turnover tank and the method avoiding the viscosity difference of slurry in the turnover tank have the beneficial effects that up-down circulation of slurry in theturnover tank can be achieved, it is guaranteed that slurry at the top and slurry at the bottom are consistent in viscosity, and a foundation is laid for coating face density stability; bubbles can beeffectively prevented from being guided into the slurry, and the slurry state is guaranteed; and production noise can be effectively lowered through usage of screw pumps.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

Frame sealant, liquid crystal panel, liquid crystal display and preparation method

ActiveCN105542685BConsistent viscosityHigh viscosityAdhesive processesNon-macromolecular adhesive additivesDisplay deviceElectrical conduction

Owner:BOE TECH GRP CO LTD +1

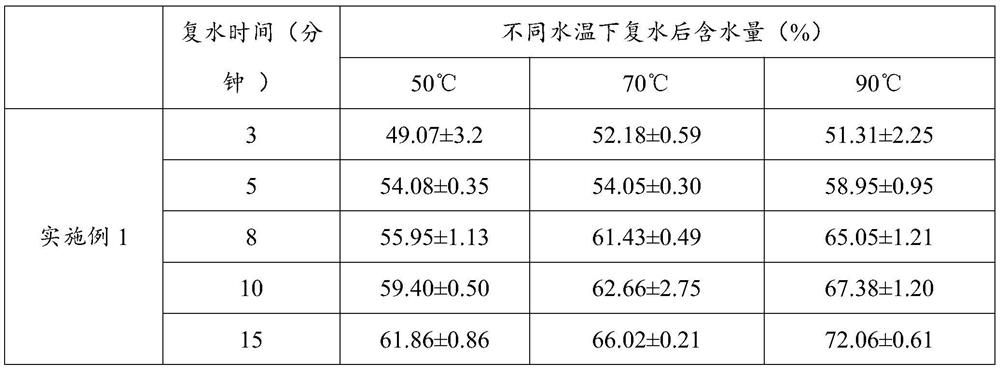

Vacuum freeze-drying method and preparation method of freeze-dried instant rice noodles

ActiveCN114651932AReduce water temperatureHigh rehydration rateFood freezingDrying solid materials without heatBiotechnologyFreeze-drying

The invention belongs to the technical field of food. The invention provides a vacuum freeze-drying method of freeze-dried instant rice noodles. According to the freeze-dried instant rice noodles disclosed by the invention, the contradiction that the rice starch increases pores and inhibits retrogradation is relieved by adopting a process step of slowly drying at a freezing temperature, so that the prepared freeze-dried instant rice noodles are high in rehydration rate and short in rehydration time, and the instant rice noodles only need to be soaked for 5-10 minutes; according to the freeze-dried instant rice noodles prepared by the vacuum freeze-drying method disclosed by the invention, the texture characteristics of hardness, viscosity, elasticity, adhesiveness and chewiness after rehydration are basically consistent with the taste of fresh and wet rice noodles. No modified material is added when the rice noodles are prepared, meanwhile, high efficiency and energy conservation are realized by adopting the temperature of-40 DEG C to 45 DEG C in the vacuum freeze-drying process, and the processing cost of the freeze-dried instant rice noodles is reduced.

Owner:AGRO PROD PROCESSING RES INST YAAS

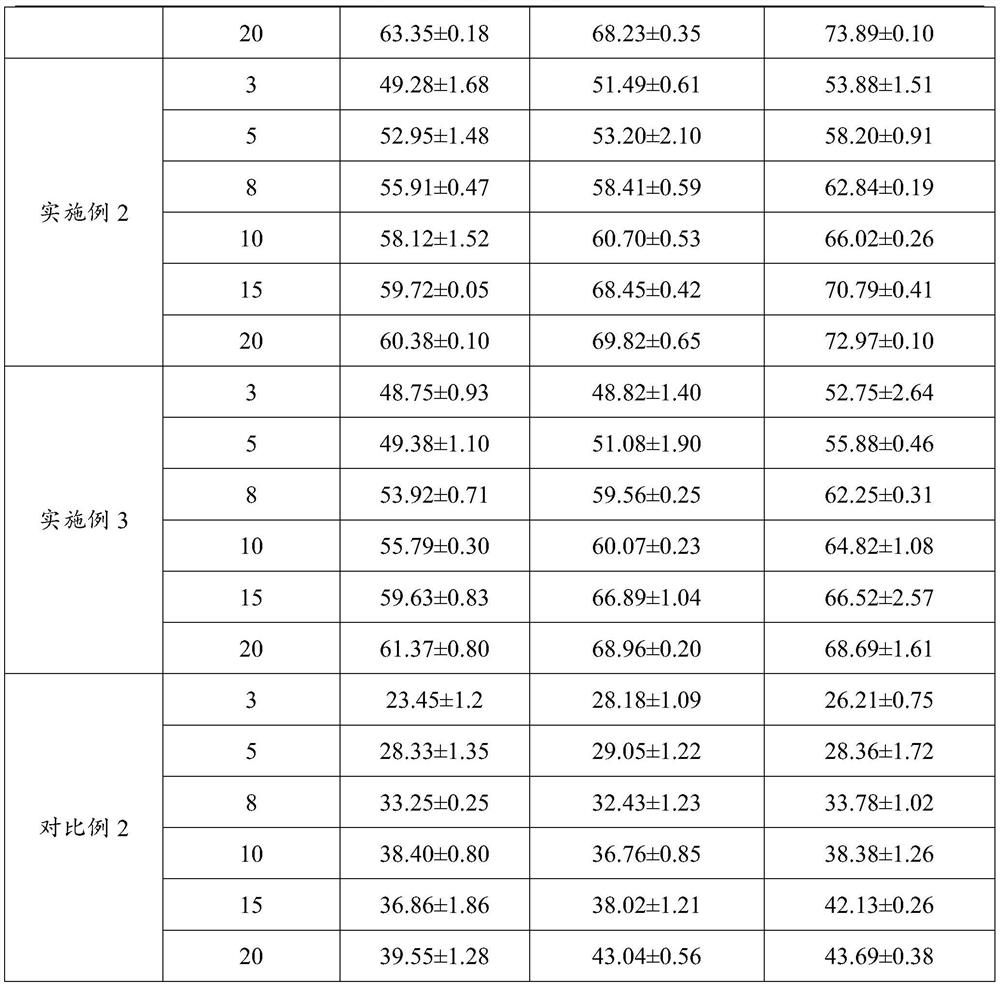

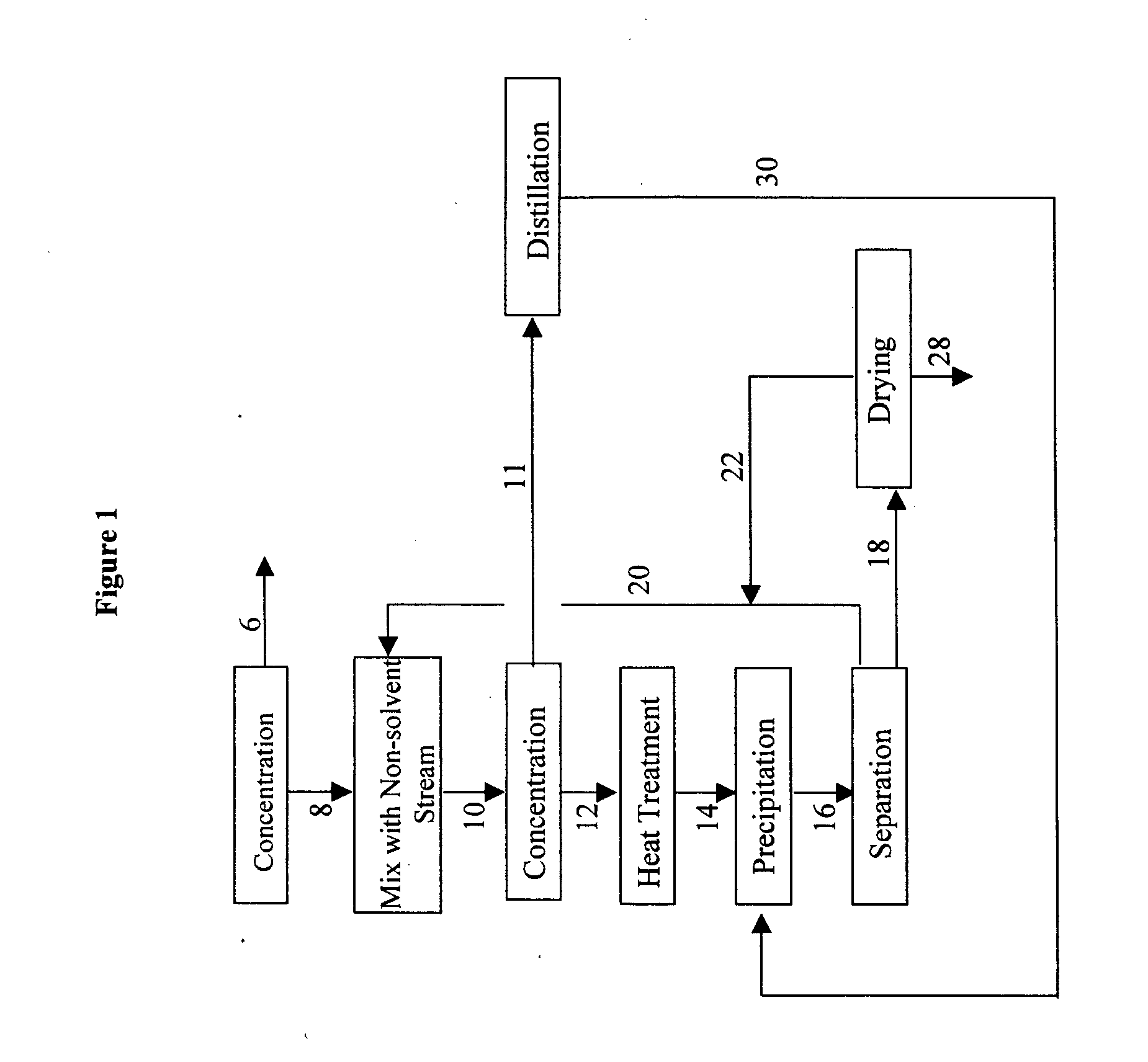

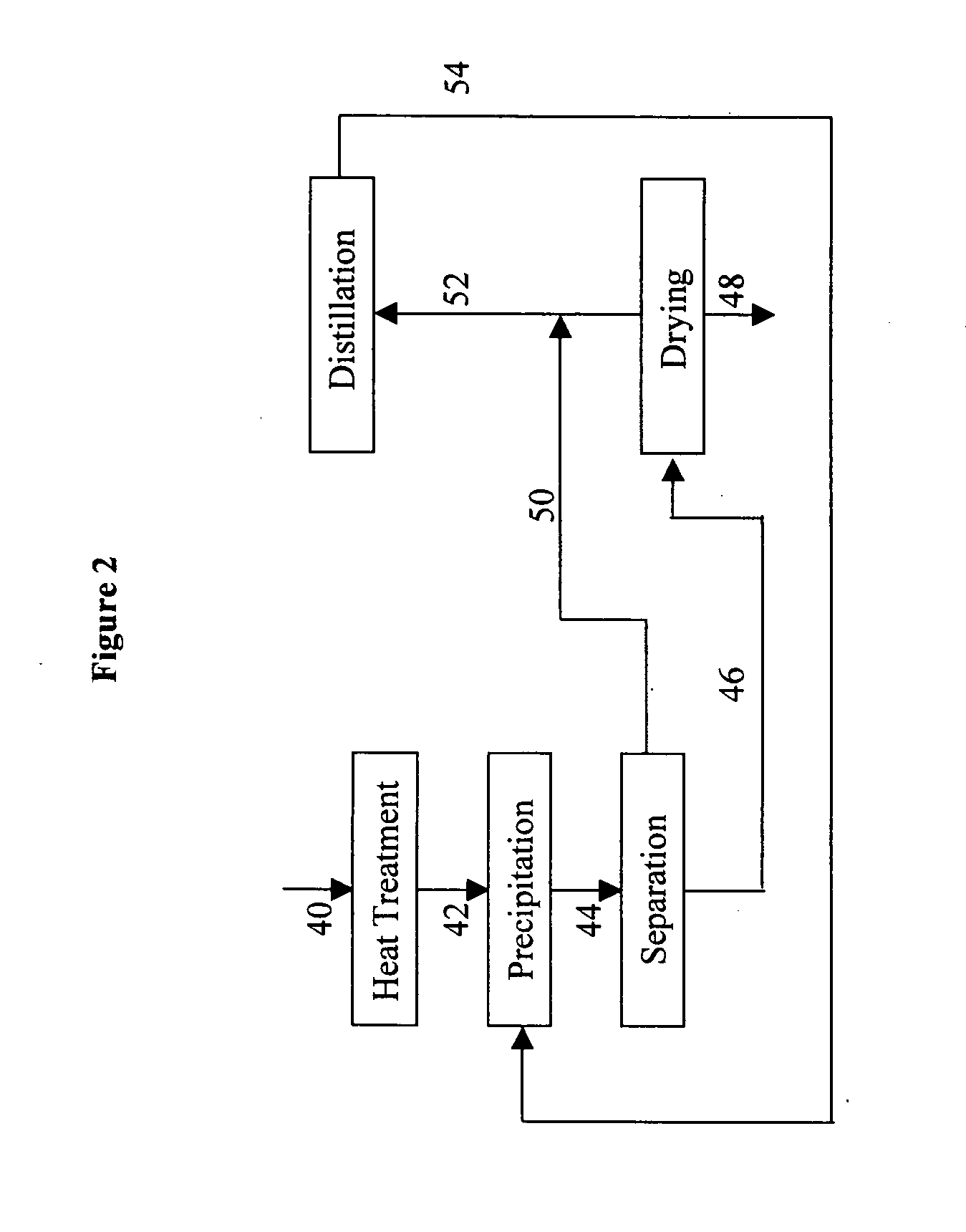

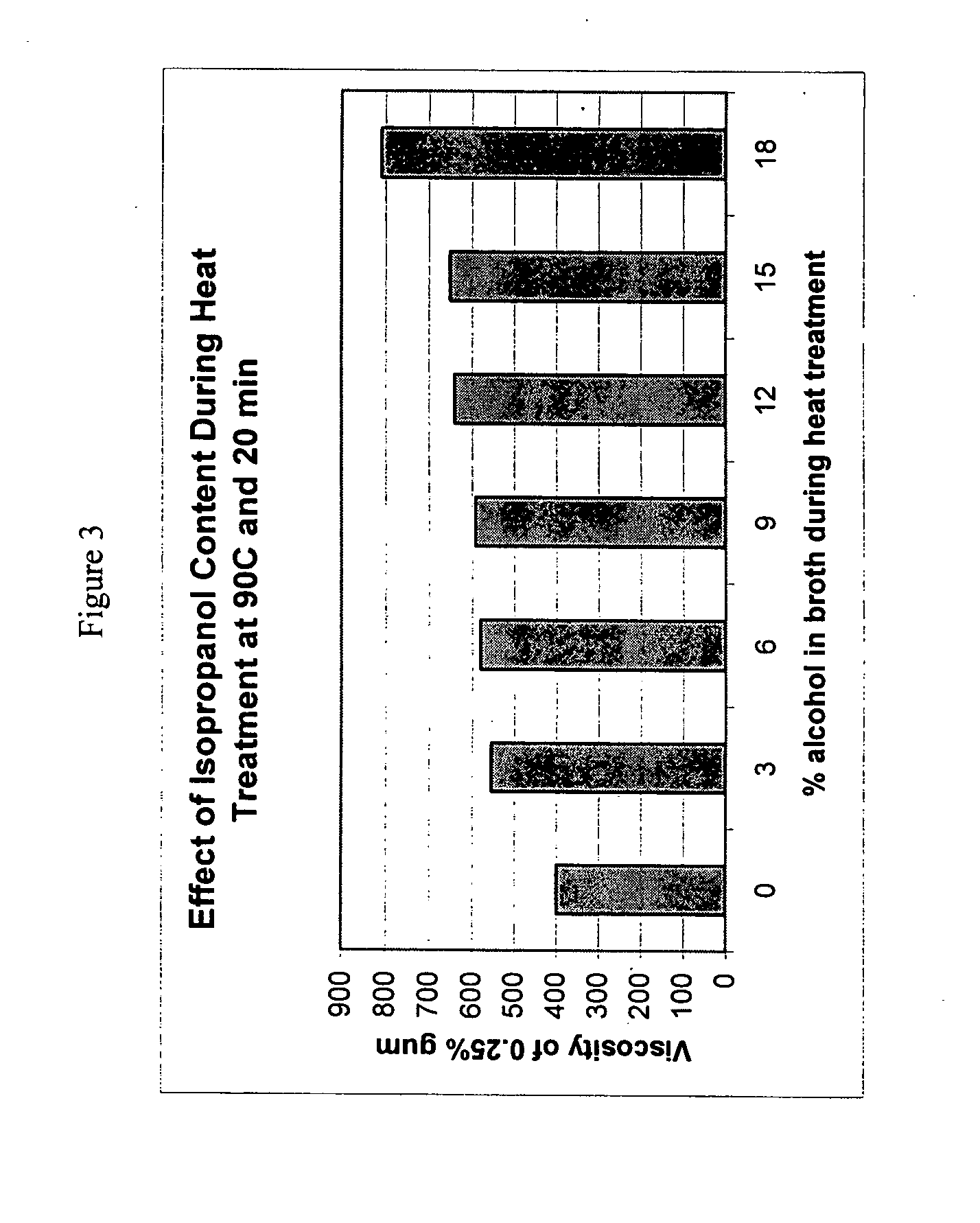

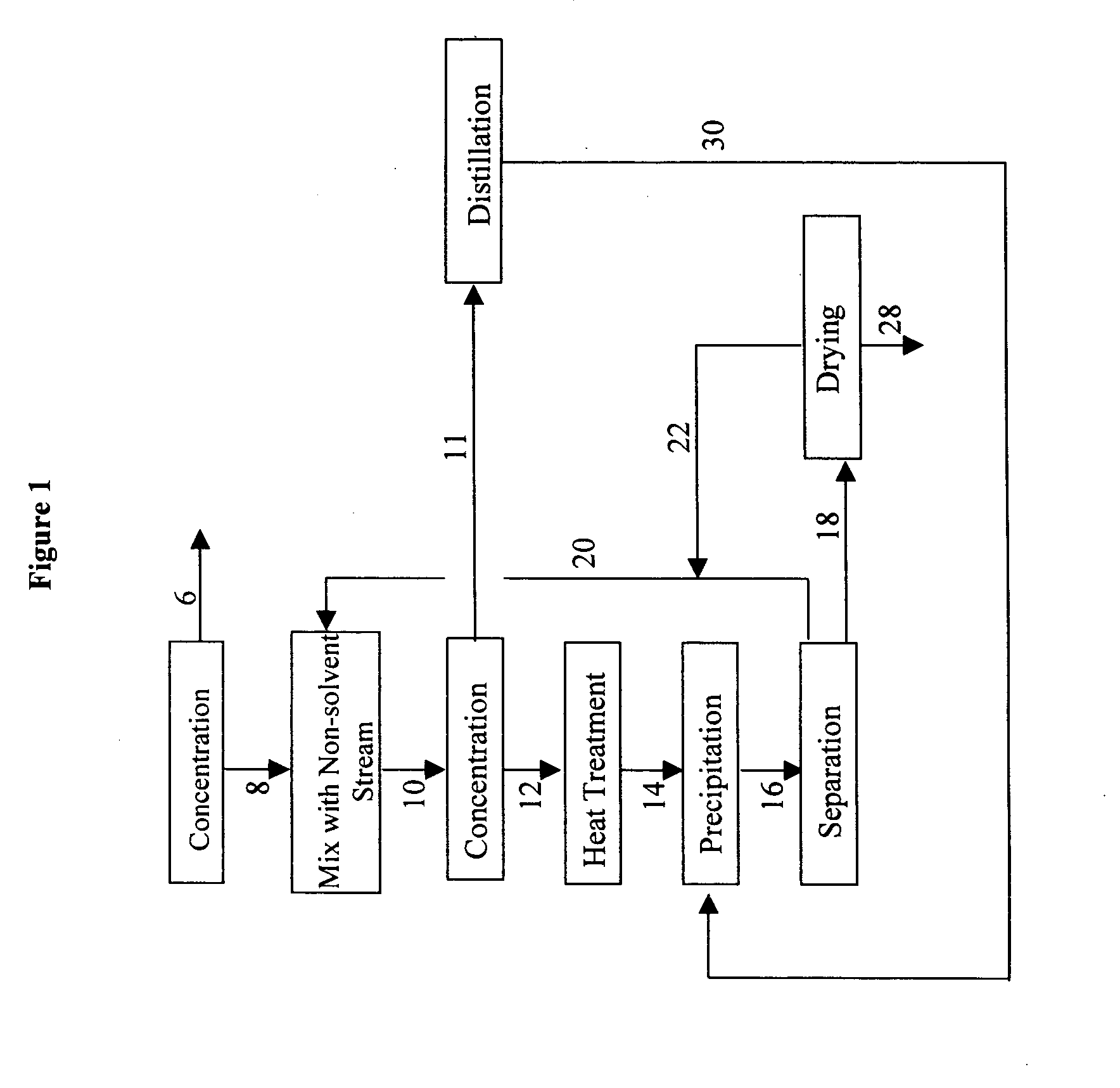

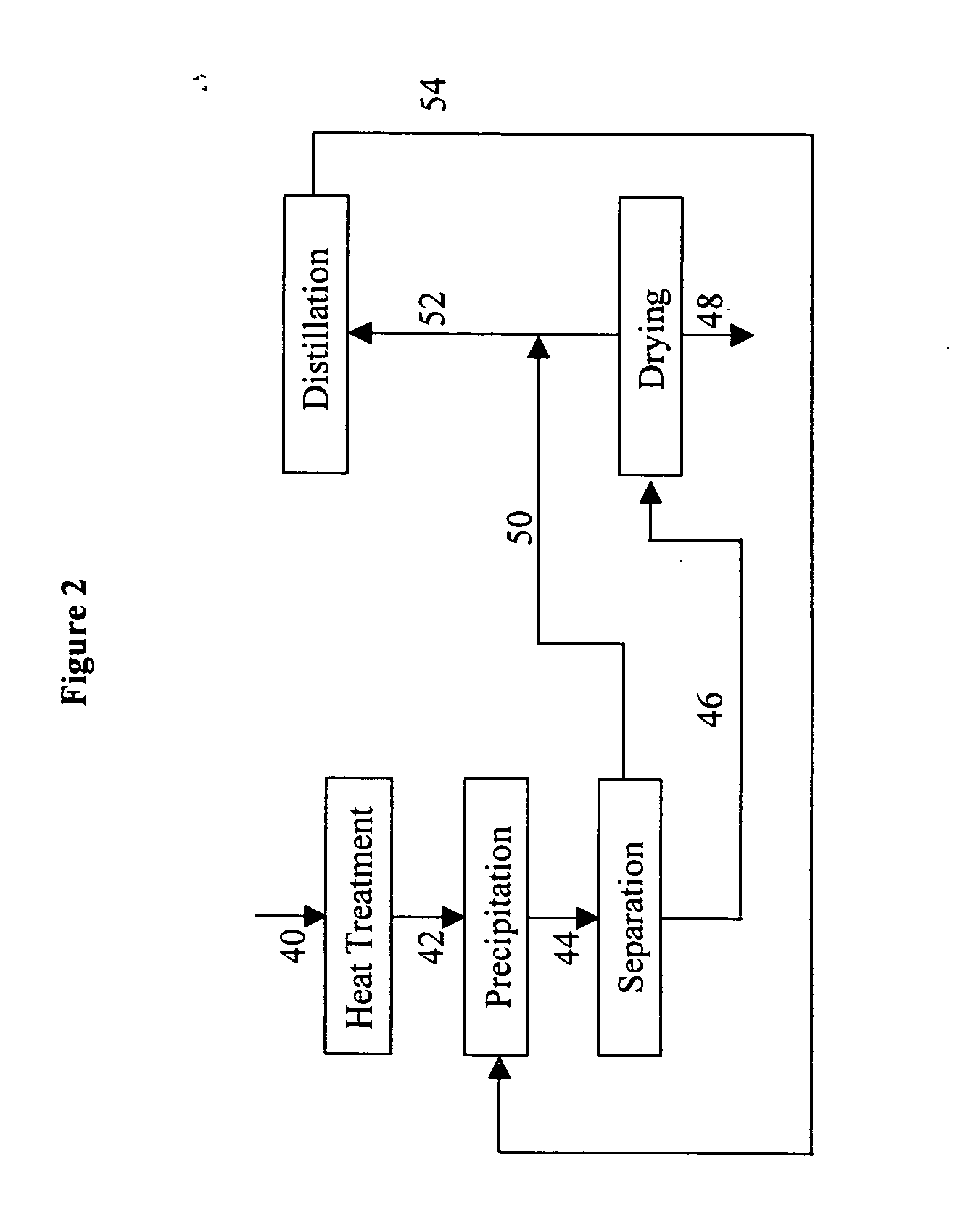

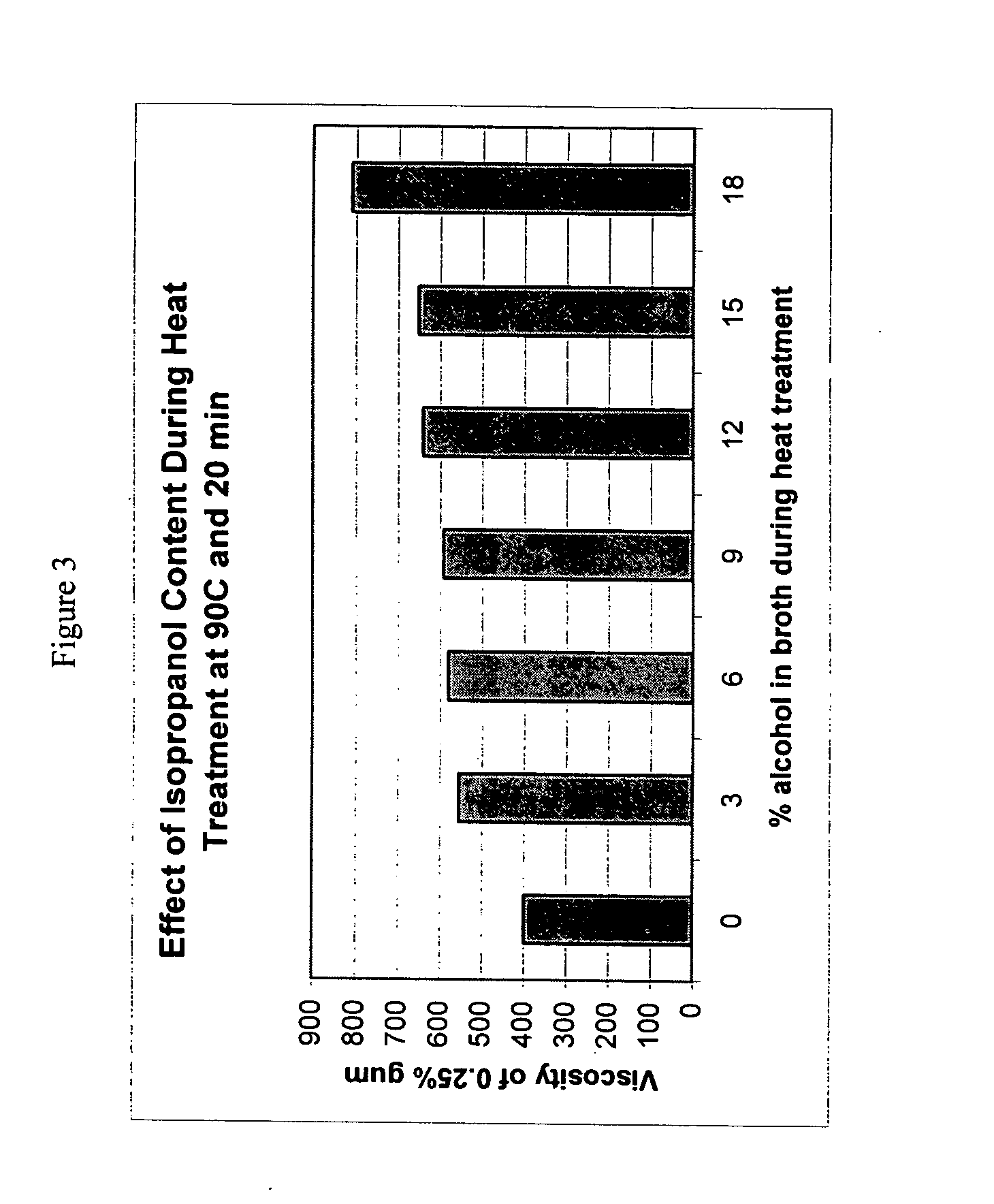

Polysaccharide gum and process for its manufacture

InactiveUS20050038241A1High viscosityQuality improvementSugar derivativesSugar derivatives preparationNon solventProcess engineering

Processes are disclosed for the purification and recovery of polysaccharide gums from an aqueous solution, particularly xanthan gum from a fermentation broth. An aqueous solution of at least one polysaccharide gum is mixed with a non-solvent stream comprising water and a subprecipitant level of a non-solvent of the polysaccharide gum. The mixture is concentrated to increase the polysaccharide gum concentration, and optionally undergoes a heat treatment. Additional non-solvent is added to the concentrated mixture to precipitate the polysaccharide gum. The precipitated gum is dried after being separated from the liquid component of the mixture. The removed liquid component can be recycled to the earlier step in the process in which the polysaccharide gum solution is mixed with the non-solvent stream.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

Dispensing process

InactiveCN111081565AConsistent viscosityConsistent dispensing volumeSolid-state devicesSemiconductor/solid-state device manufacturingSilver pasteProcess engineering

The invention relates to a dispensing process, in particular, a dispensing process during chip mounting. A constant-temperature heater is used for carrying out constant-temperature heating control onthe tube of conductive silver paste, it is guaranteed that the temperature of the conductive silver paste is kept at 33-35 DEG C and is close to final working temperature 35 DEG C in a using process,it is guaranteed that the viscosity of the conductive silver paste is relatively consistent in a working process, and therefore, it is guaranteed that a dispensing amount is consistent in a dispensingoperation process. And meanwhile, by means of standardizing operation steps and process conditions, the stability of dispensing operation is ensured, the stability and reliability of chip mounting quality are finally ensured, and the rate of finished products is increased.

Owner:江阴苏阳电子股份有限公司

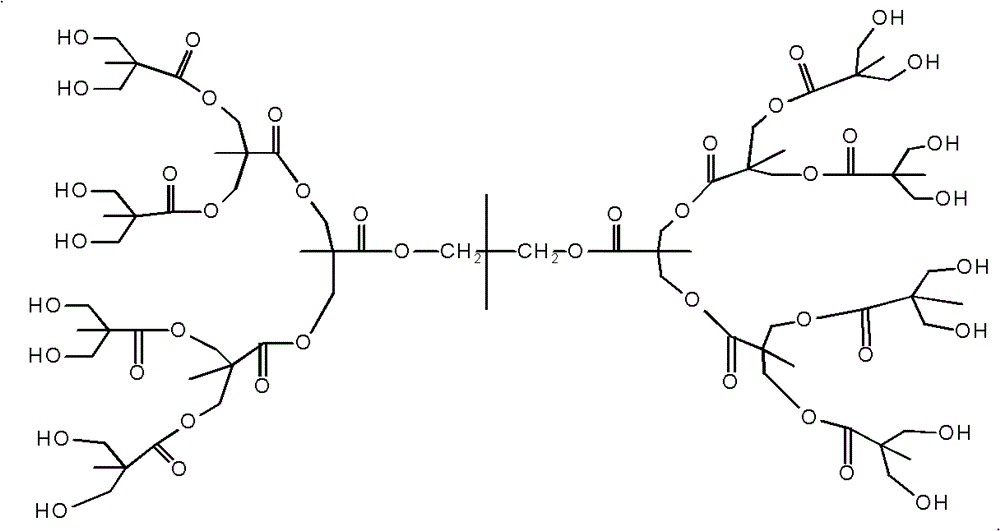

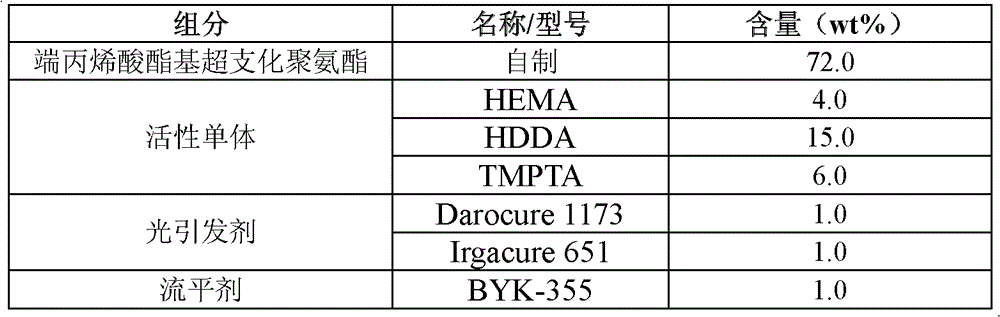

Hyperbranched ultraviolet cured coating and preparation method thereof

ActiveCN102604531BHigh reactivityNarrow molecular weight distributionPolyurea/polyurethane coatingsSolubilityUltraviolet

The invention discloses a hyperbranched ultraviolet cured coating, which comprises the following raw materials by weight: 65-80 percent of acrylic ester terminal hyperbranched polyurethane, 15-33.5 percent of an active monomer diluent, 0.5-2 percent of a photoinitiator, and 1-3 percent of a flatting agent. Moreover, the invention also discloses a preparation method of the hyperbranched ultraviolet cured coating. The hyperbranched ultraviolet cured coating has the characteristics of being low in viscosity, high in reactivity, high in solubility, good in intermiscibility and the like, can improve the construction environment, can be rapidly cured and is good in physical and chemical properties of a coating film, and is suitable for indoor and outdoor utilization.

Owner:GUANGZHOU BAIYUN CHEM IND

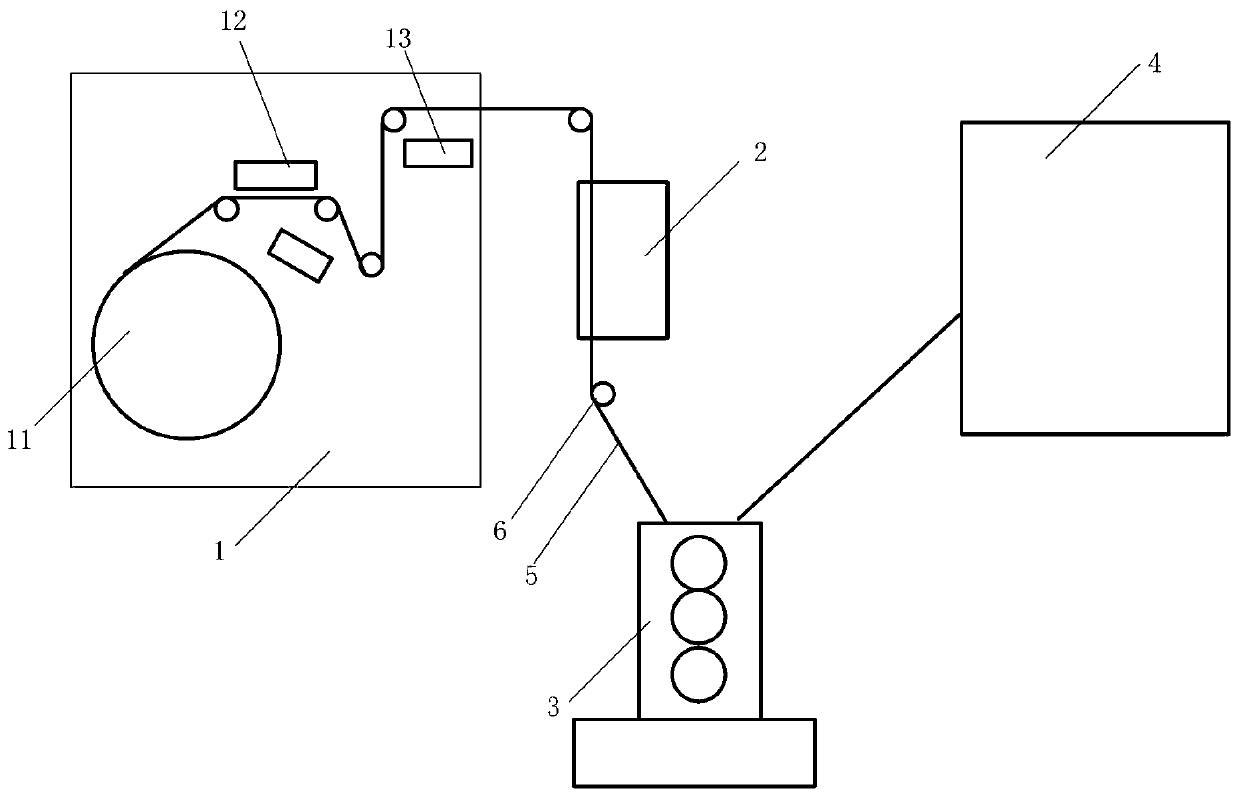

A continuous coating device for viscous materials

ActiveCN107638987BImprove performanceAvoid polarizationLiquid surface applicatorsCoatingsThin membraneSilica gel

The invention discloses a continuous coating device for viscous materials. The continuous coating device comprises a control unit, an unreeling unit, a coating and printing unit and a follow-up unit.The unreeling unit, the coating and printing unit and the follow-up unit are arranged along the movement direction of a base material sequentially. The coating and printing unit comprises a compression roller, a drive silica gel roller and a drive steel roller which are stacked from top to bottom. The drive steel roller is soaked in a colloid tank filled with the viscous materials. The base material is arranged between the compression roller and the drive silica gel roller, is supported on a support roller, and moves along the direction of centrifugal force of the upper vertex of the drive silica gel roller under power traction to transfer a colloid film to the surface of the base material. The continuous coating device has the advantages that the viscous materials are extruded, pulled andextended by the two rollers at different speeds and in different directions to form a colloid surface with a certain thickness on the surface of a rubber roller, and are transferred to the surface ofthe continuously-fed base material by the compression roller to form a thin uniform coating, so that uniform coating of materials with micron-order and submicron-order thickness and more thinner materials on the surface of the base material is realized.

Owner:陕西浩合机械有限责任公司

Dispensing process

InactiveCN111081558AConsistent dispensing volumeConsistent viscositySemiconductor/solid-state device manufacturingPhysicsElectrically conductive

The invention relates to a dispensing process, in particular, a dispensing process during chip mounting. A constant-temperature heater is used for carrying out constant-temperature heating control onthe tube of conductive silver paste, it is guaranteed that the temperature of the conductive silver paste is kept at 33-35 DEG C and is close to final working temperature 35 DEG C in a using process,it is guaranteed that the viscosity of the conductive silver paste is relatively consistent in a working process, and therefore, it is guaranteed that a dispensing amount is consistent in a dispensingoperation process. And meanwhile, by means of standardizing operation steps and process conditions, the stability of dispensing operation is ensured, the stability and reliability of chip mounting quality are finally ensured, and the rate of finished products is increased.

Owner:江阴苏阳电子股份有限公司

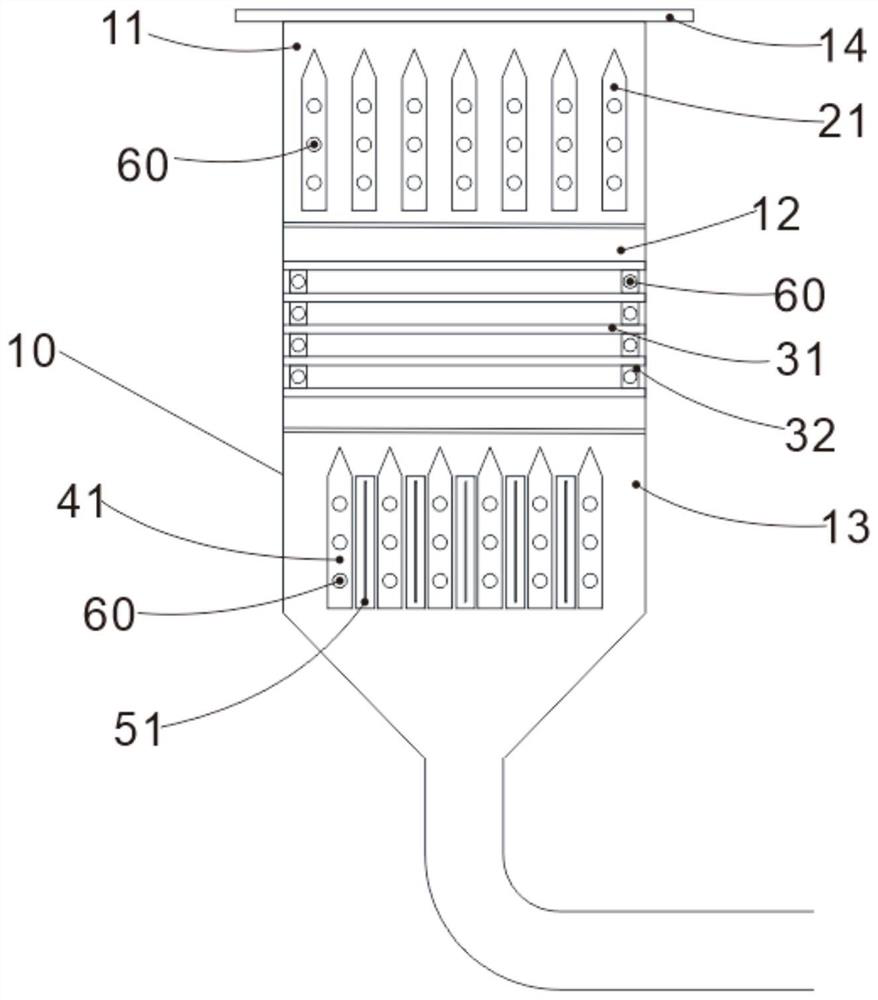

Special glue melting device for high-viscosity and high-softening-point hot melt glue

PendingCN111912228AIncrease the heat exchange areaShorten melting timeFurnace typesElectric heating for furnacesProcess engineeringHot-melt adhesive

The invention provides a special glue melting device for high-viscosity and high-softening-point hot melt glue. The special glue melting device comprises a glue melting furnace body and a heating system; the heating system is arranged in the glue melting furnace body; the glue melting furnace body is sequentially provided with an upper-section glue melting area, a middle-section glue homogenizingarea and a lower-section glue storage area from top to bottom; the upper-section glue melting area is provided with a melting cutter assembly; a transverse flow guiding plate assembly is arranged in the middle-section glue homogenizing area; and the lower-section glue storage area is provided with a shunting cutter assembly and a vertical multi-wing flow guiding assembly. The glue melting device is sequentially provided with the upper-section glue melting area, the middle-section glue homogenizing area and the lower-section glue storage area from top to bottom; a material block enters the upper-section glue melting area from a glue inlet, is sheared by the melting cutter assembly and enters the middle-section glue homogenizing area; the transverse flow guiding plate assembly in the middle-section glue homogenizing area realizes static stirring of the melt glue so that the melt glue is uniform; and the melt glue enters the lower-section glue storage area to be stored. According to the glue melting device, the glue melting amount can reach 0.75-1.5 kg / min under the control of glue melting heating temperature of 180 DEG C to 235 DEG C.

Owner:厦门鼎宏热熔胶有限公司

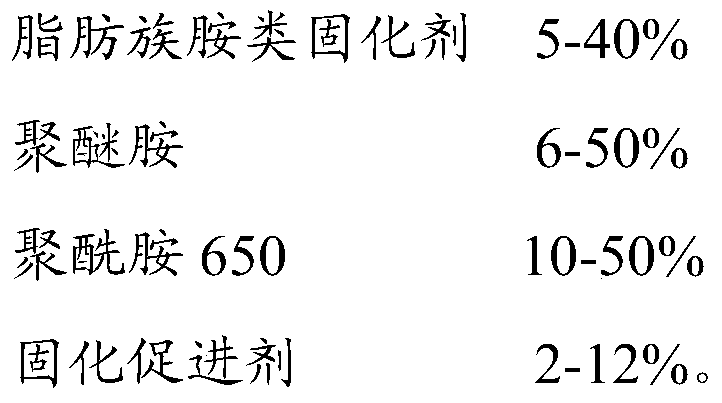

Two-component epoxy adhesive and preparation method thereof

ActiveCN105062395BImprove toughnessHigh peel strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAliphatic aminePolyamide

The invention relates to a two-component epoxy glue and a preparation method thereof. The two-component epoxy adhesive includes A component and B component, and the A component includes: epoxy resin, toughener, liquid flame retardant, powder flame retardant, diluent, defoamer, Reinforcing filler; the B component includes aliphatic amine curing agent, polyether amine, polyamide 650, and curing accelerator. The present invention screens the components of the epoxy adhesive so that the components can complement each other in performance and form a two-component epoxy adhesive system with superior comprehensive performance through synergistic cooperation, which significantly improves the toughness, anti-peel strength, The impact resistance and flame retardancy have also reached the UL94-V0 level, and the operating time is relatively suitable, and the curing time is short, which can realize continuous production.

Owner:GUANGZHOU BAIYUN CHEM IND

Polysaccharide gum and process for its manufacture

InactiveUS20050054059A1High viscosityMeet the requirementsSugar derivativesFermentationNon solventProcess engineering

Processes are disclosed for the purification and recovery of polysaccharide gums from an aqueous solution, particularly xanthan gum from a fermentation broth. An aqueous solution of at least one polysaccharide gum is mixed with a non-solvent stream comprising water and a subprecipitant level of a non-solvent of the polysaccharide gum. The mixture is concentrated to increase the polysaccharide gum concentration, and optionally undergoes a heat treatment. Additional non-solvent is added to the concentrated mixture to precipitate the polysaccharide gum. The precipitated gum is dried after being separated from the liquid component of the mixture. The removed liquid component can be recycled to the earlier step in the process in which the polysaccharide gum solution is mixed with the non-solvent stream.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

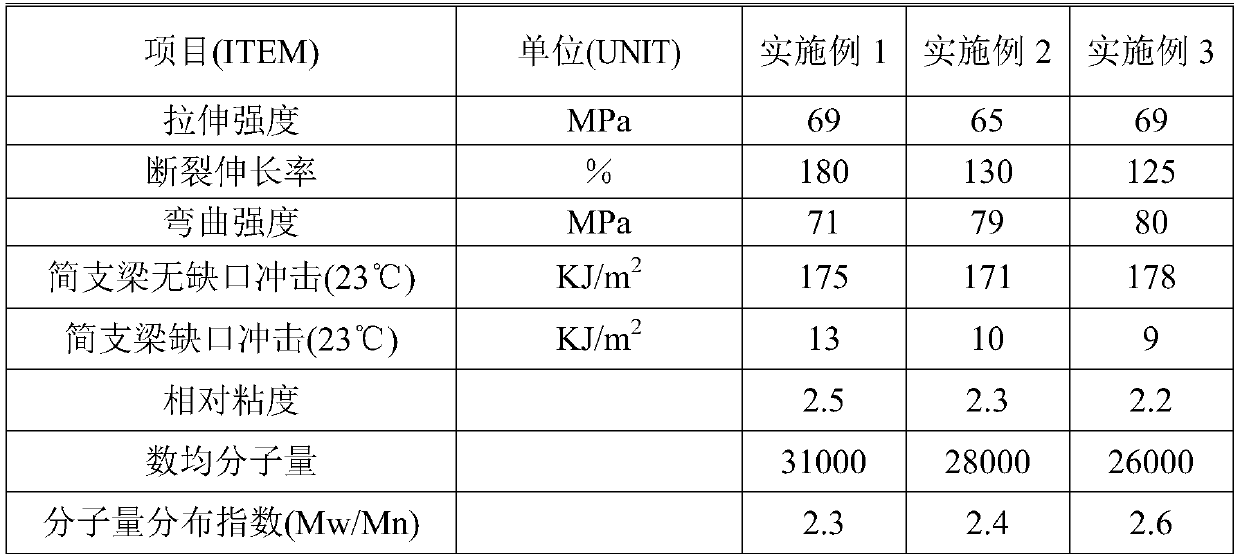

A kind of technological method for preparing nylon 12 with long-chain amino acid as monomer

Owner:WUXI YINDA NYLON

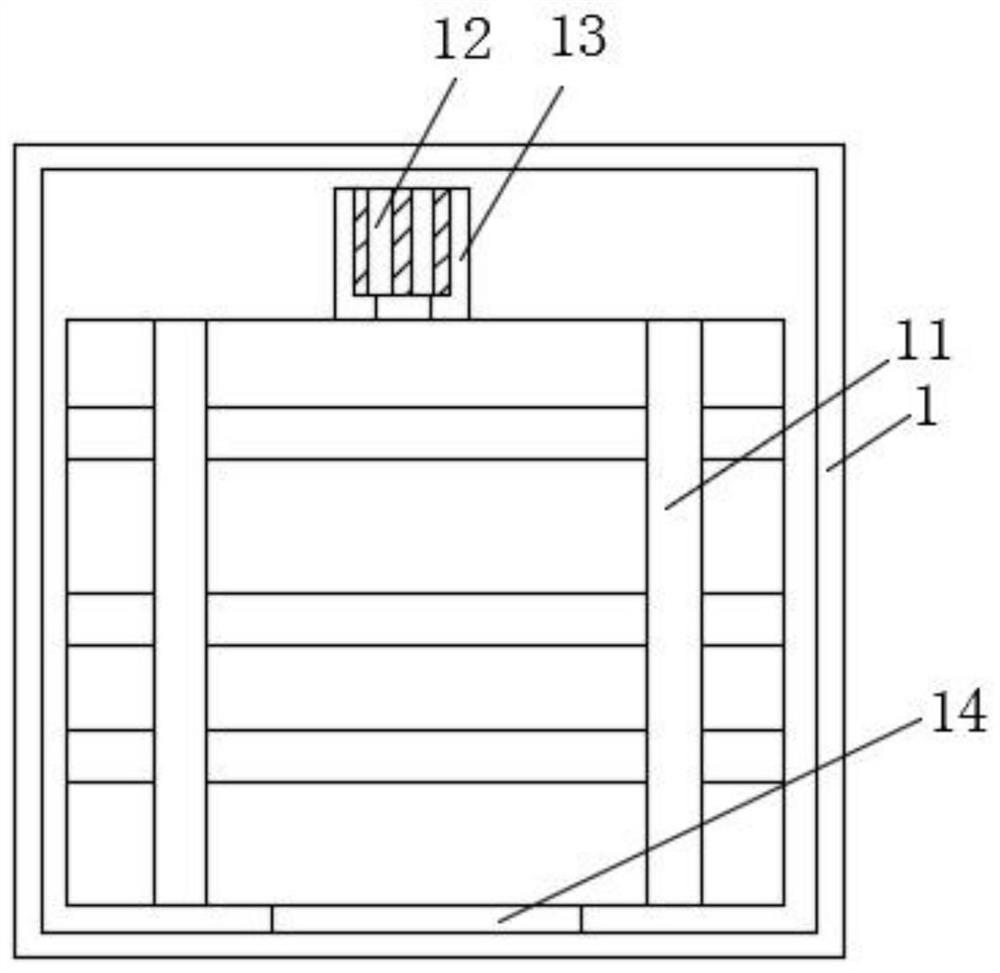

Anti-precipitation slurry pool

PendingCN110479958AUniform slurry viscosityPrevent slurry moisture volatilizationFoundry mouldsMoulding machinesPrecipitationSlurry

The invention discloses an anti-precipitation slurry pool, and belongs to the field of casting equipment. The anti-precipitation slurry pool comprises a support, a plurality of dip-coating pools installed on the support and provided with upward arc-shaped openings, and a stirring scraping mechanism fixed to the support and carrying out stirring scraping on the interiors of the dip-coating pools, wherein the stirring scraping mechanism comprises a transmission mechanism and first scraping plates; the transmission mechanism is installed on the support; the first scraping plates are installed inthe dip-coating pools and connected with the transmission mechanism; and the transmission mechanism drives the first scraping plates to carry out reciprocating swinging to carry out stirring and scraping on a slurry in the dip-coating pools. According to the anti-precipitation slurry pool, through the arrangement for the stirring scraping mechanism, the problem that a slurry in dip-coating pools in an existing slurry pool is liable to be sedimented and precipitated, is solved.

Owner:HEFEI UNIV OF TECH

A kind of high-viscosity warm antibacterial yarn and its production process

ActiveCN111020780BImprove insulation effectThere will be no deviations in thermal insulation performanceTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnFiber

The invention discloses a high-viscosity warm-keeping antibacterial yarn. The high-viscosity warm-keeping antibacterial yarn consists of a fiber layer, a high-viscosity layer, an insulating layer andan antibacterial layer, wherein the high-viscosity layer permeates the inner part and the outer side of the fiber layer through soaking, the insulating layer is arranged outside the fiber layer, and the antibacterial layer coats the outer sides of the insulating layer and the fiber layer. The fiber layer and the insulating layer are separately prepared, and the yarn is formed by combination of doubling and twisting operation, so that uniform combination of the insulating layer and the fiber layer is guaranteed and the overall insulating performance of the yarn is better; loosing drum wound with the fiber layer is fixed through rotation in a soaking device, so that the fiber layer can be prevented from falling off in soaking and the stability of the fiber layer in soaking is improved; and meanwhile, a traction wheel is arranged on a rotary frame, and by combination with spraying of a spray head, the soaking device can soak and spray the yarn, so that the efficiency of the whole yarn production process is improved.

Owner:JIESHOU HUAYU TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com