Vacuum freeze-drying method and preparation method of freeze-dried instant rice noodles

A vacuum freeze-drying and rice noodle technology, which is applied in food freezing, food drying, drying solid materials, etc., can solve the problems of long rehydration time, short rehydration time, and poor taste, and achieve short rehydration time and ease the increase Consistent porosity and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

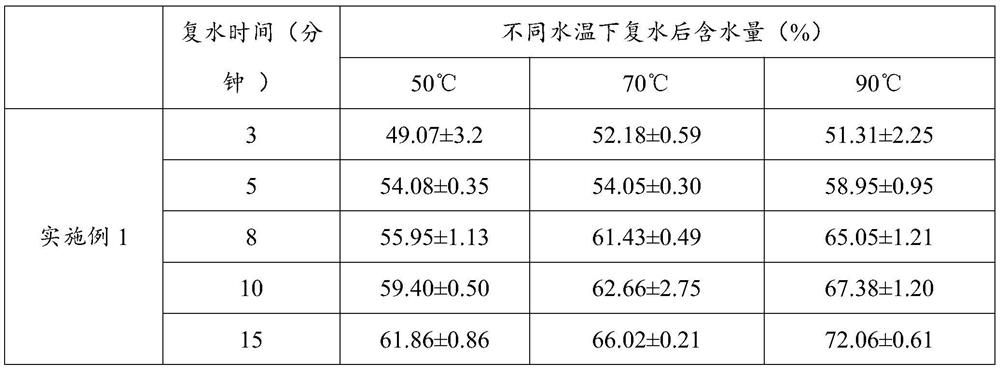

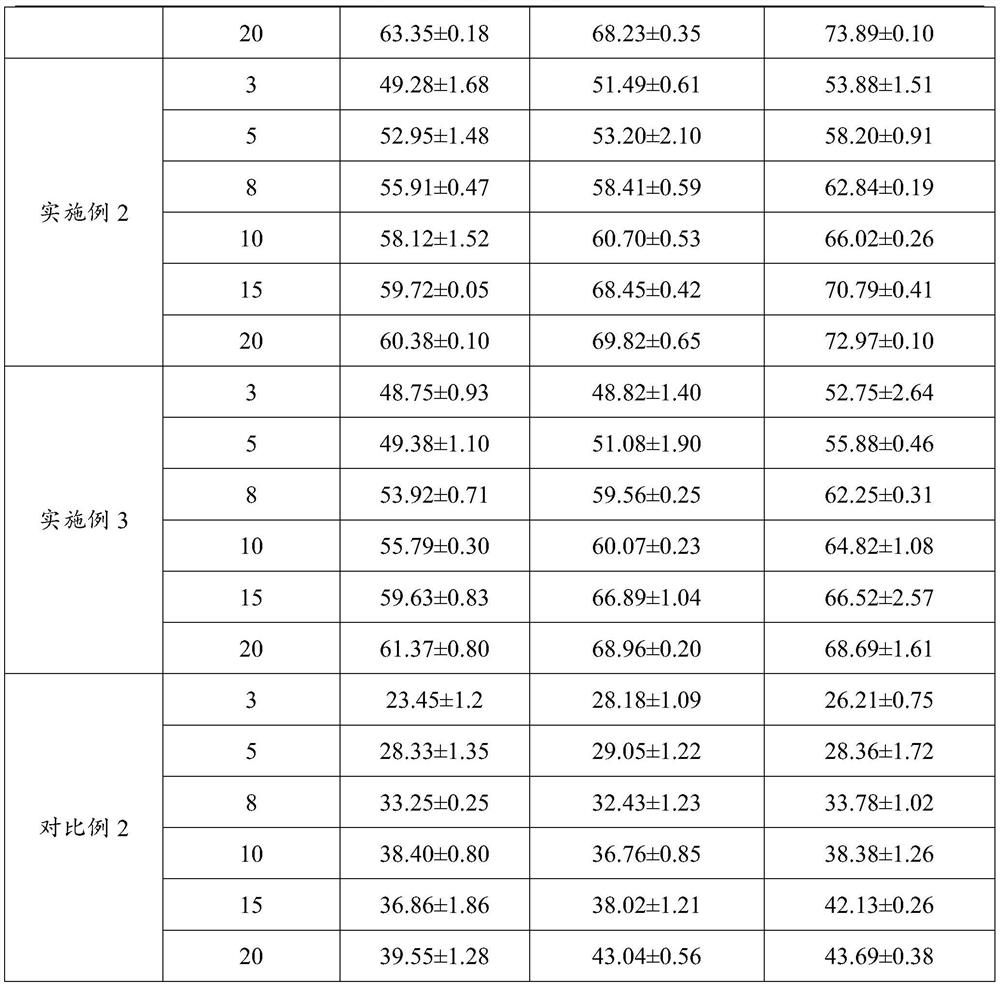

Examples

preparation example Construction

[0030] The invention provides a preparation method of freeze-dried instant rice noodles, comprising the following steps:

[0031] The fresh and wet rice noodles are dried by the vacuum freeze-drying method described above to obtain freeze-dried instant rice noodles.

[0032] In the present invention, the preparation of the fresh and wet rice noodles preferably includes: extruding the soaked rice to obtain semi-dry rice noodles; steam-aging the semi-dry rice noodles and then simmering them to obtain fresh and wet rice noodles.

[0033] In the present invention, the rice is preferably unfermented rice, more preferably indica rice with smooth surface, no pests and diseases, and no mildew, more preferably early indica rice. In the present invention, the source of the rice is not particularly limited, and conventional commercially available indica rice can be used.

[0034] In the present invention, the rice is preferably washed before soaking; in the present invention, the mass r...

Embodiment 1

[0044] (1) Rice selection: choose early indica rice with smooth surface, no pests and diseases, and no mildew.

[0045] (2) Cleaning and removing impurities: remove impurities such as sand and gravel in the high-quality early indica rice, wash the high-quality early indica rice three times with clean water, rinse it once with slow running water, and drain.

[0046] (3) Soaking: Soak the cleaned high-quality early indica rice in clean water, the rice-water mass ratio is 1:3, soak for 12 hours, and the rice grains can be easily crushed with fingers.

[0047] (4) extrusion molding: the soaked high-quality early indica rice is washed twice with clear water, drained, and the clear water of 0.5 times the quality of the rice is added, and put into the extrusion molding machine, wherein the specific parameters of the extrusion molding are : Using a single-screw self-cooking extruder to extrude the soaked and cleaned early indica rice into a round bar, which is a semi-dry rice noodle. ...

Embodiment 2

[0053] The operation steps of vacuum freeze-drying are: the first stage of pre-freezing: the fresh and wet rice noodles are kept at -20 °C for 4 hours; the second stage of sublimation drying: the shelf temperature is raised to -10 °C for 2 hours, 0 °C for 2 hours, and then , respectively, for 2 hours at 10°C, 20°C, 30°C and 40°C for a total of 12h; the third stage of analytical drying: when the shelf temperature rises to 45°C, it is kept for 6 hours. The vacuum degree of the second stage sublimation drying and the third stage desorption drying is 80Pa; the cold trap temperature of the first stage pre-freezing, the second stage sublimation drying and the third stage desorption drying is -70℃. The vacuum freeze-drying treatment was carried out for a total of 22 hours; other conditions were the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com