Device for coating graphene on surfaces of metal foils

A surface coating and metal foil technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of inability to ensure the electrical properties of pole pieces, difficulty in meeting coating requirements, and inability to realize graphene materials. Coating and other problems, to achieve the effect of reducing thermal effects, thin and uniform adhesive layer, and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

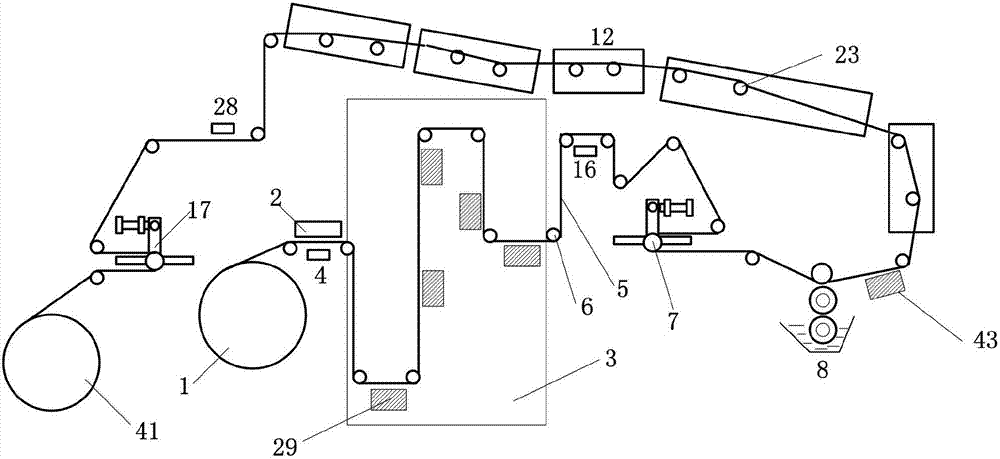

[0035] The electrode sheet coating machine for power battery / supercapacitor of the present invention is to uniformly coat the graphene slurry on the aluminum foil or copper foil at one time, and finally cut into the required electrode sheet, which requires graphene and metal foil It has good adhesion and extremely small contact resistance to reduce thermal effects and improve rate performance.

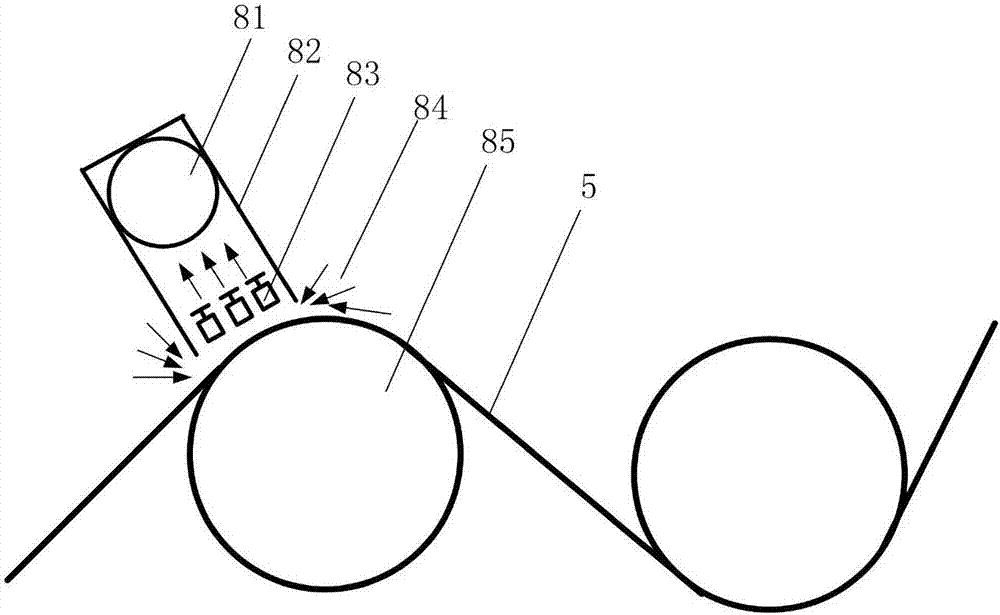

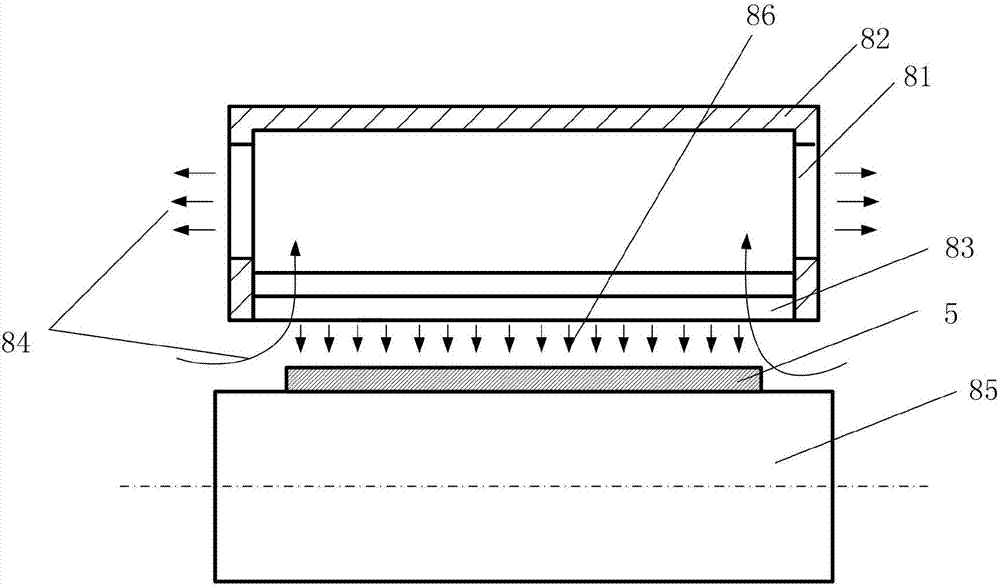

[0036] Such as figure 1 As shown, the graphene coating machine of the present invention includes a control unit and an unwinding unit 1, a high-voltage discharge treatment device 3, a coating unit, a baking unit and a winding unit 41 that are arranged successively along the metal foil 5 moving direction; Aluminum foil or copper foil is used for the foil 5 .

[0037] 1. Unwinding unit

[0038] The unwinding unit 1 includes an unwinding wheel, a tension sensor 2, a first deviation correction device 4, and several rollers 6. The power device drives the unwinding wheel under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com