A kind of technological method for preparing nylon 12 with long-chain amino acid as monomer

A process method and amino acid technology, which is applied in the field of preparing long carbon chain nylon, can solve the problems of unsuitable polymerization conditions for 12-aminododecanoic acid, etc., and achieve the effects of low cost, easy operation of steps, and cost-free pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

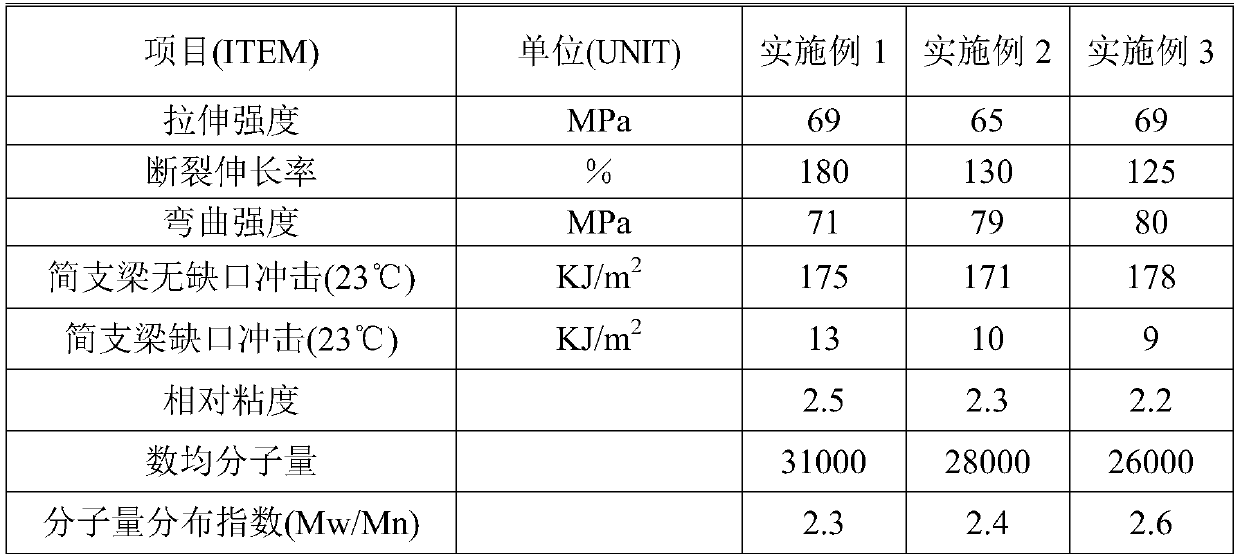

Examples

Embodiment 1

[0022] A process for preparing nylon 12 with long-chain amino acids as monomers, comprising the steps of:

[0023] (1) Initial polymerization: Add 3kg of aminododecanoic acid, 6kg of deionized water, 1g of sebacic acid, 1g of sodium hypophosphite and 1g of antioxidant 1098 into the prepolymerization reactor, and pass nitrogen for 5 minutes to eliminate the reaction The air in the kettle is then turned on to stir, heated to raise the temperature to 175°C, and the pressure to reach 0.9MPa, slowly discharge water vapor to keep the pressure at 0.9MPa, react for 4 hours, open the exhaust valve, and slowly reduce the pressure of the reaction kettle to 0.4MPa; then press the material in the prepolymerization kettle into the polymerization kettle.

[0024] (2) Polymerization: After the feeding is completed, start the stirring, start the automatic control program (PLC), heat the temperature to rise slowly to 240°C, automatically open the exhaust valve, and maintain a suitable dehydrati...

Embodiment 2

[0027] A process for preparing nylon 12 with long-chain amino acids as monomers, comprising the steps of:

[0028] (1) Initial polymerization: Add 3kg of aminododecanoic acid, 6kg of deionized water, 1g of sebacic acid, 1g of sodium hypophosphite, and 1g of antioxidant sunox508 into the prepolymerization reactor, pass nitrogen gas for 5 minutes, and remove the reactor Then turn on the stirring, heat to raise the temperature to 175°C, and the pressure to 0.9MPa, slowly discharge water vapor to keep the pressure at 0.9MPa, after 4 hours of reaction, open the exhaust valve, slowly reduce the pressure of the reactor to 0.4MPa.

[0029] Then the material in the pre-polymerization kettle is pressed into the polymerization kettle;

[0030] (2) Polymerization: After the feeding is completed, start the stirring, start the automatic control program (PLC), heat the temperature to rise slowly to 230°C, automatically open the exhaust valve, and maintain a suitable dehydration speed accord...

Embodiment 3

[0033] A process for preparing nylon 12 with long-chain amino acids as monomers, comprising the steps of:

[0034](1) Initial polymerization: Add 3kg of aminododecanoic acid, 6kg of deionized water, 1g of sebacic acid, 1g of sodium hypophosphite and 1g of antioxidant 1098 into the prepolymerization reactor, and pass nitrogen for 5 minutes to eliminate the reaction Then turn on the stirring, heat the temperature to 175°C, and the pressure reaches 0.9MPa, slowly discharge water vapor to keep the pressure at 0.9MPa, after 4 hours of reaction, open the exhaust valve, and slowly drain the reactor The pressure drops to 0.4MPa. Then the material in the pre-polymerization kettle is pressed into the polymerization kettle;

[0035] (2) Polymerization: After the feeding is completed, start the stirring, start the automatic control program (PLC), heat the temperature slowly to 240°C, automatically open the exhaust valve, and maintain a suitable dehydration speed according to the changing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com