Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Full gas-solid contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

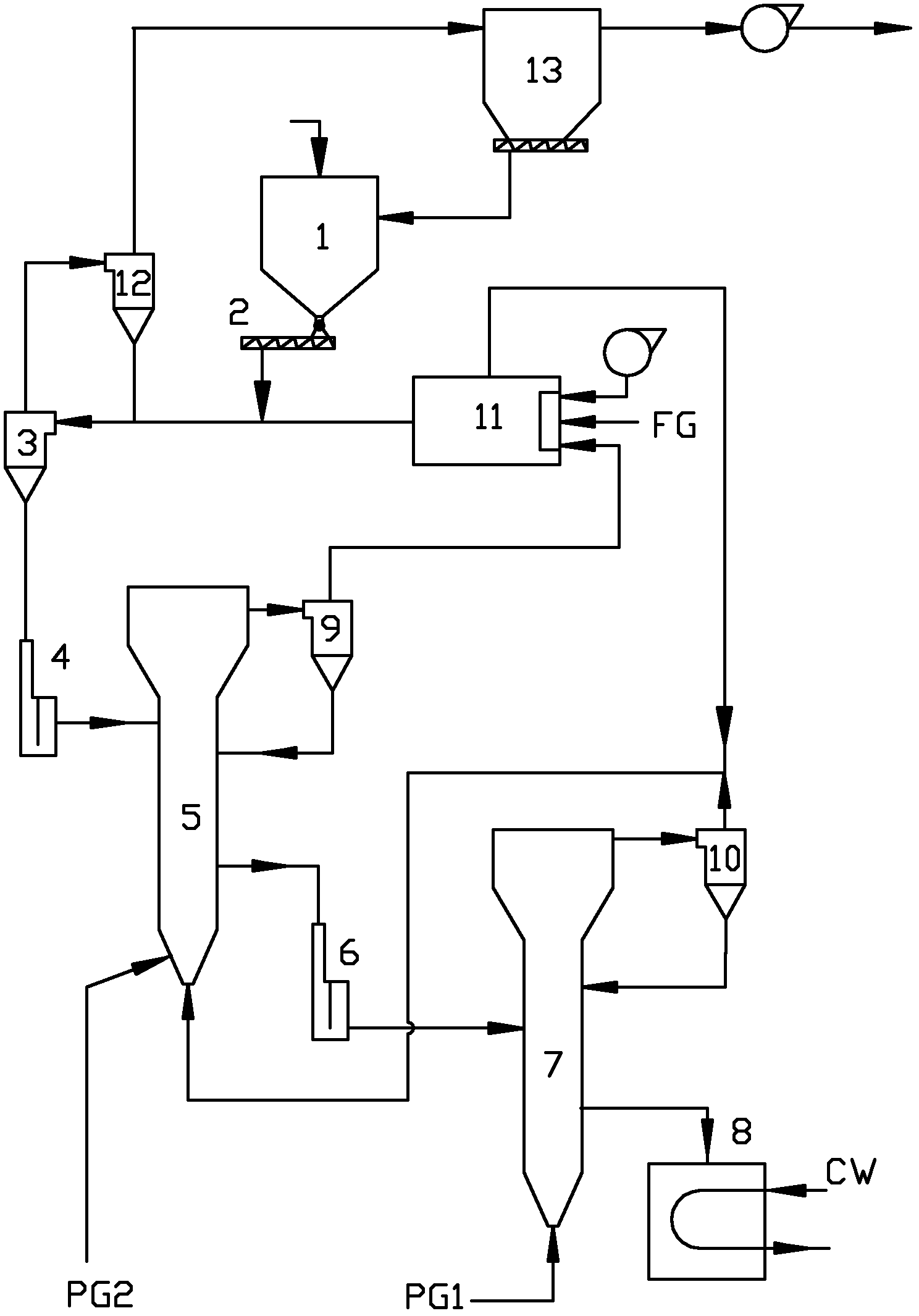

System for desulfurizing and denitrating active coke flue gas, and process method

ActiveCN102430318AIntegrated purification effect is obviousImprove utilization efficiencyDispersed particle separationSulfurDesorption

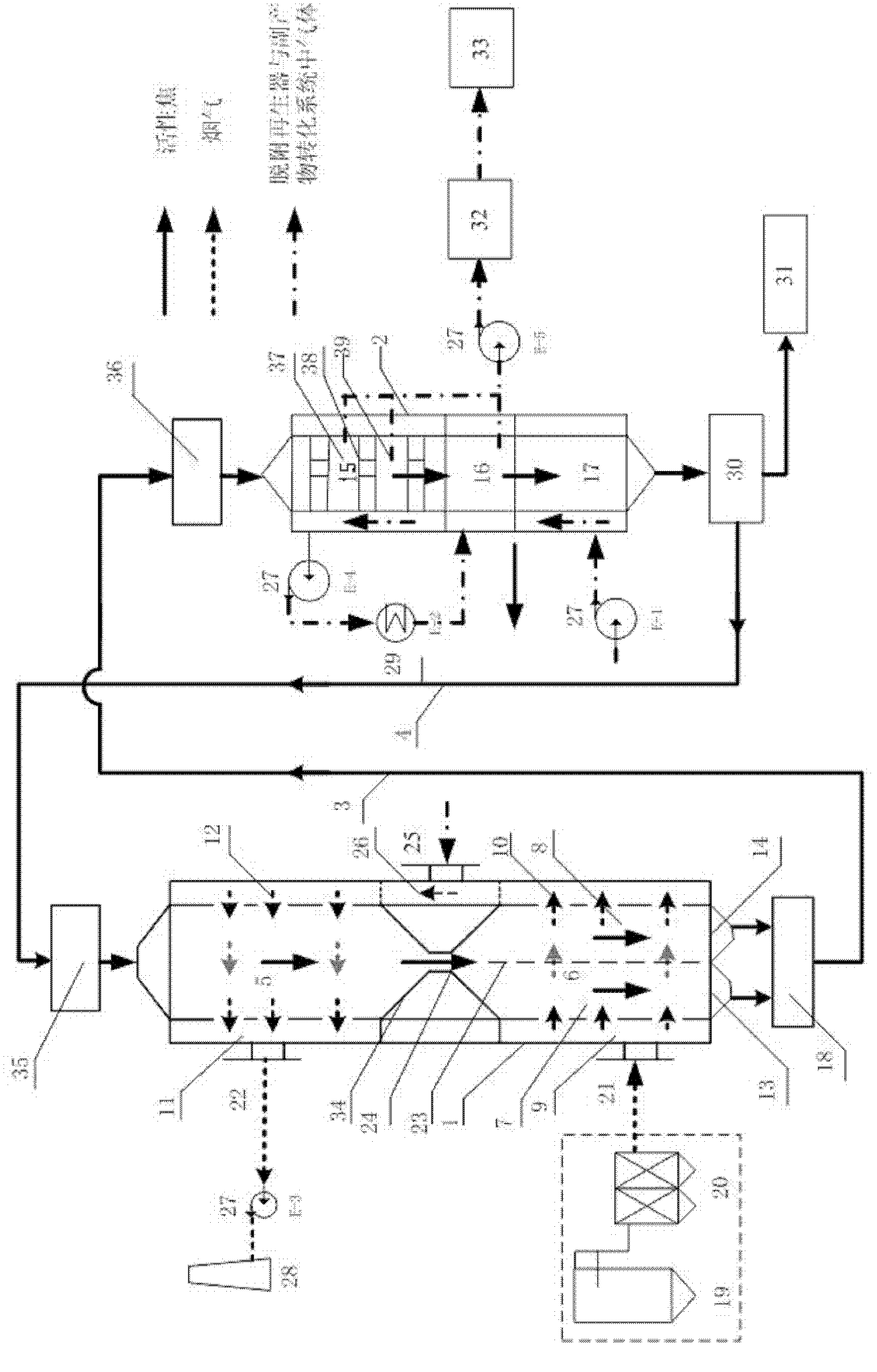

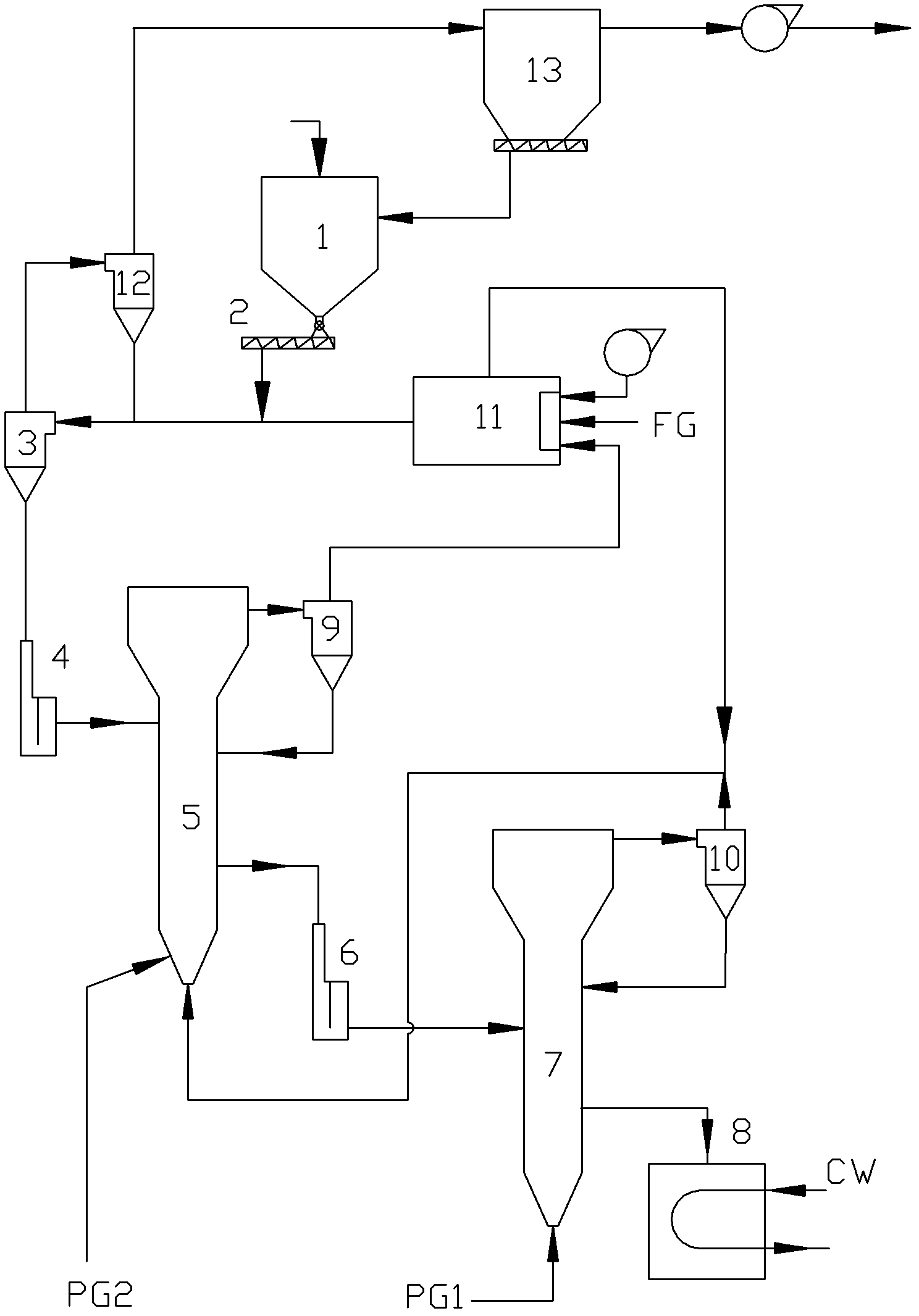

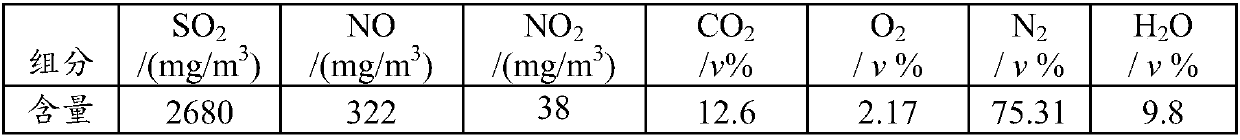

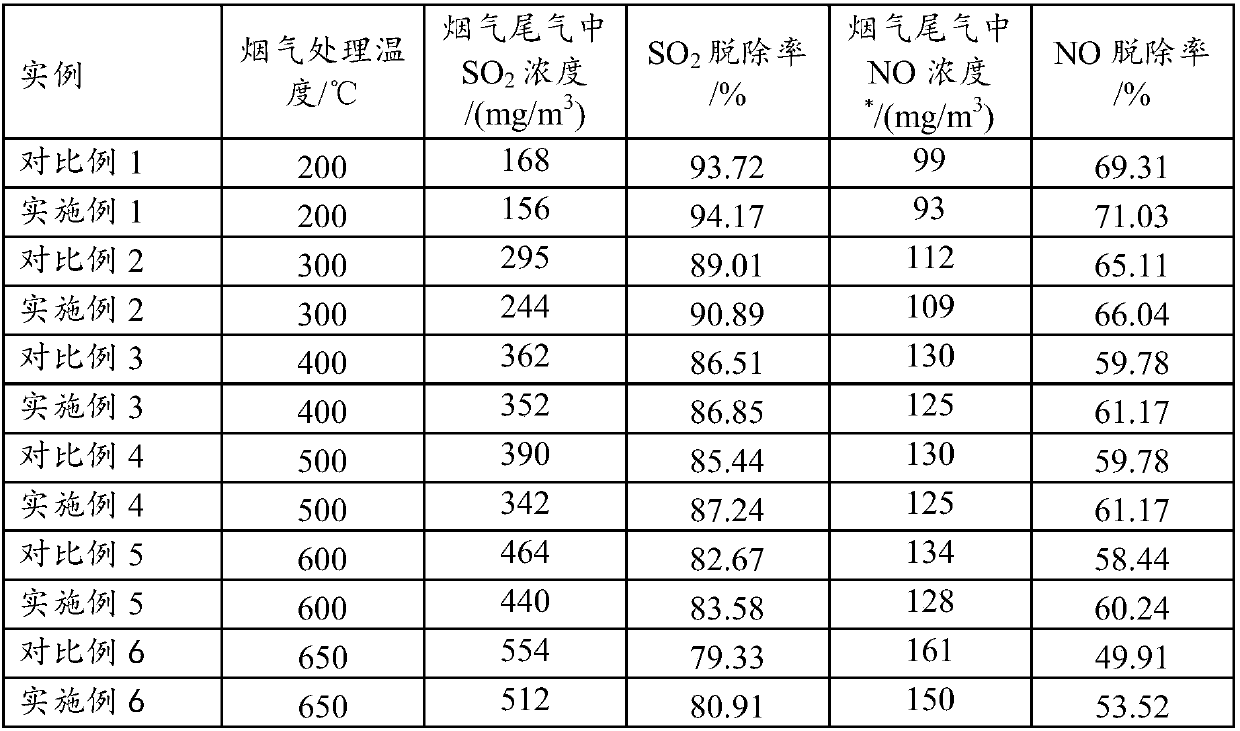

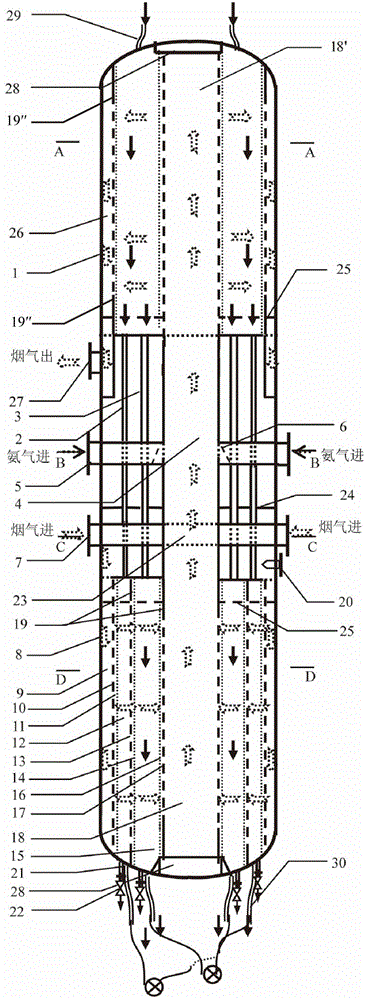

The invention discloses a system for desulfurizing and denitrating active coke flue gas, and a process method. The system comprises an adsorption reactor, a desorption regenerator, a material conveying device and a byproduct conversion device, wherein the devices are connected by specific pipelines and functions of the devices are realized by using a specific process method; the adsorption reactor is a composite layer double-section cross flow moving bed and consists of a denitration section and a desulfurization section, so that SO2, NOx, dioxin, mercury and smoke dust in flue gas are purified in an integrated mode; the desorption regenerator is divided into a preheating area, a regeneration area and a cooling area, so that active coke on which the mercury, and the dioxin are enriched are extracted, and subsequent harmless treatment of the active coke is realized; the desorption regenerator performs heat exchange by a heater and circulates heat energy for recovering, and the byproduct conversion device is used for performing sulphur recycling on desorption regenerated gas generated in the regeneration process; and by the process method, the integrated purification of the flue gas and the harmless treatment of the active coke can be realized.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

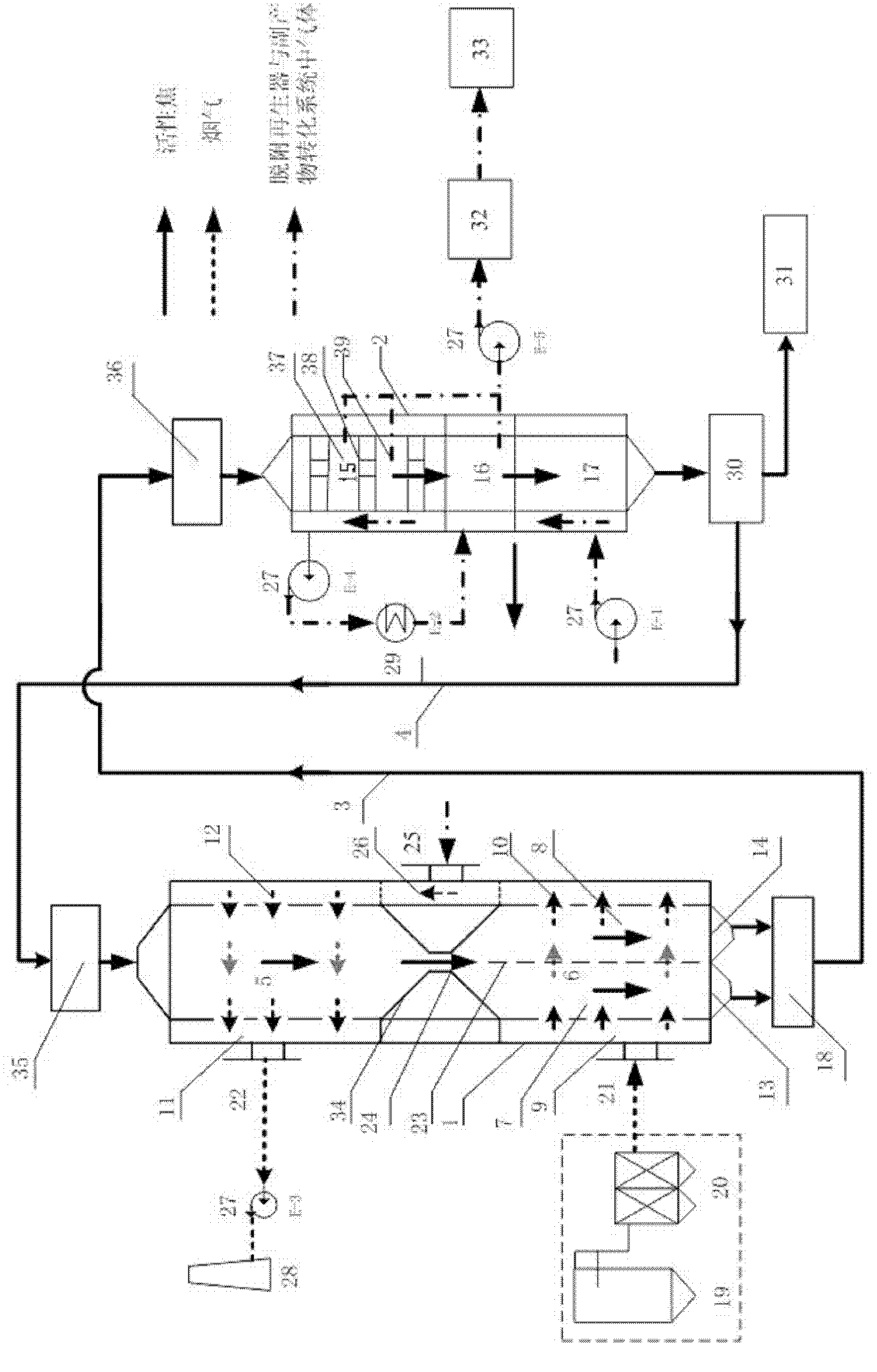

Highly effective slurry phase bed reactor

InactiveCN1593740AEasy to operateAvoid easy cloggingChemical/physical processesNuclear engineeringSpray nozzle

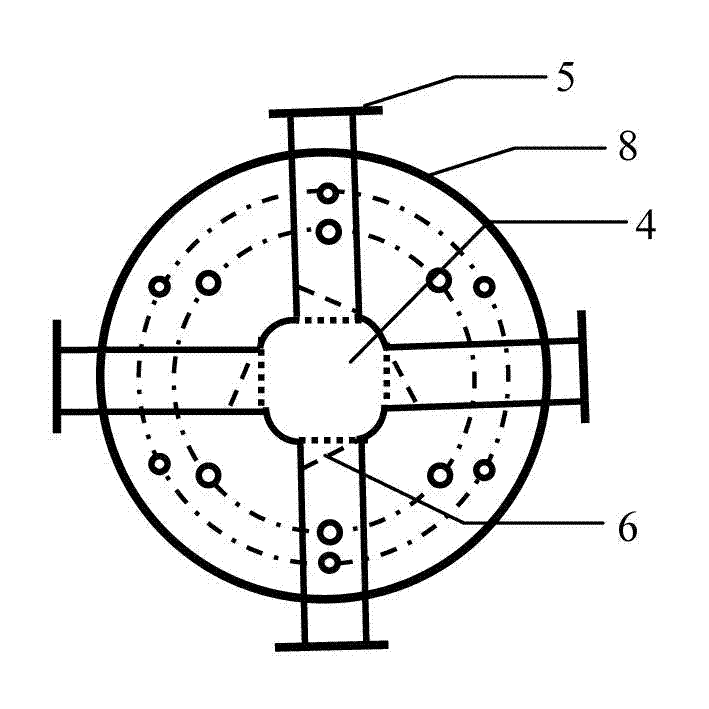

The invention relates to a kind of efficient reactor with paddle bed, which belongs to the chemical machinery field. It is composed mainly with the solid and liquid separator, the inner tube that the track is changeable, the reactor cover, the heat exchanger with an internal component, the riser with the spray nozzle, the inner-tube tank that has the heating and gas distribution function, the spray nozzle for protecting from choking, the mounting plate of the spray nozzle, the heat exchanger, the outlet of the heating coil, the quadratic distribution plate, the heating coil and so on. The beneficial effictiveness of the invention can be described as follows: the reactor and the distributor can't block up easily; the gas and the liquid can be mixed evenly; the reactive efficiency is high; the carrying amount of the catalyst and the solvent is so bit that it can not occur the bias current, channeling and dead bed; the size running quickly, and the viscosity of the size in the reactor is identical generally; the reactor can be shifted out in time, and especially in the stage of the catalytic, reducing and intensifying, it can realize to operate the reactor steadily; otherwise, the distribution of the virgin gas in the reactor along the axle is in agreement on the concentration of the catalyst, so that can make the catalyst have the most activity, and then it can be make the full use of the reactor space.

Owner:TAIYUAN UNIV OF TECH

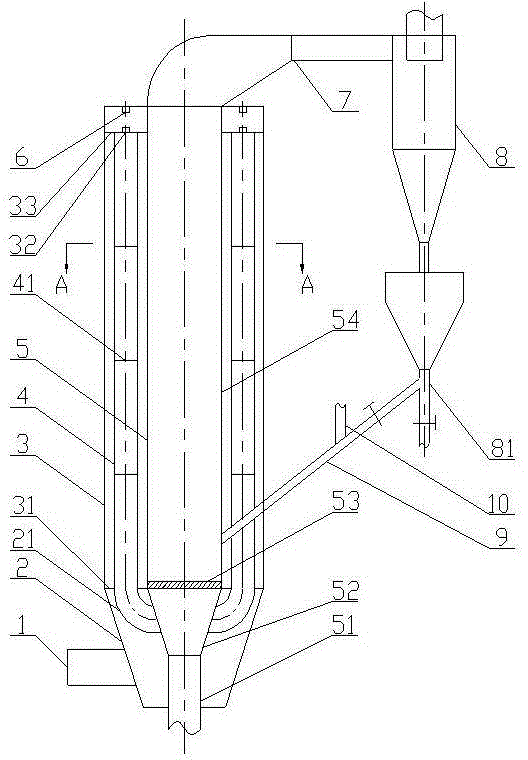

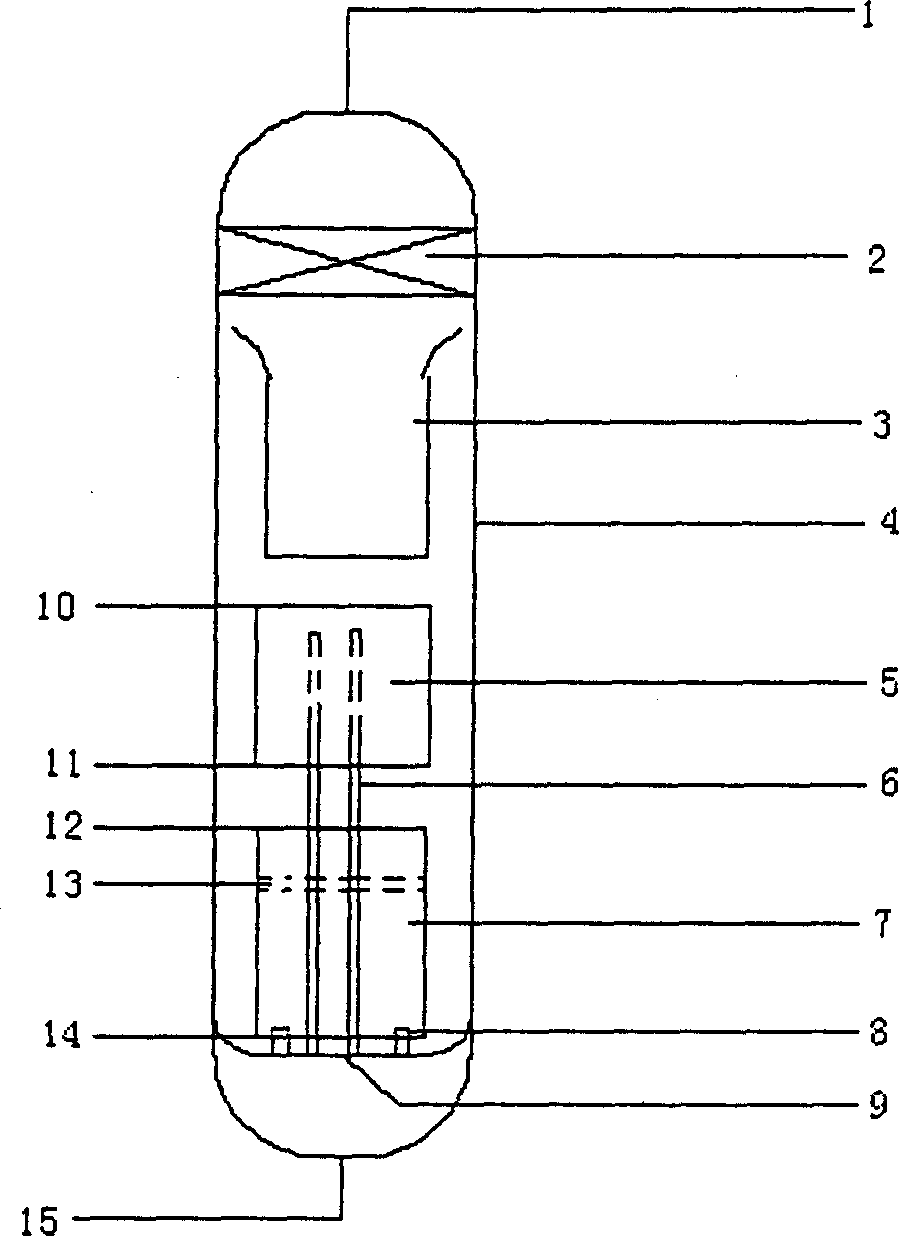

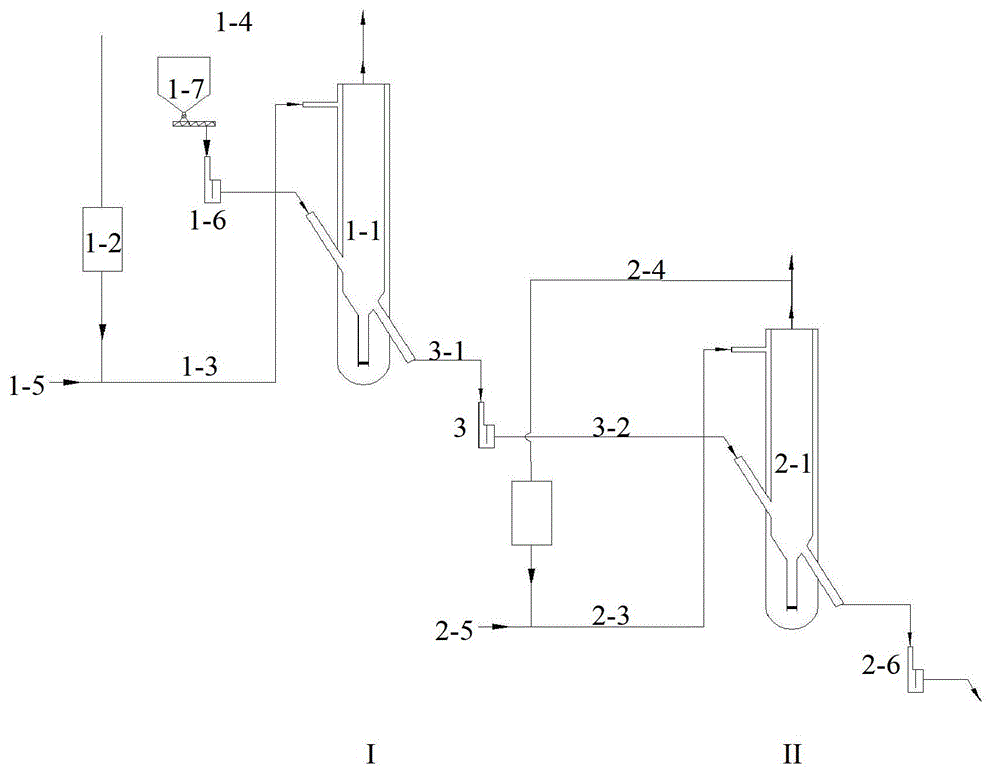

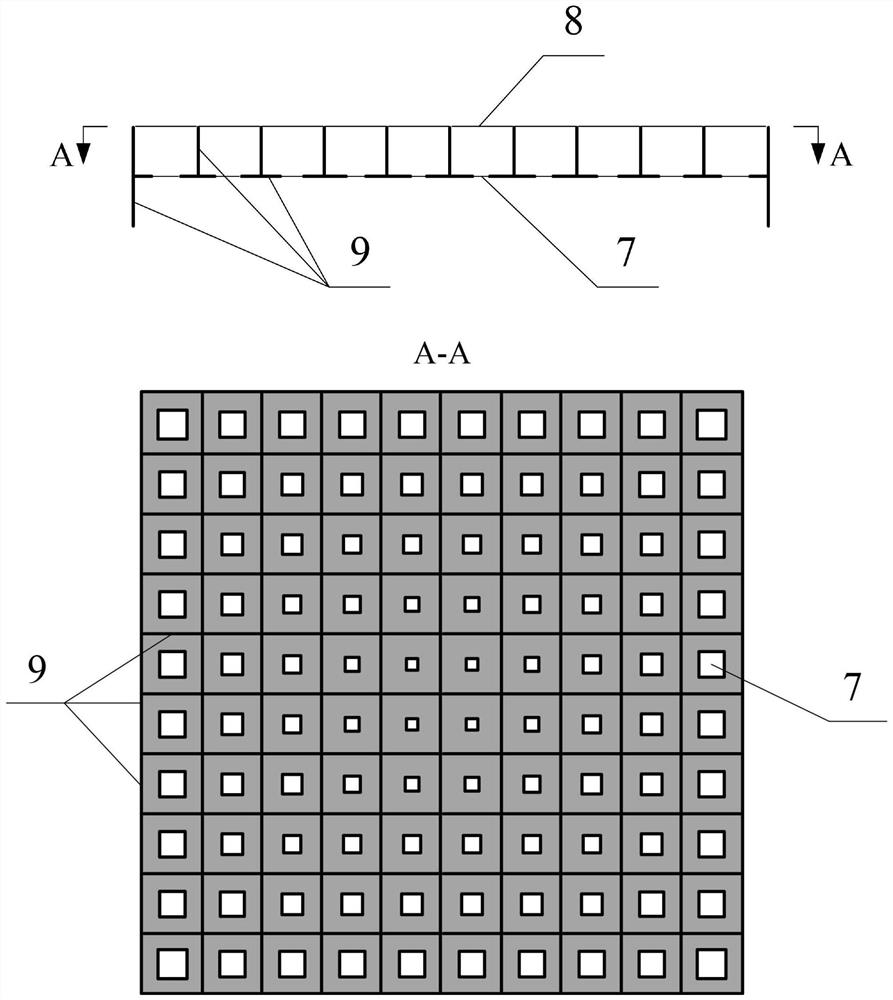

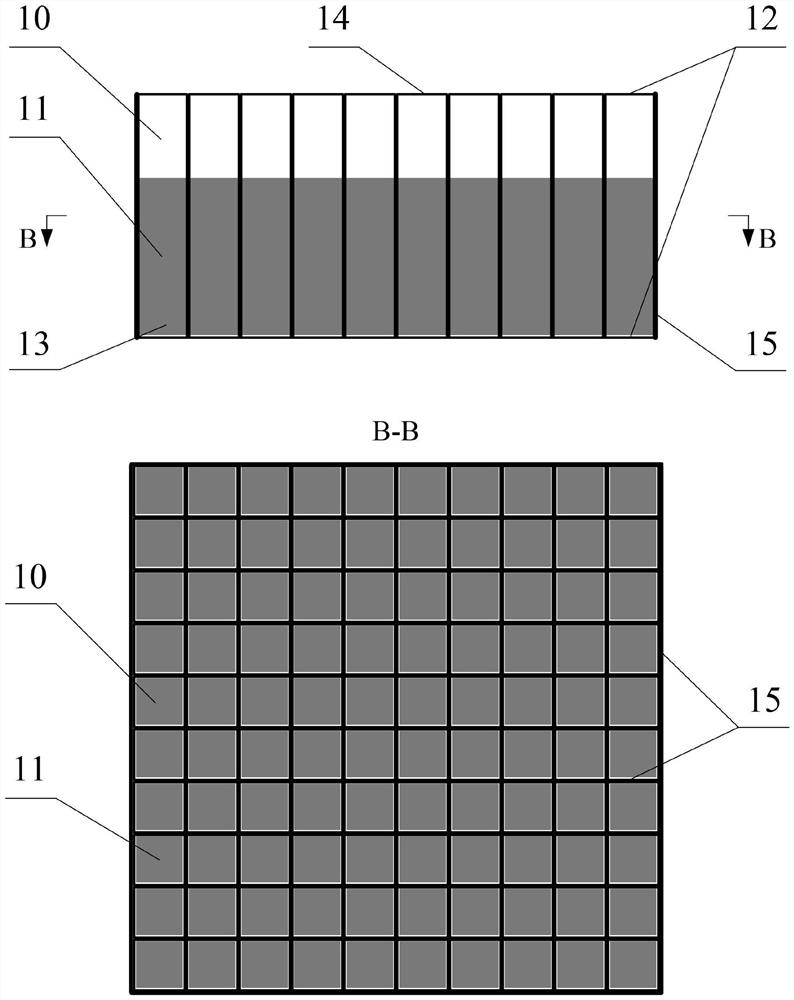

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

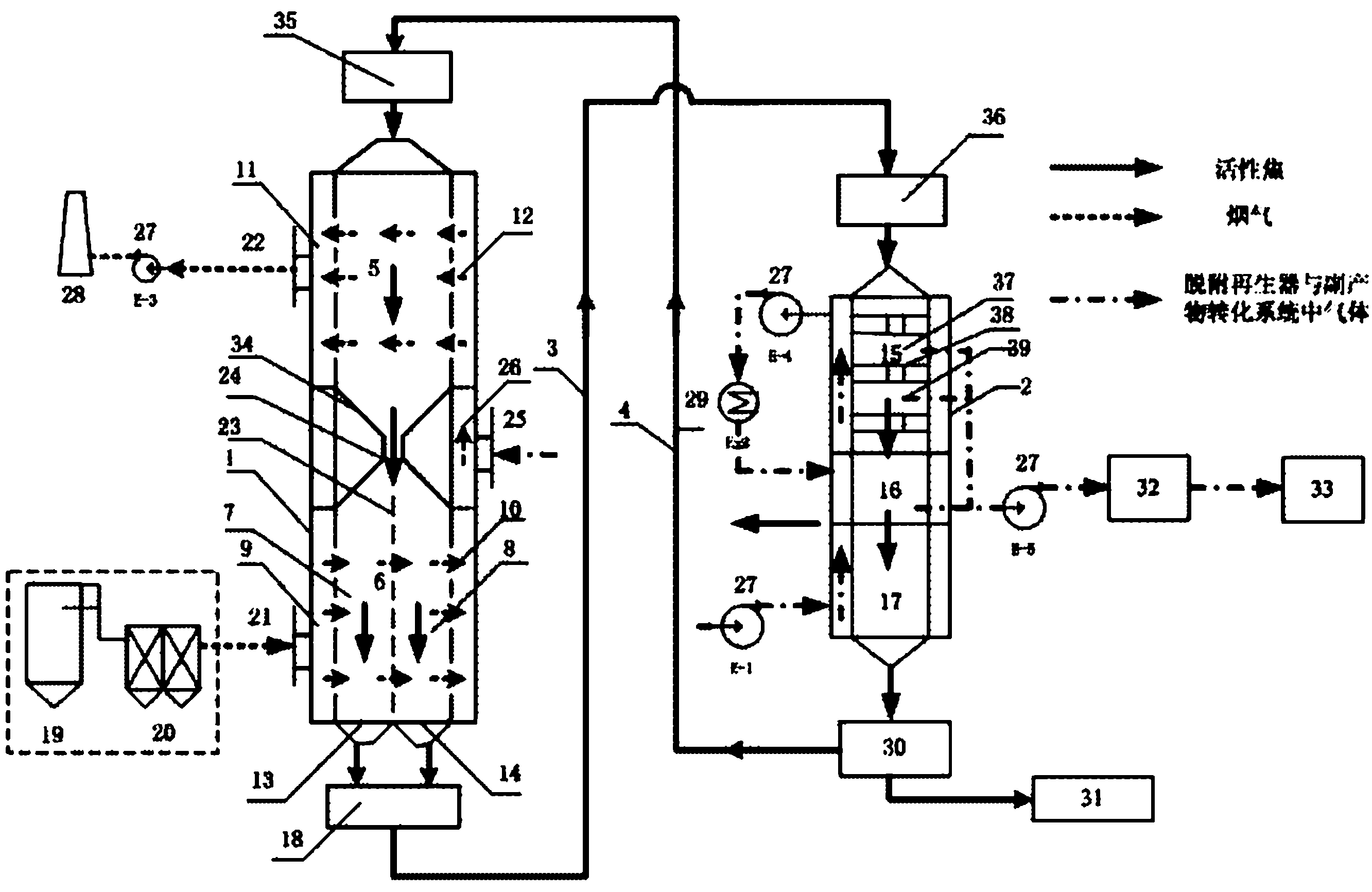

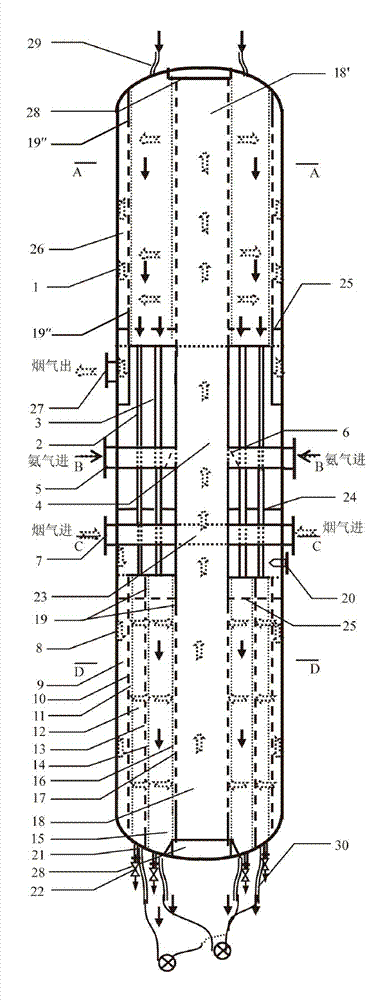

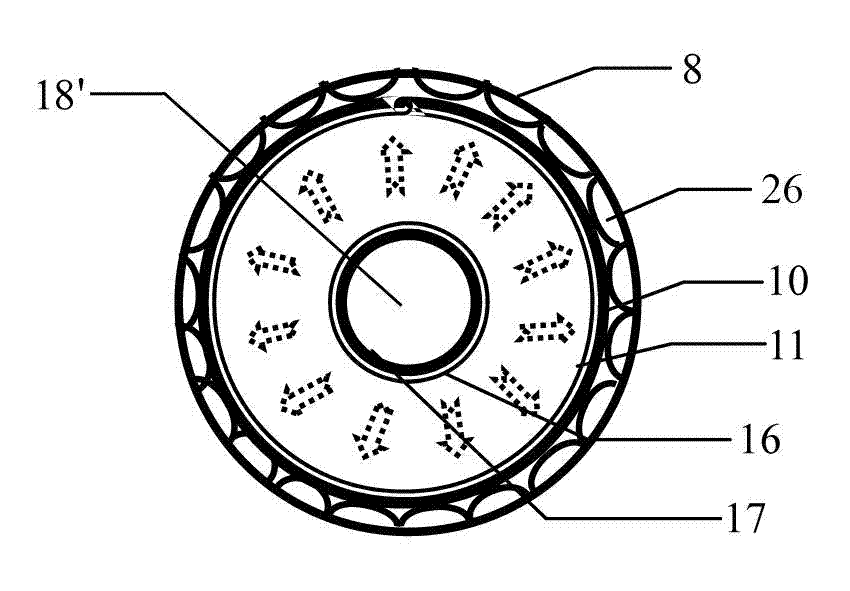

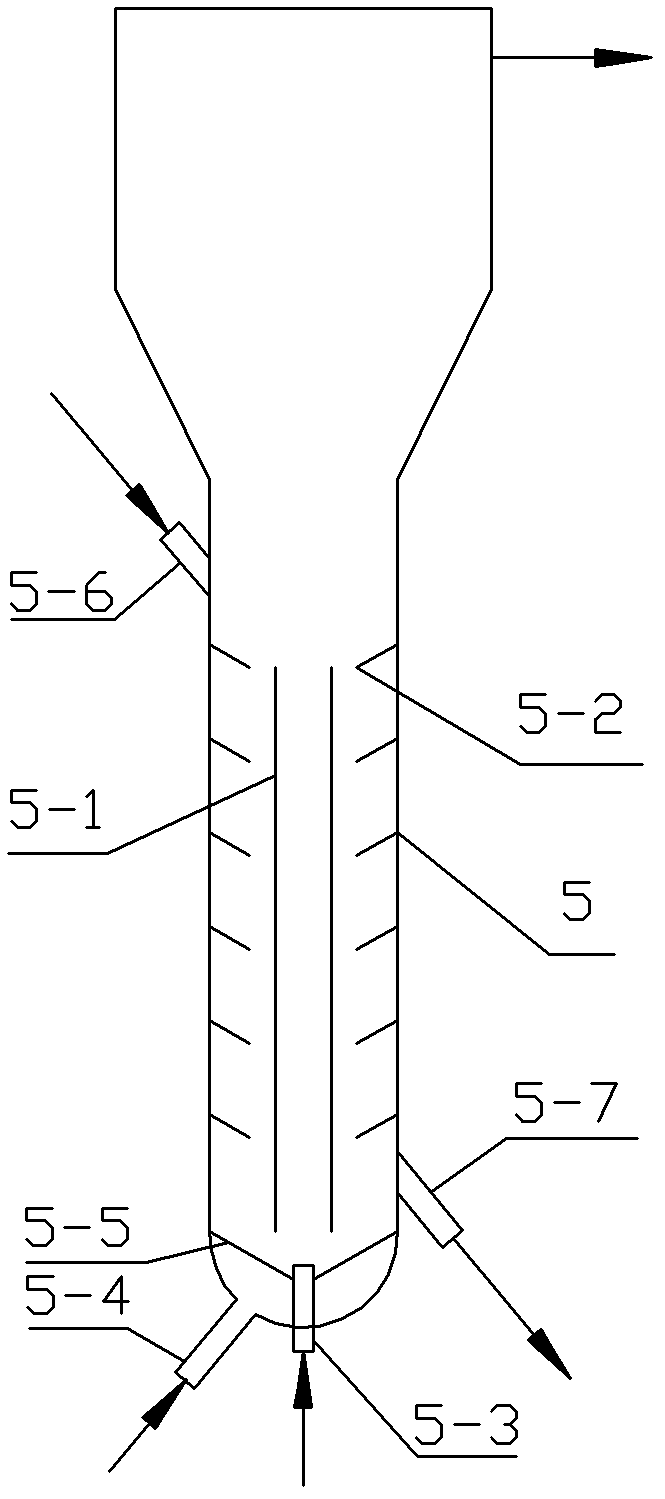

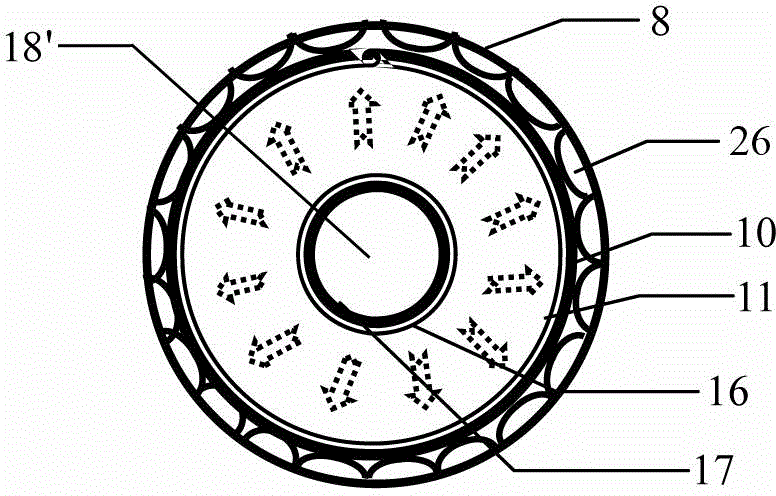

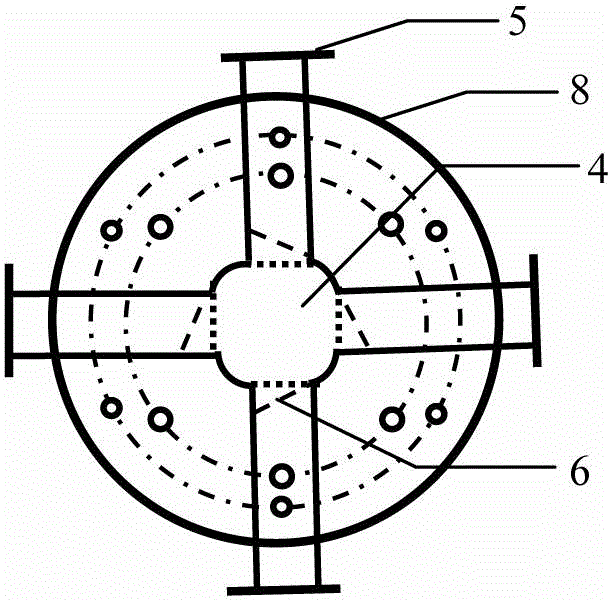

ActiveCN102824846ACombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementThermodynamicsFlue gas

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

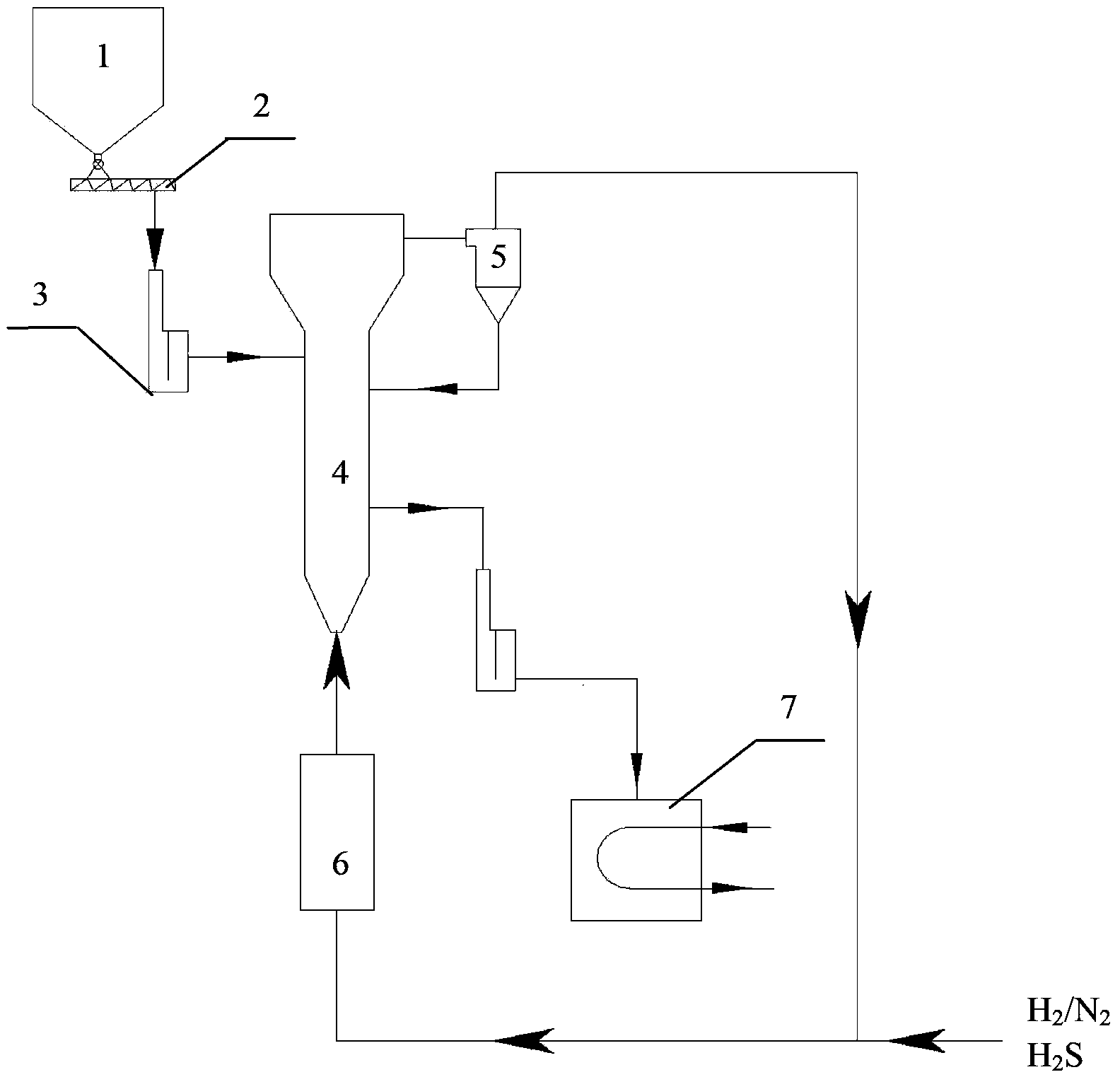

Device and method for preparing superfine nickel powder

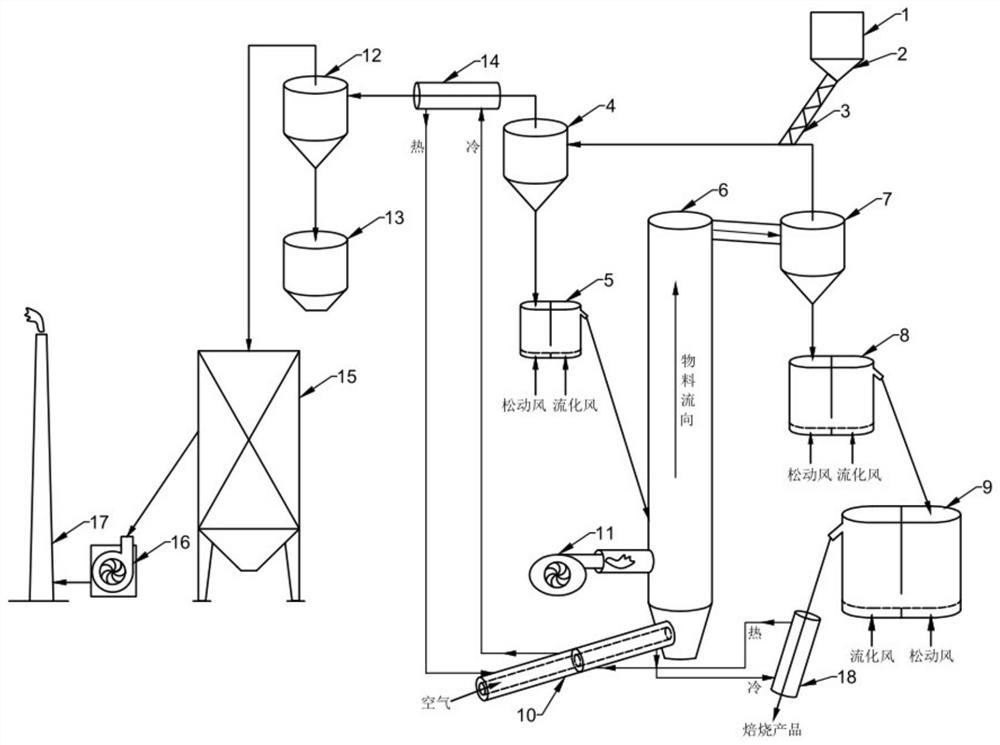

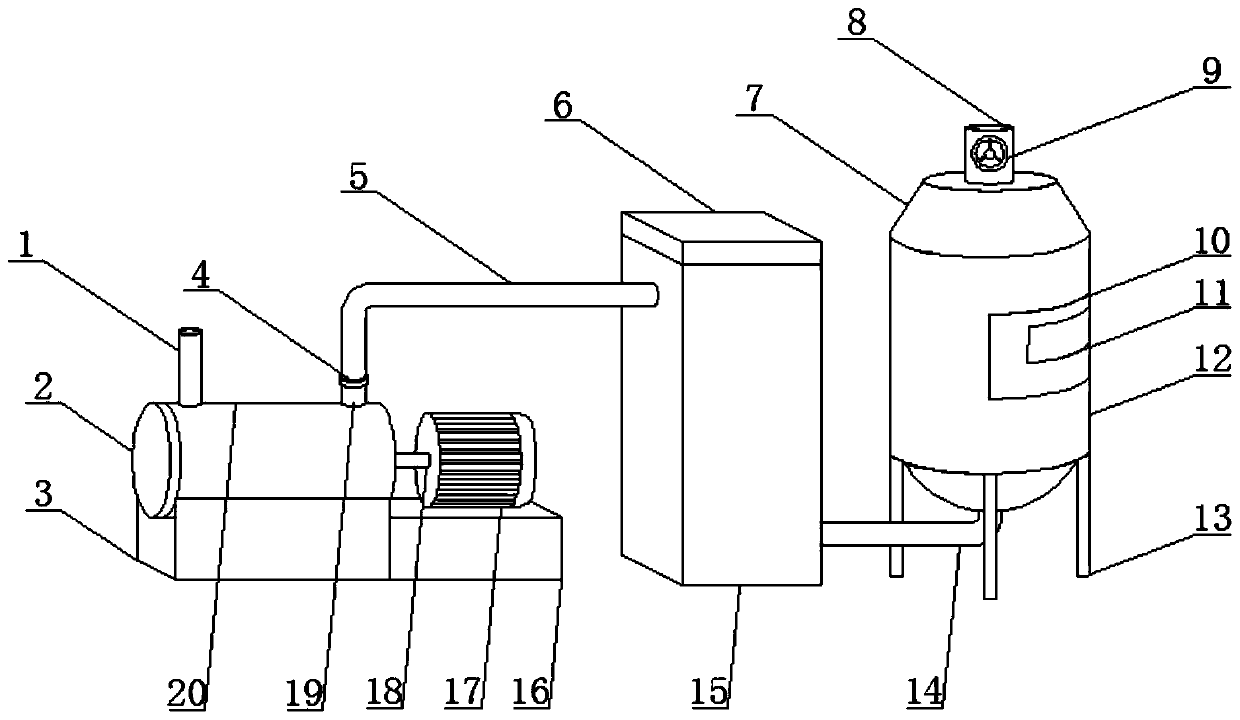

The invention relates to a device and a method for preparing superfine nickel powder. The device comprises a feeding system, a preheating system, a fluidized bed reactor and a cooling system which are sequentially connected. An outlet of the fluidized bed reactor is connected with a combustion chamber. An outlet of the combustion chamber is connected with the preheating system. After entering a cyclone preheater through the feeding system to be preheated, superfine nickel oxide enters the fluidized bed reactor to be subjected to the reduction reaction; and then the product is discharged after entering the cooling system. High temperature tail gas exhausted from the outlet of the fluidized bed reactor enters the combustion chamber to be burnt after being separated by a first cyclone separator. One path of tail gas is supplied to the preheating system and the other path of tail gas carries out heat exchange with carrier gas exhausted by a second cyclone separator and is supplied to the fluidized bed reactor through a first carrier gas inlet. The invention can solve the problems of poor fluidity, bonding defluidization and industrial scale-up of the superfine nickel powder. The preparation process is simple. The reaction temperature is low. The heat utilization rate is high. The continuous industrial scale production can be implemented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

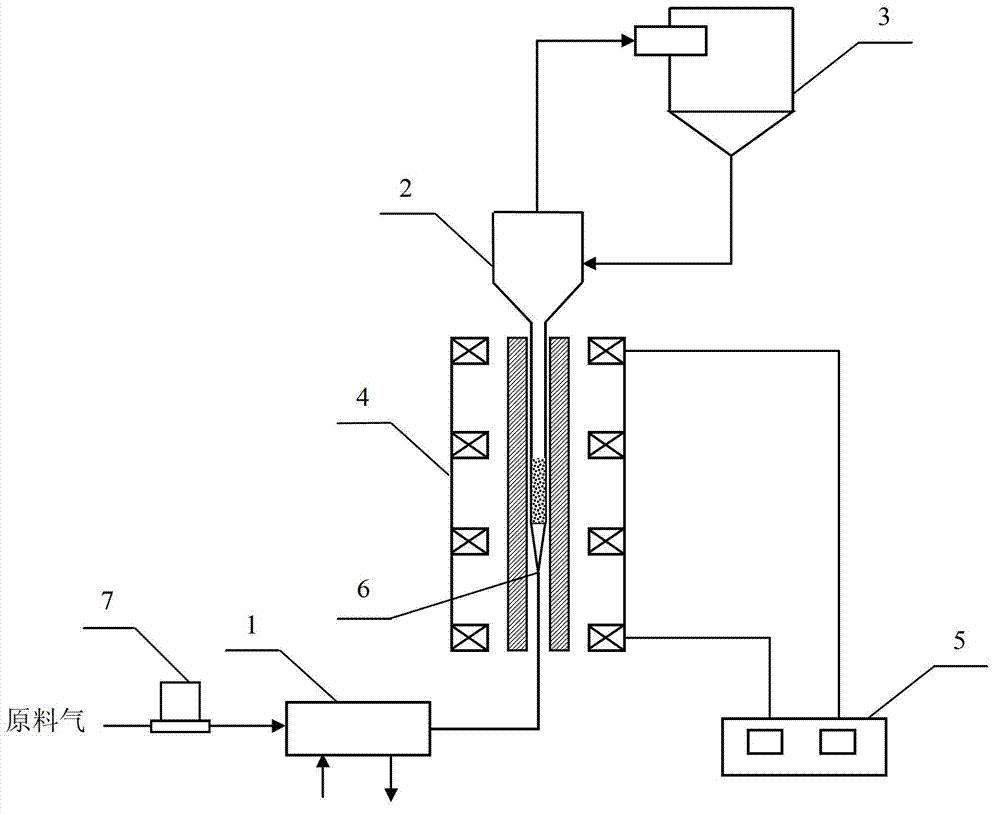

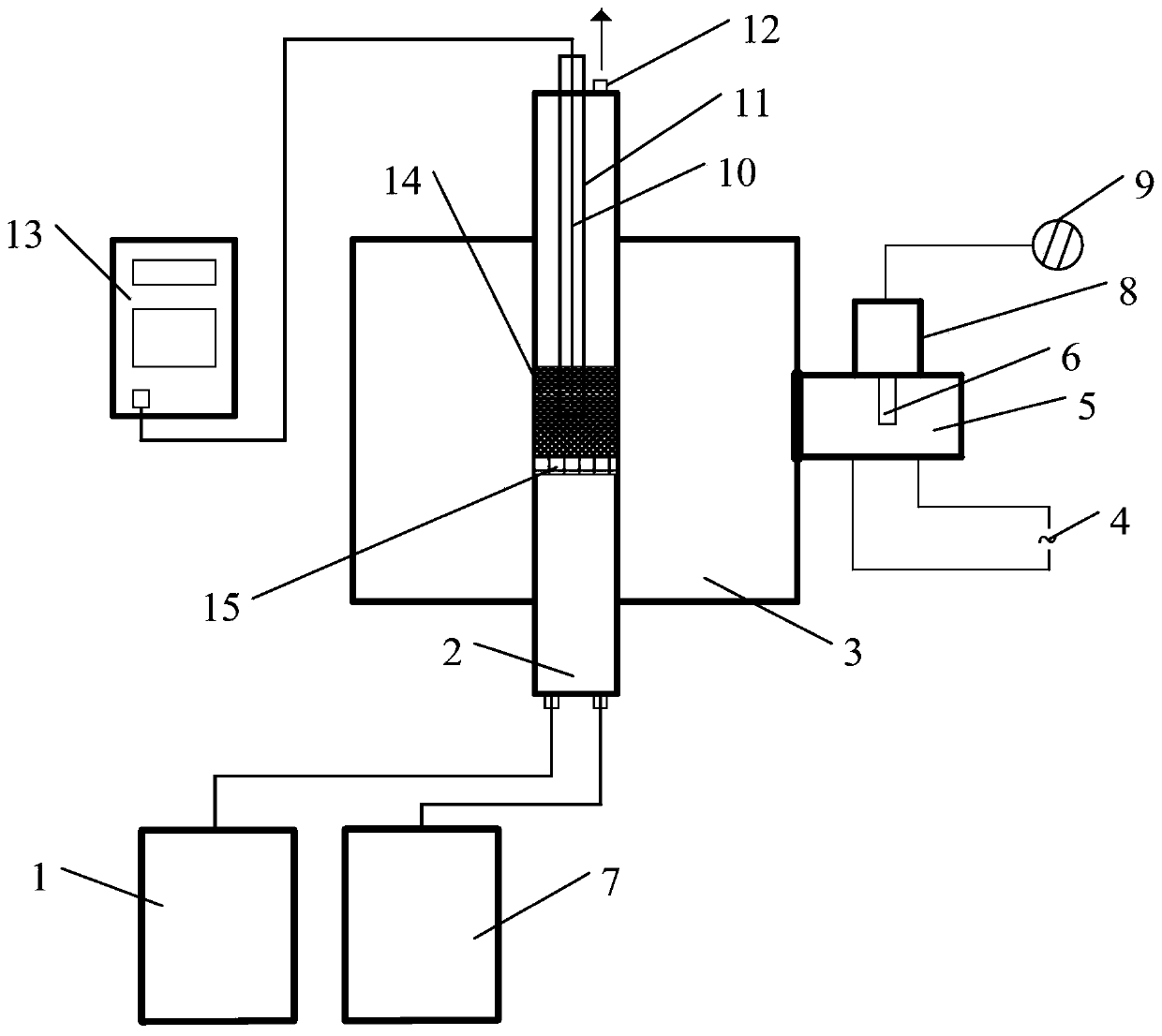

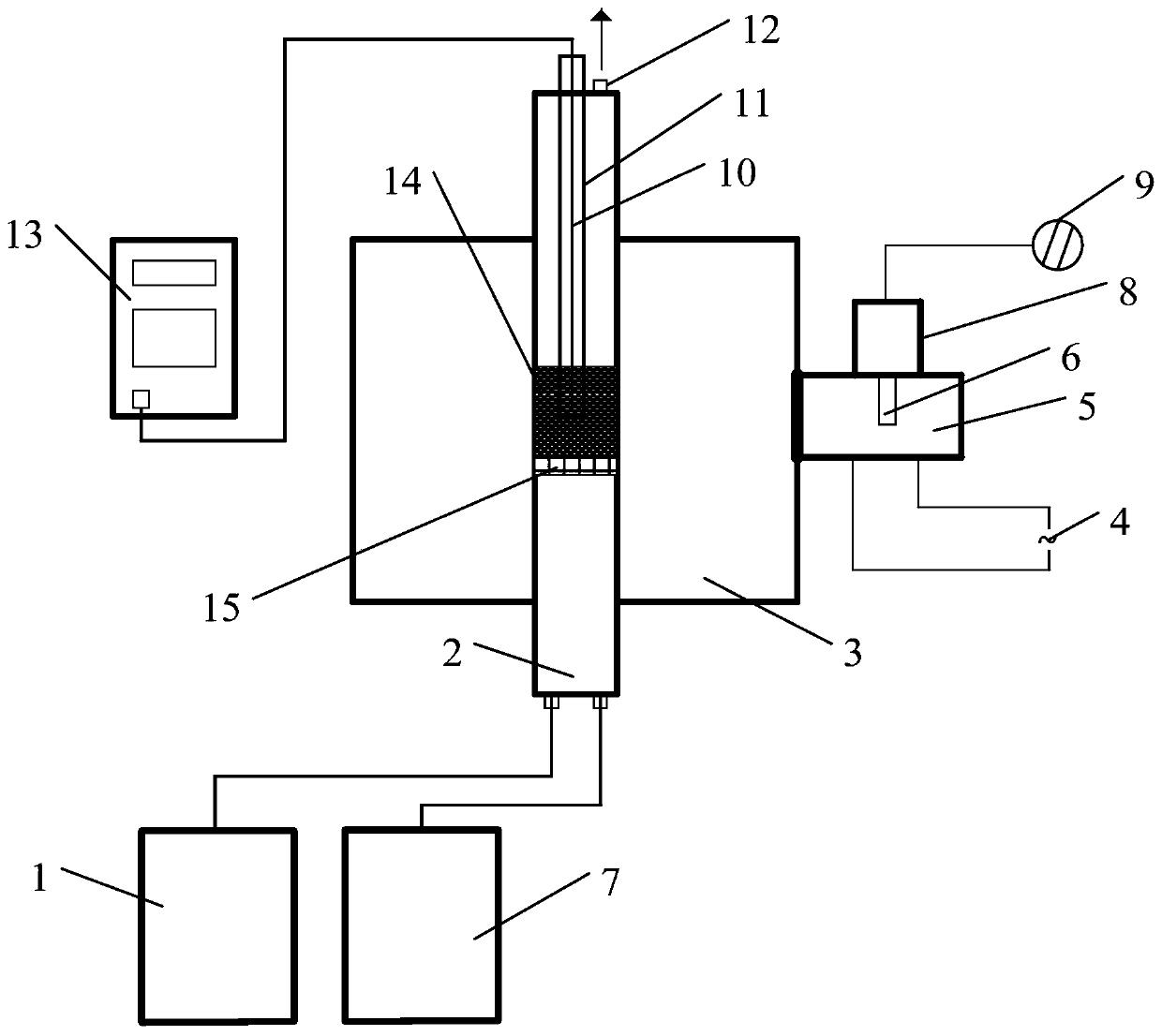

Process and device of fluidized bed for synthesis gas methanation

ActiveCN102773051AFull gas-solid contactSmall temperature differenceHydrocarbon from carbon oxidesGaseous fuelsChemistryNatural gas

The invention relates to a process and a device of a fluidized bed for synthesis gas methanation and belongs to the technical field of coal natural gas. The process includes first preheating raw material gas composed of H2 and CO, introducing the preheated gas from the bottom of a fluidized bed reactor in a magnetic field, enabling the raw material gas to be completely contacted with catalyst particles for reaction, conducting separation on mixture of gas products and a small amount of catalyst fine powder through a cyclone separator and conducting following processing to obtain purified methane. The device is composed of a fluidized bed reactor and auxiliary devices including a magnetic field generator, a current stabilizing power supply controller, a mass flow meter and the like which are sleeved on the outer portion of the fluidized bed. The process and the device enable the catalyst particles to form a magnetic stable bed by cooperative control of an external magnetic field and gas flow speed under the effect of the magnetic field, prevent catalyst particle from bonding flow loss, improve fluidization quality, strengthen gas-solid heat transfer and mass transfer, are small in temperature difference in a bed layer, improve carbon monoxide conversion rate and methane selectivity, simultaneously can prevent the catalyst particles from being brought out of the fluidized bed reactor by gas and reduce catalyst loss.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

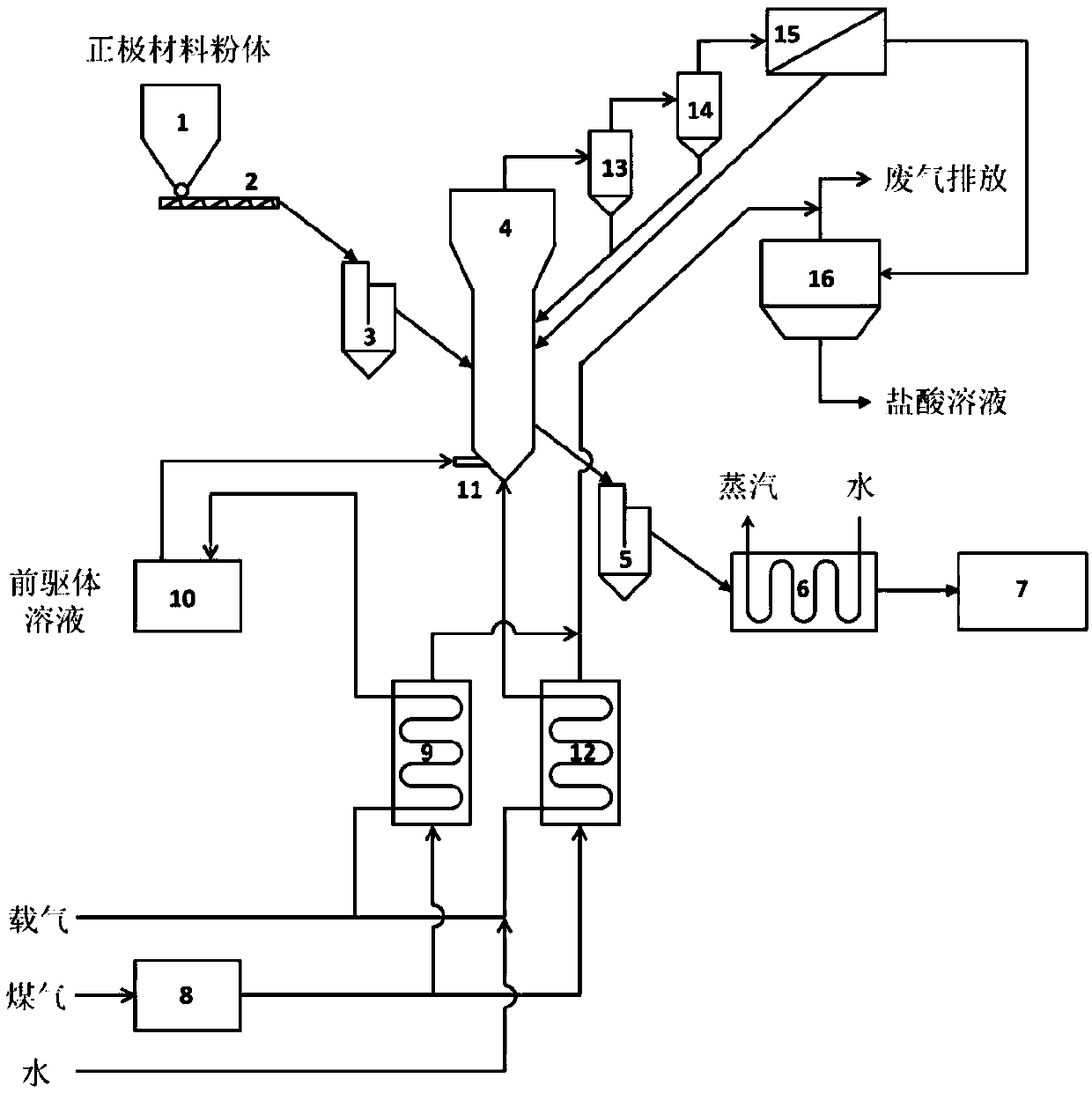

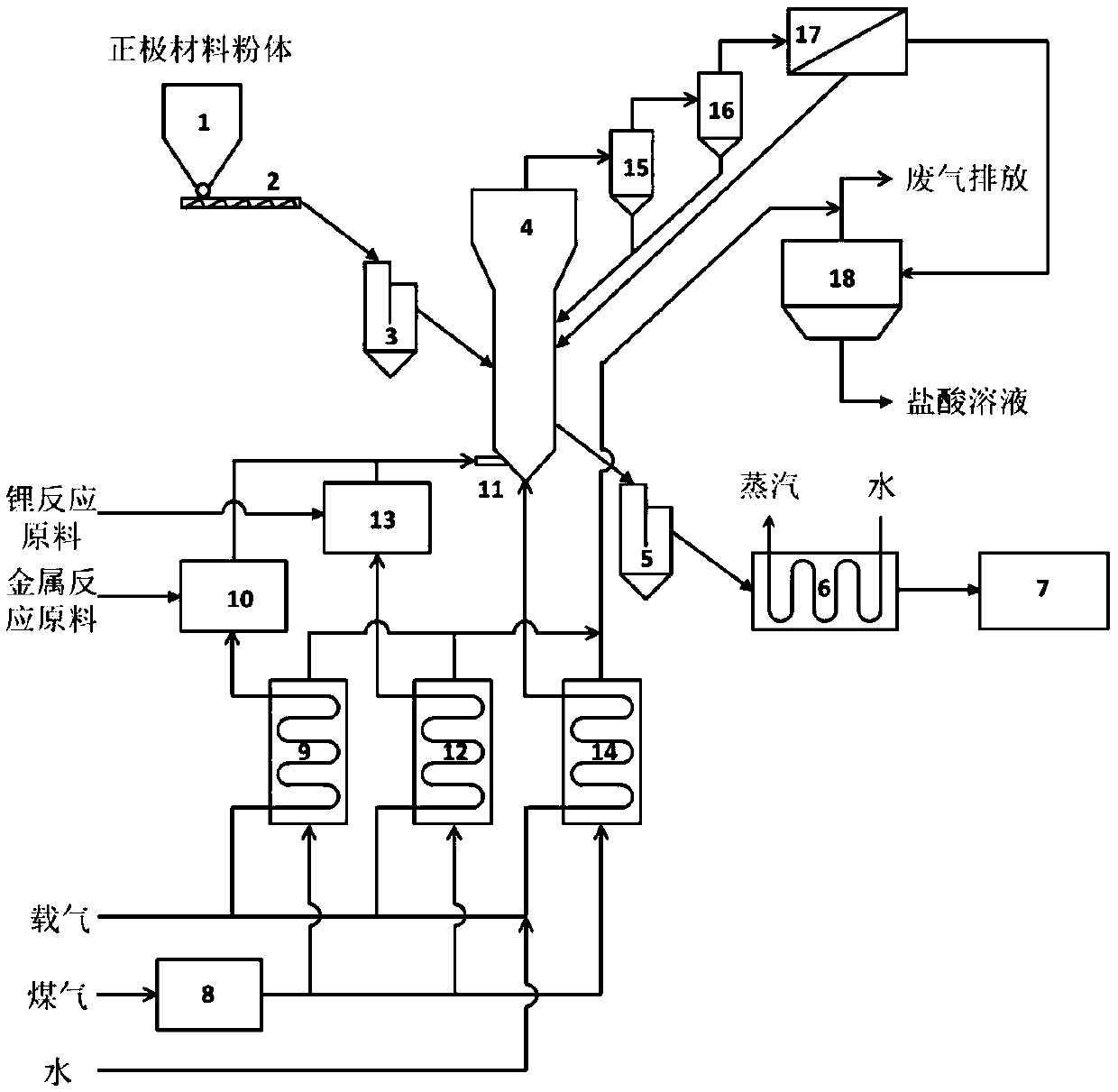

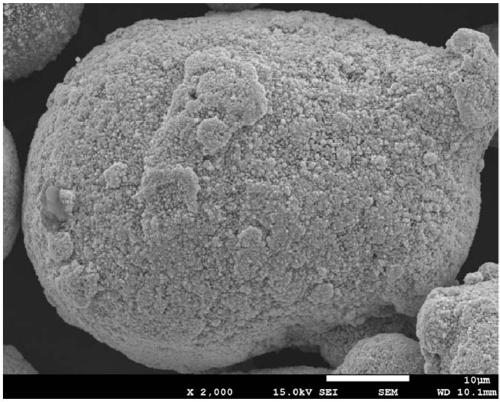

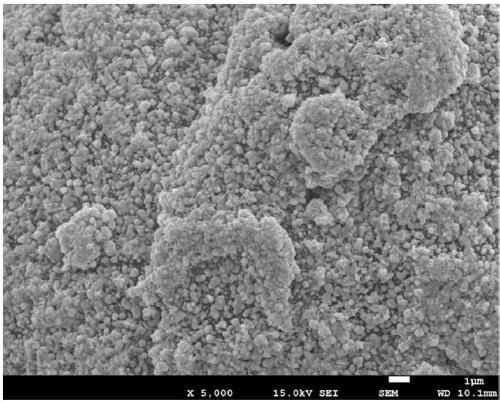

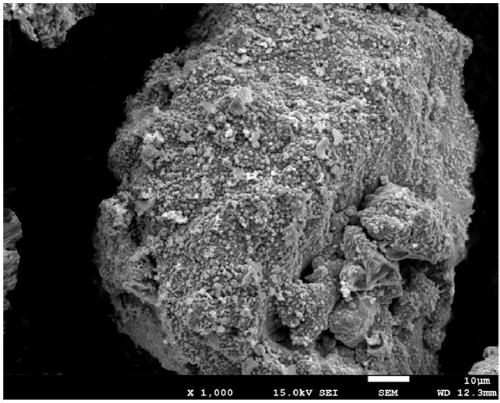

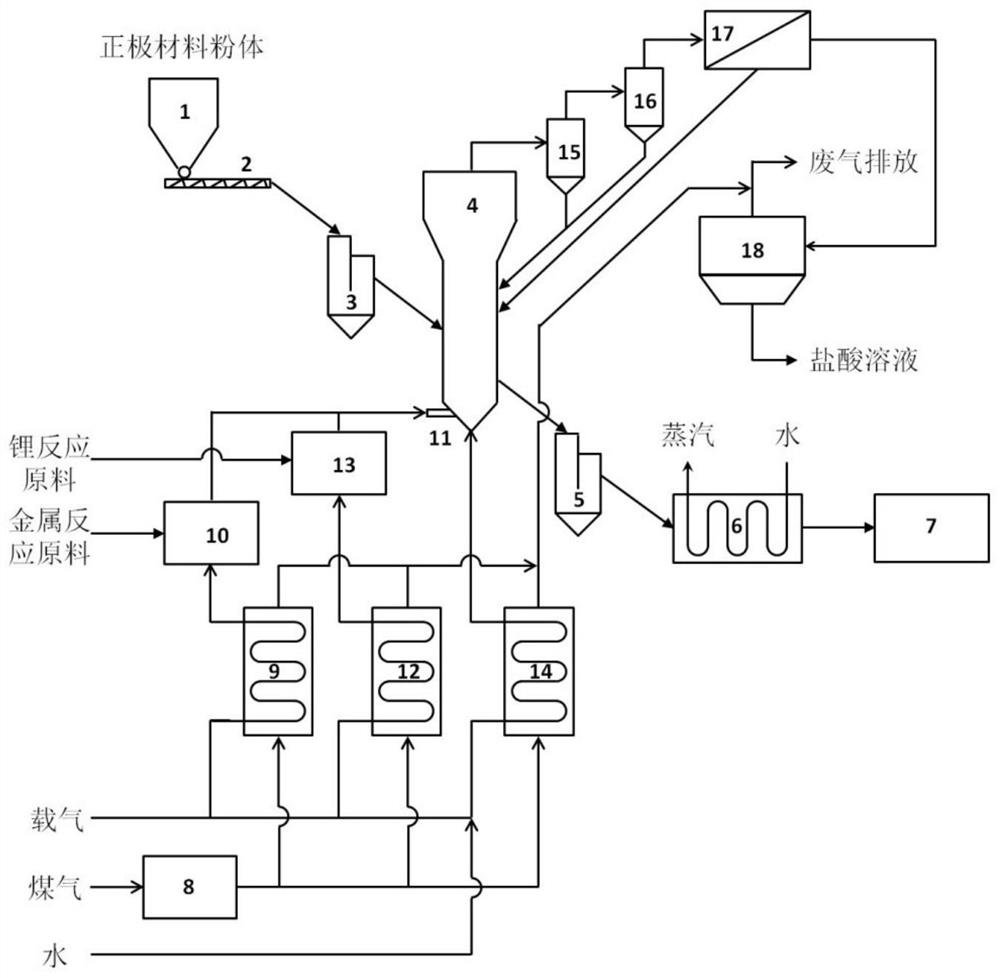

System and method for composite cladding of lithium ion battery positive electrode material with carbon and metal oxides

ActiveCN109621847AOvercoming the difficulty of fluidization of fine powderFull gas-solid contactCombination devicesCell electrodesModified methodLithium electrode

The invention relates to a system and method for the composite cladding of a lithium ion battery positive electrode material with carbon and metal oxides. The system is mainly composed of a material chamber, a spiral feeding device, a feeding valve, a fluid-bed reactor, a discharging valve, a product cooling device, a product collecting device, a combustion device, a reactor gas carrying preheating device, a precursor generator, a reactor raw material nozzle, a fluidifying gas carrying preheating device, a first-stage cyclone separator, a second-stage cyclone separator, a cloth bag dust collecting device and a hydrochloric tail gas device according to a set combination. The method is characterized in that a positive electrode composite powder body cladded by the carbon and the metal oxidesis obtained through fluidized chemical vapor deposition based on a carbon and metal oxide composite cladding modified method of the system. The system and the method have the advantages that the cladding efficiency is high, the technology is simple and controllable, the cost is low, the system and the method are suitable for the scaled industrial production of the carbon and metal oxide compositecladding modified positive electrode material of a lithium ion battery, and better economic benefits and social benefits are achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

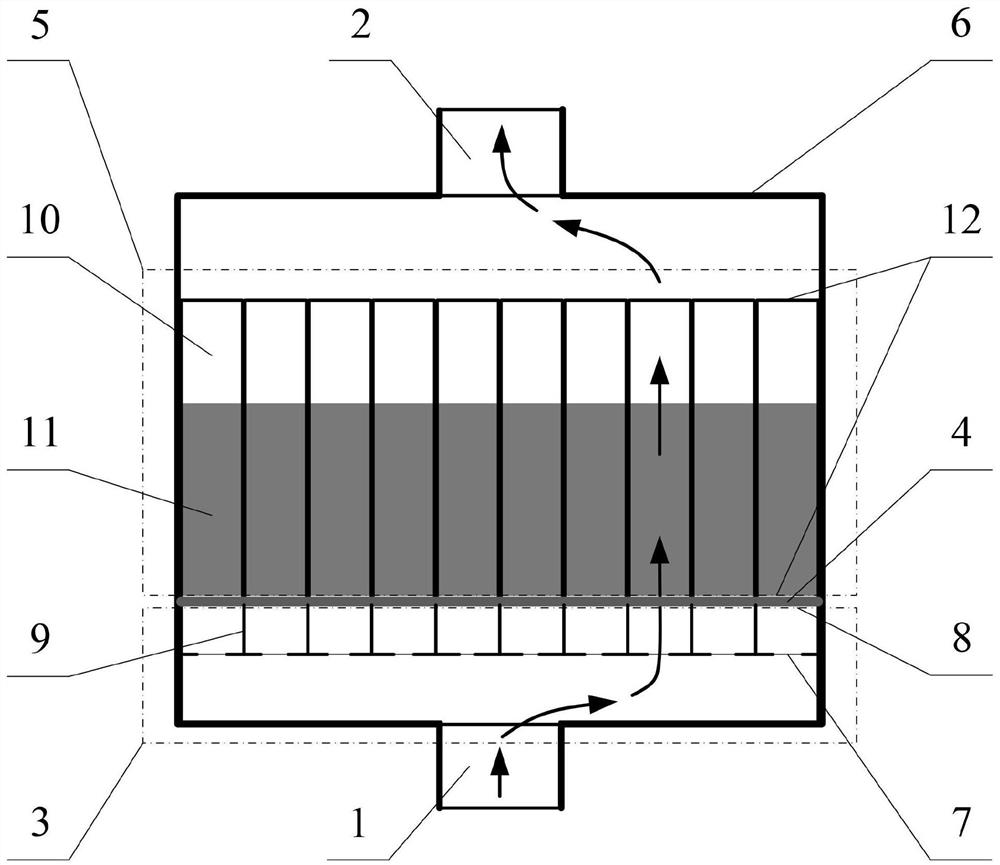

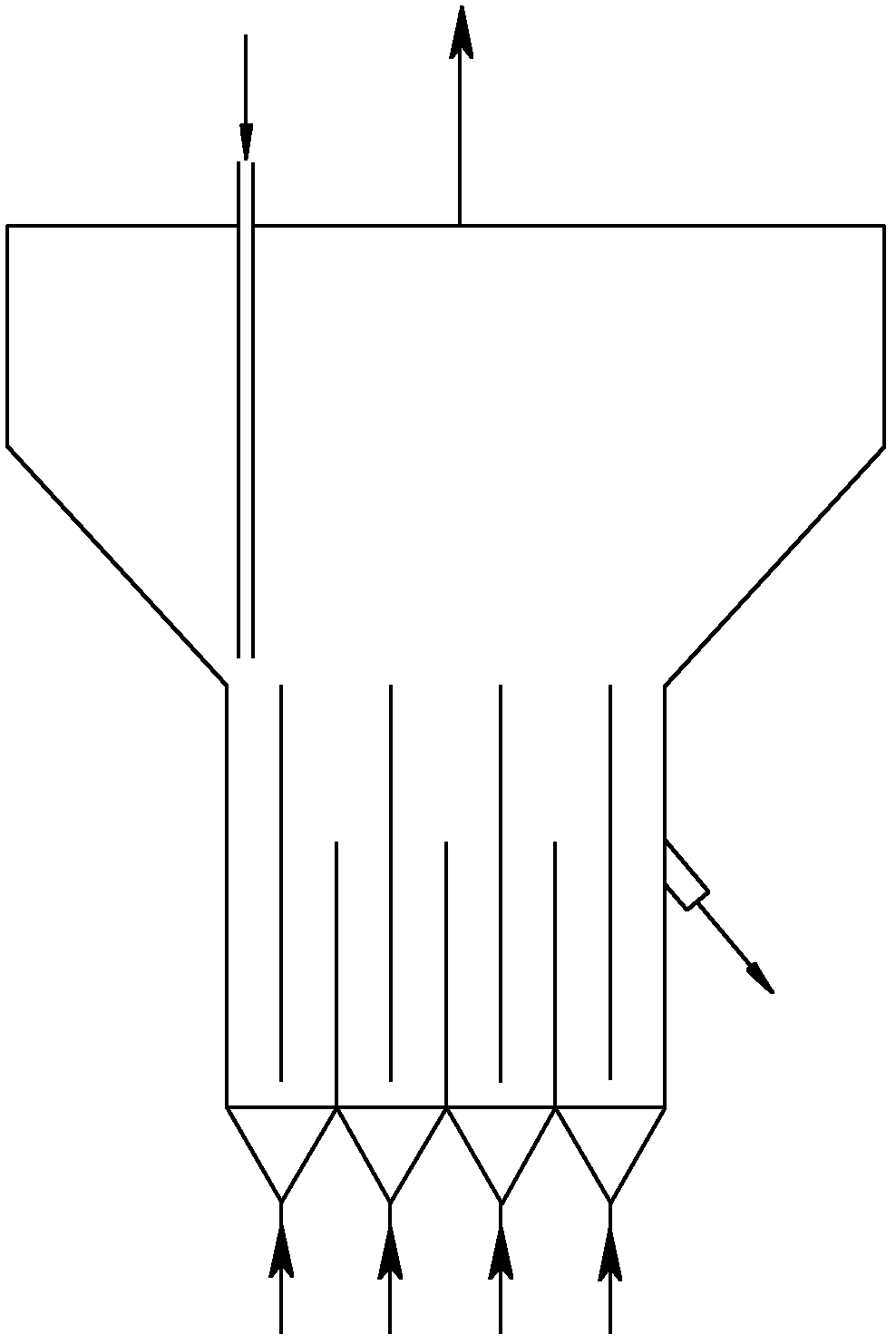

Integrated bag-type dust removal and fluidized adsorption device

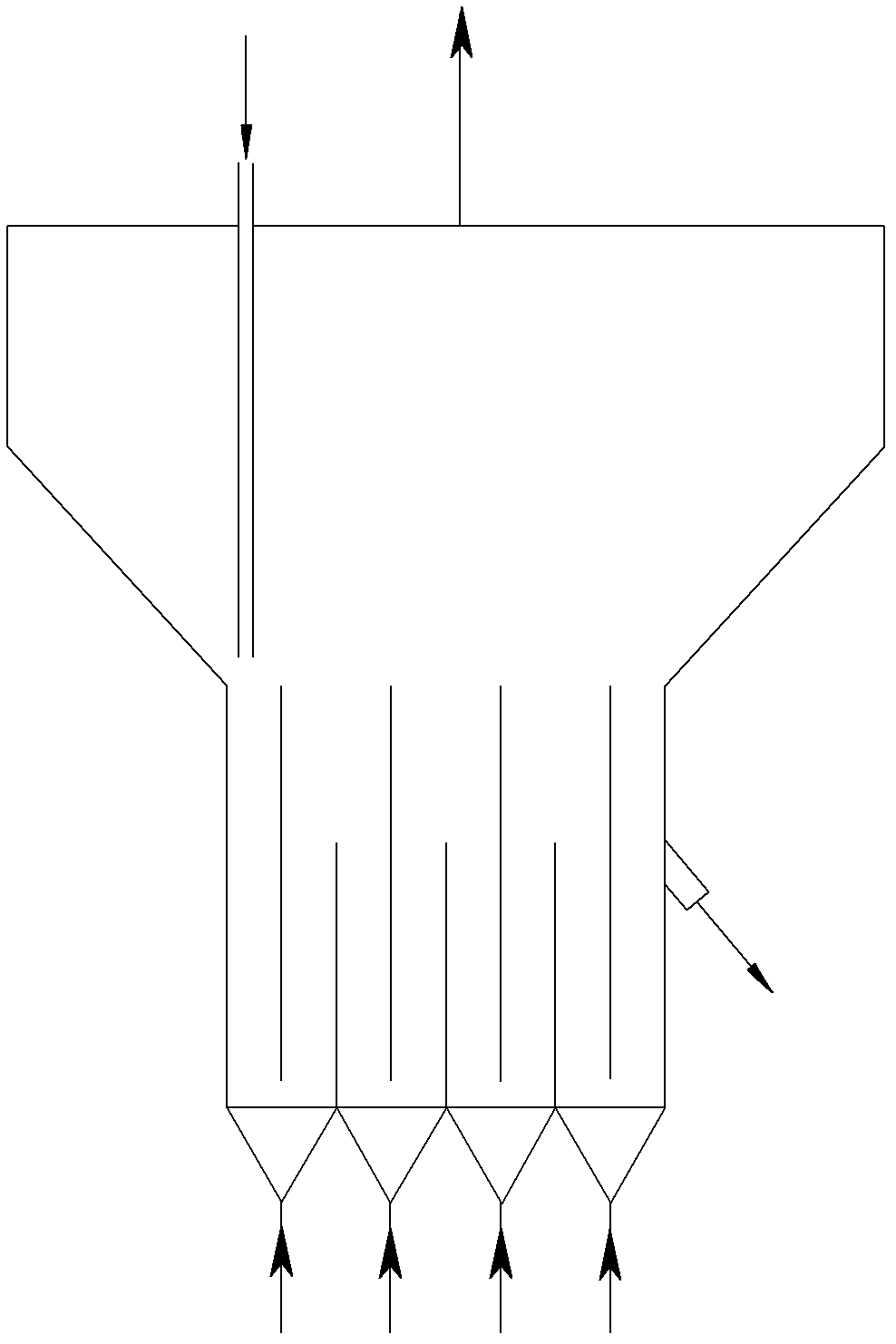

InactiveCN102716622AFull gas-solid contactPromote regenerationHuman health protectionDispersed particle filtrationSorbentAdsorption effect

The invention relates to an integrated bag-type dust removal and fluidized adsorption device. The integrated bag-type dust removal and fluidized adsorption device comprises a dust bin, a box body and a dust cleaning device, wherein the box body is divided into one or more chambers; a plurality of bag filters for removing dust are arranged in each chamber; a fluidized bed is arranged in the dust bin and the box body; the fluidized bed is provided with a discharge pipe, a flue gas collection box, a gas distribution plate and a lift pipe in sequence from the bottom up; the equivalent diameter of the lift pipe is 1 to 15 percent that of the box body; one side at the lower part of the lift pipe is connected with a feed pipe; the upper part of the fluidized bed is connected with a gas-liquid separator through a smoke exhaust pipe; and flue gas, in which the dust is removed by the bag filters, enters the flue gas collection box through a flue gas pipeline and fluidizes absorbent in the lift pipe through the gas distribution plate, and the absorbent is used for adsorbing gaseous pollutants. The integrated bag-type dust removal and fluidized adsorption device has the advantages of simple structure, convenience and reliability in operation, no secondary pollution and no water consumption. Meanwhile, the integrated bag-type dust removal and fluidized adsorption device can effectively remove the gaseous pollutants such as particles, SO2, NOx and Hg as well as various poisonous and adverse organic industrial emissions and has good dust removal and adsorption effects.

Owner:HARBIN INST OF TECH AT WEIHAI

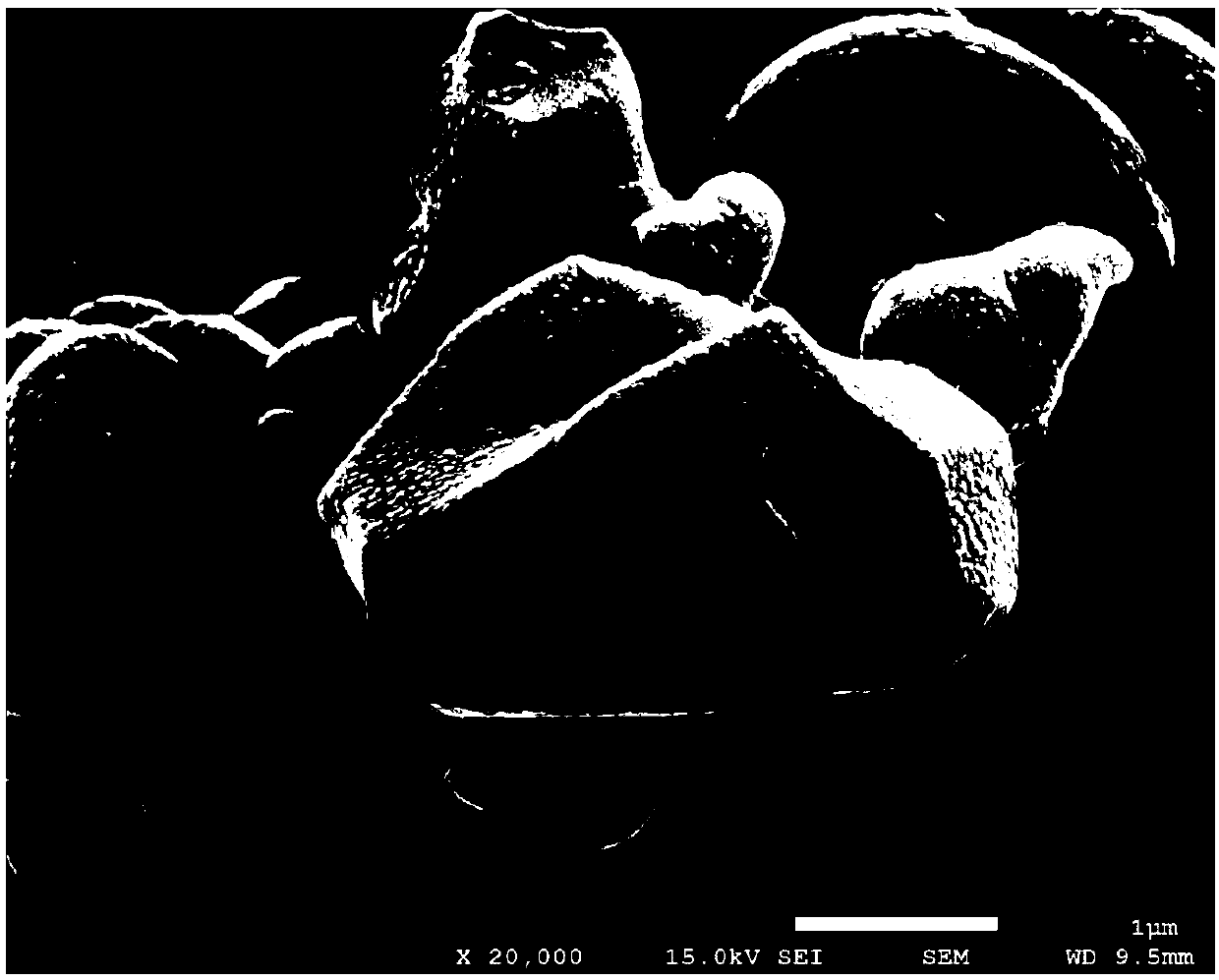

System and method for coating lithium ion battery cathode material with fast ion conductor

ActiveCN109671922AOvercome the disadvantages of difficult fluidizationFull gas-solid contactCell electrodesCycloneElectrical conductor

The present invention provides a system and a method for coating a lithium ion battery cathode material with a fast ion conductor. The system mainly comprises a stock bin, a screw feeder, a feed valve, a fluidized bed reactor, a discharge valve, a product cooler , a product collector, a burner, an No.1 reaction carrier gas preheater, a metal reaction raw material generator, a reaction raw materialnozzle, an No.2 reaction carrier gas preheater, a lithium reaction raw material generator, a fluidized carrier gas preheater, a primary cyclone separator, a secondary cyclone separator, a baghouse dust collector and a hydrochloric acid tail gas absorber according to predetermined combination; the method is a fast ion modification method based on the system. The fast ion conductor coating the cathode composite powder is obtained through fluidization chemical vapor deposition. The system and the method for coating a lithium ion battery cathode material with a fast ion conductor are high in coating efficiency, simple and controllable in the process and low in cost, are suitable for large-scale industrial production of lithium ion battery fast ion conductor coating the modified cathode material, and have good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for tungsten modification treatment of powder surface

InactiveCN109365801AImprove performanceEnhanced interface bindingTransportation and packagingMetal-working apparatusFluidized bedReactive gas

The invention discloses a method for tungsten coating modification treatment of a powder surface. A chemical vapor deposition technology of a fluidized bed is adopted, and the method comprises the following step (1) of adding matrix powder to a fluidized bed reactor arranged in a heating furnace, and regulating the speed of fluidizing gas, so that the matrix powder is in the fluidized state; and the step (2) of introducing reactive gas into a matrix powder fluidizing section in the fluidized bed, reacting in the fluidized bed, and depositing metal tungsten on the surface of the matrix powder,so that tungsten coating composite powder is formed. The method for tungsten modification treatment of the powder surface is simple in technological process and low in production cost, and continuousoperation and expanded production are easy to achieve. The synthetic tungsten coating powder is of a core-shell structure, and the combining capacity between the metal tungsten and the interface of the matrix powder is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

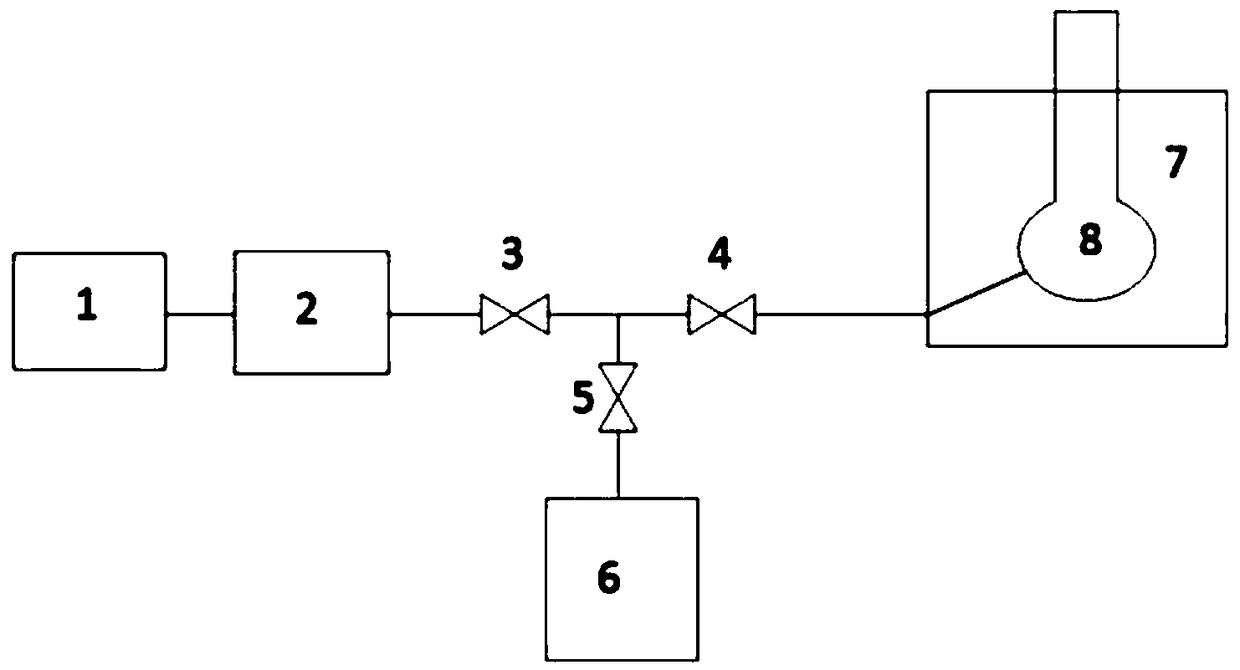

Microwave fluidized roasting-leaching method for reinforcing high phosphorous iron ore iron-extracting and phosphorus-reducing

ActiveCN109136540AEfficient use ofRaise the gradeProcess efficiency improvementMagnetic separationIronstoneMaterials science

The invention discloses a microwave fluidized roasting-leaching method for reinforcing high phosphorous iron ore iron-extracting and phosphorus-reducing. The method is performed according to the following steps: (1) preparing high phosphorous iron ore as a raw material; (2) grinding the ore after crushing, to obtain iron ore powder; (3) sending to a microwave fluidized roasting furnace, and roasting in a reducing atmosphere condition; (4) after levigating the roasted ore, performing low intensity magnetic separation; (5) performing acid leaching dephosphorization by using sulfuric acid, afterthe acid leaching dephosphorization, filtering and separating a solid material; washing the solid material, and drying. The method is capable of realizing efficient comprehensive utilization of the high phosphorous iron ore, high in iron grade and recovery rate, remarkable in phosphorus-reducing effect. A technology is more energy-saving and cost-reducing, and the iron-extracting and phosphorus-reducing effect is more remarkable. Recycling and efficient development and utilization of high phosphorous oolitic hematite are realized.

Owner:NORTHEASTERN UNIV

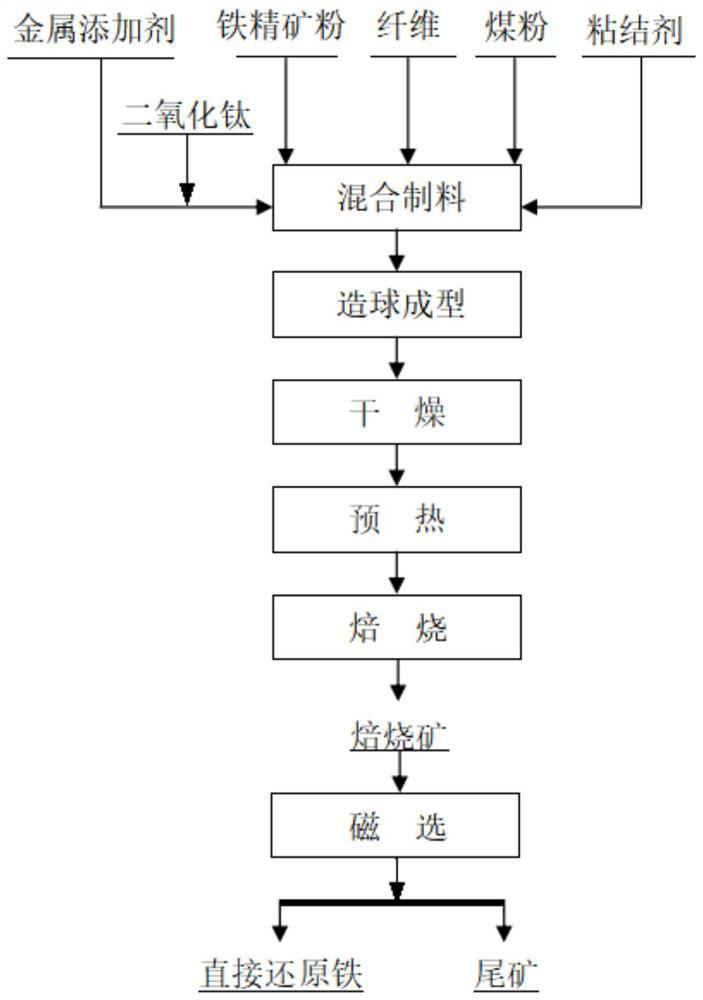

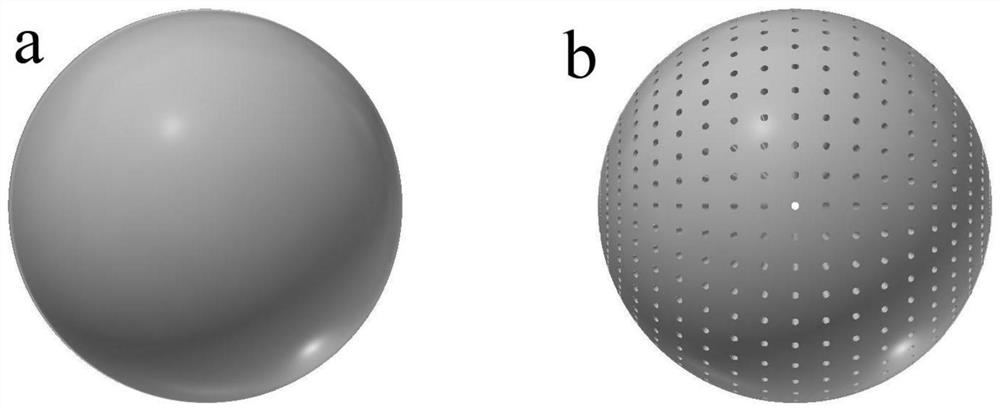

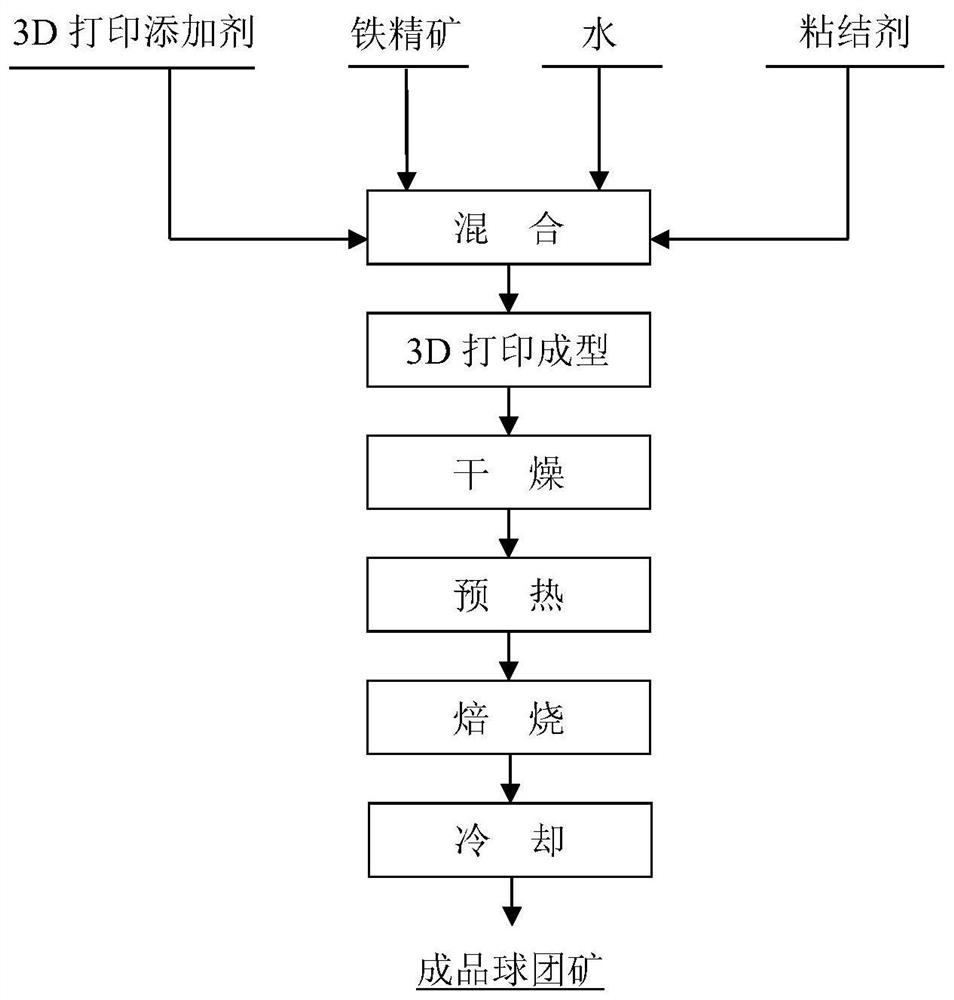

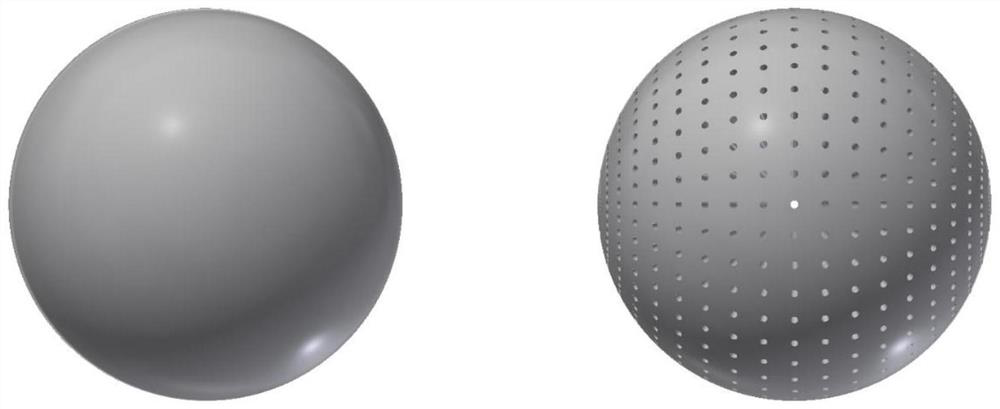

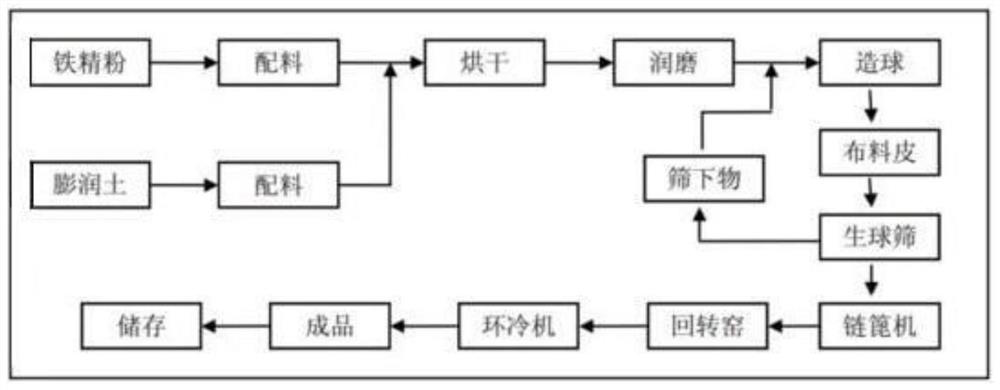

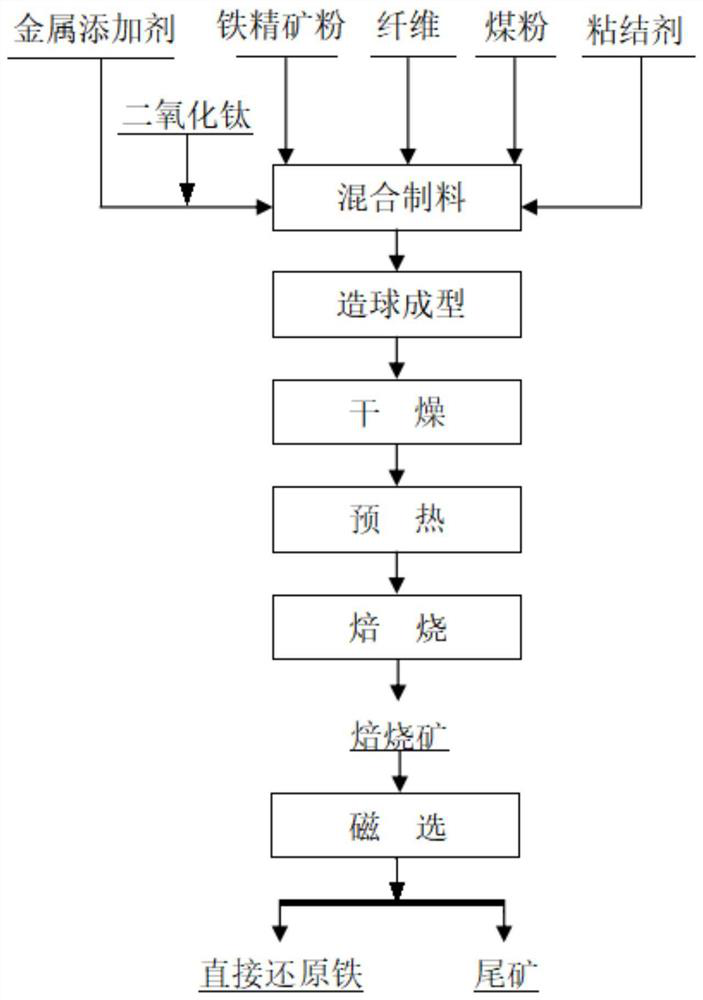

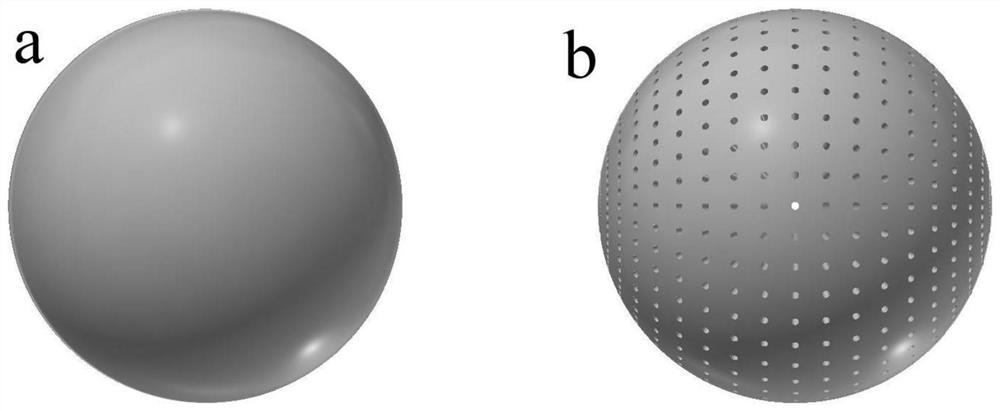

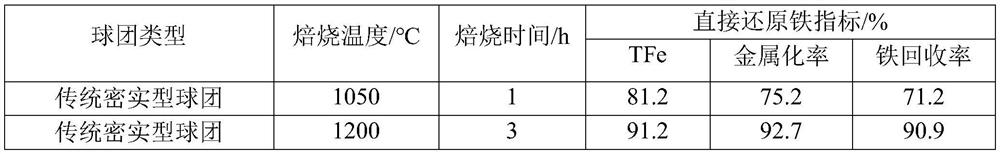

Direct reduction metallurgy method for iron ore based on 3D printing

ActiveCN112126778AImprove thermal stabilityImprove stress resistanceAdditive manufacturing apparatusMagnetic separation3d printHoneycomb like

The invention discloses a direct reduction metallurgy method for iron ore based on 3D printing. According to the metallurgy method, a direct reduction technology using an iron ore chain grate machineand a coal-based rotary kiln is combined with a 3D printing molding technology. Through optimization of a mixture formula, the feasibility, applicability and generalization performance of the 3D printing direct reduction technology are improved. Meanwhile, by utilizing the accuracy, synchronism and uniformity of the 3D printing molding technology, stable and high-quality green pellet ore with thesame honeycomb pore structure is obtained. The green pellet ore is placed in a high-temperature furnace to obtain a qualified direct reduction iron product through drying, preheating, reduction roasting, cooling, magnetic separation enrichment, etc.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

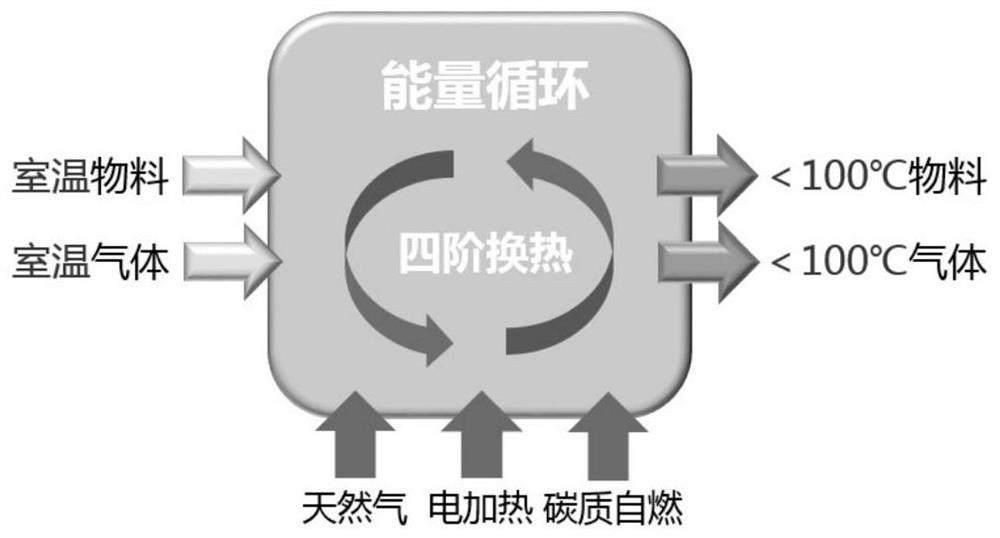

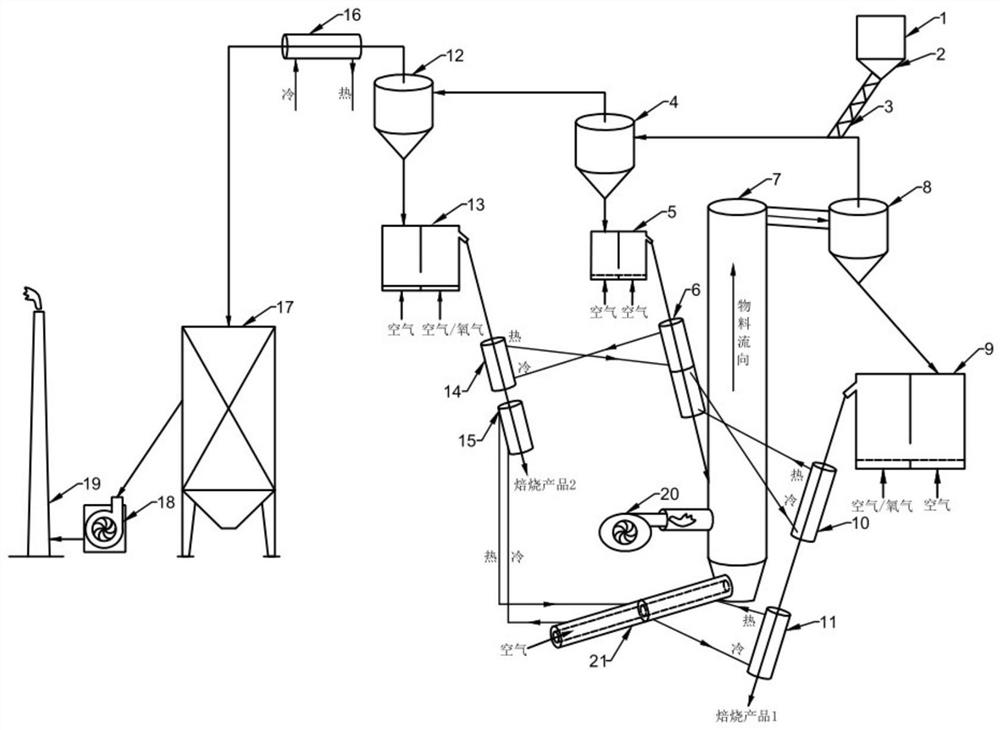

Stone coal vanadium ore cascade oxidizing roasting vanadium extraction system and oxidizing roasting method

PendingCN114111359APrevent sinteringImprove energy utilizationControl devices for furnacesWaste heat treatmentHeat transfer efficiencyDecarburization

The invention provides a stone coal vanadium ore cascade oxidizing roasting vanadium extraction system and an oxidizing roasting method. The system comprises a feeding system, a discharging system and a vanadium extraction system, wherein the feeding system is composed of a stock bin, a weightlessness scale and a spiral feeding pipe; the material circulating heat storage system consists of a primary cyclone separator, a flow sealing valve, a main furnace and a secondary cyclone separator; the stepped oxidizing roasting system consists of a decarburization roasting reactor, a crystal breaking roasting reactor and an ore discharge heat exchange pipe; the negative pressure dust removal system consists of a three-stage cyclone separator, a dust hopper, a bag-type dust remover, a Roots blower and a chimney; the decarburization roasting reactor and the crystal breaking roasting reactor are connected in series, so that the purpose of segmented suspension roasting of materials can be achieved; in addition, the system comprises a four-stage heat exchange process and a first-stage self-heating utilization process, and the overall energy utilization rate is extremely high, so that the stepped oxidation roasting system has the advantages of independent and controllable two-stage roasting, full gas-solid contact, high energy utilization rate, high mass and heat transfer efficiency, low operation cost, high efficiency, environmental protection and the like.

Owner:上海逢石科技有限公司

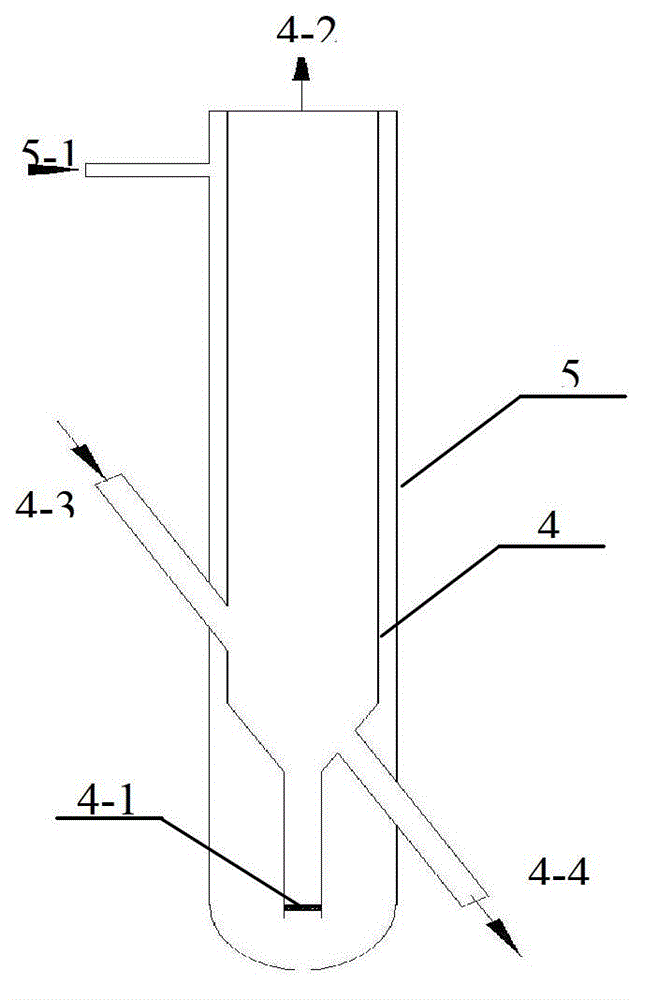

Method for removing sulfur oxides and/or nitrogen oxides from flue gas

ActiveCN109663496AFull gas-solid contactHigh removal rateDispersed particle separationChemical/physical processesUreaChemistry

The invention relates to a method for removing sulfur oxides and / or nitrogen oxides from flue gas. The method comprises: introducing an adsorbent into a flue gas adsorbing device while injecting a reducing agent, wherein the adsorbent adsorbs and removes sulfur oxides and partial nitrogen oxides from the flue gas, and simultaneously decomposes and removes the remaining nitrogen oxides to obtain purified flue gas; and introducing the spent adsorbent achieving the saturated adsorbing state into an adsorbent regenerating device, introducing a reducing gas into the adsorbent regenerating device, and at a temperature of 400-700 DEG C, carrying out desorption reduction on the sulfur oxides and / or nitrogen oxides adsorbed on the adsorbent to convert into hydrogen sulfide and nitrogen, wherein theregenerated adsorbent returns to the flue gas adsorbing device so as to be recycled, the reducing agent injected in the flue gas adsorbing device is a urea aqueous solution and / or ammonia gas, and the adsorbent is a catalytic cracking catalyst. According to the present invention, with the method, the reducing agent is injected into the flue gas adsorbing device, and the catalytic cracking regeneration flue gas in the high-temperature and pressure state is directly treated with the adsorbent, such that the removal rates of sulfur oxides and nitrogen oxides are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

System for desulfurizing and denitrating active coke flue gas, and process method

ActiveCN102430318BIntegrated purification effect is obviousImprove utilization efficiencyDispersed particle separationSulfurDesorption

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

Highly effective slurry phase bed reactor

InactiveCN1283349CEasy to operateAvoid easy cloggingChemical/physical processesGas solidSlurry reactor

Owner:TAIYUAN UNIV OF TECH

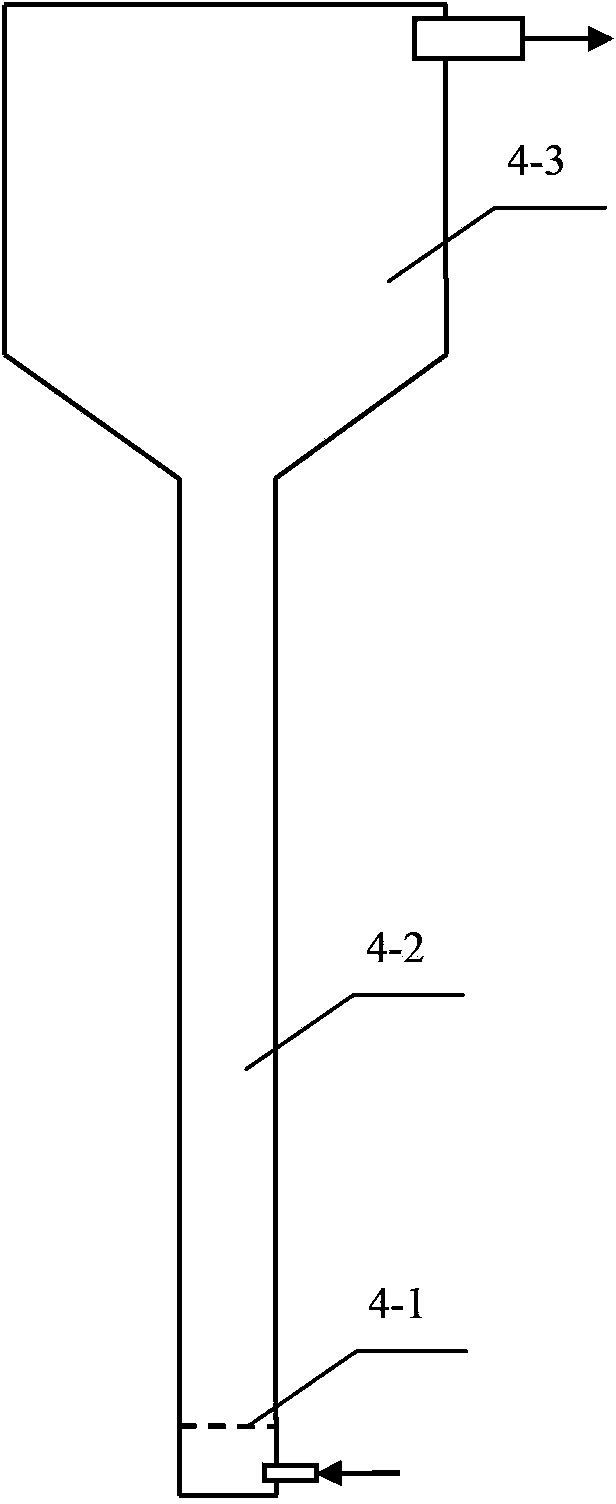

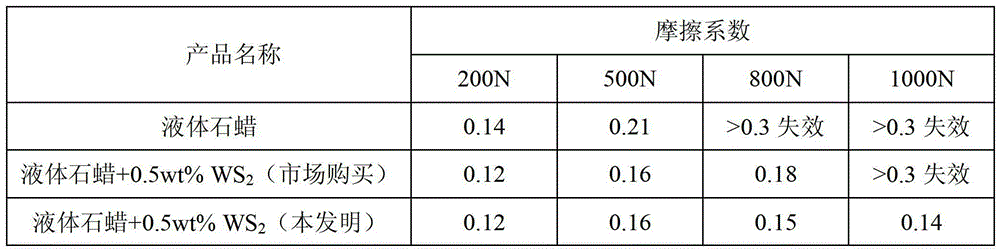

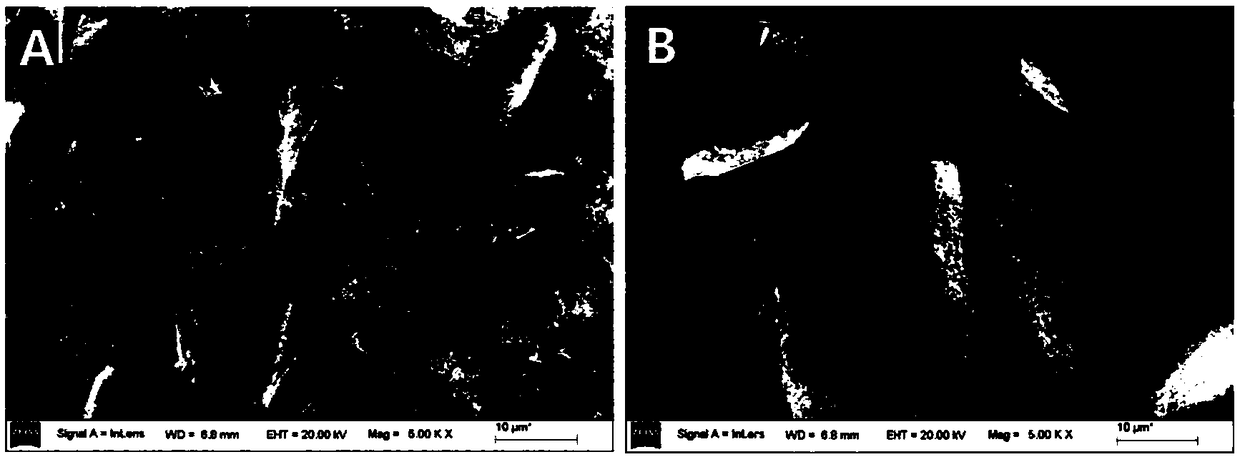

Device and method for synthesizing fullerene structure nanometer WS2 and application of fullerene structure nanometer WS2

ActiveCN102849799BUniform and rapid bulk fluidizationOvercome the disadvantage of being difficult to fluidizeMaterial nanotechnologyTungsten compoundsFluidized bedEngineering

The invention relates to a device and a method for synthesizing fullerene structure nanometer WS2 and application of the fullerene structure nanometer WS2. The device comprises a fluidized bed reactor, wherein the fluidized bed reactor comprises a gas distribution plate, a lower-layer dense phase bed and an upper-layer dilute phase bed from bottom to top. Nanometer WO3 is fed into the fluidized bed reactor through a feeding system and is contacted with and reacts with H2S / N2+H2 gas at the bottom of the fluidized bed reactor, so that WS3 powder is in a fluidized state. A reaction product WS2 flows into a cooling system from an outlet at the bottom of the fluidized bed reactor to be cooled and then is fed into a product bin. The device and the method can be used for synthesizing ullerene structure nanometer WS2 particles even in size and with average diameter of less than or equal to 500nm, overcome the defect that superfine powder is difficult to fluidize, can enable nanometer powder to be evenly and quickly fluidized and are suitable for continuous large-scale production of inorganic fullerene nanometer particles. The process and bed type are simple and easy to control and scale up.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of nano WS2 with fullerene structure, fluidized bed reactor, fluidifying method and applications

ActiveCN103101978BUniform sizeUniform dispersion fluidizationMaterial nanotechnologyTungsten compoundsNanoparticleSulfidation

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

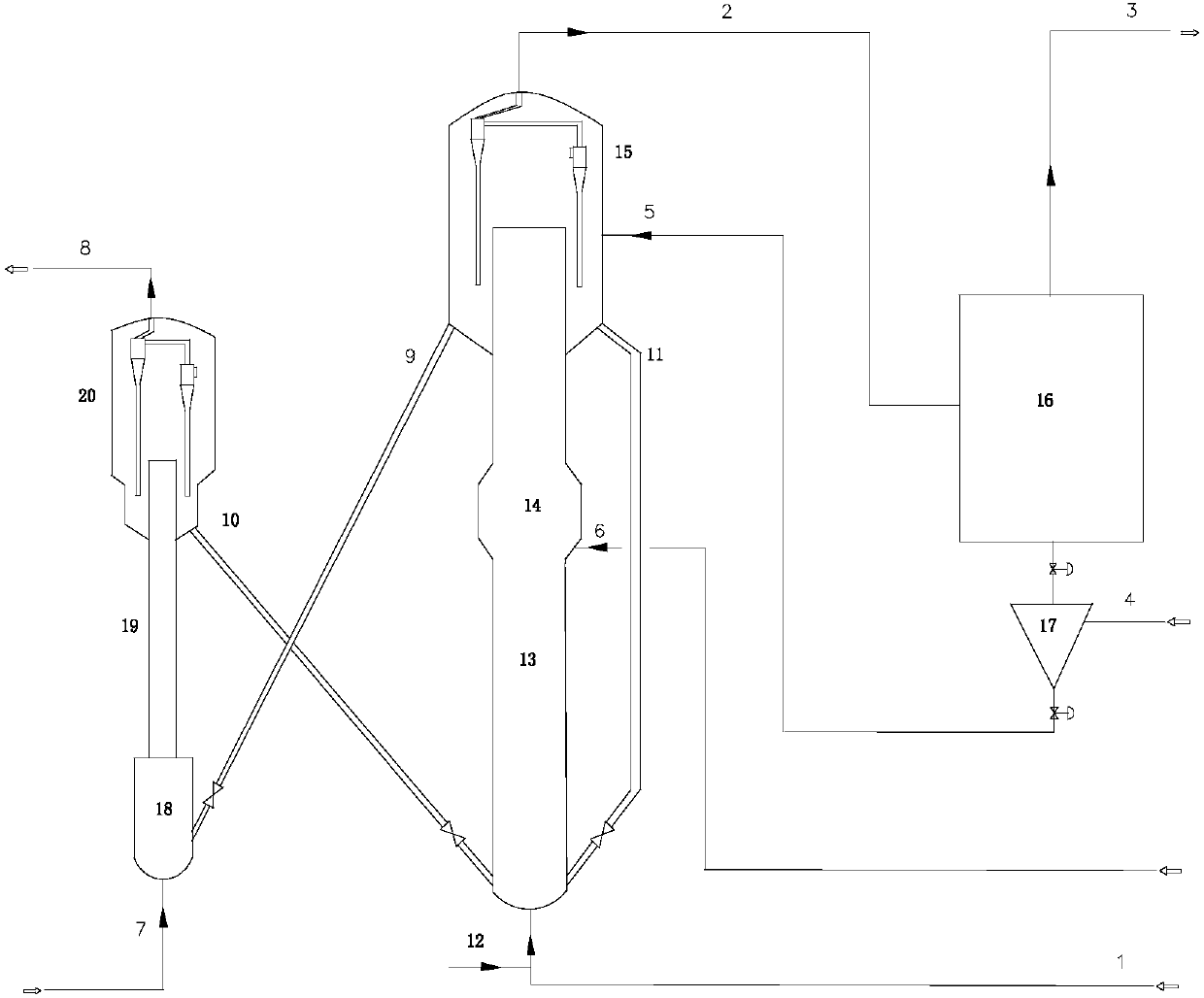

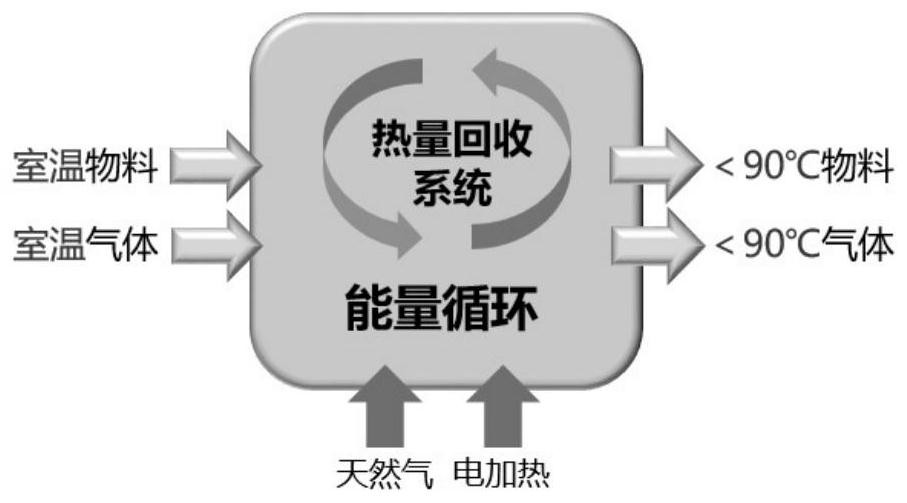

Coarse and fine grading oxidizing roasting vanadium extraction system for stone coal vanadium ore and oxidizing roasting method

PendingCN114134316AImprove energy utilizationReduce energy consumptionProcess efficiency improvementIndustrial engineeringCoarse particle

The invention provides a stone coal vanadium ore coarse and fine grading oxidizing roasting vanadium extraction system and an oxidizing roasting method. The system comprises a feeding system composed of a stock bin, a weightlessness scale and a spiral feeding pipe; the coarse grain material oxidizing roasting system consists of a first-stage cyclone separator, a flow sealing valve, a main furnace, a second-stage cyclone separator and a coarse grain roasting reactor; the fine particle material oxidizing roasting system consists of a three-stage cyclone separator and a fine particle roasting reactor; the negative pressure dust removal system consists of an exhaust heat exchanger, a bag-type dust remover, a Roots blower and a chimney; the heat recovery system consists of a heat exchanger, a first first-section cooler, a first second-section cooler, a second first-section cooler, a second second-section cooler and a heat exchange air inlet pipe; by arranging the coarse particle roasting reactor and the fine particle roasting reactor, operation parameters in the roasting process of the coarse particle stone coal and the fine particle stone coal can be independently controlled, then the leaching rate of vanadium in a roasted sample is increased, the heat utilization rate is greatly increased, and the energy consumption of the system is greatly reduced.

Owner:上海逢石科技有限公司

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

ActiveCN102824846BCombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementFlue gasProcess engineering

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

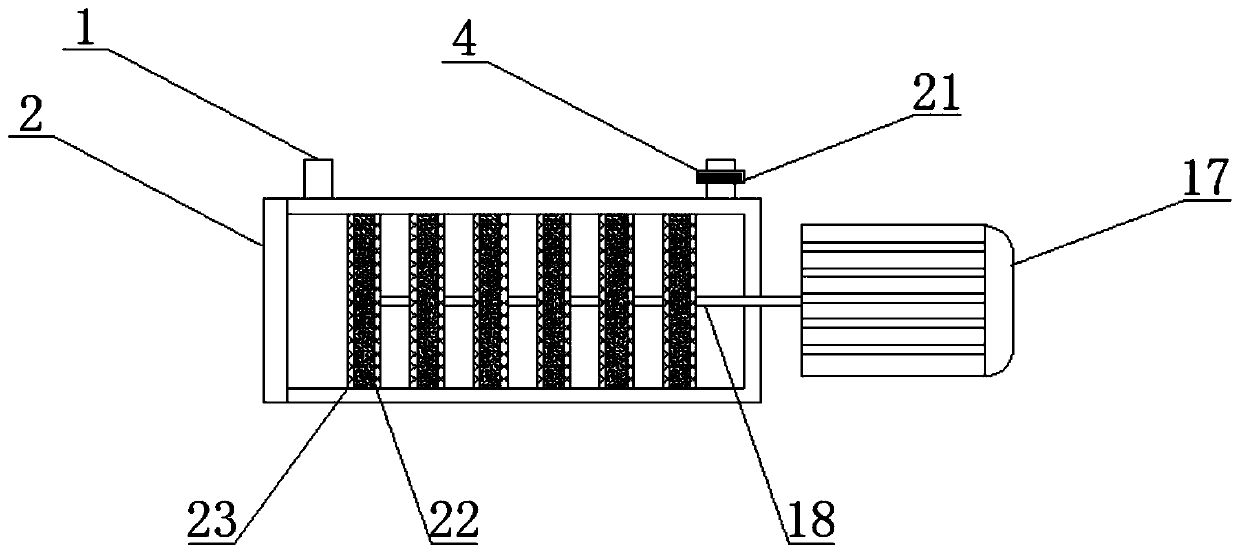

Gas drying equipment for phosphorus oxychloride production

InactiveCN111530227AAvoid wastingEvenly distributedDispersed particle filtrationActivated carbonGas solid

The invention discloses gas drying equipment for phosphorus oxychloride production. The gas drying equipment comprises a front cover and a drying cylinder, the front cover is mounted on the outer wallof the front end of the drying cylinder; an inlet pipe is arranged on the circumferential outer wall of the upper end of the front side of the drying cylinder; gas produced by phosphorus oxychlorideabsorbs moisture produced by chemical reaction after high temperature through the activated carbon adsorption layer, the goal of drying is further achieved; at the moment, gas produced by phosphorus oxychloride is introduced into the display layer, and the display layer is made of allochroic silica gel filler; when the allochroic silica gel filler adsorbs water, the color is blue and thus the operator is timely reminded that moisture adsorption is saturated and the moisture in the gas produced by phosphorus oxychloride is not completely adsorbed and dried and the gas needs to be dried again. The gas drying equipment for phosphorus oxychloride production has the advantages that the structure is simple, the gas distribution is more uniform, the gas-solid contact is more sufficient, and the moisture adsorption efficiency is greatly improved due to the multiple layers of separation nets in the drying cylinder.

Owner:FUTONG CHEM

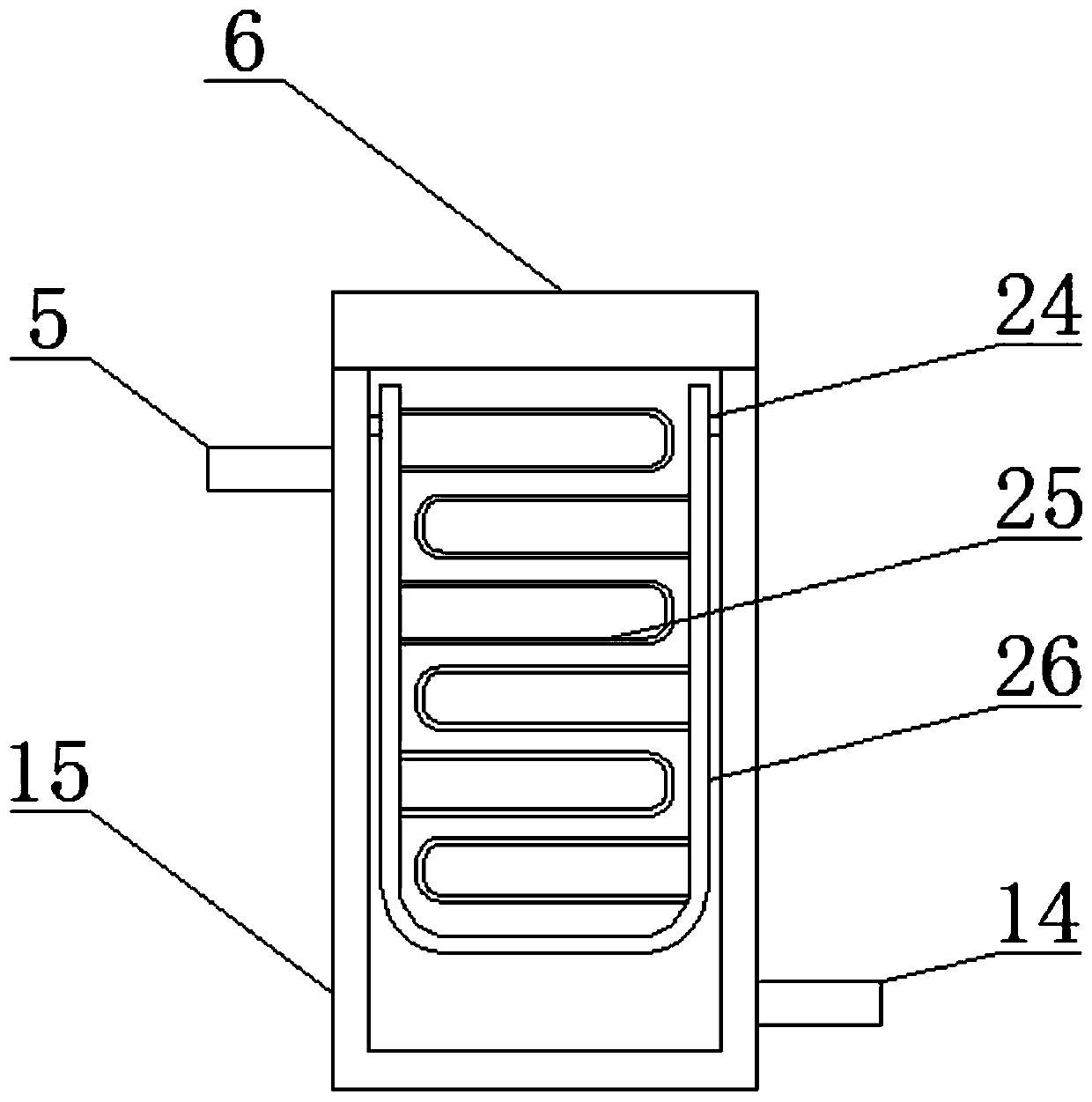

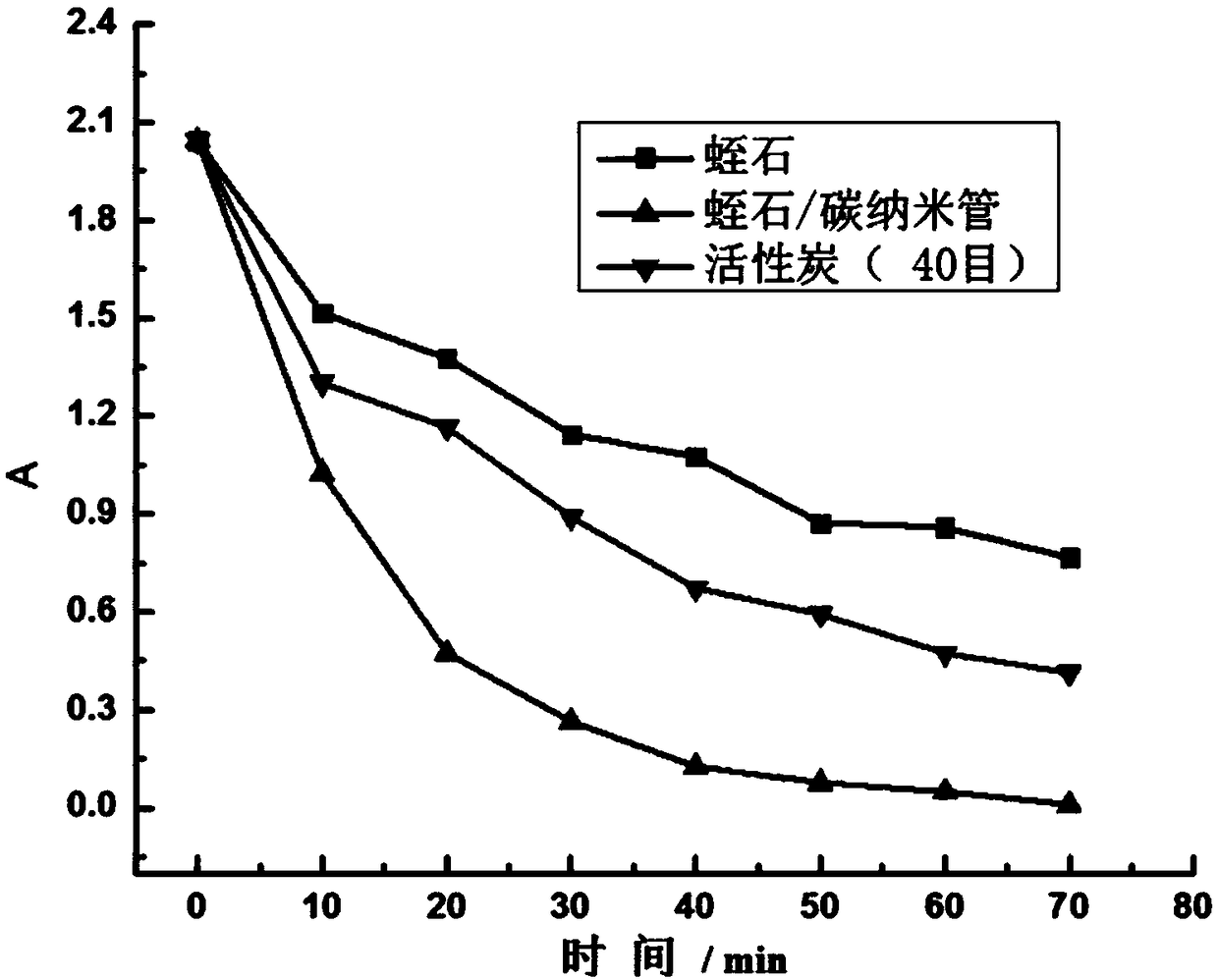

Method for preparing vermiculite carbon nanotube composite material by vertical microwave reactor

ActiveCN108840346AEasy dischargePrevent regurgitationCarbon compoundsSilicon compoundsMicrowaveReaction temperature

The invention discloses a method for preparing a vermiculite carbon nanotube composite material by a vertical microwave reactor. The method comprises the following steps: adding expanded vermiculite into the vertical microwave reactor, tangentially introducing inert gases as carrier gases, performing microwave heating, introducing reaction gas and a catalyst into the vertical microwave reactor after reaching the reaction temperature, and carrying out a catalytic reaction, thereby obtaining the vermiculite carbon nanotube composite material. According to the method disclosed by the invention, by virtue of microwave heating, the heating rate is rapid and effective. Meanwhile, due to the vertical microwave reactor, the gases are discharged, and gas suck-back is avoided. The prepared vermiculite carbon nanotube composite material is high in purity, uniform in morphology and excellent in monodispersity, and has large specific surface area, and the synthetic method is simple, effective and uniform in gas distribution, the energy consumption is low, the equipment is simple, the production efficiency is improved, the amount of pollutants is small, and the method has high economic value.

Owner:TARIM UNIV

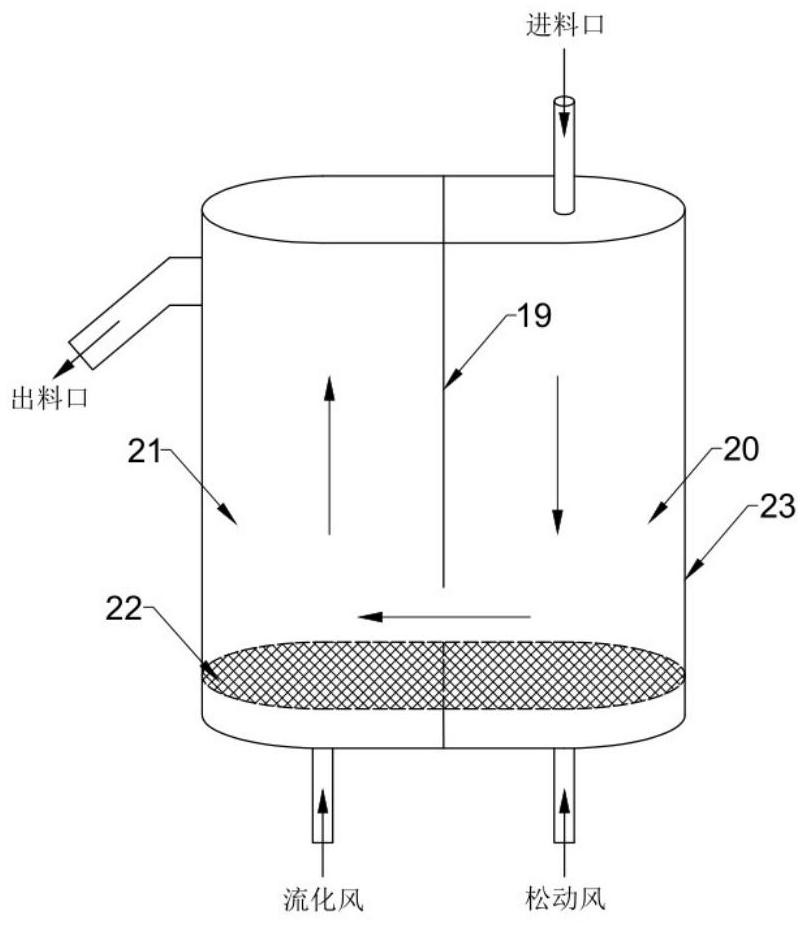

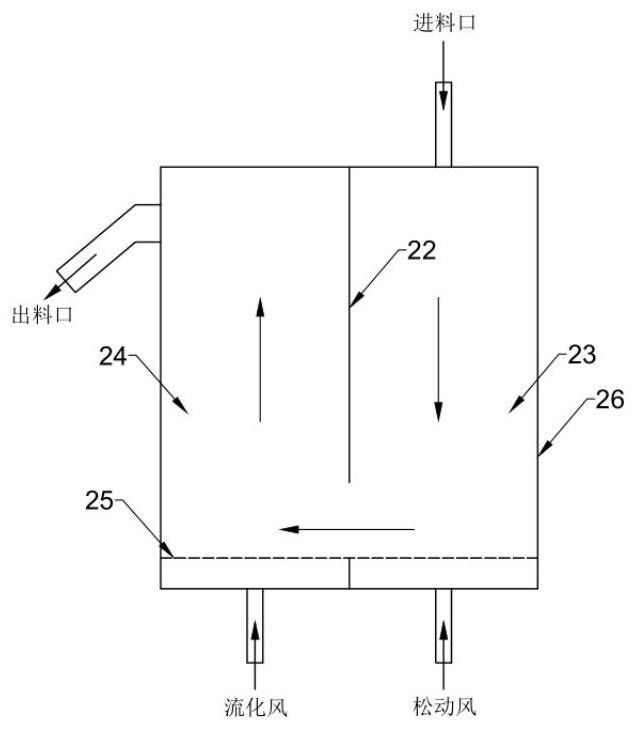

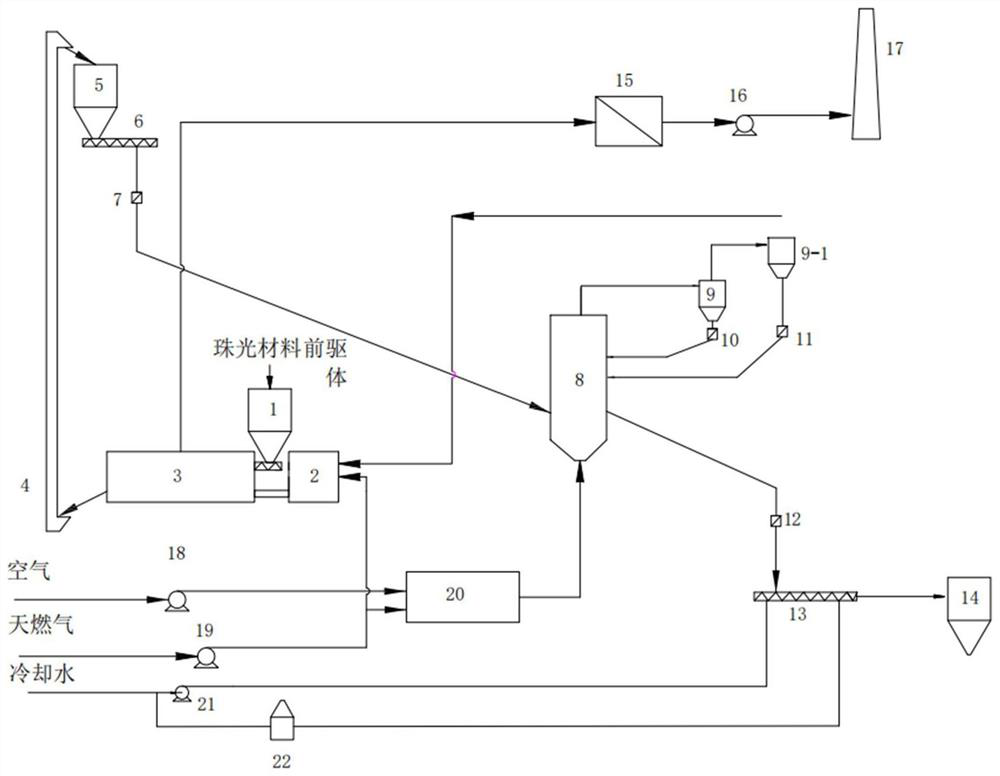

A continuous fluidized calcination system and method for pearlescent materials

ActiveCN111944333BFull gas-solid contactImprove calcination effectPigment physical treatmentSocial benefitsFluidized bed

The invention belongs to the field of calcination heat treatment of pearlescent materials, and specifically relates to a fluidized continuous calcination system and method for pearlescent materials. Fluidization technology is adopted, and a calcination process integration system with a fluidized bed reactor as the core is used to realize the calcination of pearlescent materials. Continuous calcination heat treatment. The invention has the advantages of high continuous production efficiency, good calcination effect, low production energy consumption, etc., is suitable for the industrial calcination process section of coated titanium-mica pearlescent materials, and has good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

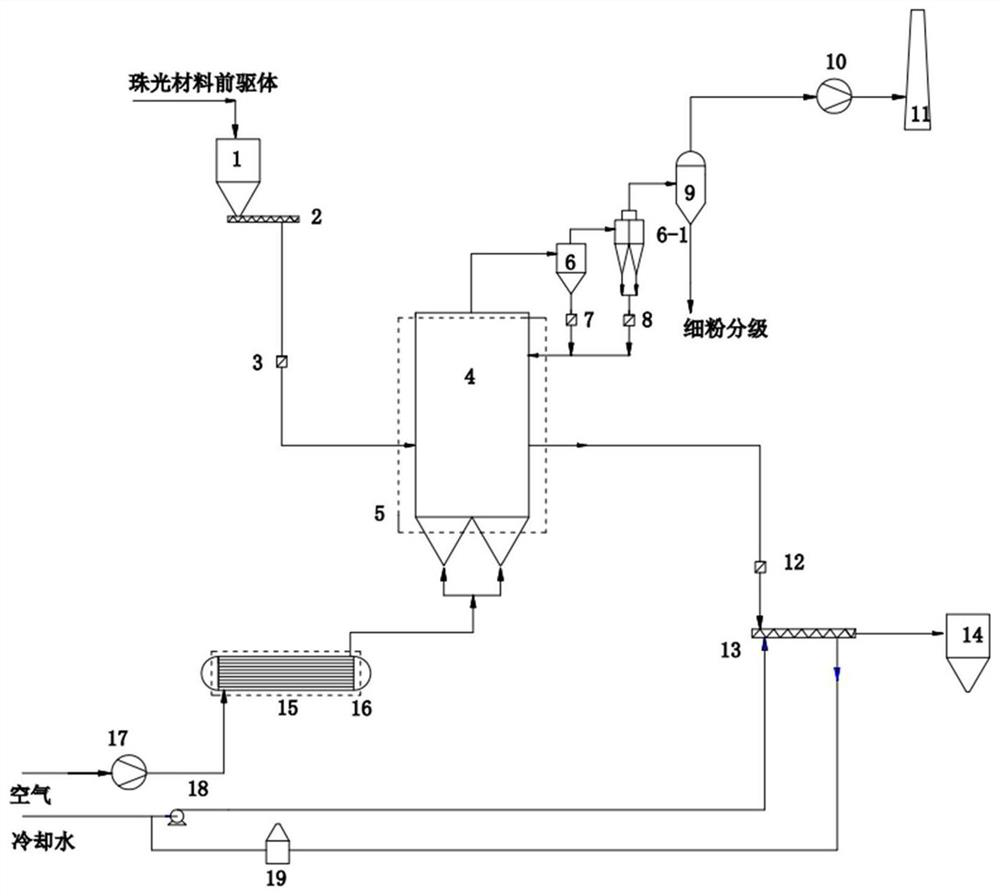

A continuous calcination system and method for pearlescent materials

ActiveCN111909538BFull gas-solid contactImprove calcination effectPigment physical treatmentSocial benefitsFluidized bed

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

A microwave-fluidized roasting method for strengthening the separation of complex refractory iron ore

Owner:NORTHEASTERN UNIV LIAONING

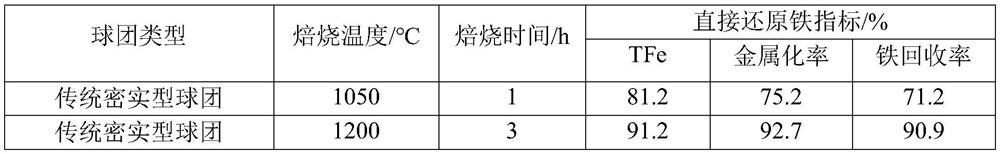

Low-temperature and rapid iron ore oxidized pellet preparation method and system

The invention discloses a low-temperature and rapid iron ore oxidized pellet preparation method and system. The method includes the following steps that (1) a 3D printing mixture is prepared, specifically, raw materials are uniformly mixed,the 3D printing mixture is obtained, and the raw materials include iron ore concentrate, a binder, titanium dioxide, vanadium pentoxide and fibers; (2) pellet ore is prepared, and specifically, the raw pellet ore is prepared from the 3D printing mixture with the 3D printing technology; (3) prefabrication treatment is performed, specifically, prefabrication drying treatment is performed on the raw pellet ore, and dried raw pellet ore is obtained; and (4) oxidizing roasting treatment is performed, specifically, oxidizing roasting treatment is performed onthe dried raw pellet ore, and the finished pellet ore is obtained. According to the technical scheme, the generation amount of powder of the pellet ore in a chain grate machine and rotary kiln systemcan be effectively reduced, the ring formation phenomenon is prevented, and the frequency of shutdown for maintenance is reduced; the air permeability and heat uniformity of the pellets are improved,the pellet roasting temperature is lowered, the pellet roasting time is shortened, and thus the energy consumption in the chain grate machine and rotary kiln technological process is reduced, and thenthe production cost of an enterprise is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A fluidized bed cluster reactor

ActiveCN109045947BApplication size increases or decreasesReasonable designDispersed particle separationChemical/physical processesGas solidSolid reaction

The invention discloses a fluidized bed cluster reactor, which relates to the field of gas-solid reaction fluidization equipment. An air inlet, an air outlet, and a header wall are arranged in the header, and the header wall separates the header into an air inlet and an air inlet. A connected long cavity and several small cavities connected with the fluidized bed cluster adsorption bed, the air inlet is arranged on the small cavity and communicated with the long cavity; the fluidized bed cluster adsorption bed includes several beds arranged side by side tube, granular material and leak-proof net; the air outlet is set on the small cavity and is facing the inlet end of the bed tube; the gas to be treated flows into the long cavity of the header through the air inlet, and passes through the air distribution through the air outlet of the header The plate flows into the bed pipe of the fluidized bed cluster adsorption bed, and then flows through the leak-proof net to the air outlet and then leaves the reactor. The invention has the beneficial effects of solving the problems of high pressure drop in the reactor and serious abrasion of granular materials, improving the utilization rate of granular materials in the reactor, reducing the replacement cost of granular materials, thereby achieving high efficiency, energy saving and cost saving. Purpose.

Owner:QINGDAO UNIV OF SCI & TECH

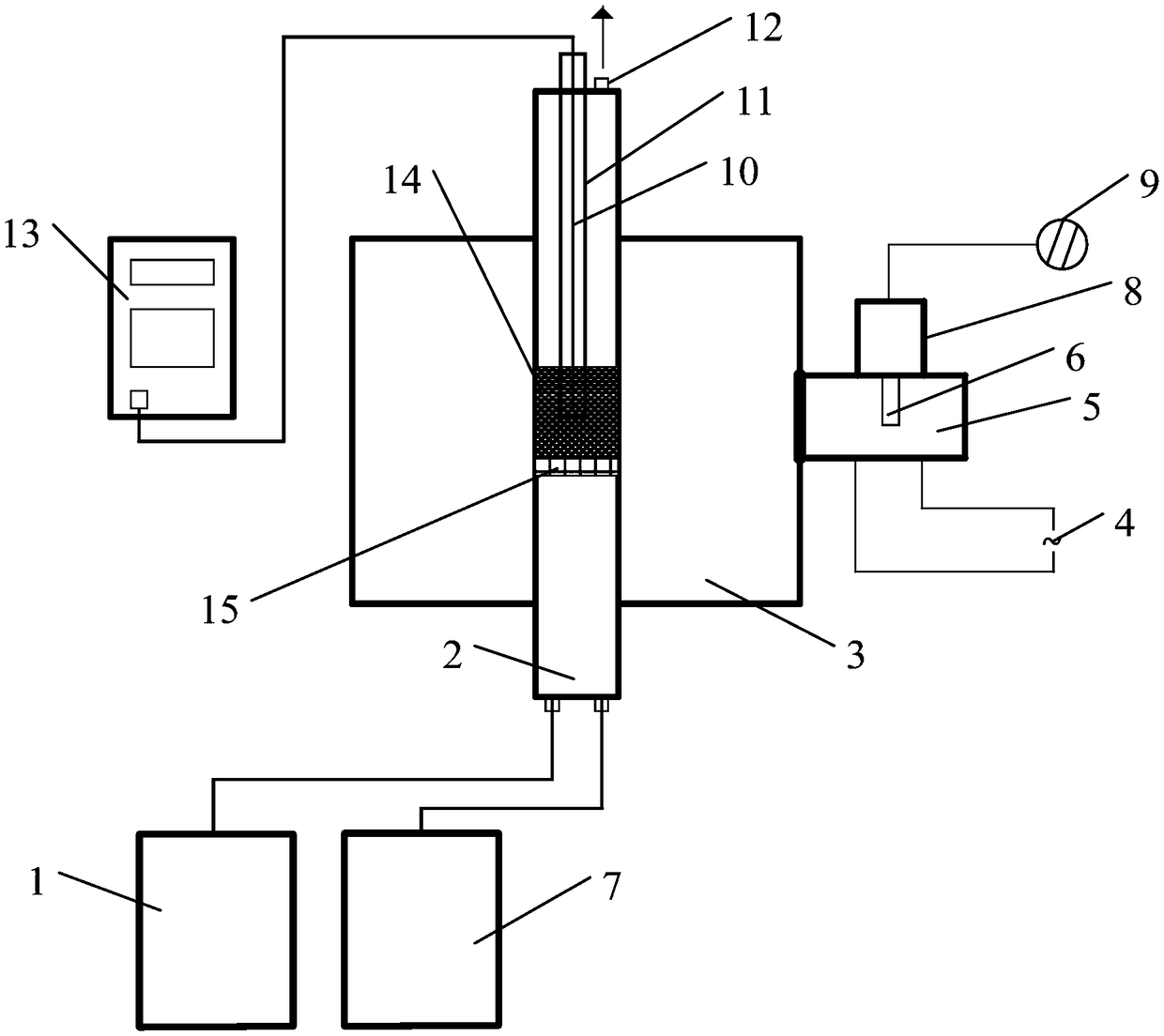

A microwave-fluidized roasting device for processing complex refractory iron ore

A microwave-fluidized roasting device for processing complex and refractory iron ore, including a reaction chamber and a microwave cavity set outside it. A quartz mesh is installed inside the reaction chamber; a thermocouple is inserted from the top of the reaction chamber, and the bottom end is connected to There are gaps between the quartz meshes; a protective gas inlet and a reducing gas inlet are provided at the bottom of the reaction chamber, and an exhaust port is provided at the top; a microwave generating device is installed outside the microwave cavity. The device of the present invention can realize efficient and comprehensive utilization of complex and difficult-to-select weakly magnetic iron ore, concentrates the advantages of fluidized roasting and microwave heating, and makes up for each other's shortcomings in their current applications.

Owner:NORTHEASTERN UNIV LIAONING

Device and method for preparing superfine nickel powder

The invention relates to a device and a method for preparing superfine nickel powder. The device comprises a feeding system, a preheating system, a fluidized bed reactor and a cooling system which are sequentially connected. An outlet of the fluidized bed reactor is connected with a combustion chamber. An outlet of the combustion chamber is connected with the preheating system. After entering a cyclone preheater through the feeding system to be preheated, superfine nickel oxide enters the fluidized bed reactor to be subjected to the reduction reaction; and then the product is discharged after entering the cooling system. High temperature tail gas exhausted from the outlet of the fluidized bed reactor enters the combustion chamber to be burnt after being separated by a first cyclone separator. One path of tail gas is supplied to the preheating system and the other path of tail gas carries out heat exchange with carrier gas exhausted by a second cyclone separator and is supplied to the fluidized bed reactor through a first carrier gas inlet. The invention can solve the problems of poor fluidity, bonding defluidization and industrial scale-up of the superfine nickel powder. The preparation process is simple. The reaction temperature is low. The heat utilization rate is high. The continuous industrial scale production can be implemented.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A system and method for fast ion conductor coating lithium-ion battery cathode material

ActiveCN109671922BThe content is easy to controlImprove electrochemical performanceCell electrodesElectrical conductorLithium-ion battery

The invention relates to a system and a method for coating a positive electrode material of a lithium-ion battery with a fast ion conductor. The system mainly includes a feed bin, a screw feeder, a feed valve, a fluidized bed reactor, a discharge valve, and a product cooler , product collector, burner, No. 1 reaction carrier gas preheater, metal reaction raw material generator, reaction raw material nozzle, No. 2 reaction carrier gas preheater, lithium reaction raw material generator, fluidized carrier gas preheater, The first-stage cyclone separator, the second-stage cyclone separator, the bag filter and the hydrochloric acid tail gas absorber are formed according to a predetermined combination; the method is based on the fast ion conductor coating modification method of the system. The fast ion conductor-coated cathode composite powder was obtained by deposition. The invention has the advantages of high coating efficiency, simple and controllable process, low cost, etc., is suitable for large-scale industrial production of lithium-ion battery fast ion conductor coated modified cathode materials, and has good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A direct reduction metallurgy method of iron ore based on 3D printing

ActiveCN112126778BImprove thermal stabilityImprove stress resistanceAdditive manufacturing apparatusMagnetic separation3d printMixed materials

The invention discloses a 3D printing-based iron ore direct reduction metallurgy method. The invention combines iron ore chain grate-coal-based rotary kiln direct reduction technology with 3D printing molding technology. Through the optimization of the mixture formula, the feasibility, applicability and promotion of 3D printing direct reduction technology are improved. At the same time, the accuracy, synchronization and uniformity of 3D printing technology are used to obtain stable and high-quality green pellets with the same honeycomb pore structure. The green pellets are placed in a high-temperature furnace and subjected to drying, preheating, reduction roasting, cooling, magnetic separation and enrichment, etc., to obtain qualified direct reduced iron products.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com