System for desulfurizing and denitrating active coke flue gas, and process method

A technology for desulfurization, denitrification, and activated coke, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

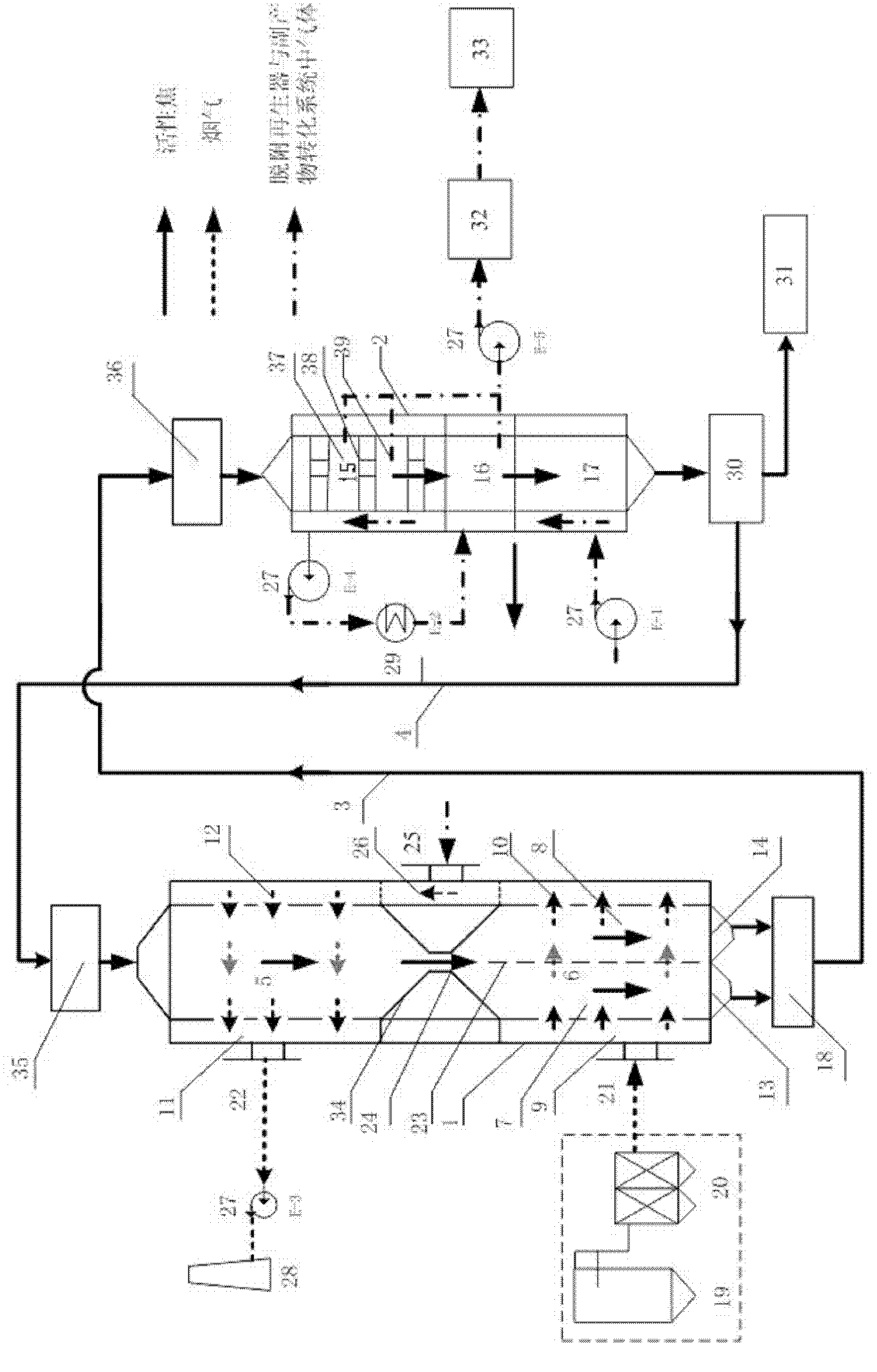

[0038] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

[0039] like figure 1 An activated coke flue gas desulfurization and denitrification system is shown, including an adsorption reactor 1; a desorption regenerator 2 for regenerating the activated coke discharged from the adsorption reactor 1; A by-product conversion device 33 for sulfur resource utilization of gas;

[0040] The cross section of the adsorption reactor 1 is rectangular, and the overall shape is approximately cuboid. The adsorption reactor can be divided into the main part and the active coke inlet and outlet parts at both ends of the main body. Since the active coke inlet and outlet parts adopt a tower design, please refer to the attached figure 1 , and the main part is a cuboid, therefore, it can be said that the adsorption reactor as a whole is approximately a cuboid. The adsorption reactor 1 is a double-stage cross-flow moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com