Preparation method of nano WS2 with fullerene structure, fluidized bed reactor, fluidifying method and applications

A fluidized bed reactor, fullerene structure technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the complex structure of the reactor, long reaction time, ultrafine powder Clogging and other problems, to achieve the effect of improving gas-solid contact efficiency and reaction rate, simple bed type, and sufficient gas-solid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

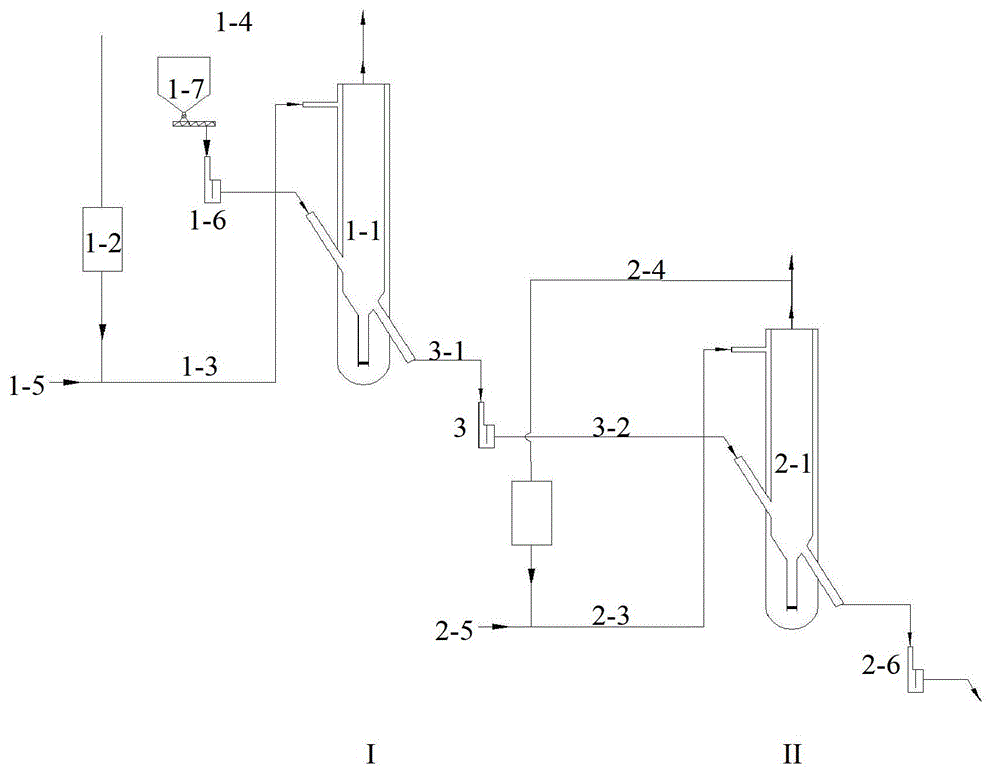

[0050] refer to figure 1 , showing a fullerene structure nano WS of the present invention 2 The process flow chart of the preparation method, the flow chart includes two stages: reduction section I and vulcanization section II. The reduction section I is connected to the vulcanization furnace inlet valve connection pipeline 3-1, the vulcanization furnace inlet valve 3, the vulcanization furnace inlet valve and the vulcanization furnace connection pipeline 3-2, and the vulcanization section II.

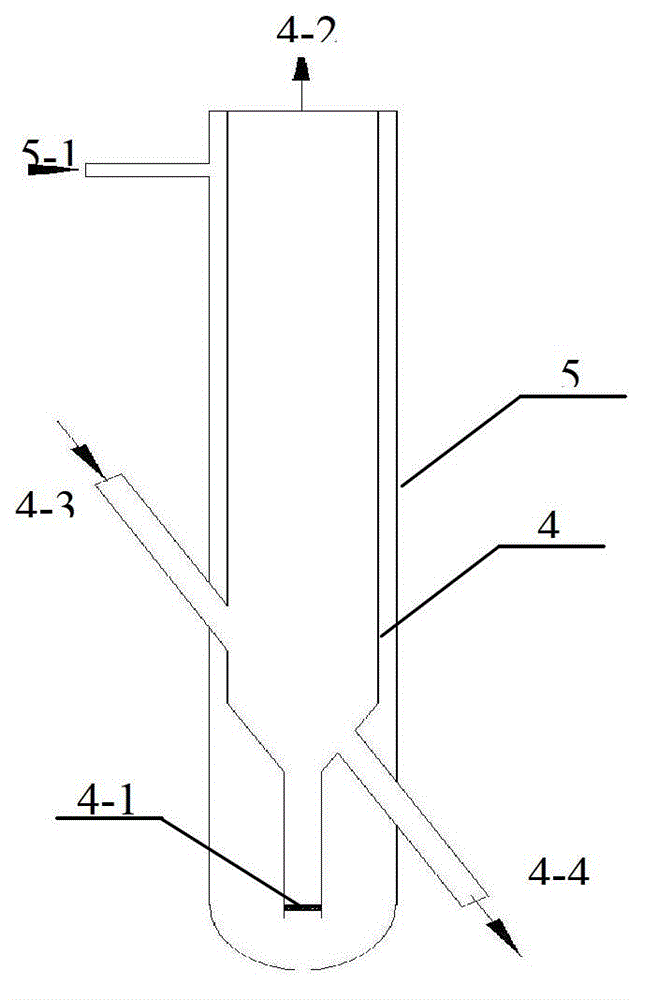

[0051] The reduction section I includes a reduction furnace 1-1 and a reducing gas purifier 1-2. The gas inlet of the reduction furnace 1-1 is connected to the outlet of the reducing gas purifier 1-2 through the reduction furnace inlet pipeline 1-3, and the gas outlet of the reduction furnace 1-1 is connected to the inlet of the reducing gas purifier 1-2 through the reduction furnace. Furnace outlet line 1-4 connection. The particle inlet of the reduction furnace 1-1 communicates wi...

Embodiment 1

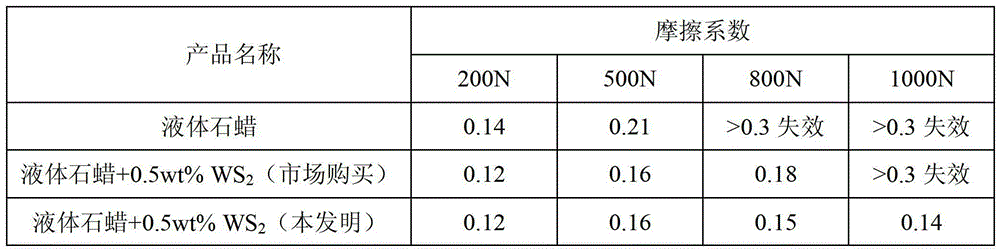

[0062] Mixed gas of hydrogen and nitrogen (50%H 2 / N 2 ) is the reducing gas. Mix the fresh reducing gas 1-5 with the reducing gas from the outlet of the reducing gas purifier 1-2, and then pass it into the reducing furnace 1-1 through the reducing furnace inlet pipeline 1-3, and the temperature of the reducing furnace 1-1 is 600°C, so that Nano WO 3 Reduction reaction occurs with reducing gas. The tail gas after the reaction enters the reduction gas purifier 1-2 through the outlet pipeline 1-4 of the reduction furnace to remove dust and moisture, and the purified gas returns to the reduction furnace 1-1 to continue the reduction reaction. The residence time of the solid material in the reduction furnace is 60 minutes, and the reduced material is sent to the vulcanization furnace 2-1 for vulcanization reaction. A mixture of hydrogen sulfide, hydrogen and nitrogen (10% hydrogen sulfide and 10% hydrogen, nitrogen as the balance gas) is used as the sulfide gas. After mixing ...

Embodiment 2

[0065] Pure hydrogen is used as reducing gas. Mix the fresh reducing gas 1-5 with the reducing gas from the outlet of the reducing gas purifier 1-2, and then pass it into the reducing furnace 1-1 through the reducing furnace inlet pipeline 1-3, and the temperature of the reducing furnace 1-1 is 600°C, so that Nano WO 3 Reduction reaction occurs with reducing gas. The tail gas after the reaction enters the reduction gas purifier 1-2 through the outlet pipeline 1-4 of the reduction furnace to remove dust and moisture, and the purified gas returns to the reduction furnace 1-1 to continue the reduction reaction. The residence time of the solid material in the reduction furnace 1-1 is 60 minutes, and the reduced material is sent to the vulcanization furnace 2-1 for the vulcanization reaction process. A mixture of hydrogen sulfide, hydrogen and nitrogen (10% hydrogen sulfide and 5% hydrogen, nitrogen as the balance gas) is used as the sulfide gas. After mixing the fresh sulfide g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com