Stone coal vanadium ore cascade oxidizing roasting vanadium extraction system and oxidizing roasting method

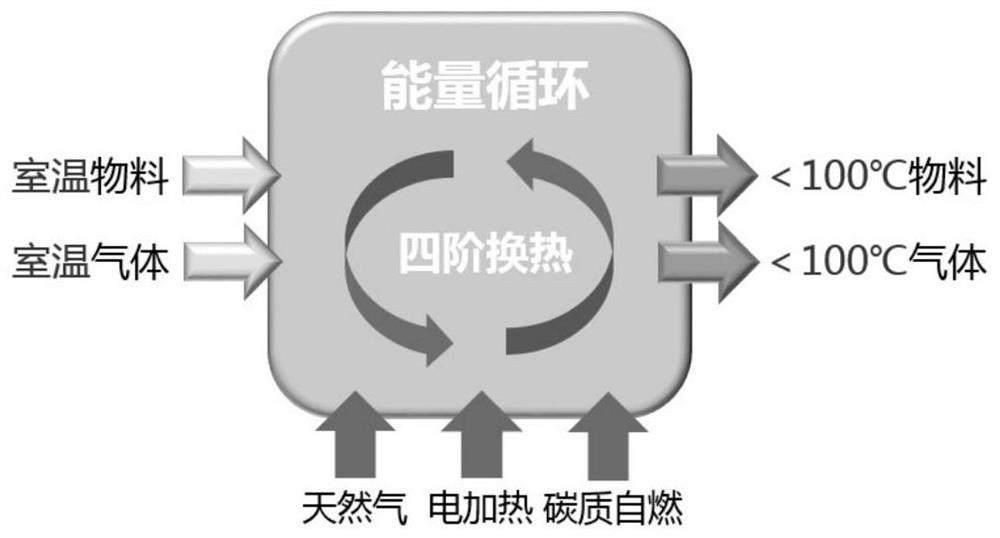

A technology of oxidative roasting and stone coal vanadium, which is applied in the field of vanadium extraction from stone coal vanadium ore, can solve problems such as ore discharge, high exhaust temperature, waste heat not being effectively recovered, and heat utilization rate to be improved, so as to prevent sintering and improve Energy utilization rate, effect of reducing natural gas and electric energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

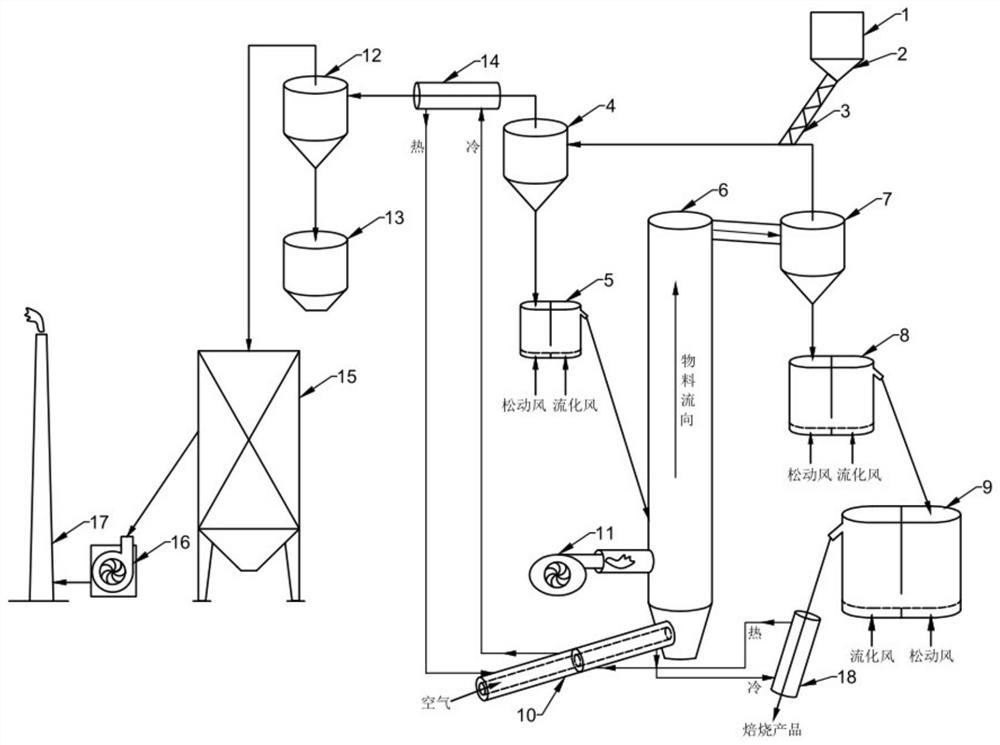

[0060] Suspension roasting of a stone coal vanadium ore, where V 2 o 5 The content is 1.30%, the carbon content is 4.8%, and the -0.1mm content is 90%.

[0061] (1), start the Roots blower 16, control the negative pressure of the blower to be -2.0kpa, provide negative pressure for the inside of the system and start the burner 11 to ignite the natural gas, so that the high-temperature flue gas enters the main furnace 6. Keep the temperature at the top of the main furnace at about 710°C.

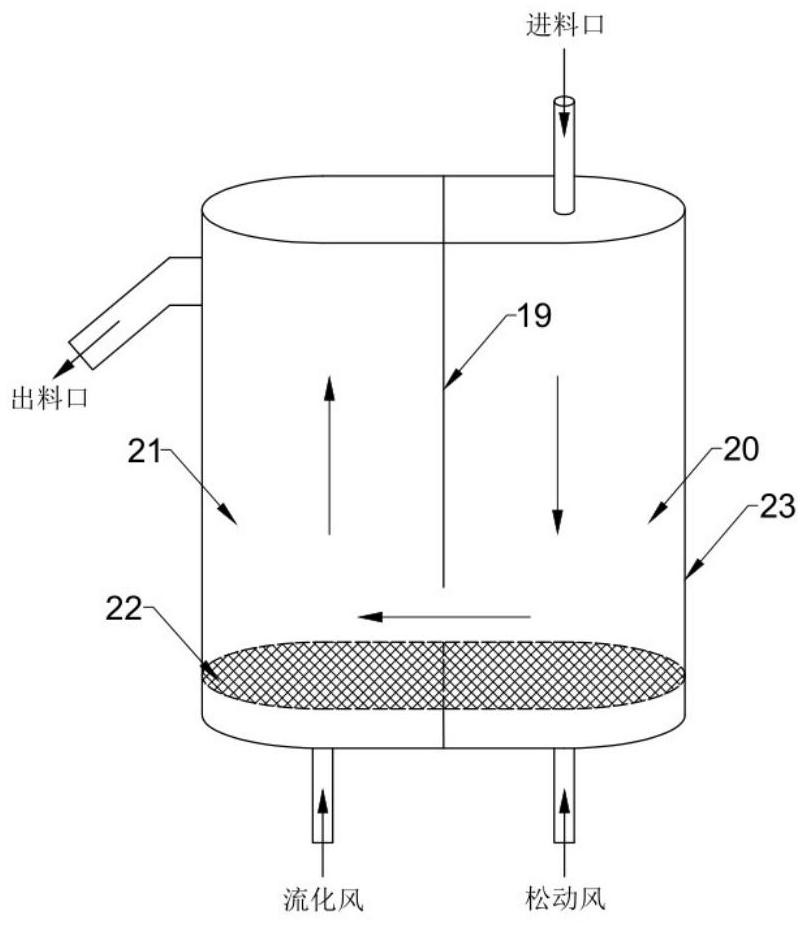

[0062] (2), pass into 3m to flow sealing valve 5 3 / h loose wind (air), 10m 3 / h fluidization wind (air); feed 6m to the decarburization roasting reactor 8 3 / h loose wind (air), 19m 3 / h fluidization wind (16m 3 / h air, 3m 3 / h oxygen); Pass into 8m to breaking crystal roasting reactor 9 3 / h loose wind (air), 20m 3 / h Fluidizing wind (air).

[0063] (3) Set the feeding of the weight loss scale 2 to 100kg / h, and carry out the sealing operation. When the output is stable at 100kg / h,...

Embodiment 2

[0070] Embodiment 2 method is the same as embodiment 1, and difference is:

[0071] (1), for a certain V 2 o 5 The high-carbon stone coal vanadium ore with a content of 0.95% and a carbon content of 12.6% is subjected to suspension roasting. Raw ore -0.045mm content accounts for 85%.

[0072] (2), the feed rate of weight loss scale 2 is 20kg / h, the temperature of the first-stage decarburization roasting reactor 8 is 630°C, and the time is 1.5h, and the temperature of the second-stage crystal-breaking roasting reactor 9 is 940°C, and the time is 12h .

[0073] (3) The amount of concentrated sulfuric acid used in roasting samples is 15wt%, the liquid-solid ratio is 1:1, the amount of leaching aid (calcium fluoride) is 2.5%, the leaching temperature is 75°C, the leaching time is 8h, and the stirring speed is 600r / min, the leaching rate of vanadium reaches 82.32%, which is 30.55 percentage points higher than that of the original ore, and 14.25 percentage points higher than th...

Embodiment 3

[0075] Embodiment 3 method is the same as embodiment 1, and difference is:

[0076] (1), for a certain V 2 o 5 The stone coal vanadium ore with a carbon content of 1.50% and a carbon content of 8.5% is subjected to suspension roasting. Raw ore -0.045mm content accounts for 90%.

[0077] (2), the feed rate of weight loss scale 2 is 35kg / h, the temperature of the first-stage decarburization roasting reactor 8 is 600°C, and the time is 1.2h, and the temperature of the second-stage crystal-breaking roasting reactor 9 is 950°C, and the time is 10h .

[0078] (3) The amount of concentrated sulfuric acid used in the roasted sample is 10wt%, the liquid-solid ratio is 1.25:1, the amount of leaching aid (calcium fluoride) is 0.5%, the leaching temperature is 85°C, the leaching time is 6h, and the stirring speed is 1000r / min, the leaching rate of vanadium reaches 89.62%, which is 28.54 percentage points higher than that of the original ore, and 18.15 percentage points higher than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com