Paint slag fishing device

A salvage device and paint slag technology, applied in the direction of filtration and separation, gravity filter, fixed filter element filter, etc., can solve the problems that cannot be discharged directly, the filter is easy to be blocked, and the efficiency is low, so as to reduce the follow-up treatment, improve efficiency and Speed, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

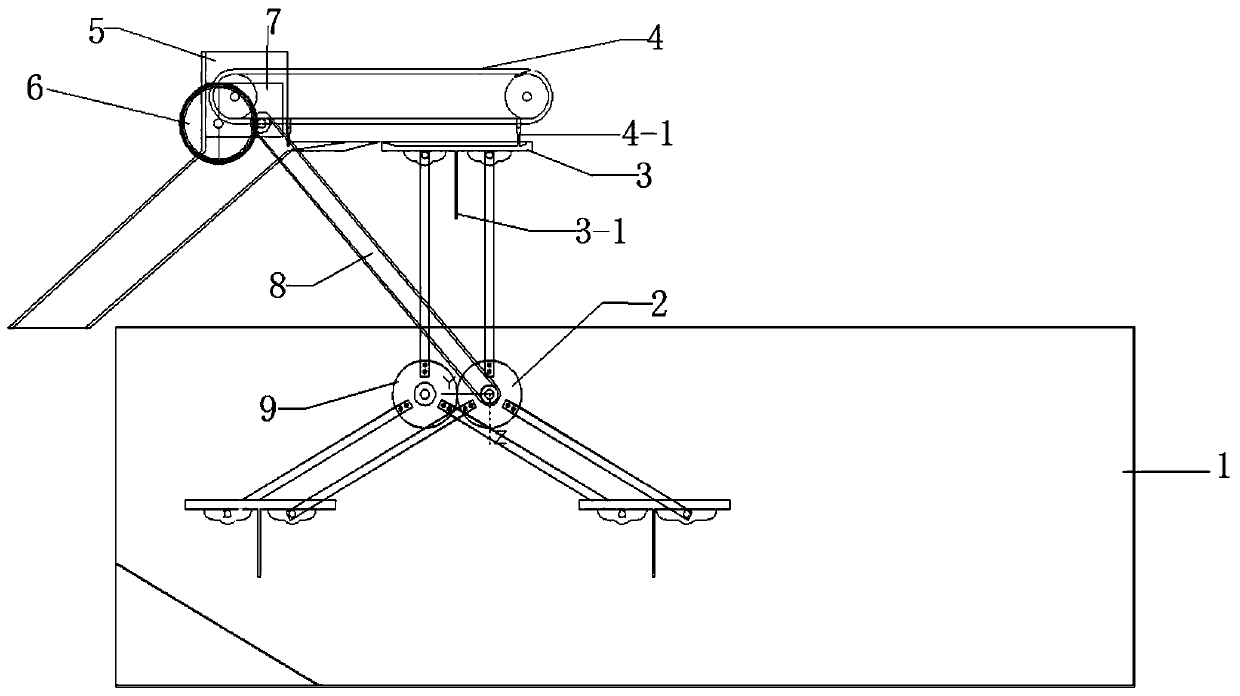

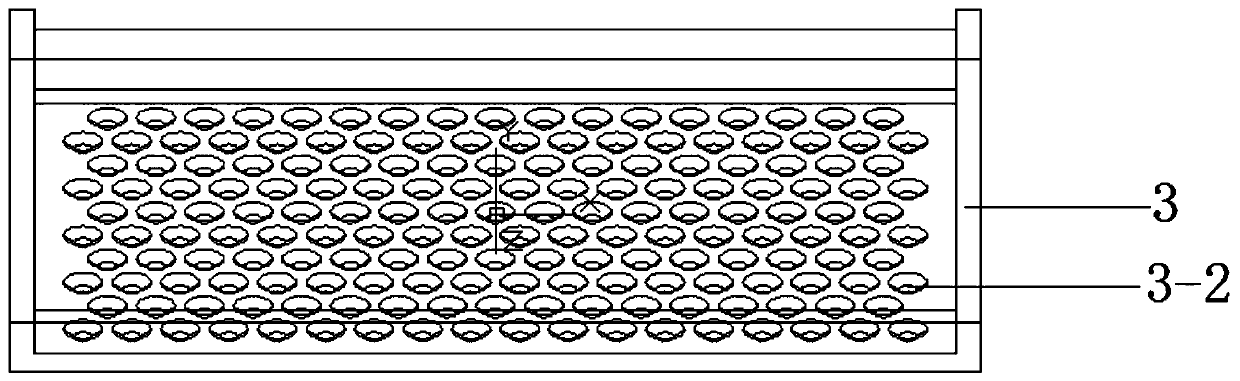

[0026] Such as figure 1 , figure 2 As shown, a paint slag fishing device includes a collecting device and a power transmission device used by the fishing device to provide power to the collecting device and the fishing device; the collecting device includes a transmission belt 4, a scraper 4-1 and a paint The slag hopper 5, the collection device is arranged above the waste liquid tank 1, the power transmission device is connected with the fishing device and is arranged below the transmission belt 4 and the paint slag hopper 5, and the fishing device includes Leakage hopper 3; one end of the transmission belt 4 is arranged in the paint slag hopper 5, a scraper 4-1 is arranged on the outer surface of the transmission belt 4, and the power transmission device is connected with the leakage hopper 3 to drive The leakage hopper 3 rotates so that the scraper 4-1 scrapes the paint slag in the leakage hopper 3 into the paint slag hopper 5, and the leakage hopper 3 is provided with gr...

Embodiment 2

[0039] Most of this embodiment is the same as the above embodiment, the difference is that a motor is installed on the side of the transmission belt and the driving wheel respectively, and the motor is installed above the waste liquid tank through a bracket; during the working process of the paint slag fishing device, two The motors work together, and the specific working process is as described in the above-mentioned embodiments.

[0040] It should be noted that, in addition to the specific examples given above, some of the structures may have different choices. Such as: the quantity of the leakage funnel in the device of the present invention can be 3 or 4 or 5; The time that the wheel turns 120° and hovers can be 20-30 seconds, during which the drive belt can rotate once or twice or three times; Basically, it can be made based on its basic skills, so I won't list them one by one here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com