Recovery system for heavy metal in surface treatment wastewater

A surface treatment and recovery system technology, applied in water/sewage treatment, water/sewage multi-stage treatment, extracted water/sewage treatment, etc., can solve problems such as incomplete recovery of heavy metals, environmental pollution, waste of resources, etc., to improve work Efficiency and fluency, improving separation efficiency and avoiding radial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

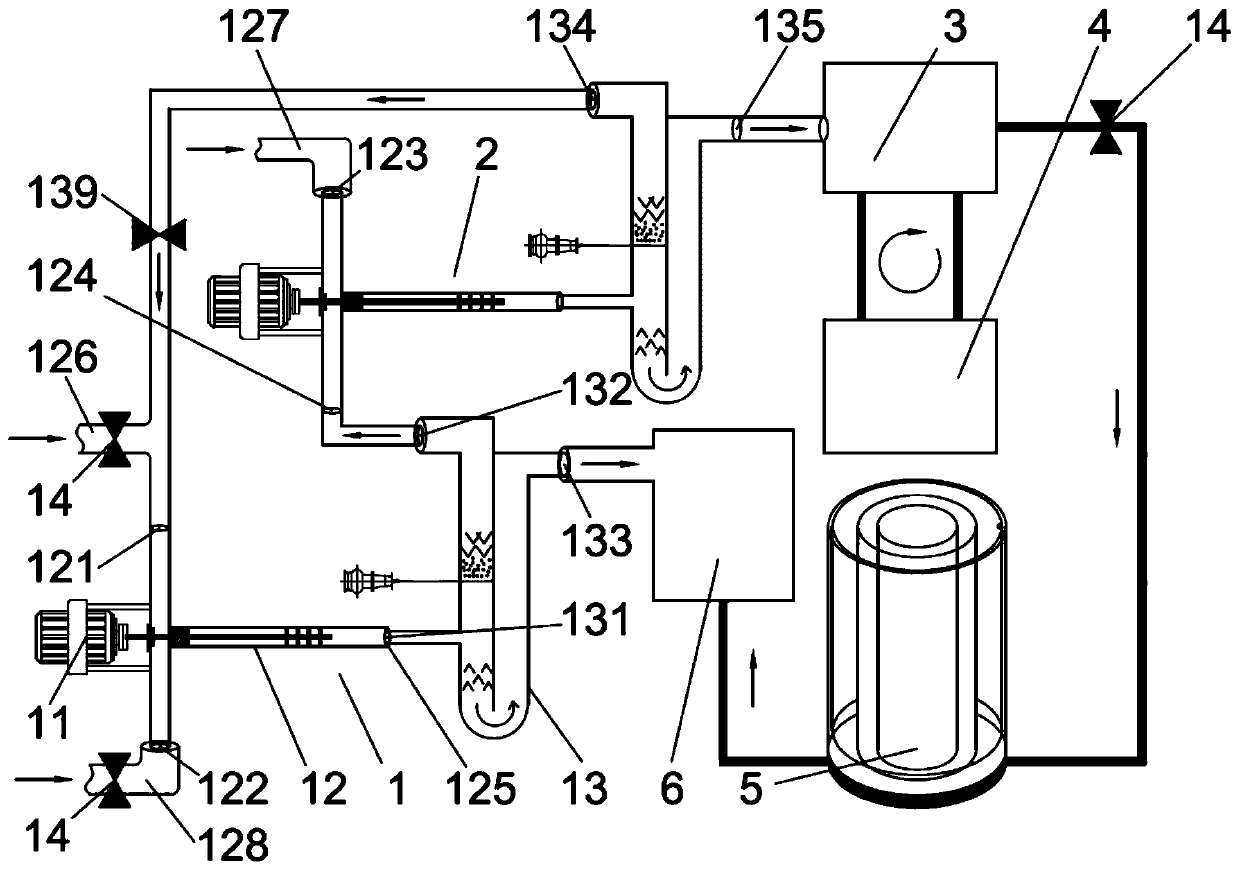

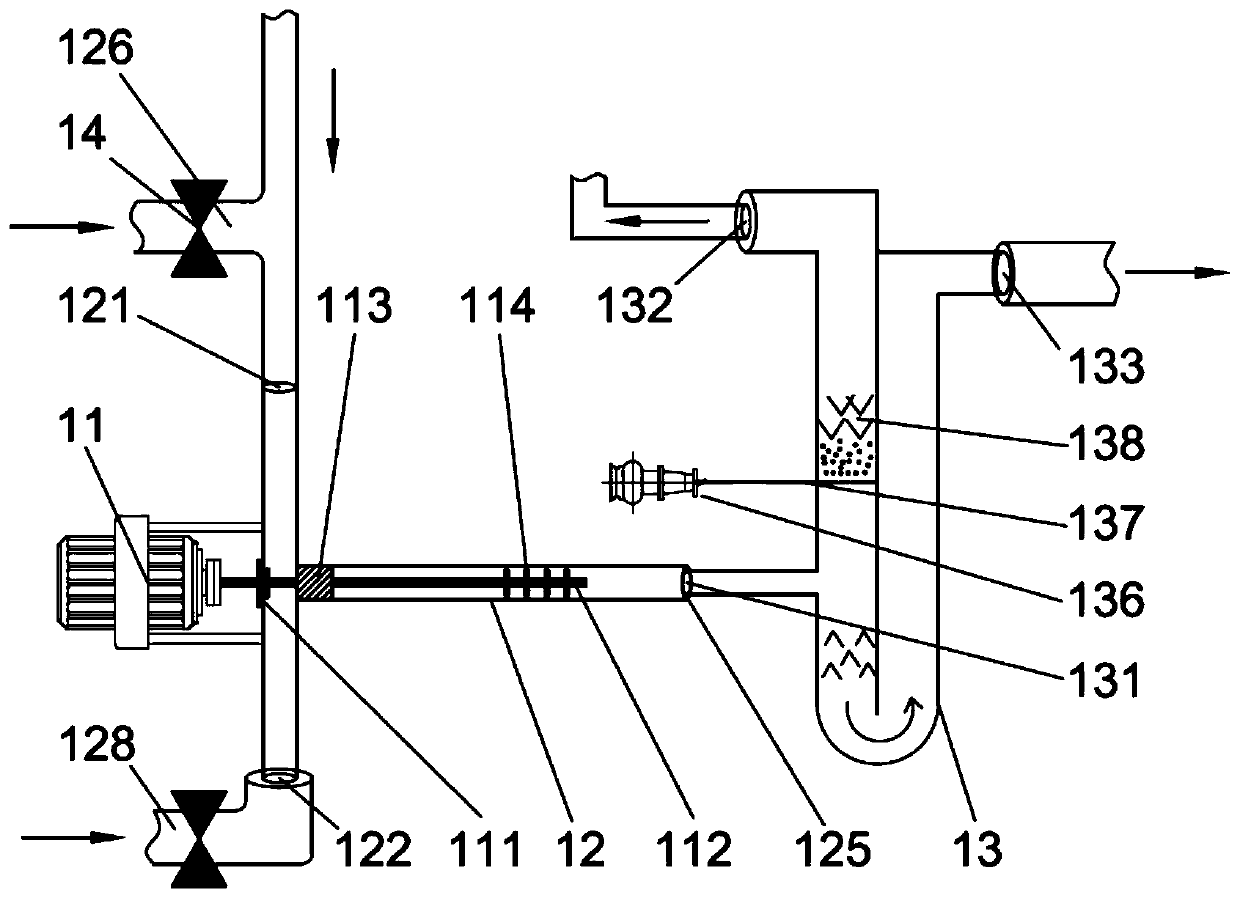

[0035] Such as Figure 1~6 As shown, a heavy metal recovery system for surface treatment wastewater is characterized in that it includes an extraction system 1, a stripping system 2, a membrane separation device 3, an electrodialyzer 4, and an electrolytic recovery device 5;

[0036] Both the extraction system 1 and the stripping system 2 include a motor 11, a three-way mixer 12 and a connected oil-water separator 13; the three-way mixer 12 is a "T"-shaped tube, and the two ends of the "T"-shaped horizontal line tube are respectively There is a feed inlet, and a flow port 125 at the end of the "T"-shaped vertical pipe; the output end of the motor 11 is connected to an output shaft 112, and the output shaft 112 passes through the three-way mixer 12 and is located at the "T" of the three-way mixer 12. In the "shaped vertical pipe, the output shaft 112 is parallel to the "T" shaped vertical pipe of the three-way mixer 12, and a sealing rubber pad 111 is set at the connection betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com