Asphalt pavement regenerant production system

A technology of production system and asphalt pavement, which is applied in the direction of cleaning hollow objects, mixers, and types of packaged objects. It can solve the problems of reducing the mixing effect, wasting raw materials, and difficult to clean, and achieves the improvement of mixing effect, stability, and ease of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

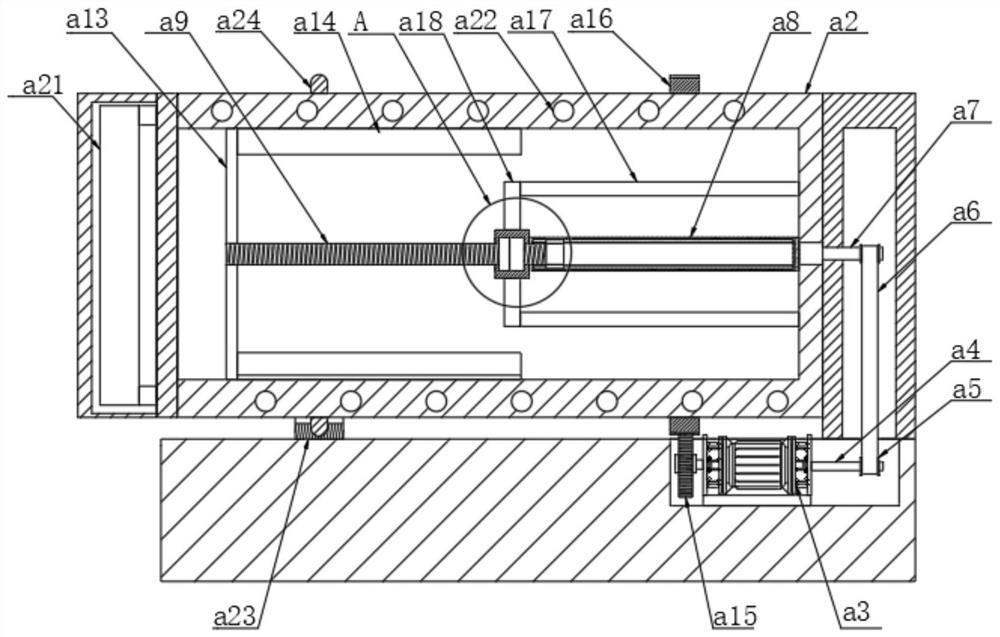

[0029] An embodiment of the present invention provides an asphalt pavement rejuvenating agent production system, the main components include a weighing device, a stirring device and a cold pouring device, the weighing device is used to weigh the material and transport it to the stirring device, the stirring device The device performs uniform rotary cutting and stirring on the material, and the cold filling device performs quantitative filling after cooling the stirred regenerant. Specifically, the stirring device structure of the present invention please refer to Figure 1-4, including a base a1 and a mixing drum a2, the mixing drum a2 is arranged on the top of the base a1, and a stirring assembly is arranged inside the mixing drum a2. The mixing assembly includes a sleeve a8 and a reciprocating screw a9. The base a1 is fixedly connected to a biaxial motor a3, and the output end of the biaxial motor a3 is fixedly connected to a drive shaft a4. The sleeve a8 is rotatably connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com